E-flite 10 - 15 Main Electric Retract Unit User Manual

Specications

Tools Required

10- to 15-Size

Electric Retract

Instructions

Thank you for purchasing the E-ite® 10- to 15-Size

Electric Retracts. These self-contained units are

powered from your model’s receiver and do not require

separate servos.

The retracts are supplied with coil struts installed, plus

adjustable axles, wheel collars, Allen wrenches and a

3-into-1 wire harness (for the tricycle set) or 2-into-1

wire harness (for main gear set). The nose gear unit is

steerable and has a slot in the sliding steering arm to

prevent binding of the steering cable when retracted.

EFLG100

EFLG110

Current draw

Idle 5mA

Operating 150mA (maximum)

Pulse width trigger points

Down 1.331ms

Up 1.690ms

Operation with FM and DSM

FM 22ms frame rate, 5V signal

DSM 20ms frame rate, 3.3V signal

Sequence time

@ 4.8V 1.25sec

@ 6.0V 1sec

@7.4V 0.8sec

Operating voltage range 4.8 – 7.4V

Aircraft weight: 2.0 - 4.5 lb (0.9 – 2.0 kg)

Unit weight: Nose gear 1.6 oz (45 g)

Main gear 1.3 oz (37 g) each

Parts Available

EFLG101 10 - 15 Main Electric Retract Unit

EFLG102 10 - 15 Left Main Wire Strut

EFLG103 10 - 15 Right Main Wire Strut

EFLG104 10 - 15 Adjustable Axles

EFLRYH9 10 - 15 Dual Plug Y-harness

EFLG111 10 - 15 Nose Electric Retract Unit

EFLG112 10 - 15 Nose Gear Wire Strut

EFLG113 10 - 15 Nose Gear Steering Arm

EFLRYH9TR 10 - 15 Triple Plug Y-harness

Pencil Screwdriver

1.5mm hex wrench 2.5mm hex wrench

Flat le Threadlock

Rotary tool with cutoff wheel

Installation

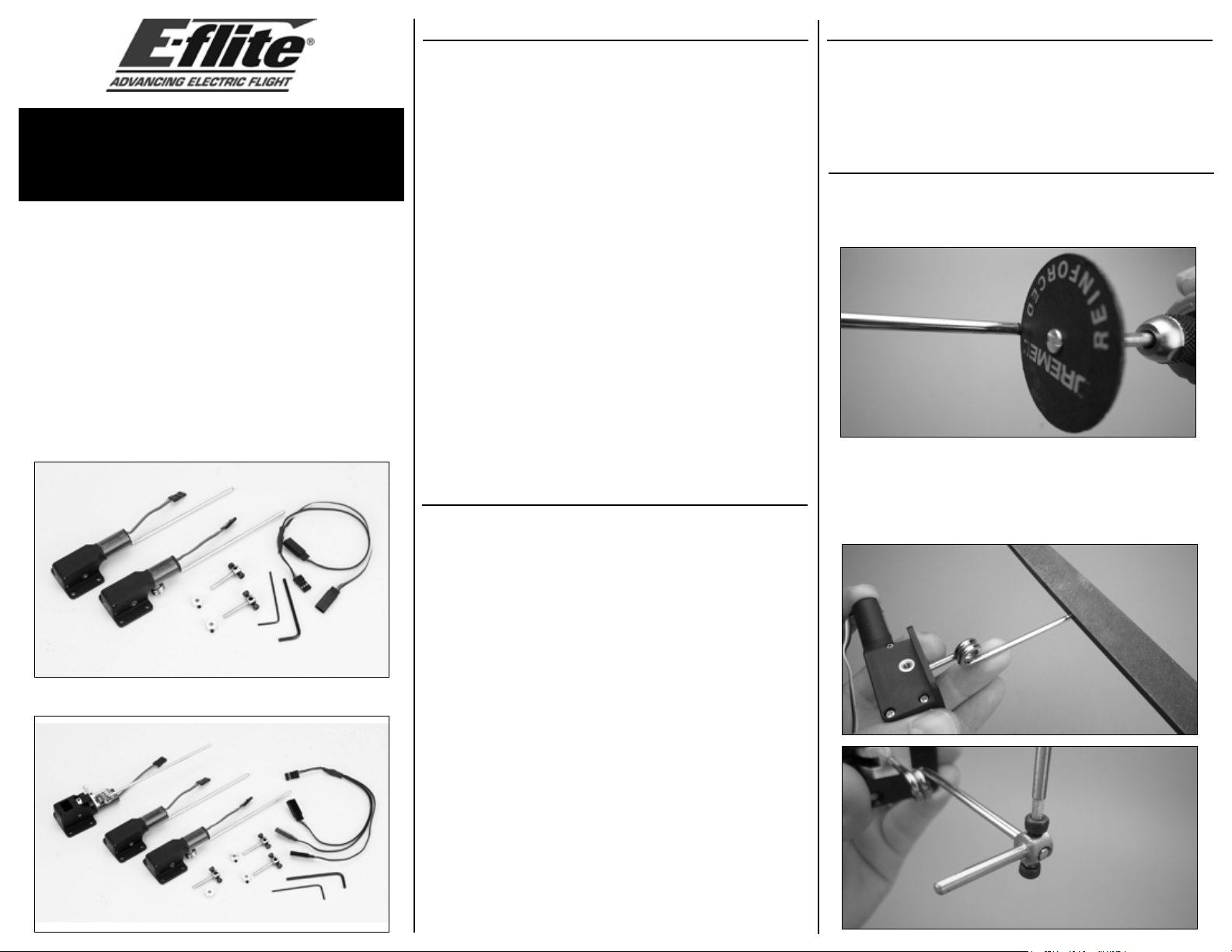

1. Test t the retract unit in the wing or fuselage to

determine the strut length and axle location. Cut the

strut to length using a cutoff wheel in a rotary tool.

2. Make two at spots on the end of the strut with a le

and use a 2.5mm hex wrench to secure the axle to the

strut. Apply threadlock to the threads of the retaining

screws so they do not loosen from vibration.

3. Install the wheels on the axles. Slide the brass wheel

collar onto the axle and secure it using a 1.5mm hex

wrench. Apply threadlock to the setscrew to prevent it

loosening due to vibration.

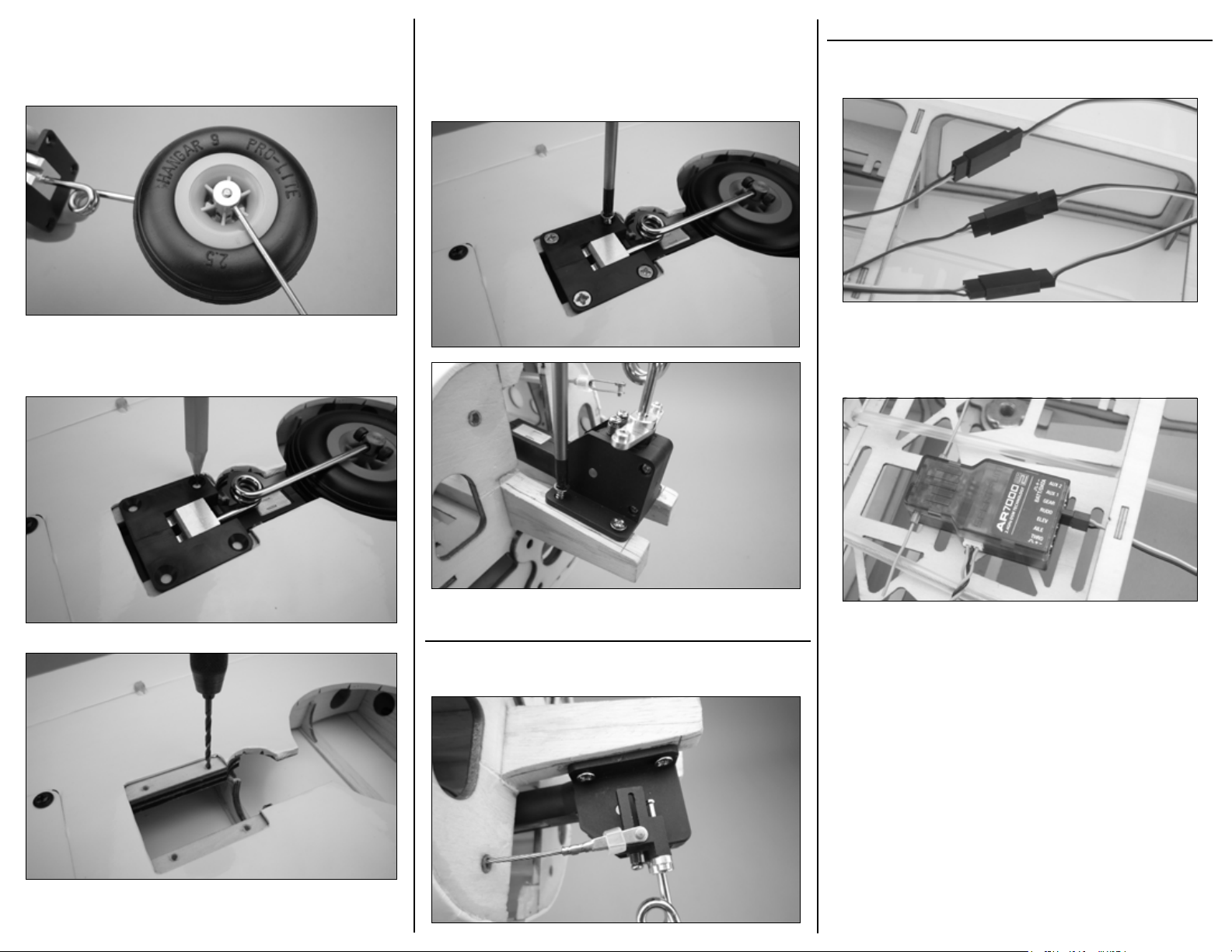

5. Install the retracts in the model using the screws

provided with the kit or those of your own choice. A #4 x

1/2-inch wood screw works well. You will nd the main units

require the use of a 100 degree countersunk woodscrew

while the nose unit requires a button head woodscrew.

Radio Connections and Operation

1. Plug the connector from each of the retract units into

the 3-into-1 wire harness supplied with the retracts.

4. Mark the retract mounting hole locations on the rails

using a pencil and drill appropriately sized holes for the

hardware you intend to use.

Nosegear Steering

Connect the steering pushrod to the steering arm on the

nosegear.

2. Plug the single lead from the wire harness into the

gear channel of your receiver. An auxiliary channel can

be used if the gear channel is occupied.

3. Before operating the retracts in the model for the rst

time check that there are no obstructions in the wheel

wells that could impede operation of the gear.

4. Turn on your transmitter and receiver. Use the gear

or other assigned switch to activate the landing gear

and check that it operates correctly.

5. If the switch direction is opposite of that desired, use

the reversing function in the transmitter to change the

retraction direction.

6. If using a 2.4GHz radio, once you have set the

correct servo direction be sure to rebind the system

before ight.

Loading...

Loading...