elco VARION C-POWER 30.0, VARION C-POWER 7.2, VARION C-POWER 25.0, VARION C-POWER 20.0, VARION C-POWER 11.0 Operation Manual

...Page 1

Operation manual

Combined heat and power unit

VARION® C-POWER S, M, M+

06.2019

Made in Germany

Page 2

Contents

1. Document information. . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Supporting documents. . . . . . . . . . . . . . . . . 4

1.3 Safety instructions . . . . . . . . . . . . . . . . . . . 5

1.4 Explanation of symbols . . . . . . . . . . . . . . . . 5

2. Safety information ...........................6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Authorised target groups . . . . . . . . . . . . . . . 6

2.2.1 Manufacturer ........................ 6

2.2.2 Operator ............................ 6

2.2.3 Trained personnel .................... 6

2.2.4 User ............................... 6

2.3 General safety instructions . . . . . . . . . . . . . . 7

3. Product information ..........................8

3.1 Functional principle . . . . . . . . . . . . . . . . . . 8

3.2 Registering with the energy provider . . . . . . . . . 8

3.3 Modes of operation . . . . . . . . . . . . . . . . . . 8

3.3.1 Ready for e-car charging button ........ 8

3.3.2 Summer operation ................... 8

3.3.3 Heat-optimised ...................... 8

3.3.4 Electricity-optimised .................. 8

3.3.5 Shutdown ........................... 8

3.4 Safety devices. . . . . . . . . . . . . . . . . . . . . . 9

3.5 Product variants . . . . . . . . . . . . . . . . . . . . 9

3.5.1 VARION® C-POWER S ................. 9

3.5.2 VARION® C-POWER M. . . . . . . . . . . . . . . . . 9

3.5.3 VARION® C-POWER M+ ............... 9

3.6 Product overview. . . . . . . . . . . . . . . . . . . 10

3.6.1 Generation unit ..................... 10

3.6.2 Control cabinet ..................... 10

3.6.3 Modem ............................ 10

3.6.4 Expansion tank connection block ...... 11

3.6.5 MSM adapter magnetic filter (“MSM

filter”) ............................. 11

3.7 Scope of supply . . . . . . . . . . . . . . . . . . . . 11

4. Storage ...................................12

5. Assembly ..................................13

5.1 Safety instructions for assembly . . . . . . . . . . 13

5.2 Installation location requirements . . . . . . . . . 13

5.2.1 Overview of the installation location ... 13

5.2.2 Premises ........................... 14

5.2.3 Heating system ..................... 15

5.2.4 Flue ............................... 15

5.2.5 Exhaust air duct ..................... 15

5.2.6 Supply air supply .................... 15

5.2.7 Gas supply ......................... 15

5.2.8 Water supply ....................... 16

5.2.9 Condensate drain ................... 16

5.2.10 Power supply ....................... 16

5.2.11 Reactive current compensation ........ 16

5.2.12 Mobile communications network ...... 16

5.3 Assembly steps . . . . . . . . . . . . . . . . . . . . 17

5.3.1 Preparing for assembly ............... 17

5.3.2 Unpacking the system ................ 17

5.3.3 Positioning the generation unit ........ 18

5.3.4 Screwing the control cabinet in position 19

5.3.5 Screwing the expansion tank

connection block in position 19

5.3.6 Connecting the generation unit ........ 19

5.3.7 Connecting the temperature sensors ... 23

5.3.8 Connecting the modem .............. 23

5.3.9 Connecting the control cabinet ........ 24

5.3.10 Checking the connections ............ 24

5.4 Test run . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4.1 Opening the generation unit .......... 25

5.4.2 Preparing the expansion tank

connection block .................... 26

5.4.3 Replenishing the cooling water ........ 26

5.4.4 Starting the test run ................. 27

5.4.5 Checking the system ................. 27

5.4.6 Stopping the test run ................ 28

5.4.7 Closing the generation unit ........... 28

6. Commissioning .............................29

7. Operation .................................30

8. Cleaning ...................................31

9. Service repairs .............................32

9.1 Maintenance . . . . . . . . . . . . . . . . . . . . . 32

9.2 Fault resolution . . . . . . . . . . . . . . . . . . . . 32

9.3 Repair . . . . . . . . . . . . . . . . . . . . . . . . . 33

10. Disassembly ...............................34

11. Disposal ...................................35

11.1 Disposing of packaging. . . . . . . . . . . . . . . . 35

11.2 Disposing of the system . . . . . . . . . . . . . . . 35

2

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 3

12. Appendix ..................................36

12.1 Hydraulic diagrams . . . . . . . . . . . . . . . . . . 36

12.1.1 Heating system variant 1 –

1 VARION® C-POWER, 1 buffer tank,

peak load boiler connected directly to

buffer tank ......................... 37

12.1.2 Heating system variant 2 –

1 VARION® C-POWER, 2 buffer tanks,

peak load boiler connected directly to

buffer tank ......................... 38

12.1.3 Heating system variant 3 –

1 VARION® C-POWER, 1 buffer tank,

peak load boiler connected to buffer

tank via hydraulic separator ........... 39

12.1.4 Heating system variant 4 –

1 VARION® C-POWER, 2 buffer tanks,

peak load boiler connected to buffer

tank via hydraulic separator ........... 40

12.1.5 Heating system variant 5 –

2 VARION® C-POWER, 2 buffer tanks,

peak load boiler connected to buffer

tank via hydraulic separator ...........

12.2 Energy label . . . . . . . . . . . . . . . . . . . . . . 42

12.2.1

12.2.2 VARION® C-POWER M. . . . . . . . . . . . . . . . 42

12.2.3

12.3 EC declaration of conformity .

VARION® C-POWER S ................

VARION® C-POWER M+ ..............

. . . . . . . . . . .

41

42

42

43

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

3

Page 4

Document informaon

i

1. Document information

1.1 Validity

Original operation manual.

This manual is valid for the following products and

performance categories:

B VARION® C-POWER S

B VARION® C-POWER 5.0

B VARION® C-POWER 7.2

B VARION® C-POWER M

B VARION® C-POWER 11.0

B VARION® C-POWER 16.0

B VARION® C-POWER 20.0

B VARION® C-POWER M+

B VARION® C-POWER 25.0

B VARION® C-POWER 30.0

1.2 Supporting documents

i

Additional documents belong to this operation manual and

must be observed.

“ELCO/Control” operation manual

The “ELCO/Control” operation manual describes how

to control the system via the operational display and is

included in the scope of delivery.

Wiring diagrams

The wiring diagrams are located on the inside of the control

cabinet door.

Technical data

The document for technical data is included in the scope of

delivery.

Manuals for system components

The manuals for the supplied system components (e.g. MSM

filter, modem) are included in the scope of delivery.

Manuals for accessories

The manuals for optional accessories (e.g. flue gas silencer,

exhaust air kit) are provided with each product.

This document is valid for all products with a serial number

starting with “ID 2000” onwards.

The descriptions are identical for all products; any

differences are specifically highlighted.

All illustrations show the product “VARION® C-POWER S”.

In this manual, the word “system” is used to denote the

product.

This manual is protected by copyright law. Duplication,

reproduction and transmission is only permitted with the

permission of the manufacturer.

Subject to change without notice.

Maintenance manual

The maintenance manual describes specific tasks for

maintaining the system that must only be performed by the

manufacturer. The maintenance manual is not included in

the scope of delivery.

Forms

Various forms for exchanging information (e.g. commissioning

request, datasheet for the generation system) are included

with the delivery.

4

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 5

Document informaon

i

1.3 Safety instructions

D DANGER!

Information highlighted with the word HAZARD warns

against a hazardous situation that will lead to death or

severe injury.

D WARNING!

Information highlighted with the word WARNING warns

against a hazardous situation that can lead to death or

severe injury.

D CAUTION!

Information highlighted with the word CAUTION warns

against a situation that can lead to minor or moderate

injuries.

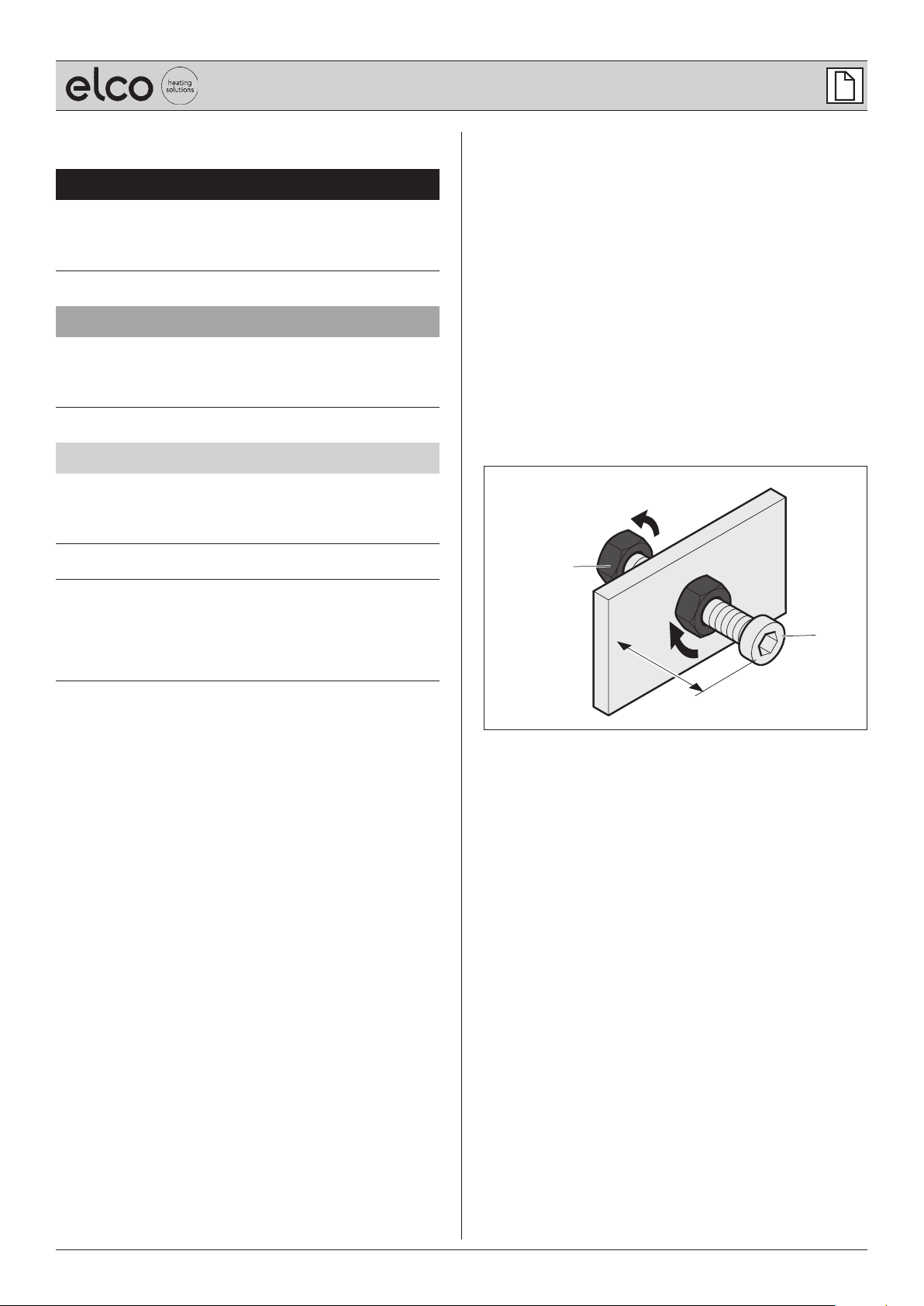

1.4 Explanation of symbols

Text

A Required action

B List

Cross reference to another point in this document

D

Cross reference to other documents that must be

observed

Internet link

Ј

Illustrations

2.

B

D ATTENTION!

Information highlighted with the word ATTENTION

warns against a situation that can lead to material or

environmental damage.

1.

x

1. Numbered action sequence

A Part designations with upper case letters

x Dimensions with lower case letters or units in mm

Arrows indicating movement and direction

A

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

5

Page 6

Safety informaon

2. Safety information

2.1 Intended use

The system is a combined heat and power unit for

generating electricity and heat. The system is intended

exclusively for incorporation in heating circuits in buildings.

The system is designed for bivalent operation, i.e. it must

be combined with an additional heat source (“peak load

boiler”) in order to operate.

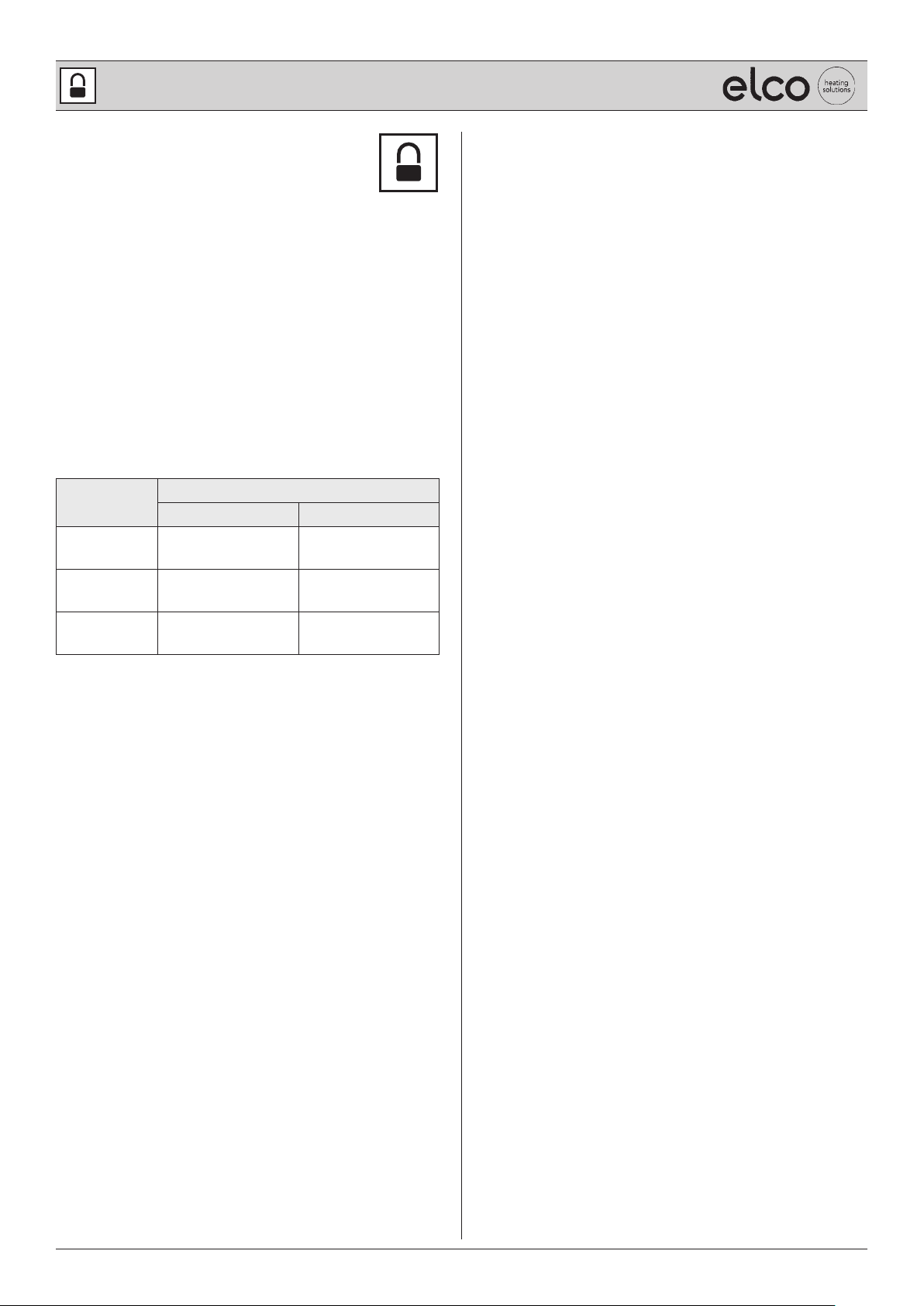

The system is designed for the following energy demand.

System Annual energy requirement

Electricity kWh Heat kWh

VARION®

C-POWER S

VARION®

C-POWER M

VARION®

C-POWER M+

The system is only permitted for use in a technically

sound condition once it has been commissioned by the

manufacturer or a specialist partner authorised by the

manufacturer.

Intended use also includes reading and following this

manual.

20,000 - 50,000 60,000 - 100,000

80,000 - 130,000 180,000 - 300,000

100,000 - 250,000 200,000 - 400,000

2.2.2 Operator

The operator is responsible for the building in which the

product is installed. The operator has the following duties:

B Fulfilling the requirements specified by the energy

provider (e.g. registration, approval, compensation).

B Meeting the installation location requirements.

B Training the user.

B Complying with statutory occupational health and safety

obligations.

B Complying with the valid safety, accident prevention and

environmental protection regulations.

B Providing and complying with the documentation.

B Ensuring that the product is always kept in a technically

sound condition.

B Storing the system when necessary.

2.2.3 Trained personnel

Trained personnel are responsible for the assembly,

maintenance, disassembly and disposal of the product.

The following points must be observed:

B All tasks must only be performed by qualified personnel

who have been trained by the manufacturer and who

are familiar with assembly technology, gas and water

installations, and current safety regulations.

B Special installation tasks (e.g. tasks involving the

building structure or the ventilation system) must only

be performed by the suitably qualified personnel of

specialist companies.

B Electrical installations must only be performed by

qualified, skilled electricians.

Only qualified personnel trained by the manufacturer have

access to the “Specialist” area of the “ELCO/Control” control

mechanism.

Any other use is considered contrary to intended use.

2.2 Authorised target groups

This manual is intended for various target groups that are

authorised for specific duties.

2.2.1 Manufacturer

The manufacturer, ELCO GmbH, supplies the product and

has the following duties:

B Training experts on assembly, maintenance, disassembly

and disposal.

B Commissioning the system.

Only the manufacturer has access to the “Experts” area of

the “ELCO/Control” control mechanism.

6

2.2.4 User

Users may perform operational and cleaning tasks on this

product. Obligations of the user:

B To be trained on the product by the operator.

B To be familiar with this manual.

Trained users have access to the non-protected areas of the

“ELCO/Control” control mechanism, but not to the “Experts”

and “Specialist” areas.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 7

Safety informaon

2.3 General safety instructions

D WARNING!

Hazard caused by failing to observe the manual.

This manual contains important information for handling the

system safely. Potential hazards are specifically highlighted.

Failing to observe such information can lead to death or

severe injuries.

A Read the manual carefully.

A Follow the safety instructions contained in this manual.

A Follow the safety instructions on the system

A Store the manual in an accessible place.

If you can smell gas, immediately proceed as follows:

B Close the gas valve.

B Do not generate any naked flames.

B Do not operate any electrical switches

(e.g. light switches, all-pole separating points).

B Do not use any electrical appliances in the

hazardous area (e.g. telephone).

B Ventilate the rooms.

B Inform the manufacturer, gas utility company or qualified

service company.

The manufacturer does not accept any liability or guarantee

for damage or loss in the following cases:

B Failing to observe this manual.

B Contrary-to-intended use.

B Improper handling.

B Use by unauthorised target groups.

B Failing to meet the installation location requirements.

B Using replacement parts that have not been authorised

by the manufacturer.

B Bypassing the system’s safety devices.

B Removing the system’s seals and sealants.

B Failing to comply with the maintenance intervals.

Additional safety instructions are provided in the respective

chapters of this manual.

“4. Storage” (page 12).

D

“5. Assembly” (page 13).

D

“6. Commissioning” (page 29).

D

“7. Operation” (page 30).

D

“8. Cleaning” (page 31).

D

“9. Service repairs” (page 32).

D

“10. Disassembly” (page 34).

D

“11. Disposal” (page 35).

D

Use of the system is prohibited in the following cases:

B If the system or individual components are damaged.

B If the system has been altered or modified without

authorisation.

B If the supply and return lines (e.g. gas, flue gas, water,

electricity, condensate drain) are altered or modified

without authorisation.

B If any safety devices are missing or inoperable.

“3.4 Safety devices” (page 9).

D

B During the construction phase of the building.

B If the system has been in storage for more than

16 weeks after delivery.

“9. Service repairs” (page 32).

D

B If the system has been decommissioned for more than

16 weeks.

B For children or individuals who are incapable of

assessing the hazards associated with operating the

system.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

7

Page 8

Product informaon

3. Product information

3.1 Functional principle

The combustion of gas powers a high-performance

alternator that produces electricity.

The heat that is generated by this process is used for hot

water provision and heating.

This principle is referred to as combined-heat-and-power.

3.3 Modes of operation

The system can be operated in five modes of operation

(including shutdown). The modes of operation are set via

the operational display.

“ELCO/Control” operation manual.

3.3.1 Ready for e-car charging button

Special mode for charging electric

to produce electricity in this mode if the storage battery is

fully charged.

3.3.2 Summer operation

In summer operation mode, the system only operates at

minimum capacity. The system only starts if the storage

battery has insufficient charge.

3.3.3 Heat-optimised

The system starts if a temperature requirement has been

set. If the storage battery has reached a specific percentage

charge, the system begins to power down steplessly.

vehicles. It is still possible

The control mechanism manages and monitors the

combustion process in the generation unit. The system is

operated via the operational display on the control cabinet.

3.2 Registering with the energy provider

The energy provider must be informed about the installation

of the system. Obligations of the operator:

A Inform the energy provider about the system before it is

assembled.

A Fulfil the requirements specified by the energy provider

(e.g. registration, approval, compensation).

A Provide the energy provider with all the relevant system

data.

Technical data.

The electricity produced over and above the operator’s own

requirement can be fed into the energy provider’s local

electricity network in return for compensation. A suitable

application must be submitted to the energy provider for

this purpose.

3.3.4 Electricity-optimised

The system starts to operate according to a temperature

requirement. Once a specific storage battery charge has

been reached, the system aligns itself to the electricity

consumption of the building.

3.3.5 Shutdown

The system is in hibernation mode. The system does not

start according to temperature requirements.

8

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 9

Product informaon

3.4 Safety devices

D WARNING!

Risk of burns, pinching or electric shock.

The safety devices are intended to ensure the system is

handled safely. Missing or faulty safety devices can lead to

hazardous situations.

A Ensure that the protection devices are not removed.

A Follow the safety instructions on the system.

A Only remove the covers if you are required and

authorised to do so.

The system is equipped with the following safety devices:

B Emergency stop switch

B Pressure-relief valve

B Protective covers

B Safety stickers

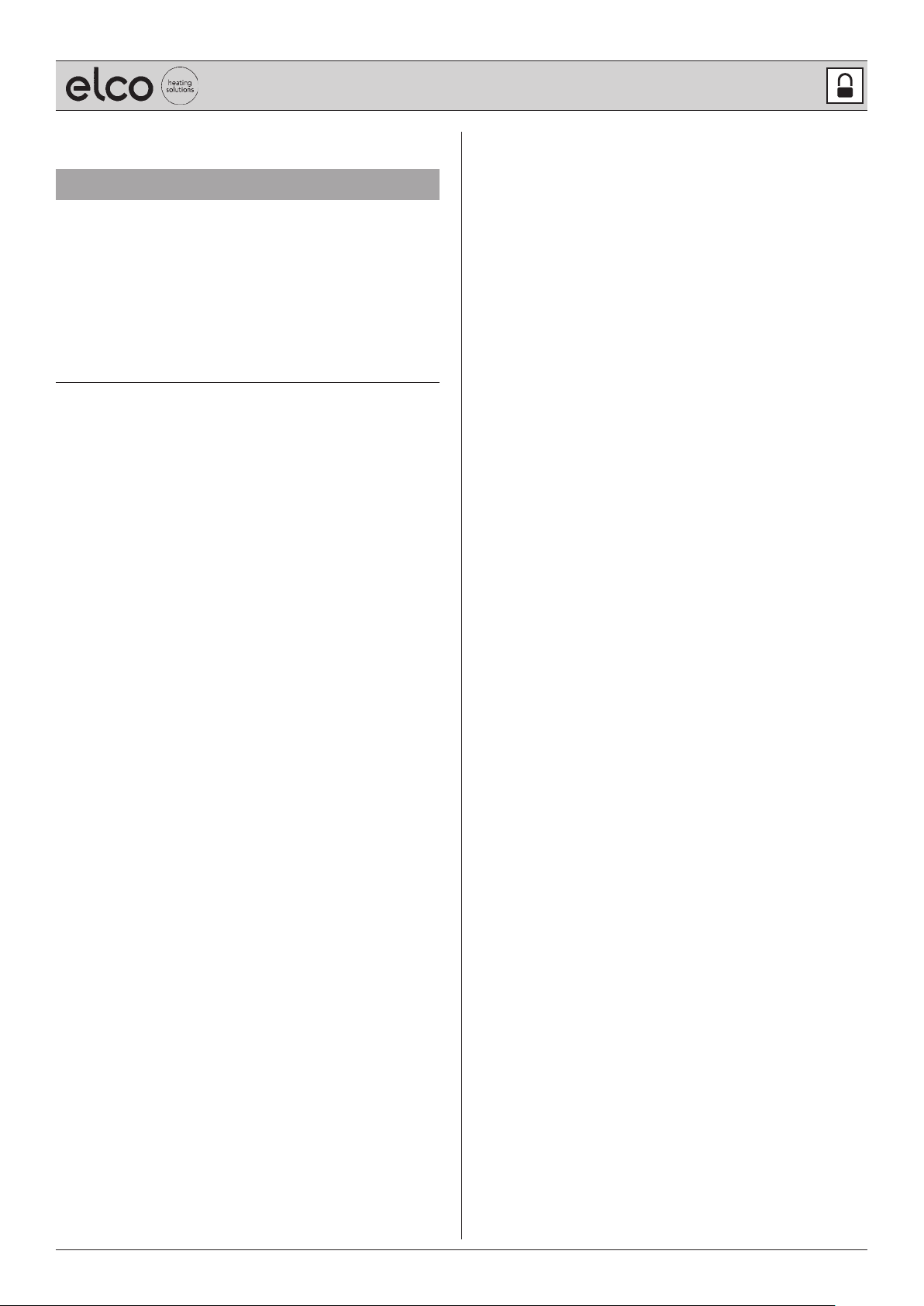

3.5 Product variants

3.5.1 VARION® C-POWER S

3.5.2 VARION® C-POWER M

B VARION® C-POWER 11.0

B VARION® C-POWER 16.0

B VARION® C-POWER 20.0

B VARION® C-POWER 5.0

B VARION® C-POWER 7.2

3.5.3 VARION® C-POWER M+

B VARION® C-POWER 25.0

B VARION® C-POWER 30.0

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

9

Page 10

Product informaon

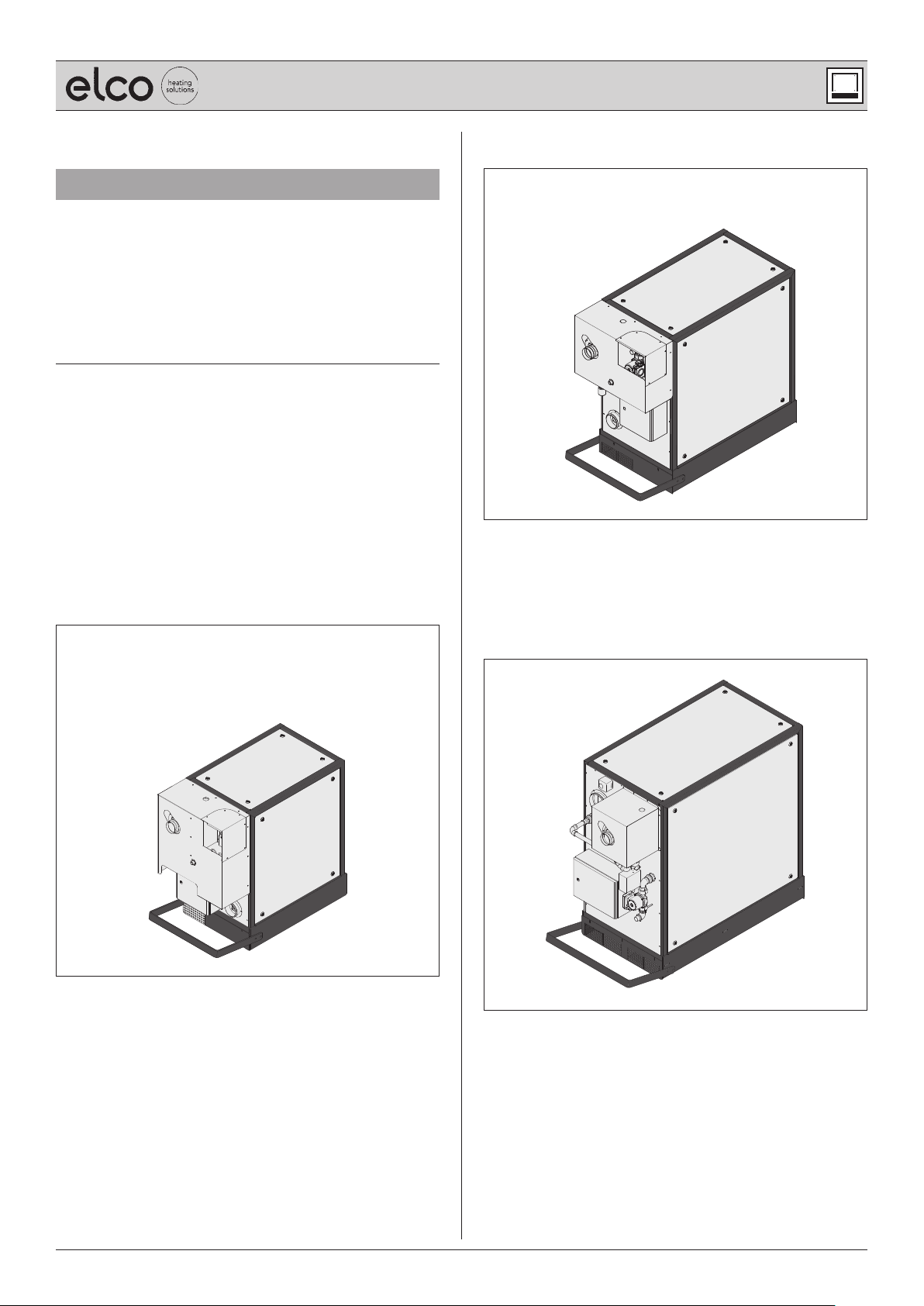

3.6 Product overview

3.6.1 Generation unit

The generation unit contains the actual combined heat and

power unit with the combustion engine, the alternator unit

and the heat exchangers.

The generation unit is the core piece of equipment for

producing the electricity and heat.

H

A

B

I

C

J

D

E

K

F

G

L

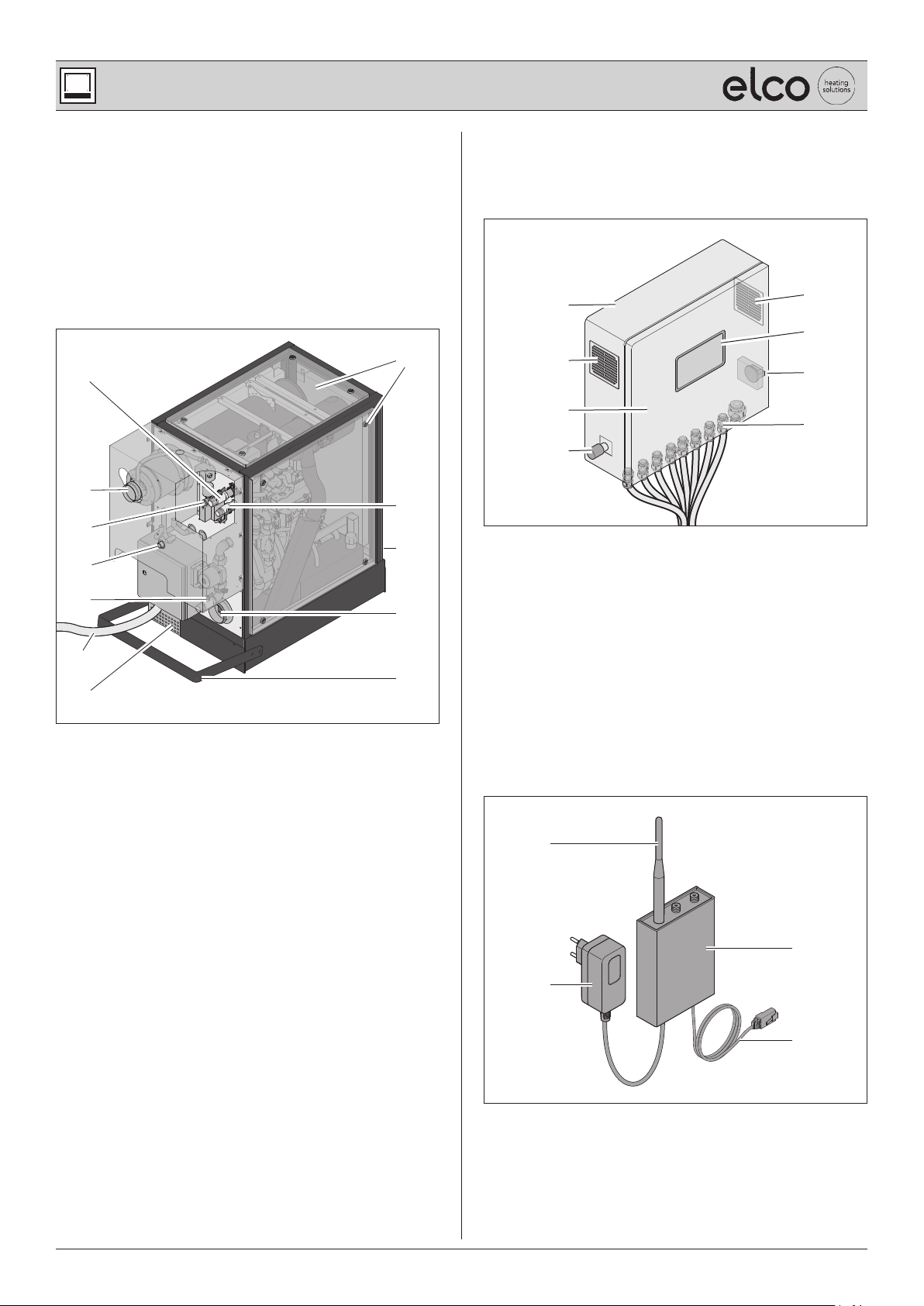

3.6.2 Control cabinet

The control cabinet contains all the components required to

control the system.

A

B

E

B

F

C

G

D

A Housing

B Aeration and ventilation

C Control cabinet door

D Emergency stop switch

E Operational display

F Master switch

G Cable bushings

3.6.3 Modem

A “Buffer water supply line” connection

B “Flue gas” connection

C “Gas” connection

D “Condensate” connection

E “Buffer water return line” connection

F Control cabinet wiring harness

G Supply air intake grille

H Housing cover

I Expansion tank connection

J Type plate

K “Exhaust air” connection (room-air dependent)

L Hoop guard

The modem makes it possible to monitor the system

remotely and read data via the mobile communications

network.

A

C

B

D

A Antenna (slot “GSM Main”)

B Power supply

C GSM modem

D Connection cable (slot “LAN 1”)

10

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 11

Product informaon

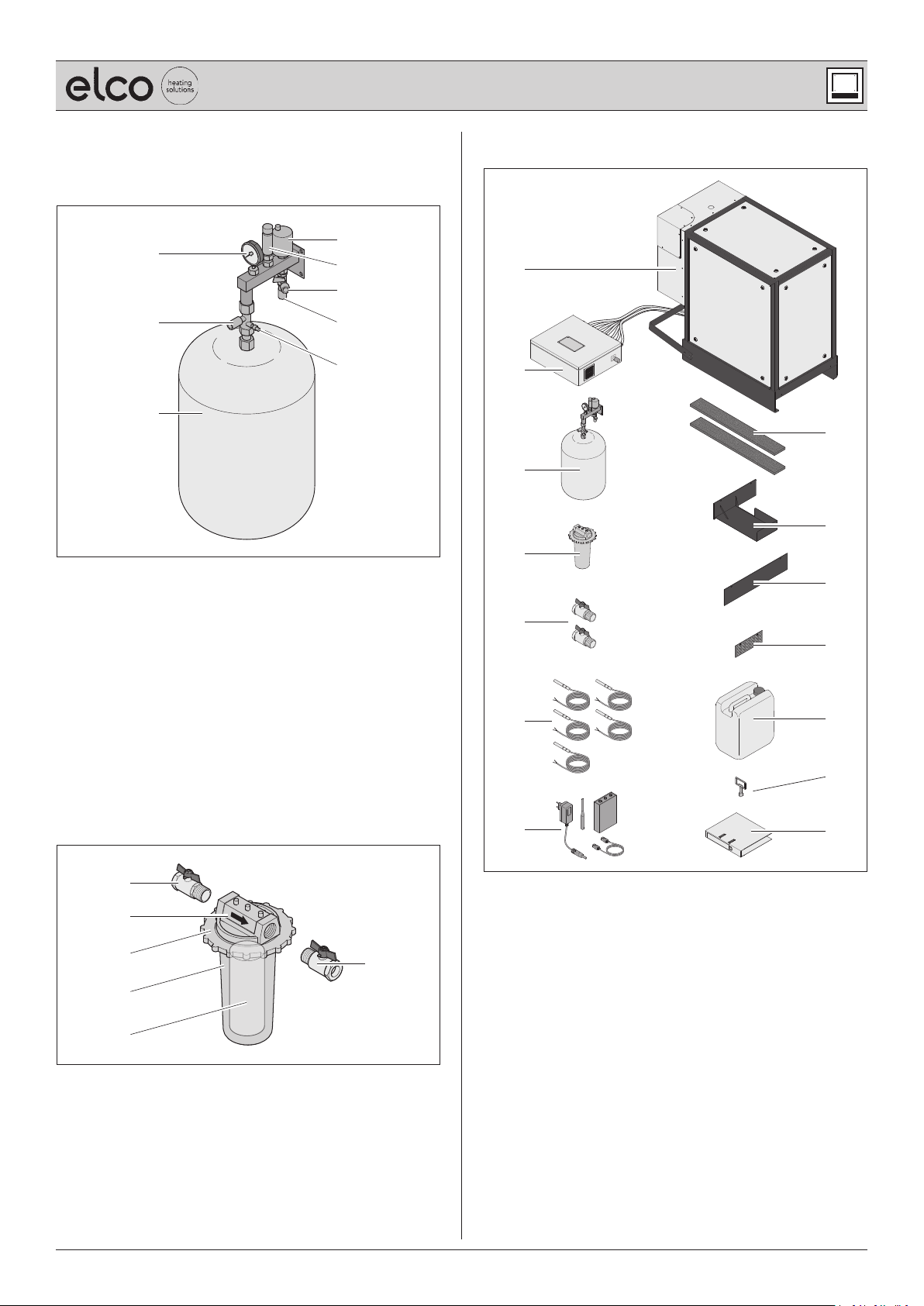

3.6.4 Expansion tank connection block

The expansion tank offsets temperature-related fluctuations

in volume within the motor circuit (primary circuit).

D

A

E

F

B

G

H

C

A Manometer

B Cap valve

C Expansion tank

D Self-bleeding device

E Pressure-relief valve

F Fill-and-drain valve (connection for replenishing "water-

glycol mixture 60:40")

G Connection to generation unit

H Drain valve

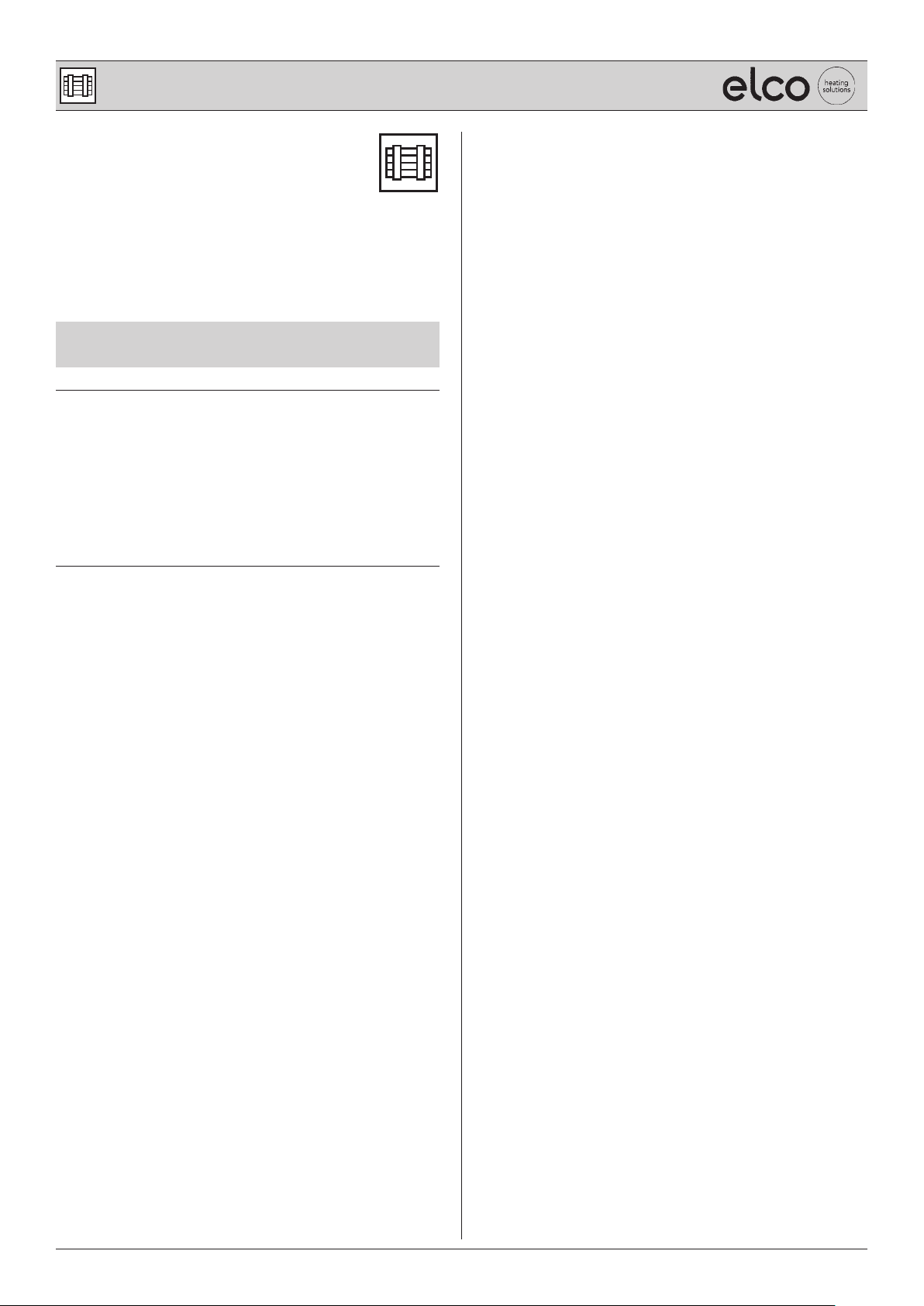

3.7 Scope of supply

A

B

C

D

E

F

H

I

J

K

L

3.6.5 MSM adapter magnetic filter (“MSM filter”)

The combination filter filters magnetite and suspended

solids out of the water in the heating system.

A

B

C

A

D

E

A Valve

B Filter head (with indication of the direction of flow)

C Lock nut

D Brass cup

E Filter cartridge

M

G

A Generation unit

B Control cabinet

C Expansion tank connection block

D MSM filter

E Valve

F Temperature sensor

G Modem

H Balance strips

I Rear cover

J Front cover

K Supply air intake grille

L Cooling medium ("water-glycol mixture 60:40")

M Square spanner

N Documentation (e.g. operation manual)

1

Includes 24 months of remote monitoring (effective from

commissioning; extension available subject to charge)

1

N

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

11

Page 12

Storage

4. Storage

The system is prepared by the manufacturer for operation

on delivery. The system must be put into operation within

16 weeks following delivery. If that is not possible, the

system must be put into storage.

Storage of the system by the operator.

“2.2.2 Operator” (page 6).

D

D ATTENTION!

Risk of damage caused by improper storage.

During long periods of downtime, lubricants and liquids

settle within the system. Frost and damp conditions can

damage parts of the system.

A Store the system in a frost-free, dry place.

A Arrange for the manufacturer to rust-proof the system if

it is to be kept out of operation for more than 16 weeks.

When taking the system out of storage, the next steps must

be discussed with the manufacturer.

A Contact the manufacturer.

12

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 13

Assembly

5. Assembly

5.1 Safety instructions for assembly

D WARNING!

Hazard caused by failing to observe the assembly

instructions.

Errors made when installing the system can cause serious

injuries or material damage to the system or the building.

This chapter contains important information regarding the

safe assembly of the system.

A Read this chapter carefully before assembling the

system.

A Follow the safety instructions.

A Carry out the assembly as described.

The assembly must only be performed by trained

personnel.

Electrical work must only be performed by qualified, skilled

electricians.

“2.2.3 Trained personnel” (page 6).

D

B The system must be undamaged and in a faultless

condition before assembly.

B Only use suitable fittings.

B Cables and lines must not be damaged, kinked or

crimped.

B Before assembling, ensure that the supply voltage has

been and remains disconnected.

The supply voltage is only reconnected when instructed

in the respective assembly step.

B The generation unit must be transported to

the installation location by means of a suitable

transportation device (e.g. lift truck).

If it is not possible to transport it to the installation

location (e.g. lack of space):

A Contact the manufacturer.

5.2 Installation location requirements

D WARNING!

Risk of suffocation, gas explosions or material damage

caused by incorrectly installing the system.

Failing to observe these requirements can lead to hazardous

situations when handling electricity or gas. This chapter

contains important information for preventing hazardous

situations.

A Ensure that all of the installation location requirements

are complied with.

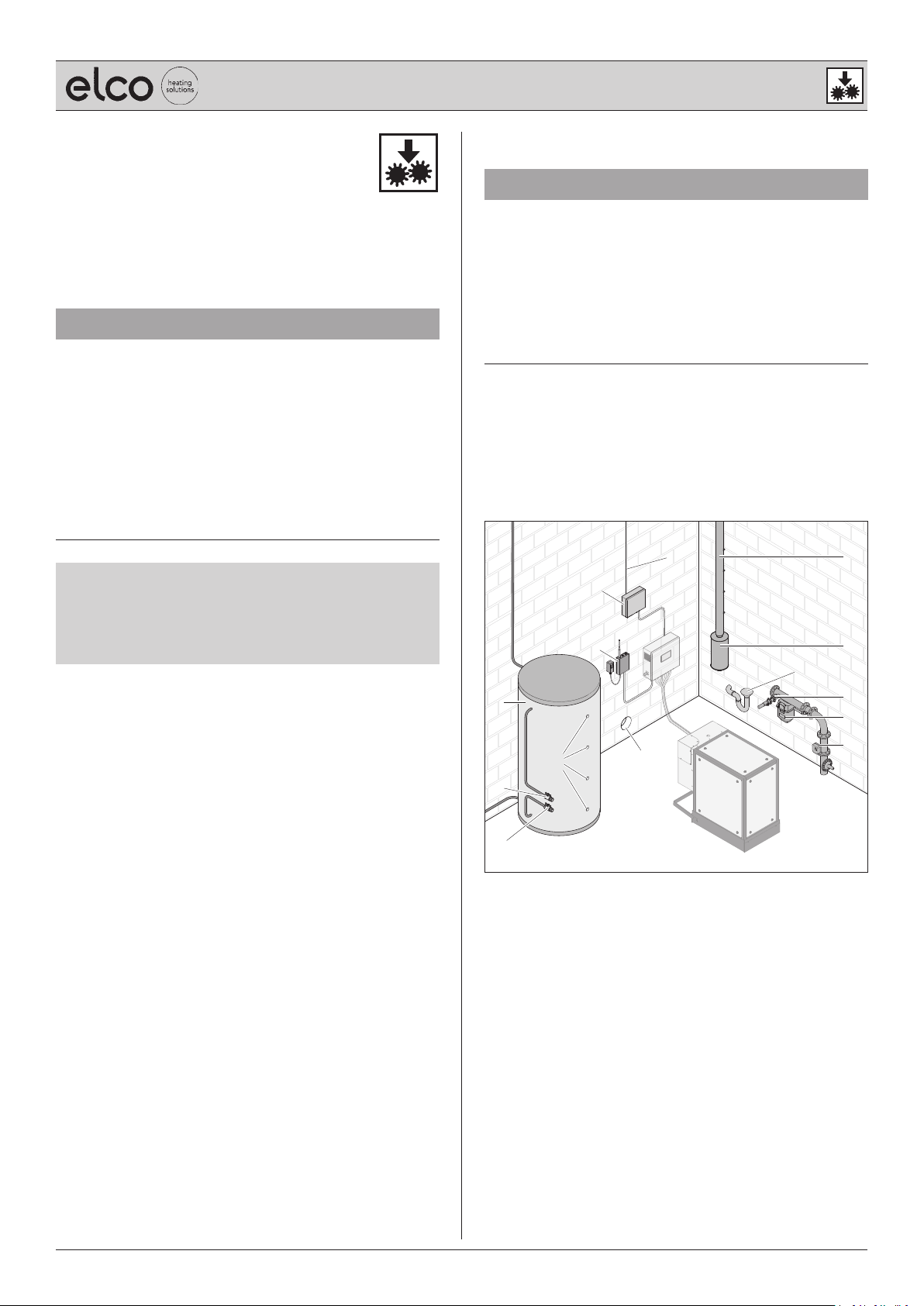

5.2.1 Overview of the installation location

To operate the system, some equipment must be provided

on site. The following illustration shows examples of the

required components.

H

E

F

A

B

G

C

D

A Buffer tank

B Temperature sensor holding fixture

A Buffer water supply line

E Buffer water return line

E Reactive current compensation

F Modem

G Supply air opening

H Supply voltage

I Flue

J Flue gas silencer

K Condensate drain

L Gas supply

M Gas meter

N Gas flow monitor

K

I

J

L

M

N

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

The heating system also includes the peak load boiler and

pipework system that connects the system via the buffer

tank.

13

Page 14

Assembly

5.2.2 Premises

The premises must meet the following requirements:

B The installation location must comply with the effective

applicable laws and regulations for boiler rooms

(e.g. in Germany, the ordinance for heat-producing

appliances (Feuerstättenverordnung)).

B The substrate on which the generation unit is to be

installed must be flat, even, solid, dry and load-bearing.

B The ambient air temperature must be between

+5°C and +30°C.

B The system must be protected against frost and the

elements.

The following are not permitted:

B Installation on floating screed.

B Operation of tumble dryers in the same room.

B Storage of explosive or highly flammable materials

(e.g. paper, paints, petrol) within the installation

location.

B Use of aggressive substances (e.g. sprays, solvents,

chlorinated cleaning agents, paints, adhesives) in the

vicinity of the system.

If the system is installed in vaulted cellars or bare smoothwalled rooms (hard-walled), there is a risk of noise and

sound resonance.

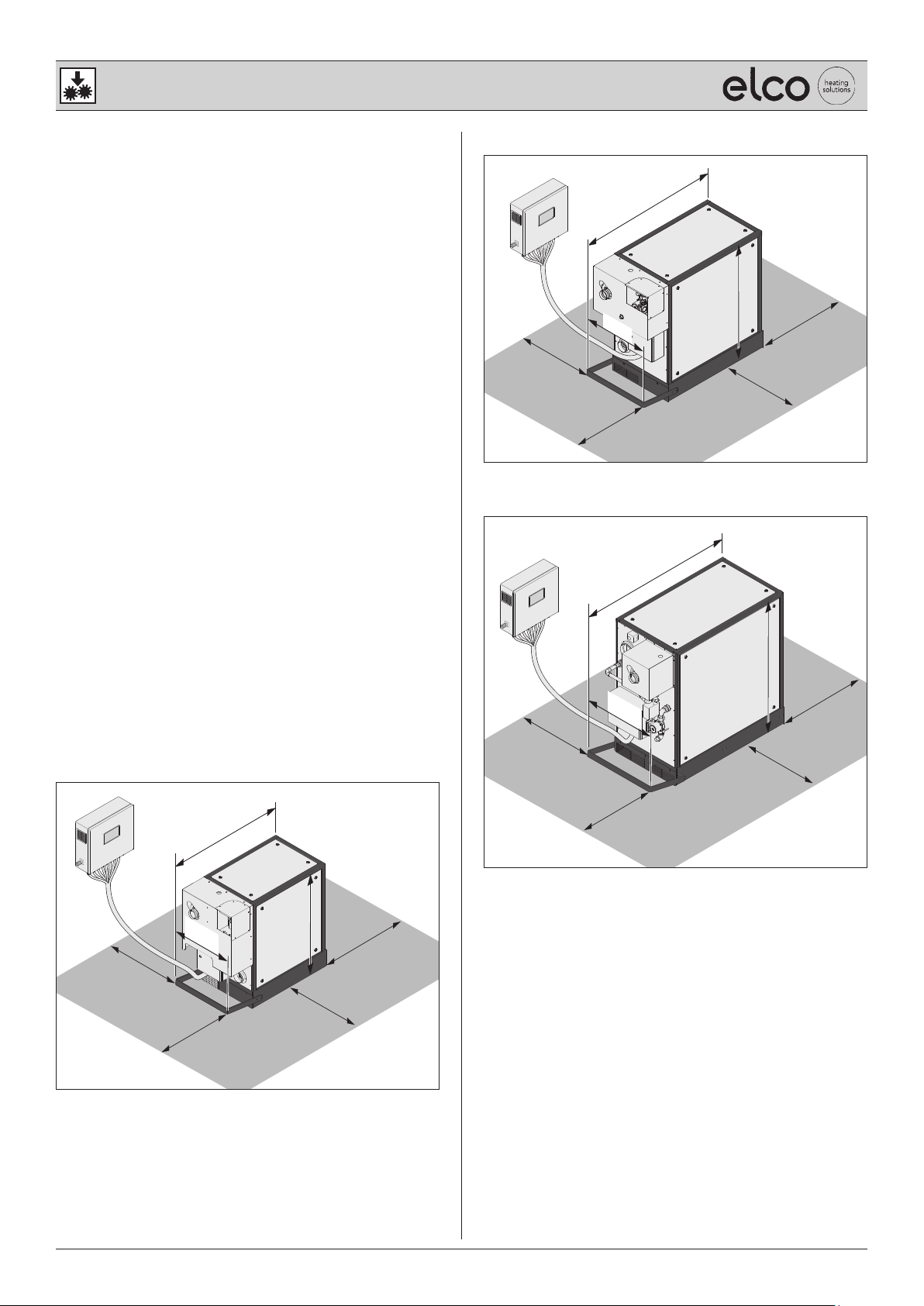

Space requirement for VARION® C-POWER M

1480

643

708

> 1000

> 1000

1097

1233

> 1000

Space requirement for VARION® C-POWER M+

1659

> 1000

The system must be positioned so that the following

requirements are fulfilled:

B None of the system’s ventilation or extraction devices

may be blocked or closed.

B The emergency stop switch must always be accessible.

Space requirement for VARION® C-POWER S

1226

635

> 1000

> 1000

1097

> 1000

> 1000

1400

> 1000

781

> 1000

> 1000

> 1000

The minimum clearance to the generation unit (> 1,000 mm

on all sides) must be maintained.

14

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 15

Assembly

5.2.3 Heating system

The structural elements of the building’s heating system

primarily comprise the peak load boiler, the buffer tank,

and the pipework system and radiators.

The peak load boiler supplies the required residual heat if

the heating energy requirement exceeds the capacity of the

system (e.g. in extremely cold weather).

The buffer tank acts as a hydraulic separator and isolates the

system from the building’s heating system.

For the system to operate, a buffer tank is required, which

must comply with the following requirements:

B The buffer tank must have holding fixtures for the

temperature sensors.

B The buffer tank must have shut-off devices fitted on the

connections to the system.

B The buffer tank must be designed to meet the system

specifications.

B Minimum 100 litres per kW thermal

for installations < 10 kW

B Minimum 50 litres per kW thermal

for installations > 10 kW

th

th

5.2.5 Exhaust air duct

D WARNING!

Risk of suffocation due to improper use of exhaust air.

The exhaust air must not be used for heating purposes.

Poisonous gases may be produced inside the generation unit

that can lead to death by suffocation.

A Ensure that the exhaust air from the generation unit is

guided outside.

A Ensure that the supply air is not contaminated by the

exhaust air.

An accessory is required (optionally available) if exhaust air

and flue gas are extracted together:

B Exhaust air kit if extracting from one system.

B Backflow preventer if extracting in combination with

another heat source (peak load boiler or another

system).

Additional devices with exhaust air (e.g. washer-dryers)

may only be installed subject to consultation with a suitable

specialist or chimney sweep.

These specifications are technical minimum conditions.

Regional or national funding guidelines (e.g. in accordance

with BAFA in Germany) may differ and must be checked.

The dimensioning of the pipework system must be designed

to meet the following requirements:

B Maximum heat requirement of the building.

B Maximum thermal capacity of the system.

5.2.4 Flue

For the system to operate, the building must have a flue,

which must comply with the following requirements:

B The local laws and regulations must be complied with

(e.g. in Germany, the building regulations).

B The flue gas routing must comply with the local

regulations (e.g. in Germany, DIN 18160).

B The flue gases must be removed via a flue.

B As a fundamental rule, the flue must extract the flue

gases via the roof.

B The dimensions for the exhaust gas ducting and flue

must be calculated on an individual basis.

B The gradient of the horizontal section must be min. 5 cm

per metre.

B The flue must be inspected and approved for operation

(e.g. by a master chimney sweep).

B A flue gas silencer must be fitted in the flue gas routing.

The flue gas silencer (optionally available) must be

installed near the generation unit.

B The flue gas routing must have a water-filled siphon at

its lowest point.

5.2.6 Supply air supply

Sufficient supply air must be supplied for the combustion

process and the ambient temperature:

B The total requirement of the heating system (e.g. for the

peak load boiler) must be born in mind.

B The supply air supply must meet the system

specification.

Technical data.

5.2.7 Gas supply

For the system to operate, a gas supply is required that must

comply with the following requirements:

B The gas supply must comply with the established

regulations (e.g. in Germany, TRGI).

B The system specifications (e.g. type and composition of

the gas) must be complied with.

Technical data.

B The building’s system must be fitted with a gas flow

monitor and a gas meter.

B The gas flow monitor must meet the system

specifications.

Technical data.

B Connection via a gas appliance outlet is never permitted.

An accessory is required (optionally available) if exhaust air

and flue gas are extracted together:

B Exhaust air kit if extracting from one system.

B Backflow preventer if extracting in combination with

another heat source (peak load boiler or another

system).

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

15

Page 16

Assembly

5.2.8 Water supply

D ATTENTION!

Risk of damage caused by poor water quality.

Too high a proportion of suspended solids and magnetite

along with the incorrect water hardness can damage the

generation unit or shorten its service life.

A Check the water quality regularly.

A Use the MSM filter.

B The water quality must comply with the specifications of

the applicable standards and Directives

(e.g. in Germany, VDI Regulation 2035).

B The heating system water must be free from mechanical

impurities.

B The hardness of the water must be < 0.11 °dH.

B Conductivity < 100 µS/cm.

B PH value > 8.2 and < 9.0.

5.2.9 Condensate drain

For the system to operate, the building must have a

condensate drain, which must comply with the following

requirements:

B The condensate drain must be depressurised.

B The local water disposal regulations must be considered.

B The siphon must be constructed from a corrosion- and

acid-resistant material (e.g. plastic or stainless steel).

B The drain’s siphon must remain filled with water even

during an interruption to operation.

5.2.12 Mobile communications network

Remote monitoring via the modem requires access to the

mobile communications network. The modem must be

accessible. The position of the modem has an influence on

the reception quality.

The reception quality may be improved as required by

means of the following accessory (optionally available):

B External antenna

B Patch cable (max. 100 m)

5.2.10 Power supply

For the system to operate, the building requires a

connection to the electricity supply that must comply with

the following requirements:

B The specifications and technical connection conditions

of the energy provider must be taken into consideration

(e.g. electricity meter).

B The start-up power and cable lengths must be taken into

account when calculating the cable cross-sections.

B The supply voltage must meet the system specifications.

Technical data.

5.2.11 Reactive current compensation

For the system to operate, the energy provider stipulates

the need for reactive current compensation.

The reactive current compensation reduces the reactive

current generated by the system and thus relieves the

supply network. The reactive current compensation must

meet the system specifications.

Technical data.

16

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 17

Assembly

5.3 Assembly steps

Brief overview:

5.3.1 Preparing for assembly

5.3.2 Unpacking the system

5.3.3 Positioning the generation unit

5.3.4 Screwing the control cabinet in position

5.3.5 Screwing the expansion tank connection block in

position

5.3.6 Connecting the generation unit

5.3.7 Connecting the temperature sensors

5.3.8 Connecting the modem

5.3.9 Connecting the control cabinet

5.3.10 Checking the connections

5.3.1 Preparing for assembly

A Familiarise yourself with the assembly situation and the

documentation.

B System

B System components

B Safety devices

B Accessories

B Installation location

B Operation manual and supporting documents

A Gather together the required tools and materials.

A Keep the assembly area clear of objects than may get in

the way or be damaged.

A Check that all of the installation location requirements

have been fulfilled.

“5.2 Installation location requirements” (page 13).

D

A Ensure that the supply voltage has been and remains

disconnected. Only connect the supply voltage when

instructed in the respective assembly step.

5.3.2 Unpacking the system

D ATTENTION!

Risk of damage caused by improper handling.

The system may be damaged during unpacking or

transportation.

A Do not cut through the protective packaging.

A Keep objects that might damage the system away from it

(e.g. tools).

A Remove the packaging material from the system.

A Remove the parts included in the scope of delivery from

on top of the generation unit.

A Check the system and all the parts it contains for

damage.

A Check the scope of delivery according to the delivery

note for completeness.

If parts are missing or damaged:

A Contact the manufacturer.

A Remove the packaging material from the installation

location.

“11.1 Disposing of packaging” (page 35).

D

If accessories (e.g. flue gas silencer, exhaust air kit) are

required for the assembly process:

A Ensure that the accessory is correctly assembled and

ready for connection.

A Ensure that the lines from the accessories have been laid

correctly and are accessible.

Manuals for accessories.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

17

Page 18

Assembly

5.3.3 Positioning the generation unit

D ATTENTION!

Risk of damage to the generation unit caused by improper

transportation.

In narrow transportation routes, it may be necessary to

disassemble parts of the generation unit in order to move

the device into the installation location. The parts may

only be disassembled following consultation with the

manufacturer.

A Contact the manufacturer.

A Only dismantle the generation unit in accordance with

the manufacturer’s instructions.

A Select a suitable installation location.

“5.2.2 Premises” (page 14).

D

A Screw on the front cover.

A Position the balance strips.

A Place the generation unit on the balance strips.

A Ensure that the generation unit stands level.

A Screw on the rear cover.

A Screw on the Supply air intake grille.

18

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 19

Assembly

5.3.4 Screwing the control cabinet in position

A Open the control cabinet.

A Mark the drill hole positions on the wall.

A Drill the holes for the screws.

A Screw the control cabinet onto the wall.

5.3.5 Screwing the expansion tank connection block in

position

5.3.6 Connecting the generation unit

When connecting the system to the heating system it is

necessary to follow the appropriate hydraulic diagram.

“12.1 Hydraulic diagrams” (page 36).

D

Always match the connections to the identifiers on the

generation unit.

Pay attention the to connection sizes and type when

connecting the lines.

Generation unit connection sizes

Connection Connection size and type

VARION®

C-POWER S

Buffer water

return line

Buffer water

supply line

Expansion tank 3/4” male

Condensate 3/4” male

Flue gas DN 80 DN 80 DN 80

Exhaust air DN 100 DN 100 DN 150

Gas 1/2” female

1” male

thread

1” male

thread

thread

thread

thread

VARION®

C-POWER M

1” male

thread

1” male

thread

3/4” male

thread

3/4” male

thread

1/2” female

thread

VARION®

C-POWER M+

1” male

thread

1” male

thread

3/4” male

thread

3/4” male

thread

1/2” female

thread

A Mark the drill hole positions on the wall.

A Drill the holes for the screws.

A Screw the expansion tank connection block onto the

wall.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

A Remove the cover.

If necessary, the entire rear cover can be released and

removed.

19

Page 20

Assembly

D ATTENTION!

Risk of damage caused by improper connection of lines.

Fixed supply lines will transfer vibrations to the building. The

permissible sound insulation values will be exceeded.

Vibrations may damage the supply lines.

A Only use flexible lines for all the lines connected to the

generation unit.

A Pay close attention when matching the lines and

connections.

MSM filter

The MSM filter must be installed so that the following

requirements are fulfilled:

B Installation near the buffer tank.

B Connection must be made such that a 5-litre vessel can

be placed underneath to catch water. An elevation elbow

(optionally available) can be used if required.

B The arrow on the filter head points in the direction of

flow.

B Horizontal installation of the filter head.

B Installation of a valve upstream and downstream from

the KMS filter.

MSM filter manual.

Buffer water return line

A Connect the line to the return line of the buffer tank.

A Connect the line to the MSM filter.

MSM filter manual.

Buffer water supply line

A Connect the line to the “Buffer water return line”

connection on the generation unit.

A Connect the line to the MSM filter.

MSM filter manual.

20

A Connect the line to the supply line of the buffer tank.

A Connect the line to the “Buffer water supply line”

connection on the generation unit.

In order to incorporate into the heating circuit:

A First open the valve in the return line.

A Check the sealing.

A Then open the valve in the supply line.

A Check the sealing again.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 21

Assembly

Expansion tank

A Before connecting, ensure that the system pressure of

the expansion tank connection block is 1.0 bar.

A Connect the line to the “expansion tank” connection on

the generation unit.

A Connect the line to the expansion tank connection block.

Condensate

Flue gas

The line must be laid with a sufficient gradient to the

generation unit.

A Make sure that a suitable flue gas silencer (optionally

available) is present:

B In the flue gas routing.

B In close proximity to the generation unit.

B With horizontal installation with correct discharge of

the condensate water.

A Connect the line to the “flue gas” connection on the

generation unit.

A Connect the line to the flue.

A Ensure that the line is not interrupted (e.g. that it does

not slip out of vertically installed parts).

A Ensure that the flue gas guide cannot come loose from

the connecting piece due to vibrations.

Exhaust muffler manual.

The line for the condensate water must be corrosion

resistant.

The line must have a sufficient gradient between the

generation unit and the drain.

A Connect the line to the “Condensate” connection on the

generation unit.

A Connect the line to the condensate drain.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

21

Page 22

Assembly

Exhaust air

A Connect the line to the “exhaust air” connection on the

generation unit.

A Guide the line outside.

A Secure the line.

A Ensure that when the exhaust air duct is connected, the

system is protected against frost and the elements.

Cover

A Fit the cover.

Gas

The gas supply must comply with the established regulations

(e.g. in Germany, TRGI). Connection via a gas appliance

outlet is not permitted.

A Connect the line to the “gas” connection on the

generation unit.

A Connect the line to the connection on the gas supply.

22

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 23

Assembly

5.3.7 Connecting the temperature sensors

T1

T2

T3

T4

A Attach four temperature sensors (T1-T4) to the buffer

tank. When attaching, bear in mind the number of buffer

tanks.

“12.1 Hydraulic diagrams” (page 36).

D

A Connect a temperature sensor (T5) to the supply line of

the heating circuit.

“12.1 Hydraulic diagrams” (page 36).

D

A Guide the cables from the temperature sensors (T1-T5)

to the control cabinet.

Observe the associated wiring diagrams for the electrical

connection.

Wiring diagrams.

5.3.8 Connecting the modem

When connecting the modem, the following points must be

observed:

B If the modem is subjected to high temperatures, it may

not function properly.

B The length of the connection cable between the control

cabinet and the modem must not exceed 100 m.

A Fit the modem such that reception is guaranteed.

A Connect the modem:

Modem manual.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

23

Page 24

Assembly

5.3.9 Connecting the control cabinet

D WARNING!

Risk of injury from electric shock.

The cables must be deenergised during assembly.

A Deenergise the cables.

A Ensure that the cables remain deenergised during

installation.

D ATTENTION!

Risk of damage caused by the incorrect matching of

connectors.

Having the wrong polarity on the connection terminals can

seriously damage the control mechanism.

A Ensure correct polarity on the connection terminals.

A Connect the supply voltage to a right-rotating field.

All cables must be fed into the control cabinet through the

cable connections from underneath.

Use the enclosed wiring diagrams to identify the connection

terminals.

Wiring diagrams.

The connection of additional components depends on the

heating system.

“12.1 Hydraulic diagrams” (page 36).

D

A Connect any additional components (e.g. peak load

boiler, equipment of the building control technology) to

the control mechanism.

Once all components have been connected:

A Make sure that the mains connection is de-energised.

A Connect the supply voltage to the control cabinet.

A Close the control cabinet.

5.3.10 Checking the connections

Once the assembly process is complete, the following points

must be checked:

B Leak-tightness of all lines.

B Flexibility of all lines to the generation unit.

B Tight fit of all connections in the control cabinet.

B No damage, kinks or pinches in the cabling and lines.

B The siphon of the condensate drain is filled with water.

B Tension-free installation of all lines to the generation

unit.

A Check the system.

Please refer to the technical data for the permissible crosssectional areas of the supply lines.

Technical data.

A Open the control cabinet.

A Connect the temperature sensors (T1-T5).

A Connect the modem.

If the exhaust air and flue gas are extracted together:

A Ensure that the system is fitted with a suitable exhaust

air kit.

If the exhaust air or flue gas is extracted in combination with

another heat source (peak load boiler or another system):

A Ensure that the system is fitted with a suitable backflow

preventer.

24

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 25

Assembly

5.4 Test run

Once the installation process has been successfully

completed, it is necessary to perform a test run. The system

must run for a minimum of 15 minutes.

The factory setting of the system on delivery enables the

test run to run for maximum one hour. The system will then

automatically switch off.

Brief overview:

5.4.1 Opening the generation unit

5.4.2 Preparing the expansion tank connection block

5.4.3 Replenishing the cooling water

5.4.4 Starting the test run

5.4.5 Checking the system

5.4.6 Stopping the test run

5.4.7 Closing the generation unit

5.4.1 Opening the generation unit

D WARNING!

Risk of burns from hot components.

During operation, the components inside the generation

unit become very hot.

A Use work gloves.

A Only touch components if it is necessary to do so for the

work step.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

A Open the generation unit.

25

Page 26

Assembly

5.4.2 Preparing the expansion tank connection block

D ATTENTION!

Risk of material damage to the generation unit.

If the connection between the expansion tank connection

block and the generation unit is interrupted during

operation, the water supply to the generation unit can

burst.

A Ensure that the expansion tank connection block is

correctly connected to the generation unit.

A Open the valve for the expansion tank connection block

on the generation unit.

A Remove the valve lever.

A Store the valve lever in a safe place.

5.4.3 Replenishing the cooling water

D ATTENTION!

Hazard caused by contamination of the cooling system.

Contaminated or incorrect cooling medium will damage the

generation unit’s cooling system.

A Only use originalcooling medium "water-glycol mixture

60:40" from the manufacturer.

A Only use pumps for filling that have been cleaned and

are free from other substances.

26

A Connect the pump for the cooling medium to the fill-

and-drain valve of the expansion tank connection block.

A Fill the system with the "water-glycol mixture 60:40"

coolant until an operating pressure is achieved of 2.0 bar

in warm condition, 1.8 bar in cold condition.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 27

Assembly

5.4.4 Starting the test run

To ensure the system is bled fully, perform the following in

the correct order.

A Open the valves on the generation unit as follows:

1. Buffer water return line

2. Buffer water supply line

3. Gas

A Ensure that the heating system is ready for the test run.

A Open the valves on the buffer tank.

5.4.5 Checking the system

A Check the gas and exhaust gas sealing within the

generator unit.

A Check the gas and exhaust gas sealing of the system.

A Bleed the cooling system.

A Remove any leaking cooling medium.

A Check the pressure of the cooling system.

A Unlock the emergency stop switch.

A Switch on the master switch.

A Start the test run via the operating display.

Observe the associated instructions for operation.

“ELCO/Control” operation manual.

A Vent the heating circuit system at the heat exchanger.

If necessary, the venting procedure should be carried out

several times.

A Remove the pump from the MAG connection group.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

27

Page 28

Assembly

5.4.6 Stopping the test run

A Stop the test run via the operating display.

“ELCO/Control” operation manual.

A Switch off the master switch.

5.4.7 Closing the generation unit

A Close the generation unit.

The test run has been successful if the following conditions

have been met:

B The cooling system has been bled.

B All lines are leak-tight.

B The control mechanism does not display any error

messages.

B The system has run for a minimum of 15 minutes.

If the test run has not been successful:

A Check the assembly steps again up until the connection

inspection.

“5.3 Assembly steps” (page 17).

D

A Carry out another test run.

“5.4 Test run” (page 25).

D

If the test run has still not been successful:

A Contact the manufacturer.

After the test run has been successfully completed,

commissioning must be requested from a specialist partner.

Commissioning request.

Download forms:

www.elco.net

Ј

A Arrange a time and date for the commissioning.

28

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 29

6. Commissioning

D WARNING!

Hazard caused by improperly assembling the system.

Improperly installed systems can cause serious injuries or

material damage to the system or the building.

A Ensure that the system is installed in accordance with

the regulations and that the commissioning can be

carried out.

The system must be inspected by the manufacturer (or

a specialist partner authorised by the manufacturer) in

accordance with the specifications of the commissioning

certificate.

Once the inspection has been passed, the system will be

released for permanent operation

Commissioning

If the system fails the check, the manufacturer will take

appropriate measures, e.g. request a repair.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

29

Page 30

Operaon

7. Operation

D ATTENTION!

Hazard caused by failing to observe the operating

instructions.

This chapter contains important information regarding

the safe operation of the system. Incorrect settings in the

control mechanism can damage the system or shorten its

service life.

A Read this chapter carefully before operating the system.

A Follow the safety instructions.

Only the manufacturer has access to the “Experts” area of

the “ELCO/Control” control mechanism.

“2.2.1 Manufacturer” (page 6).

D

Only qualified personnel trained by the manufacturer

have access to the “Specialist” area of the “ELCO/Control”

control mechanism.

“2.2.3 Trained personnel” (page 6).

D

Trained users have access to the non-protected areas of

the “ELCO/Control” control mechanism, but not to the

“Experts” and “Specialist” areas.

The system must only be operated by qualified users.

“2.2.4 User” (page 6).

D

The “ELCO/Control” control mechanism regulates and

monitors the system. The system is operated via the

operational display on the control cabinet.

Its operation is described in the accompanying manual.

“ELCO/Control” operation manual.

30

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 31

8. Cleaning

D WARNING!

Risk of burns when cleaning hot system components.

This chapter contains important information regarding the

correct way to clean the system. The parts of the system

that can become very hot (e.g. flue gas routing) must not be

cleaned while the system is in operation.

A Read this chapter carefully before cleaning the system.

A Do not clean any hot components.

A Follow the safety instructions.

The system must only be cleaned by qualified users.

“2.2.4 User” (page 6).

D

Cleaning

D ATTENTION!

Risk of damage caused by cleaning agents.

Sprays, solvents and chlorinated cleaning agents can cause

corrosion and changes in properties.

A Only use suitable cleaning agents.

At least once a year:

A Clean the system with a damp cloth.

In the case of heavier soiling:

A Clean the system with warm water and a neutral, non-

abrasive cleaning agent (domestic washing-up liquid,

pH value 7).

If work that creates considerable dust has being performed

in the installation location

(e.g. drilling, abrasive cutting):

A First switch off the system.

A Clean the air filter in the generation unit.

A Clean the ventilation system in the control cabinet.

When cleaning the MSM filter, refer to the respective

manual.

MSM filter manual.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

31

Page 32

Service repairs

9. Service repairs

9.1 Maintenance

D WARNING!

Risk of injuries caused by faulty safety components.

This chapter contains important information regarding

the safe maintenance of the system. Important safety

components may fail or become faulty as a result of

insufficient maintenance.

A Read this chapter carefully before performing

maintenance work.

A Wait for the system to cool down before carrying out

maintenance.

A Perform the maintenance according to the specified

intervals.

9.2 Fault resolution

D WARNING!

Hazard caused by failing to observe the error messages.

Malfunctions indicate faults with the system or incorrect

settings in the control mechanism. Malfunctions must

be rectified immediately to prevent further subsequent

damage.

A Rectify all faults immediately.

System malfunctions are displayed by the control

mechanism in the operational display.

“ELCO/Control” operation manual.

In the case of malfunctions that cannot be resolved using

the control mechanism:

A Initiate remote maintenance.

A Follow the manufacturer’s instructions.

Maintenance work must only be performed by trained

personnel.

Electrical work must only be performed by qualified, skilled

electricians.

“2.2.3 Trained personnel” (page 6).

D

The system will indicate the pending maintenance 300 hours

before the maintenance interval expires.

If the maintenance is not performed, the system will run for

another 200 hours at minimum capacity after the interval

has expired.

After the 200 hours have passed, the system will switch off.

The system can only be put back into operation once the

maintenance has been performed.

The maintenance must be performed and documented

according to the points in the maintenance log.

“12.2 Maintenance schedules” (page 42).

D

Specific tasks for maintaining the system are only

performed by the manufacturer.

“2.2.1 Manufacturer” (page 6).

D

In the case of specific tasks for maintaining the system:

A Contact the manufacturer.

Maintenance manual.

32

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 33

9.3 Repair

D WARNING!

Risk of injuries caused by faulty components.

This chapter contains important information regarding the

safe repair of the system.

Defective components can cause additional subsequent

damage to the system.

A Read this chapter carefully before performing repairs on

the system.

A Defective components must be replaced promptly.

A The system must be taken out of operation until any

safety-related parts have been replaced.

A Wait for the system to cool down before replacing any

components.

A Only use components authorised by the manufacturer.

Repair work must only be performed by trained personnel.

Electrical work must only be performed by qualified, skilled

electricians.

“2.2.3 Trained personnel” (page 6).

D

Service repairs

A Switch off the system.

“ELCO/Control” operation manual.

A Switch off the master switch.

A Replace any faulty components.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

33

Page 34

Disassembly

10. Disassembly

D WARNING!

Hazard caused by failing to observe the disassembly

instructions.

This chapter contains important information regarding the

correct way to disassemble the system. Failing to observe

such information can lead to severe injuries.

A Read this chapter carefully before disassembling the

system.

A Follow the safety instructions.

A Wait for the system to cool down before disassembling

it.

A Ensure that the cables are deenergised.

A Ensure that the cables remain deenergised during the

work.

The disassembly must only be performed by trained

personnel.

Electrical work must only be performed by qualified, skilled

electricians.

“2.2.3 Trained personnel” (page 6).

D

A Switch off the system.

“ELCO/Control” operation manual.

A Close all valves in the system.

A Close all valves in the heating system.

A Remove all cables from the control cabinet that are not

connected to the generation unit.

A Remove the lines from the generation unit:

B Buffer supply line

B Buffer return line

B Gas

B Expansion tank

B Condensate

B Flue gas

B Exhaust air

A Remove the MSM filter.

A Remove the lower covers from the generation unit.

A Remove the ventilation grill.

A Remove the lines from the expansion tank connection

block.

A Unscrew the expansion tank connection block.

34

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 35

11. Disposal

11.1 Disposing of packaging

D ATTENTION!

Risk of environmental damage caused by failing to dispose

of the packaging in the proper manner.

A Do not dispose of the packaging in the normal domestic

waste.

A Send the packaging to the appropriate environmental

recycling facility.

The packaging is used to protect the system against

transportation damage.

The packaging materials have been selected from an

environmentally sustainable perspective and are produced

from recyclable materials. The packaging materials can be

put back into to the raw materials cycle after use. This will

save valuable resources.

A Separate the packaging according to material and

dispose of it in an environmentally friendly manner.

Disposal

11.2 Disposing of the system

D ATTENTION!

Risk of environmental damage caused by failing to dispose

of the system in the proper manner.

A Do not dispose of the system in the normal domestic

waste.

A Send the system to the appropriate environmental

recycling facility.

The disposal must only be performed by trained personnel.

“2.2.3 Trained personnel” (page 6).

D

A Dispose of the system in accordance with the statutory

requirements via a specialist waste management

company or your municipal disposal facility.

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

35

Page 36

Appendix

12. Appendix

12.1 Hydraulic diagrams

The following hydraulic diagrams illustrate examples

for connecting the system to the heating system. These

hydraulic diagrams do not replace the need to correctly

design the technical aspects heating system.

The hydraulic diagram applicable to the heating system

must be checked for correctness and completeness.

The installation location requirements must be observed. In

particular:

B The building’s heating system.

“5.2.3 Heating system” (page 15).

D

B Water quality.

“5.2.8 Water supply” (page 16).

D

Further hydraulic plans:

www.elco.net

Ј

36

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 37

12.1.1 Heating system variant 1 –

1 VARION® C-POWER, 1 buffer tank, peak load boiler connected directly to buffer tank

Appendix

neoTowerVARION®

SLKSLK

C-POWER

25

24

T

23

M

22

21

20 19

T5

26

T1

T1

T2

T2

T3

1

2 3

4 5

6

T3

T4

T4

11

8

7

10

9

14

17

16 15

T

13

18

12

1 Shut-off

2 Circulating pump

3 Shut-off

4 Shut-off

5 Combination filter

6 Shut-off

7 Drain

8 Safety valve

9 Cap valve

10 Pressure expansion vessel

11 Buffer tank

12 Drinking water tank

13 Temperature sensor

14 Ventilation

15 Shut-off

16 Shut-off

17 Non-return valve

18 Circulating pump

19 Shut-off

20 Shut-off

21 Non-return valve

22 3-way mixer

23 Circulating pump

24 Temperature sensor

25 Heating circuit consumers

26 Circulating pump

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

37

Page 38

Appendix

12.1.2 Heating system variant 2 –

1 VARION® C-POWER, 2 buffer tanks, peak load boiler connected directly to buffer tank

SLKSLK

neoTowerVARION®

C-POWER

29

28

T5

11

T1T2T1

30

T2

1

5

6

2 3

4

27

12

T3T4T3

T4

25

T

26

24

M

21

23

22

7

19

14

T

18

20

17

8

16

15

13

10

9

1 Shut-off

2 Circulating pump

3 Shut-off

4 Shut-off

5 Combination filter

6 Shut-off

7 Drain

8 Safety valve

9 Cap valve

10 Pressure expansion vessel

11 Buffer tank

12 Buffer tank

13 Drinking water tank

14 Temperature sensor

15 Shut-off

16 Circulating pump

17 Shut-off

18 Non-return valve

19 Ventilation

20 Shut-off

21 3-way mixer

22 Shut-off

23 Non-return valve

24 Circulating pump

25 Heating circuit consumers

26 Temperature sensor

27 Ventilation

28 Ventilation

29 Ventilation

30 Circulating pump

38

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 39

12.1.3 Heating system variant 3 –

1 VARION® C-POWER, 1 buffer tank, peak load boiler connected to buffer tank via hydraulic separator

Appendix

SLKSLK

neoTowerVARION®

C-POWER

26

25

1

2 3

23

24

5

6

4

T5

7

T1

T1

T2

T2

T3

T3

T4

T4

22

20

T

21

19

M

18

17

15

14

10

T

13

12

16

9

11

8

1 Shut-off

2 Circulating pump

3 Shut-off

4 Shut-off

5 Combination filter

6 Shut-off

7 Buffer tank

8 Drinking water tank

9 Circulating pump

10 Temperature sensor

11 Shut-off

12 Shut-off

13 Non-return valve

14 Ventilation

15 Shut-off

16 Shut-off

17 Non-return valve

18 3-way mixer

19 Circulating pump

20 Heating circuit consumers

21 Temperature sensor

22 Ventilation

23 Hydr. switches

24 Circulating pump

25 Non-return valve

26 Ventilation

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

39

Page 40

Appendix

12.1.4 Heating system variant 4 –

1 VARION® C-POWER, 2 buffer tanks, peak load boiler connected to buffer tank via hydraulic separator

SLKSLK

neoTowerVARION®

C-POWER

28

27

2930

1

2

3

456

T5

31

11

T1T2T1

T3T4T3

T2

T4

12

25

T

26

24

M

21

23

22

7

19

14

T

18

20

17

8

16

15

13

10

9

1 Shut-off

2 Circulating pump

3 Shut-off

4 Shut-off

5 Combination filter

6 Shut-off

7 Drain

8 Safety valve

9 Cap valve

10 Pressure expansion vessel

11 Buffer tank

12 Buffer tank

13 Drinking water tank

14 Temperature sensor

15 Shut-off

16 Circulating pump

17 Shut-off

18 Non-return valve

19 Ventilation

20 Shut-off

21 3-way mixer

22 Shut-off

23 Non-return valve

24 Circulating pump

25 Heating circuit consumers

26 Temperature sensor

27 Hydr. switches

28 Ventilation

29 Circulating pump

30 Non-return valve

31 Ventilation

40

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 41

12.1.5 Heating system variant 5 –

2 VARION® C-POWER, 2 buffer tanks, peak load boiler connected to buffer tank via hydraulic separator

Appendix

VARION®

C-POWER

1 Circulating pump

2 Shut-off

3 Combination filter

4 Circulating pump

5 Shut-off

6 Combination filter

7 Drain

8 Safety valve

9 Cap valve

10 Pressure expansion vessel

11 Buffer tank

12 Buffer tank

13 Drinking water tank

14 Temperature sensor

15 Shut-off

16 Circulating pump

17 Shut-off

18 Non-return valve

VARION®

C-POWER

19 Ventilation

20 Shut-off

21 3-way mixer

22 Shut-off

23 Non-return valve

24 Circulating pump

25 Heating circuit consumers

26 Temperature sensor

27 Hydr. switches

28 Ventilation

29 Circulating pump

30 Non-return valve

31 Non-return valve

32 Shut-off

33 Non-return valve

34 Shut-off

35 Ventilation

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

41

Page 42

Appendix

12.2 Energy label

12.2.1 VARION® C-POWER S

ELCO GmbH VARION® C-POWER 20.0

ELCO GmbH VARION® C-POWER 5.0

kW

++

A

++

A

+

A

A

B

C

D

E

F

G

67

dB

2015 811/2013

12

ELCO GmbH VARION® C-POWER 7.2

++

A

+

A

A

B

C

D

E

F

G

18

68

dB

2015 811/2013

kW

VARION® C-POWER 5.0 VARION® C-POWER 7.2

12.2.2 VARION® C-POWER M

kW

++

A

++

A

+

A

A

B

C

D

E

F

++

A

G

73

dB

2015 811/2013

46

VARION® C-POWER 20.0

12.2.3 VARION® C-POWER M+

ELCO GmbH VARION® C-POWER 25.0

ELCO GmbH VARION® C-POWER 30.0

ELCO GmbH VARION® C-POWER 11.0

kW

++

A

++

A

+

A

A

B

C

D

E

F

G

70

dB

2015 811/2013

25

ELCO GmbH VARION® C-POWER 16.0

++

A

+

A

A

B

C

D

E

F

G

70

dB

2015 811/2013

38

A

kW

VARION® C-POWER 11.0 VARION® C-POWER 16.0

kW

++

A

++

A

+

A

A

B

C

D

E

F

G

77

dB

2015 811/2013

63

++

A

+

A

A

B

C

D

E

F

++

G

76

dB

2015 811/2013

55

kW

++

A

VARION® C-POWER 25.0 VARION® C-POWER 30.0

42

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

Page 43

12.3 EC declaration of conformity

Declaration of Conformity

en

i.V. Stefan Salewsky

We, ELCO GmbH, D-71379 Hechingen on behalf of the marketing companies

Appendix

Declaration of Conformity

ELCO Austria GmbH, A - 2544 Leobersdorf

ELCOTHERM AG, CH - 7324 Vilters

ELCO BV, NL - 6465 AG Kerkrade

ELCO Belgium SA, B - 1070 Brussel

ELCO Italia S.p.A., I - 31023 Resana

ELCO United Kingdom, UK - Basildon, Essex, SS15 6SJ

ELCO France / Chaffoteaux SAS, F - 93521 Saint-Denis Cedex

Gastech-Energi A/S, DK - 8240 Risskov

Ariston Thermo Rus LLC, RU – 127015 Moscow

Ariston Thermo Türkiye, TK – 34775 Istanbul

Ariston Thermo Polska Sp. z o.o. ,PL – 31 408 Kraków

Ariston Thermo Hungária Kft., HU - 1135 Budapest

Ariston Thermo România, RO - 010505 Bucharest

Ariston Thermo CZ , CZ – 198 00 Praha 9

declare under our responsibility that the products

VARION C-POWER Modell S

VARION C-POWER Modell M

VARION C-POWER Modell M+

with CE number:

CE – 0063CM3648

are in conformity with the following standards:

Gas Appliance Directive 90/396//EWG

Mac

hinery Directive 92/42/EE

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

VDEW » D

parall

self-pr

Machine safety DIN E

Hechingen, 03.01.2017 ELCO Gm

irective for the

el operation of a

oduction plant. DIN

C

VDE 0100 - 551

N ISO 14121 -1

bH

Operation manual VARION® C-POWER – S, M, M+ / 06.2019

43

Page 44

www.elco.net

ELCO Belgium SA

ƌŝƐƚŽŶdŚĞƌŵŽZƵƐ>>

ƌŝƐƚŽŶdŚĞƌŵŽdƺƌŬŝLJĞ

ƌŝƐƚŽŶdŚĞƌŵŽWŽůƐŬĂ^ƉnjŽŽ

ƌŝƐƚŽŶdŚĞƌŵŽ,ƵŶŐĄƌŝĂ<Ĩƚ

ƌŝƐƚŽŶdŚĞƌŵŽZŽŵąŶŝĂ

ƌŝƐƚŽŶdŚĞƌŵŽ

'ĂƐƚĞĐŚͲŶĞƌŐŝ^

Loading...

Loading...