Photovoltaic Solar Inverter Series ES

ES2200 / ES3300 / ES4200 / ES5000

Operating Manual V. 3.2

Article number: SLWRABSI2K0Wx000

SLWRABSI3K0Wx000

SLWRABSI4K0Wx000

SLWRABSI5K0Wx000

Translation of the original Operating Manual

Photovoltaic Solar Inverter Series ES

Legal notice

ES series

2

Legal notice

by EFFEKTA Regeltechnik GmbH

EFFEKTA Regeltechnik GmbH, 78628 Rottweil, retains the copyright to this

documentation.

This documentation is solely intended for the operator and his staff. The

content of this documentation (texts, figures, drawings, graphics, plans, etc.)

may not be copied or distributed in part or in full without our consent in writing,

nor can it be used without authorisation for competitive purposes or given or

made accessible to third parties.

EFFEKTA Regeltechnik GmbH

Rheinwaldstraße 34

D – 78628 Rottweil

Phone: + 49 (0) 74 1 / /1 74 51 - 0

Fax: + 49 (0) 74 1 / /1 74 51 - 22

E-mail: ups@effekta.com

Internet: www.effekta.com

Manual: Operating manual

Language: English

Release date: 03/2011

We reserve the right to make changes to the design and the system that

will improve the system, the production process or the product.

Photovoltaic Solar Inverter Series ES

Contents

ES series

3

Contents

1. Introduction ............................................................................................................. 5

1.1 Foreword ................................................................................................................... 5

1.2 Validity ...................................................................................................................... 6

1.3 Storage ..................................................................................................................... 6

1.4 Symbols in this Manual .............................................................................................. 6

1.5 Information Obligation ..............................................................................................10

1.6 Warranty Conditions .................................................................................................10

1.7 Transport and Storage ..............................................................................................12

1.8 Positioning................................................................................................................13

2. Safety Instructions .................................................................................................14

2.1 Introduction ..............................................................................................................14

2.2 Proper Use ...............................................................................................................14

2.3 Avoiding Personal Injury / Property Damage ............................................................15

2.4 Protecting the environment .......................................................................................15

2.5 Connection ...............................................................................................................16

2.6 Advice about specific dangers ..................................................................................17

2.7 Operation .................................................................................................................18

2.8 Working with PV modules .........................................................................................18

2.9 Maintenance, Service and Malfunctions ...................................................................19

2.10 Advice about connecting to the mains power ............................................................19

3. Device Description .................................................................................................20

3.1 Dimensions ..............................................................................................................20

3.2 Display and connections ...........................................................................................21

4. Assembly ................................................................................................................23

4.1 Assembly of the wall mounting .................................................................................23

4.2 Ambient conditions for assembly ..............................................................................25

4.3 Assembling photovoltaic solar inverters ....................................................................29

5. Electrical Installation ..............................................................................................31

5.1 Connecting AC power cable ..................................................................................... 32

5.2 Connecting PV module .............................................................................................36

6. Control Panel ..........................................................................................................41

Photovoltaic Solar Inverter Series ES

Contents

ES series

4

7. Commissioning ...................................................................................................... 43

7.1 Starting device for the first time ................................ ................................................ 44

7.2 Country settings, operating mode settings and ID settings ....................................... 45

7.3 Commissioning the photovoltaic solar inverter ......................................................... 47

7.4 Checking measurement readings and numbers ....................................................... 49

7.5 Operating states of the photovoltaic solar inverter .................................................... 52

8. Communication Interfaces .................................................................................... 54

8.1 Standard communication interface ........................................................................... 54

8.2 Solar-LogTM .............................................................................................................. 55

8.3 Optional data cards .................................................................................................. 55

9. Status Diagnosis and Troubleshooting ................................................................ 65

9.1 Error codes and explanations .................................................................................. 65

9.2 Mains error alarm codes and explanations ............................................................... 68

10. Service .................................................................................................................... 70

11. Technical Data ....................................................................................................... 71

11.1 Device specifications ............................................................................................... 71

11.2 ES2200 / ES3300 Block diagram ............................................................................. 74

11.3 ES4200 / ES5000 Block Diagram ............................................................................ 75

11.4 Scope of Delivery / (Optional) Accessories .............................................................. 76

12. Declaration of Conformity ..................................................................................... 80

Photovoltaic Solar Inverter Series ES

Introduction

ES series

5

1. Introduction

1.1 Foreword

Dear Operator,

You are about to operate a photovoltaic solar inverter.

This operating manual should provide you with support for working responsibly

and basic information about the photovoltaic solar inverter, namely how it

operates, its application and what you should do in the event of malfunctioning.

Furthermore, this operating manual contains instructions for the transport and

storage as well as the handling and installation of the photovoltaic solar

inverter.

The plan guidelines in this operating manual only relate to special requirements

for the photovoltaic solar inverter. During installation, make sure you follow the

national and local requirements for electrical installations.

The content of this device description may change due to technological

progress. We have tried to present the content correctly and clearly. If,

however, we have made errors, we would be grateful for information about this.

The photovoltaic solar inverter is intended to convert the energy generated

by solar modules into 230 VAC and to feed it into the power grid.

Please read this operating manual carefully and take note particularly of

the safety instructions.

If you have questions about the device, the technical supervisor in your

company or our employees will be glad to help you.

Your

EFFEKTA Regeltechnik GmbH

Photovoltaic Solar Inverter Series ES

Introduction

ES series

6

1.2 Validity

The descriptions in this operating manual relate solely to the

Photovoltaic solar inverter

defined in the technical data as a whole or as it refers to modules, components

and individual parts that were developed and built by EFFEKTA Regeltechnik

GmbH.

11. Technical Data

1.3 Storage

This operating manual for the device must be stored in the vicinity of the device

at all times so it is immediately available if need be.

1.4 Symbols in this Manual

The abbreviation PV in this manual stands for photovoltaic.

Read this documentation carefully and make yourself familiar with the

product before using it.

Store this operating manual in an easily accessible place to refer to it if

necessary.

Please pass this operating manual on to later users of the product.

1.4.1 Danger warning levels

Text that is marked with DANGER! provides a warning about dangers. If

accident prevention measures are not taken, these dangers may result in

serious (irreversible) injuries or even death!

Photovoltaic Solar Inverter Series ES

Introduction

ES series

7

Text that is marked with WARNING! provides a warning about hazards. If

accident prevention measures are not taken, these hazards may result in

serious (irreversible) injuries or even death!

Text that is marked with CAUTION! provides a warning about hazards. If

accident prevention measures are not taken, these dangerous situations

can lead to slight or medium reversible injuries.

Text that is marked with ATTENTION! contains very important

instructions for situations that, if accident prevention measures are not

taken, may result in damage to the product and / or its functions or an

object in its vicinity.

This symbol indicates text that contains important instructions / comments or

tips.

Photovoltaic Solar Inverter Series ES

Introduction

ES series

8

1.4.2 Warning information

1.4.2.1 Warning about danger spots

General warning about danger spots!

1.4.2.2 Specific warning

Warning about dangerous electrical voltage!

1.4.3 Instruction symbols

Take note of the provided documentation and/or instructions!

Disconnect before work!

Photovoltaic Solar Inverter Series ES

Introduction

ES series

9

1.4.4 General symbols

●

This dot marks descriptions of activities that you should carry out.

–

This dash marks specifications.

This arrow marks a cross reference.

If a cross reference to another chapter is necessary in the text, this is

shortened for clarity.

Example: OM, 2 Safety Instructions

This means: See Operating Manual, Chapter 2 Safety

Instructions.

If the cross reference refers to a page, figure or position number, this

information is added at the end of the cross reference.

Example: Fig. 4 - 4, Pos. 1

This means: See position number 1 in figure 4 in Chapter 4

of this manual.

(3)

Numbers in brackets refer to the positions in the figures.

Identifies instructions for recycling.

Identifies components that are subject to the Electronic Scrap Regulation.

Identifies components or parts that must be disposed of. Do not throw these

in the household waste.

Requirement that must be fulfilled:

The DC circuit breaker is on "OFF."

Photovoltaic Solar Inverter Series ES

Introduction

ES series

10

1.5 Information Obligation

This operating manual must be read, understood and all its points must be

taken note of by all persons that are responsible for the

– Operation

– Cleaning and

– Disposal

of the device.

EFFEKTA Regeltechnik GmbH is not liable for damage incurred or caused

by staff who have not been trained or who have been insufficiently

trained!

1.6 Warranty Conditions

The receipt of delivery is considered as the record for the initial purchase and

should be kept in a safe place. It will be necessary for making use of the

warranty. If the product is passed on to another user, he has the right to the

warranty for the remainder of the warranty period. The purchase receipt as well

as this declaration should also be given to the new owner if the device is

passed on.

We guarantee that this device, upon delivery, is in a functional state and

technically conforms to the descriptions in the appended documentation.

The warranty period for special devices corresponds to the minimum periods

stipulated by law.

The warranty ceases to apply in the following cases:

In the event of defects caused by: freight damage, accident, natural

catastrophies, misuse, vandalism, improper use, defective maintenance or

incorrect repair by third parties.

– In the event of changes, unauthorised intervention, incorrect operation,

another device or accessories, false installation or other modifications not

approved by us.

– Improper use such as plugging the device into unsuitable energy sources,

attempts to overload the photovoltaic solar inverter, use in an unsuitable

environment, etc.

– In the event of failure to follow instructions in the provided documentation.

Photovoltaic Solar Inverter Series ES

Introduction

ES series

11

– In the event that the product is incompatible due to possible technical

innovations or regulations that occur after the purchase.

– In the event of incompatibility or malfunctioning that was caused by product

components we did not install.

– In the event of developments that are related to the normal aging process

of the product (wear parts).

– In the event of defects that were caused by external fixtures.

The warranty period for replaced and/or repaired parts as part of this warranty

expires together with the original warranty for the product.

Devices that are supplied without accessories are replaced without

accessories. The return of the device is only accepted if this is done in the

original packaging.

Incurred transport costs are generally not included in the warranty.

You shall bear the cost of repair and exchange, and EFFEKTA Regeltechnik

GmbH is not liable for damage, whether directly, unintentionally, specifically, or

for subsequent damage, even if it was caused by negligence or other errors.

EFFEKTA Regeltechnik GmbH does not provide either explicit or implicit

warranties related to this device and its quality, performance, saleability or

suitability for a certain purpose. In some countries, the exclusion of implicit

warranties is not permitted by law. In this case, the validity of all explicit and

implicit warranties is limited to the warranty period. With the expiration of these

periods, all warranties lose their validity. In some countries, a limitation of the

validity period of implicit warranties is not permitted by law so that the

aforementioned limitation does not take effect.

Photovoltaic Solar Inverter Series ES

Introduction

ES series

12

1.6.1 Limitation of liability

Claims to damage compensation are excluded unless they involve intent or

gross negligence by EFFEKTA Regeltechnik GmbH or its employees. This

does not affect liability according to the Product Liability Act. Under no

circumstances are we liable for:

– Claims that third parties make against you due to losses or damage.

– Loss or damage of your records or data or the costs of recovering this

data.

– Economic subsequent damage (including lost profits or savings) or

concomitant damage, including in the event that we were informed of the

possibility of such damage.

Under no circumstances is EFFEKTA Regeltechnik GmbH responsible for

any accidental, indirect, specific, subsequent or other damage of any kind

(including, without any limitation, damage related to a loss of profits,

interruption of business, loss of business information, or any other losses) that

result from use of the device or are connected with the device whether they are

based on the contract, damage compensation, negligence, strict liability or

other claims, even if EFFEKTA Regeltechnik GmbH was informed about the

possibility of such damage in advance. This exemption also includes any

liability that can result from the claims of third parties against the initial

purchaser.

In some countries, the exemption or the limitation of concomitant or

subsequent damage is not permitted by law so that the aforementioned

declaration does not enter into force.

1.7 Transport and Storage

The photovoltaic solar inverter may only be transported to the intended location

in the original packaging. The same applies to moves or returns.

The packaging plays no role as fall protection, so all fallen devices must be

checked by EFFEKTA Regeltechnik GmbH before commissioning.

Photovoltaic Solar Inverter Series ES

Introduction

ES series

13

1.8 Positioning

Do not install in an area in which combustible vapours result e.g. from

petrol tanks, engine compartments, etc.

The photo voltaic solar inverter is designed for operation in ventilated rooms

with an ambient temperature of 0° to 40°C.

If the photovoltaic solar inverter is exposed to severe and quick temperature

changes, there is danger of condensation. Before you take additional steps, an

acclimatisation period of at least 2 hours is to be observed.

Never place or operate the device in a moist environment. Keep liquids away

from the device.

The photovoltaic solar inverter may not be placed in the vicinity of heat

sources.

It is to be placed in a horizontal position.

Ensure that the external side and the front side of the device are at least 20 cm

from other objects for ventilation in order to prevent trapped air and too much

warming. Make sure that the air openings cannot be covered, e.g. through

sucked-in paper, material, etc.

Photovoltaic Solar Inverter Series ES

Safety Instructions

ES series

14

2. Safety Instructions

2.1 Introduction

The photovoltaic solar inverter is a device that has been produced

according to the rules and regulations of technology for the generation of

230 VAC from a solar module. The device and its related components,

modules and parts meet individually and in their entirety the currently

valid safety standards.

The device is safe when used properly and under consideration of the

safety requirements and instructions provided in this operating manual.

2.2 Proper Use

The photovoltaic solar inverter and its related components may only be

used for purposes in accordance with its design - for the generation of

230 VAC from a solar module.

Any other use is considered improper and can lead to personal injury or

damage to the device!

Improper use:

The device is not designed for use in

– explosive,

– dusty,

– radioactive or

– biologically or chemically contaminated atmospheres!

This is equipment of class A. This equipment can cause radio

interference in residential areas. In this case, the operating company may

be requested to take appropriate measures!

Photovoltaic Solar Inverter Series ES

Safety Instructions

ES series

15

2.3 Avoiding Personal Injury / Property Damage

Please read this operating manual carefully to familiarise yourself with the

device.

In particular, take note of the information regarding the installation and

commissioning of the device.

Only operate the product in an appropriate and proper way and within the

parameters stated in the technical data.

Only perform maintenance and service work that is described in the

documentation. Observe the required steps. Only use original replacement

parts from EFFEKTA Regeltechnik GmbH.

2.4 Protecting the environment

Send the product back to EFFEKTA Regeltechnik GmbH after the end of

its use. We will ensure environmentally friendly disposal.

Photovoltaic Solar Inverter Series ES

Safety Instructions

ES series

16

2.5 Connection

Before connecting, always compare the indicated voltages of the

photovoltaic solar inverter. These values must match.

Before connecting your PV modules to the photovoltaic solar inverter,

check whether this is suitable for operation with your PV modules.

When reading off the values, note that PV modules achieve a higher open

circuit voltage at lower temperatures and unchanged solar radiation.

The EFFEKTA Regeltechnik GmbH Company is not liable for damage

caused by this to the PV modules and to the photovoltaic solar inverter.

2.8 Working with PV modules

Wrongly polarised connections cause the fuses in the photovoltaic solar

inverter to blow out and can result in longterm damage to the device.

Our warranty does not cover damage that is caused by reverse polarity.

Make sure that all connections are firmly in place, since loose

connections overheat and represent a potential danger.

The operation of the photovoltaic solar inverter without a correct

grounded contact can cause electrical safety hazards.

The requirements for the earthing vary depending on the country and the

application. All installations must meet the requirements of the applicable

national regulations.

You must use suitable power cables, e.g. cable diameter, insulation, VDEapproved and CE-labelled, with appropriate cable ends for the connection

of the photovoltaic solar inverter to the PV modules.

Use only a VDE-approved and CE-labelled power cable with the appropriate

cable diameter to connect the PV modules to the photovoltaic solar inverter. Do

not connect any PV modules to the photovoltaic solar inverter, which could

overload the device (take note of the high starting currents).

Dangers such as stumbling, squeezing, clipping, etc. are to be avoided with the

cables.

Photovoltaic Solar Inverter Series ES

Safety Instructions

ES series

17

2.6 Advice about specific dangers

2.6.1 Danger from electrical energy

There is risk of receiving a life-threatening electric shock if you touch live

components.

Only authorised electricians may work on electrical components or

equipment in accordance with electrotechnical rules

Covers of live components may not be removed.

In the case of faults in the supply of electrical energy to the device

and the ancillary devices, switch off immediately at the main

switch(es) and/or separate the device from the power supply.

Check the electrical equipment of the device and the ancillary devices

regularly. In the case of damage to the electrical equipment of the

device and the ancillary devices, switch off immediately at the main

switch(es) Have any loose connections and/or burnt/damaged cables

rectified immediately.

If there is a risk of an electric shock, switch the device and the

ancillary devices off.

Secure the device and the ancillary devices against being started up

again, e.g. by posting corresponding signs / notices and/or by

cordoning off the area of risk with a coloured safety chain or tape. If

required, ask for assistance.

Even after the separating the device from the power supply, there is still

life-threatening current present through the charged capacitors.

Make sure no voltages are still present before starting work on electrical

components.

Photovoltaic Solar Inverter Series ES

Safety Instructions

ES series

18

2.7 Operation

When the supply voltage is applied, the photovoltaic solar inverter is ready for

operation mode straight away.

2.8 Working with PV modules

Before connecting your PV modules to the photovoltaic solar inverter,

check whether this is suitable for operation with your PV modules.

When reading off the values, note that the PV modules achieve a higher

open circuit voltage at lower temperatures and unchanged solar

radiation.

The EFFEKTA Regeltechnik GmbH Company is not liable for damage

caused by this to the PV modules and to the photovoltaic solar inverter.

At -20°C, the open circuit voltage of the PV modules may not be above

500 V. To determine the theoretical open circuit voltage at -20°C, use the

temperature factors in the data sheet of the PV modules.

If the PV module open circuit voltage is above 500 V, the PV modules

may not be connected as this will cause damage to the photovoltaic solar

inverter.

The PV solar inverter contains a monitoring unit for fault currents in

accordance with VDE 0126-1-1. This unit measures the ground current of

the PV modules and prevents the feeding into the mains in the event of

an earthing fault.

Photovoltaic Solar Inverter Series ES

Safety Instructions

ES series

19

2.9 Maintenance, Service and Malfunctions

There is risk of receiving a life-threatening electric shock if you touch live

components.

Even after separating the device from the power supply, parts of the

photovoltaic solar inverter can still have high voltages.

2.10 Advice about connecting to the mains power

The photovoltaic solar inverter may only be connected to the mains by

appropriately licensed customers.

Please contact your regional energy supplier with regard to special

requirements.

Permission from the energy supplier must be present for connection of the

photovoltaic solar inverter.

Photovoltaic Solar Inverter Series ES

Device Description

ES series

20

3. Device Description

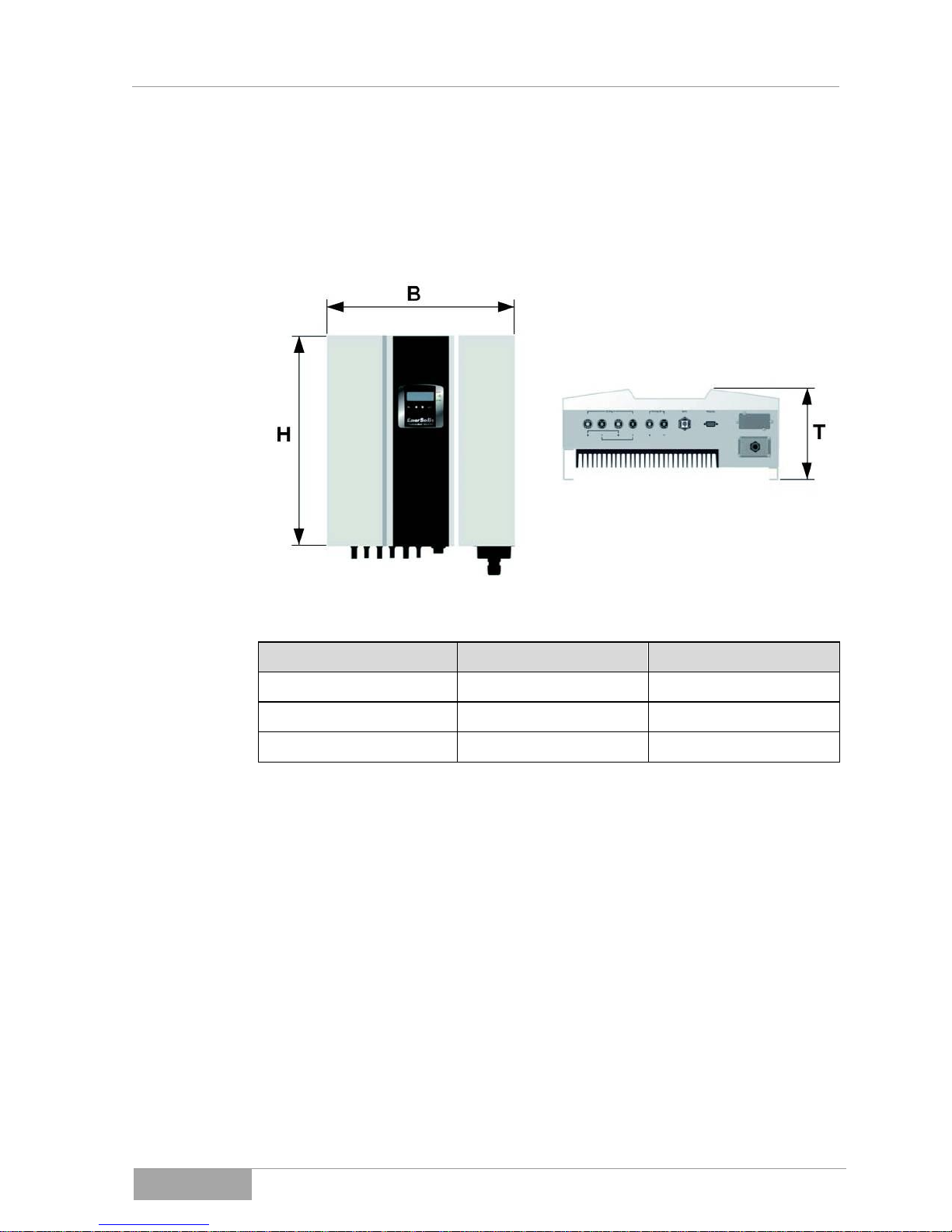

3.1 Dimensions

ES2200 / ES3300

ES4200 / ES5000

H (Height)

[mm]

430

510

W (Width)

[mm]

455

455

D (Depth)

[mm]

190

190

Fig. 3-1 - 1 Dimensions of the photovoltaic solar inverter

Photovoltaic Solar Inverter Series ES

Device Description

ES series

21

3.2 Display and connections

3.2.1 Display and connections ES2200 / ES3300

1 Front panel with LCD display and LED displays

Operation and display of the operating state of the photovoltaic solar

inverter

2 Data transmission interface to (option)

USB, RS485, floating contact, TCP/IP

3 AC output terminal

AC output for power supply connection

4 Data transmission interface (standard)

RS232

5 Interface for emergency shutdown

EPO

6 Feed for PV module

Plug and holders for the connection of the solar module:

ES2200: 3 connections (1 MPPT)

ES3300: 3 connections (1 MPPT)

Fig. 3-2 - 1 Display and connections ES2200 / ES3300

Photovoltaic Solar Inverter Series ES

Device Description

ES series

22

3.2.2 Display and connections ES4200 / ES5000

1 Front panel with LCD display and LED displays

Operation and display of the operating state of the photovoltaic solar

inverter

2 Data transmission interface (option)

USB, RS485, floating contact, TCP/IP

3 AC output terminal

AC output for power supply connection

4 Data transmission interface (standard)

RS232

5 Interface for emergency shutdown

EPO

6 Feed for PV module

Plug and holders for the connection of the solar module:

ES4200: 3 connections (2 MPPT)

ES5000: 3 connections (2 MPPT)

Fig. 3-2 - 2 Display and connections ES4200 / ES5000

Photovoltaic Solar Inverter Series ES

Assembly

ES series

23

4. Assembly

Before starting the assembly of the photovoltaic solar inverter, take note

of Chapter 2, Safety instructions.

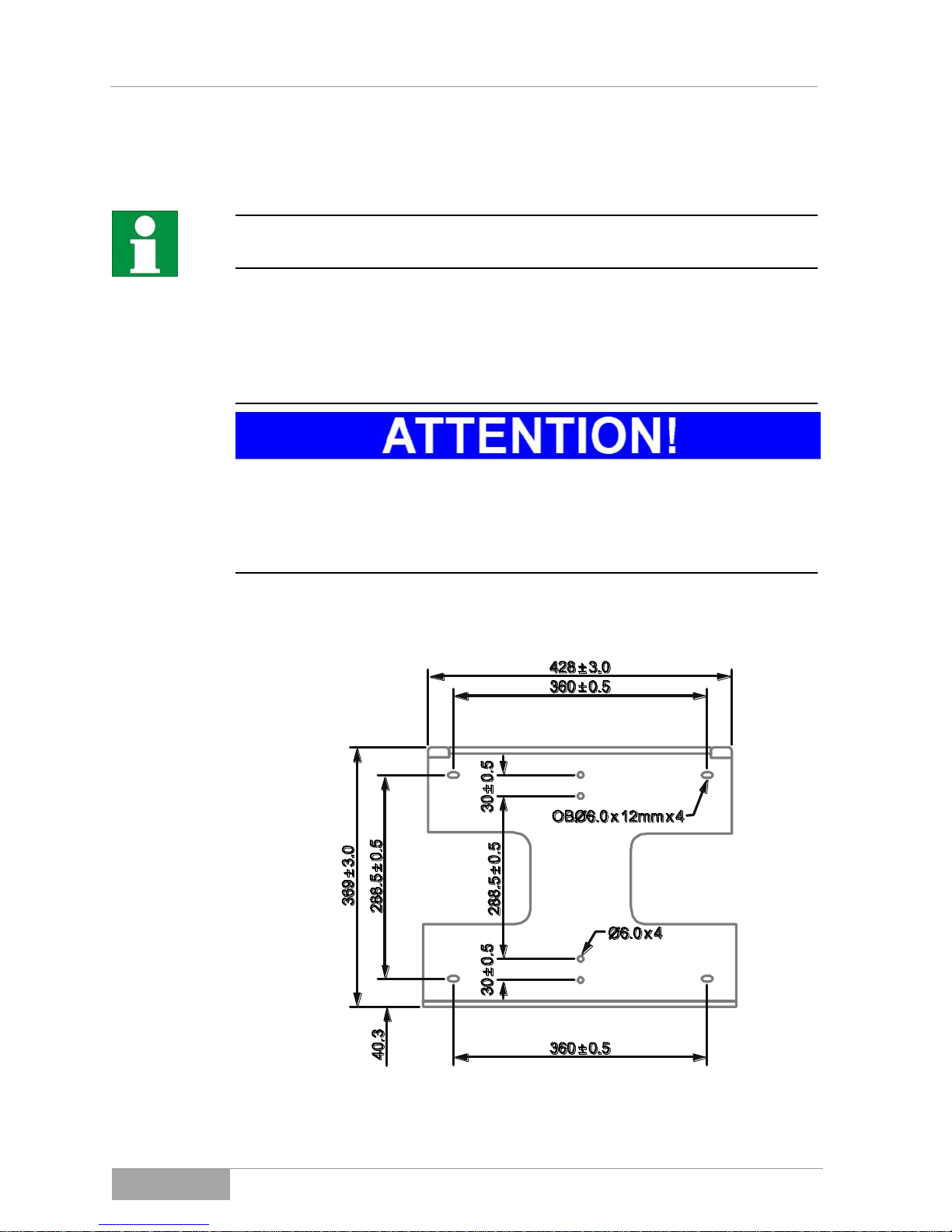

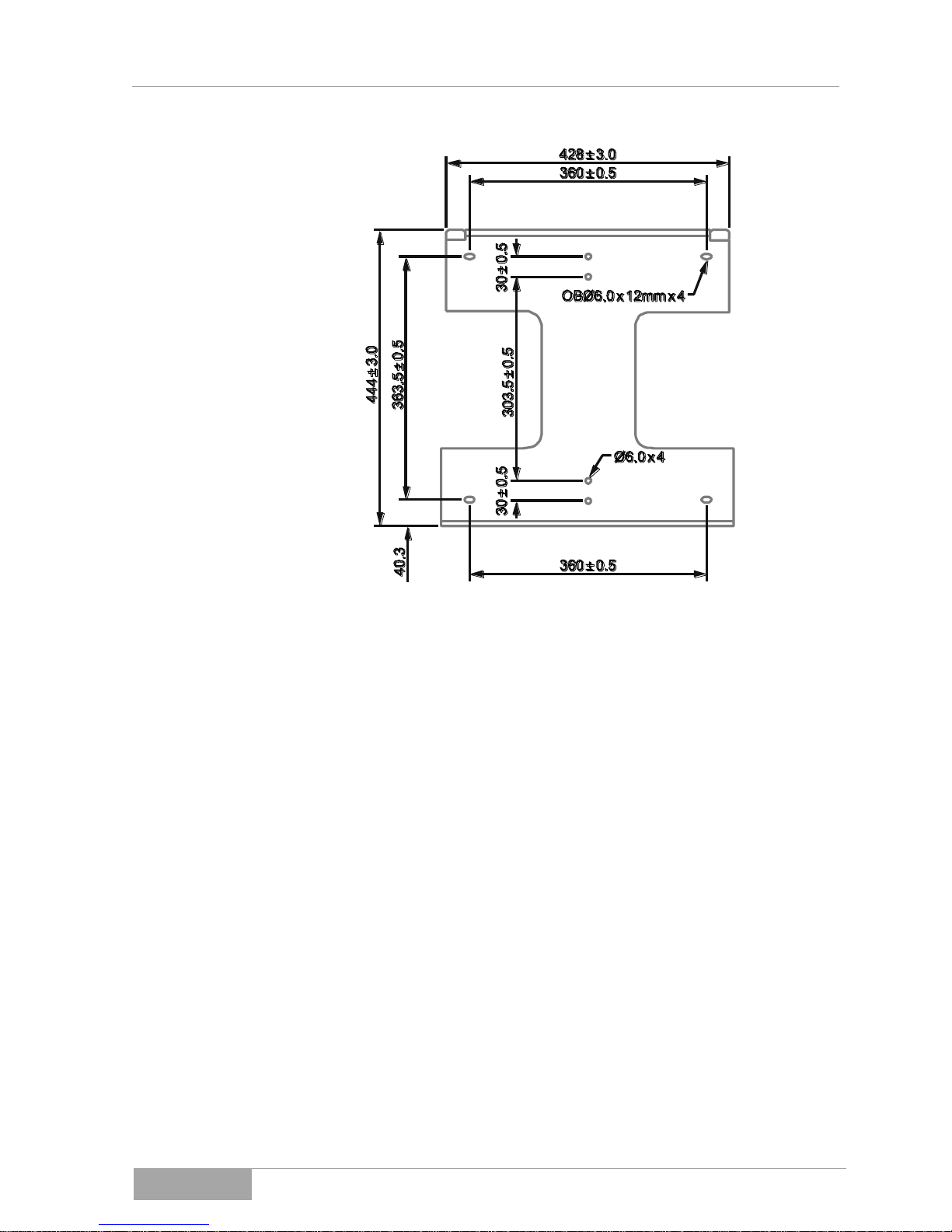

4.1 Assembly of the wall mounting

Before starting the assembly of the photovoltaic solar inverter, take note

of load bearing capacity of the wall.

There is a requirement for a load bearing capacity of at least 300 kg/m3.

Plasterboard or metal stud partition walls are not sufficient.

Dimensions for wall mounting

Fig. 4-1 - 1 Wall mounting for photovoltaic solar inverter ES2200 / ES3300

Photovoltaic Solar Inverter Series ES

Assembly

ES series

24

Fig. 4-1 - 2 Wall mounting for photovoltaic solar inverter ES4200 / ES5000

Photovoltaic Solar Inverter Series ES

Assembly

ES series

25

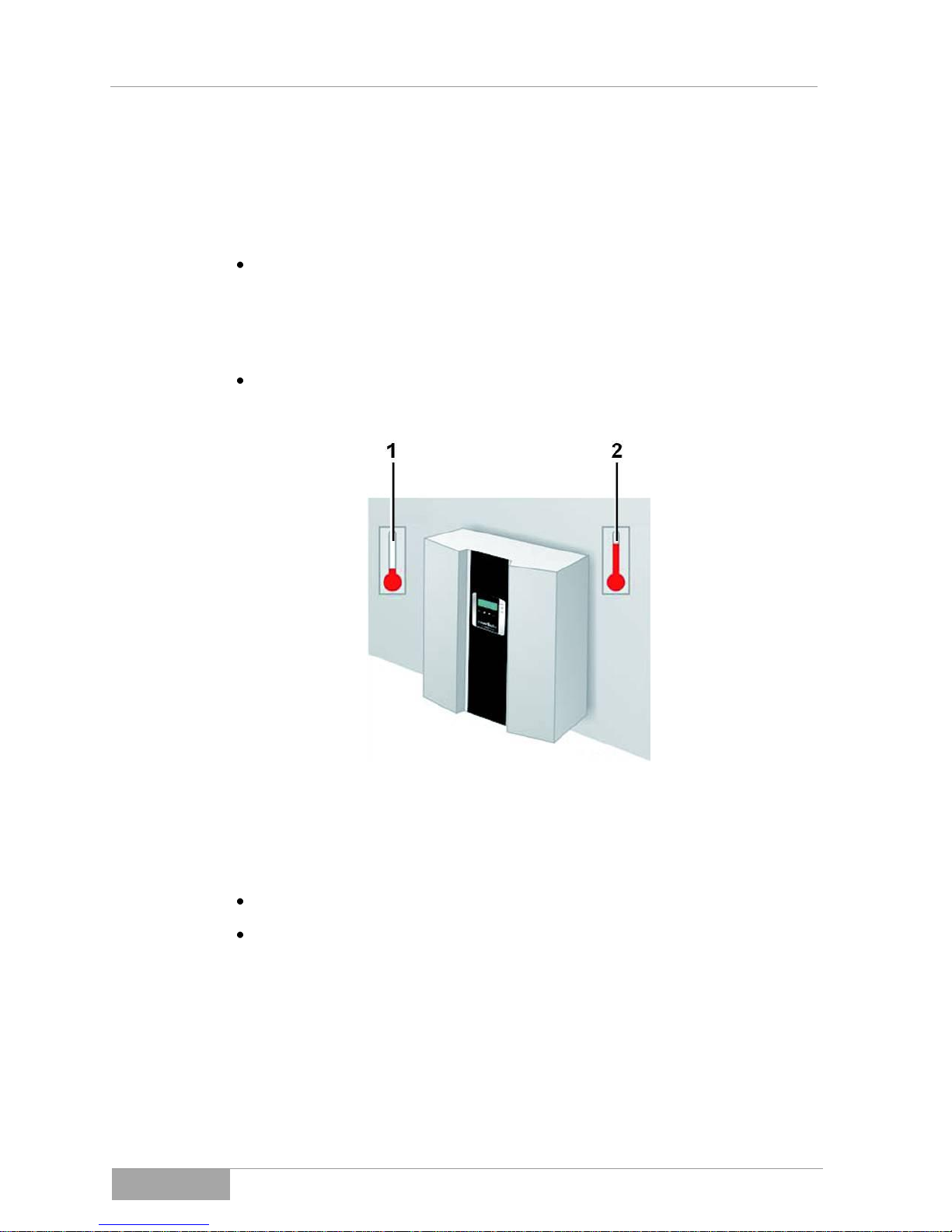

4.2 Ambient conditions for assembly

To guarantee perfect operation and a long service life, assemble the

photovoltaic solar inverter in accordance with the following requirements.

Select the coolest possible location for assembly.

High temperatures hamper the effectiveness and shorten the service

life of the photovoltaic solar inverter. If need be, install an additional

cooling system in the room in which the photovoltaic solar inverter is

assembled.

When assembling the photovoltaic solar inverter, the ambient

temperature must be in the range from - 25 °C to + 50 °C.

1 – 25 °C

2 + 50 °C

Fig. 4-2 - 1 Ambient conditions for assembly (temperature)

Relative humidity 0 % to 90 % (without condensation)

The photovoltaic solar inverter may not be exposed to any direct

solar radiation.

Photovoltaic Solar Inverter Series ES

Assembly

ES series

26

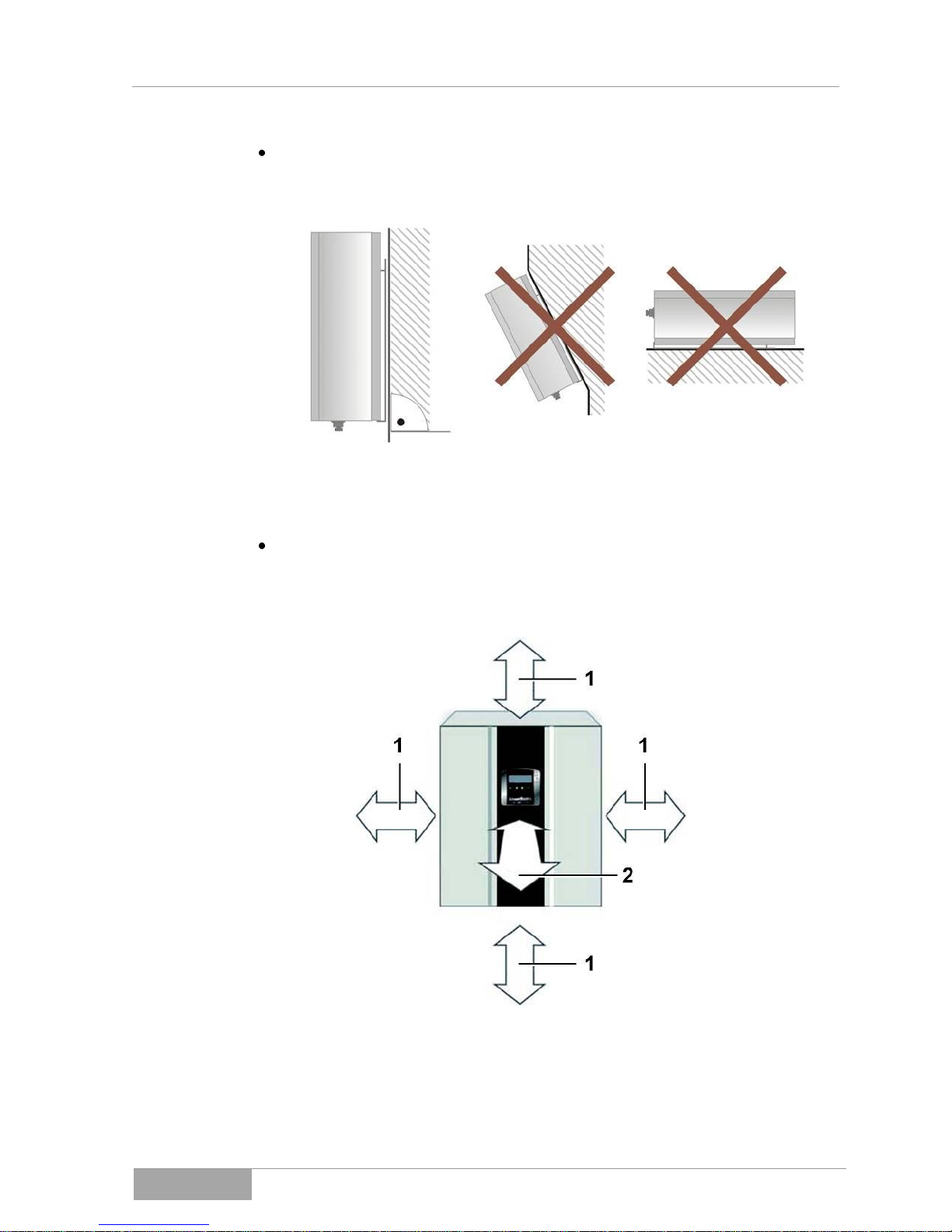

The photovoltaic solar inverter is constructed for vertical assembly.

Never assemble the photovoltaic solar inverter in a horizontal

position and make sure it does not tilt forward if assembled outdoors.

Fig. 4-2 - 2 Ambient conditions for assembly (positioning)

When selecting the assembly location for the photovoltaic solar

inverter, you must ensure that there is sufficient heat dissipation.

The following minimum amounts of free space around the

photovoltaic solar inverter must be maintained:

1 Spacing of at least 20 cm

2 Spacing of at least 5 cm

Fig. 4-2 - 3 Ambient conditions for assembly (spacings)

Photovoltaic Solar Inverter Series ES

Assembly

ES series

27

If the photovoltaic solar inverters are to be assembled above each other, we

recommend offsetting them because of the heat emissions.

1 Spacing of at least 20 cm

Fig. 4-2 - 4 Spacings with offset assembly

Photovoltaic Solar Inverter Series ES

Assembly

ES series

28

If the photovoltaic solar inverters are assembled directly above each other, the

spacings must be adhered to.

1 Spacing of at least 50 cm

Fig. 4-2 - 5 Spacings with inline assembly

Photovoltaic Solar Inverter Series ES

Assembly

ES series

29

4.3 Assembling photovoltaic solar inverters

When lifting heavy loads, take note of the local regulations of the

employers' liability insurance association and if necessary, use several

persons to lift the photovoltaic solar inverter.

Use the supplied wall mounting for the assembly of the photovoltaic solar

inverter.

When selecting the fixing material for vertical assembly using the wallmounting, take into account the weight of the photovoltaic solar inverter.

See Chapter 11, Technical data.

You can use the wall mounting to mark the holes for drilling. If you do not

want to use the wall mounting as a template for the drill holes, please

refer to the dimensions of the wall mounting in Chapter 4.1, Assembly of

the wall-mounting.

The selection of the fixing material is dependent on the characteristics of

the wall. Fixing material is not included in the scope of delivery and must

be supplied by the customer.

When selecting the fixing material, take into account the characteristics

of the wall and the weight of the photovoltaic solar inverter.

Photovoltaic Solar Inverter Series ES

Assembly

ES series

30

To mount the photovoltaic solar inverter, proceed as follows:

1. Mark the positions for the drill holes on the wall.

2. Drill the holes in accordance with the screws you have selected.

3. Screw on the wall mounting.

Fig. 4-3 - 1

4. Hang the photovoltaic solar inverter on the wall mounting. Use the upper

carrier plate so that the photovoltaic solar inverter cannot slip.

5. Check whether the photovoltaic solar inverter is safely attached to the

mounting.

1 Photovoltaic solar inverter

2 Wall

Fig. 4-3 - 2 Assembly of the photovoltaic solar inverter in the wall-mounting

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

31

5. Electrical Installation

There is risk of receiving a life-threatening electric shock if you touch live

components.

Only authorised electricians may work on electrical components or

equipment in accordance with electrotechnical rules.

2 Safety Instructions

1 String A

2 String B

3 Data transfer

4 AC output

Fig. 5 - 1 Wiring of the photovoltaic solar inverter

(Example ES4200 / ES5000)

Two strings can be connected with the ES4200 / ES5000 models. Here it

should be ensured that the load on both strings is symmetrical.

This means: One input on the photovoltaic solar inverter can process

50 % of the rated power and may be overloaded by a maximum of 10 %.

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

32

5.1 Connecting AC power cable

There is risk of receiving a life-threatening electric shock if you touch live

components.

Only authorised electricians may work on electrical components or

equipment in accordance with electrotechnical rules.

2 Safety Instructions

There is risk of receiving a life-threatening electric shock if a grounding is

missing or is incorrectly connected.

Make sure that the grounding conductor is correctly connected

before you start operating the photovoltaic solar inverter.

Position the cable inlet and screw it to the housing of the

photovoltaic solar inverter.

Connection conditions

Take note of the connection conditions of your mains power supplier.

Pay attention to the locally required country settings on the photovoltaic

solar inverter.

7.2 Country settings, operating mode settings and ID settings

Ground fault circuit breaker

The photovoltaic solar inverter is equipped with an integrated ground

fault circuit breaker.

If an external RCD or FI circuit breaker is required, please use a type B

circuit breaker which triggers above a 100 mA fault current.

Cable line layout

The mains line resistance should not exceed 0.1 Ω as this causes a high

voltage drop and a loss.

Your electricity supplier must calculate the maximum line lengths after

taking the cross section of the line into consideration.

The following cable sizes are recommended for the AC power cables:

Model

Line cross section

ES2200 / ES3300

4 mm2

ES4200 / ES5000

6 mm2

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

33

1 String B

2 String A

3 DC connection socket switched off

4 AC connection socket switched off

5 Bi-directional measuring instrument

6 Public supply network

Fig. 5-1 - 1 Overview of the cable lines

To connect the AC cable, please proceed as follows:

Measure the voltage and frequency of the supply mains.

Supply voltage and frequency are country-specific.

In order to separate the photovoltaic solar inverter from the mains power and

the PV modules, a customer-supplied circuit-breaker must be installed for each

circuit.

11.4 Scope of Delivery / (Optional) Accessories

The AC circuit-breaker may not break the grounding.

In order to separate the photovoltaic solar inverter on the AC side, customer-

supplied circuit-breakers must be supplied.

l

ES2200

ES3300

ES4200

ES5000

Circuit-breaker

B10

B16

B20

B25

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

34

Even after the circuit-breaker is switched off, individual sub-assemblies

and components of the photovoltaic solar inverter still have a lifethreatening level of voltage charge.

You should make sure that all the sub-assemblies and components of the

photovoltaic solar inverter are voltage-free before starting work.

Fig. 5-1 - 2 Removing cable inlet

Loosen the screws of the cable inlet and remove it.

Fig. 5-1 - 3 Cable inlet

Insert the supply cable through the cable inlet and connect the wires as

indicated on the splitter:

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

35

1 PE Grounding conductor (yellow-green)

2 N Neutral

3 L Conductor

Fig. 5-1 - 4 Power cable connection

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

36

5.2 Connecting PV module

Before installation, check whether your PV modules are suitable for

operation with your photovoltaic solar inverter.

Not all PV modules are suitable for operation with transformerless

photovoltaic solar inverters.

Check with the PV module manufacturer.

5.2.1 Requirements the PV modules have to meet

The ES4200 / ES5000 photovoltaic solar inverters both have two MPP trackers

(each with approx. 50% of the total output of the inverter). Of these, tracker A

has a connection for up to 2 strings and tracker B for one string.

The ES2200 / ES3300 photovoltaic solar inverters have only one MPP tracker

with a connection for up to 3 strings. Both the maximum DC input voltage of

500 V and the maximum input current may not be exceeded.

The PV module connection cables must be suitable for these connections.

A set of connectors for connecting the line ends of a string is included in the

scope of delivery. The type descriptions for other PV connectors are:

– Connection plug: PV-KST4/6II-UR

– Coupling socket: PV-KBT4/6II-UR

You will find more information online at www.multi-contact.com.

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

37

5.2.2 Cabling to the PV module

The photovoltaic solar inverters are equipped with type MC4 PV quick

connecting terminals. These allow up to three of the same strings to be directly

connected with the ES2200 / ES3300 and up to two of the same strings to

tracker A and one string to tracker B with the ES4200 and ES5000.

Please take note of the symmetrical power distribution between tracker A

and B.

The connection of additional strings is possible. These must be externally

connected. We recommend connecting further strings in parallel to the DC

circuit-breaker.

1 PV quick connections

Fig. 5-2-2 - 1

There is risk of receiving a life-threatening electric shock if you touch live

components.

Only authorised electricians may work on electrical components or

equipment in accordance with electrotechnical rules.

2 Safety Instructions

Make sure that the DC circuit breaker is in the "OFF" position before you

connect the PV module.

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

38

Attention! Danger of material damage

In determining the required panels in the PV string, please take note of

the following points:

To avoid damage to the photovoltaic solar inverter, make sure that

the output on the PV module is never above 500 VDC.

Make sure that the maximum open circuit voltage UOC of each PV

string is less than 500 VDC. Voltages of over 500 VDC may damage

the photovoltaic solar inverter.

Make sure that the short circuit current of the module is not greater

than the measurement on the photovoltaic solar inverter.

To achieve the maximum energy output from your PV module, make

sure that the voltage does not fall below 150 VDC at maximum UMP

performance or exceed 450 VDC.

Within one tracker, only modules of the same type with the same power

can be used.

Two strings can be connected with the ES4200 / ES5000 models. Here it

should be ensured that the load on both strings is symmetrical.

This means: One input on the photovoltaic solar inverter can process

50% of the rated power and may be overloaded by a maximum of 10%.

To connect the PV module to the photovoltaic solar inverter, proceed as

follows:

1. Check whether the generator terminals have the correct polarity and do not

exceed the maximum voltage for each string.

2. Connect the positive (+) wire of the PV string 1 to the positive quick

connection terminal on the photovoltaic solar inverter.

3. Connect the negative (-) wire of the PV string 1 to the negative quick

connection terminal on the photovoltaic solar inverter.

Repeat steps 2 and 3 for other PV strings.

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

39

4. Check whether all wires and contacts have been connected correctly.

5. Cover the unused sockets of the DC input with the supplied protective caps.

6. Start up the photovoltaic solar inverter.

5.2.3 Overview of cabling for the PV module

1 String A

2 String B

3 DC connection socket switched off

Fig. 5.2.3 - 1 ES4200 / ES5000 cabling overview using 4-pin

DC disconnector for each string on tracker A and/or B

Photovoltaic Solar Inverter Series ES

Electrical Installation

ES series

40

1 String A

2 DC connection socket switched off

Fig. 5.2.3 - 2 ES4200 / ES5000 cabling overview in parallel operation

using 2-pin DC disconnector (all modules before the DC

disconnector cabled on one string)

In the case of wiring with one string, you must switch the operating mode in the

configuration to "parallel"; see Chapter

ê 7.2 Country settings, operating mode settings and ID settings

Please note that the ES2200 / ES3300 only have one tracker with connections

for three of the same strings (internally switched in parallel).

If you connect the strings individually, you need a corresponding DC

disconnector for several (4-pin of 6-pin) strings.

Photovoltaic Solar Inverter Series ES

Control Panel

ES series

41

6. Control Panel

1 LCD display

2 LED display

3 Operating keys

Fig. 6 - 1 Control panel

1

LCD display

LINE

Power source

Service operation

Solar cells

Flow chart of the photovoltaic solar inverter in

operation

4-position measurement display

Photovoltaic Solar Inverter Series ES

Control Panel

ES series

42

2

LED display

Red LED lights up constantly - indicates a ground fault or an

isolation fault at the DC input.

Yellow LED lights up constantly - indicates that the supply

(voltage, frequency, etc.) does not correspond to the entered

standard of the photovoltaic solar inverter.

o Green LED lights up constantly - indicates that the

performance of the solar cells is greater than 5 % of the

nominal performance of the photovoltaic solar inverter.

o Green LED blinks - indicates that the performance of the

solar cells is less than 5 % of the nominal performance of

the photovoltaic solar inverter.

3

Operating keys

Confirm a change to the settings of the photovoltaic solar

inverter.

Continue to next page or change the settings of the

photovoltaic solar inverter.

Return to the previous page or change the settings of the

photovoltaic solar inverter.

Special function Log in / Log out.

Log in / Log out

The Log in / Log out function gives you the option of displaying the internal

settings of the photovoltaic solar inverter.

The settings can only be display but not changed.

The following settings are displayed when you operate the Log in / Log out key:

– Bus address

– Country setting

– Operating mode

You can scroll up and down through the settings with the arrow up/arrow down

keys.

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

43

7. Commissioning

There is risk of receiving a life-threatening electric shock if you touch live

components.

Only authorised electricians may work on electrical components or

equipment in accordance with electrotechnical rules.

2 Safety Instructions

Check the following points before you start up the photovoltaic solar

inverter:

The housing is safely screwed in place.

The DC cables (PV strings) are completely connected and unused DC

connection terminals on the bottom of the housing are covered with

safety caps.

The AC cable is connected correctly.

The AC switch is "OFF".

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

44

7.1 Starting device for the first time

Switch on the voltage of the PV string by turning on the DC circuit breaker.

The photovoltaic solar inverter starts automatically when the voltage reaches

120 VDC. All LEDs light up. The following is shown on the LCD display:

Fig. 7-1 - 1 Display A

After 3 seconds, the LCD display changes from Display A to Display B1 (total

feed power) and Display B2 (alarm code).

The green LED blinks to indicate that the output performance of the alternating

current is below 5 % of the nominal performance.

The yellow LED lights up constantly and indicates no power.

Fig. 7-1 - 2 Display B1

Fig. 7-1 - 3 Display B2

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

45

7.2 Country settings, operating mode settings and

ID settings

Make sure before changing the settings that the AC switch is "OFF".

1. Press the key and the key simultaneously for about 5 seconds.

The solar inverter switches to the mode "Settings" and you see the

following display:

2. Press the key to select the appropriate country settings:

dE (Germany), ES (Spain), It (Italy), Fr (France), bE (Belgium),

Pt (Portugal), Gb (Great Britain), CZ (Czech Republic), Gr (Greece),

nL (Netherlands), Au (Austria), EC (User defined).

Incorrect country settings can compromise your mains electricity, cause the

photovoltaic solar inverter to malfunction and lead to the termination of your

authorisation to operate the device.

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

46

3. Press the key to confirm the selection and to proceed to the operating

mode selection.

4. Select either "Standard" or "Parallel" operation with the key.

The display shows:

5. Press the key to confirm the selection and to proceed to the setting

of the ID number.

You can assign an identification number (ID no.) to your photovoltaic

solar inverter in the range from 1 - 200.

You need the ID number to be able to differentiate between different

photovoltaic solar inverters in one system. To do this, each photovoltaic solar

inverter must be assigned a different ID number.

6. Change the ID number in a range of 1 to 200 with the key or the

key.

The display shows:

7. Press the key to save the settings.

The display shows:

The photovoltaic solar inverter goes into normal operating mode automatically

after 2 seconds.

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

47

7.3 Commissioning the photovoltaic solar inverter

Check whether the DC circuit breaker is switched on and set it to "ON" if

necessary.

Set the AC circuit breaker to "ON".

Wait 30 seconds (legally required waiting period).

The LCD display changes between the Displays C1 (total feed power) and

Display C2 (alarm code). The yellow LED lights up and the green LED

blinks.

Fig. 7-3 - 1 Display C1

Fig. 7-3 - 2 Display C2

After 30 seconds, the yellow LED goes off and the green LED blinks again. The

LCD display shows Display D.

Fig. 7-3 - 3 Display D

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

48

After 5 seconds, the LCD display shows Display E. The green LED lights up

constantly.

Fig. 7-3 - 4 Display E

If the photovoltaic solar inverter is working incorrectly, e.g. short circuit, an error

code or the error status will appear on the display.

Fig. 7-3 - 5 Display F

A list of possible error codes with explanations can be found in

Chapter 9, Error codes and explanations.

If the photovoltaic solar inverter was started up completely and successfully,

the LCD display shows Display E.

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

49

7.4 Checking measurement readings and numbers

You can check the measurement readings and numbers determined by the

photovoltaic solar inverter through the LCD display.

Use the and buttons to scroll the displays.

The measurement readings and numbers are shown in the following order

when scrolling downwards:

Fig. 7-4 - 1 Display G - Total feed power

Fig. 7-4 - 2 Display H - Internal temperature of the photovoltaic solar

inverter in °C

Fig. 7-4 - 3 Display I - Temperature of cooling element in °C

Fig. 7-4 - 4 Display J - Internal temperature of the photovoltaic solar

inverter in °F

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

50

Fig. 7-4 – 5 Display K - Temperature of cooling element in °F

Fig. 7-4 - 6 Display L - String A voltage

Fig. 7-4 - 7 Display M - String B voltage

Fig. 7-4 - 8 Display N - String A current

Fig. 7-4 - 9 Display O - String B current

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

51

Fig. 7-4 - 10 Display P - String A output power

Fig. 7-4 - 11 Display Q - String B output power

Fig. 7-4 - 12 Display R - Output voltage of the photovoltaic solar inverter

Fig. 7-4 - 13 Display S - Frequency of the photovoltaic solar inverter

output voltage

Fig. 7-4 - 14 Display T - Output current of the photovoltaic solar inverter

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

52

Fig. 7-4 - 15 Display U - Current feed power

7.5 Operating states of the photovoltaic solar

inverter

The photovoltaic solar inverter starts automatically when the PV panel DC

power is sufficient.

After starting, the photovoltaic solar inverter goes into the following operating

states.

Operating

state

Display on the

LCD display

Explanation

Normal

The photovoltaic solar inverter

is working normally.

When the delivered

performance of the PV panel

is sufficient

(500 VDC > PV >120 VDC), it

supplies the energy to the

mains.

The green LED lights up and

shows that energy is being fed

into the mains.

Standby

If the performance is

insufficient

(60 VDC < PV < 100 VDC),

the photovoltaic solar inverter

switches to standby operation

and searches for a connection

to the mains.

It has only limited power from

the PV module to monitor the

internal system state.

Photovoltaic Solar Inverter Series ES

Commissioning

ES series

53

Operating

state

Display on the

LCD display

Explanation

Error

The internal regulator

continually monitors the

system state and adjusts it.

If the photovoltaic solar

inverter registers malfunctions,

such as mains problems or

internal errors, this is showed

on the display and the red

LED lights up.

EPO

Emergency power off.

The photovoltaic solar inverter

does not receive any power

from the mains in this state.

Shut down

process

No display

If there is too little sunlight, the

photovoltaic solar inverter

automatically ends operation.

It does not receive any power

from the mains. The display

and the LEDs on the control

panel are out of operation.

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

54

8. Communication Interfaces

You can connect external devices such as PC, Solar-Log or Ethernet (SNMP

card) to the photovoltaic solar inverter to call up data from it. The various

communication interfaces are designed for this.

8.1 Standard communication interface

The standard communication interface for the photovoltaic solar inverter is an

RS232 serial interface (otherwise known as EIA-232).

8.1.1 Settings for the RS232 interface

The RS232 interface is set as follows:

– Baud rate: 9600 bps

– Data length: 8 Bit

– Stop bit 1 Bit

– Parity: None

8.1.2 Pin assignment of the RS232 interface

Pin 3: RS232 Rx

Pin 2: RS232 Tx

Pin 5: GND

Fig. 8-1-2 - 1 Pin assignment:

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

55

8.2 Solar-LogTM

Our photovoltaic solar inverters are suitable for operation

with Solar-LogTM. Our Sales and Service team

will be pleased to give you information about accessories

and technical details.

8.3 Optional data cards

If you need other interfaces than the standard communication interface, you

can install an optional communication card.

Data cards should only be plugged in when the photovoltaic solar inverter is

switched off. Otherwise, the photovoltaic solar inverter can be seriously

damaged as a result.

8.3.1 Installing communication cards

Fig. 8-1-3 - 1 Open the housing cover

Loosen the screws and open the cover of the housing.

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

56

Fig. 8-1-3 - 2 Data cable

Insert the data cable through the cable inlet of the cover.

Fig. 8-1-3 - 3 Connect the communication card

Connect the data cable to the communication card.

Fig. 8-1-3 - 4 Insert the communication card

Insert the communication card in the receiver.

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

57

Fig. 8-1-3 – 5 Fasten the cover

Place the cover back on top and tighten the four screws evenly.

8.3.2 RS485 card

Fig. 8-1-2 - 1 RS485 card

CN1 is intended for the terminating resistor. You can activate the function with

pin 1 - 2 (terminating resistor jumper "ON"); you can deactivate the function

with pin 2 - 3 (terminating resistor jumper "OFF"). CN2 is intended for RS485

and CN3 for remote start-up.

Definition:

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

58

8.3.3 RS485 interface wiring

DC Several photovoltaic solar inverters with Solar-LogTM

1 Solar inverter address 1

2 Solar inverter address 2

3 Solar inverter address 3

4 Solar inverter address 4

5 Solar-LogTM

6 RS485

7 Terminating resistor jumper "ON"

Fig. 8-3-3 - 1 Solar-LogTM

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

59

2. Several photovoltaic solar inverters connected to a PC

1 Solar inverter address 1

2 Solar inverter address 2

3 Solar inverter address 3

4 Solar inverter address 4

5 PC

6 RS485/RS232 adapter

7 RS485

8 Terminating resistor jumper "ON"

Fig. 8-3-3 - 2 Connection to the PC

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

60

DCI Connection to the RS485 card (first photovoltaic solar

inverter)

1 Nothing should be connected here

2 4-core, twisted-pair, screened cable

Fig. 8-3-3 - 3 Connect the RS485 card (first photovoltaic solar inverter)

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

61

DCII Connection to the RS485 card (several photovoltaic

solar inverters)

1 Free

2 Jumper = OFF

3 Screen to PE

4 4-core, twisted-pair, screened cable

5 Screen, one-sided, to PE

6 4-core, twisted-pair, screened cable

7 Screen, one-sided, to PE

Fig. 8-3-3 - 4 Connect the RS485 card

(several photovoltaic solar inverters)

In the case of several photovoltaic solar inverters, the RS485 bus is looped

through the individual photovoltaic solar inverters. The bus cables D-, D+ and

GND (incoming and outgoing) are connected in parallel to the screw

connectors on the Rs485 card. The screening on the bus cables should each

only be connected at one end with the PE on the photovoltaic solar inverter

housing.

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

62

8.3.4 USB card

Fig. 8-3-4 - 1 USB card

Definition:

– Compatible USB version 1.0, 1.5 MBit/s

– Compatible HID Version 1.0

Pin assignment for the USB card

1 VCC (+ 5 V)

2 D –

3 D +

4 GND

Fig. 8-3-4 - 2 USB card pin assignment

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

63

8.3.5 Relay contact card (DCE-B card)

Fig. 8-3-5 - 1 Relay contact card (DCE-B card)

The pin assignment of the 10 pin terminal

1 Pin 1:

One DC input voltage within and one DC

input voltage below the range

2 Pin 2:

At least one DC input above the minimum

limit

3 Pin 3:

All DV input voltage below the minimum

limit

4 Pin 4:

Frequency of the AC output (mains)

outside the tolerance

5 Pin 5:

Isolated operation switched off

6 Pin 6:

Output current of the photovoltaic solar

inverter above the tolerance

7 Pin 7:

The cooling element temperature of the

photovoltaic solar inverter is too high

8 Pin 8:

Common

Fig. 8-3-5 - 2 The pin assignment of the 10 pin terminal

Photovoltaic Solar Inverter Series ES

Comunication Interfaces

ES series

64

Each relay contact can take a load of max 40 VDC / 25 mA.

You can switch the output signal from N.C. (normal close) to N.O. (normal

open) by bridging Pin 1 and 2 or Pin 2 and 3 from JP1-5 with the jumpers.

8.3.6 SNMP card

Fig. 8-3-6 - 1 SNMP card

You will find more information and installation advice in the documents that

accompany the SNMP card.

Photovoltaic Solar Inverter Series ES

Status Diagnosis and Troubleshooting

ES series

65

9. Status Diagnosis and

Troubleshooting

The photovoltaic solar inverter is equipped with a self-diagnosis system that

identifies a large number of possible operating procedures independently and

shows them on the LCD display. This makes it possible to quickly eliminate

technical problems.

Furthermore, a differentiation is possible between

– Service codes concerning installation and

– Service codes that relate internally to the photovoltaic solar inverter

Whenever the self-diagnosis system identifies a particular problem, the

appropriate service code is showed on the LCD display.

The following work may only be performed by trained technical staff

9.1 Error codes and explanations

LCD

display

Description

Explanation

Troubleshooting

Er00

DC_BUS

pre-Charge fail

The device is in soft start

mode, but after 2 seconds,

no stable charging

voltage is determined on

the DC bus.

1. Disconnect all PV (+)- or

PV (-) connections.

2. Wait a few seconds.

3. After the LCD display goes

out, reinsert all the

connections and check it

again.

4. If the error occurs again,

please contact your dealer.

Er03

Inverter voltage

abnormal

The output voltage is not

correct.

Er07

DC_BUS

over-voltage

The internal voltage of the

DC bus is outside the

tolerance.

Er08

DC_BUS

under-voltage

Photovoltaic Solar Inverter Series ES

Status Diagnosis and Troubleshooting

ES series

66

LCD

display

Description

Explanation

Troubleshooting

Er19

DC_BUS

discharge failure

The capacitors of the DC bus

cannot be discharged

correctly.

1. Disconnect all

PV (+)- or PV (-)

connections.

2. Wait a few seconds.

3. After the LCD

display goes out,

restore all the

connections and

check again.

4. If the error occurs

again, please

contact your dealer.

Er22

Output Relay fail

Malfunction on the output relay

of the photovoltaic solar

inverter.

Er24

Output current

sense fail

Error in the output current

reading.

Er25

BOOSTER_A

over-current

The current in the DC mains is

higher than expected.

Er26

BOOSTER_B

over-current

Er29

PV inverter output

DC current over

spec.

DC current at output of

photovoltaic solar inverter is

too high.

Er06

EPO

The photovoltaic solar inverter

is in emergency power off

mode.

5. Detach the

connection at the

EPO connection.

6. If the error occurs

again, please

contact your dealer.

Er09

PV inverter

over-current

Over-current on the AC side.

The current in the AC mains is

higher than expected.

7. Turn off the AC

current switch, check

the peripheral AC

current system

configurations and

the mains

conditions.

8. If the error occurs

again, please

contact your dealer.

Er11

PV inverter

over-load

Over-load on the AC side.

The mains load in the AC

mains is higher than

expected.

Er13

PV inverter

short-circuit

Short circuit on the AC side.

Er14

PV inverter

PLL failure

The photovoltaic solar inverter

is not in phase with the mains

electricity.

Photovoltaic Solar Inverter Series ES

Status Diagnosis and Troubleshooting

ES series

67

LCD

display

Description

Explanation

Troubleshooting

Er10

PV inverter

over temperature

The indoor temperature is

too high.

9. Try to reduce the

surrounding

temperature.

10. Install the photovoltaic

solar inverter in a cooler

place.

11. If the error occurs again,

please contact your

dealer.

Er18

Heat sink

over temperature

The temperature on the

cooling element is too

high.

Er01

Ground fault

The fault current has

reached the authorised

upper limit.

12. Disconnect the feed from

the PV generator and

check the peripheral AC

system.

13. When the reason is

found, reconnect the PV

panel and check the

status of the photovoltaic

solar inverter.

14. If the error occurs again,

please contact your

dealer.

Er17

EEPROM

ERROR on the

control board

EEPROM data is faulty.

15. Please contact your

dealer.

Photovoltaic Solar Inverter Series ES

Status Diagnosis and Troubleshooting

ES series

68

9.2 Mains error alarm codes and explanations

LCD

display

Description

Explanation

Troubleshooting

AL00

Utility Voltage

Over-Voltage

The mains voltage is

higher or lower

than the authorised

amount.

16. Wait 5 minutes. When the

mains supply returns to

normal, the photovoltaic

solar inverter starts up

automatically.

17. Check the mains

connection (cable and

terminals).

18. Make sure the mains

voltage and frequency

meet the requirements.

19. If the error occurs again,

please contact your dealer.

AL01

Utility Voltage

Under-Voltage

AL02

Utility Voltage

Over Frequency

The mains frequency

is higher or lower than

the authorised

amount.

AL03

Utility Voltage

Under Frequency

AL04

BOOSTER_A

Input

Over-Voltage

Under or over-voltage

of the DC input.

20. Disconnect all PV (+)- or

PV (-) connections.

21. Check whether the PV

voltage is under 120 VDV

or above 500 VDC.

22. If the voltage is within this

range and the problem

continues, please contact

your dealer.

AL05

BOOSTER_A

Input

Under-Voltage

AL06

BOOSTER_B

Input

Over-Voltage

AL07

BOOSTER_B

Input

Under-Voltage

AL08

Anti-Islanding

No mains supply or

mains outside the

tolerances.

23. Disconnect all PV (+)- or

PV (-) connections.

24. Check the mains

connection (cable and

terminals).

25. Check the phasing and the

waveform of the mains

supply.

26. If the supply is normal and

the problem persists,

please contact your dealer.

AL13

Phase of

Utility fail

AL14

Waveform of

Utility fail

Photovoltaic Solar Inverter Series ES

Status Diagnosis and Troubleshooting

ES series

69

LCD

display

Description

Explanation

Troubleshooting

AL09

Inverter Voltage

unbalance

The waveform of the

voltage of the

photovoltaic solar

inverter is outside the

tolerance.

27. Shut down the photovoltaic

solar inverter (disconnect

PV generator from the

feed).

28. Restart the photovoltaic

solar inverter (plug the PV

generator into the feed).

29. If the error occurs again,

please contact your dealer.

AL10

GFDI

The fault current of the

grounding wire is too

high.

30. Disconnect the PV

generator from the feed

and check the peripheral

AC system.

31. When the problem is

resolved, reconnect the

PV. Check the status of

the photovoltaic solar

inverter.

32. If the error occurs again,

please contact your dealer.

AL11

Isolation Fault

The insulation

between the PV

connections and the

earth is less than

1 MΩ.

33. Disconnect all PV (+)- or

PV (-) connections.

34. Check the impedance

between PV (+), PV (-)

and the ground (must be

more than 2 MΩ).

35. If the error occurs again,

please contact your dealer.

Photovoltaic Solar Inverter Series ES

Service

ES series

70

10. Service

There are no parts on the photovoltaic solar inverter that have to be maintained

by the customer.

Clean the device at regular intervals with a dry, soft towel to avoid an

accumulation of dust.

In particular, clean the cooling fins on the back of the device.

Service hotline and contact addresses

If unexpected problems occur with the photovoltaic solar inverter or you need

safety information, please contact our service hotline:

Phone no.: 0049 / (0) 741 – 17451-0

Fax no.: 0049 / (0) 741 – 17451-29

If you cannot reach us by phone or fax, we have set up an e-mail contact for

you:

solar-service@effekta.com.

You will also find additional contact addresses online at:

http://www.effekta.com/html/kontakt.html.

You will find the entire spectrum of our services at:

http://www.effekta.com/html/service/html.

You will find an exchange form to download under:

http://www.effekta.com/pdf/Austausch_SolarPhotovoltaik-Wechselrichter.zip.

Photovoltaic Solar Inverter Series ES

Technical Data

ES series

71

11. Technical Data

11.1 Device specifications

ES2200

ES3300

ES4200

ES5000

Photovoltaic

solar inverter

technology

Implementation

Sinusoidal, power source,

high frequency pulse width modulation (PWM)

Isolation method

Execution without isolation transformer

(without galvanic isolation)

Input data

DC

Rated DC

360 VDC

Max. input DC

500 VDC

Work area

120 VDC to 500 VDC**

Max. electricity

per MPP tracker

14.6 A

22 A

(2 x) 14 A

(2 x)

17.65 A

Max. power per

MPP tracker

2200 W

3300 W

2100 W

2650 W

MPPT range

150 VDC to 450 VDC

MPP tracker 1 2

Output data

AC

Nom. AC power

2000 W

3000 W

4000 W

4600 W

Max. AC power

2200 W

3300 W

4200 W

5000 W

Nominal AC

voltage

230 V~

Type of output

connection

Single-phase, mains connection (L, N, PE)

AC voltage range

184 VAC to 264.5 VAC (Base 230 VAC)

Nominal

alternating

current

8.69 A

13 A

17.7 A

20.0 A

Frequency

50/60 Hz, automatic settings

Power factor

>0.99 with nominal alternating current

Distortion factor

of current (sinus

deviation)

Percentage of total harmonious vibration: Below 5 %

of harmonious individual vibration: Below 3 %

Photovoltaic Solar Inverter Series ES

Technical Data

ES series

72

ES2200

ES3300

ES4200

ES5000

Efficiency

data

Max.

implementation

performance

> 96 %

Euro power

> 94 %

CEC power

> 94 %

Standby

consumption

< 7 W

Night-time

consumption

approx. 1 W

Environment

Operating

temperature

- 25 ℃ to + 50 ℃ (- 13 °F to 122 °F)

Humidity

0 to 90 % (without condensation)

Technology

Dimensions

(H x W x D mm)

430 x 455 x 190

510 x 455 x 190

Weight (net)

27 kg

29 kg

Weight (gross)

30.5 kg

32.5 kg

Protective class

IP65 (outdoor area)

Cooling

Convection

AC connection

Screw connection

DC connection

MC4 plug

Communicati

on

Standard

RS232

Optional

USB, RS485, relay contact, SNMP

Photovoltaic Solar Inverter Series ES

Technical Data

ES series

73

ES2200

ES3300

ES4200

ES5000

Control

Panel

LCD display

Input DC voltage / input direct current / input DC power /

output AC voltage / output alternating current / output

frequency / output AC power /

Energy output / internal temperature / cooling element

temperature / status message / error message

LED display

Red:

Grounding fault or

DC input isolation fault

Yellow:

Supply conditions do not

correspond to the

input standard of the

photovoltaic solar inverter

Green:

Performance of solar cells

is above or below 5 % of

the nominal performance

of the

photovoltaic solar inverter

Operating keys

Navigation keys / function key / enter key

Safety

Mains

Over-/ under-voltage, over-/ under-frequency,

grounding fault, DC isolation error, no isolated

operation

Short circuit

DC input:

Reverse pole protection / electronic switching

AC output:

Output relay / electronic switching

EPO

(emergency

power off)

The photovoltaic solar inverter switches off immediately

Overtemperature

≤ 50 °C (122 °F) at full capacity

≥ 50 °C(122 °F) at reduced capacity

Certification

Safety

Europe VDE0126-1-1, EN50178, IEC62103

EMI/EMC

EN 61000-6-1, EN 61000-6-2,

EN 61000-6-3, EN 61000-6-4

** The nominal range should be between 150 VDC and 500 VDC to achieve nominal power.

Photovoltaic Solar Inverter Series ES

Technical Data

ES series

74

11.2 ES2200 / ES3300 Block diagram

Photovoltaic Solar Inverter Series ES

Technical Data

ES series

75

11.3 ES4200 / ES5000 Block Diagram

Photovoltaic Solar Inverter Series ES

Technical Data

ES series

76

11.4 Scope of Delivery / (Optional) Accessories

Check the completeness of the delivery after receiving the goods:

Description

Function / View

Article number

***

1

Photovoltaic solar

inverter

ES2200:

SLWRABSI2K0Wx000

or

ES3300:

SLWRABSI3K0Wx000

or

ES4200:

SLWRABSI4K0Wx000

or

ES5000:

SLWRABSI5K0Wx000

X

1

Wall mounting

Assembly plate for

wall mounting

Upon request

X

3

PV coupling plug

Coupling plug

PV-KST4/6II-UR

PV-KST-4-6.0

X

3

PV coupling bush

Coupling bush PV-KBT4/6II-

UR

PV-KBT-4-6.0

X

3

PV closure cap

for coupling plug

Upon request

X

Photovoltaic Solar Inverter Series ES

Technical Data

ES series

77

Description

Function / View

Article number

***

3

PV closure cap

for coupling bush

Upon request

X 2 Cable inlets

Including assembly material

Upon request

X

IP65 protection

IP65 protection consists of:

Upon request

X

2 covers

Upon request

X

2 washers

Upon request

X

8 screws

Upon request

X

1

DC circuit-breaker

SLDFKNMS32AWX000

O

1

AC circuit-breaker

to be provided by the

customer

*** X = included in standard scope of delivery

O = can be ordered as an option. The EFFEKTA sales team will be pleased to advise you.

Photovoltaic Solar Inverter Series ES

Technical Data

ES series

78

In the following, you will find a list of components that EFFEKTA Regeltechnik GmbH has

approved and tested especially for this photovoltaic solar inverter.

Description

Function / View

Article number

***

Solar-LogTM

Monitoring

Remote diagnostics system

SLZBSLDL21022000

(Solar Log 200 for 1

photovoltaic solar inverter)

SLZBSLDL21050100

(Solar Log 500 up to 10

photovoltaic solar

inverters)

SLZBSLDL21100100