ASSEMBLY ISTRUCTIONS

Mod. VECTOR 70

Mod. VECTOR 80

GB

MC

advanced mobular stair system

Code MD.K.001 Rev 01 Edition 04.2008

advanced mobularstairsystem

- VECTOR 70 - VECTOR 80 -

CONTENTS

Structureof the manual .......................................... Pag. 2

PART 1. ................................................................. Pag. 3

Wooden components VECTOR 70 - VECTOR 80. “ 3

Components VECTOR 70 - VECTOR 80. ............ “ 4

PART 2. ................................................................. Pag. 7

Configuration VECTOR 70 - VECTOR 80 . .......... “ 7

Usefulheightmeasurement.................................... “ 8

Calculatingthe tread............................................... “ 9

Calculating the rise.......................................... “ 10

Configuration.......................................................... “ 13

Configuration “L”. ................................................ “ 13

Configuration “U”................................................. “ 14

Traking ................................................................... “. 16

Preparing columns and steps................................. “ 17

Assembling the steps............................................. “ 18

Mounting the column and bracket..........................“ 25

Checking and mounting additional columns........... “ 28

Assembling the handrail ......................................... “ 29

Assembling handrail cables ................................... “ 31

Completion and checks .......................................... “ 32

STRUCTURE OF THE MANUAL

The present assembly instructions are sub-divided into two sections as follows:

Part 1

-All the parts included in the package are listed and illustrated:

woodencomponents listed in progressive order, the letter“L” preceding thenumber.

The partscomposingthe VECTOR 70 - VECTOR 80 models are identifiedby a number preceded by the letters

“K”“B”“P”.

Part 2

-the preliminaryoperations and various stages for a correctprocedure are listed.

The assemblystages of steps, banister columns and handrail shared by both models are illustrated.

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

- 2 -

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

PART 1

WOODEN COMPONENTS Mod. VECTOR 70 - VECTOR 80

Before proceeding to the various assembly stages, empty the cardboard package and arrange all parts on a flat

surface to check that all components included in the list attached are present, that the number of components

matches the indications of both the “L” and “U” configurations of the stairs and that no damaged parts are present.

- VECTOR 70 - VECTOR 80 -

Stair shape

Ref. Draw N. pcs. Ref. Draw N. pcs.

L15 5 5

L20 9 6

L21 1 2

L23 1 2

D03 1 1

D04 1 1

Stair shape

L22 1 2

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

VECTOR 70 - VECTOR 80

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

- 3 -

advanced mobularstairsystem

COMPONENTS Mod. VECTOR 70 - VECTOR 80

- VECTOR 70 - VECTOR 80 -

Ref. Draw N. pcs.

M6x70

M6x6

Ø6x12

K18 1 1

K23 5 5

K133 1 1

Ref. Draw N. pcs.

K63 11 9

1125 mm

Ø 22 mm

K65 12 10

K66 30 30

K36 6 8

K38 1 1

K60 32 48

K84 Length.6500 mm 7 7

K68 4 6

K71 5 5

K76 4 6

K77 7 9

4.2x19

K80 30 30

K82 1 2

- 4 -

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

Ref. Draw N. pcs. Ref. Draw N. pcs.

K100 2 2

K122 1 1

K101 10 10

- VECTOR 70 - VECTOR 80 -

K102 1 1

K103 1 1

K104 11 11

K119 11 11

K120 11 11

K123 1 1

K125 1 2

1100mm

Ø 22 mm

K126 11 11

M16x30

K127 11 11

K121 1 1

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

VECTOR 70 - VECTOR 80

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

K129 2 2

- 5 -

advanced mobularstairsystem

- VECTOR 70 - VECTOR 80 -

Ref. Draw N. pcs. Ref. Draw N. pcs.

K130 2 2

K131 8 8

B200 4 4

B201 2 2

B202 1 1

B207 2 2

P90 1 1

P105 23 23

P106a 22 22

P106 143 143

B203 23 23

B204 12 12

B205 48 48

M10x40

B206 1 1

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

- 6 -

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

P107 23 23

P110 3 5

B300 1 1

B301 1 1

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

PART 2

CONFIGURATION VECTOR 70 - VECTOR 80

These are called “modular stairs” because the rise “A” and tread “P” may be adjusted according to the availabe

space.

The “VECTOR 70” label identifies the stairmodel having a 700 mm stepwidth

The “VECTOR 80” label identifies the stair modelhaving a 800 mm stepwidth.

The type and instructions for a correct assembly are identical.

Before passing on to the assembly instructions, the correct configuration must be established.

The staircase may lean on a wall or be placed in an openenvironment.

In the first case, thebanister will be mounted only on the inner side oppositethe wall, and the gangway size may be

derivedfrom figureb.

If the banister needs to be mounted on both sides, the gangwayis highlighted in fig. a.

Moreover, the locationand available space determine the climbing directions, which may be right- or left-oriented,

andthe actualstaircase configuration, accordingto an “L-”or“U-”shapedconfiguration,asillustratedinthe following

pages.

- VECTOR 70 - VECTOR 80 -

Mod. VECTOR 70 Width. 740 mm

Mod. VECTOR 80 Width. 840 mm

VECTOR 70 - 700

VECTOR 80 - 800

VECTOR 70 - 785

VECTOR 80 - 885

10 - 40 mm

Fig.a Fig.b

VECTOR 70 - 742.5

VECTOR 80 - 842.5

VECTOR 70 - 700

VECTOR 80 - 800

VECTOR 70 - VECTOR 80

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

- 7 -

advanced mobularstairsystem

USEFUL HEIGHT MEASUREMENT

- VECTOR 70 - VECTOR 80 -

The measures that need to be assessed are

reported infig. 1.

“A” Rise size to be defined based on

“Table “A” on pages 9-10-11

“P” Treadsize, calculatedaccording

to the instructions reported on page 8

“H” Height(fig. 2)

N.B. All measures reportedin the manual are

in “mm” (millimetres)

Measure the distance between upper and lower

floor“H”.

The measure assessed thanksto this operation

playsanimportant role since it sets the rise size.

The size “H” needs to be identified in the

dedicated box of “table A” on pages 9-10-11.

After having identified the “H” height, the

adjacentboxes report the rise value “A”andhow

many steps are needed to achieve the desired

height. (Fig. 2)

However, follow the detailed explanation on the

followingpages.

P

A

Fig.1

H

- 8 -

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig.2

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

CALCULATING THE TREAD

The treadmaybe calculatedaccordingtothefollowingformulas,referringtobothVECTOR70- VECTOR80 staircase

models.

In case of the “L” configuration, only the formula 1 shall be applied and all steps will have the same tread size; in

case of the “U” configuration, the formula 1 shall be applied for the W stretch, whereas the formula 2 shall be

implemented for the J tread.Consequently, two different treadsizes mayemerge,one for the J and Q stretches and

onefor theW stretch. Please notice that the values of the VECTOR 70 model mustrange between 200 mm min and

230 mm max, whereas those of the VECTOR 80 model must range between 220 mm min and 250 mm max.

P = Tread

W = Staircase length with“L” configuration

J = Staircasewidthwith“U” configuration

WARNING

The measures to be reported in the documents below must be expressed in millimetres.

- VECTOR 70 - VECTOR 80 -

Formula 1

VECTOR 70 Config. “L” e “U” P =

Formula 2

VECTOR 70 Config. “U” P =

J - 1460

Config.

“L”

Right

W

Q

n° G

W - 990

n° G - 1

n° G

Formula 1

VECTOR 80 Config. “L” e “U” P =

Formula 2

VECTOR 80 Config. “U” P =

Config.

“U”

Right

W

J

W - 1110

n° G - 1

J - 1660

n° G

n° G

Left

VECTOR 70 - VECTOR 80

L

n° G

Left

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Q

Fig.c

- 9 -

advanced mobularstairsystem

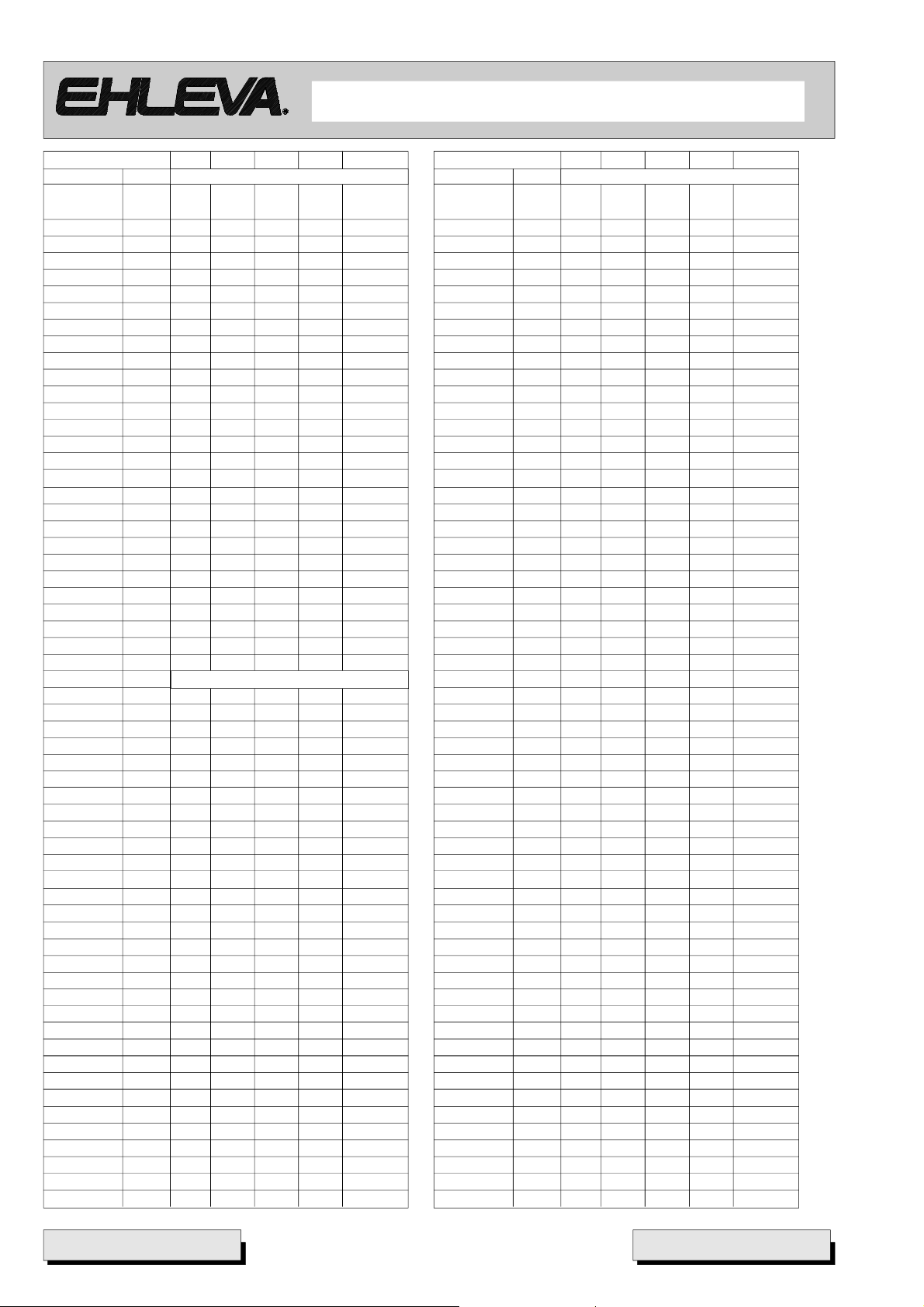

CALCULATING THE RISE (table “A”)

The “table A” below shows the values for the rise according to the “H” height measured previously. Moreover the

number of K106 spacers to be mounted is reported, also with referenceto theheight.

How to read and use the table: example. Measured height: “H” 2390 mm

The 2390 line shows that the staircase will be composed of 12 steps and that 7 180 mm rises and 5 185 mm rises

need to be created (the first rise is always 205 mm).

To create the rises described above, a spacer packagemust be installed including:

four spaces (two P106a with rounded corners and two normal P106) to achieve the 180 mm rise

five spacers (two P106a with roundedcorners and three normalP106) to achieve the 185 mm rise

- VECTOR 70 - VECTOR 80 -

Spacer number 4 5 6 7 8

Alzata

Rise “A” Rise “A”

H. G. 180 185 190 195 200

2365 12 12

2370 12 11 1

2375 12 10 2

2380 12 9 3

2385 12 8 4

2390 12 7 5

2395 12 6 6

2400 12 5 7

2405 12 4 8

2410 12 3 9

2415 12 2 10

2420 12 1 11

2425 12 12

2430 12 11 1

2435 12 10 2

2440 12 9 3

2445 12 8 4

2450 12 7 5

2455 12 6 6

2460 12 5 7

2465 12 4 8

2470 12 3 9

2475 12 2 10

2480 12 1 11

2485 12 12

2490 12 11 1

2495 12 10 2

2500 12 9 3

2505 12 8 4

2510 12 7 5

2515 12 6 6

2520 12 5 7

2525 12 4 8

2530 12 3 9

2535 12 2 10

2540 12 1 11

2545 12 12

2550 12 11 1

2555 12 10 2

2560 12 9 3

2565 12 8 4

2570 12 7 5

2575 12 6 6

2580 12 5 7

2585 12 4 8

2590 12 3 9

2595 12 2 10

2600 12 1 11

- 10 -

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

Spacer number 8 9 10 11 12

H. G. 200 205 210 215 220

2605 12 12

2610 12 11 1

2615 12 10 2

2620 12 9 3

2625 12 8 4

2630 12 7 5

2635 12 6 6

2640 12 5 7

2645 12 4 8

2650 12 3 9

2655 12 2 10

2660 12 1 11

2665 12 12

2670 12 11 1

2675 12 10 2

2680 12 9 3

2685 12 8 4

2690 12 7 5

2695 12 6 6

2700 12 5 7

2705 12 4 8

2710 12 3 9

2715 12 2 10

2720 12 1 11

2725 12 12

2730 12 11 1

2735 12 10 2

2740 12 9 3

2745 12 8 4

2750 12 7 5

2755 12 6 6

2760 12 5 7

2765 12 4 8

2770 12 3 9

2775 12 2 10

2780 12 1 11

2785 12 12

2790 12 11 1

2795 12 10 2

2800 12 9 3

2805 12 8 4

2810 12 7 5

2815 12 6 6

2820 12 5 7

2825 12 4 8

2830 12 3 9

2835 12 2 10

2840 12 1 11

ehleva@ehleva.it

By Mobirolo S.p.A.

Alzata

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

- VECTOR 70 - VECTOR 80 -

Spacer number 12 13 14 15

Alzata

Rise “A” Rise “A”

H. G. 220 225 230 235

2845 12 12

2850 12 11 1

2855 12 10 2

2860 12 9 3

2865 12 8 4

2870 12 7 5

2875 12 6 6

2880 12 5 7

2885 12 4 8

2890 12 3 9

2895 12 2 10

2900 12 1 11

2905 12 12

2910 12 11 1

2915 12 10 2

2920 12 9 3

2925 12 8 4

2930 12 7 5

2935 12 6 6

2940 12 5 7

2945 12 4 8

2950 12 3 9

2955 12 2 10

2960 12 1 11

2965 12 12

2970 12 11 1

2975 12 10 2

2980 12 9 3

2985 12 8 4

2990 12 7 5

2995 12 6 6

3000 12 5 7

3005 12 4 8

3010 12 3 9

3015 12 2 10

3020 12 1 11

3025 12 12

Spacer number 11 12 13 14

Alzate

Rise “A”

H. G. 215 220 225 230

3030 13 7 6

3035 13 6 7

3040 13 5 8

3045 13 4 9

3050 13 3 10

3055 13 2 11

3060 13 1 12

3065 13 13

3070 13 12 1

3075 13 11 2

3080 13 10 3

3085 13 9 4

3090 13 8 5

3095 13 7 6

3100 13 6 7

3105 13 5 8

3110 13 4 9

Spacer number 11 12 13 14 15

Alzata

H. G. 215 220 225 230 235

3115 13 3 10

3120 13 2 11

3125 13 1 12

3130 13 13

3135 13 12 1

3140 13 11 2

3145 13 10 3

3150 13 9 4

3155 13 8 5

3160 13 7 6

3165 13 6 7

3170 13 5 8

3175 13 4 9

3180 13 3 10

3185 13 2 11

3190 13 1 12

3195 13 13

3200 13 12 1

3205 13 11 2

3210 13 10 3

3215 13 9 4

3220 13 8 5

3225 13 7 6

3230 13 6 7

3235 13 5 8

3240 13 4 9

3245 13 3 10

3250 13 2 11

3255 13 1 12

3260 13 13

Spacer number 11 12 13 14

Alzate

Rise “A”

H. G. 215 220 225 230

3265 14 4 10

3270 14 3 11

3275 14 2 12

3280 14 1 13

3285 14 14

3290 14 13 1

3295 14 12 2

3300 14 11 3

3305 14 10 4

3310 14 9 5

3315 14 8 6

3320 14 7 7

3325 14 6 8

3330 14 5 9

3335 14 4 10

3340 14 3 11

3345 14 2 12

3350 14 1 13

3355 14 14

3360 14 13 1

3365 14 12 2

3370 14 11 3

3375 14 10 4

VECTOR 70 - VECTOR 80

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

- 11 -

advanced mobularstairsystem

- VECTOR 70 - VECTOR 80 -

Spacer number 11 12 13 14 15

Rise “A” Rise “A”

Alzata

H. G. 215 220 225 230 235

3380 14 9 5

3385 14 8 6

3390 14 7 7

3395 14 6 8

3400 14 5 9

3405 14 4 10

3410 14 3 11

3415 14 2 12

3420 14 1 13

3425 14 14

3430 14 13 1

3435 14 12 2

3440 14 11 3

3445 14 10 4

3450 14 9 5

3455 14 8 6

3460 14 7 7

3465 14 6 8

3470 14 5 9

3475 14 4 10

3480 14 3 11

3485 14 2 12

3490 14 1 13

3495 14 14

Spacer number 11 12 13 14 15

Alzata

H. G. 215 220 225 230 235

3645 15 2 13

3650 15 1 14

3655 15 15

3660 15 14 1

3665 15 13 2

3670 15 12 3

3675 15 11 4

3680 15 10 5

3685 15 9 6

3690 15 8 7

3695 15 7 8

3700 15 6 9

3705 15 5 10

3710 15 4 11

3715 15 3 12

3720 15 2 13

3725 15 1 14

3730 15 15

Spacer number 11 12 13 14

Alzate

Rise “A”

H. G. 215 220 225 230

3500 15 1 14

3505 15 15

3510 15 14 1

3515 15 13 2

3520 15 12 3

3525 15 11 4

3530 15 10 5

3535 15 9 6

3540 15 8 7

3545 15 7 8

3550 15 6 9

3555 15 5 10

3560 15 4 11

3565 15 3 12

3570 15 2 13

3575 15 1 14

3580 15 15

3585 15 14 1

3590 15 13 2

3595 15 12 3

3600 15 11 4

3605 15 10 5

3610 15 9 6

3615 15 8 7

3620 15 7 8

3625 15 6 9

3630 15 5 10

3635 15 4 11

3640 15 3 12

- 12 -

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

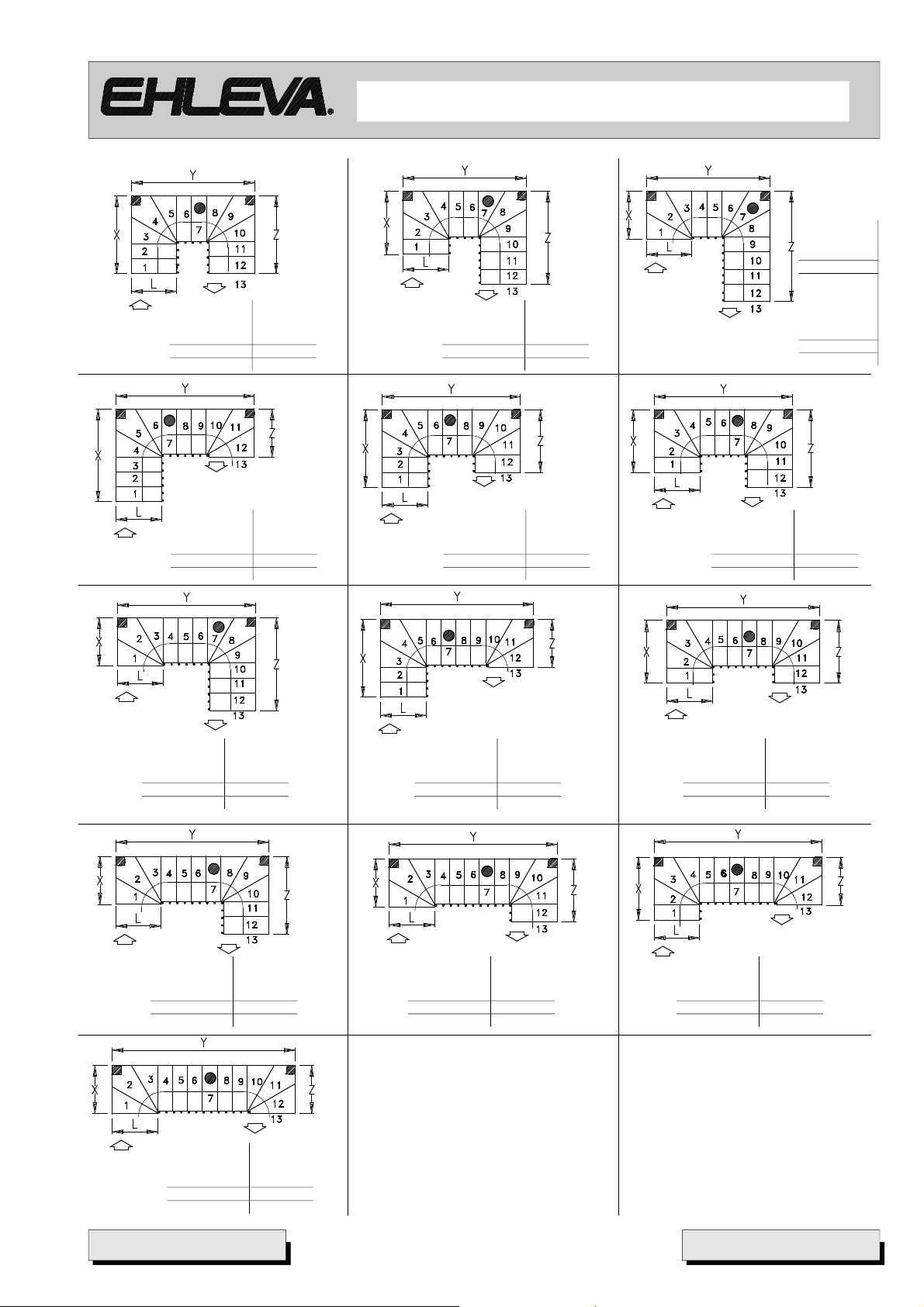

CONFIGURATION

Theavailable configurations and their relevant sizes are reported below.Please noticethat, for brevity’s sake, only

right-climbing staircases are illustrated.Each of the drawings presented ismatched by its left-climbingcounterpart.

Moreover,the points where the staircase can be anchored or supportedduringtheassemblystagesare also shown.

Wall anchoringpoint Wall anchoring point Support point

CONFIGURATION “L”

- VECTOR 70 - VECTOR 80 -

VEC. 70 VEC. 80

L=740 L=840

X 740 840

Z 2580-2820 2840-3100

VEC. 70 VEC. 80

L=740 L=840

X 1340-1430 1500-1590

Z 1980-2130 2200-2350

VEC. 70

L=740

X 1940-2120

Z 1380-1440

VEC. 70 VEC. 80

L=740 L=840

X 940-970 1060-1090

Z 2390-2600 2640-2850

VEC. 70 VEC. 80

L=740 L=840

X 1540-1660 1720-1840

Z 1780-1900 1980-2100

VEC. 70

L=740

X 2140-2350

Z 1180-1210

VEC. 70 VEC. 80

L=740 L=840

X 1140-1200 1280-1340

Z 2180-2360 2420-2600

VEC. 70 VEC. 80

L=740 L=840

X 1740-1890 1940-2090

Z 1580-1670 1760-1850

VEC. 70

L=740

X 2340-2580

Z 980

X 2160-2340

Z 1540-1600

X 2540-2810

Z 750

X 2820-3090

Z 850

VECTOR 70 - VECTOR 80

VEC. 80

L=840

VEC. 70

L=740

VEC. 80

L=840

VEC. 80

L=840

X 2380-2590

Z 1320-1350

H

Z

X

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

By Mobirolo S.p.A.

L

ehleva@ehleva.it

Z

VEC. 80

L=840

X 2060-2840

Z 1100

L

H

Y

X

- 13 -

advanced mobularstairsystem

CONFIGURATION “U”

- VECTOR 70 - VECTOR 80 -

VEC. 70

L=740

X 1940-2120

Y 1440

Z 750

VEC. 80

L=840

X 2160-2340

Y 1640

Z 850

VEC. 70

L=740

X 1340-1430

Y 1440

Z 1380-1440

VEC. 80

L=840

X 1500-1590

Y 1640

Z 1540-1600

VEC. 70

L=740

X 740

Y 1440

Z 1980-2130

VEC. 80

L=840

X 840

Y 1640

Z 2200-2350

VEC. 70

L=740

X 1740-1890

Y 1440

Z 980

VEC. 80

L=840

X 1940-2090

Y 1640

Z 1100

VEC. 70

L=740

X 1140-1200

Y 1440

Z 1580-1670

VEC. 80

L=840

X 1280-1340

Y 1640

Z 1760-1850

VEC. 70

L=740

X 1740-1890

Y 1640-1670

Z 750

VEC. 80

L=840

X 1940-2090

Y 1860-1890

Z 850

VEC. 70

L=740

X 1540-1660

Y 1440

Z 1180-1210

VEC. 80

L=840

X 1720-1840

Y 1640

Z 1320-1350

VEC. 70

L=740

X 940-970

Y 1440

Z 1760-1880

VEC. 80

L=840

X 1060-1090

Y 1640

Z 1990-2100

VEC. 70

L=740

X 1540-1660

Y 1640-1670

Z 980

VEC. 80

L=840

X 1720-1840

Y 1860-1890

Z 1100

- 14 -

VEC. 70

L=740

X 1340-1430

Y 1640-1670

Z 1180-1210

VEC. 80

L=840

X 1720-1590

Y 1860-1890

Z 1320-1350

VEC. 70

L=740

X 740

Y 1640-1670

Z 1780-1900

VEC. 80

L=840

X 840

Y 1860-1890

Z 1980-2100

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

VEC. 70

L=740

X 1140-1200

Y 1640-1670

Z 1380-1440

VEC. 80

L=840

X 1280-1340

Y 1860-1890

Z 1540-1600

VEC. 70

L=740

X 1540-1660

Y 1840-1900

Z 750

VEC. 80

L=840

X 1720-1840

Y 2080-2140

Z 850

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

VEC. 70

L=740

X 940-970

Y 1640-1670

Z 1580-1670

VEC. 80

L=840

X 1060-1090

Y 1860-1890

Z 1760-1850

VEC. 70

L=740

X 1340-1430

Y 1840-1900

Z 980

VEC. 80

L=840

X 1500-1590

Y 2080-2140

Z 1100

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

- VECTOR 70 - VECTOR 80 -

VEC. 70

L=740

X 740

Y 840-1900

Z 1580-1670

VEC. 70 VEC. 80

L=740 L=840

X 1140-1200 1280-1340

Y 1840-1900 2080-2140

Z 1180-1210 1320-1350

VEC. 70 VEC. 80

L=740 L=840

X 1340-1430 1500-1590

Y 2040-2130 2300-2390

Z 750 850

VEC. 70 VEC. 80

L=740 L=840

X 740 840

Y 2040-2130 2300-2390

Z 1380-1440 1540-1600

VEC. 70 VEC. 80

L=740 L=840

X 940-970 1060-1090

Y 1840-1900 2080-2140

Z 1380-1440 1980-2100

VEC. 70 VEC. 80

L=740 L=840

X 1140-1200 1280-1340

Y 2040-2130 2300-2390

Z 980 1100

VEC. 70 VEC. 80

L=740 L=840

X 1140-1200 1280-1340

Y 2240-2360 2520-2640

Z 750 850

VEC. 80

L=840

X 840

Y 2080-2140

Z 1760-1850

VEC. 70 VEC. 80

L=740 L=840

X 940-970 1060-1090

Y 2040-2130 2300-2390

Z 1180-1210 1320-1350

VEC. 70 VEC. 80

L=740 L=840

X 940-970 1060-1090

Y 2240-2360 2520-2640

Z 980 1100

VEC. 70 VEC. 80

L=740 L=840

X 740 840

Y 2240-2360 2520-2640

Z 1180-1210 1320-1350

VEC. 70 VEC. 80

L=740 L=840

X 740 840

Y 2640-2820 2960-3140

Z 750 850

VECTOR 70 - VECTOR 80

VEC. 70 VEC. 80

L=740 L=840

X 740 840

Y 2440-2590 2740-2890

Z 980 1100

VECTOR 70 = VEC. 70

VECTOR 80 = VEC. 80

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

VEC. 70 VEC. 80

L=740 L=840

X 940-970 1060-1090

Y 2440-2590 2740-2890

Z 750 1100

- 15 -

advanced mobularstairsystem

TRAKING

Afterhavingidentifiedandsetthe parametersidentifying

the staircase characteristics (H height,P tread and A

rise) assembly operations can actually start.

Alwaysbegin from the arrivalposition.

- VECTOR 70 - VECTOR 80 -

On the arrival floor slab, the correct position must be

identified toanchor the step support.

Position the D03 template on the floor slab, make sure

it is aligned with the floor (use a level) and comply with

thefollowingreferences:

value V = 260mm min. for the VECTOR 70 model

(sidewithout banister)

310mmmin.fortheVECTOR80model(side

withoutbanister)

value A = corresponding to the value of the “A” rise

calculatedpreviously.

The D03 template includes six holes. To anchor the

module, two holes areenough.

Identifytheholesthatneedtobereproduced:in general

refer to those halfway the floor slab width,not too close

to the floor surface. fig. 3.

V

Vector 70= min. 260 mm

Vector 80= min. 310 mm

m

0 m

5

1

Ø

D03

1

6

A

Fig.3

- 16 -

K129

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig.4

K103

Fig.5

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

PREPARING COLUMNS AND STEPS

Before proceeding to assemble the steps, mount the

- VECTOR 70 - VECTOR 80 -

P107 banister column support fig. 7 -8 - 9 - 10.

Drill a Ø4 hole by means of a wood drill in the points

identified on the step and achieve a 30 mm depth as

shown in fig. 9.

WARNING!!!

Be very careful when operating on the bottom side

of the step, where anchoring holes are already

present, and on the correct side where the banister

will be mounted.

Mount columns as shown in fig. 6

K66

st

1

nd

2

P107

20 mm

Fig.7

P107

K80

K65

K63

Length. 1125 mm

Fig.8

Ø4

30mm

Fig.9

L20

VECTOR 70 - VECTOR 80

B203

Fig.6

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig.10

- 17 -

advanced mobularstairsystem

ASSEMBLING THE STEP

- VECTOR 70 - VECTOR 80 -

L20

B205

At this point form the P106 - P106a spacer

package which will determine the size of the

rise set previously.

To define the numberof spacers to be used,

refer to the “table A” attached to the pages

9-10-11.

Form the spacer packagebyassemblingthe

P106 - P106a spacers as shown in fig. 12.

Insert the K120 plate into the K101 support

module and maintain its position by means

of the D04 template as shownin fig. 12.

Screw the K104 pin into the K120plate

described aboveas shown in fig. 12

P107

Fig.11

P106a

K104

P106

K120

P106a

K101

D04

Fig.12

- 18 -

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

Havingformedaunit,inserttheprojectingpart

of the pin into the hole placed under the step

supportmodulemountedpreviously. Insertthe

K119 plate into the pipe of the unit described

aboveandanchoreverythingby means of the

K127 screw and theK126 washer.

To facilitate screwing operations, we

recommend using a jack spanner to screw in

the screw until it starts tightening. Since the

tread must stillbe adjusted, theunit must not

be tightened fully.

Moreover, before assembling the module,

insert theP105 plug from behind.

(fig.13)

- VECTOR 70 - VECTOR 80 -

K127

K126

K119

P105

Now adjust the moduleaccording to the “P”

tread size.

Thisvaluemustbemeasuredstartingfrom the

front part of the spacer package until the

reference present on the support flange as

shown in fig. 14.

Fully tighten the K127 screw which was

previouslyleft lose, payingparticularattention

to the position of the spacer package, which

needs to remain aligned with the support.

The use of a rigid reference guide is

recommended to be applied to the sides of

the pipe with clamps during the operation.

Assemble the L20 step on the K101 support

by means of the B205 screws as shown in

fig. 15.

K101

Fig.13

P

Fig.14

VECTOR 70 - VECTOR 80

L20

B205

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig.15

- 19 -

advanced mobularstairsystem

Insert the K63 columninto the P107 support

mountedpreviously.

By means of a level check that it is vertical

and lock it temporarily in the position

illustrated in fig. 16.

Insert a P107 supportand mark the position

of the holes on the bottom part of the step

fig. 16 -17

- VECTOR 70 - VECTOR 80 -

K63

Drill in the points marked and mount the

P107supportbyfollowingthesameprocedure

illustratedabove.

(fig.7-8-9-10page16)

Fig.16

Fig.17

P107

B203

Ø4

- 20 -

Fig.18

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

B204

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

- VECTOR 70 - VECTOR 80 -

Continue assembling the following steps

according to the same procedure until the first

L21 is achieved where the staircase starts

turning.MounttheP107supportontheL21 step

by using the pre-existing holes and make sure

to insert the square nut with relevant security

dowel as illustrated above. Inset a K63banister

column into the top step support and lock it

temporarily in the position illustrated in fig. 19.

Check that the module is positioned in the P

Max tread position, then place the L21 step as

shown in fig.19 and lock it by means of B205

Adjust the step in the maximum tread position,

i.e.allthewayinthefront,untilthemostadvanced

position is achieved. (fig. 19)

Lock the module in the position achieved and

make sure that during the operation the spacer

package remains aligned with the module,

including thevertical direction of the column.

WARNING!!!

While the steps are being assembled, the

unit that is being formed should be

supported so that it does not press on the

support of spacer package (see the “SUPP.”

example fig. 20). This should be done every

three/four steps (see Example in fig. 20) to

facilitate assembling the starting module

after having reached the ground.

P Max

Vector 70= 230 mm

Vector 80= 250 mm

L21

x

a

m

P

P Min

Vector 70= 200 mm

Vector 80= 220 mm

K63

P107

Fig.19

Similarly, proceed to assemble the L23 central

step.

In this case, the K125 extension should be

mounted and connected to the top rod.

The packagecontains a K125 column.

Cut K125 to achievealength amountingtothree

times the size of the rise T=3*A, and proceed

asshowninfig.20,connectbothpiecesbymeans

of the threaded rod K130 and K23 bushing.

Thestep supporting module

will take the direction set by

theanchoring holes present

in the step.

In this case adjust the “P”

tread until it reaches its

minimumvalue.

Alignthespacerpackageby

means of one of the two

supports and keep it still

while it is being anchored.

K127

K126

K119

L23

SUPP.

B205

K130

K23

n

i

m

P

T=3*A

K125

Fig.20

VECTOR 70 - VECTOR 80

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

- 21 -

advanced mobularstairsystem

- VECTOR 70 - VECTOR 80 -

Similarly, proceed to mount the L22 turning step by

followingthe same procedure described above.

Also in this case, the step must be positioned in the

furthestbackwardpossibletreadposition(P min) (fig.

21)

Anchor the column and extension definitivelyto their

P107 supports, insert the P110 plug into the column

hole as shown in fig. 22.

After havingcompletedtheassemblyof the staircase,

according to the selected configuration, one further

turning step (U configuration) or straight step (L or

wideU configurations)must be inserted.

In either case, the procedure is the same as the

proceduredescribedabove.

Rememberthatif a straightstepismounted,theK101

support modulemust be adjusted again accordingto

the .P. tread as shown in fig. 22.

Complete the assembly of the steps until you reach

theground.

P Min

Vector 70= 200 mm

Vector 80= 220 mm

P

m

i

n

.

L22

B205

Fig.21

P110

P

- 22 -

K101

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig.22

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

After having reached the ground, the K102 element must be used as the last step.

Assemble the module as described above without tightening fully and adjust its position according to the tread.

(fig.24)

P

- VECTOR 70 - VECTOR 80 -

K102

B200

Fig.24

Fig.26

Ø12

Fig.25

B200

Fig.27

Fig.28

VECTOR 70 - VECTOR 80

B205

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

- 23 -

advanced mobularstairsystem

The last column must be cut before being assembled. The cutting length T is calculated according to the formula

reportedinfigure29.

WhereA is the rise value(fig. 29)

T = A - 146 (mm)

K23

- VECTOR 70 - VECTOR 80 -

Fig.29

T

Fig.30

Ø10

Drillthepointmarked by means of a Ø10 drill (fig. 30)

A

After having assembledthe K63 starting column,

mount the K133 stiffener as shown in fig. 31A,

by means of the K36 clamps and position it with

the lower arm under the step

- 24 -

K36

K63

K18

K36

Fig.31

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

K133

Fig.31A

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

MOUNTING THE COLUMN AND/OR BRACKET

WARNING!!!

It is strictly prohibited to use and climb on the stairs before having carried out the stiffening and support

operations.

Moreover,the point wheretoinsert thek122supportColumn must be identified.Thedrawingson12-13-14reportthe

- VECTOR 70 - VECTOR 80 -

points where the staircase may be adequately supported SEE symbol.

Afterhaving identified the position, measure its H1 (mm) height from the floor as shown in fig. 32.

Drill the support from below and in the centre line by means of a Ø12 drill.

SOLUTION 1

Ø12

B206

K123

K122

H1 mm

VECTOR 70 - VECTOR 80

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig.32

- 25 -

advanced mobularstairsystem

- VECTOR 70 - VECTOR 80 -

Cut the K122 Column according to the H1 - 10 mm

height(K123 spacer).

(fig.33)

Drill in the marked point by means of a Ø12 drill and

insert the B202 kit small block into the hole

(fig.34-35)

Fig.33

K122

H

1

-

1

0

m

m

B202

Place the Columnback and anchor itbymeansof the

B202 kit screws (fig.36).

Adjust the K123 washer so that it touchesthe bottom

side of the module and join with the B206 screw by

means of the hole drilled before.

(fig.32previouspage)

Tocompletetheoperation,coverallanchoringscrews

(arrivalanddeparturemodules)with theirrelevantK131

caps. In the arrival module, the heads of the screws

must be covered directly, whereas the cap must be

glued on the holes left empty, Fig, 37

Ø12

Fig.34

Fig.35

B202

Fig.36

- 26 -

K131

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig.37

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

In certain cases, no support column may be added, as shown above; in such cases it is advisable to support the

staircase by means of a K121 support bracket to be inserted by drilling a min 150 mm deep hole in the wall closer

to the staircase and embed the bracket as described in fig. 38.

Then mount the P90 closing cap on the pipe head.

SOLUTION 2

- VECTOR 70 - VECTOR 80 -

VECTOR 70 - VECTOR 80

P90

K121

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

1

5

0

Fig. 38

- 27 -

advanced mobularstairsystem

CHECKING AND MOUNTING ADDITIONAL COLUMNS

Nowthe correct positionof the columns assembled needs to be checked. Check that they arevertical and that the

- VECTOR 70 - VECTOR 80 -

cable supports face outside the staircase, as shown in fig. 39

Near the step preceding the first turning step an additional column must be assembled. It must be cut to achieve a

height that is half the rise .A.: T = A / 2

Between the two supports anchoredbefore, trace the position of a third element as shown in fig. 39.

The assemblyprocedure isthe same as the procedure describedabove.

Anchor everything bymeans of the relevant B203 kit screws. Then, insert the P110 cap at the foot of the column.

Mount an additional column on the last step, at a distance equal to the tread size, as shown in fig. 39. Moreover, it

is advisableto assemble an additional support anchored to thetop side of thestep, so thatthe column is anchored

in a stiffer and safer way.

Adjust the height so that it matches those mounted before and does not project beyond its support.

B207

P107

B207

B204

P107

T

=

A

/

2

P110

- 28 -

A

Fig.39

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

ASSEMBLING THE HANDRAIL

Placethe handrail on the first support approx. 40-50 mm farfrom thefirst column (fig. 40)

- VECTOR 70 - VECTOR 80 -

By referring to the housing, drill a Ø3 preliminary hole to anchor the handrail in its K65 housing.

Make sure that it is correctlyplaced into its housings, no gaps areleft between them Anchor the handrail by means

of the dedicated K66 kit screw.

Proceed until the last column before the staircase turnshas been reached.

WARNING!!!

When assembling the handrail make sure that the k65 supports shaped like a “saddle” face the inner part

of the staircase.

After having reached the last column before the staircase turns, cutthe handrailand leavetheexceedingpart so that

the K68 plug can be mounted.

We suggest to mount the plug before thefinal anchoring of the handrail on the column.

Resume assemblingthehandrailafterthe staircase has turned by proceedinginthe same way untilreachingthe last

column mountedon the finalstep.

Cut the excessive partof thehandrail andleave a 40-50 mm projectingpart.

All configurationsenvisage that an additional column must bemounted on the last straight step before the staircase

turns. Figure 41 shows the example of a “U” staircase.

L15

B301

K71

L15

K77

L15

4

0

/

5

0

m

m

L15

VECTOR 70 - VECTOR 80

K80

Ø 3

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

K65

Fig. 40

- 29 -

advanced mobularstairsystem

After having assembled the handrail the K68 plug must be mounted at both ends.

Place the plug at one hand and trace the position of the anchoring holes.

Drill with a Ø 4 wood drilland mount the K68 plug with the relevant K76 screw (Fig. 41)

That operation mustbe implemented at both ends of the handrail.

Ø 4

m

m

0

5

/

0

4

- VECTOR 70 - VECTOR 80 -

K68

K76

Ø 4

- 30 -

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig. 41

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

ASSEMBLING THE BANISTER CABLES

Finally, mount the flexible cables.

Proceed as follows:

startingfrom above, insert one endof the K84 cable into theforks mounted on thecolumns and anchor it bymeans

of the relevant K60 clamp.

Continueinsertingthecablesintotherelevantsupportsuntilreachingthe last column, thus completing the banister.

NB. Make sure that the cables are correctly inserted in the relevant supports.

After completing the operation, make sure that the cables are sufficiently tight between columns.

Insert the K60 clamp and anchor it on the cable end; cut the excessive part. Eliminate any scrap or sharp edges

resulting from cutting.

Repeat the same steps with the other stretches of banister.

- VECTOR 70 - VECTOR 80 -

K84

K60

K60

VECTOR 70 - VECTOR 80

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig. 42

- 31 -

advanced mobularstairsystem

COMPLETION AND CHECKS

- VECTOR 70 - VECTOR 80 -

K38

K36

Ø10

K38

K36

K82

K36

Mount the P105 plugs both in the front and back side of the step support modules (fig. 44)

Tass.

Fig. 43

P105

- 32 -

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

P105

Fig. 44

VECTOR 70 - VECTOR 80

advanced mobularstairsystem

After the assemblyoperations have been completed,checkandtest that the staircase is stableandallcomponents

arefirmlyanchored.

As regards the wall anchoring points, refer to the drawings reported on page 12-13-14.

Example of staircase anchoringand supportpoints

bracket application and anchoringpoint K100

pillar staircase support point K122

- VECTOR 70 - VECTOR 80 -

Block

bracket application and anchoringpoint K100

K100

Ø12

B201

B201

Ø6

- 33 -

Via C.Colombo, 22/A - 42046 - Reggiolo - Reggio Emilia - Italy

Tel. +39 - 0522-97 32 34 - Fax +39 - 0522-97 31 39

ehleva@ehleva.it

By Mobirolo S.p.A.

Fig. 45

VECTOR 70 - VECTOR 80

Loading...

Loading...