Page 1

REFERENCE NO. SM5110785-00

PRODUCT CODE :

LC-XT4U KF6B 1 122 342 01 U.S.A., Canada

LC-XT4E LF6B 1 122 343 01 Europe

(Projection lens is optional.)

Multimedia Projector

SERVICE MANUAL

ORIGINAL VERSION

Chassis No. KF6-XT4U00

LF6-XT4E00

MODEL NO. LC-XT4U U.S.A., Canada

LC-XT4E Europe

Give complete “Chassis No.” for parts

order or servicing, it is shown on the

rating sheet on the cabinet on the projector.

FOREWORD

For your convenience, all service parts, identified in this manual are available through Eiki’s normal distribution

channels.

In addition to service part number, the generic descriptions have been given, where possible, to allow your service technicians to substitute equivalent components which might be available from other sources.

All orders for service parts will be honored. However, in instances where generic components are considered to

be available from several common sources, as would be the case with an industry standard fuse, resistor, or

semiconductor, it may be more economical and expeditious to purchase the part locally.

Page 2

- 2 -

■ Contents

■ Contents ..................................................................................................................2

■ Safety Instructions...................................................................................................3

■ Specifications ..........................................................................................................4

■ Circuit Protections ...................................................................................................5

■ Lamp Replacement .................................................................................................9

■ Maintenance and Cleaning....................................................................................13

■ Mechanical Disassemblies ....................................................................................15

■ Optical Unit Disassemblies....................................................................................39

■ Optical Parts Location and Direction .....................................................................50

■ Troubleshooting.....................................................................................................53

● No Picture ...................................................................................................53

● No Power ....................................................................................................58

● No Audio Output..........................................................................................62

● Temperature Abnormality............................................................................63

● Power Lens System Abnormality ................................................................64

● Lamp Abnormality .......................................................................................65

■ Optical Adjustments .............................................................................................66

● Adjustments after Parts Replacement (Optical Parts).................................66

■ Electrical Adjustments ...........................................................................................77

● Adjustments after Parts Replacement (Electrical Parts) .............................77

● Service Adjustment Menu Operation ..........................................................78

● Circuit Adjustments .....................................................................................79

● Service Mode Adjustment Menu .................................................................84

● Service Adjustment Data Table...................................................................86

■ Waveforms ............................................................................................................94

■ Control Port Functions...........................................................................................95

■ IC Block Diagrams...............................................................................................101

■ Mechanical and Optical Parts list ........................................................................109

■ Electrical Parts List..............................................................................................121

Drawings & Diagrams ............................................................................ A1-A25

■ Parts description and reading in schematic diagram .......................................... A2

■ Block Diagrams ....................................................................................................A3

■ Schematic Diagrams ....................................................................................A4-A14

■ Printed Wiring Board Diagrams.................................................................. A15-A24

■ Pins description of ICs, transistors, diodes ........................................................ A25

Page 3

- 3 -

WARNING:

The chassis of this projector is isolated (COLD) from AC line by using the converter transformer. Primary side of

the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit is

identified with the line ( ) in the schematic diagram. For continued product safety and protection of personnel injury, servicing should be made with qualified personnel.

The following precautions must be observed.

SAFETY PRECAUTIONS

1: An isolation transformer should be connected in the

power line between the projector and the AC line

before any service is performed on the projector.

2: Comply with all caution and safety-related notes

provided on the cabinet back, cabinet bottom, inside

the cabinet or on the chassis.

3: When replacing a chassis in the cabinet, always

be certain that all the protective devices are

installed properly, such as, control knobs, adjustment covers or shields, barriers, etc.

DO NOT OPERATE THIS PROJECTOR WITHOUT

THE PROTECTIVE SHIELD IN POSITION AND

PROPERLY SECURED.

4: Before replacing the cabinet cover, thoroughly

inspect the inside of the cabinet to see that no

stray parts or tools have been left inside.

Before returning any projector to the customer, the

service personnel must be sure it is completely safe

to operate without danger of electric shock.

SERVICE PERSONNEL WARNING

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always

turn off Lamp before opening cover. The Ultraviolet radiation eye protection required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages(approx.8kV) at its starts.

Since the lamp is very high temperature during units operation replacement of the lamp should be done at least

45 minutes after the power has been turned off, to allow the lamp cool-off.

PRODUCT SAFETY NOTICE

Product safety should be considered when a component replacement is made in any area of the projector.

Components indicated by mark in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is, therefore, particularly recommended that the replacement of there

parts must be made by exactly the same parts.

■ Safety Instructions

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

CAUTION

Not for use in a computer room as defined in the Standard for the Protection of Electronic Computer/Data

Processing Equipment, ANSI/NFPA 75.

Ne puet être utillisé dans une salle d’ordinateurs telle que définie dans la norme ANSI/NFPA 75 Standard for

Protection of Electronic Computer/Data Processing Equipment

Page 4

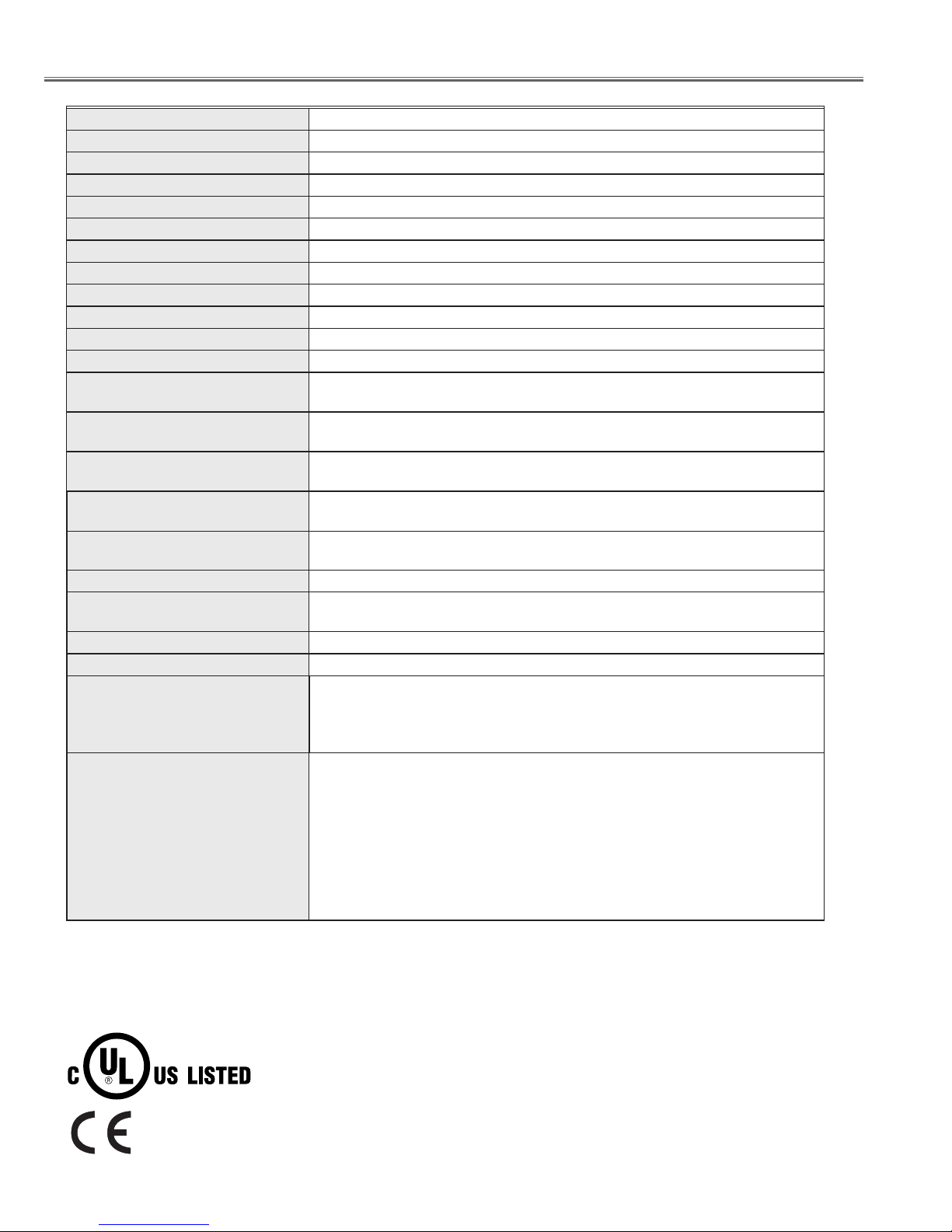

Owner’s Manual (CD-ROM)

Quick setup manual

AC Power Cord

Wireless/Wired Remote Control Transmitter and Batteries

Remote Control Cable

VGA Cable

6 Types Light-Block Sheet (For option lens)

2 Types Lens Attachment (For option lens)

Real Color Manager Pro

Accessories

1.8" TFT Active Matrix type, 3 panels

Multi-media Projector

80.3 lbs (36.5 kg)

22.9" x 10" x 30.9" (581 mm x 252 mm x 783 mm)

1024 x 768 dots

2,359,296 (1024 x 768 x 3 panels)

PAL, SECAM, NTSC, NTSC4.43, PAL-M and PAL-N

Up, Down, Left and Right

800 TV lines

41 ˚F ~ 95 ˚F (5 ˚C ~ 35 ˚C)

14 ˚F ~ 140 ˚F (-10 ˚C ~ 60 ˚C)

Projector Type

Net Weight

Dimensions

(W x H x D)

Panel Resolution

Number of Pixels

Color System

Scanning Frequency

Horizontal Resolution

Operating Temperature

Storage Temperature

LCD Panel System

300 watt type x 4

Projection Lamp

0˚ to 5.7˚

Feet Adjustment

Power Source : AA or R06 Type x 2

Operating Range : 16.4’ (5m) / ±30˚

Dimensions : 1.97” x 1.06” x 6.61” (50mm x 27mm x 168mm)

Net Weight : 4.4 oz (126 g) (including batteries)

Remote Control Transmitter

480i, 480p, 575i, 575p, 720p, 1035i, 1080i-50 and 1080i-60

High Definition TV Signal

AC 120 V (16 A Max. Ampere), 50 / 60 Hz

(The U.S.A and Canada)

AC 200 ~ 240 V (9.0 A Max. Ampere), 50 / 60 Hz

(Continental Europe)

Voltage and

Power Consumption

H-sync. 15 ~ 120 KHz, V-sync. 50 ~ 120 Hz

Motorized Lens Shift

DVI-I Terminal (Digital/Analog), RCA Type (Audio R and L)

and DIN 8-pin (Control port)

Input 1 Jacks

BNC Type x 5 (R/Pr, G/Y, B/Pb, H/HV and V), RCA Type (Audio R and L)

and DIN 8-pin (Control port)

Input 2 Jacks

BNC Type x 2 (VIDEO/Y, C), RCA Type (Audio R and L)

and DIN 4-pin (S-Video)

Input 3 Jacks

Serial port in (DB 9), Serial port out (DB 9), USB port,

Audio out (RCA Type R and L) and Wired Remote Jack

Other Jacks

HDB 15-pin Terminal (Analog), RCA Type (Audio R and L)

and DIN 8-pin (Control port)

Input 4 Jacks

● The specifications are subject to change without notice.

● LCD panels are manufactured to the highest possible standards. Even though 99.99% of the pixels are effective, a tiny

fraction of the pixels (0.01% or less) may be ineffective by the characteristics of the LCD panels.

This symbol on the nameplate means the product is Listed by Underwriters Laboratories

Inc. It is designed and manufactured to meet rigid U.L. safety standards against risk of

fire, casualty and electrical hazards.

The CE Mark is a Directive conformity mark of

the European Community (EC).

- 4 -

■ Specifications

Page 5

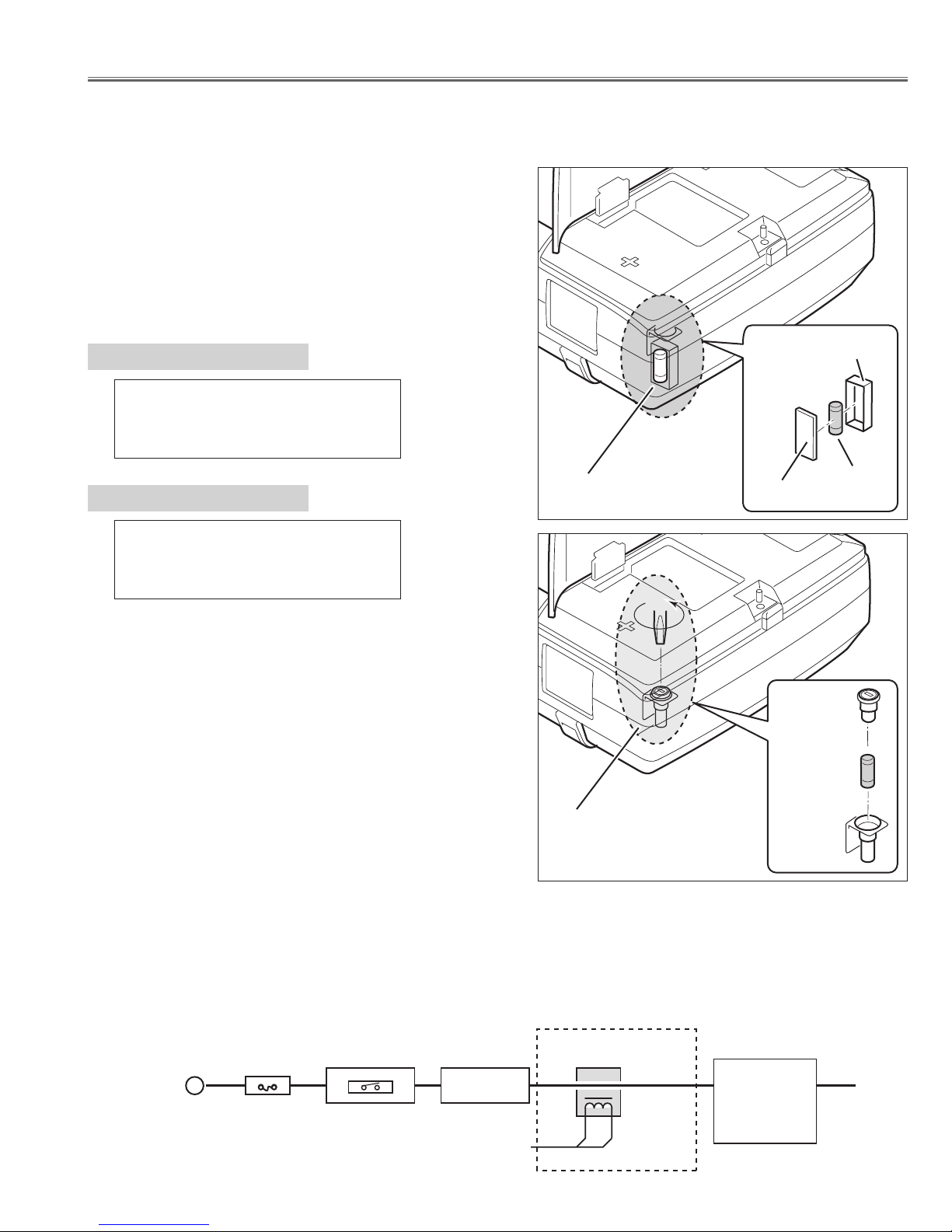

This projector provides the following circuit protections to operate in safety. If the abnormality occurs inside the projector, it will automatically turn off by operating one of the following protection circuits.

A fuse(F901) is located inside of the projector. When the

POWER indicator is not lighting, the fuse may be opened.

Check the fuse as following steps.

The fuse should be used with the following type;

● Fuse

How to replace the fuse

1. Remove the cabinet top following to "Mechanical

Disassemblies".

2. Remove the cover and the fuse from fuse holder.

To install the fuse, take reversed step in the above.

- 5 -

■ Circuit Protections

Fuse Part No.: 423 028 4209

TYPE 15.0A400V FUSE

SOC CORP. SHV14 15A N4

Fuse Part No.: 423 033 1804

TYPE 30.0A250V FUSE

SOC CORP. KST2 30A

PLC-XT4E

PLC-XT4U

Fuse (F901)

Fuse (F901)

Cover

Cover

Fuse

Fuse

Holder

Holder

● AC Current Sensor

AC current sensor is used only for LC-XT4E.

The AC Current Sensor is provided to prevent damage to the power supply circuits.

When AC input voltage is under 108V at MAINS SW ON, the AC Current Sensor will be operated and the CPU

does not turn the projector on, and both of READY and WARNING TEMP. indicators start flashing.

Check that the AC current sensor signal is correct. L : Abnormality

K96W

Hot circuit

AC-INPUT

FUSE

F901

MAINS SW

SW901

NOISE FILTER

LF901

CURRENT SENSOR

A903

ASS'Y POWER

Page 6

- 6 -

Circuit Protections

Lamp Cover switch

SW902

When the lamp cover is removed or no close completely, the lamp cover switch (SW902) cuts off

12V_PFC line to the PFC unit, and then a projector

will be shut down.

After opening the lamp cover for replacing the lamp

unit, place the lamp cover correctly, otherwise the projector can not be turned on.

Lamp Cover

● Lamp cover switch

● Power Failure Protection

Power failure protection diodes detect abnormal voltage on the power supply circuits or the fan operation stop.

When both of the WARNING TEMP. and READY Indicators are flashing:

When the projector detects an internal problem, it will shut down

automatically and both of the WARNING TEMP. and READY Indicators starts

flashing. In this condition, the projector cannot be turned on even if you press

the POWER ON-OFF button on the remote control unit or on the side control.

If this case happened, disconnect and reconnect the AC power cord, and

then turn on the projector again to check its operation. If the projector shuts

down again or fails to be turned on, the internal check and repair will be

required.

Check items listed below;

● Power Failure Protection

● AC Current Sensor (See the previous page.)

● Temperature Check of Lamps

● Lamp Cover Switch

READY

LAMP

LAMP

REPLACE

WARNING

TEMP.

FRONT INDICATORS

WARNING TEMP.

Indicator

READY

Indicator

WARN ING

TEMP.

READY

LAMP

REPLACE

LAMP

REAR INDICATORS

Temperature switches (SW 903~906)

are arranged near the four lamps.

Temperature switches will operate, if

temperature reaches 110 degrees.

Temperature switches

--- open at 110 degrees.

SW903 ---Lamp1

SW904 ---Lamp2

SW905 ---Lamp3

SW906 ---Lamp4

When temperature switches become

open, they cut off 12V_PFC line to

PFC(power factor control) unit, and

then a projector will be shut down.

● Temperature Check of Lamps

Temperature switch

SW906 (For Lamp4)

Temperature switch

SW905 (For Lamp3)

Temperature switch

SW903 (For Lamp1)

Temperature switch

SW904 (For Lamp2)

Page 7

- 7 -

Circuit Protections

READY

LAMP

LAMP

REPLACE

WARNING

TEMP.

When the WARNING TEMP. Indicator is flashing:

The WARNING TEMP. Indicator flashes red to let you know the internal

temperature of the projector exceeds the normal level. If the temperature goes

up further, the projector will be turned off automatically and the Ready indicator

will go out. (The WARNING TEMP. Indicator continues flashing.) After the

cooling-off period, the READY Indicator lights on again and the projector can be

turned on by pressing the POWER ON-OFF button on the remote control unit or

on the side control. When you turn on the projector, the WARNING TEMP.

Indicator will go out.

If the WARNING TEMP. Indicator is still flashing, check items listed below;

● Installation

● Air Filter

● Temperature Monitor System

FRONT INDICATORS

WARNING TEMP.

Indicator

WARNING

TEMP.

READY

LAMP

REPLACE

LAMP

REAR INDICATORS

This projector is equipped with cooling fans for protection

from overheating. Pay attention to following to ensure proper ventilation and avoid a possible risk of fire and malfunction.

- Do not cover vent slots.

- Keep bottom clear any objects. Obstructions may block cooling air.

AIR INTAKE VENTS

EXHAUST VENTS

HOT AIR EXHAUSTED !

Air blown from exhaust vent is hot. When using

or installing a projector, following precautions

should be taken.

● Do not put flammable objects near these vents.

● Keep rear grills at least 3’ (1m) away from any object,

especially heat-sensitive object.

● Do not touch this area, especially screws and metallic

parts. This area will become hot while a projector is used.

HOT

● Installation

● Air Filter

- Air filter is clogged with dust particles. Remove dust from the air filter by following instruction in the "Air filter care

and cleaning".

- Ventilation slots of the projector are blocked. In such case, reposition the projector so that ventilation slots are not

obstructed.

- Check if projector is used at higher temperature place(Normal operate is 5 to 35°C or 41 to 95°F)

AIR FILTER

Page 8

- 8 -

Circuit Protections

■ To control the driving power of the cooling fans.

This projector detects internal temperature and automatically controls operating power of cooling fans.

The CPU checks the temperature and atmospheric pressure inside a projector. It checks a temperature using

temperature sensor-IC5801and it checks an atmospheric pressure using pressure sensor-IC886.

The CPU controls the driving power of the cooling fans so the temperature inside the projector is maintained to

normal temperature.

■ To shut down the projector.

The CPU checks temperature of Blue polarized glass (PTH901) and inhalation air(IC5801). If each part temperature reaches to abnormal temperature, the CPU will turn off a projector, and will blink WARNING TEMP. indicator at intervals of 0.5 seconds. Cooling fans operate until temperature returns to normal. WARNING TEMP.

indicator will stop blink, if temperature returns to normal.

● Temperature Monitor System

Main Board

A-side

Front side

B-side

Temp. Sensor

IC2541

Temp. Sensor

(Inhalation air)

IC5801

Pressure Sensor

IC886

Temp. Sensor

(Blue polarized glass)

PTH901

Temperature sensors location

Blue polarizer unit

Page 9

- 9 -

■ Lamp Replacement

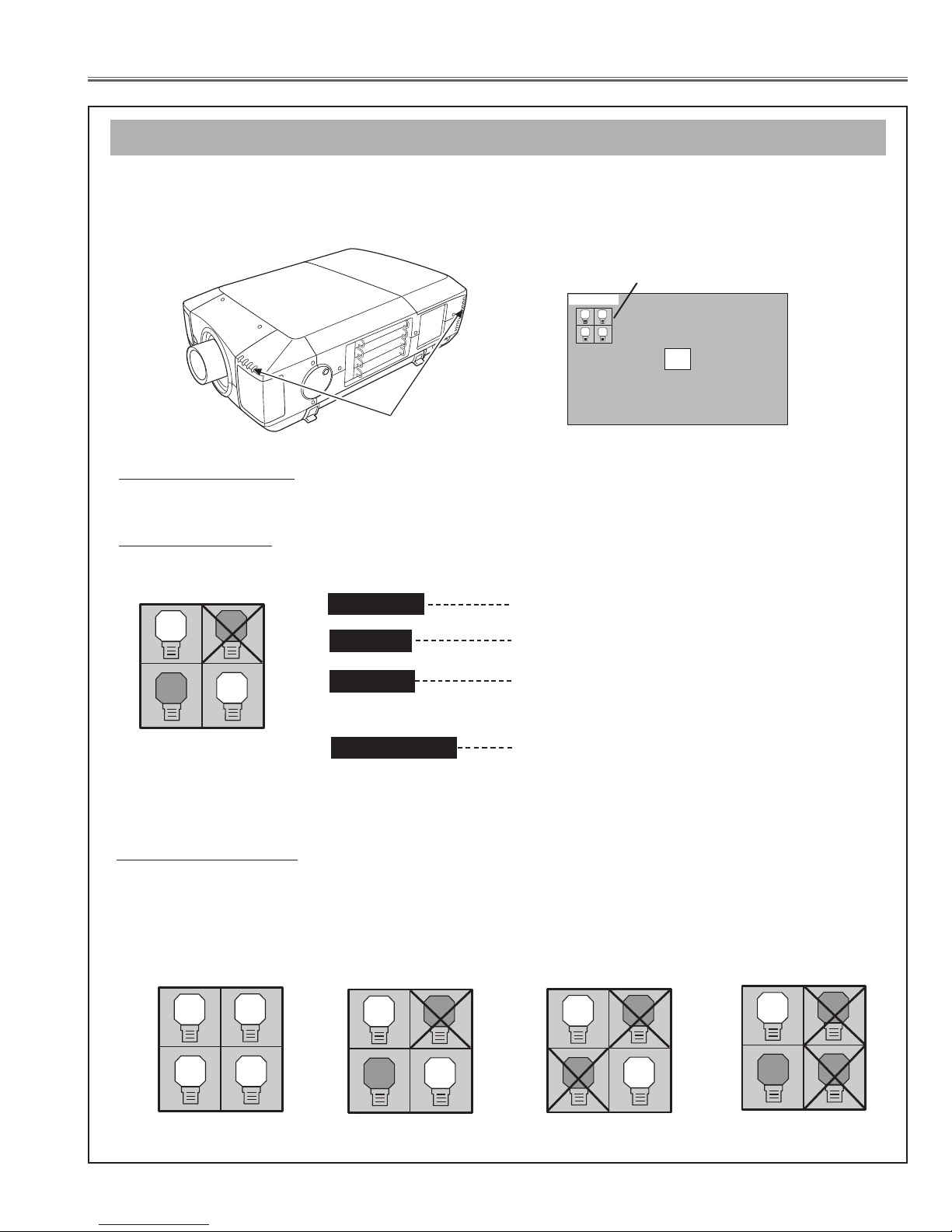

This Projector is equipped with 4 Projection Lamps to ensure brighter image and those lamps are controlled by Lamp

Management Function. Lamp Management Function detects status of all lamps and shows status on screen or on LAMP

REPLACE indicator. This function also automatically controls Lamp Mode when any of lamps is out for end of life or

malfunctions.

Projection Lamp lights normally.

Lamp Replace Indicator

This LAMP REPLACE indicator lights yellow when any of Projection Lamps is nearing its end, and flashes when any of them

becomes out. Check number of lamp on Lamp Status Display and replace lamp.

Yellow Lamp

Dim Lamp

X Mark on Lamp

Red Lamp

LAMP REPLACE

INDICATOR

Projection Lamp is turned off.

Projection Lamp is nearing its end. When image becomes

darker or color becomes unnatural, replace lamp. (LAMP

REPLACE indicator lights yellow.)

(LAMP REPLACE indicator flashes yellow.)

Projection lamp is defective or fails to be turned on. Restart

a projector on, and make sure lamp is on. If this mark still

appears, replace lamp corresponding with number marked

X.

LAMP STATUS

DISPLAY

1

4

3

2

Lamp Mode Changeover

Lamp Management Function automatically changes combination of lighting lamp (Lamp Mode) by detecting status of lamp.

When any of 4 lamps becomes out, Lamp Mode is changed over from 4 lamps to 2 lamps. And when any of 2 lamps are out,

a projector operates with 1 lamp. But, in case of combination that the Lamp of 1-4, or 2-3 does not light up, it becomes a 2

lamps mode.

Lamp Mode can be switched to 4 lamps or 2 lamps manually. Refer to SETTING section of Owner's manual

.

1

2 4

3

1

4

3

2

4 LAMP MODE

2 LAMP MODE

(Example)

1

4

3

2

2 LAMP MODE

(Example)

1

3

2

4

1 LAMP MODE

(Example)

Lamp Status Display

Lamp Status Display appears on screen when power switch is on or changed input position (input 1, input 2, Input 3 or input 4).

This shows status of each lamp as; ON, OFF, NEAR END, or OUT. Refer to following for each status.

20

LAMP STATUS

INPUT 1

1

2 4

3

LAMP MANAGEMENT (before replacement)

Page 10

- 10 -

LAMP REPLACEMENT

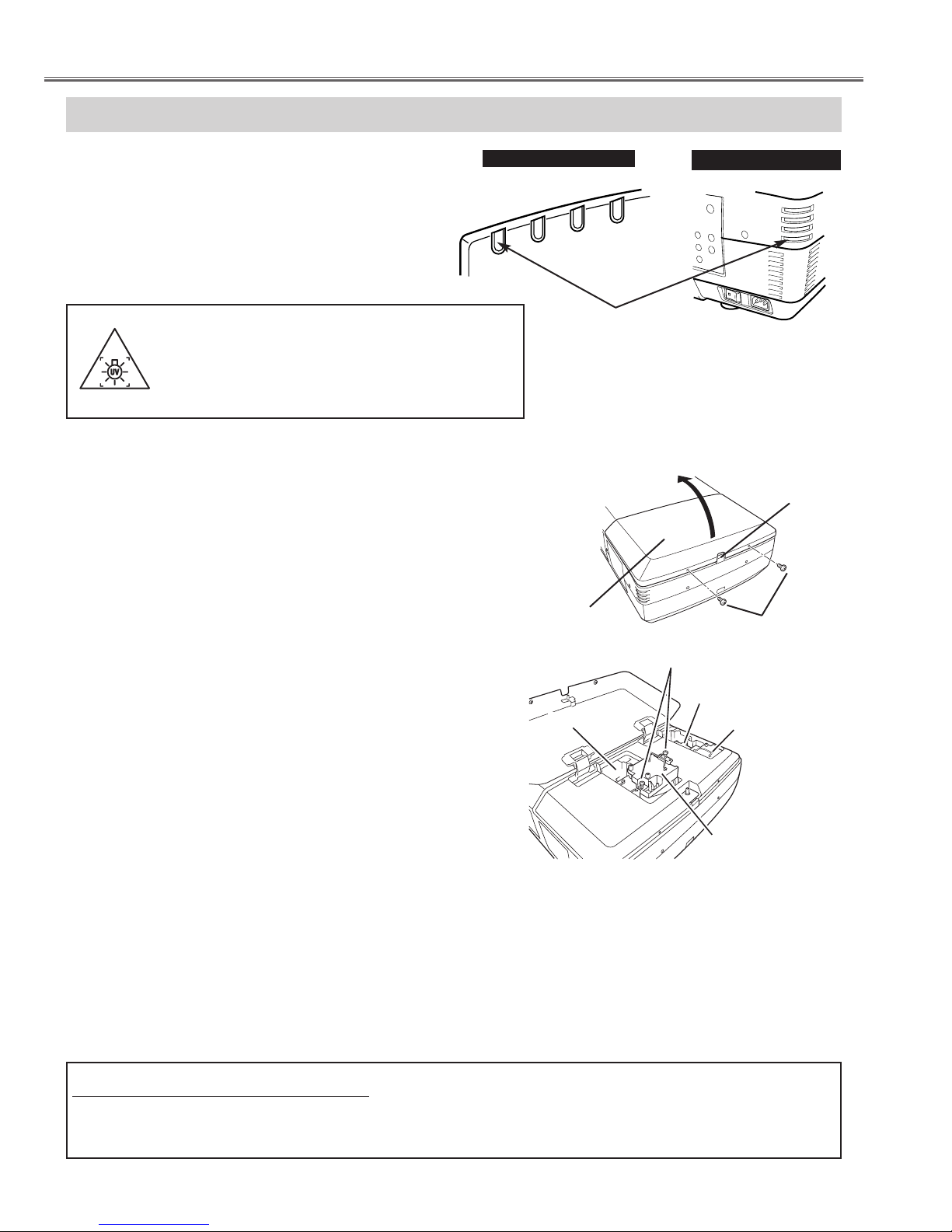

Check number of lamp to be replaced on Lamp Status

Display.

Remove two screws on Lamp Cover and press button to

open Lamp Cover. (See right figure.)

1

3

Loosen two screws and pull out Lamp Assembly to be

replaced by grasping handle.

4

Turn off a projector and disconnect AC Power Cord.

Allow a projector to cool down for at least 45 minutes.

2

Replace Lamp Assembly with a new one and tighten two

screws. Make sure Lamp is set properly.

6

Follow these steps to replace lamp assembly.

Replace Lamp Cover and tighten two screws.

5

7

8

Connect AC Power Cord to a projector and turn a

projector on.

Reset Lamp Replacement Counter. (Refer to section

"Lamp Replace Counter".)

NOTE : Do not reset LAMP REPLACEMENT COUNTER when

lamp is not replaced.

BUTTON

SCREWS

SCREWS

LAMP1

LAMP2

LAMP

COVER

Make sure which number of lamp needs to

be replaced on Lamp Status Display.

Figure shows case of replacing LAMP 2.

CAUTION : Do not operate a Projector while any of lamps removed.

It may result in malfunctions, fire hazard, or other accidents.

NOTES ON LAMP REPLACEMENT

To maintain quality of picture (better balance of color and brightness in entire screen), we recommend replacing all 4 lamps at a time.

CAUTION : High pressure lamp may explode if improperly handled.

Refer to lamp replacement instructions.

When the life of the projection lamp of this projector

draws to an end, the LAMP REPLACE indicator

lights yellow. If this indicator lights yellow, replace

the lamp with a new one promptly.

The time when the LAMP REPLACE indicator lights

is depending on the lamp mode.

Lamp Replacement

LAMP3

LAMP4

WARNING :

TURN OFF THE UV LAMP BEFORE OPENING

THE LAMP COVER. USE UV RADIATION EYE

AND SKIN PROTECTION DURING SERVICING.

REAR INDICATORS

READY

LAMP

LAMP

REPLACE

WARNING

TEMP.

WARNING

TEMP.

READY

LAMP

REPLACE

LAMP

FRONT INDICATORS

LAMP REPLACE

INDICATOR

Page 11

- 11 -

CAUTION

Do not drop a lamp assembly or touch a glass

bulb! Glass can shatter and may cause injury.

CAUTION

For continued safety, replace with a lamp

assembly of same type.

Allow a projector to cool for at least 45 minutes

before you open Lamp Cover. Inside of a

projector can become very hot.

ORDER REPLA

CEMENT LAMP

Replacement Lamp can be ordered through your dealer. When ordering a Projection Lamp, give the

following information to the dealer.

● Model No. of your projector : LC-XT4U / LC-XT4E

● Replacement Lamp Type No. : POA-LMP100

(Service Parts No. 610 327 4928)

Lamp Replacement

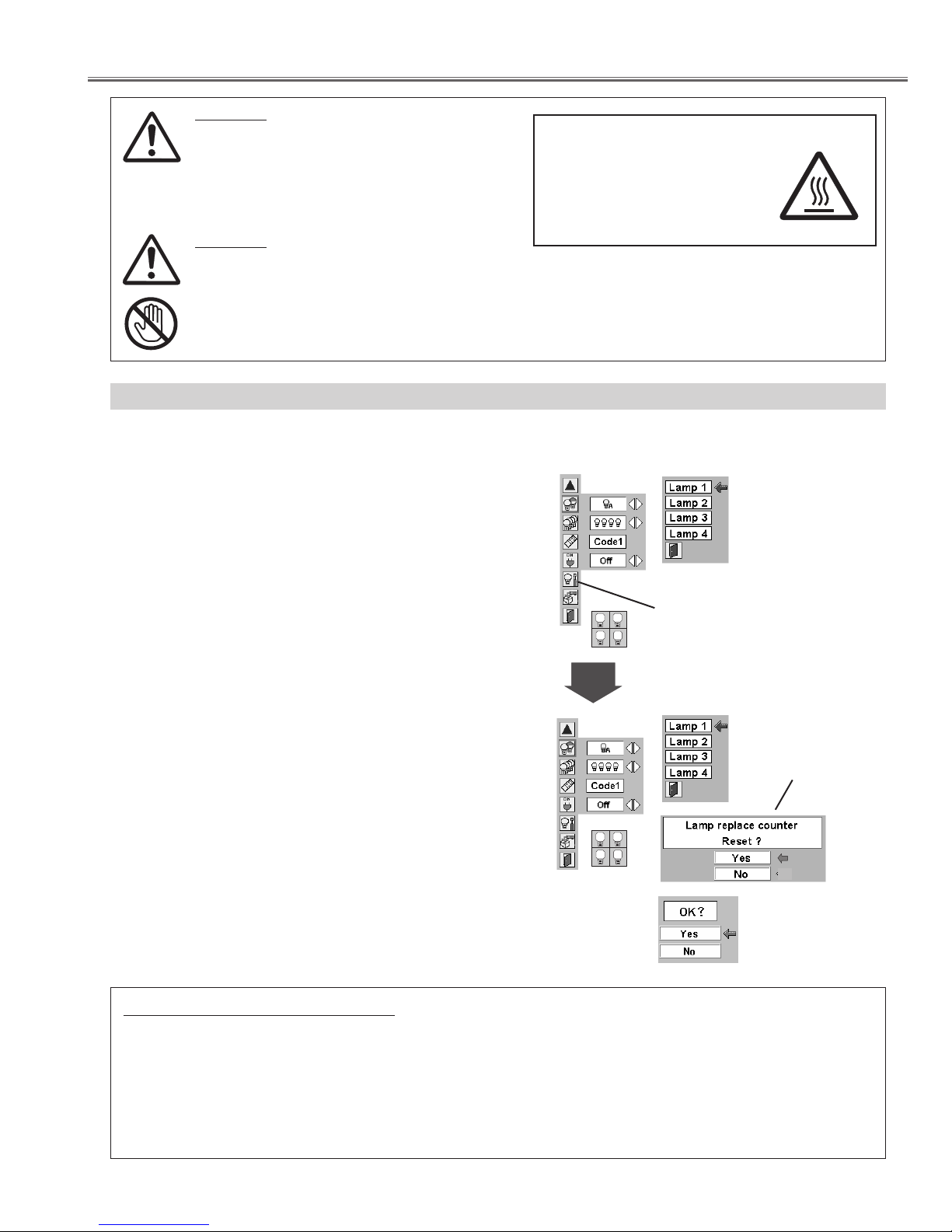

Move pointer to Lamp counter reset and

then press SELECT button. Move

arrow to replaced lamp number (Lamp

1, Lamp 2, Lamp 3 or Lamp 4) and then

press

SELECT button.

Be sure to reset Lamp Counter when Lamp Assembly is replaced. When Lamp Replace Counter is reset, LAMP

REPLACE indicator stops lighting.

Turn projector on, press MENU button and ON-SCREEN

MENU will appear. Press POINT LEFT/RIGHT button(s) to

move a red frame pointer to SETTING Menu icon.

1

Press POINT DOWN button to move a red frame pointer to

“Lamp counter reset” and then press

SELECT button.

2

Do not reset Lamp Replace Counter except after Projection lamp is

replaced.

Another confirmation dialog box appears and select [Yes] to

reset Lamp Replace Counter.

4

Move arrow to replaced lamp number (Lamp 1, Lamp 2, Lamp 3

or Lamp 4) and then press

SELECT button. Message "Lamp

replace counter Reset?" is displayed. Move pointer to [Yes] and

then press SELECT button.

3

NOTE: Be sure to reset correct lamp number otherwise LAMP

REPLACE indicator continues lighting.

Message "Lamp replace

counter Reset?" is

displayed. Move pointer

to [Yes] and then press

SELECT button.

Select [Yes] to

activate it.

LAMP REPLACE COUNTER

CAUTION

HIGH VOLTAGE

HOT

1

2 4

1

2 4

3

3

Page 12

- 12 -

This projector uses a high-pressure lamp which must be handled carefully and properly. Improper handling

may result in accidents, injury, or create a fire hazard.

● Lamp lifetime may differ from lamp to lamp and according to the environment of use. There is no

guarantee of the same lifetime for each lamp. Some lamps may fail or terminate their lifetime in a shorter

period of time than other similar lamps.

● If the projector indicates that the lamp should be replaced, i.e., if the LAMP REPLACE INDICATOR lights

up, replace the lamp with a new one IMMEDIATELY after the projector has cooled down.

( Follow carefully the instructions in the LAMP REPLACEMENT section of owner's manual. ) Continuous

use of the lamp with the LAMP REPLACE INDICATOR lighted may increase the risk of lamp explosion.

● A Lamp may explode as a result of vibration, shock or degradation as a result of hours of use as its

lifetime draws to an end. Risk of explosion may differ according to the environment or conditions in which

the projector and lamp are being used.

IF A LAMP EXPLODES, THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE TAKEN.

If a lamp explodes, disconnect the projector’s AC plug from the AC outlet immediately. Contact an

authorized service station for a checkup of the unit and replacement of the lamp. Additionally, check

carefully to ensure that there are no broken shards or pieces of glass around the projector or coming out

from the cooling air circulation holes. Any broken shards found should be cleaned up carefully. No one

should check the inside of the projector except those who are authorized trained technicians and who are

familiar with projector service. Inappropriate attempts to service the unit by anyone, especially those who

are not appropriately trained to do so, may result in an accident or injury caused by pieces of broken glass.

LAMP HANDLING PRECAUTIONS

The LAMP REPLACE indicator will light yellow when

the total lamp used time (corresponding value) reaches

2,500 hours

- (✽). This is to indicate that lamp replacement is required.

The total lamp used time is calculated by using the

below expression;

Total lamp used time =

Teco + Tnormal x 1.25 - (✽)

Teco : used time in the Eco mode

Tnormal : used time in the Normal and Auto mode

You can check the lamp replacement counter following

to below procedure.

1 Press and hold POWER ON-OFF button on the side

control of the projector or the remote control unit for

more than 20 seconds.

2 The projector used time and lamp used time will be

displayed on the screen briefly.

(✽) The specifications are subject to change without

notice.

Total lamp used time

(Corresponding value)

● How to check Lamp Used Time

Projector used time

Lamp Replacement

Counter

Projector

Lamp

Normal

Eco

Corresponding

150H

No.1 No.2 No.3 No.4

100H

50H

175H

100H

50H

175H

100H

50H

175H

100H

50H

175H

Value

Page 13

After long periods of use, dust and other particles will accumulate on the LCD panel, prism, mirror, polarized glass,

lens, etc., causing the picture to darken or color to blur. If this occurs, clean the inside of optical unit.

Remove dust and other particles using air spray. If dirt cannot be removed by air spray, disassemble and clean the

optical unit.

● Cleaning with air spray

1. Remove the cabinet top following to "Mechanical Disassemblies".

2. Clean up the LCD panel and polarized glass by using the air spray from the cabinet top opening.

Caution:

Use a commercial (inert gas) air spray designed for cleaning camera and computer equipment. Use a resin-based nozzle only. Be vary careful not to damage optical parts with the nozzle tip. Never use any kind of cleanser on the unit. Also,

never use abrasive materials on the unit as this may cause irreparable damage.

● Disassembly Cleaning

Disassembly cleaning method should only be performed when the unit is considerable dirty and cannot be sufficiently

cleaned by air spraying alone.

Be sure to readjust the optical system after performing disassembly cleaning.

1. Remove the cabinet top and main units following to "Mechanical Disassemblies".

2. Remove the optical base top following to"Optical Unit Disassemblies". If the LCD panel needs cleaning, remove

the LCD panel unit following to "LCD panel/Prism ass'y replacement".

3. Clean the optical parts with a soft cloth. Clean extremely dirty areas using a cloth moistened with alcohol.

Caution:

The surface of the optical components consists of multiple dielectric layers with varying degrees of refraction.

Never use organic solvents (thinner, etc.) or any kind of cleanser on these components.

Since the LCD panel is equipped with an electronic circuit, never use any liquids (water, etc.) to clean the unit. Use of

liquid may cause the unit to malfunction.

- 13 -

■ Maintenance and Cleaning

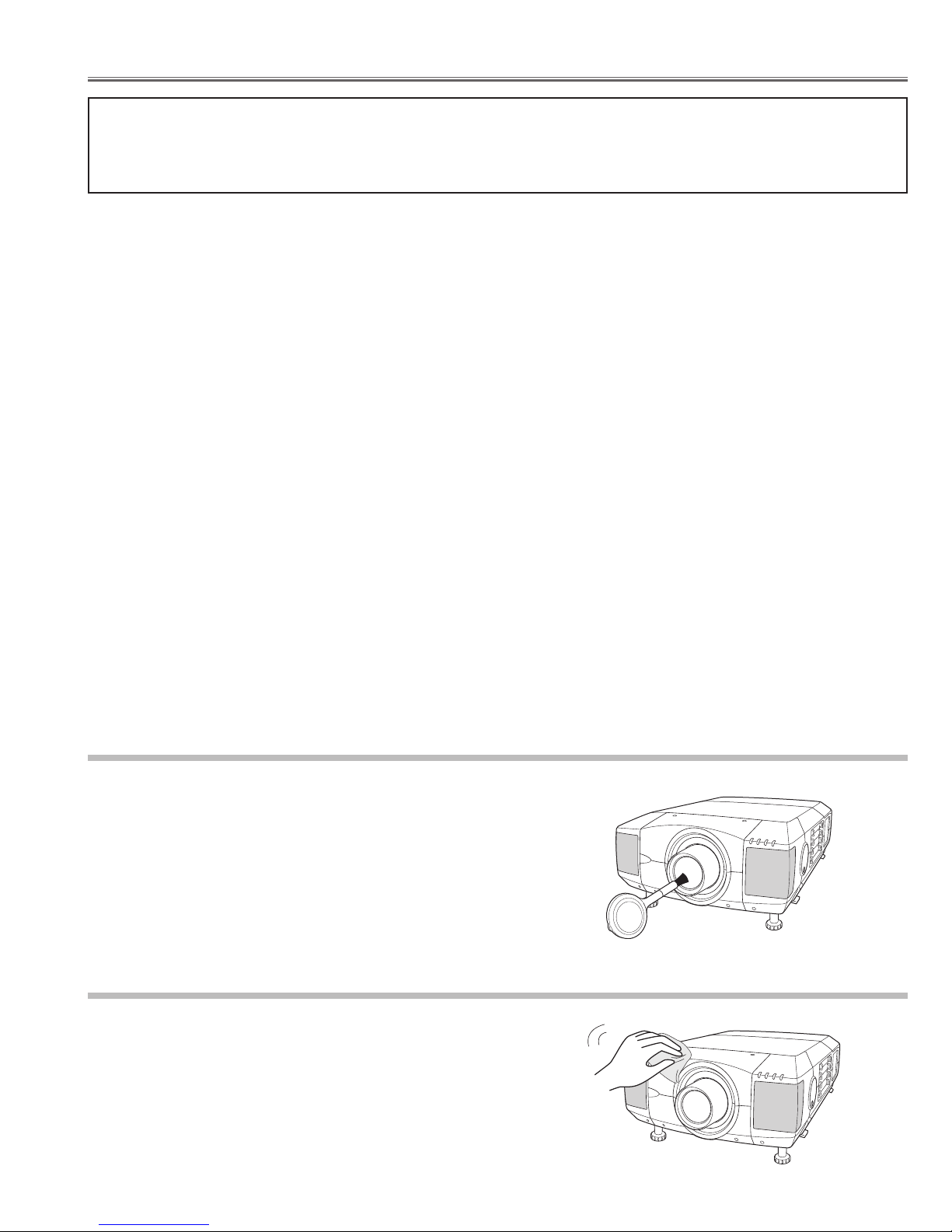

Unplug the AC power cord before cleaning.

Gently wipe the projection lens with a cleaning cloth that contains

a small amount of non-abrasive camera lens cleaner, or use a

lens cleaning paper or a commercially available air blower to

clean the lens. Avoid using an excessive amount of cleaner.

Abrasive cleaners, solvents, or other harsh chemicals might

scratch the surface of the lens.

Cleaning the Projection Lens

Cleaning the Projector Cabinet

Unplug the AC power cord before cleaning.

Gently wipe the projector body with a dry soft cloth. When the

cabinet is heavily soiled, apply a small amount of mild detergent

and finish with a dry soft cloth. Avoid using an excessive amount

of cleaner. Abrasive cleaners, solvents, or other harsh chemicals

might scratch the surface of the cabinet.

Page 14

- 14 -

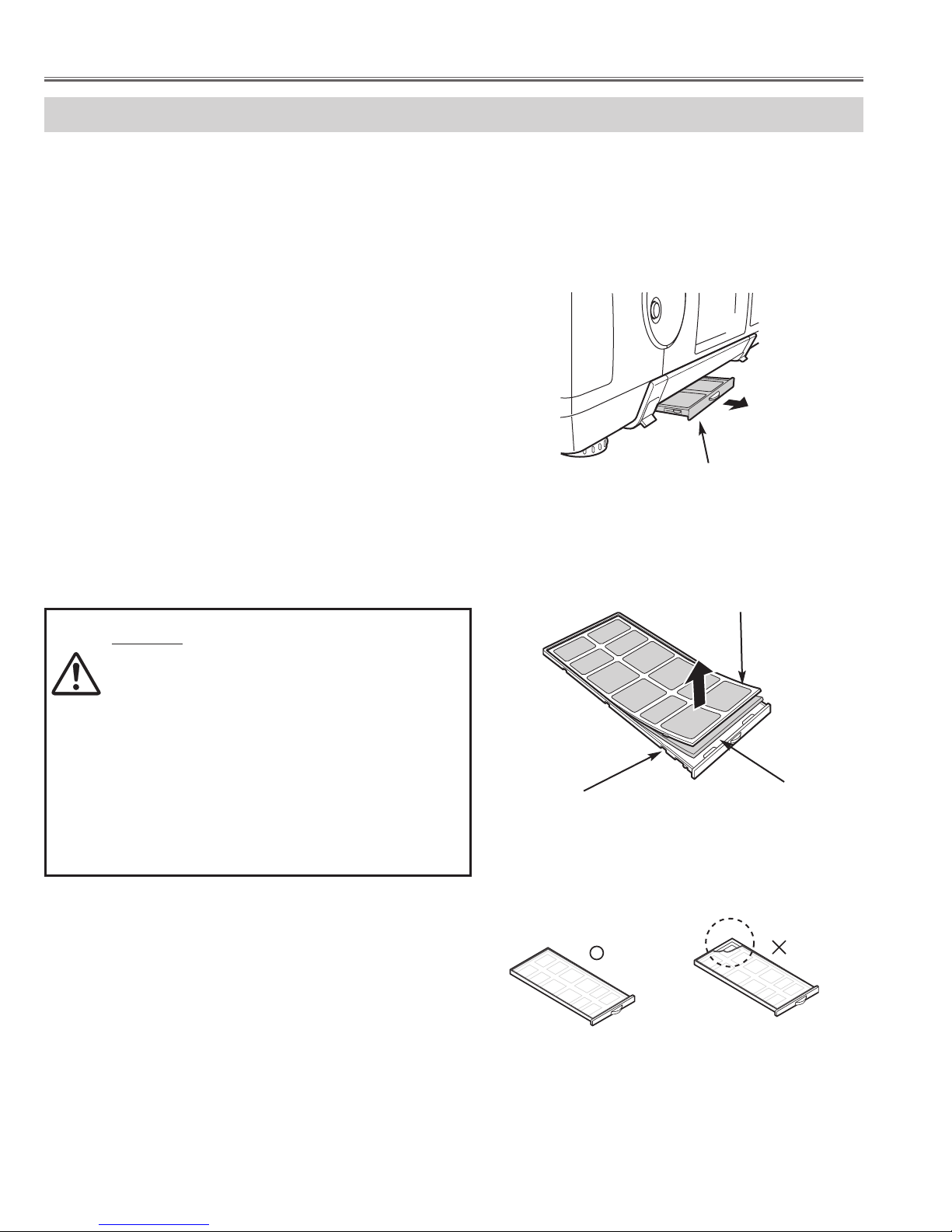

AIR FILTER CARE AND CLEANING

Air Filter prevents dust from accumulating on surface of Projection Lens and Projection Mirror. Should Air Filter

become clogged with dust particles, it will reduce Cooling Fans' effectiveness and may result in internal heat build up

and adversely affect life of a projector.

Clean Air Filter following steps below:

1

Turn power off, and disconnect AC power cord from AC

outlet.

2

Pull out air filter unit from the projector.

3

Pulling up center frame of air filter top, separate air filter

top and sheet from air filter base.

4

Clean each parts with brush, vacuum cleaner or wash

out dust and particles.

Be sure to dry them out.

5

Assemble sheet, air filter top and air filter base, and

replace air filter unit to a projector.

CAUTION

- Do not operate a projector with air filter removed.

Or dust may accumulate on LCD panel and

Mirror degrading picture quality.

- Do not put small parts into air Intake Vents. Or It

may result in malfunction of a projector.

- The filter be careful and handle. The effect of the

filter runs out in case of a leak and it being

broken off.

AIR FILTER UNIT

AIR FILTER TOP

AIR FILTER BASE

SHEET

Caution; Assembles sheet and filter base

Maintenance and Cleaning

Page 15

- 15 -

Before Disassemblies :

Turn off a projector and disconnect the AC power cord.

When remove the lens shift unit, shift to the position from which the attachment screws of a lens shift unit and an

optical base unit can be removed.

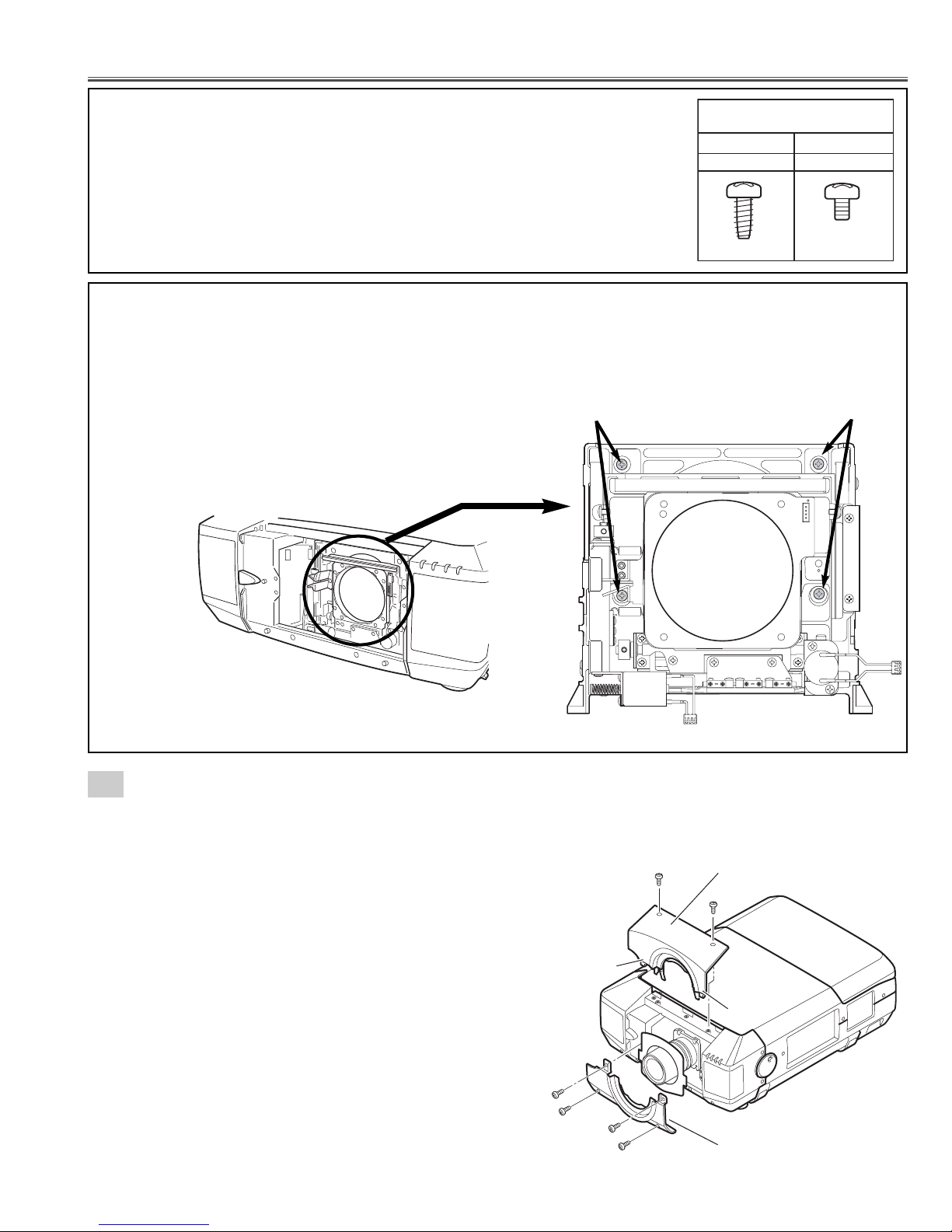

■ Mechanical Disassemblies

Disassemble should be made following procedures in numerical order.

Following steps show the basic procedures, therefore unnecessary step may be

ignored.

Caution:

The parts and screws should be placed exactly the same position as the original, oth-

erwise it may cause loss of performance and product safety.

The wiring method of the leads and ferrite cores should be returned exactly the same

state as the original, otherwise it may cause loss of performance and product safety.

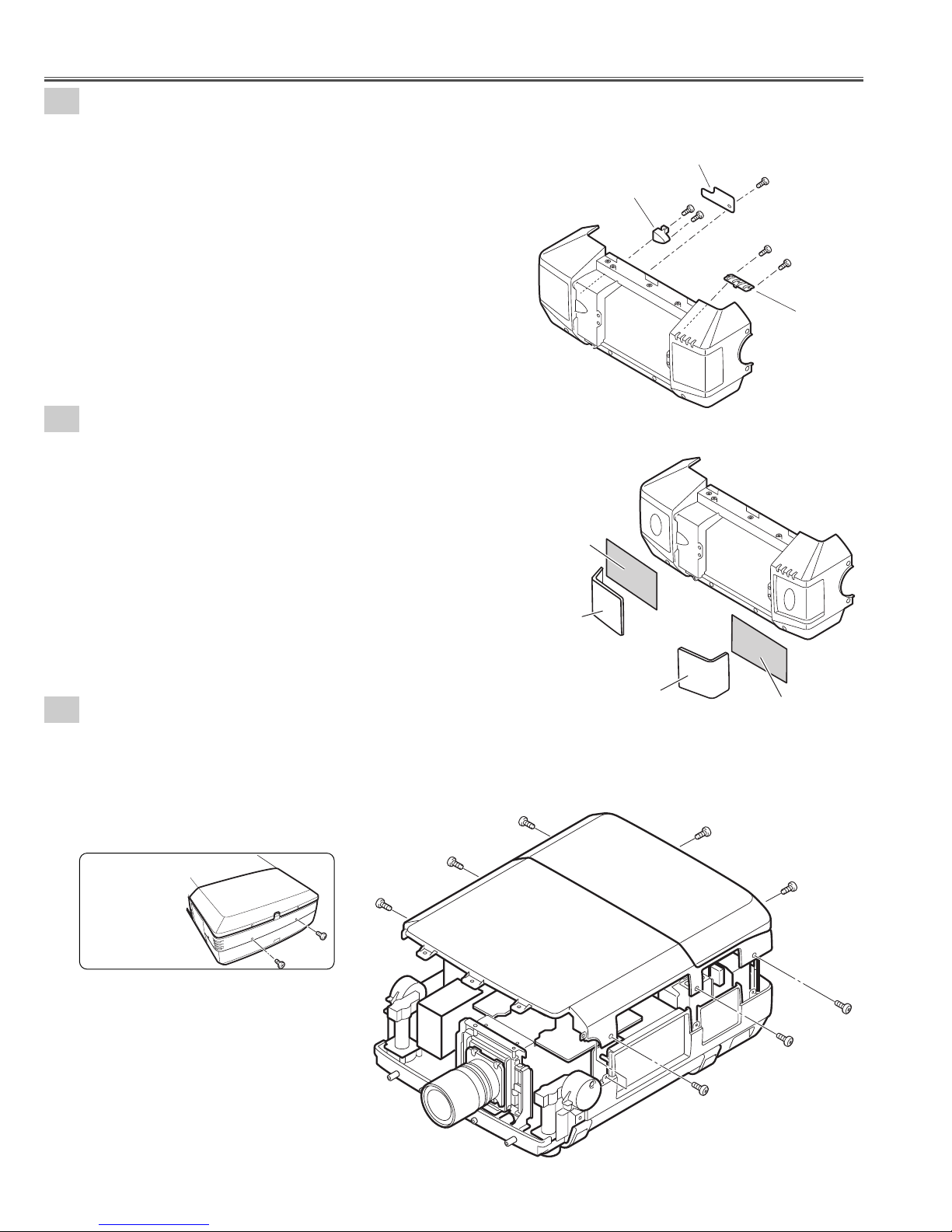

Fig.1-1

1-1

Cabinet front top unit and Cabinet front bottom unit removal.

Note :Be careful not to damage Hook. The cabinet front top unit is being fixed with cabinet front bottom by hook.

1. Remove 2 screws-A.

Push part(a) and pull the Cabinet front top unit upward.

2. Remove 4 screws-B and remove the Cabinet front bottom

unit.

(See Fig.1-1)

Refer to Lens replacement and installation manual.

Screw

Screw

Lens shift unit is moved to the position

from which an attachment screws can

be removed, as shown in a figure.

Lens shift unit

Screws Expression

(Type

Diameter x Length) mm

T type M Type

Ta pping screw Machine screw

A

Hook

(a)

B

B

B

B

Cabinet front top

unit

A

(a)

Cabinet front bottom unit

Page 16

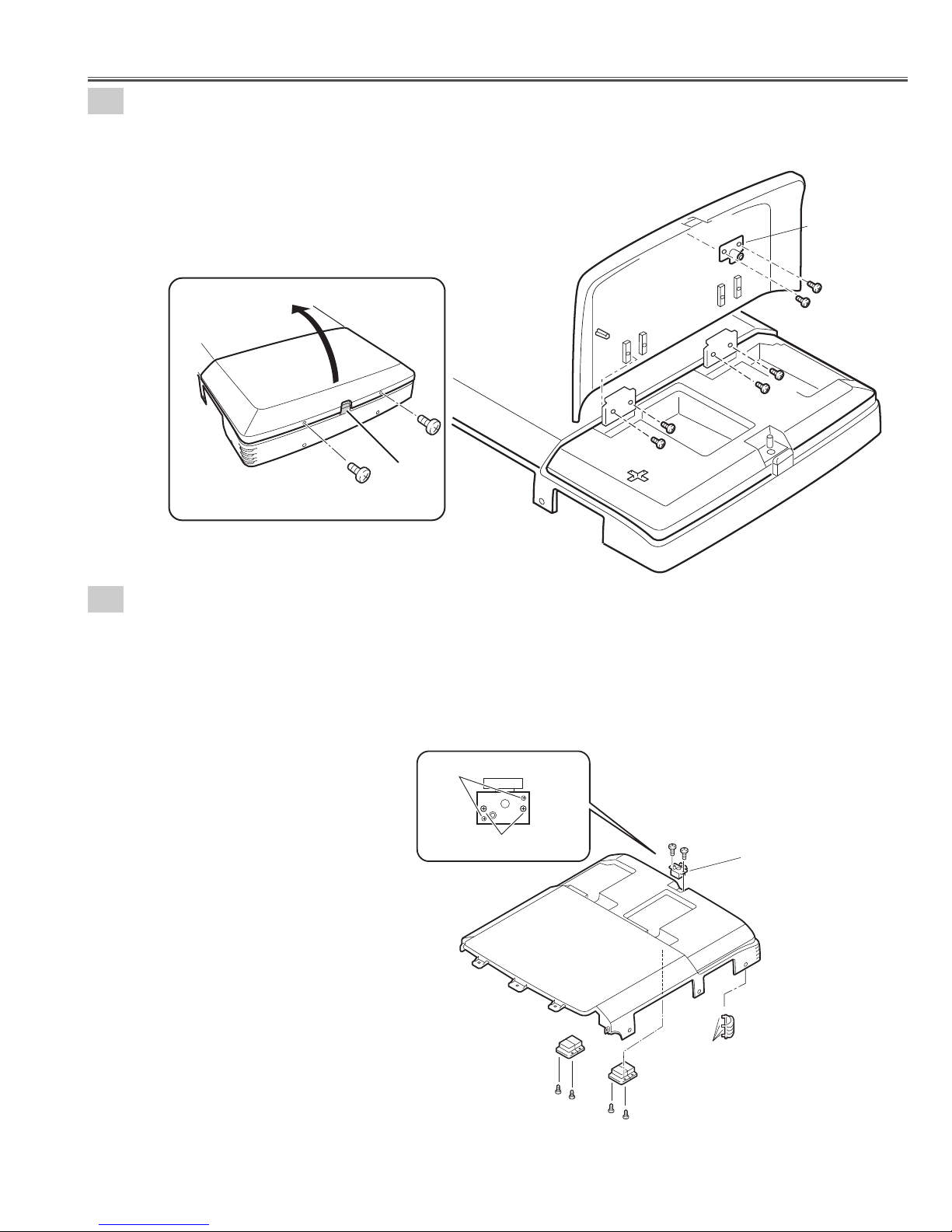

- 16 -

Fig.1-3

Fig.1-4

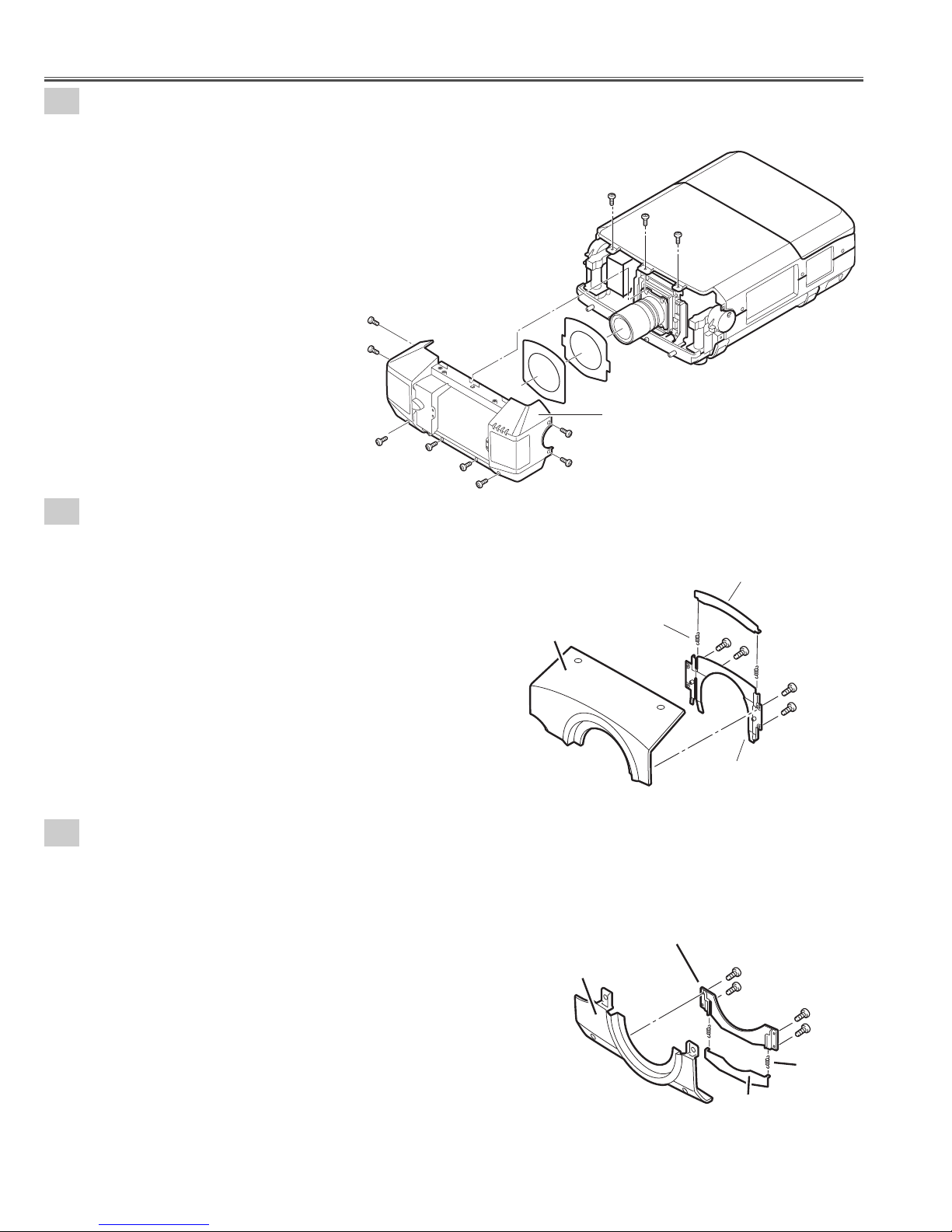

1

-3

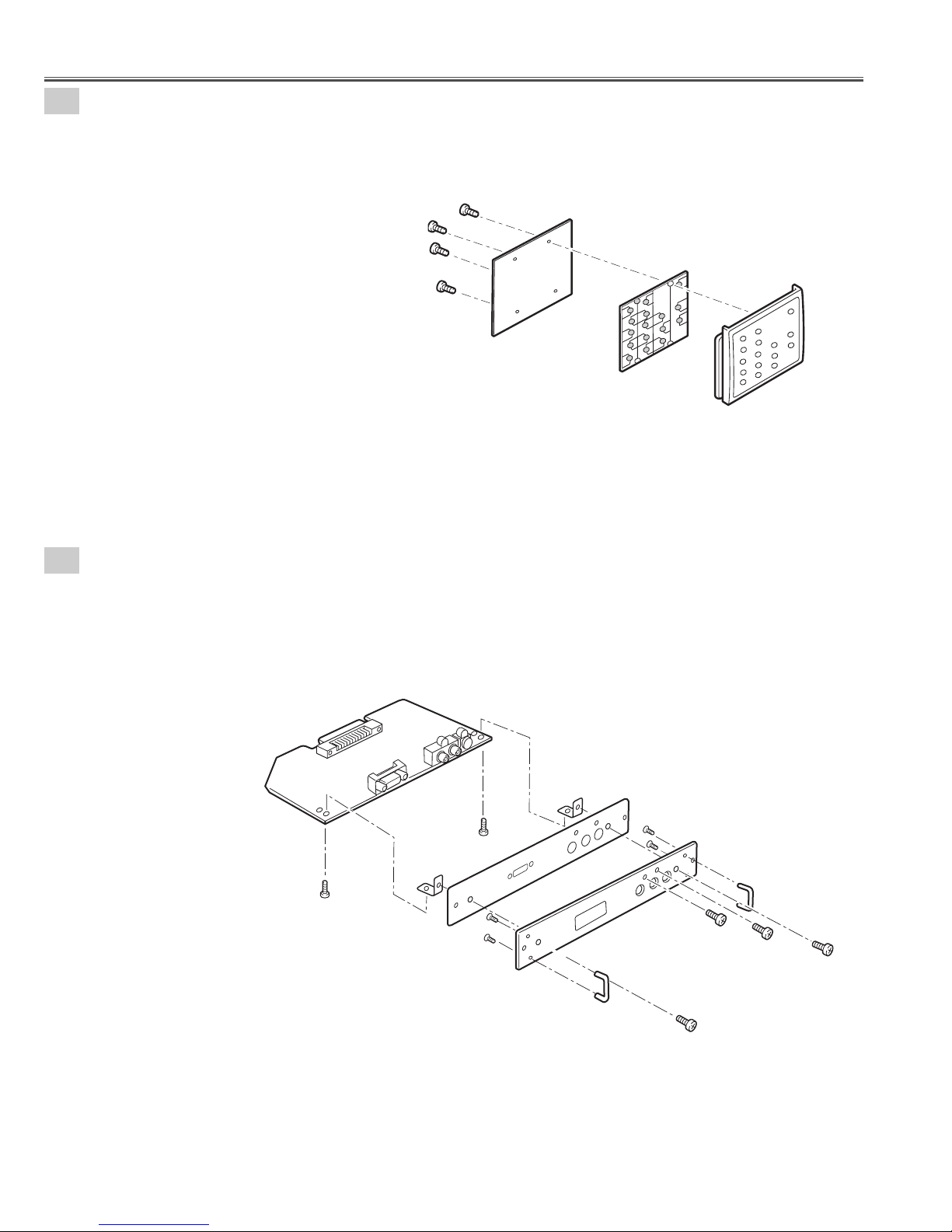

Cabinet front top unit disassemblies.

1. Remove 4 screws and remove the Mounting cover

lens-A.

2. Remove 2 Spring coils and remove Cover lens-A.

(See Fig.1-3)

1-4

Cabinet front bottom unit disassemblies.

1. Remove 4 screws and remove the Mounting cover lens-B.

2. Remove 2 Spring coils and remove Cover lens-A.

(See Fig.1-4)

Mechanical Disassemblies

Fig.1-2

1-2

Cabinet front unit removal.

1. Remove 11 screws and remove the Cabinet front unit.

(See Fig.1-2)

A

A

A

A

A

Cabinet front unit

A

A

A

A

A

A

Cover lens-A

Spring coil-A

Cabinet front top

Mounting cover lens-A

Mounting cover lens-B

Cabinet front bottom

Spring

coil-B

Cover lens-A

Page 17

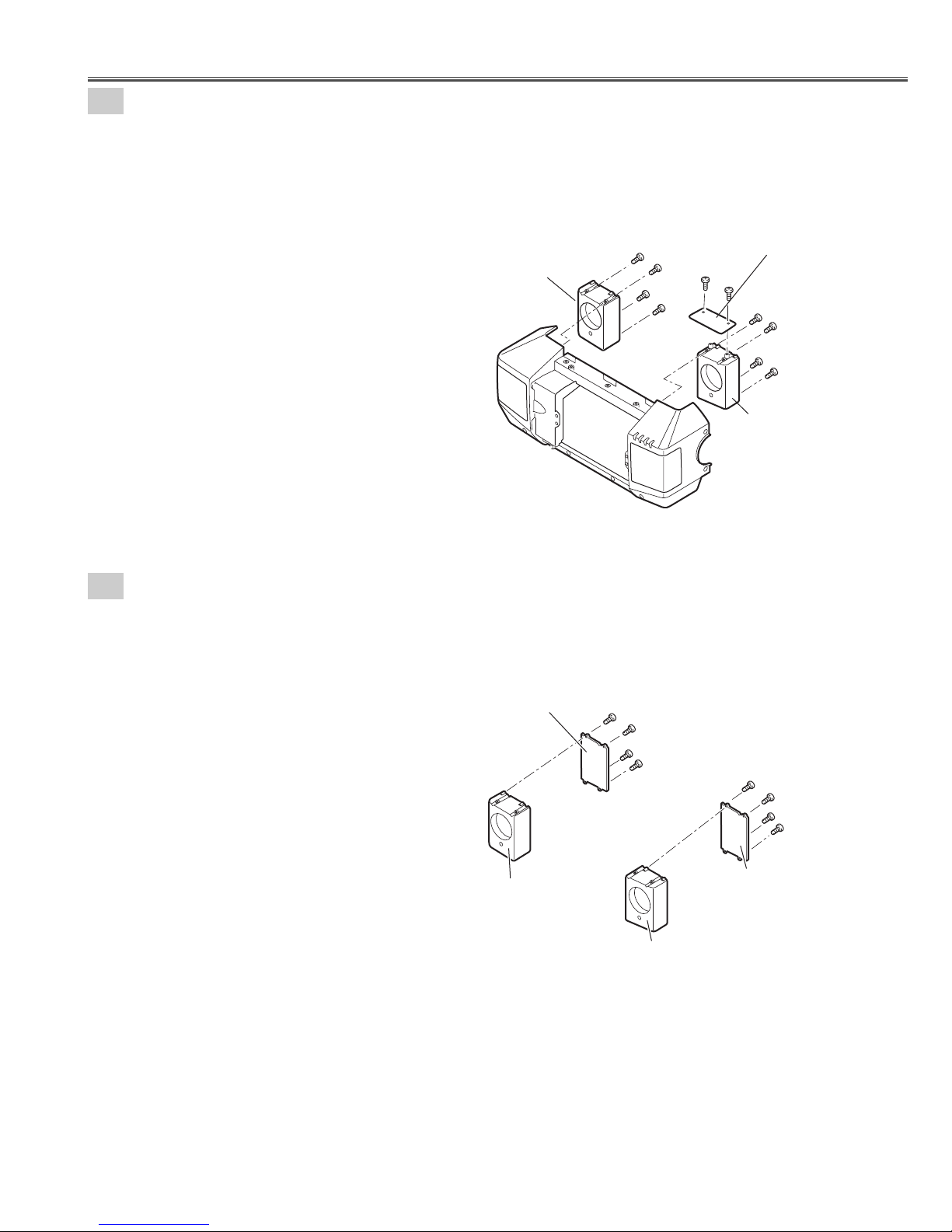

- 17 -

1

-6

Speaker units disassemblies.

1. Remove 4 screws-A and remove the Mounting SP-D.

2. Remove 4 screws-B and remove the Mounting SP-C.

(See Fig.1-6)

Fig.1-6

Mechanical Disassemblies

1-5

Speaker boxes and Front LED Board removal.

1. Remove 4 screws-A and remove the Speaker box-A.

2. Remove 4 screws-B and remove the Speaker box-B.

3. Remove 2 screws-C and remove the Front LED Board.

(See Fig.1-5)

Fig.1-5

Speaker box-A

Speaker box-B

Front LED Board

Cabinet Front

A

A

A

A

C

C

B

B

B

B

Mounting SP-D

Mounting SP-B

A

A

A

A

Mounting SP-A

B

B

B

B

Mounting SP-C

Page 18

- 18 -

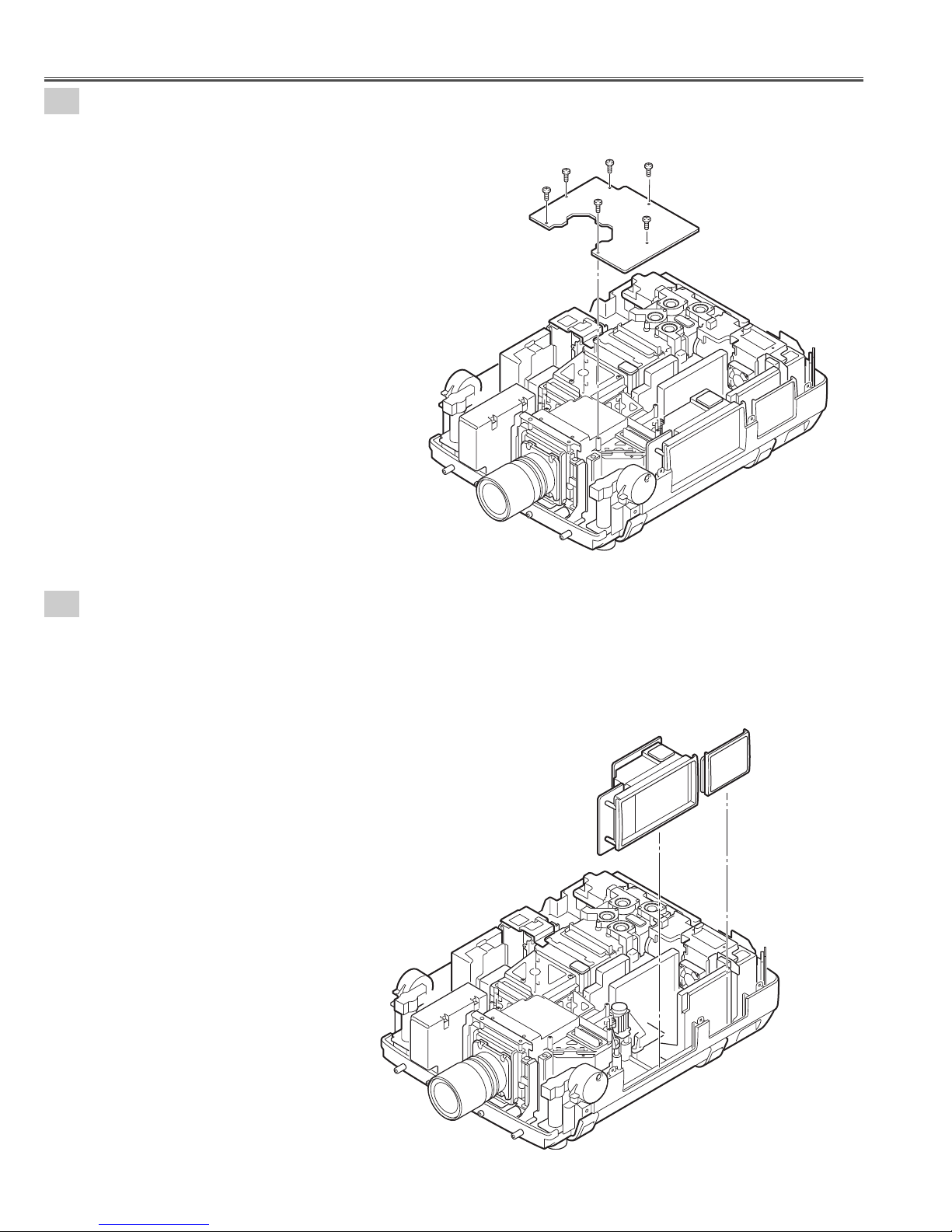

2-1

Cabinet-top unit removal.

1. Remove 8 screws and remove the Cabinet top unit.

(See Fig.2-1)

Fig.2-1

Fig.2-1a

Back View

Mechanical Disassemblies

1-7

Decoration Inlays and R/C-1 Board removal.

1. Remove screw-A and remove the R/C-1 Board.

2. Remove 2 screws-B and remove the DEC Inlay R/C-F.

3. Remove 2 screws-C and remove the DEC Inlay-A.

(See Fig.1-7)

1-8

Speaker Grills and Nets removal.

1. The bent portion is stretched and remove the Grille SP-L,

remove the Grille SP-R from cabinet front.

2. Remove the Nets.

(See Fig.1-8)

Mark the Grills as they are removed from the Cabinet front so that

they may be reassembled in the same location from which they

were removed. Be careful of the attached direction of Grills.

Fig.1-7

Fig.1-8

DEC Inlay R/C-F

Net

R/C 1 Board

B

B

A

C

C

DEC Inlay A

Cabinet front

Grill SP-L

Cabinet top unit

Grill SP-R

Net

Page 19

- 19 -

2-3

Decoration Inlay-B, Push Latch-A, and Hinges removal.

1. Remove 4 screws-A and remove the 2 Hinges.

2. Remove 2 screws-B and remove the push Latch-A.

3. Remove DEC Inlay-B. (Unhook the Cabinet top and take the DEC Inlay off inside.)

Push part(a) and pull the DEC Inlay inside.

(See Fig.2-3, 2-3a)

Fig.2-3

Fig.2-3a

Mechanical Disassemblies

2-2

Lamp cover and Push Latch-B removal.

1. Remove 2 screws-A and press button to open the Lamp cover.

2. Remove 4 screws-B and remove the Lamp cover.

3. Remove 2 screws-C and remove the Push Latch-B.

(See Fig.2-2, 2-2a)

Fig.2-2

Fig.2-2a

Cabinet top

Lamp cover

Push Latch-B

C

C

Lamp cover

A

Press

A

Button

Do not remove

B

B

B

B

Remove the screws

Cabinet top

Hinge

A

A

B

B

Push Latch-A

Hook

Hinge

A

A

DEC Inlay-B

(a)

Page 20

- 20 -

3

Main Board removal.

1. Remove 6 screws-A and remove the Main Board.

(See Fig.3)

4

-1

Control switch unit and Terminal slots unit removal.

1. Remove the Control switch unit upward.

2. Remove the Terminal slots unit upward.

(See Fig.4-1)

Fig.3

Fig.4-1

Mechanical Disassemblies

A

A

A

A

A

MAIN Borad

A

Terminal slots

Unit

Control Switch

Unit

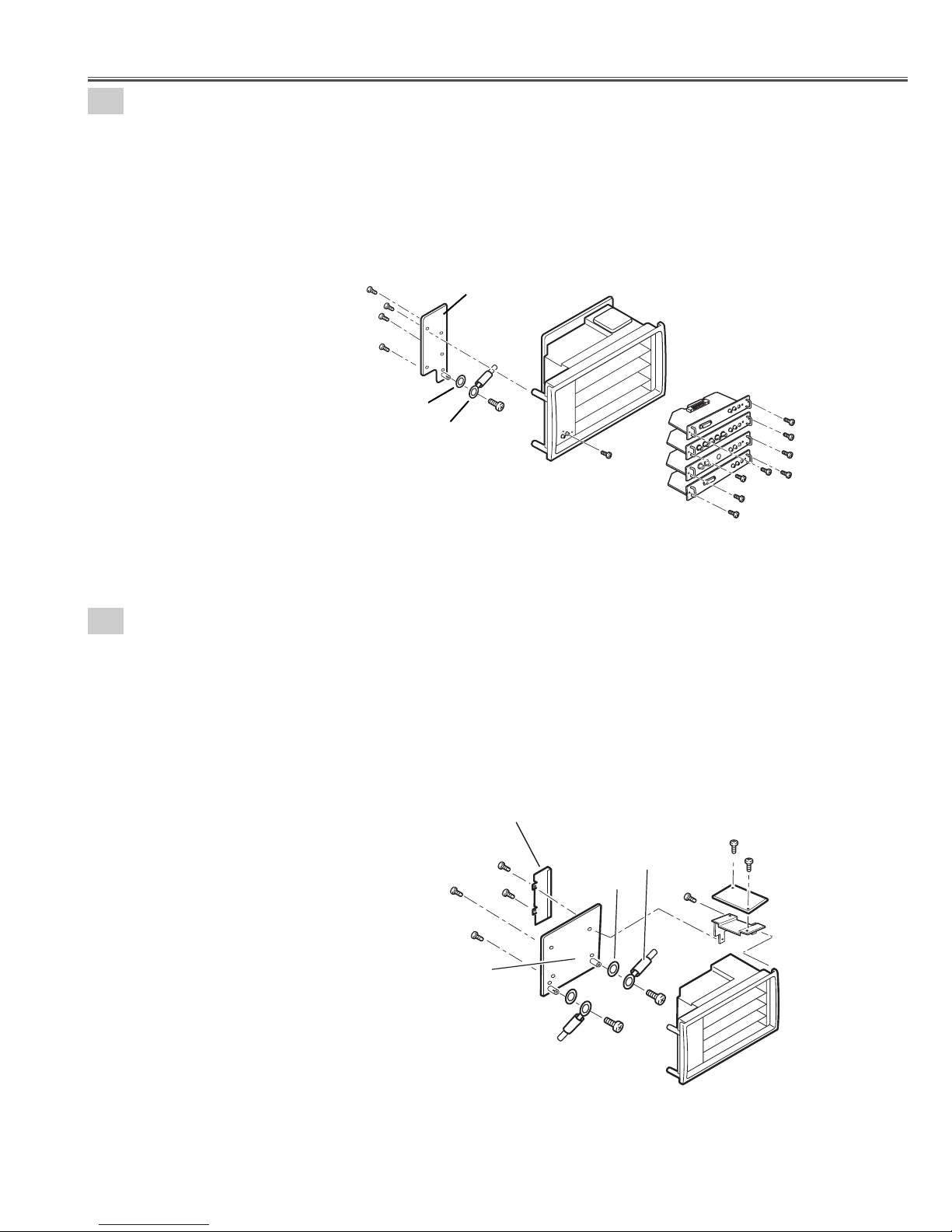

Page 21

- 21 -

Fig.4-3

4

-3

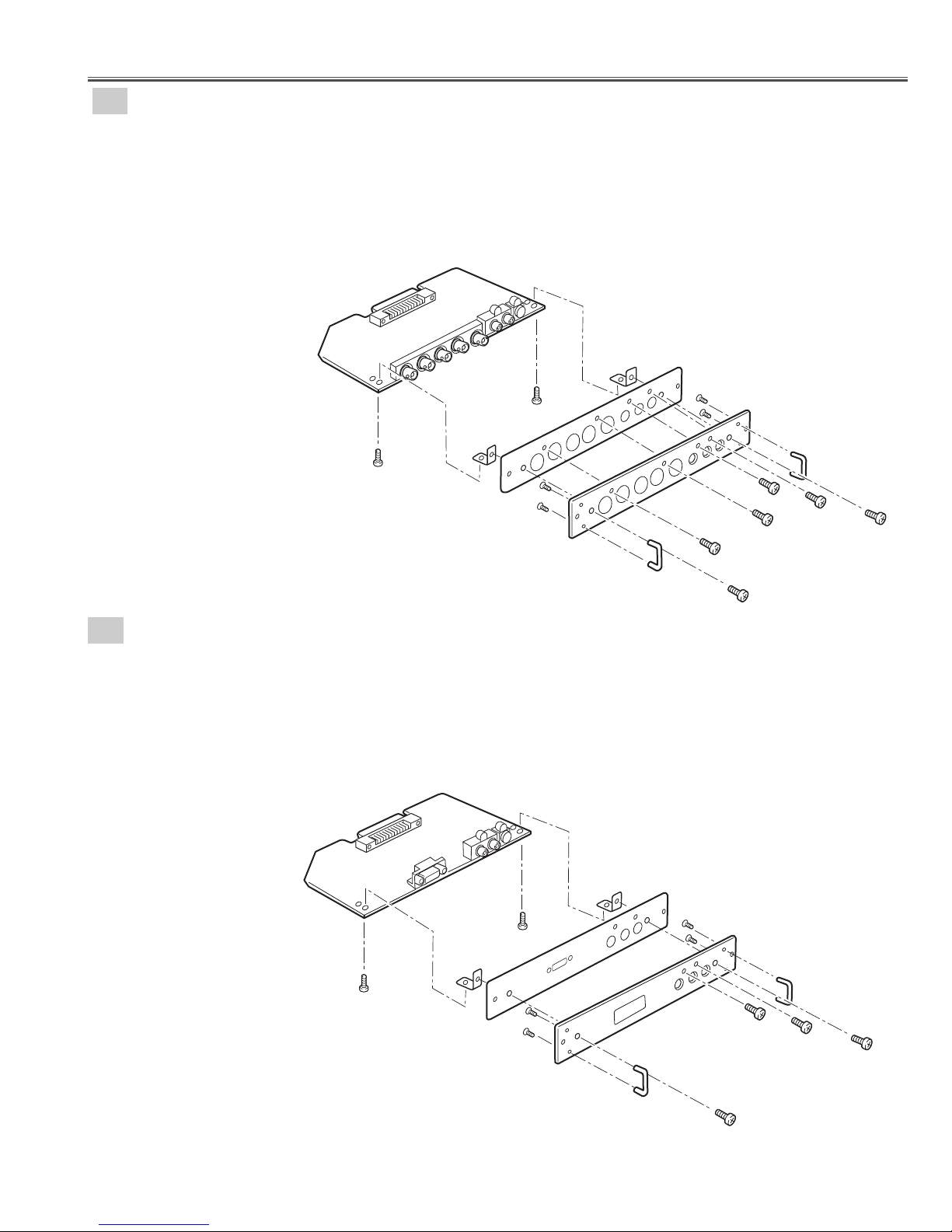

Terminal Slot units disassemblies.

1. Remove 2 screws-A and remove the Lamp net Board.

2. Remove 2 screws-B and remove the Holder-B.

3. Remove 3 screws-C, remove the Holder-A and remove the CG Mother Board.

4. Remove 2 screws-D, remove 2 washers and remove Grounding Lead from the CG Mother Board.

(See Fig.4-3)

Mechanical Disassemblies

4-2

Terminal Board units and RS232C Board removal.

Fig.4-2

1. Remove 8 screws-A and remove the Terminal Board units 1-4.

2. Remove screw-B.

3. Remove 4 screws-C and remove the RS232C Board.

4. Remove screw-D, remove washer and remove Grounding Lead from the RS232C Board.

(See Fig.4-2)

Washer

Grounding

lead

RS232C Board

C

C

C

C

D

B

Terminal Board

units 1-4

A

A

A

A

A

A

A

A

C

C

CG Mother Board

Holder-B

B

B

Washer

Grounding Lead

Grounding Lead

Washer

D

D

A

A

C

Lamp net Board

Holder-A

Panel

Page 22

- 22 -

Mechanical Disassemblies

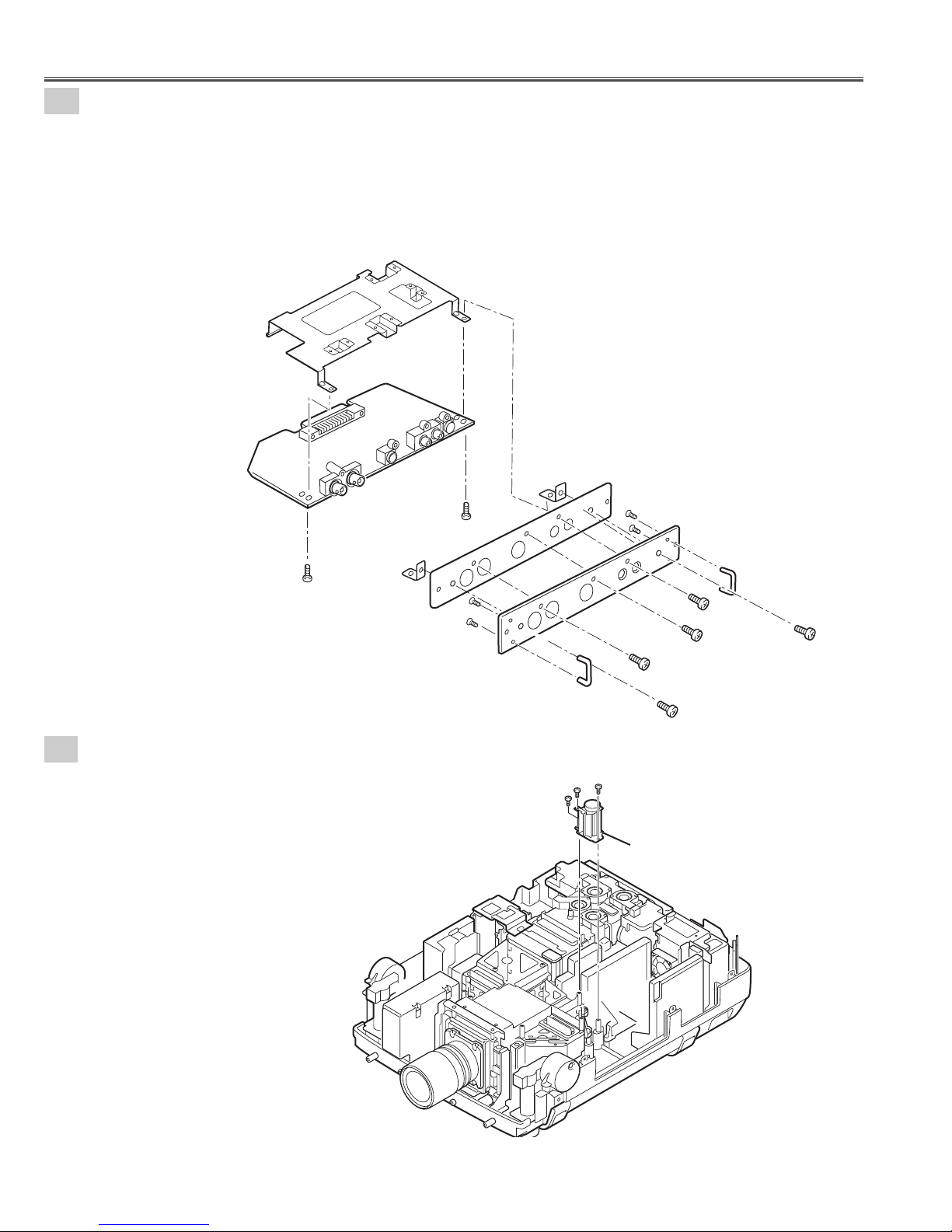

4-4

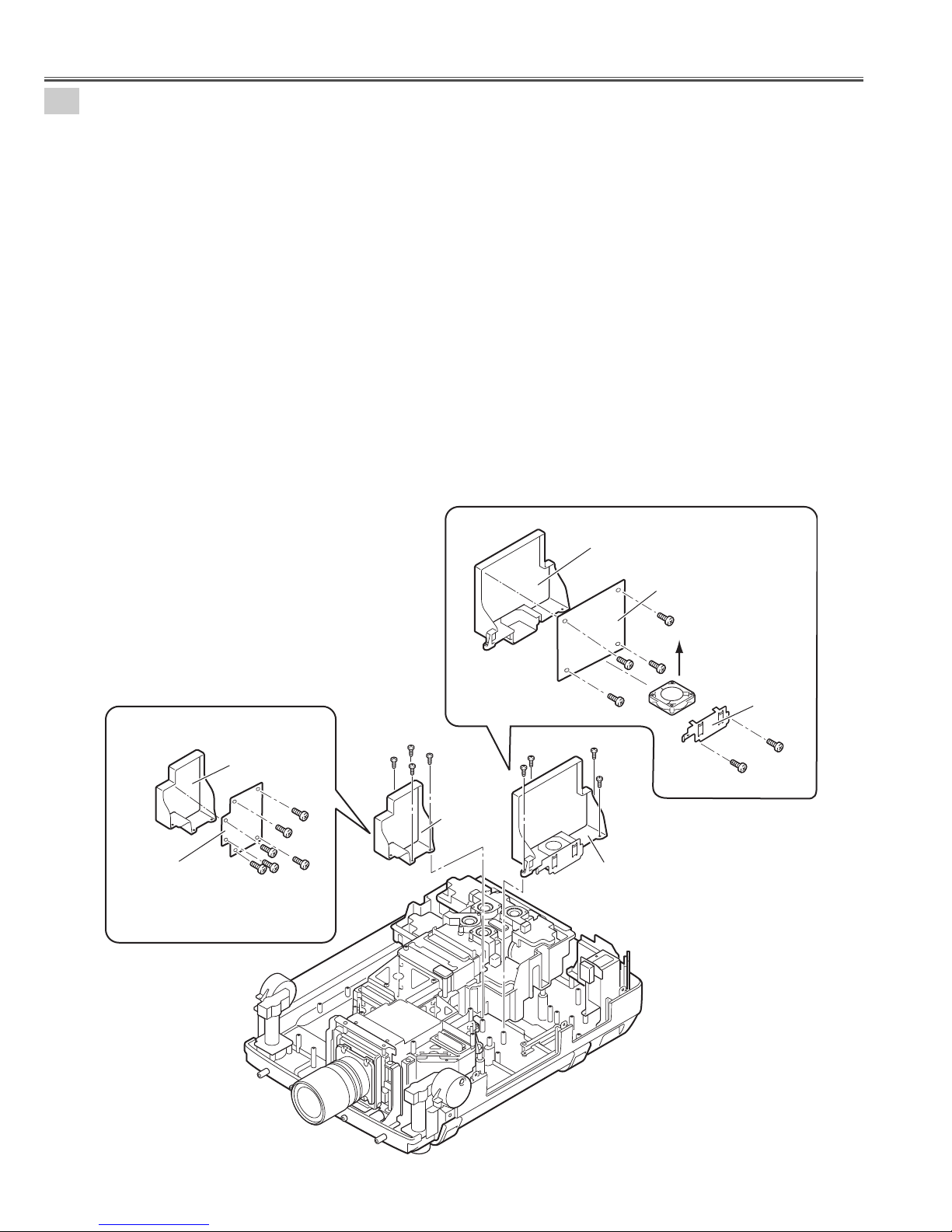

Control Switch unit disassemblies.

1. Remove 4 screws, remove the Control Button and remove the Control Board.

(See Fig.4-4)

Fig.4-4

4-5

Terminal Board DVI disassemblies.

1. Remove 2 screws-A, remove screw-B, remove screw-C, and remove the Terminal Board DVI.

2. Remove 2 screws-D, remove the Holders and remove the Earth BRKT Slot.

3. Remove 4 screws-F and remove the Handles.

(See Fig.4-5)

Fig.4-5

Control Button

Control Board

Control Panel

A

Terminal board DVI

Holder

Earth BRKT Slot

A

F

F

Panel

Holder

F

F

Handle

B

C

D

Handle

D

Page 23

- 23 -

4

-7

1. Remove 2 screws-A ,remove screw-B, remove screw-C and remove the Terminal Board D-SUB15.

2. Remove 2 screws-D, remove the Holders and remove the Earth BRKT Slot.

3. Remove 4 screws-F and remove the Handles.

(See Fig.4-7)

Mechanical Disassemblies

4-6

Terminal Board Component disassemblies.

1. Remove 2 screws-A ,remove 2 screws-B, remove screw-C,remove screw-D and remove the Terminal Board

Component.

2. Remove 2 screws-E, remove the Holders and remove the Earth BRKT Slot.

3. Remove 4 screws-G and remove the Handles.

(See Fig.4-6)

Fig.4-6

Fig.4-7

Terminal Board D-SUB15 disassemblies.

Terminal board Component

A

Holder

Holder

G

G

Handle

A

Earth BRKT Slot

Terminal board D-SUB

A

Holder

G

G

Panel

Holder

Handle

C

D

B

B

E

F

F

Handle

E

A

Earth BRKT Slot

F

F

Panel

B

C

D

Handle

D

Page 24

- 24 -

4-8

Terminal Board AV disassemblies.

1. Remove 2 screws-A, remove screw-B, remove screw-C,remove screw-D, remove the Heat sink and

remove the Terminal Board AV.

2. Remove 2 screws-E, remove the Holders and remove the Earth BRKT Slot.

3. Remove 4 screws-G and remove the Handles.

(See Fig.4-8)

Mechanical Disassemblies

Fig.4-8

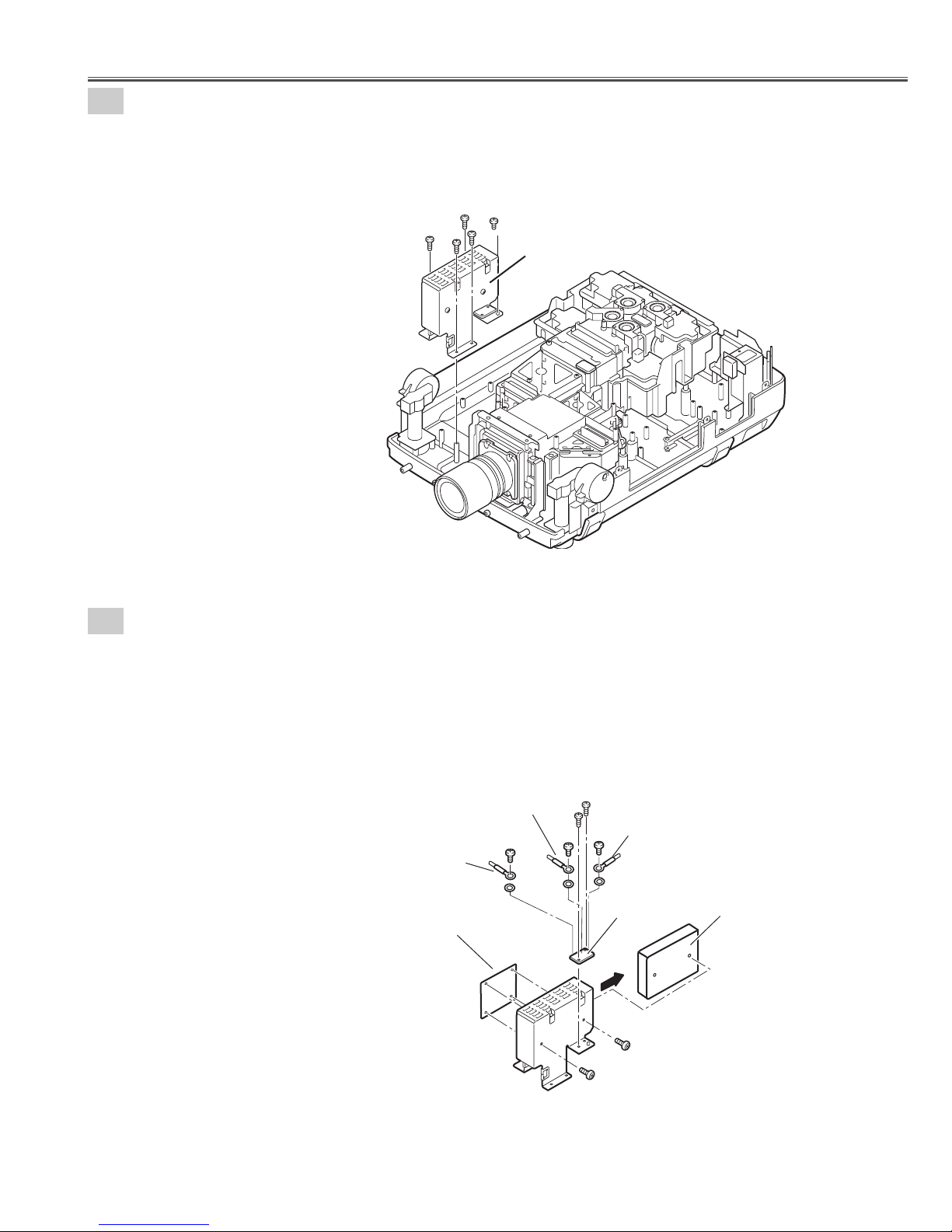

5-1

Fan(FN901) removal.

1. Remove 3 screws-A and remove the Fan(FN901).

(See Fig.5-1)

Fig.5-1

Heat sink

Holder

Terminal board AV

A

Earth BRKT Slot

Holder

A

G

G

Panel

Handle

A

A

A

G

G

B

Fan(FN901)

Handle

D

C

E

E

Page 25

- 25 -

5-2

Switch Power Supply(25V) unit removal.

Fig.5-2

1. Remove 4 screws-A, remove screw-B and remove the Switch power supply(25V) unit.

(See Fig.5-2 )

5-3

Switch Power Supply(25V) unit disassemblies.

1. Remove 2 screws-A and remove the Switch power supply(25V)Board.

2. Unhook the 4 Fixer Clamps and remove the Motor &Audio Board.

3. Remove 2 screws-B and remove the F-G net Board.

4. Remove 3 screws-C, remove 3 washers and remove the grounding lead.

(See Fig.5-3 )

Mechanical Disassemblies

Fig.5-3

A

B

A

A

A

SW-Power supply unit(25V)

Grounding

Lead

Washer

Motor and Audio

Board

Grounding

Lead

C

Washer

B

B

C

C

Grounding

Lead

Washer

F-G net Board

A

Switch Power Supply (25V)

Board

A

The Motor and Audio Board is fixed with

holder by hook.

Page 26

- 26 -

5-4

Lamp Ballast Units removal.

1. Remove screws-C, remove washer and remove the grounding lead. (Lamp ballast 3-4 units. See Fig.5-4)

Fig.5-4

Fig.5-4

Fig.5-4a

Fig.5-4b

Mechanical Disassemblies

2. Remove screw-A, remove washer and remove the grounding lead from the Holder.

(Lamp ballast 1-2 units. See Fig.5-4a)

3. Remove 2 screws-B and remove the Holder-D.

4. Remove the Lamp Ballast Unit1 and Lamp Ballast Unit2.

5. Remove 3 screws-F and remove the Holder-F.

6. Remove 2 screws-D, remove screw-E and remove the Holder-E.

7. Remove the Lamp Ballast Unit3 and Lamp Ballast Unit4.

(See Fig.5-4, 5-4a, 5-4b,)

Holder -F

C

Grounding

Lead

Lamp ballast

3-4 unit

Washer

A

F

F

F

B

Grounding Lead

Washer

B

Holder -E

Ballast4

Lamp ballast 3-4

units

D

D

E

Ballast3

Holder -D

Ballast2

Ballast1

Lamp ballast 1-2

units

Page 27

- 27 -

Note;

Mark the Fans as they are removed from the holder so that they may be reassembled in the same

location from which they were removed. Be careful of the attachment direction of Fans.

See arrow mark in a figure.

Ballast units may be reassembled in the same location and direction from which they were removed.

Be careful of the attached direction of Ballast units.

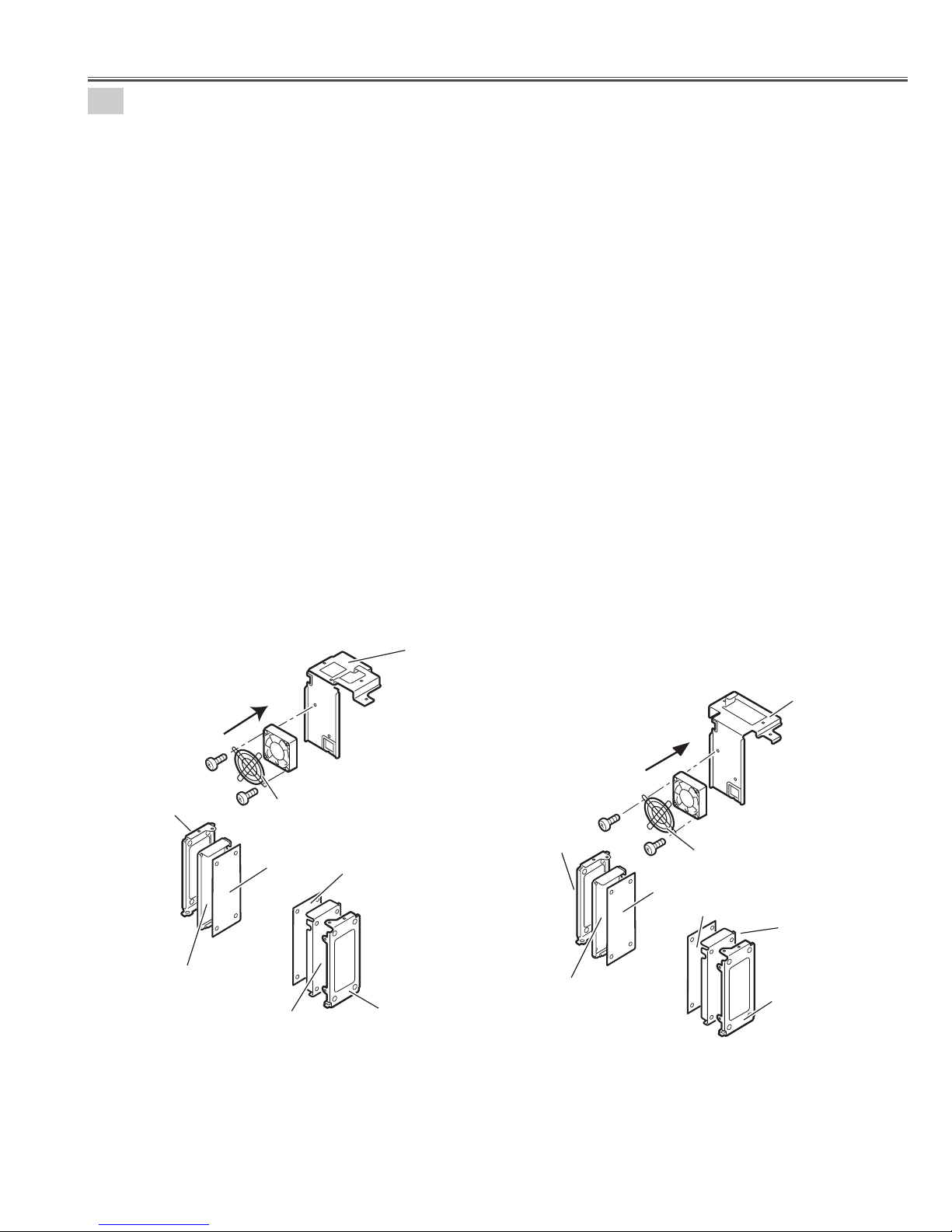

Lamp Ballast Units 1-2

1. Remove 2 screws-A, remove the Fan(FN908) and FAN Guard.

2. Remove Lamp Ballast unit 1 and remove the Spacer.

(Unhook the Fixer Clamp and remove the Lamp Ballast unit .)

3. Remove Lamp Ballast unit 2 and Spacer.

(Unhook the Fixer Clamp and remove the Lamp Ballast unit .)

(See Fig.5-5a)

Lamp Ballast Units 3-4

4. Remove 2 screws-B, remove the Fan(FN907) and FAN Guard.

5. Remove Lamp Ballast unit 3 and Spacer.

(Unhook the Fixer Clamp and remove the Lamp Ballast unit .)

6. Remove Lamp Ballast unit 4 and remove the Spacer.

(Unhook the Fixer Clamp and remove the Lamp Ballast unit .)

(See Fig.5-5b)

5-5

Lamp Ballast Units disassemblies.

Fig.5-5aFig.5-5b

Mechanical Disassemblies

Holder -C

Spacer

The direction

of a wind.

(FN907)

B

Ballast 4

FN907

FAN GUARD

B

Spacer

Ballast 3

Holder

Holder -E

A

Holder-C

Spacer

The Ballast Board is being fixed with

Holder by hook. (4places)

The direction

of a wind.

(FN908)

A

Ballast 2

Holder-D

FN908

FAN GUARD

Ballast 1

Spacer

Holder-C

Page 28

- 28 -

5-6

PFC Unit 3-4 and Power Unit removal.

PFC Unit 3-4 removal.

1. Remove 4 screws-A and remove the PFC 3-4 Unit.

2. Remove 4 screws-B and remove the Fan (FN914).

3. Remove 3 screws-C and remove the Holder FN.

4. Remove 4 screws-D and remove the PFC 3-4 Board.

5. Remove 2 screws-E and remove the AC net Board.

(See Fig.5-6, 5-6a)

Note;

Mark the Fans as they are removed from the holder so that they may be reassembled in the same location from

which they were removed. Be careful of the attached direction of Fan.

See arrow mark in a figure.

PWB board may be reassembled in the same location and direction from which they were removed. Be careful of

the attached direction of PWB board.

Fig.5-6

Fig.5-6a

Mechanical Disassemblies

E

E

AC net Board

Holder PFC

PFC3-4 Board

D

D

D

D

Holder FN

C

C

The direction

of a wind.

(FN914)

C

B

B

A

A

B

A

A

PFC3-4 unit

B

Page 29

- 29 -

5-7

Current sensor removal and replacement.

(Current sensor is used only for PLV-HD2000E.)

Power unit

Ass'y Power unit

K6A

Current sensor

Current

sensor

K

L

K96W

Noise Filter

LF901

Blue lead wire

Blue lead wire

K6A

LF901

Printed mark

A903

(a)

1. Unhook the part(a) and remove the current sensor.

Note:The way of installing a current sensor is very important on the performance and the safety. Install in the

condition which is the same as the time of disassemble.

Replacement

1. The Current sensor is attached in the blue lead wire between a noise filter (LF901) and power unit (K6A).

2. The Current sensor (L) side is attached in the K6A side.

Refer to schematic diagrams.

PWB board may be reassembled in the same location and direction from which they were removed. Be careful of the

attached direction of PWB board.

(See Fig.5-7b)

Power Unit removal.

Power Unit removal.

1. Remove 2 screws-A, remove 2 screws-B and remove the Power Unit.

2. Remove 4 screws-C and remove the Power Board.

(See Fig.5-7, 5-7a)

Fig.5-7b

Fig.5-7a

Fig.5-7

Mechanical Disassemblies

Current sensor replacement

C

C

C

C

Power Board

Holder Power

A

B

B

A

Power unit

Page 30

- 30 -

5-8

PFC 1-2 Unit and Sub Power Unit removal.

PFC 1-2 Unit removal.

1. Remove 4 screws-A and remove the PFC 1-2 Unit.

2. Remove 2 screws-B and remove the Holder FAN.

3. Remove the Fan (FN913).

4. Remove 4 screws-C and remove the PFC 1-2 Board.

(See Fig.5-8, 5-8a)

Sub Power Unit removal.

5. Remove 4 screws-D and remove the Sub Power Unit.

6. Remove 6 screws-E and remove the Sub Power Board.

(See Fig.5-8, 5-8b)

Note;

Mark the Fans as they are removed from the holder so that they may be reassembled in the same location from

which they were removed. Be careful of the attachment direction of Fan.

See arrow mark in a figure.

PWB boards may be reassembled in the same location and direction from which they were removed. Be careful of

the attached direction of PWB boards.

Fig.5-8

Fig.5-8a

Fig.5-8b

Mechanical Disassemblies

Sub Power Board

Holder Sub power

E

E

E

E

E

E

Holder PFC1-2

PFC 1-2 Board

C

The direction

C

C

D

D

D

D

Sub power

Unit

A

A

C

A

A

PFC1-2 Unit

of a wind.

(FN913)

Holder FAN

B

B

Page 31

- 31 -

6

Optical Unit removal.

1. Remove 10 screws-A, remove 4 screws-B and remove the Optical unit.

(See Fig.6)

Warning;

Do not hold the projection lens.

It may damage projection lens.

7

-1

Fan(FN906) Unit and Adjustable-feet removal.

1. Remove 6 screws-A and remove the Adjustable-foot-left.

2. Remove 6 screws-B and remove the Adjustable-foot-right.

3. Remove 2 screws-C and remove the Fan(FN906) Unit.

4. Remove 4 screws-D and remove the Fan(FN906).

5. Remove 3 screws-E and remove the Rear LED Board.

6. Remove screw-F and remove the PWB Holder.

(See Fig.7-1, 7-1a)

Note;

Mark the Fans as they are removed from the holder so that

they may be reassembled in the same location from which

they were removed. Be careful of the attached direction of

Fans.

See arrow mark in a figure.

Fig.6

Fig. 7-1

Fig. 7-1a

Mechanical Disassemblies

Warning!

Do not hold the Projection lens

B

B

B

B

B

B

A

Adjustable

foot-left

A

A

A

A

Adjustable

foot-right

A

A

A

A

A

A

B

B

B

B

A

A

A

A

A

Optical Unit

D

The direction

of a wind

FN906

C

C

C

C

Fan(FN906) unit

Holder FN

Rear LED Board

PWB Holder

F

D

D

D

E

E

E

Page 32

- 32 -

7-2

Fan Units removal and disassemblies.

Fan(R) Unit removal and Disassemblies.

1. Remove 3 screws-A and remove the Fan(R) Unit.

2. Remove 2 screws-B and remove the Duct-A.

3. Remove 2 screws-C and remove the Fan(FN903).

(See Fig. 7-2, 7-2a)

Fans(G,B) UNIT removal and Disassemblies.

4. Remove 4 screws-D and remove the Fan (G,B) Unit.

5. Remove 6 screws-F and remove the Duct-C.

6. Remove screw-G and remove the Sensor Board.

7. Remove 2 screws-H and remove the Fan (FN905).

8. Remove 2 screws-I and remove the Fan (FN916).

9. Remove 2 screws-J and remove the Fan (FN904).

10. Remove 2 screws-L and remove the RGB IN Fan net

Board.

(See Fig. 7-2, 7-2b)

Note :

Mark the Fans as they are removed from the duct so

that they may be reassembled in the same location

from which they were removed.

Fig 7-2

Fig.7-2b

Fig.7-2a

Mechanical Disassemblies

L

L

RGB IN Fan net Board

Duct-D

Duct-C

Duct-B

FN903

Duct-A

C

C

B

B

A

A

Fans (B,G) Unit

A

Fan (R) Unit

D

D

D

D

F

F

FF

Sensor Board

F

F

FN905

G

FN916

I

H

H

FN904

J

J

I

Page 33

- 33 -

Note : Removed grounding lead from the grounding mark may be reassembled in the same location.

8-1

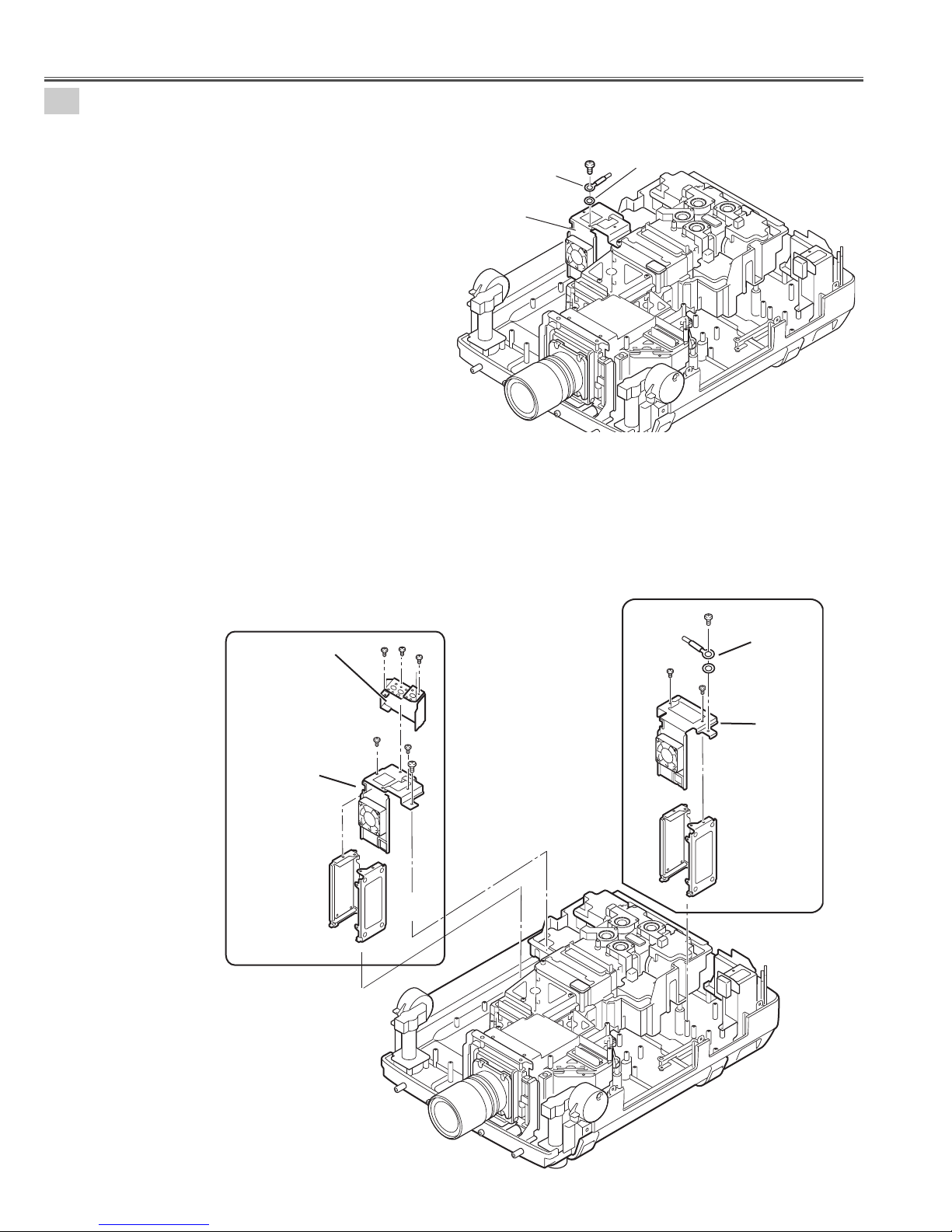

Fans(FN909,FN910) and Holders removal.

1. Remove 2 screws-A and remove the Cover -E.

2. Remove 2 screws-B and remove the Fan(FN909).

3. Remove 3 screws-C and remove the Cover -F.

4. Remove 2 screws-D and remove the Fan(FN910).

5. Remove 4 screws-E and remove the Holder-A.

6. Remove 4 screws-F and remove the Holder-B.

7. Remove 4 screws-G and remove the Holder-C.

8. Remove 2 screws-H and remove the Holder-D.

(See Fig.8-1)

8-2

Grounding Leads removal.

1. Remove 2 screws-A, remove 2 washers and remove the grounding leads from the Holder.

(See Fig.8-2,8-2a)

Fig. 8-1

Mechanical Disassemblies

Fig. 8-2

Fig. 8-2a

Holder-C

G

A

A

Cover-E

Holder-B

G

G

G

F

F

F

B

F

FN909

Cover-F

C

B

C

D

FN910

C

D

E

Holder-A

E

E

H

E

H

A

Grounding

Lead

Washer

Grounding

Lead

Holder-D

A

Grounding

Lead

Washer

Grounding

Mark

Page 34

- 34 -

Fig. 8-3

Fig. 8-3a

8-3

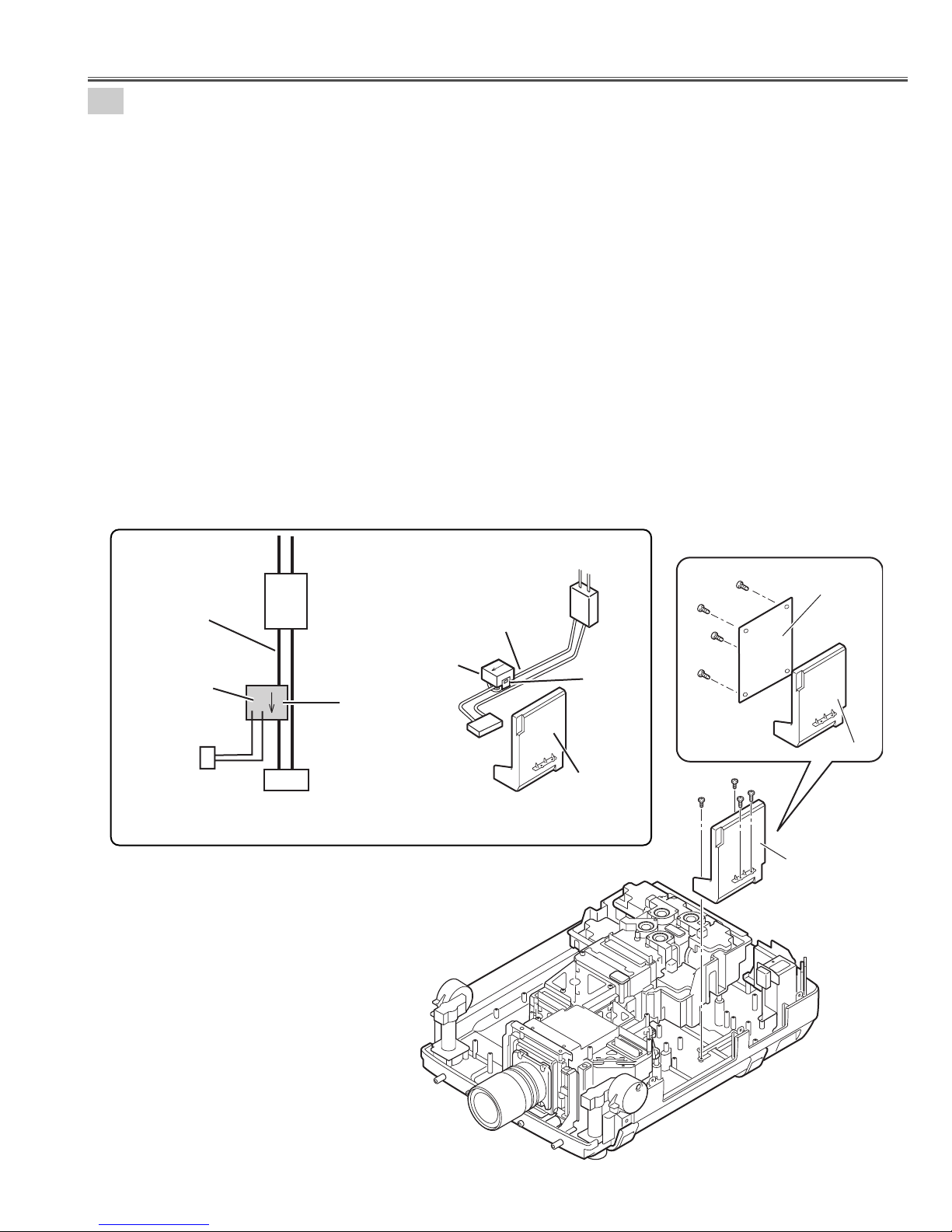

Mains switch Unit removal.

1. Remove 4 screws-A and remove the Main-SW Unit.

2. Remove 2 screws-B and remove the Lamp Cover Switch(SW902).

3. Remove 2 screws-D and remove the AC Inlet.

4. Unhook the stoppers and remove the Mains Switch(SW901).

Push part(a) and pull the Main Switch.

5. Remove 2 screws-C and remove the Noise Filter.

(See Fig.8-3, 8-3a)

Mechanical Disassemblies

To remove the Fuse.

LC-XT4E

Turn the fuse holder cover with the slot screw driver.

Remove the fuse and the fuse holder cover upward.

LC-XT4U

Remove the fuse and the fuse holder cover forward.

Fuse holder

cover

Fuse

Fuse

Fuse holder

Fuse holder

cover

Fuse holder

Fig. 8-3b

Fig. 8-3c

MAIN-SW Unit

SW902

B

A

A

A

A

B

C

Noise Filter

LF901

Holder

C

AC Inlet

D

(a)

(a)

SW901

D

Hook

Page 35

- 35 -

9-1

Ducts, R/C 2 Board, Filter Unit, NET Board and Panel removal.

1. Remove 2 screws-A and remove the Duct D.

2. Remove 2 screws-B and remove the Duct C.

3. Remove screw-C and remove the R/C 2 Board.

4. Pull out Air Filter Unit.

5. Pulling up center frame of Filter top, separate Filter top and Sheet from Filter base.

6. Remove 3 screws-D and remove the Panel.

7. Remove 2 screws-E and remove the Lens NET Board.

(See Fig.9-1, 9-1a)

Fig. 9-1

Fig.9-1a

Mechanical Disassemblies

CAUTION

Do not operate a projector with air filter removed. Dust may accumulate on LCD panel and

Mirror degrading picture quality.

Do not put small parts into air Intake Vents. It may result in malfunction of a projector.

The filter be careful and handle. The effect of the filter runs out in case of a leak and it being

broken off.

Duct D

A

A

B

B

Duct C

Lens NET Board

E

E

R/C 2 Board

C

Filter Top

Air Filter Unit

Sheet

Filter Base

Panel

D

D

D

Page 36

- 36 -

1. Remove the Retaining ring(ER-type) by leaving it against the adjustable foot with slot screwdriver.

2. Turn the adjustable feet and to take from the Cabinet bottom off. (2 places)

3. Remove 20 screws and remove the Handles.

(See Fig.9-2, 9-2a)

9-2

Rear adjustable feet and Handles removal.

Mechanical Disassemblies

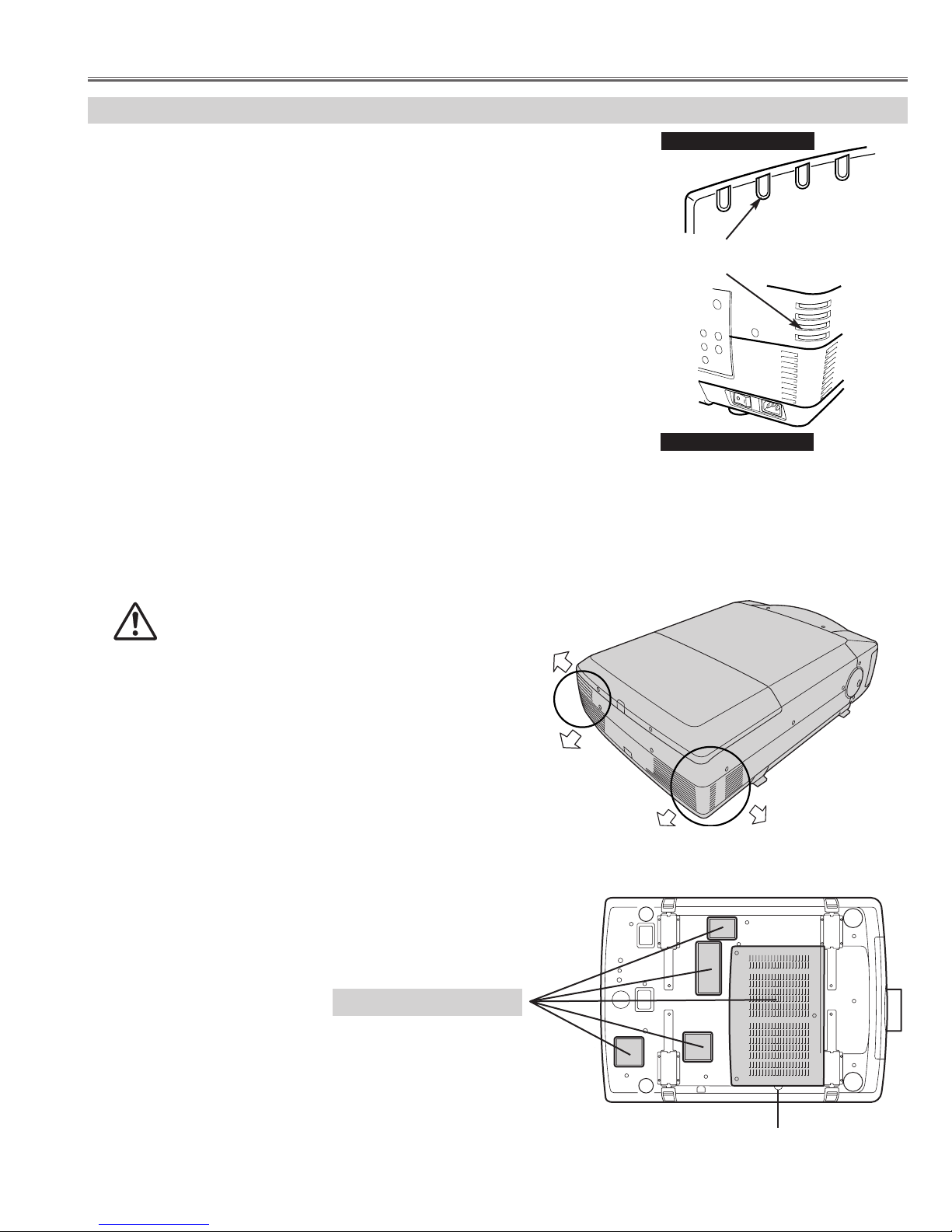

9-3

Shield plates and Sheets removal.

1. Remove the shield plates and sheets from the cabinet bottom.

(Shield plates are bent and attached in the cabinet bottom.)

(See Fig.9-3)

Fig.9-2

Fig.9-3

Fig.9-2a

Shield plates and Sheets

Slot screwdriver

Adjustable foot

(Rear)

Retaining

Ring

Adjustable feet

(2 Places)

Handle

Adjustable foot

(Rear)

Adjustable foot

(Rear)

Handle

Sheet-B

Shield Plate-B

Sheet-C

Shield Plate-C

Sheet-A

Shield Plate-A

Page 37

- 37 -

10-1

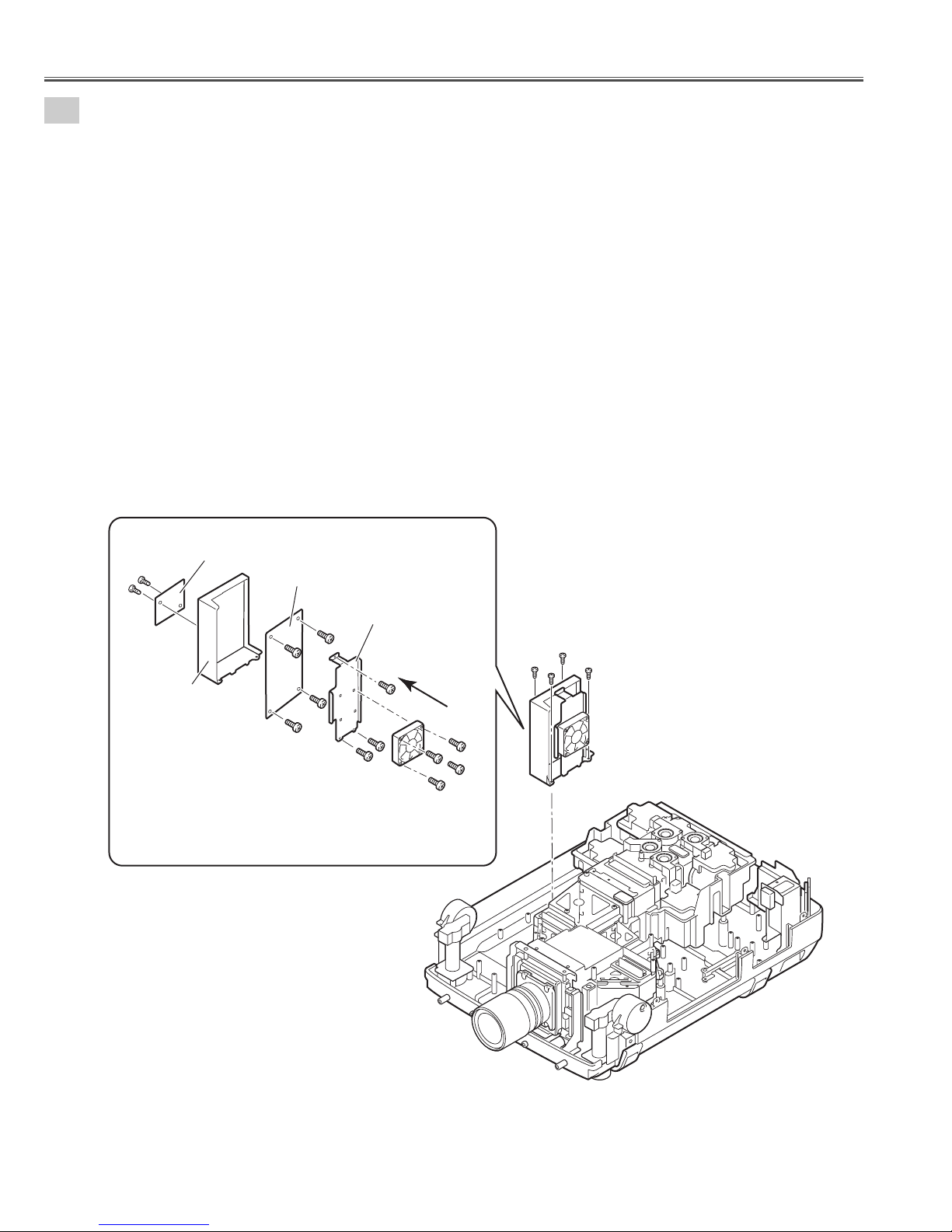

Net Boards(PBS Fan net, Lamp Fan net) removal.

1. Remove 2 screws-A and remove the PBS Fan net Board.

2. Remove 2 screws-B and remove the Lamp Fan net Board.

(See Fig.10-1)

10

-2

Fans(FN911, FN912), EXH Fan net Board and Duct removal.

1. Remove 3 screws-A and remove the Duct.

2. Remove 2 screws-B and remove the Fan(FN911).

3. Remove 2 screws-C and remove the Fan(FN912).

4. Remove 2 screws-D and remove the EXH Fan net Board.

(See Fig.10-2)

Mechanical Disassemblies

Fig. 10-1

Fig. 10-2

PBS Fan net

Board

B

A

A

B

Lamp Fan net

Board

FN912

C

C

EXH Fan net

Board

A

Duct

D

D

A

A

B

B

FN911

Page 38

- 38 -

Fig. 10-3

10-3

Fan(FN915), Ducts, and Temperature switches removal.

1. Remove 2 screws-A and remove the Fan(FN915).

2. Remove 2 screws-B and remove the Duct PBS.

3. Remove 4 screws-D and remove the temperature switches (SW903,SW904,SW905,SW906).

(See Fig.10-3)

Mechanical Disassemblies

Fig. 10-4

10

-4

Holders removal.

Note;

Mark the temperature switches as they are

removed from the optical base so that they

may be reassembled in the same location from

which they were removed.

1. Remove 2 screws-A, remove 3 screws-b and remove the Holder-A.

2. Remove 3 screws-C and remove the Holder-B.

(See Fig.10-4)

Temperature switch

SW906

Temperature switch

SW905

D

D

Temperature switch

SW903

D

B

Duct PBS

B

FN915

AA

Temperature switch

SW904

D

Holder-A

A

C

A

B

B

B

Holder-B

C

C

Page 39

- 39 -

■ Optical Unit Disassemblies

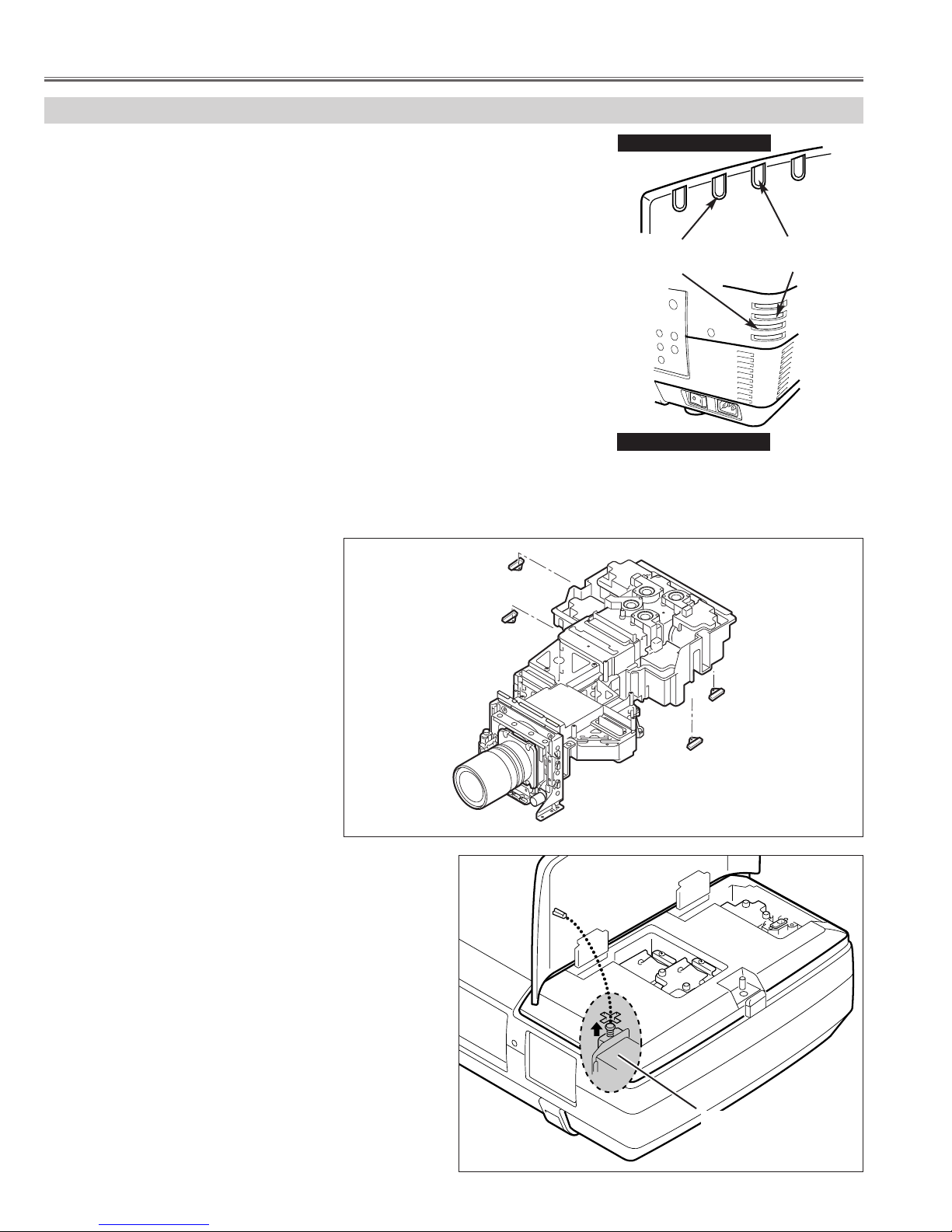

11

Projection lens and Lens shift unit removal.

1. Loosen the screw-D and remove the Safety Clamp. (See Fig. 11-a)

2. Slide the lens lock lever on the projector to "UNLOCK" (UPPER) position and detach

the Projection lens with Mount Parts to the Lens shift unit. (See Fig. 11-b)

(Refer to Lens replacement and Installation procedures manual)

3. Loosen 4 screws-A and remove the Projection lens.

4. Remove 4 screws-B and remove the Lens shift unit.

5. Remove 2 screws-C and remove the plate.

(See Fig.11, 11-c, 11-d)

Fig.11

Fig.11-d

Fig.11-c

B

B

B

B

Lens lock lever

Unlock(upper) position

Fig.11-b

Fig.11-a

Safety Clamp

Screw-D

C

C

Plate

Projection lens &

B

B

B

B

Lens shift unit

Attachment parts

A

Projection lens

Attachment parts

A

A

A

Page 40

- 40 -

t

12-2

LCD panels removal.

1. Remove 9 screws-A and remove the LCD panels.

Except when there is the necessity for replace, do not remove the LCD panel.

(See Fig.12-2,12-2a)

Note :

Do not remove all three LCD panels at the same time. The standard in convergence adjustment

runs out and it becomes not possible to do an adjustment. When exchanging three LCD panels at

the same time, it recommends to exchange every in the Prism/LCD panel unit.

Optical Unit Disassemblies

12-1

Prism/LCD panel unit removal.

1. Remove 4 screws and remove the Prism / LCD panel unit.

(Be careful not to damage the Prism / LCD panel unit with the driver.)

(See Fig.12-1)

Note :

Prism / LCD panel unit is a precision part. Be sure to

handle this part with special attention. Do not drop it

or give it excessive force. It may damage the parts

and alignment.

Caution :

(1). Do not touch the LCD panel and prism part

directly with hand. Otherwise the optical parts

may get dirty.

(2). Since the LCD panel is equipped with CMOS-

LSI, pay attention to static electricity. And do not

touch the electrode of flexible cables.

Fig.12-1

Fig.12-2

Fig.12-2a

Do not touch

the electrode of flexible cables.

Prism/LCD panel unit

A

A

A

A

A

A

A

A

A

LCDpanel

(Red)

LCDpanel

(Green)

LCDpanel

(Blue)

Prism/LCDpaneluni

Page 41

- 41 -

12-3

Optical filters and Polarized glasses disassemblies.

1. Remove 3 screws-A and remove the stoppers.

2. Remove the plate.

3. Remove the polarized glasses and Prepolarized glasses upward.

(See Fig.12-3)

Note:

Each polarized glasses use different characteristic polarization glasses. Mark the polarizer units as they

are removed from the optical unit so that they may be reassembled in the same location from which they

were removed.

Fig.12-3

Glass should be placed as the film attached side comes to the LCD panel side.

Optical Unit Disassemblies

A

Stopper

A

Stopper

Prepolarized glass

(out)

Prepolarized glass(out)

Polarized glass(out)

A

Stopper

Polarized glass(out)

Plate

Polarized glass(out)

(film side)

Prepolarized glass(out)

(film side)

Page 42

- 42 -

Integrator lens-in unit removal.

1. Remove 2 screws A and remove the Integrator lens in unit.

2. Remove 4 screws B and remove the 2 Plates.

3. Unhook the holder 4 places and remove the Integrator lens. (Integrator lens is bonded on the Holder.)

(See Fig.13-1, 13-1a)

13-1

Fig.13-1

Fig.13-1a

13

-2

Integrator lens-out / PBS unit removal.

1. Remove 3 screws-A and remove the Integrator lens out / PBS unit.

2. Remove 4 screws-B, remove the 2 Plates and remove the PBS.

3. Unhook the holder 4 places and remove the Integrator lens. (Integrator lens and PBS are bonded on the Holder.)

(See Fig.13-2, 13-2a)

Fig.13-2

Fig. 13-2a

Optical Unit Disassemblies

Plate

Slot part comes this top side

Unhook

Unhook

Unhook

Unhook

* Lens should be placed as the rugged surface

side comes to the Holder side.

Lens bonded on the Holder.

Holder

B

B

Plate

Integrator

lens-in

B

B

Rugged

surface

A

A

Integrator-lens-in

unit

A

A

A

Lens and PBS bonded on the holder.

Integrator-lens-out/

PBS unit

Plate

B

PBS

B

Slot part come this top side,

*Lens should be place

as the rugged surface

side comes to the Holder

side.

Integrator-lens-out

Unhook

Unhook

Holder

Rugged surface

B

B

Film attached side comes to the this side.

Plate

Page 43

- 43 -

13-4

Relay lens unit removal.

1. Remove 2 screws-A and remove the Relay lens unit.

2. Remove 4 screws-B, remove the plate and remove the Relay lens.

(See Fig.13-4, 13-4a)

Fig.13-4

Fig.13-4a

13-3

Condenser lens unit removal.

1. Remove 2 screws-A and remove the Condenser lens unit.

2. Remove 4 screws-B, remove the plate and remove the Condenser lens.

(See Fig.13-3, 13-3a)

Fig.13-3

Fig.13-3a

Optical Unit Disassemblies

A

A

Flat surface

plane comes this side

Condenser-lens

unit

B

* Lens should be placed as the flat surface side

comes to the Holder side.

B

Plate

B

Holder

B

Condenser lens

A

A

Relay lens

unit

Spherical surface

comes this side.

B

B

B

The printed marker comes this side.

B

Plate

Holder

Relay lens

Spherical surface

Side View

Page 44

- 44 -

13-5

Polarized units removal.

1. Remove 6 screws-A and remove the Polarized glass units. (See Fig.13-5)

Blue Polarized unit

5. Remove screw-E remove the plate(D) and remove

the Prepolarized glass(IN).

6. Remove 2 screws-F, remove the plates(E) and

remove the Optical filter (HCP).

7. Remove 2 screws-G, remove the plates(F) and

remove the Polarized glass (IN).

8. Remove screw-H, and remove the Temperature

sensor (PTH901) unit.

(See Fig.13-5b)

Red and Green Polarized Units

2. Remove screw-B, remove the plate(A) and remove

the Prepolarized glass(IN).

3. Remove 2 screws-C, remove the plates(B) and

remove the Optical filter (HCP).

4. Remove 2 screws-D, remove the plates(C) and

remove the Polarized glass (IN).

(See Fig.13-5a)

Optical Unit Disassemblies

Fig.13-5

Fig.13-5a

Fig.13-5b

A

A

Red

A

Green

A

Blue

Temperature sensor

(PTH901)

A

A

Prepolarized

glass (IN)

Polarized

glass (IN)

Plate (C)

Plate (B)

C

C

D

Plate (B)

D

Plate (C)

Optical

filter(HCP)

Holder

B

Plate (A)

Plate (E)

F

Temp. sensor unit

(PTH901)

H

Polarized

glass (IN)

Plate (F)

G

F

Plate (E)

G

Plate (F)

Optical filter(HCP)

Prepolarized

glass (IN)

E

Plate (D)

Page 45

- 45 -

13-6

Mirrors removal.

14

Assembly Lamps removal.

Loosen 8 screws-A and remove the 4 Lamp assemblies upward.

(See Fig.14)

Note :The characteristics and ages of lamps are managed by

CPU. Mark the lamp assemblies as they are removed

from the optical unit so that they may be reassembled in

the same location from which they were removed.

Remove 5 stoppers and pull the 5 mirrors upward.

(See Fig.13-6)

Note : Do not touch the mirrors surface directly with hand.

Each mirror uses different characteristic optical filter glasses. Mark the mirrors as they are

removed from the optical unit so that they may be reassembled in the location and direction

from which they were removed.

Fig.14

Fig.13-6

Optical Unit Disassemblies

CAUTION :

Do not operate a Projector while any of lamps removed. It may

result in malfunctions, fire hazard, or other accidents.

Do not drop a lamp assembly or touch a glass bulb! Glass may

shatter and may cause injury.

Stopper-A

Dichroic Mirror(C)

Stopper-B

Mirror(R)

Stopper-B

Mirror(B-cold)

Stopper-B

Dichroic Mirror(Y)

Stopper-B

Mirror(B-cold)

Lamp-3

Lamp-4

A

A

A

A

A

A

A

Lamp-2

A

Lamp-1

Page 46

- 46 -

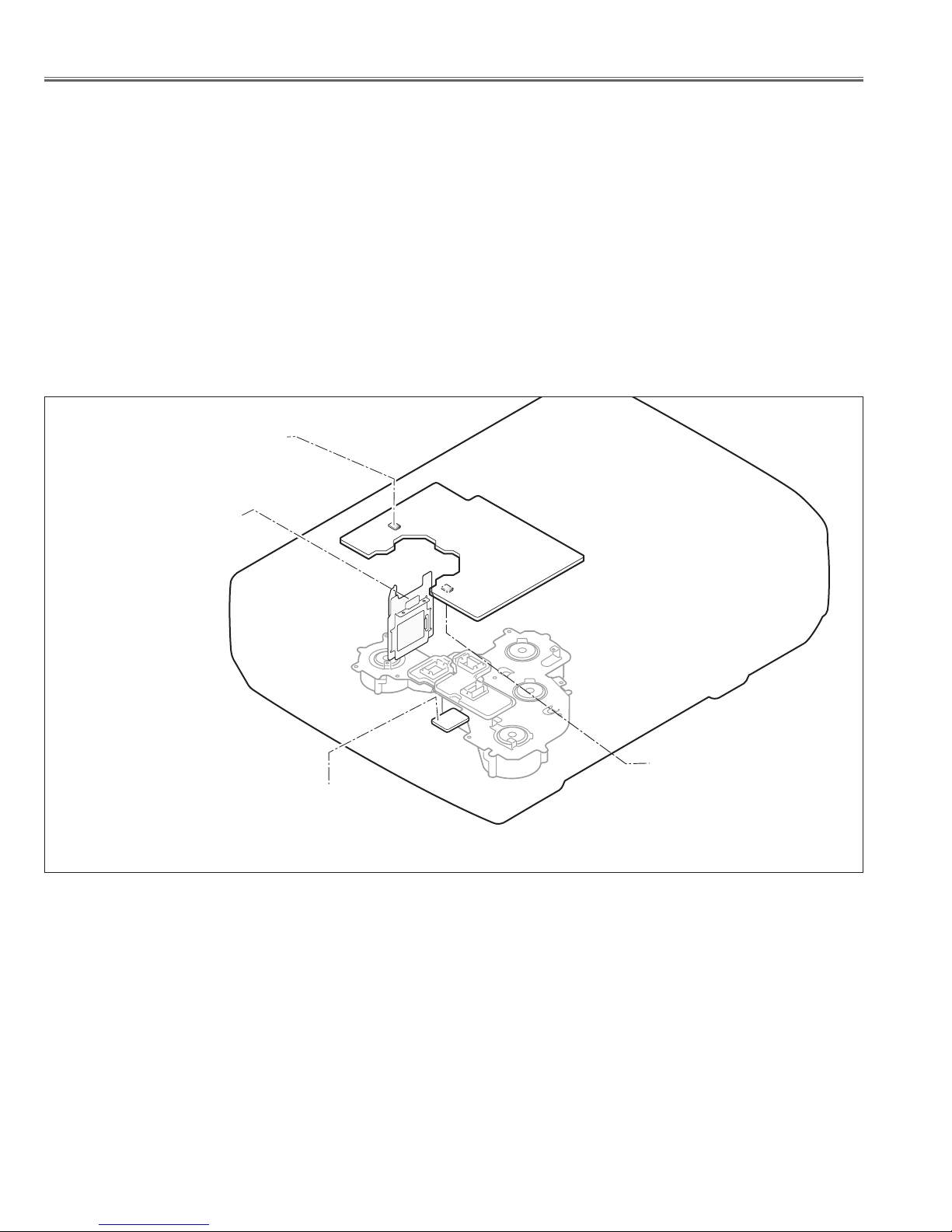

15

Optical base top removal.

1. Remove 11 screws and remove the Optical base top.

Be careful not to damage the optical parts.

(See Fig.15)

Note:

Be careful of the optical base top slowly and remove it. Otherwise optical parts follow together and become

cause to damage.

16

Cover mirror and Fans (FN917, FN918, FN919, FN920) removal.

1. Remove 4 screws-A and remove the Cover mirror.

2. Remove 8 screws-B , unhooks the plates and remove the Fans.

(See Fig.16,16a)

Note :

Mark the Fans as they are removed from the cover mirror so that they may be reassembled in the

same location from which they were removed.

Fig.15

Fig.16

Fig.16a

Optical Unit Disassemblies

Optical base top

B

B

BB

Fan(FN920)

Fan(FN917)

B

Plate-C

Hook

Fan(FN919)

B

B

B

Plate-A

Plate-B

Fan(FN918)

Cover mirror

A

A

A

A

Page 47

- 47 -

17-1

Mirror units removal and disassemblies.

1. Remove 4 screws-A and remove the Mirror units.

2. Remove 4 screws-B and remove the Stoppers(C).

3. Remove screw-C and remove the Stopper(E).

4. Remove screw-D and remove the Stopper(D).

5. Remove 2 screws-E and remove the Stoppers(B).

6. Remove 4 screws-F and remove the Stoppers(A).

(See Fig.17-1, 17-2a)

Mirror units are same as.

Note : Do not touch mirrors surface directly with hand.

Fig.17-1

Fig.17-1a

Optical Unit Disassemblies

A

A

Mirror units

A

A

Mirror units

Stopper (A)

Stopper (C)

F

B

F

Stopper (D)

D

F

F

Stopper (A)

B

B

Mirror

Stopper (B)

E

Stopper (E)

C

The printed marker comes Holder side.

Holder

Mirror

Stopper (B)

E

Stopper (C)

B

Page 48

- 48 -

17-2

Optical Filter units removal and disassemblies.

1. Remove 2 screws-A and remove the Optical filter unit1.

2. Remove screw-E, remove the plate and remove the Optical filter upward. (See Fig.17-2a)

3. Remove 2 screws-B and remove the Optical filter unit2.

4. Remove screw-F, remove the plate and remove the Optical filter upward. (See Fig.17-2b)

5. Remove 2 screws-C and remove the Optical filter unit3.

6. Remove screw-G, remove the plate and remove the Optical filter upward. (See Fig.17-2c)

7. Remove 2 screws-D and remove the Optical filter unit4.

8. Remove screw-H, remove the plate and remove the Optical filter upward. (See Fig.17-2d)

(See Fig.17-2, 17-2a, 17-2b, 17-2c, 17-2d)

Note : Do not touch optical filters surface directly with hand.

Each mirror uses different characteristic optical filter glasses. Mark the mirrors as they are removed from

the optical unit so that they may be reassembled in the location and direction from which they were

removed.

Fig.17-2

Fig.17-2a

Fig.17-2b

Fig.17-2d

Fig.17-2c

Optical Unit Disassemblies

Printed marker

comes this

surface side.

OPTICAL FILTER UNIT 3

Plate

Optical filter

Holder

F

H

D

D

C

C

OPTICAL FILTER UNIT 4

B

B

A

A

OPTICAL FILTER UNIT 2

Plate

Optical filter

Printed marker

comes this surface

side.

Holder

Optical filter

Printed marker

comes this

surface side.

Plate

Holder

OPTICAL FILTER UNIT 1

G

E

Plate

Optical filter

Printed marker

comes this surface

side.

Holder

Page 49

- 49 -

A

s

18

Optical Filters and Lenses removal.

1. Remove Optical filter(UV/IR), remove the Condenser lens(IN), remove the Condenser lens(OUT), remove the

Relay lens(IN), remove the Condenser lens(R-FIL), remove the Condenser lens(UV-FIL), and remove the

Condenser lens(G) upward.

(See Fig.18)

Note : Do not touch optical filters and lenses surface directly with hand.

Mark the mirrors as they are removed from the optical unit so that they may be reassembled in the location

and direction from which they were removed.

19

Optical base BTM disassemblies.

1. Remove 6 screws-A, remove the Optical Base BTM-A and the Optical Base BTM-B disassemblies.

(See Fig.19)

Fig.18

Fig.19

Optical Unit Disassemblies

Lens condenser (R-FIL)

Lens condenser (UV-FIL)

Lens Condenser (OUT)

Optical filter (UV/IR)

Lens condenser (G)

Lens condenser (IN)

Arrow mark come

this figure.

Lens relay (IN)

Lens relay (IN)

A

Optical base BTM-B

A

A

A

A

Optical base BTM-A

Page 50

- 50 -

■ Optical Parts Location and Direction

Fig.31

Note: There are 2 types of Optical unit. (Type-R and Type-L)

Each Optical unit must combine and use the specific Optical parts.

TYPE-R TYPE-L

R

Marking (R or L)

Confirm the label of a LCD

panel/prism assembly and the

optical unit. (R or L)

R

114

A

128R

128L

105

107

114

107

120

127R

127L

104

121

A

121

130R

130L

122

102

125

B

118

129R

129L

106

117

119

L

107

115

A

118

103

B

112

Lamp1

Lamp2

101

126

123

116

116

A

110

A

111

A

Lamp3

A

Lamp4

A

110

A

A

A

111

A

Page 51

- 51 -

101

PRISM ASSEMBLY (PBS)

102 DICHROIC MIRROR (Y)

103 DICHROIC MIRROR (C)

104 POLARIZED GLASS (IN/B)

105 POLARIZED GLASS (IN/G)

106 POLARIZED GLASS (IN/R)

107 PREPOLARIZED GLASS (IN)

110

OPTICAL FILTER

111 OPTICAL FILTER

112 OPTICAL FILTER (UV/IR)

114 MIRROR (B-COLD)

115 MIRROR (R)

116 MIRROR (COLD)

117 LENS-CONDENSER(R-FIL)

119 LENS-CONDENSER (IN)

120 LENS-RELAY (OUT)

121 LENS-RELAY (IN)

122 LENS-CONDENSER(G)

123 LENS-INTEGRATOR

125 LENS-CONDENSER(UV-FIL)

126 LENS-INTEGRATOR(OUT)

127R OPTICAL FILTER (HCP)(TYPE-R)

127L OPTICAL FILTER (HCP)(TYPE-L)

128R OPTICAL FILTER (HCP)(TYPE-R)

128L OPTICAL FILTER (HCP)(TYPE-L)

129R OPTICAL FILTER (HCP)(TYPE-R)

129L OPTICAL FILTER (HCP)(TYPE-L)

130R PRISM/LCD PANEL ASSEMBLY(TYPE-R)

118 LENS-CONDENSER(OUT) 130L PRISM/LCD PANEL ASSEMBLY(TYPE-L)

KEY No. DESCRIPTION KEY No. DESCRIPTION

130-1

130-1

130-2

130R-7

130R-6

130R-8

130-3

130-4

130-5

(RED)

(GREEN)

(BLUE)

NO.130R

LCD Panel/Prism ass'y (TYPE-R)

Optical Unit Type-R

130-1

130-2

130-3

130-4

130-5

POLARIZED GLASS(OUT)RB

POLARIZED GLASS(OUT)G

POLARIZED GLASS(OUT/R)

POLARIZED GLASS (OUT/G)

POLARIZED GLASS (OUT/B)

130-6R LCD PANEL (R) (TYPE-R)

130-7R LCD PANEL (G) (TYPE-R)

130-8R LCD PANEL (B) (TYPE-R)

130-1

130-2

130-3

130-4

130-5

POLARIZED GLASS(OUT)RB

POLARIZED GLASS(OUT)G

POLARIZED GLASS(OUT/R)

POLARIZED GLASS (OUT/G)

POLARIZED GLASS (OUT/B)

130-6L LCD PANEL (R) (TYPE-L)

130-7L LCD PANEL (G) (TYPE-L)

130-8L LCD PANEL (B) (TYPE-L)

Fig.32a

130-1

130-1

130-2

130L-7

130L-6

130L-8

130-3

130-4

130-5

(RED)

(GREEN)

(BLUE)

NO.130L