Page 1

09/2005 - Art. Nr. 13 019 526A

Operating instructions

For the authorised specialist

Gas burners .........................................2-31

VECTRON G 05.700 MODULO

VECTRON G 05.1000 MODULO

Ersatzteilliste

Spare parts list

Pièces de rechange

Wisselstukkenlijst

Elektro- und Hydraulikschema

Electric and hydraulic diagrams

Schémas électr. et hydraulique

Elektr. en hydraulische schema

Art. Nr.

13 018 839

EN

}

Art. Nr.

13 019 525

}

Page 2

2

09/2005 - Art. Nr. 13 019 526A

Contents

Overview

Contents, Declaration of

conformity ............................................2

Important notes .................................. 3

Description of burner, Scope of

delivery, Optional accessories.............4

Technical data, Power graphs ............5

Gas valve selection .............................6

Dimensional drawings and

measurements.....................................7

Gas valve assembly ............................8

Hydraulics diagrams ............................9

Control panel .....................................10

Overview of combustion control unit

MPA22

Function description ..........................11

Display and operating unit ................12

Programme structure .......................13

Assembly

Burner head, burner housing ............14

Gas valve assembly ..........................15

Checking/Setting Mixer unit for

natural gas/propane gas....................16

Gas supply, Electrical supply............17

Start-up

Default settings..................................18

Burner head, gas and air

pressure switch settings,

gas pressure regulator ......................19

Checks before start-up......................20

Control unit auto-test.........................20

Adjustment mode .........................21-25

Access....................................21

Parameters menu..............21-22

Cold adjustment menu ...........23

Hot adjustment menu........24-25

Operating mode .................................26

Info mode ..........................................27

Voice mode ....................................... 28

Maintenance................................ 28-29

Burner-specific adjustment

settings of the MPA 22 .....................30

Troubleshooting ................................31

Declaration of conformity for

gas burners

We, CEB, of

18, rue des Bûchillons Ville-la-Grand

F-74106 ANNEMASSE Cedex

declare under our sole responsibility

that the products

VECTRON G 05.700 MODULO

VECTRON G 05.1000 MODULO

conform to the following standards

EN 60335

EN 50081

EN 50082

EN 676

In accordance with the stipulations of the

European Directives

90 / 396 / EEC Gas device guidelines

89 / 336 / EEC EMC directive

73 / 23 / EEC Low voltage

directive

92 / 42 / EEC Working efficiency

directive

these products bear the CE marking

Ville-la-Grand, 01 January 2005

J. HAEP

Overview

Page 3

3

09/2005 - Art. Nr. 13 019 526A

Overview

Important notes

Important instructions

The G 05.700/1000 MODULO burners

are designed to burn natural gas or

propane gas in category II 2 ELL 3P.

The special construction of the burner

head with internal recirculation of

exhaust gases means that combustion

is very low in nitric oxide when burning

natural gas.

The design and function of the burners

meet standard EN676.

Assembly, start-up and maintenance

must be carried out only by authorised

specialists and all applicable guidelines

and regulations complied with.

Gas pipes and fittings must likewise be

installed in compliance with all

applicable guidelines and regulations

(e.g. DVGW-TRGI 1986/96; TRF 1988;

DIN 4756).

Only DVGW-tested and -approved

sealing materials should be used.

Connections should be leak-tested

using non-corrosive foam-producing

materials or similar.

Gas piping should be vented before

start-up. Under no circumstances

should venting be carried out over the

furnace.

Repair work to switches, limiters,

control and safety units and other

individual items of safety equipment

must be carried out by the relevant

manufacturer or his representatives.

The replacement of original parts must

be carried out by specialist staff.

Basic regulations

The following standards should be

observed in order to ensure safe,

environmentally sound and

energy-saving operation:

DIN 4705

Calculation of flue dimensions

EN 676

Forced-draught gas burners

EN 226

Connection to heating systems of

vaporising-fuel-oil and forced-draught

gas burners

VDE 0116

Electrical equipment for furnace

systems

EN 60335-1

Safety of electrical equipment for

domestic use and similar purposes

VDE 0722

Electrical Equipment for non-electrically

powered heating devices.

Installation location

The burner must not be used in rooms

with aggressive vapours (e.g. hair

spray, perchlorethelen, carbon

tetrachloride), high levels of dust or

high air humidity (e.g. washhouses).

An air inlet must be present:

–

up to 50 kW: 150 cm²

–

for every further kW: +2 cm²

Variations may arise as a result of local

regulations.

The guarantee does not cover

damage resulting from:

·

Inappropriate use

·

Incorrect installation and/or initial

start-up on the part of the buyer or

any third party, including the fitting

of non-original parts.

·

Operation of the system at

excessive pressure.

Final delivery and instructions for use

The combustion system manufacturer

must supply the operator with operating

and maintenance instructions on or

before final delivery. These instructions

should be displayed in a prominent

location at the point of installation of the

heating unit, and should include the

address and telephone number of the

nearest customer service centre.

Notes for the operator

The system should be inspected by a

specialist at least once a year. It is

advisable to enter into a maintenance

contract in order to ensure trouble-free

running.

EN

Page 4

4

09/2005 - Art. Nr. 13 019 526A

Overview

Description of burner

Burner description

The G 05.700/1000 MODULO burners

are low emission, modulating gas

burners with a monoblock type

electronic connection. They are suitable

for use with all heat generators in

accordance with DIN 4702/EN 303

within the respective performance range.

Scope of delivery

The burner is supplied in three

packaging units:

·

Burner housing with operating

instructions, flow diagram, spare parts

list, combustion chamber board.

·

Burner head with flange seal and

fixing screws.

·

Gas valve assembly with gas throttle

module, DMV gas valve with built-in

pocket filter or with external filter,

connection parts, screws, seals.

Optional accessories:

–

Separate air intake box

–

Air intake silencer

–

Gas stop valve

–

Thermal safety cut-out valve

–

Compensator

–

Power regulator

–

Potentiometer

–

Test burner

–

Pressure gauge

A1 Combustion control unit

A4 Display and operating unit

B10 Ionisation bridge

F6 Air pressure switch

F12 Protective motor relay

K1 Motor contactor

M1 Burner motor

T1 Ignition transformer (concealed)

Y10 Servomotor air flap

7 Control panel

8 Blast tube

13 Burner cover

113 Air box

Page 5

5

09/2005 - Art. Nr. 13 019 526A

Overview

Technical Data

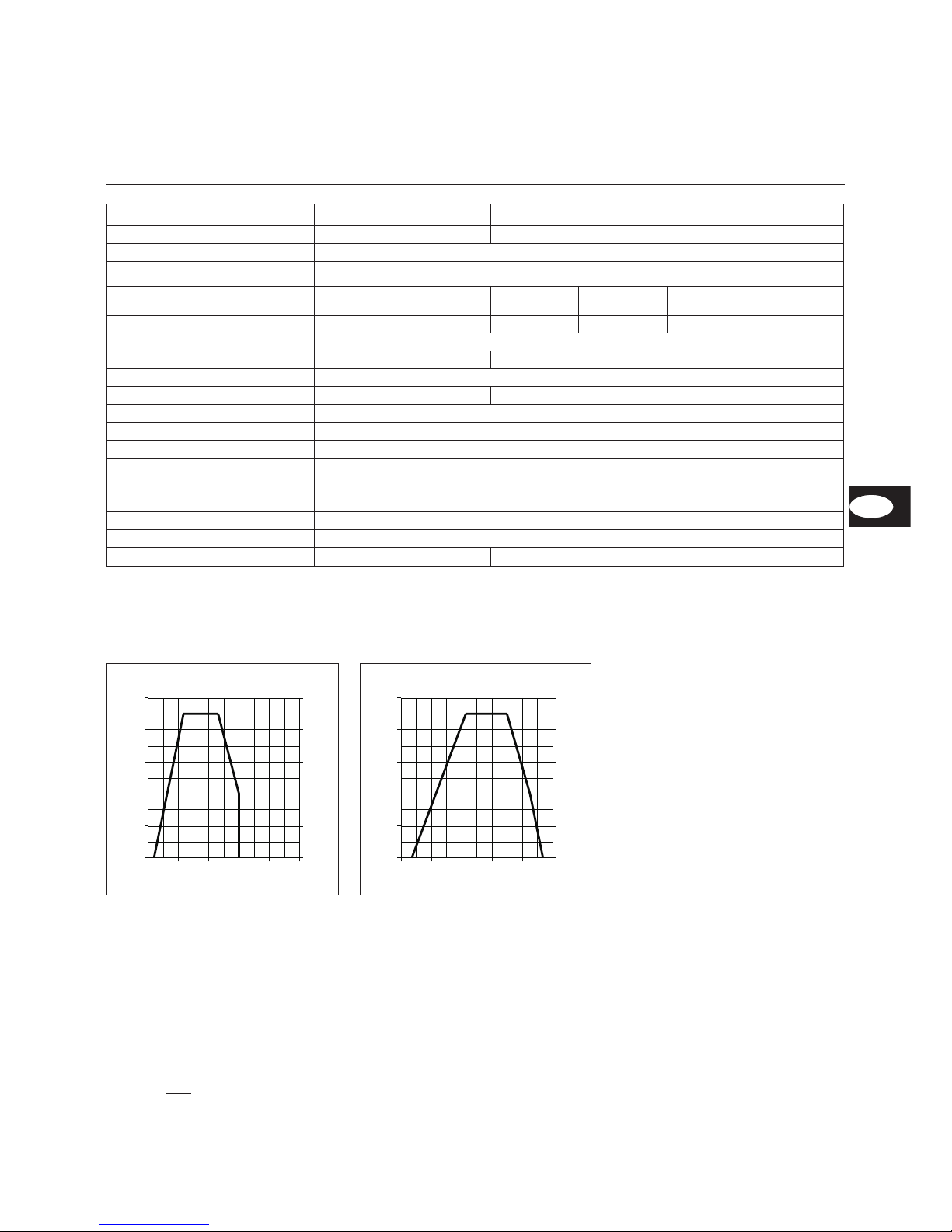

Power graphs

Power graph

When selecting the burner and gas

valves, the boiler efficiency must be

taken into account.

Power graphs are expressed as burner

power relative to furnace pressure. This

corresponds to the maximum value in

accordance with EN676, measured on

the test blast tube.

Calculation of the burner power:

Q

F

= Burner power (kW)

Q

N

= KRated boiler power (kW)

hK = Boiler efficiency (%)

Q

N

QF=

hK

Type description

G 05.700 MODULO G 05.1000 MODULO

Burner power kW

140-700 170-1040

Operating mode

two-stage sliding/modulating

Fuel

Natural gas (LL, E) Hi = 8.83-10.35 kWh/m

3

or propane gas (F) Hi = 25.89 kWh/m

3

Gas valve DMVSE

512-T

DMVSE

520-T

DMVSE

512-T

DMVSE

520-T

DMVSE

525-R

DMVSE

5065-R

Gas connection

Rp 1, 1/2 Rp 2 Rp 1, 1/2 Rp 2 Rp 2 DN 65

Gas flow pressure m bar

20-100

Burner motor 2800 ¹/min

230/400 V, 50 Hz, 1.1 kW 230/400 V, 50 Hz, 1.5 kW

Combustion control unit/flame sensor

MPA 22/ionisation/alternative IRD probe

Power consumption W

1800 2000

Protection level

IP 41

Ambient temperature max. °C

60° C

Ignition transformer

EBI-M; 2 x 7.5 kV

Air flap drive

Servomotor STE 4.5 Q5.51/6-02R; Runtime: aspprox. 40 sec with adjustment travel of 90°

Gas throttle drive

Servomotor STE 4.5

Burner tube-Ø x Insertion depth mm

170 x 215 (KN)/325 (KM)/KL (435)

Air pressure switch

LGW 10 A 2

Burner weight incl. gas valve kg

100 kg

CE Mark

1312 AQ 0924 1312 AQ 0925

Note on type designation

G = Natural gas/Propane gas

05 = Size

700 = Power rating

MODULO = Modulating with

electronic connection

KN = Normal burner head length

KM = Medium burner head length

KL = Long burner head length

daPa mbar

kW

335

0

20

40

60

80

100

100 300 500 700 900 1100

0

2

4

6

8

10

daPa mbar

kW

530

1040

0

20

40

60

80

100

100 300 500 700 900 1100

0

2

4

6

8

10

G 05.700 MODULO G 05.1000 MODULO

EN

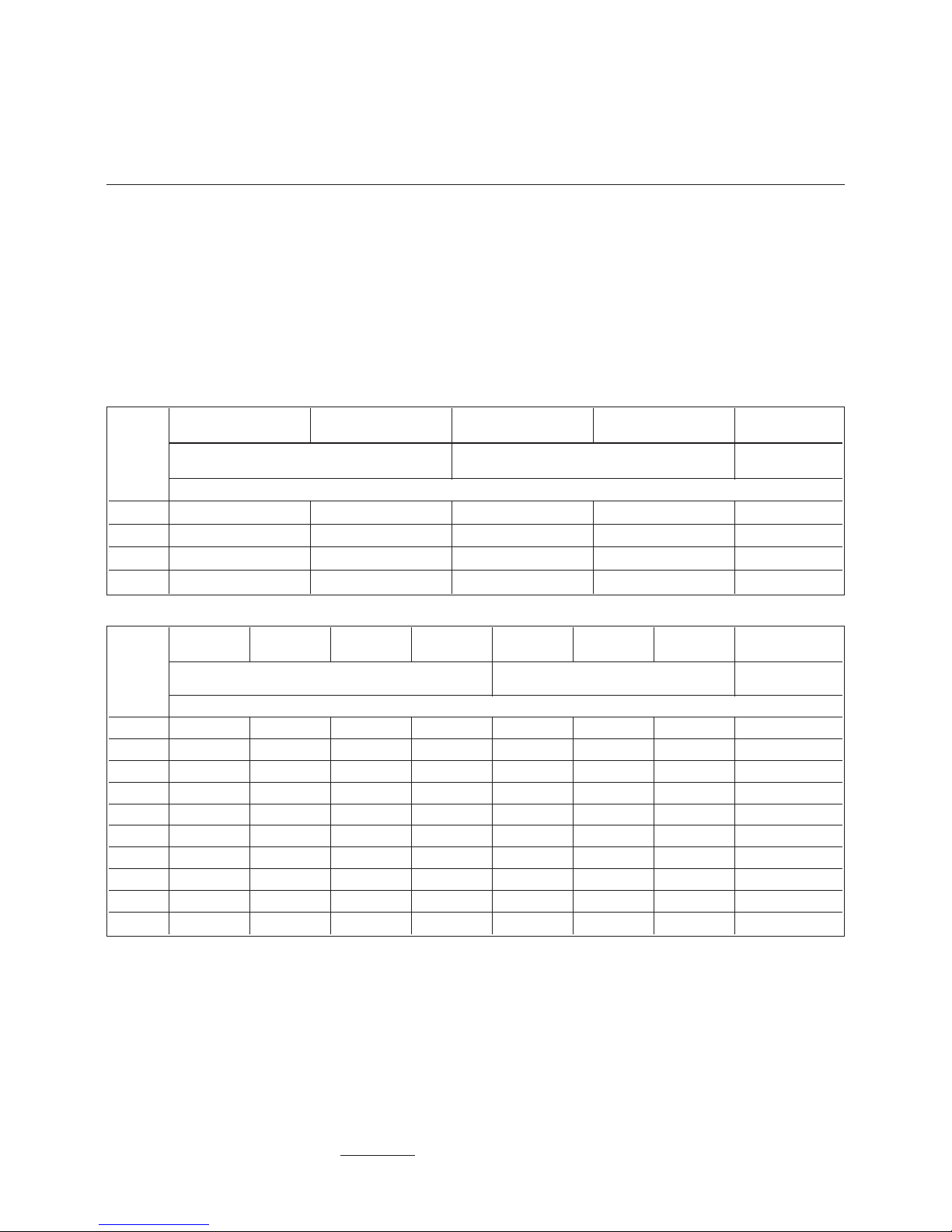

Page 6

6

09/2005 - Art. Nr. 13 019 526A

Overview

Burner

power

(kW)

DMV512-T

Rp1,1/2

DMV520-T

Rp 2

DMV512-T

Rp1,1/2

DMV520-T

Rp 2

DMV512-T

Rp1,1/2

Natural gas E Hi = 10.365 kWh/m

3

Natural gas LL Hi = 8.83 kWh/m

3

Propane gas

Hi=25.89kWh/m³

Gas pressure loss (from gas valve inlet)

550 16 15 17 15 15

600 19 15 21 16 15

650 22 18 24 19 17

700 26 21 28 22 20

Gas valve selection

The gas pressure loss specified in the

table is to be added on to the combus

-

tion chamber pressure in mbar.

N.B.:

The calculated gas flow pressure is to

be complied with at the gas valve inlet.

To calculate the gas flow pressure

required at the transfer station, the

resistance of the burner supply conduit

including valves (ball valve, TAS, addi

tional filter or counter) must also be

taken into account.

Example (for Burner G 05.1000 MODULO):

·

System data:

–

Gas type: natural gas E

–

Gas flow pressure: 20 mbar (N.B.: at gas valve inlet)

–

Required burner power: 700 kW

–

Combustion chamber pressure with boiler rated load: 2.5 mbar

·

Condition: working point must be within the burner’s permissible field of work.

·

Selected gas valve: DMV 520-T

·

Checking the selection:

–

Gas pressure loss (from table): 17 mbar

–

Combustion chamber pressure: 2.5 mbar

Total 19.5 mbar

–

Hence: Gas flow pressure 20 mbar >19.5 mbarðSelection of DMV520-T correct.

Burner

power

(kW)

DMV512-T

Rp1,1/2

DMV520-T

Rp 2

DMV525-R

Rp 2

DMV5065-R

DN65

DMV520-T

Rp 2

DMV525-R

Rp 2

DMV5065-R

DN65

DMV512-T

Rp1,1/2

Natural gas E Hi = 10.365 kWh/m³ Natural gas LL Hi = 8.83 kWh/m³

Propane gas

Hi=25.89kWh/m³

Gas pressure loss (from gas valve inlet)

550 17 15 15 15 15 15 15 15

600 20 15 15 15 17 15 15 15

650 23 15 15 15 20 17 17 16

700 27 17 15 15 24 20 20 18

750 31 20 18 18 27 23 23 21

800 35 23 20 20 31 26 26 24

850 40 26 23 23 35 29 29 27

900 44 29 25 25 39 33 33 30

950 49 32 28 28 44 37 37 34

1000 55 36 31 31 48 41 41 38

1

G 05.700 MODULO

G 05.1000 MODULO

Page 7

7

09/2005 - Art. Nr. 13 019 526A

Space requirements

There should be a space of no less

than 0.60 m on each side of the burner

for maintenance purposes.

Gas valve assembly

The valve assembly can be fitted on the

left or the right.

Overview

Dimensional drawings and measurements

G 05.700/1000 MODULO

With DMV SE gas valve

KN

KM

KL

KN

KM

KL

KN

KM

KL

EN

Page 8

8

09/2005 - Art. Nr. 13 019 526A

Overview

Gas valve assembly

Installation position:

Vertical with upwards facing magnet.

Description, technical data

The compact gas valve

DMV SE 512,520 is a compact unit with

2 class A solenoid valves, class A

servo-pressure regulator, pocket filter

and pressure switch.

For the DMV SE 525, 5065 types the

tube filter is installed externally.

–

Pressure switch GW A5:

adjustment range 5.....50 mbar

–

Magnetic valve V1/V2 quick

opening/quick closing.

–

Servo-pressure regulator, can be

adjusted via a spindle.

–

Max. operating overpressure

500 mbar

–

Inlet pressure range

pe 15-500 mbar

–

Voltage/frequency:

230 V/50-60 Hz

The gas valve assembly consists of:

–

a gas throttle controlled by a

servomotor

–

a DMV-SE gas valve

–

a gas filter (pocket filter or external filter)

–

a thermally triggered safety cut-off

valve and a gas ball valve are to be

provided by the manufacturer.

DMV SE gas valve

1 Electrical connection of the

solenoid valves (DIN 43650)

2 Electrical connection of the gas

pressure switch (DIN 43650)

3 Gas pressure switch

4 Gas inlet flange

5 Pocket filter (under cover)

6 Gas pressure adjusting screw pBr

8 Gas pressure measuring nipple G1/8

9 Pipe filter

DMV SE 512, 520

with pocket filter

DMV SE 525 with

pipe filter

DMV SE 5065 with

pipe filter

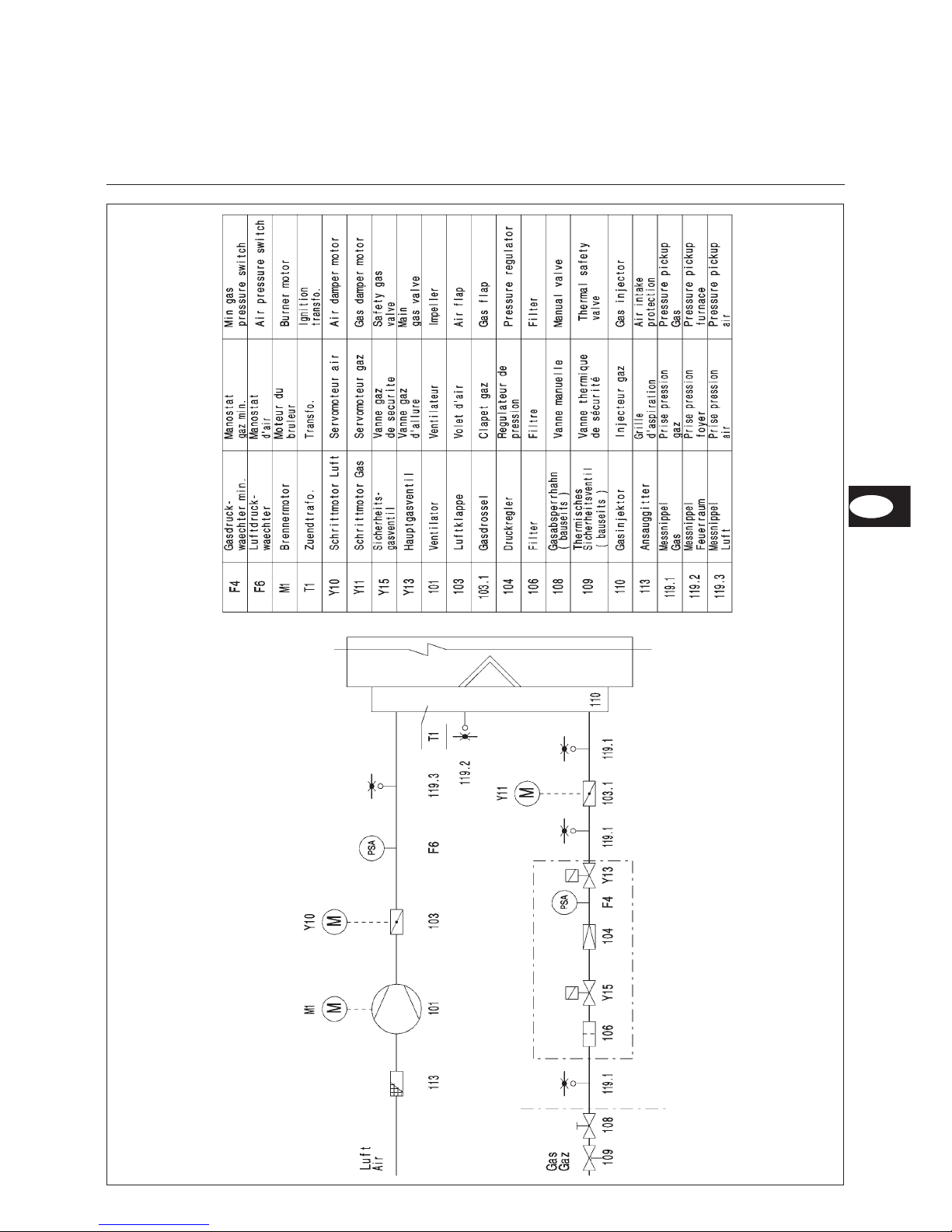

Page 9

9

09/2005 - Art. Nr. 13 019 526A

Overview

Hydraulics diagram

EN

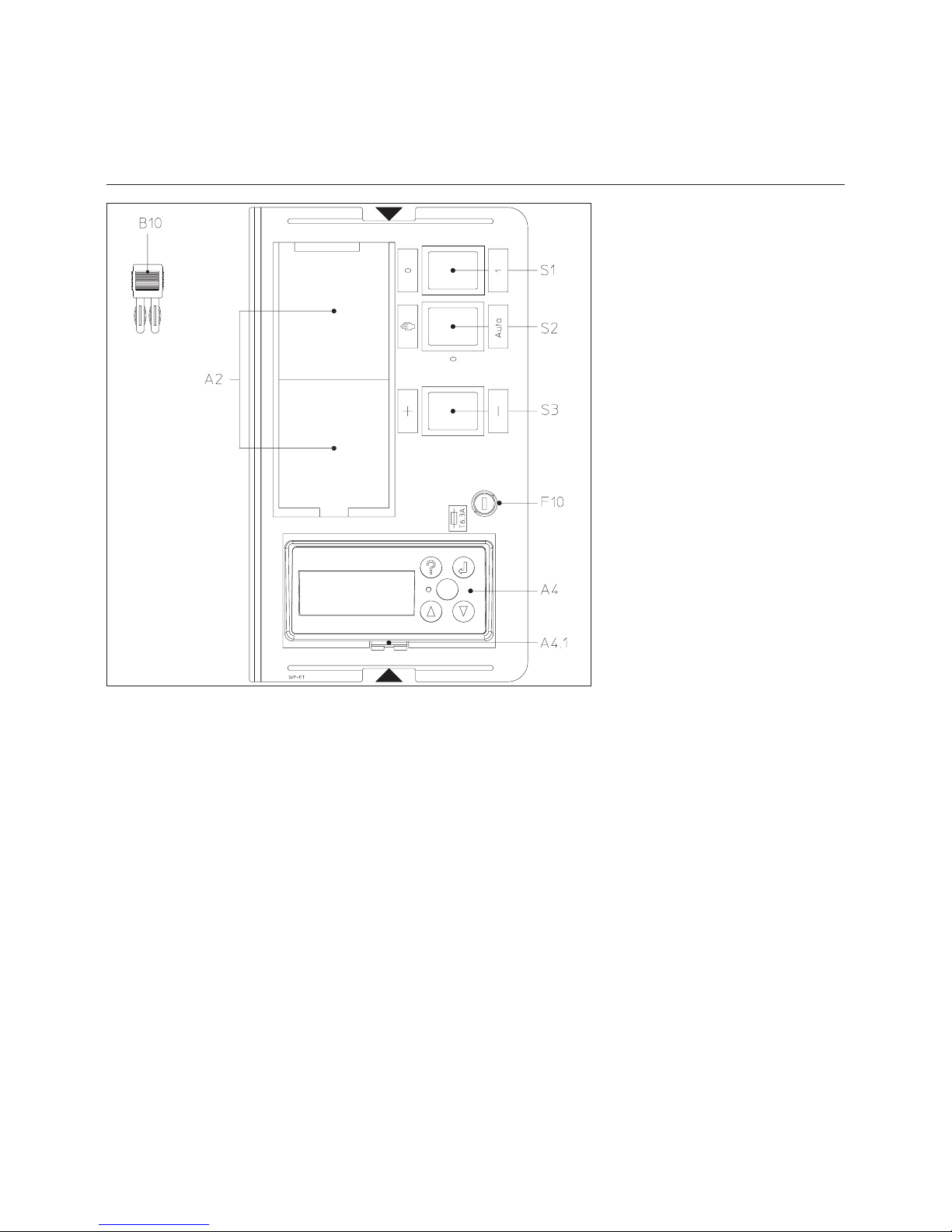

Page 10

10

09/2005 - Art. Nr. 13 019 526A

Overview

Control panel

Function

A2 Standardised position for

fitting three-point regulator

A4 Display and operating unit

A4.1 Mounting location with clips

for removing the display and

operating unit

B10 Flame signal measuring

bridge (concealed)

F10 Fuse

S1/H10 Main switch

0 Off

1On

(operating light in switch lights up).

S2 Operating mode selector

switch Auto/Manual N

S3 + Manual increase of

burner power

- Manual reduction of

burner power

All control elements are visible

externally. A removable transparent

cover clipped to the burner cover gives

access to the monitoring and control

elements for setting and operating

the burner.

The control panel contains the

switching circuit cut-out.

To remove the cover, press in one or

both sides gently and pull out at the

same time.

To replace the cover, position the two

clips at the appropriate openings and

push in.

m

N.B.:

The main switch of the control panel

only operates the control voltage.

Before working in the control area of

the burner, disconnect it fully from the

mains, incl. burner motor AC

connection.

Page 11

11

09/2005 - Art. Nr. 13 019 526A

Overview

Combustion control unit MPA22

Function description

In addition to the function of a gas

combustion control unit, the MPA 22

combustion control unit also realises

power modulation of the burner via the

actuation of air flaps and gas throttle in

an electronic connection. The electronic

connection controls the opening of the

gas throttle proportional to the air flap

along a curve based on 10 adjustment

points. During start up, the adjustment

points are defined based on the

measurement values of the exhaust

gas analysis.

This guarantees optimal combustion

across the entire performance

modulation of the burner.

With adjustment point P0, a separate

ignition load can be defined for the

burner.

The thresholds for the normal range are

defined with adjustment points “bu” and

“bo” (lower operasssting point and

upper operating point). In addition,

other optional functions, such as leak

checks, reventilation or waiting times

can be activated.

The combustion control unit is operated

via a display and operating unit.

1 Additional propane gas valve ¬

2 Safety gas valve Y15

3 Main gas valve Y13

4 Burner motor M1

5 Ignition transformer T1

6 Power 230V-50Hz

7 GW max: Bridge connector

(Safety chain inlet ¬)

8 GW min F4

9 GW VPS ¬

10 Air pressure switch F6

11 Light sensor ¬

12 Flame monitor UV/Ion ¬

13 Pulse counter ¬

14 Gas servomotor Y11

15 Air servomotor Y10

16 Display and operating unit

connection A

17 e-Bus connection ¬

18 Power regulator connection 4P

19 Boiler control panel connection 7P

¬ Option

¬

¬

¬

¬

¬

EN

Page 12

12

09/2005 - Art. Nr. 13 019 526A

·

Access to Info mode (t < 5 s).

·

Access to voice mode (t > 5 s).

·

Return to next highest program level.

· Activating a function.

· Confirming a value.

· Moving the cursor anti-clockwise.

· Increasing the marked value.

· Moving the cursor clockwise.

· Reducing the marked value.

·

Unlocking the combustion control unit.

·

Red light diode flashes in the event of a fault.

Overview

Combustion control unit MPA 22

Display and operating unit

Display

Button

Current values and operating statuses are displayed via the display and operating

unit. By activating certain keys, it is possible to switch to info mode, operating

mode or voice mode in addition to adjustment mode.

Page 13

13

09/2005 - Art. Nr. 13 019 526A

Overview

Combustion control unit MPA 22

Program structure

Adjustment mode

Enter access code

Set key data

P9/P1/P0

Start burner via

boiler regulator

for hot

adjustment

Operation at bu

(lower operating

point)

Back to

operating display

–

eBus address

–

Reventilation time

–

Waiting time

–

Pulses per L/m³

–

Rest pos. Air flap

–

Delete error list

–

Check for leaks

–

Valve 1 check time

–

Valve 2 check time

–

Address regulation

Voice mode

Parameters SettingsCountersErrors

Info mode

Burner start-up

Adjustment of

upper/lower threshold

points

Setting for points P0

to P9

Temperature

controller on

Operating mode

Ready for operation

Temperature

controller on

Operation

t>5 s

t<5 s

Start-up

Check air pressure

switch

Pre-ventilation

Safety time

Stabilization time

·

Error 0

·

Error 1

·

Error 2

·

Error 3

·

Error 4

·

Error 5

·

Fuel

·

Value P0

·

Value P1

·

Value P2

·

Value P3

·

Value P4

·

Value P5

·

Value P6

·

Value P7

·

Value P8

·

Value P9

Hot adjustment

Parameter

adjustment

Cold adjustment

Burner burns in

ignition setting

Calculation of

characteristics curve

points P2 .....P8

·

Francais

·

English

·

Deutsch

·

Italiano

·

Nederlands

·

eBus address.

·

Rest pos. Air

·

Check for leaks

·

Reventilation

·

Error list

·

Software

·

Automatic

control unit

·

Version

·

Date

·

Product

·

No.

·

Fuel

consumption (m)

·

Total operating

time (hours)

·

Successful

burner starts

EN

Page 14

14

09/2005 - Art. Nr. 13 019 526A

Boiler door preparation

·

Prepare the burner plate/boiler doors

as per the drawing.

·

Stipulate interior diameter Ø 195 mm.

·

Four M10 holes (220-260 mm

diameter circle) are required, as

indicated in the accompanying

diagram.

DE

Assembly

Burner head

Burner housing

Fitting the burner housing

·

Dismantle the mixing unit before fitting

the burner housing.

·

Undo the fixing screw (M10 counter

nut and Allen screw) on the side of

the unit (opposite the gas connection)

and withdraw the mixing unit.

If the burner housing hangs below the

burner head axis, proceed as follows:

·

Unscrew and remove the two lower

nuts on the burner housing and

unscrew the two upper nuts as far as

possible.

·

Place the burner housing sloping

diagonally forwards and fit the two

upper bolts into the two slots in

the burner head flange.

·

Press the burner housing against

the burner head flange and tighten

the 4 nuts.

The housing can be mounted above

the axis of the burner head if

required. In this case, the procedure

must be reversed.

No other positions for the burner

housing are possible.

Fitting the burner head

·

Screw M10 stay bolts into the

burner plate/boiler door and add the

insulation. If the bolt circle is <260,

cut slots to the required size.

·

Fix the burner head with 4

hexagonal nuts M10

Blast tube installation depth

On boilers with reverse firing or on

three-pass boilers, the blast tube

installation depth must be complied with

for correct operation. The following

standards are to be reconciled with the

boiler manufacturer’s specifications.

–

Boiler in reverse firing chamber

Dimension A = Boiler front to reverse

edge of second pass

–

Three-pass boiler

80-190 mm

Insertion depth

-20 to +90 mm

Insertion depth

Øa Øb c d

195 220-260 M10 45°

Page 15

15

09/2005 - Art. Nr. 13 019 526A

Assembly

Gas valve assembly

Assembly Gas valve assembly

·

Press the gas throttle module 5 against

the burner head and tighten the 4

nuts. Then secure the gas connection

pipe 3 to the gas throttle module.

Check that O-Ring 6 and flat gasket 4

are in the correct position.

·

Secure gas valve 2 so that the

solenoids of DMV SE are positioned

vertically over the gas valve.

·

Fit the supplied gas pressure tube 7

between the gas throttle module and

DMV SE.

·

If available, secure external filter 1.

·

Note the direction of the flow.

·

Fit a thermally triggered safety valve

and a gas ball valve (provided by

manufacturer) before the gas valve.

m

If the position of the gas train is

angled, use the enclosed

right-angled pressure release pipe

with screw connection.

If the gas valve is changed, the

applicable guidelines and

regulations must be observed. All

connections should be leak-tested

using foam-producing or similar

materials.

Caption

1 External filter

2 Gas valve

3 Gas connection pipe

4 Flat gasket between gas

connection pipe and gas throttle

module

5 Gas throttle module

6 O-Ring between gas throttle

module and burner head flange

7 Gas pressure tube

1

2

3

4

65

7

EN

Page 16

16

09/2005 - Art. Nr. 13 019 526A

Assembly

Checking/Setting

Mixer unit for natural gas/propane gas

Recommended setting for propane gas

On the gas diffusers labelled C, 2

outwards-facing slots and 1

inwards-facing slot should be left

covered by sleeve E.

Secure the turbulator with 5 solid

M5x6 screws (diffuser D) and 1 drilled

M5x6 screw F (diffuser C).

On the gas diffusers labelled D, 2

outwards-facing slots and 0

inwards-facing slots should be left

covered by sleeve E.

1

Checking the mixing unit

·

Check and adjust the setting of the

ignition electrodes and the

turbulator.

Recommended setting for natural gas

On the gas diffusers labelled A, 5

outwards-facing slots and 1

inwards-facing slot should be left

covered by sleeve E.

Secure the turbulator with 6 drilled

M5x6 screws F.

On the gas diffusers labelled B, 5

outwards-facing slots and 0

inwards-facing slots should be left

covered by sleeve E.

Fitting the mixing unit

·

Release and remove the mixing unit

cover by unscrewing the three Allen

screws 1.

·

Check the gas connection O-ring.

·

Fit the mixing unit and tighten with

screw at side (M10 counter nut and

Allen screw).

·

Fit the extension rod with 0-40 scale

(loose in accompanying pack) for

setting the turbulator.

·

The extension rod must be pushed

into the steel sleeve until it makes

contact.

·

Feed ignition cable 2 and ionisation

cable 3 through the opening and

push in the rubber bushing.

·

Screw down the cover, connect the

ignition cables 2 and ionisation

cable 3.

Page 17

17

09/2005 - Art. Nr. 13 019 526A

Assembly

Gas supply

Electrical supply

Electrical supply to the burner

For connection of the burner and

regulator, the corresponding circuit

diagram is mandatory.

The power supply and the electrical

connections must comply with the

applicable standards.

m

N.B.:

·

Before connecting the burner to the

electrical supply, close the gas

ball valve.

· Set the main switch of the burner

control panel to zero.

Before any intervention on the

connector of the gas and air servomotors, the display or the e-Bus connection, the burner must be switched off by

disconnecting the 7-pin plug.

Burner motor connection

The burner is delivered with a neutral

wire and earthing for a mains voltage of

400V-50Hz AC.

The connection cable for the burner

motor must be run through the cable

fittings and wired to the terminal strip as

indicated in the electrical diagram.

Check the direction of rotation of the

fan motor (see arrow on burner casing)

via manual activation of the burner

protection device.

Gas valve connection

·

Connect the gas valve to the plugs

located on the burner (black to

black, grey to grey).

·

Insert connector 1 between burner

and gas throttle servomotor in

accordance with the diagram below.

Burner and regulation connection

Insert the 4-pin and 7-pin plug of the

boiler control panel in the correspond

-

ing sockets of the burner.

General regulations for the gas supply

·

Connection of the gas valve

assembly to the gas mains must be

carried out by a recognised

specialist.

·

The cross-section of the gas cable

must be such that the prescribed

gas flow pressure at the gas valve

inlet is not undershot.

Burner start-up automatically implies

acceptance of the system. This is the

responsibility of the installer or his

representative as he alone can

guarantee that the system conforms to

the current standards and regulations.

The installer must hold a licence issued

by the gas authority, must have

checked the system for leaks and must

have vented it.

EN

Page 18

18

09/2005 - Art. Nr. 13 019 526A

Start-up

Default settings

Burner power Dimension

Y

mm

Air flap opening Gas throttle opening Pressure

adjustment

setting

pVA mbar

Low loadkWRated load

kW

Ignition

load

P0 (°)

Low load

P1 (°)

Rated load

P9 (°)

Ignition

load

P0 (°)

Low load

P1 (°)

Rated load

P9 (°)

140 400

10 0 0 25 23 23 39 15

150 500

20 0 0 29 23 23 43 15

160 600

35 5 5 40 24 24 50 15

170 700

40 5 5 45 24.5 24.5 62 15

Natural gas settings table G 05.700 MODULO

Natural gas settings table G 05.1000 MODULO

Burner power Dimension

Y

mm

Air flap opening Gas throttle opening Pressure

adjustment

setting

pVA mbar

Low loadkWRated load

kW

Ignition

load

P0 (°)

Low load

P1 (°)

Rated load

P9 (°)

Ignition

load

P0 (°)

Low load

P1 (°)

Rated load

P9 (°)

170 600

20 0 0 38 26.5 26.5 56 15

170 700

25 2 2 41 26.5 26.5 65 15

200 800

30 6 6 68 27 27 90 18.5

220 900

35 8 8 68 28 28 90 18.5

250 1000

40 9 9 68 29 2 90 18.5

Propane gas settings table G 05.700 MODULO

Propane gas settings table G 05.1000 MODULO

Burner power Dimension

Y

mm

Air flap opening Gas throttle opening Pressure

regulator

setting

pVA mbar

Low loadkWRated load

kW

Ignition

load

P0 (°)

Low load

P1 (°)

Rated load

P9 (°)

Ignition

load

P0 (°)

Low load

P1 (°)

Rated load

P9 (°)

140 400

10 4 4 20 19 19 30.5 15

150 500

20 4 4 29 19 19 36 15

160 600

30 4 4 36 19 19 41 15

170 700

40 4 4 40 19 19 45 15

Burner power DimensionY

mm

Air flap opening Gas throttle opening Pressure

regulator

setting

pVA mbar

Low loadkWRated load

kW

Ignition

load

P0 (°)

Low load

P1 (°)

Rated load

P9 (°)

Ignition

load

P0 (°)

Low load

P1 (°)

Rated load

P9 (°)

170 600

15 6 6 36 19.5 19.5 42 17.5

170 700

20 6 6 63 19.5 19.5 75 17.5

200 800

25 7 7 63 19.5 19.5 75 17.5

220 900

35 7 7 68 19.5 19.5 75 17.5

250 1000

40 8 8 68 22 22 75 17.5

The above setting data are basic settings. The factory setting data are in boxes with thick black borders. The burner can

normally be run using these settings. Check the setting values carefully in each case. System-specific corrections may be

necessary.

Page 19

19

09/2005 - Art. Nr. 13 019 526A

Start-up

Burner head position setting,

Gas pressure switch and air pressure switch

Burner head position

Dimension Y is set by turning screw V.

Set the burner head setting in accordance

with the table. The burner head setting can

influence the starting performance and

burner performance.

Gas pressure switch

·

Remove the transparent cover.

·

Set the setting scale to 5 mbar

(natural gas and propane gas).

The gas pressure switch min. is

installed between the valves. The gas

safety valve Y15 is actuated one

second before the safety time. Within

this time, the gas pressure switch must

release. If there is insufficient gas

pressure, the burner starting is

interrupted and a waiting time of 2

minutes starts. Start-up is then

attempted again. The waiting time can

only be reset by cutting the power supply

to the device.

Waiting times: 3 x 2 minutes, then 1 hour

Air pressure switch

·

Remove the transparent cover.

·

Provisionally set the air pressure

switch to the minimum setting.

Pressure regulator setting

The gas pressure regulator is set to the

default setting in the factory (see page

18). Check the gas pressure after the

first time the burner is started up

(measuring point: gas valve output

flange) and if necessary correct the gas

pressure pBr using setting screw S. Do

not change it again after start-up.

EN

Page 20

20

09/2005 - Art. Nr. 13 019 526A

Start-up

Checks before start-up

Control unit auto-test

Air Gas

Burner check

Control unit unprogrammed

Control unit auto-test

Switch the burner on via the main switch. The combustion control unit executes an

auto-test. If the control unit has not yet been programmed, the display shows

“Control unit unprogrammed”

Auto-test of the control unit and of the air and gas servomotors

This display loads the values contained in the combustion control unit.

The control unit has not yet been programmed.

Loading values

100%

0%

Pre-start-up check

·

Disconnect the burner by unplugging

it from the power supply.

·

Close gas valves.

·

Note the operating regulations of the

heat generator and regulation

producer.

·

Check that the gas type and gas

pressure are appropriate to the

burner.

·

Check the gas conduit for leaks

·

Vent the fuel supply pipes.

·

Check the flame pipe insertion depth

in accordance with the boiler

manufacturer’s instructions.

·

Check:

–

if the fresh air supply and the

exhaust gas paths correspond to the

burner power.

–

if there is water pressure in heating

circuit,

–

if the circulation pump is running,

–

if the mixer opens,

–

if the draught regulator in the

chimney opens,

–

if the power supply is in order,

–

thermostat settings,

·

Check the direction of rotation of the

fan motor (see arrow on burner

casing) via manual activation of the

burner protection device.

If all the checks were successful, then

ensure that:

·

Main switch 0/1 is set to zero

·

Manual/Auto operating type selector

switch is at the centre position

·

Gas ball valve is closed

·

Re-energise the burner.

Page 21

21

09/2005 - Art. Nr. 13 019 526A

Start-up

Access to adjustment mode

Parameters menu: Programming additional functions

Access to adjustment mode

·

Press and hold the key and after 0.5 seconds, press the key.

·

Enter the numbers for the access code with the or key.

· Confirm each number with .

· For input fields, switch back to the next highest level with .

After entering the correct code, three menus are available for selection.

Parameter: for programming additional functions.

Cold adjustment: for pre-adjusting the burner for initial start-up.

Hot adjustment: for only partial programming, e.g. after regulator

shutdown during adjustment or with subsequent

correction of the adjustment values.

Parameter

The “Parameters” menu item is selected from adjustment mode. This allows

various additional functions and function parameters to be configured.

–

E-Bus address: 03H: standard address (factory setting).

This parameter is required for communication with a PC.

The following addresses are possible: F3H, 73H, 33H, 13H.

Access to next parameter: continue with key.

–

This parameter allows you to configure a reventilation time.

Adjustment range: 0 seconds (= no reventilation) to 240 seconds

–

This parameter allows you to configure a waiting time between a regulator

shutdown and a burner restart.

Adjustment range: 0 minutes (= no waiting time) to 100 minutes

–

The pulse factor gives the number of pulses that the control unit receives from

the gas counter with the flow rate of a cubic metre of natural gas (accessory).

Adjustment range: 1 (1 pulse = 1m

3

) to 255 ( 255 pulses = 1m3).

Cold adj. Hot adj.

Parameters

?

Code ____

Accessing the adjustment settings

It is only possible to access adjustment

mode when the burner is idle (display:

“Control unit unprogrammed” or “Ready

for operation”.) To do this, set the

Manual/Auto operating type selector

switch on the burner control panel to

the centre position. In addition, the

access code must be entered to

activate adjustment mode.

N.B.:

Only a specialist with sufficient

training in and authorisation to deal

with MPA 22 may activate

adjustment mode via the access

code and adjust the burner.

The access code is located at the

bottom of the information label on

the MPA 22.

During the setup process, a timeout of

30 minutes is active, which is reset by

pressing a key on the keypad. Upon

expiry of the timeout, a safety shutdown

is executed. This ensures that a longer

operating time is not possible without

the setup process being completed. In

adjustment mode, all safety functions

are activated. A flame failure, air

pressure switch failure or an error in the

servomotor actuation leads to a

malfunction shutdown or safety

shutdown.

?

Next

E-Bus address

03H

Next Back

Reventilation time

000s

Next Back

Waiting time (0-100 min)

000 min

?

Pulses per l/m

3

?

EN

Page 22

22

09/2005 - Art. Nr. 13 019 526A

Next Back

Rest pos. Air flap

00.0°

Next Back

Delete error list

Next Back

Check for leak

Y

Next Back

Valve 1 check time

006s

Next Back

Valve 2 check time

006 s

Next Back

Address Regulation

10H

Connection setup

Save parameters

–

This parameter allows you to adjust the rest position of the air flap.

This parameter (in degrees) may be required after reventilation.

Default setting 00.0°

–

With this function, accumulated errors are deleted from the error log

(display information: “Empty”). The next new error is written under

No. 0 in the error log.

–

Leak check: Y= Yes/N= No

With this function, you can deactivate the valve leak check.

–

Valve 1 check time:

For proper execution of the leak check, at least the 6 seconds set in the

factory are required.

Adjustment range: 1-240 s

–

Valve 2 check time:

For proper execution of the leak check, at least the 6 seconds set in the

factory are required.

Adjustment range: 1-240 s

–

Address regulation (factory setting to 10H)

Other addresses are possible: F7H, F0H, 77H, 70H, 37H, 30H, 17H.

–

After confirming “Next” in the “Address regulation” menu item, the newly

adjusted parameters are saved in the control unit. The control unit then

switches back to “Ready for operation”.

Start-up

Adjustment mode

Parameters menu: programming of additional functions

Control unit unprogrammed

Page 23

23

09/2005 - Art. Nr. 13 019 526A

Start-up

Adjustment mode

Cold adjustment menu: Burner pre-adjustment

Cold adjustment (with ball valve closed)

In the “Cold adjustment” menu item, the P9/P1/P0 key data are pre-adjusted in

accordance with the setting table (page 18) for the desired burner power.

The control unit then calculates the intermediate points P2 to P8 and switches to

the “Hot adjustment” menu.

·

Accessing the adjustment mode.

·

Select cold adjustment with or .

·

Confirm with .

Adjust air and gas setting.

·

Position the cursor on air or gas with or .

·

Activate with (cursor flashes).

·

Set new value with or .

·

Confirm with .

Switch between adjustment points P9/P1/P0.

· Position cursor on “Next” or “Back” with or .

· Confirm with .

· If the position “Next” is confirmed for adjustment point P0 with , the

control unit calculates the intermediate points P2 to P8 and then switches to

the hot adjustment menu .

Direct access to this menu via adjustment mode/hot adjustment

.

?

Next

Next Back

Low load

P1

Air: .. ` . Gas: ..´ .

Next Back

Ignition load P0

?

?

start adjustment

Burner via boiler

regulator for hot adj

?

Air: .. ` . Gas: ..´ .

Air: .. ` . Gas: ..´ .

Full load P9

EN

Page 24

24

09/2005 - Art. Nr. 13 019 526A

Start-up

Adjustment mode

Hot adjustment menu: Adjusting the burner

Hot adjustment (with first start for function check, still with closed ball valve)

Hot adjustment of the burner

In the “Hot adjustment” menu items, the fine adjustments for the air and gas flap

are made for the ten adjustment points P0 to P9 using the exhaust gas analysis.

Then, the definitive working range of the burner is defined based on the bu (lower

operating point) and bo (upper operating point) thresholds.

Note: if normal shutdown takes place during the adjustment procedure,

select the “Hot adjustment” menu item immediately after activating

adjustment mode. By doing this, you will keep the values of the points that

have already been adjusted, while a recalculation is carried out in the “Cold

adjustment” menu.

·

For burner start, set the Manual/Auto burner selector switch to manual on the

control panel, ensure heat request via boiler regulator.

The burner starts with the following function sequence:

–

Air flap opens for ventilation. Air: .........................

–

Blower motor on. ....................................

–

Check air pressure switch

–

Pre-ventilation 20 seconds: time remaining is displayed.

–

Gas throttle moves to ignition position. Gas: .................

–

Servomotor air flap moves to ignition position. Air: ............

–

Ignition on .........................................

Because the ball valve is closed, the burner shuts down after the safety time as the

gas pressure is too low.

The display shows: “Gas pressure too low”.

·

If the function check was successful, the gas valve is opened.

After a two-minute waiting time, the burner is automatically restarted and the

above-mentioned process is repeated.

–

Valve energised. ....................................

–

Safety time 3 seconds. After the safety time, the ignition transformer is

de-energised.

–

Flame signal present. .................................

During the stabilisation time, the burner remains in ignition setting.

Burner check

Air: - Gas: -

Start-up

Air pressure check

Pre-ventilation: 20 s

Air: - Gas:

Pre-ignition

Air: Gas: -

Safety time

Stabilisation time

Air: Gas: -

Air: - Gas: -

Air: - Gas: -

Air: - Gas: -

Page 25

25

09/2005 - Art. Nr. 13 019 526A

Start-up

Adjustment mode

Hot adjustment menu: adjusting the burner

Next

Ignition load P0

Air: .. ` . Gas: ..´ .

Next Back

Low load P1

Next Back

Adjustment point P2

Point P3 .... Point P8

Next Back

Full load P9

Next

Lower load point bu (lower

operating point)

Next

Upper load point bo

(upper

operating point)

Operation

Burner remains in ignition load, adjustment point P0.

·

Check gas pressure pBr (for factory setting, see default setting on page 18).

In the event of a later change, all adjustment settings must be corrected.

Therefore, start fine adjustment of the burner at P9. In each adjustment point,

check the combustion values and, if necessary, change the gas throttle setting

or air flap setting. To do this:

·

Select air or gas with or .

·

Activate with (cursor flashes).

·

Change value with or .

·

Confirm with .

Access to the next adjustment point by selecting Next and confirm by pressing key .

Important:

The values for each adjustment point are only saved when you access the

next adjustment point.

·

Enter the adjustment values in the log (page 30).

·

Move the individual adjustment points to point 9 (full load).

· Check gas flow rate full load, if necessary increase or reduce gas and air.

· If all adjustment points from P0 to P9 are optimised in adjustment point P9,

confirm with “Next” .

The burner moves to the lower operating point (bu).

· Check the low load exhaust gas temperature and gas flow rate, if necessary

adjust the burner power by correcting bu (lower operating point).

· Confirmation “Next”.

The burner moves to the upper operating point (bo).

·

Check the high load exhaust gas temperature and gas flow rate. If necessary

adjust the burner power by correcting bo (upper operating point). The

adjustment is made by changing the air flap.

·

Confirm with “Next” to complete the adjustment procedure. The burner

switches to operating mode.

·

Burner moves to lower operating point and waits for a request for heat.

·

Manual/Auto operating type selector switch to manual: burner power can be

changed manually via the +/- switch.

·

Manual/Auto operating type selector switch to Auto:

burner adjusts bu/bo within the specified power range in accordance with the

requirements of the regulation thermostat.

Adjust air pressure switch

·

When the burner is running at rated load, calculate the blower pressure.

·

Set air pressure switch approx. 15% below calculated value.

Air: .. ` . Gas: ..´ .

Air: .. ` . Gas: ..´ .

Air: .. ` . Gas: ..´ .

Air: .. ` . Gas:

Air: .. ` . Gas:

Air: .. ` . Gas:

EN

EN

Page 26

26

09/2005 - Art. Nr. 13 019 526A

Start-up

Operating mode

Burner check

Air: Gas:

Start-up

Air: Gas:

Air pressure check

Pre-ventilation: 20 s

Pre-ignition

Safety time

Stabilisation time

Operation

Burner ready for operation

Boiler thermostat requests heat.

Burner start flowchart:

The burner starts with the following function sequence:

–

Air flap opens for ventilation. Air: .........................

–

Blower motor on. ....................................

–

Pre-ventilation 20 seconds: time remaining is displayed.

–

Gas throttle moves to ignition position. Gas: .................

–

Air flap moves to ignition position. Air: .....................

–

Ignition on .........................................

–

Valve energised. ....................................

–

Safety time 3 seconds

–

Flame formation. ....................................

After the safety time, the ignition transformer is de-energised.

·

During the stabilisation time, the burner remains in ignition setting.

·

The burner is in operation and adjusts bu (lower operating point) to bo

(upper operating point) within the specified performance range

(manual/Auto operating type selector switch to Auto). The current setting

of the air flap is displayed.

Standby

Air: Gas:

Air: Gas:

Air: Gas:

Air: Gas:

Air: Gas:

Air: Gas:

Page 27

27

09/2005 - Art. Nr. 13 019 526A

Start-up

Info mode

Voice mode

·

Press key t < 5s.

·

Select desired menu with or .

·

Confirm selected menu with .

· Scroll with or .

· Return to the next highest level with .

Error Counter

Parameter Setting

?

Establishing connection

?

0% 100%

Info 1

Info 2

?

Info 3

Parameters SettingsCountersErrors

Comment: info mode can be activated

with the button during burner operation

and burner idle time. To exit info

mode, press the button again.

·

Error 0

·

Error 1

·

Error 2

·

Error 3

·

Error 4

·

Error 5

·

Fuel Gas.

·

Value P0

·

Value P1

·

Value P2

·

Value P3

·

Value P4

·

Value P5

·

Value P6

·

Value P7

·

Value P8

·

Value P9

Voice mode can be activated with the button during burner operation and burner

idle time.

·

Press button t > 5s .

·

Select desired language with or .

·

Scroll with or (5 languages possible).

·

Confirm selected language with . This will close voice mode.

FRANCAIS

ENGLISH

DEUTSCH

DEUTSCH

ITALIANO

NEDERLANDS

·

eBus address.

·

Rest pos. Air

·

Check for leaks

·

Reventilation

·

Error list

·

Software

·

Automatic

control unit

·

Version

·

Date

·

Product

·

No.

·

Fuel

consumption (m)

·

Total operating

time (hours)

·

Successful

burner starts

EN

Page 28

28

09/2005 - Art. Nr. 13 019 526A

Burner and boiler servicing can only

carried out by a trained specialist.

The system operator is advised to

take out a service contract to

guarantee regular servicing.

N.B.:

Before maintenance and cleaning work,

completely separate the burner from

the mains, including the power supply

AC motor, and close the gas ball valve.

A1 Combustion control unit

A4 Display and operating unit

B10 Ionisation bridge

F6 Air pressure switch

F12 Protective motor relay

K1 Motor contactor

M1 Burner motor

T1 Ignition transformer (concealed)

Y10 Servomotor air flap

7 Control panel

8 Blast tube

13 Burner cover

113 Air box

Maintenance

Checking the exhaust gas temperature

·

Check the exhaust gas temperature.

·

Clean the boiler if the exhaust gas

temperature is over 30 K above the

start-up value.

Checking the ignition electrodes

and the mixing unit.

·

Disconnect the 2 ignition cables

from the ignition transformer.

·

Remove the grommet for the two

cables from the cover by pressing

into the burner head.

·

Unscrew completely the 3 screws

securing the cover.

·

Slip the cover off over the cables.

·

Loosen the side screw securing the

mixing unit.

·

Pull out the mixing-ignition unit.

·

Check the condition of the turbulator.

·

Check the position of the ignition

electrodes and the turbulator.

·

If necessary, remove dust from the

parts accessible with the cover

removed.

·

Check the presence and condition of

the O-ring seal J1 when assembling.

Cleaning the fan

·

Disconnect the motor by unplugging

it from the power supply.

·

Unscrew the 7 screws of the motor panel.

·

Remove the panel and motor, taking

care not to damage the gas

pressure tube of the differential air

pressure switch.

·

“Dry” clean the air pressure pipes.

·

Do not use pressurised materials.

·

Take out the 4 screws securing the

air guiding piece.

·

Thoroughly clean the air duct and fan.

·

Reassemble.

Page 29

29

09/2005 - Art. Nr. 13 019 526A

Valves

No special maintenance is required for

the valves.

Valves must not be repaired.

Defective valves must be replaced by a

qualified professional, who must check

the leak, function and combustion

values following replacement.

Remove the blast tube.

To carry out this procedure, the

combustion chamber door must be

opened or the burner removed.

–

Variant 1 -Access via the

combustion chamber doors

·

Remove the mixer control/ignition

device.

·

Loosen the 3 fixing screws on the

blast tube support by 1 to 2 turns.

N.B.: the screws are threaded to the

left (Allen 3).

·

Remove the blast tube, check,

clean, and where necessary, replace

if a deformity is found.

·

Refit the blast tube in the reverse

sequence.

·

The space between the blast tube

and the door insulation should be

fitted with flameproof material.

–

Variant 2 - Removing the burner

·

Remove the mixer control/ignition

device.

· Loosen the electrical connections.

· Remove the gas valve assembly.

· Unscrew the gas connection

(2 M8 nuts).

· Loosen the burner housing

(2 M8 screws) and remove.Do not

damage electrical cables.

· Unscrew the burner head and then

proceed as under variant 1.

· Refit in the reverse sequence.

Precautions

After each intervention, check the

combustion performance under real

operating conditions (doors shut,

cover fitted etc.).

Note down the results in the

corresponding report forms.

Replacing the filter on the gas valve

The filter must be checked once a year

and replaced if dirty.

Pocket filter:

·

Release the cover fixing screws on

the filter.

·

Remove the filter.

·

Insert new filter.

·

Refit the cover with the screws.

Tube filter:

·

Dismantle the gas connection flange

at the inlet side.

·

Remove the filter.

·

Insert new filter.

·

Fit a gas connection flange.

·

Open the manual stop valve; check

tightness.

Cleaning the hood

·

Clean the cover with water and a

cleaning product.

·

Do not use chlorine-based or

abrasive cleaning products.

Maintenance

EN

Page 30

30

09/2005 - Art. Nr. 13 019 526A

Burner-specific adjustment settings of the MPA 22

Measurement/Date:

Parameters Dim Range M1/ M2/ M3/ M4/

eBus address

Reventilation time [s] 0-240

Waiting time [min] 0-100

Pulses per L/m³ 1-255

Rest pos. Air flap [°]

Delete error list blank/

Check seals Y/N

Valve check time 1 [s] 0-240

Valve check time 2 [s] 0-240

Address regulation

Software

Product No.

Counters Dim.

Fuel consumption [m³]

Total operating hours [hours]

Successful burner starts

Measurement/Date:

M1/ M2/ M3/ M4/

Measurement Measurement

Air M1 M2 M3 M4 Gas M1 M2 M3 M4

Value P0 [°] [°]

Value P1 [°] [°]

Value P2 [°] [°]

Value P3 [°] [°]

Value P4 [°] [°]

Value P5 [°] [°]

Value P6 [°] [°]

Value P7 [°] [°]

Value P8 [°] [°]

Value P9 [°] [°]

bu/flow rate [°] [m³/h]

bo/flow rate [°] [m³/h]

bu/Value CO2/CO [%] [ppm]

bo/Value CO2/CO [%] [ppm]

System: ..........................................

Burner No.: .....................................

Boiler manufacturer: ...............................

Boiler type: ..............................................

Observer M1: .....................................................

Observer M2: .....................................................

Observer M3: .....................................................

Observer M4: .....................................................

Page 31

31

09/2005 - Art. Nr. 13 019 526A

Service

Troubleshooting

Fault diagnosis and repair

Before carrying out fault diagnosis,

check that the basic requirements for

correct operation are being fulfilled:

·

Is there any current?

·

Is there any gas pressure?

·

Is the gas stop valve open ?

·

Are all control and safety devices,

such as the boiler thermostat,

low-water detector, limit switch, etc.

adjusted properly?

Error/fault Cause Corrective action

Display without information No mains voltage present

External cut-out defective

Display-control unit plug-and-socket

connection interrupted

Display defective

MPA 22 defective

Check

Check/replace

Check/establish connection

Replace

Replace

Display “Safety chain” No feedback on terminal 7 Insert bridge connector or given

Check switch/limiter

Motor does not start Control unit-motor plug-and-socket

connection interrupted

Capacitor defective

Motor defective

Control unit/servomotors feedback not

correct

Establish connection

Check/replace

Check/replace

Control unit/servomotors

Check/replace

Motor only runs briefly Air pressure switch does not activate

Gas pressure switch does not activate

Gas filter dirty

Magnetic valve V1 does not open

No gas available

Check/change adjustment

Check/change adjustment

Clean/replace gas filter

Check/replace compact valve

Notify gas supplier

Note: in the event of a gas shortage,

the waiting time can be reset by

de-energising the burner (7-pin plug)

Burner does not start Compact valve defective

Ignition transformer defective

Ignition electrode position/Ignition cable

MPA 22 control unit defective

Ionisation probe/IRD probe

Replace

Replace

Check/replace

Check/replace

Check/replace

Crack formation on ionisation probe Too much gas on probe

Circulation insufficient

Fit solid screws (propane gas set)

If a fault occurs on the burner, the red

light diode flashes on the display unit.

At the same time, the cause of the fault

is displayed and a fault code is

displayed.

EN

Page 32

32

09/2005 - Art. Nr. 13 019 526A

Adresse Service-Hotline

ELCO Austria GmbH

Aredstr.16-18

2544 Leobersdorf

0810-400010

ELCO Belgium n.v./s.a.

Pontbeeklaan-53

1731 Zellik

02-4631902

ELCOTHERM AG

Sarganserstrasse 100

7324 Vilters

0848 808 808

ELCO GmbH

Dreieichstr.10

64546 Mörfelden-Walldorf

0180-3526180

ELCO France

18 rue des Buchillons

74106 Annemasse

0450877624

ELCO-Rendamax B.V.

Amsterdamsestraatweg 27

1410 AB Naarden

035-6957350

Fabriqué en EU. Made in EU. Hergestellt in der EU. Gefabriceerd in de EU

Document non contractuel. Non contractual document. Angaben ohne Gewähr.

Niet-contractueel document

AT

BE

CH

FR

DE

NL

Loading...

Loading...