Page 1

Operating Instructions

Rain Barrel Pump

Art.-Nr.: 41.703.04 I.-Nr.: 11010

BG-SP

400 RB

Anleitung_BG_SP_400_RB_SPK1:_ 04.07.2008 11:03 Uhr Seite 1

Page 2

2

Read and follow the operating instructions and safety information

before using for the first time.

Anleitung_BG_SP_400_RB_SPK1:_ 04.07.2008 11:03 Uhr Seite 2

Page 3

3

21

2

1

5

3

4

7

10

8

9

6

3

5

4

6

9

6

7

10

8

6

7

A

10

8

6

10

7

A

Anleitung_BG_SP_400_RB_SPK1:_ 04.07.2008 11:04 Uhr Seite 3

Page 4

4

87

5

A

B

5

Anleitung_BG_SP_400_RB_SPK1:_ 04.07.2008 11:04 Uhr Seite 4

Page 5

GB

5

Important!

When using equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating manual with due

care. Keep this manual in a safe place, so that the

information is available at all times. If you give the

equipment to any other person, give them these

operating instructions as well.

We accept no liability for damage or accidents which

arise due to non-observance of these instructions

and the safety information.

1. Safety regulations

Caution!

In stagnant water bodies, garden ponds,

swimming ponds and their surrounding areas

the unit may only be used with an earth-leakage

circuit breaker with an actuating rated current of

up to 30 mA (according to VDE 0100 Part 702

and 738).

The equipment is not designed for use in

swimming pools and paddling pools of any kind

or other bodies of water in which people or

animals may be present during operation. It is

prohibited to operate the equipment if a person

or animal is in the danger area. Ask your

electrician!

This equipment is not designed to be used by people

(including children) with limited physical, sensory or

mental capacities or those with no experience and/or

knowledge unless they are supervised by a person

who is responsible for their safety or they have

received instructions from such a person in how to

use the equipment safely. Children must always be

supervised in order to ensure that they do not play

with the equipment.

Important!

Before you put the equipment into operation,

arrange for a specialist to check that the

- earthing

- protective multiple earthing

- residual-current operated circuit-breaker circuit

comply with the safety regulations of the power

supply company and work correctly.

The electrical plug-in connections must be

protected from wet conditions.

If there is a risk of flooding, place the plug-in

connections in an area which is safe from

flooding.

Strictly avoid pumping aggressive liquids and

abrasive substances.

Protect the equipment from frost.

Protect the equipment from dry running.

Take suitable measures to keep the equipment

out of the reach of children.

CAUTION!

Read all safety regulations and instructions.

Any errors made in following the safety regulations

and instructions may result in an electric shock, fire

and/or serious injury.

Keep all safety regulations and instructions in a

safe place for future use.

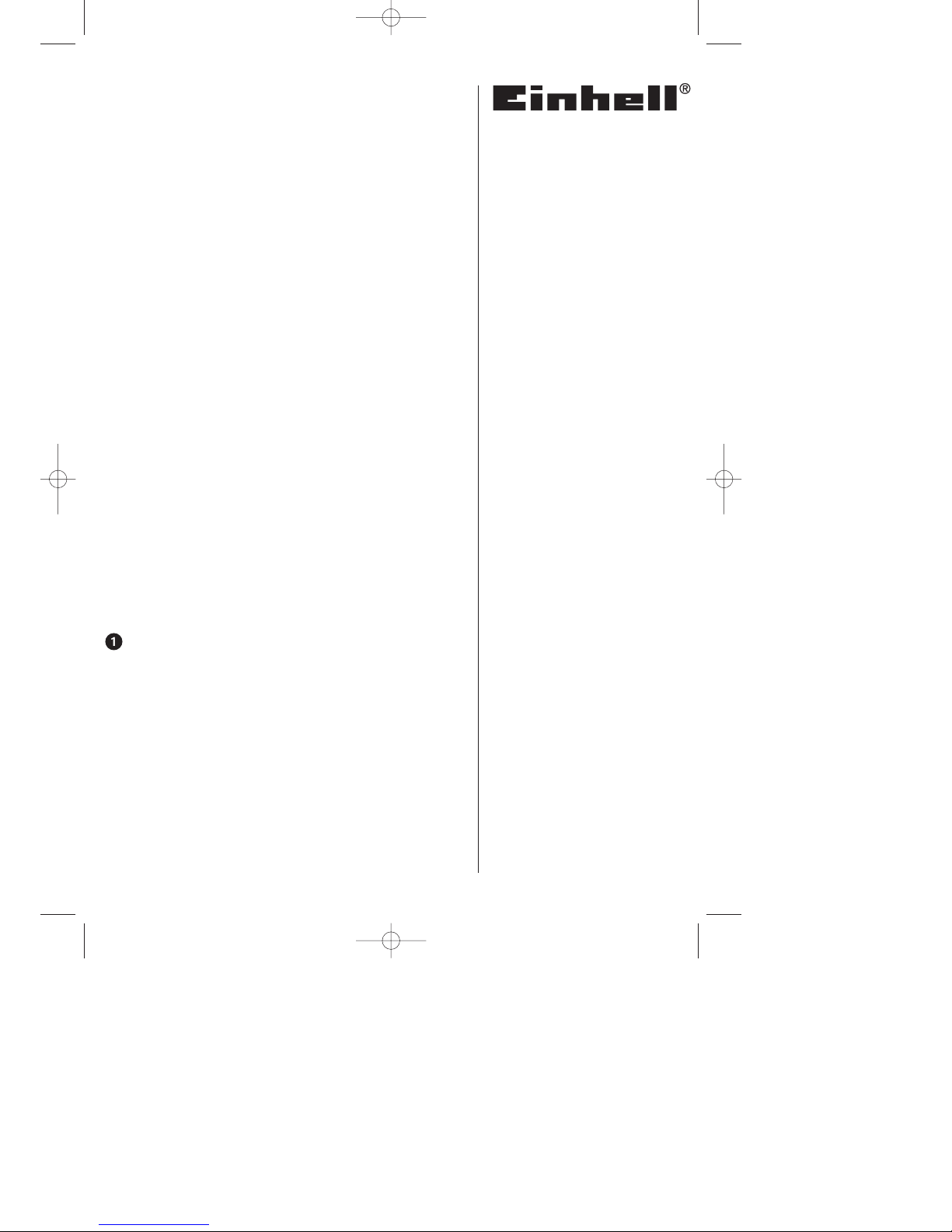

2. Layout (Figs. 1 and 2)

1. Carry handle

2. Mains cable

3. Pressure connection

4. Floating switch

5. Intake cage

6. Pressure hose

7. Distributor

8. Draw-off hose

9. Hose connection

10. Stopcock

3. Proper use

The equipment you have purchased is designed to

pump water with a maximum temperature of 35 °C.

This equipment must never be used for other liquids,

especially engine fuels, cleaning agents and other

chemically-based products! Installed in a shaft, the

equipment provides protection from flooding.

However, it can be used wherever you want to move

water, e.g. in the house, in the garden, and for many

other applications. The equipment must not be used

to operate swimming pools!

If you want to use the equipment in bodies of water

with a natural, muddy bottom, place the equipment in

a slightly elevated position, e.g. on bricks.

The equipment is not designed for continuous

operation, e.g. as a circulating pump in a pond. In this

case the equipment’s anticipated life will be greatly

shortened because the equipment was not designed

for continuous loading.

The equipment is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

Anleitung_BG_SP_400_RB_SPK1:_ 04.07.2008 11:04 Uhr Seite 9

Page 6

6

GB

misuse. The user / operator and not the

manufacturer will be liable for any damage or injuries

of any kind caused as a result of this.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

machine is used in commercial, trade or industrial

businesses or for equivalent purposes.

4. Technical data

Mains connection 230V ~ 50 Hz

Power rating 400 W

Max. pumping rate 4,200 l/h

Max. delivery head 11 m

Max. immersion depth 5 m

Max. water temperature 35 °C

Hose connection 3/4“ AG

Max. size of foreign bodies: Ø 3 mm

Switching point height: ON max. approx. 50 cm

Switching point height: OFF min. approx. 5 cm

5. Before putting the equipment into

operation

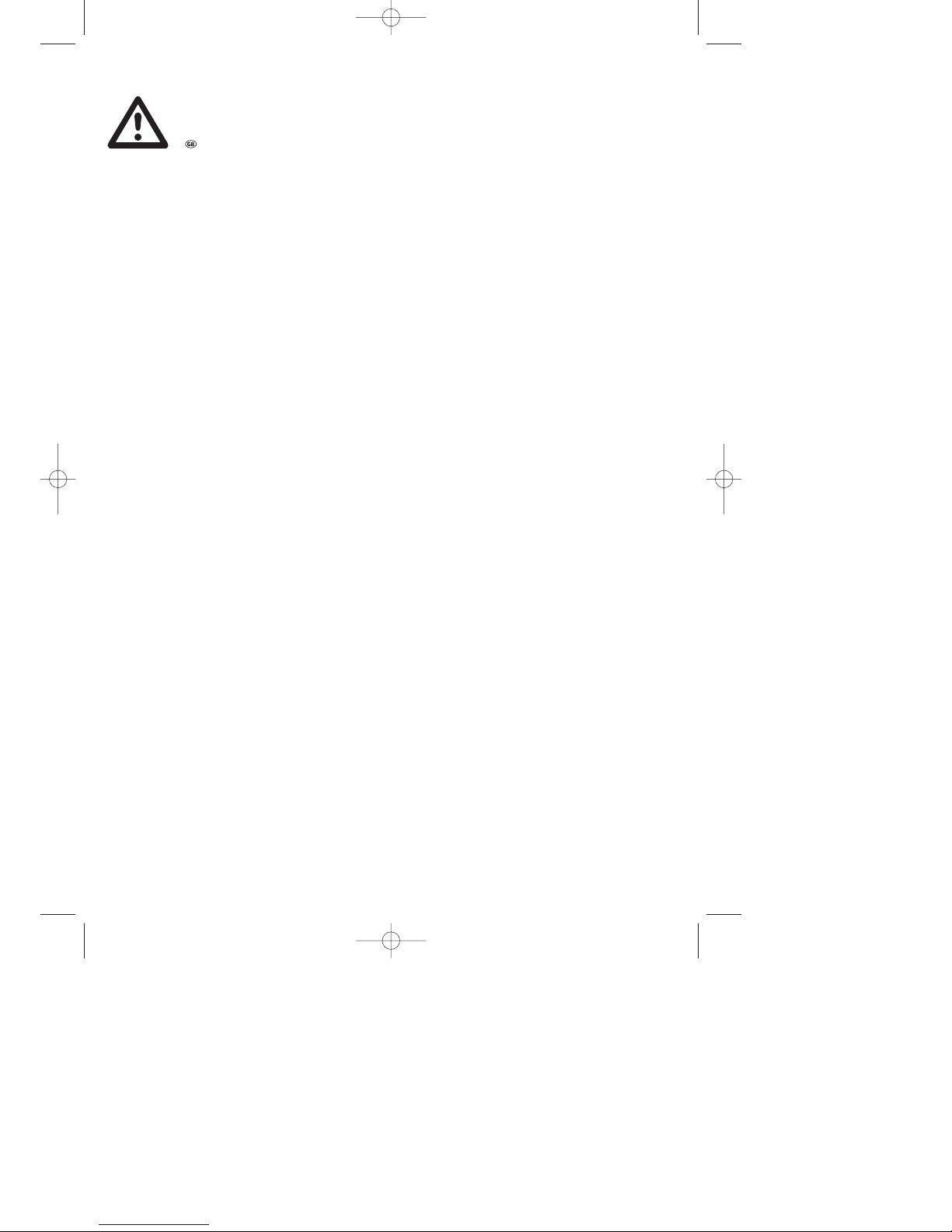

5.1. Assembly (Figs. 3 and 4)

1. Screw the hose connection (9) onto the

equipment.

2. Connect the pressure hose (6) and the draw-off

hose (8) to the distributor (7). Please make sure

that the draw-off hose (8) is mounted on the side

of the stopcock (10).

3. Now connect the pressure hose (6) to the hose

connection (9) of the equipment.

5.2 Inserting the pump into the rain barrel (Fig. 5)

1. Place the equipment in the rain barrel.

2. Secure the distributor to the rim of the rain barrel.

To do so, twist the eccentrically mounted rubber

fasteners (A) such that the distributor (7) can be

clamped to the rim of the rain barrel.

Note!

When installing, never hang the equipment by the

discharge line or by the power cable. The equipment

must be hung up with the provided carry handle or it

must rest on the bottom of the shaft. To ensure that

the equipment works properly, the bottom of the shaft

always must be free of sludge and other

accumulations of dirt. If the water level is too low, the

sludge in the shaft can quickly dry out and hinder the

equipment from starting. It is necessary therefore to

check the equipment regularly (carry out trial startups).

Note:

The pump shaft should measure at least

40 x 40 x 50 cm so that the floating switch can move

freely.

5.3 Mains connection

The equipment you have purchased comes with an

earthing-pin plug. The equipment is designed for

connection to a socket outlet with earthing contact for

230 V ~ 50 Hz. Make sure that the socket-outlet is

sufficiently fused (at least 6 A) and in good working

order. Insert the power plug in the socket-outlet and

the equipment is ready for operation.

Important!

To rule out danger, this work must be left strictly to a

specialist electrician or Customer Service.

6. Operation

You can put the equipment into operation after you

have thoroughly read the installation and operating

instructions. Pay attention to the following points:

Make sure that the equipment is set up securely.

Check that the discharge line is fitted correctly.

Make sure that the electrical connection is 230 V

~ 50 Hz.

Check that the electrical socket-outlet is in good

working order.

Make sure that no moisture or water can ever

reach the power connection.

Make sure that the equipment does not run dry.

To withdraw water, open the stopcock (10).

To switch off the equipment, pull the power plug

out of the socket outlet.

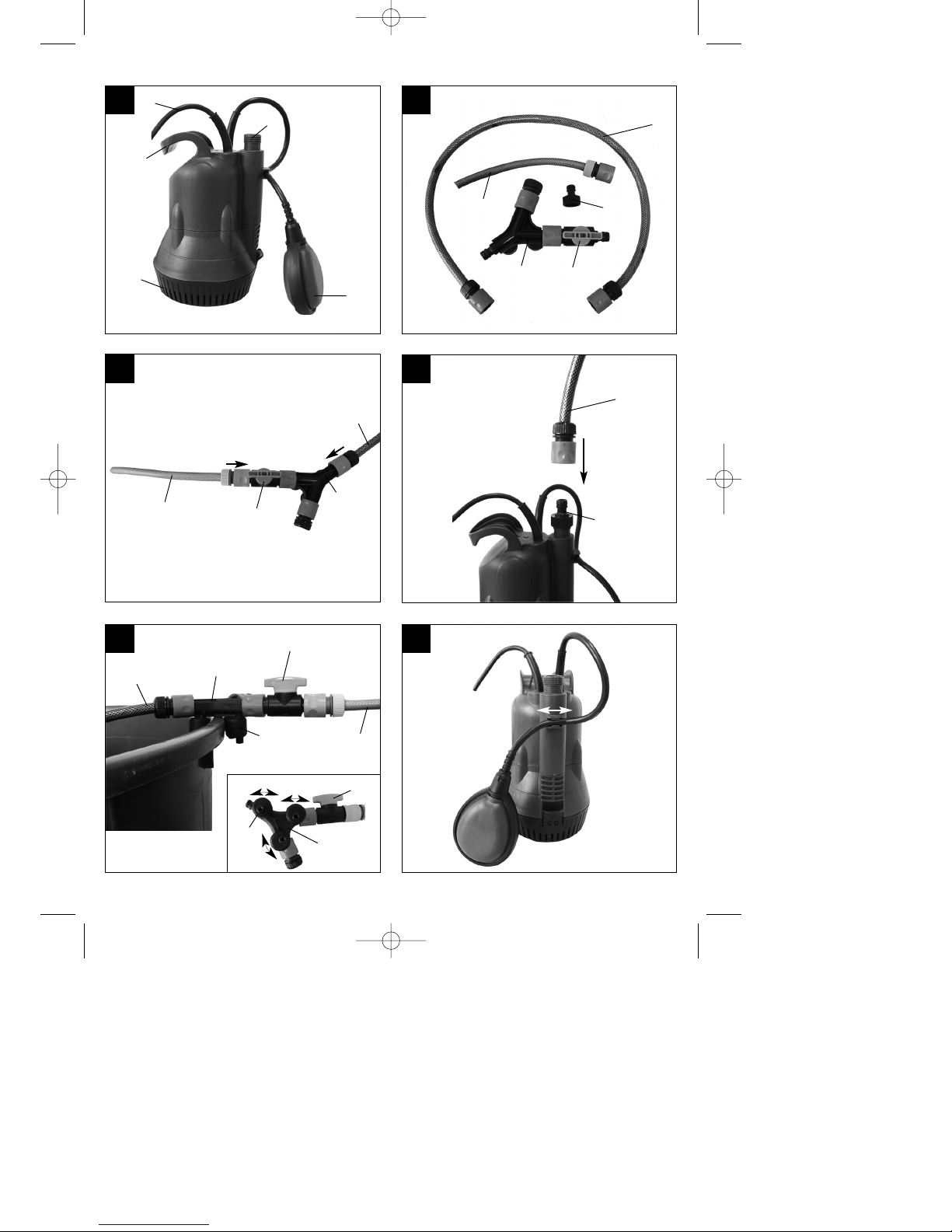

Setting the ON/OFF switching point:

The ON/OFF switching point of the floating switch can

be infinitely adjusted. This is done by moving the

floating switch cable in the cable holder (Fig.

6).Check the following points before putting the

equipment into operation:

The floating switch must be fitted so that the

switching point height: ON and the switch point

height: OFF can be reached easily and with little

force. Check this by placing the equipment in a

container filled with water and carefully raising

and lowering the floating switch with your hand.

Anleitung_BG_SP_400_RB_SPK1:_ 04.07.2008 11:04 Uhr Seite 10

Page 7

GB

7

You can then see whether the equipment

switches on and off.

Make sure that the distance between the floating

switch head and the cable holder is not too small.

If the distance is too small, there is no guarantee

that the equipment will work correctly.

When adjusting the floating switch, make sure

that the floating switch does not touch the bottom

before the equipment is switched off. Important!

Risk of dry running.

7. Replacing the power cable

If the power cable for this equipment is damaged, it

must be replaced by the manufacturer or its aftersales service or similarly trained personnel to avoid

danger.

8. Cleaning, maintenance and

ordering of spare parts

Important!

Unplug the power plug prior to any maintenance

work.

For mobile applications, the equipment should be

cleaned with clear water after every usage.

For stationary installation, it is recommended that

you check the floating switch for proper

functioning every three months.

Use a water jet to remove any lint or fibrous

particles that may have become trapped in the

housing.

Remove sludge from the shaft bottom and clean

the shaft walls every 3 months.

Use clear water to remove deposits from the

floating switch.

8.1 Cleaning the filter (Figs. 7 and 8)

In order to protect the equipment and the impeller

from severe soiling, an additional filter has been

installed in the bottom intake cage. Please proceed

as follows when cleaning the filter:

1. Gently press the lateral tab (A) in the direction of

the arrow until the intake cage (5) can be

disconnected from the pump.

2. Remove the filter (B) and wash it out under

running water.

3. Now insert the filter back into the intake cage and

reconnect the intake cage to the equipment.

8.2 Maintenance

There are no parts inside the equipment which

require additional maintenance.

8.3 Ordering replacement parts:

Please quote the following data when ordering

replacement parts:

Type of machine

Article number of the machine

Identification number of the machine

Replacement part number of the part required

For our latest prices and information please go to

www.einhell.com.au��

9. Disposal and recycling

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material

and can therefore be reused or can be returned to

the raw material system.

The unit and its accessories are made of various

types of material, such as metal and plastic.

Defective components must be disposed of as

special waste. Ask your dealer or your local council.

Anleitung_BG_SP_400_RB_SPK1:_ 04.07.2008 11:04 Uhr Seite 11

Page 8

8

GB

Faults Cause Remedy

The equipment does not start

- Power supply not connected

- Floating switch does trigger

- Check power supply

- Raise position of floating switch

The equipment does not pump

- Intake sieve clogged

- Discharge hose kinked

- Clean intake sieve with water jet

- Unkink the hose

The equipment does not cut out

- Floating switch cannot sink - Place equipment correctly on

shaft bottom

Insufficient pumping rate

- Intake sieve clogged

- Performance reduced due to

heavily contaminated and

abrasive water impurities

- Clean intake sieve

- Clean equipment and replace

wear parts

The equipment switches off after

briefly running

- Motor circuit-breaker switches

the equipment off due to

excessive water contamination

- Water temperature too high;

motor circuit-breaker switches

the equipment off

- Unplug power plug and clean

equipment and shaft

- Ensure that maximum

permissible water temperature

(35 °C) is not exceeded

10. Troubleshooting guide

Anleitung_BG_SP_400_RB_SPK1:_ 04.07.2008 11:04 Uhr Seite 12

Page 9

The guarantee provided in this Guarantee Certificate is given by Einhell Australia Pty Limited

ACN 134 632 858 of 6/166 Wellington Street, Collingwood, Victoria (Telephone number 1300 922 271)

GUARANTEE

CERTIFICATE

EINHELL AUSTRALIA PTY LTD

6/166 Wellington Street

Collingwood VIC 3066

Australia

Phone: 1300 922 271

Dear

Customer,

All of our products undergo strict quality checks. In the unlikely event that your device develops a fault, please

contact our service department at the address shown on this guarantee certificate. Of course, if you would

prefer to call us then we are also happy to offer our assistance under the service number printed below.

Please note the following terms under which claims under the Einhell Express Guarantee can be made:

1. The benefits conferred by the Einhell Express Guar

antee are in addit

ion to all rights and remedies which

you may be entitled to under the Australian Consumer Law, and any other statutory rights you may have

under other applicable laws. This Einhell Express Guarantee does not exclude, restrict or modify any

We do not charge you for the Einhell Express Guarantee.

2. Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for compensation for any othe

r reasonabl

y

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods

fail to be of acceptable quality and the failure does not amount to a major failure.

3. The Einhell Express Guarantee only covers problems caused by material or manufacturing defects, and

our liability under the Einhell Express Guarantee is limited, at our discretion, to the rectification of these

defects or replacement of the product. Please note that the product has not b

een de

signed for use in

commercial, trade or industrial applications. Consequently, the Einhell Express Guarantee will not apply

if the product is used in commercial, trade or industrial applications or for other equivalent activities.

4. The following are also excluded from the Einhell Express Guarantee: compensation for transport

damage, damage caused by failure to comply with the installation/assembly instructions or damage

caused by unprofessional installation, failure to comply with the op

era

ting instructions (e.g. connection to

the wrong mains voltage or current type), misuse or inappropriate use (such as overloading of the

product or use of non-approved tools or accessories), failure to comply with the maintenance and safety

regulations, ingress of foreign bodies into the product (e.g. sand, stones or dust), effects of force or

external influences (e.g. damage caused by the product being dropped) and normal wear resulting from

proper operation of the product. The

Einhel

l Express Guarantee will also not apply if any attempt is made

5. The Einhell Express Guarantee is valid for a period of 2 years starting from the purchase date of the

product. Claims made under the Einhell Express Guarantee should be submitted before the end of this

guarantee period and within two weeks of the defect being noticed. No claims under the Einhell Express

Guarantee will be accepted if submitted after the end of this guarantee period. The original guarantee

period remains applicable to the

device

even if repairs are carried out or parts are replaced. In such

cases, the work performed or parts fitted will not result in an extension of the guarantee period for the

Einhell Express Guarantee, and the Einhell Express Guarantee will not apply for the work performed or

6. To make a claim under the Einhell Express Guarantee, please send the relevant product postage-free to

the address shown below and enclose either the original or a copy of your sales receipt or another dated

proof

of purchase. It would help us if you could describe the nature of the problem in as much detail as

possible. If the defect is covered by the Einhell Express Guarantee, your product will be repaired

immediately and returned to you, or we will send you a new device (at our election).

Any costs incurred by you in making a claim under this Einhell Express Guarantee, unless specified

otherwise in this guarantee certificate, must be borne by you.

Of course, we are also happy to offer a chargeable

repair

service for any defects which are not covered by the

scope of the Einhell Express Guarantee or for products which are no longer covered by the Einhell Express

Guarantee. To take advantage of this service, please send the product to our service address.

such rights or remedies.

to tamper with the product.

parts fitted. This also applies when an on-site service is used.

(Einhell Express Guarantee).

Page 10

EH 04/2012 (02)

Page 11

EH 04/2012 (02)

Page 12

EH 04/2012 (02)

Loading...

Loading...