Eemax AP032208, AP036208, AP041208, AP054208, AP064208 Installation Manual

...

INSTALLATION, OPERATION, AND

MAINTENANCE MANUAL FOR ELECTRIC TANKLESS WATER HEATERS

SPECADVANTAGE | SAFE ADVANTAGE

i

IMPORTANT SAFETY INFORMATION

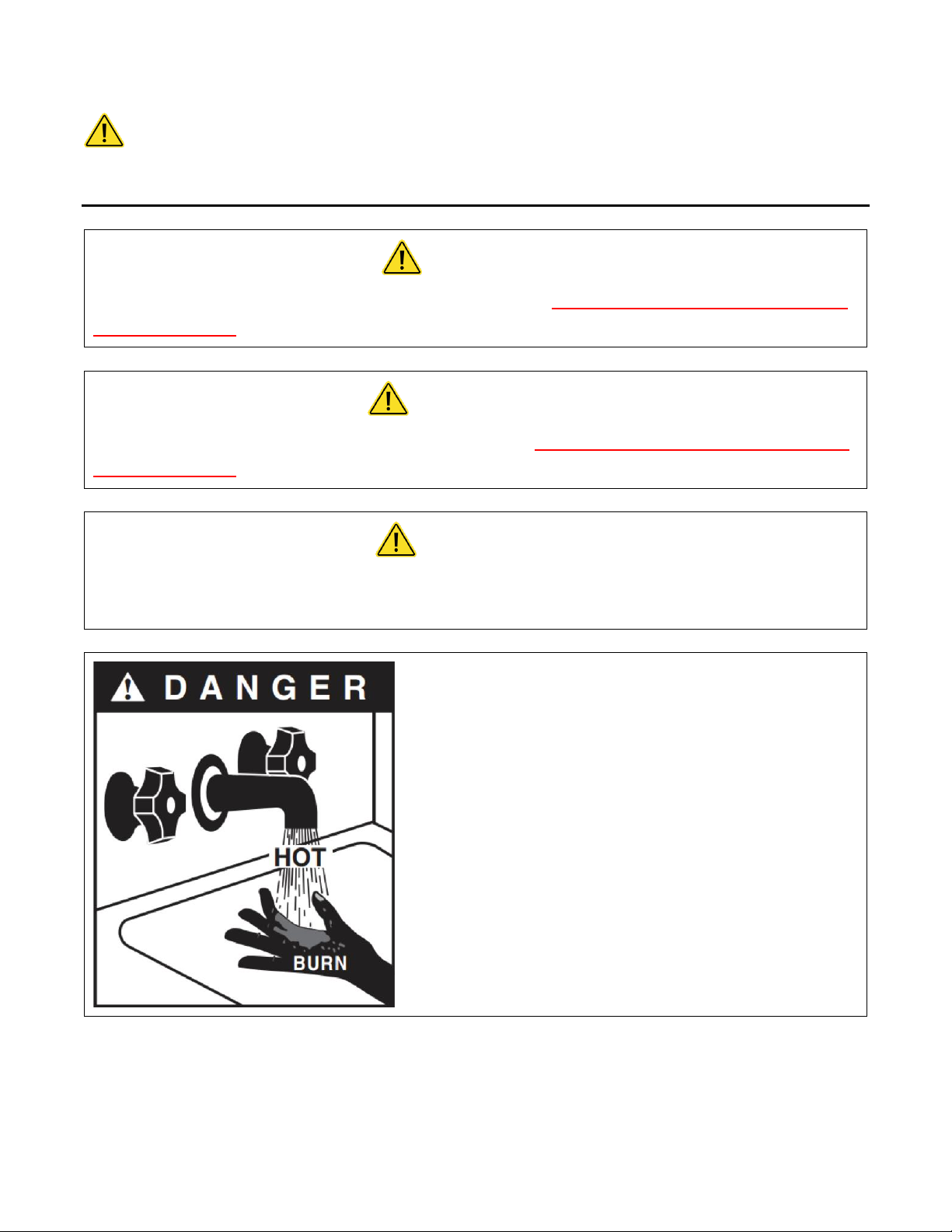

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury.

Hot water can be dangerous. There is a high scald

potential if the thermostat is set too high.

Water temperatures over 125 °F (51 °C) can cause

severe burns or scalding resulting in death.

Hot water can cause first degree burns with

exposure for as little as:

3 seconds at 140 °F (60 °C)

20 seconds at 130 °F (54 °C)

8 minutes at 120 °F (48 °C)

READ ALL INSTRUCTIONS BEFORE USING

ii

IMPORTANT SAFETY INFORMATION

1. You must read and follow all

instructions. Serious bodily injury or

death could occur if you ignore this

warning.

2. All circuit breakers and/or disconnect

switches servicing the heater must be

turned off when installing, uninstalling,

or repairing this water heater.

3. The unit must be installed by a

licensed electrician and plumber.

4. The unit must be wired in accordance

with the current version of the

National Electrical Code (US) or

Canadian Electric Code (Canada).

5. This installation must comply with all

national, state, and local plumbing and

electrical codes.

6. When the heater is not within sight of

the electrical circuit breakers, an

additional local means of

disconnection of all ungrounded

conductors must be provided that is

within sight of the appliance or a

circuit breaker lockout must be used.

(Ref. NEC 422.31)

7. Per UL 499, this water heater is not

required to be installed with a

Temperature and Pressure relief valve

(T&P). However, local codes may vary.

In case a T&P relief valve is required, it

must be installed on the outlet hot

water line heater between the heater

and the isolation valve.

8. If the Eemax Tank less Water Heater is

installed in a location where water

damage could occur in the event of a

leak, it is recommended that a drip

pan be installed and connected to a

suitable drain. Alternatively, an active

water leak detector and shut off valve

can be installed to turn off your water

supply in the event a leak is detected.

9. If water supply has a high mineral

content, a water softening system is

recommended. Damage to the water

heater resulting from scale or hard

minerals will not be covered under

warranty.

READ ALL INSTRUCTIONS BEFORE USING

iii

IMPORTANT SAFETY INFORMATION

10. When the heater is installed in a well

water system or if the plumbing

system is prone to introducing air into

the heater, it is highly recommended

that an air separator be installed in the

cold water feed to the heater to avoid

possible failure of the heating element

and/or heating chamber.

11. In accordance with NEC guideline, this

water heater is designed for a

continuous duty cycle of 3 hours at

100% power output. Exceeding this

rating could damage the heater and

void the warranty

12. Provide your heater with potable,

uninterrupted supply of water at a

constant minimum pressure of 35PSI

(based on model) and maximum

pressure of 150 PSI.

13. Use of Water Hammer Arrestors in

applications with excess pipe lengths

or fast acting valves strongly

recommended, neglecting to do so will

damage the heater and void the

warranty

14. This heater must be in a location

where it is not subject to freezing

temperatures unless supplied with

factory installed freeze protection

15. Properly purge air out of system

before power is applied.

Recommended to purge water

through system for minimum 2

minutes at a minimum 15 gpm, closing

and opening drain valve 3 times to

move any lodged air before power is

applied.

16. Sanitation models used in a circulator

system, a 30 second factory set delay

program will be installed to establish

flow before power is applied. Contact

Eemax for information 1-800-543-6163

17. Applications with the use of a

recirculation circulator must be

installed according schematics.

18. The use of Ethylene glycol antifreeze

is strictly prohibited. Propylene Glycol

is the only recommended antifreeze

READ ALL INSTRUCTIONS BEFORE USING

iv

v

TABLE OF CONTENTS

PERFORMANCE FEATURES................................................................................................................. 1

OPERATION PRINCIPLE ...................................................................................................................... 3

MOUNTING THE HEATER TO THE WALL ............................................................................................. 4

ELECTRICAL HOOKUP ........................................................................................................................ 5

PLUMBING HOOKUP ......................................................................................................................... 7

COMMISSIONING THE WATER HEATER ............................................................................................ 10

MONITORING & PREVENTIVE MAINTENANCE .................................................................................. 14

CONTROL FEATURES ....................................................................................................................... 15

TROUBLESHOOTING PROCEDURES .................................................................................................. 18

TECHNICAL SUPPORT ...................................................................................................................... 20

APPLICATIONS SCHEMATICS ............................................................................................................ 24

WIRING SCHEMATICS ...................................................................................................................... 61

1

PERFORMANCE FEATURES

Heating Technology

Field Replaceable, non-ferrous, lead-free cartridge-style direct heating element

Safety and Reliability

Thermo-Optical sensor for protection against entrained air or improper commissioning

Materials and Construction

NSF-61 listed materials of construction

Control and Consumption

Active energy management to ensure optimal application of energy based on real-time system demands

Multistage element turn-on

Visual user interface for field programming

Turn-on Flow Rate

Integrated high-capacity flow meter

Field adjustable maximum activation flow rate (minimum activation flow rate factory set and is not field

adjustable.)

Pressure Rating

Operating pressure range not to exceed 60 – 90 PSI. Maximum pressure rating 150 psi

Available Enclosures

N4 – NEMA 4 (Standard)

N4X – NEMA 4X 304SS

N4X6 – NEMA 4X 316SS

Class l Div II enclosures

Optional Features

Indoor disconnect switch (fused or non-fused)

Stand Kits (for freestanding applications)

Beacon

Siren

Alarm contacts

GFCI

FREEZE PROTECTION

Additional Options available per customer request

2

3

OPERATION PRINCIPLE

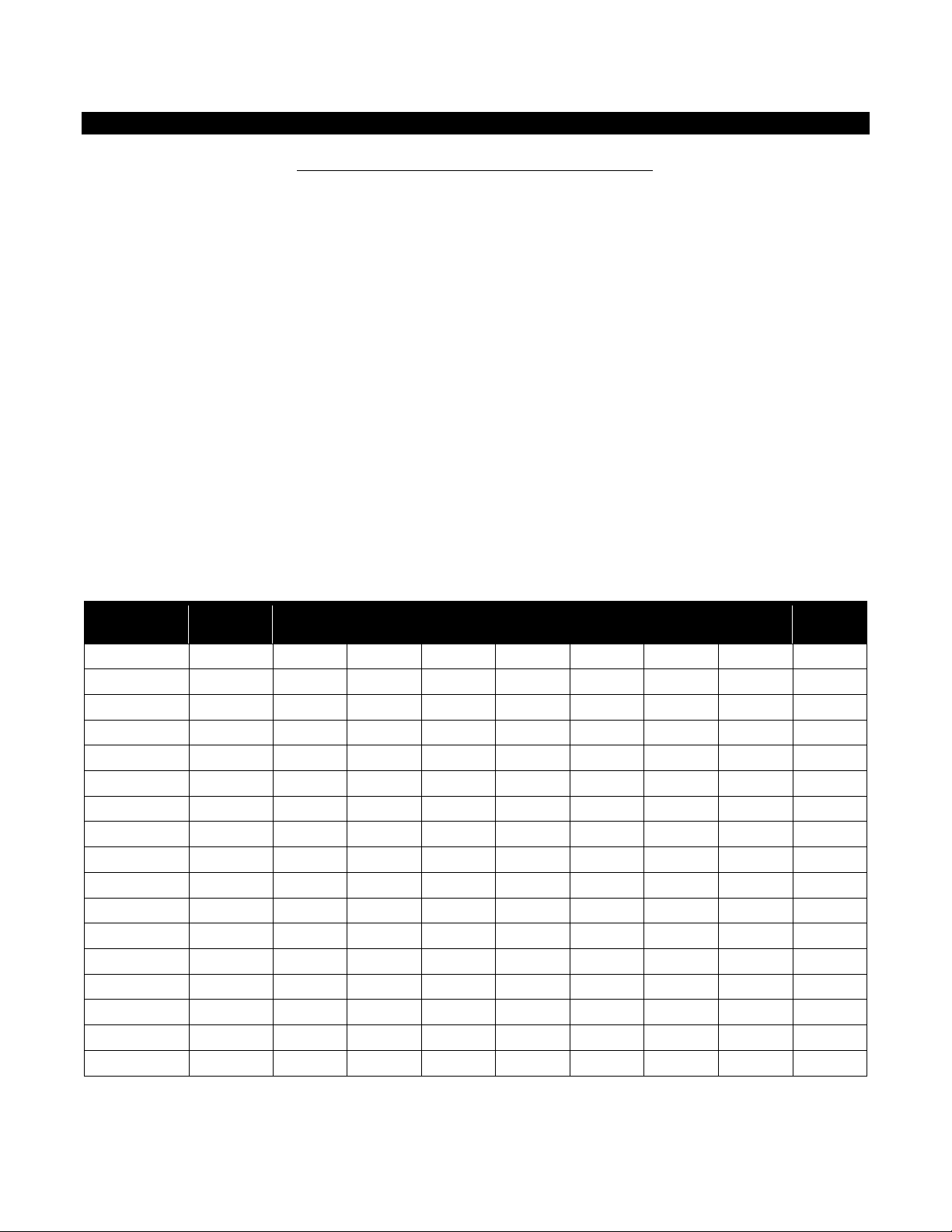

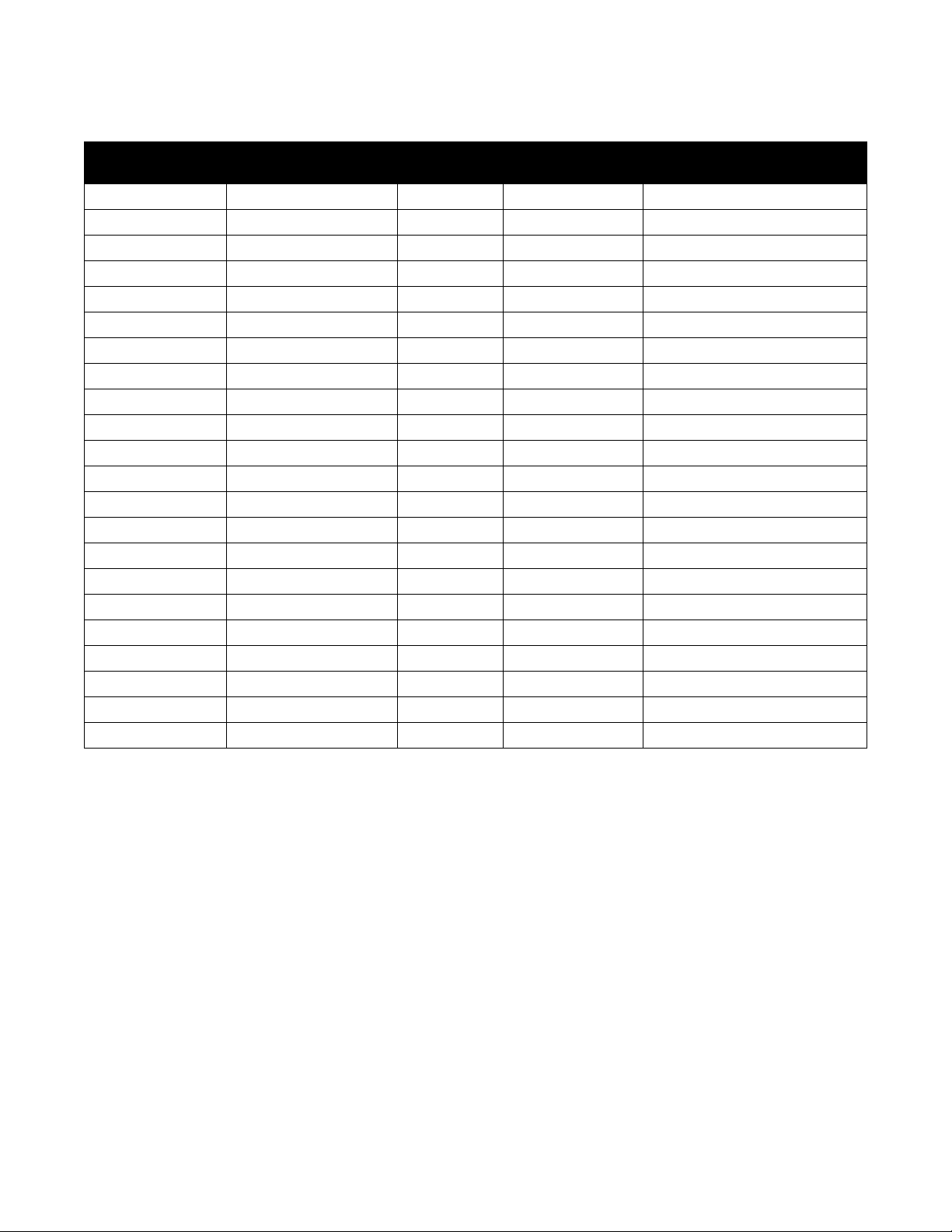

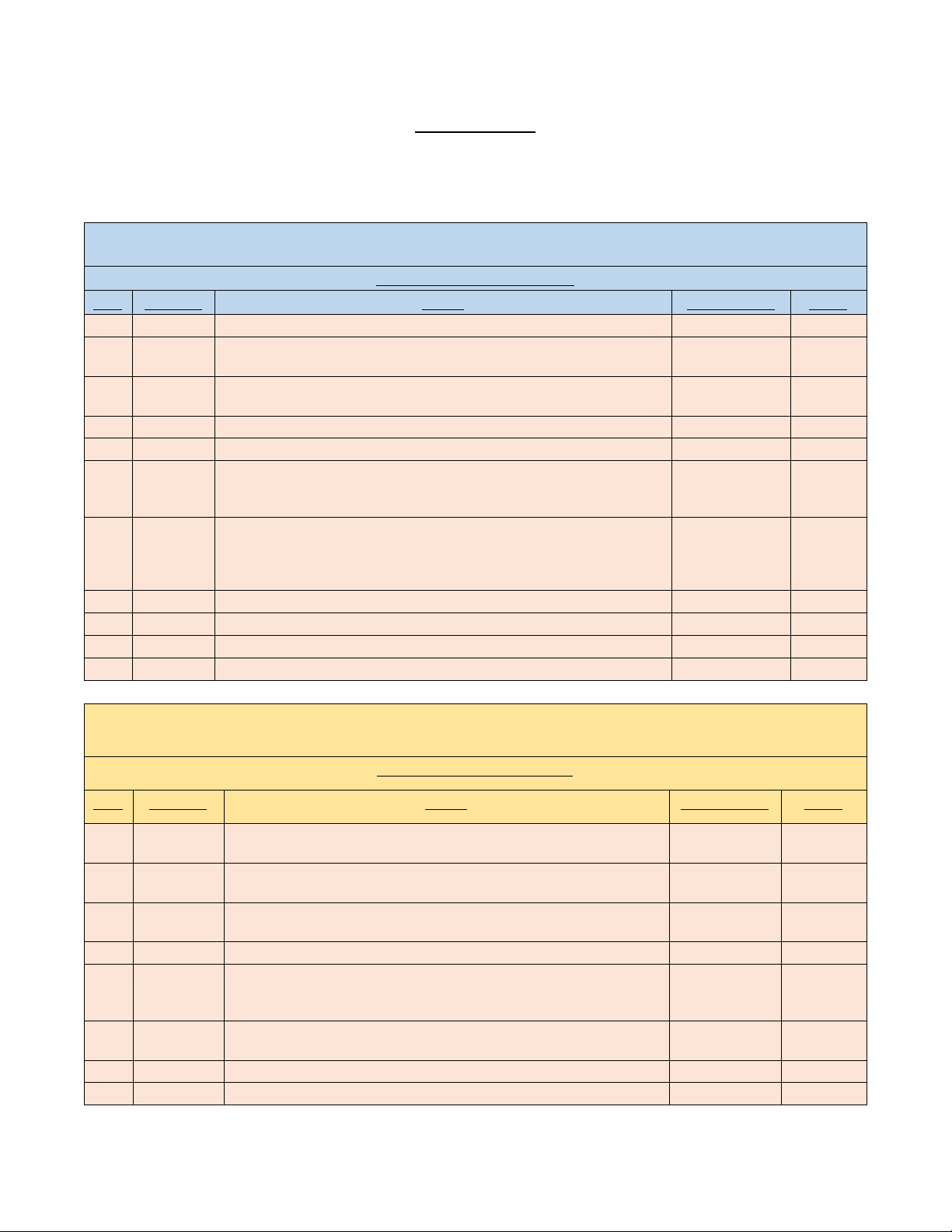

MODEL

TURN-ON

GPM

3.0

GPM

4.0

GPM

6.0

GPM

8.0

GPM

12.0

GPM

20.0

GPM

25.0

GPM

30.0

GPM

AP032208

1.0

73

55

36

27

18

10 8 7

AP036208

1.0

82

61

41

29

20

12 9 8

AP041208

1.0

93

70

47

35

23

13

11

9

AP054208

1.5

123

92

61

46

31

18

14

12

AP064208

2.5

146

109

73

55

36

22

17

15

AP036480

1.0

82

61

41

31

20

12 9 8

AP039480

1.0

89

67

44

33

22

13

11

7

AP048480

1.0

109

82

55

41

27

16

13

11

AP054480

1.5

123

92

61

46

31

18

14

12

AP063480

2.5

143

108

72

53

36

22

17

14

AP072480

2.5

147

123

82

61

41

25

20

16

AP096480

2.5 - -

109

82

54

33

26

22

AP108480

2.5 - -

99

92

61

37

30

25

AP126480

2.5 - -

143

107

72

43

34

29

AP144480

2.5 - - - 122

82

49

40

34

AP130600

2.5 - - - 111

73

44

35

30

AP150600

2.5 - - - 128

85

52

40

35

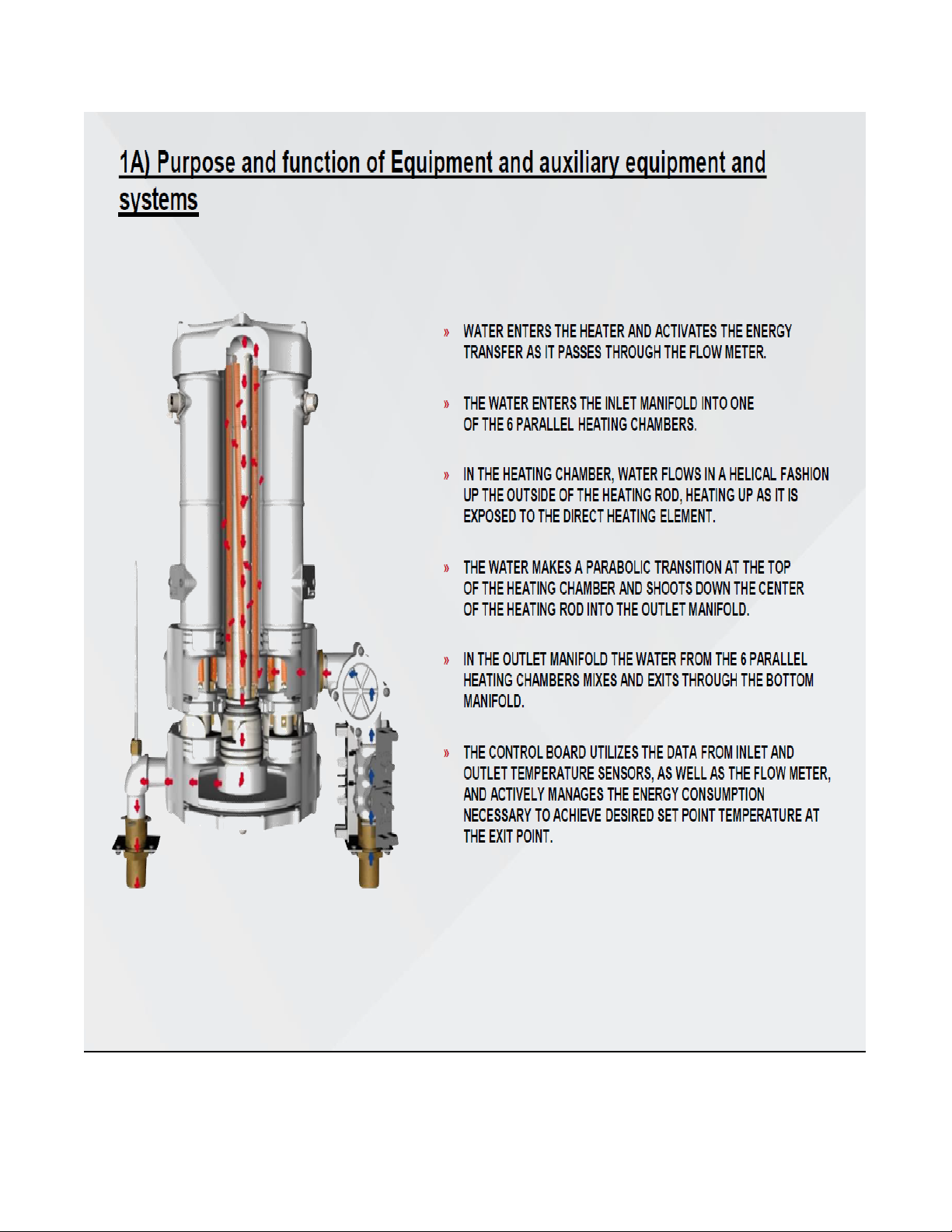

How the Eemax Tankless Water Heater Works

Operating the new Eemax tankless water heater is similar to using any traditional water heater system. However, it is

very important that all of the set-up procedures and operating instructions are carefully read to ensure maximum

performance and energy savings from the water heater.

The Eemax tankless water heater does not store hot water like a conventional tank-type water heater. It contains high

powered bare wire technology heating elements that are capable of heating water instantly on-demand. Whenever

there is a hot water demand, the patented flow meter within the heater recognizes the demand and initiates the

heating process. This meter measures the water flow rate while two thermistor sensors measure the incoming and

outgoing water temperature. This information is transmitted continually to the microprocessor controller which

determines the precise amount of power to send to the heating elements to heat the water to the desired temperature.

The Eemax tankless water heater only uses as much power as is needed to meet the demand by fully modulating the

heating elements from 0 to 100%.

It is important to keep in mind that all tankless water heaters are subject to a maximum flow rate. If this flow rate is

exceeded, the heater will not be capable of fully heating water. The amount of water that can be heated by the tankless

water heater at any given time will depend on the model selected and the incoming water temperature. See diagram

on below to determine the maximum flow rates. Since a tankless water heater eliminates the ongoing thermal losses

caused by storing hot water in a tank, there will be a significant energy savings compared to a conventional tank type

water heater.

Temperature Rise at Specified Flow Rate (°F)

4

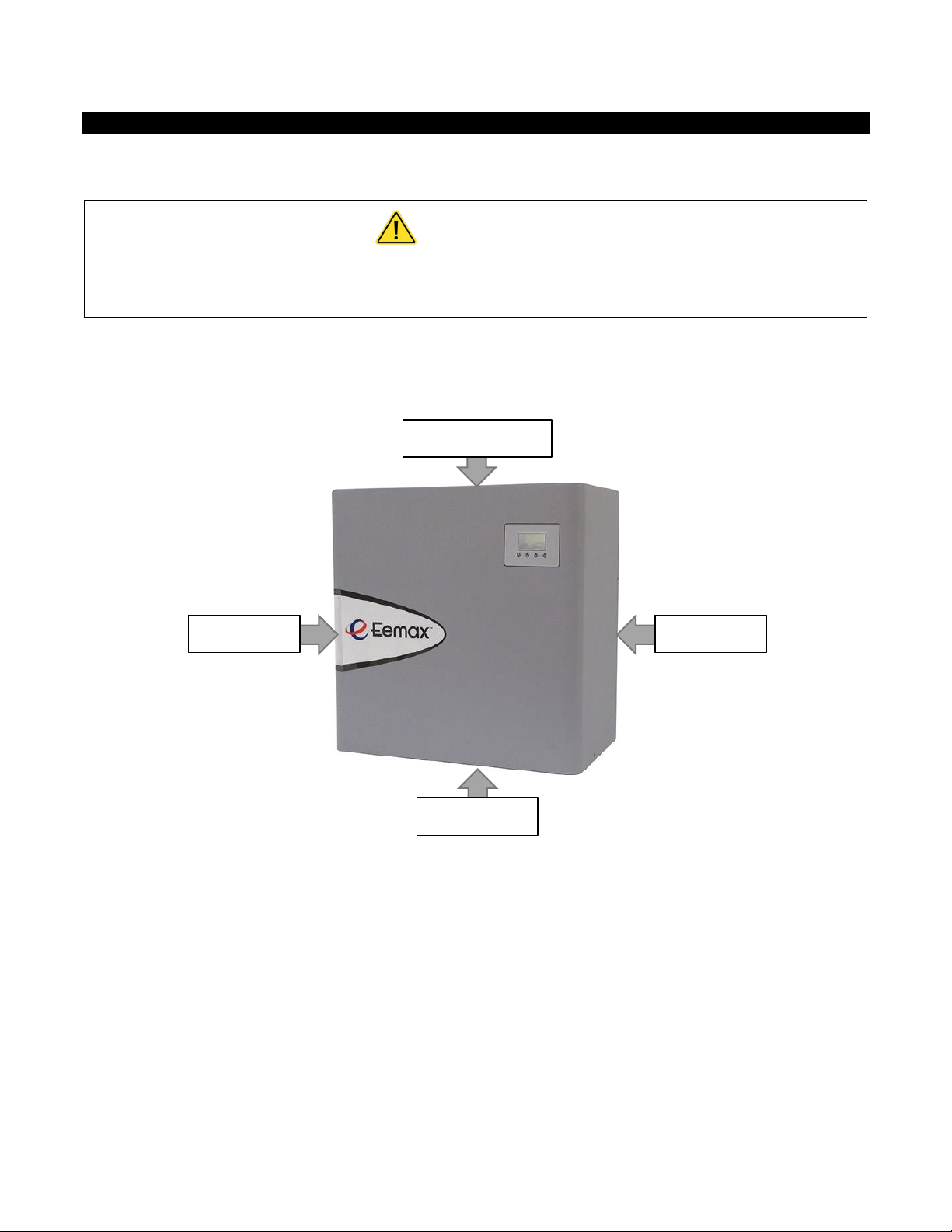

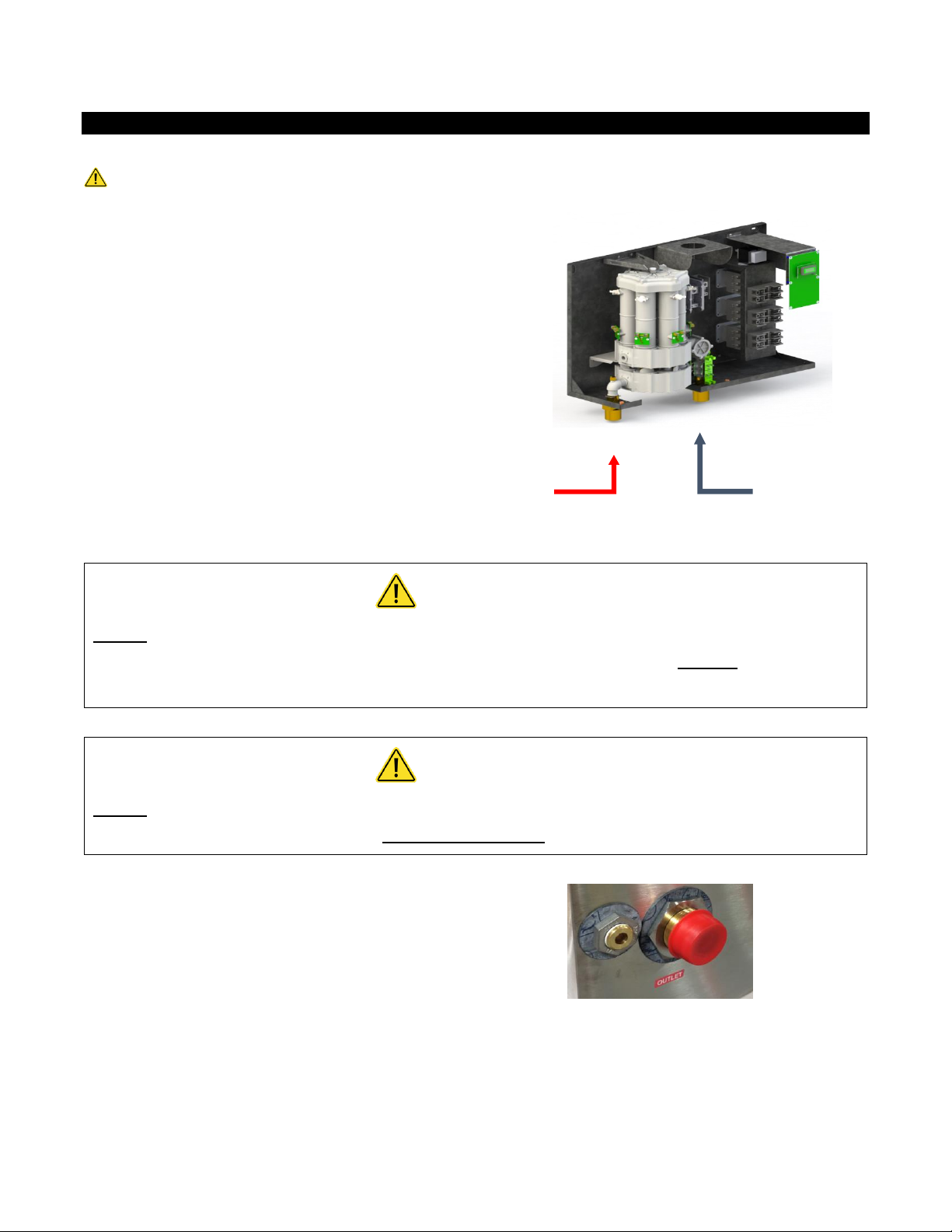

MOUNTING THE HEATER TO THE WALL

CAUTION

This heater must be installed in a location where it is not subject to freezing

temperatures, unless supplied with factory installed freeze protection

10” Top Clearance

8” Clearance

8” Clearance

18” Clearance

Please follow the mounting instructions as appropriate to your installation. Eemax recommends the heater be installed

close to the point of use.

Make sure the brass fittings are at the bottom of the heater. No other heater orientation is permitted.

The AP series is approved for zero clearance to combustibles.

Above clearances recommended for service and installation.

5

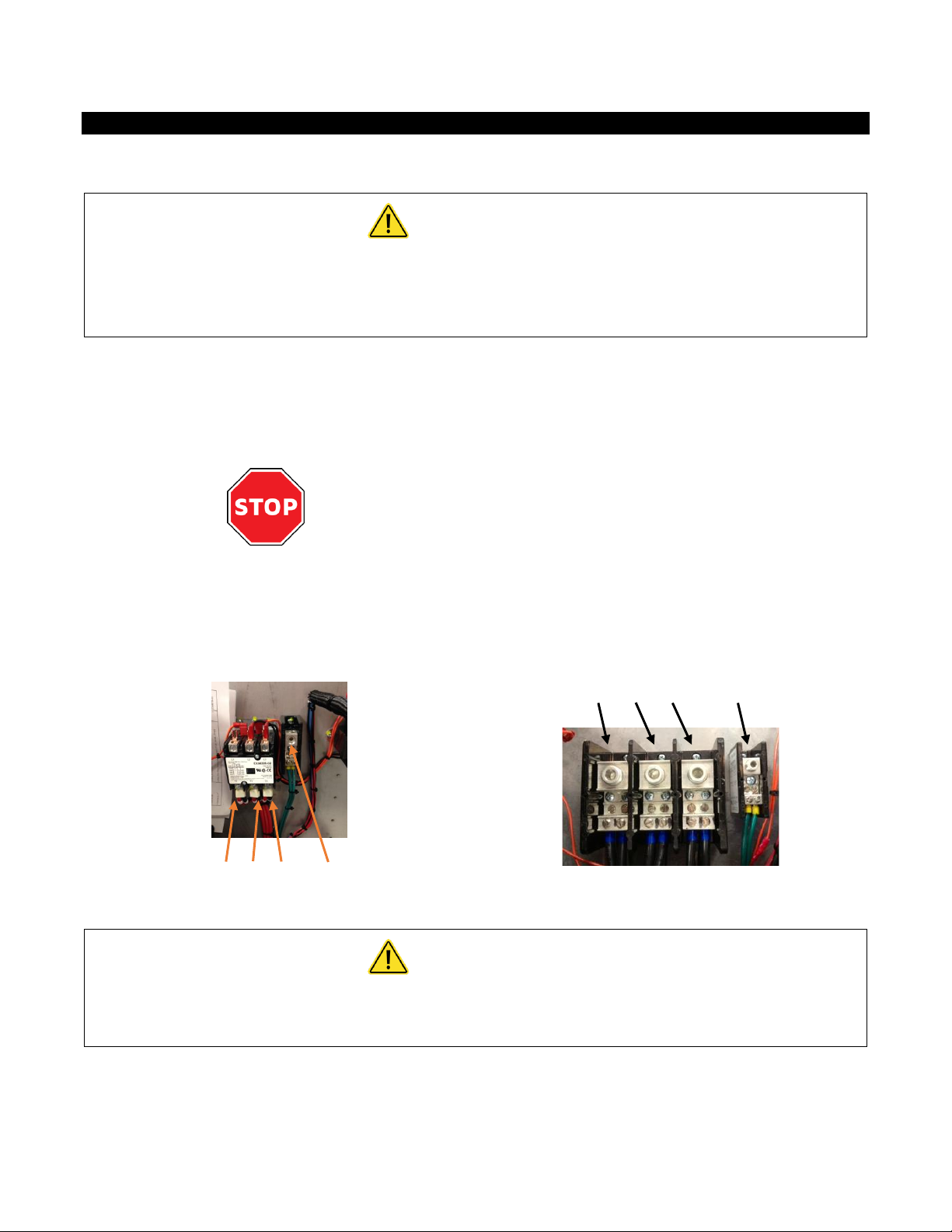

ELECTRICAL HOOKUP

WARNING

Before beginning any work on this installation, BE SURE THAT THE ELECTRICAL

BREAKER IS “OFF” AND THAT ALL MOUNTING AND PLUMBING WORK HAS BEEN

COMPLETED PER THESE INSTRUCTIONS.

Before starting any electrical work VERIFY there is

no power at the heater before proceeding

Fig. 1

L1 L2 L3 GND

Fig. 2

L1 L2 L3 GND

WARNING

FAILURE TO GROUND THE SYSTEM MAY RESULT IN SERIOUS INJURY,

DEATH AND/OR PROPERTY DAMAGE.

Eemax recommends your heater be installed or serviced by a licensed plumber and electrician.

This heater must have its own independent circuit using insulated, UL listed wire conductors of the appropriate size

suitable for up to 90° C and protected by the correctly rated circuit breaker.

See chart on next page.

The power conductors are to be secured to the L1, L2 and L3 connectors on the terminal block (Fig. 1) or

contactor (Fig. 2). The ground is to be secured to the GND connector to the right of the terminal block.

6

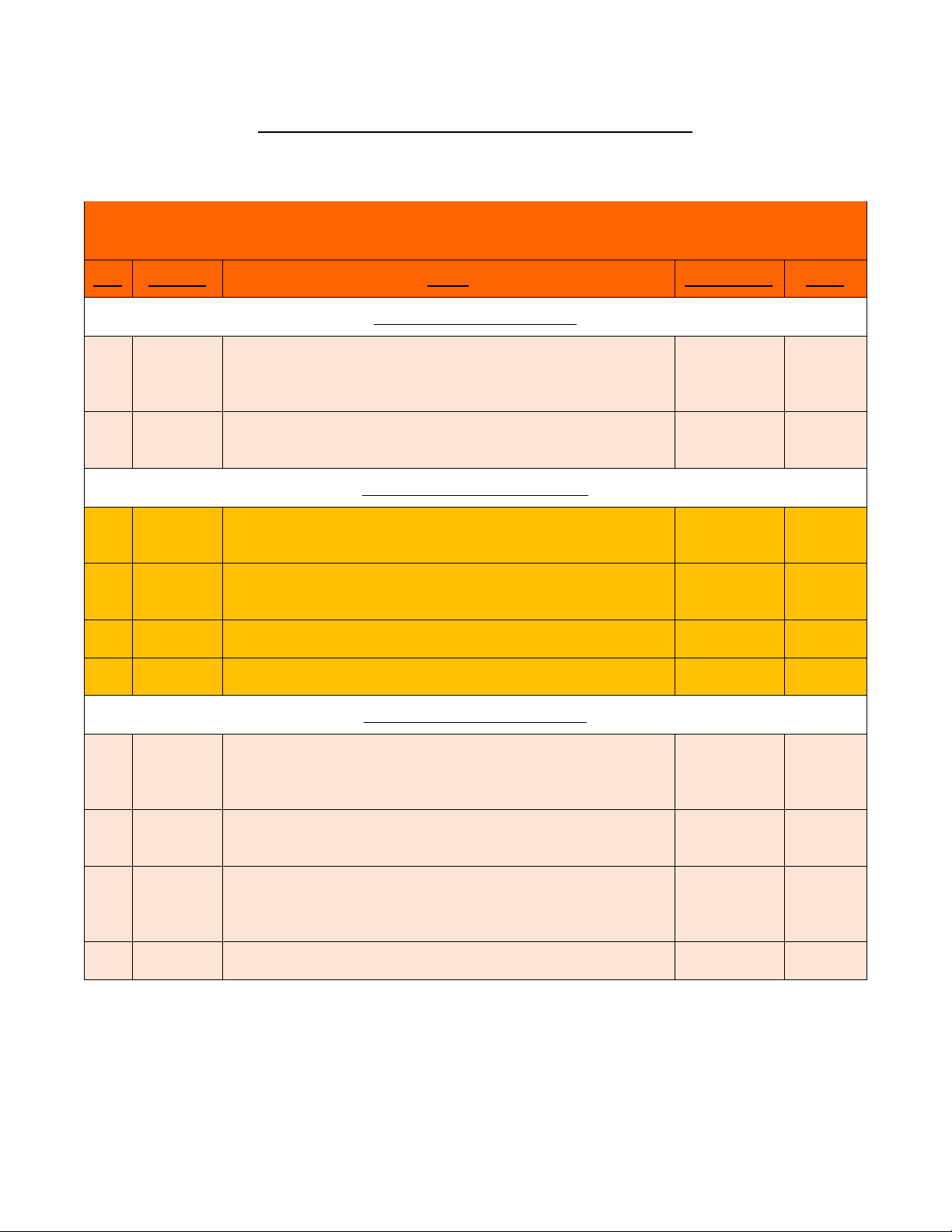

Electrical Specifications

MODEL

VOLTS

3-PHASE DELTA

KW

AMPS

PER PHASE

RECOMMENDED

WIRE SIZE (CU) 90° C

AP032208

208

32

89

1 AWG

AP036208

208

36

100

1 AWG

AP041208

208

41

114

1 AWG

AP054208

208

54

150

2/0

AP064208

208

64

178

3/0

AP036480

480

36

44

8 AWG

AP039480

480

39

47

8 AWG

AP048480

480

48

58

6 AWG

AP054480

480

54

65

4 AWG

AP063480

480

63

76

3 AWG

AP072480

480

72

86

3 AWG

AP096480

480

96

116

1 AWG

AP108480

480

108

130

1/0

AP126480

480

126

152

2/0

AP144480

480

144

173

3/0

AP048600

600

48

47

8 AWG

AP051600

600

51

50

6 AWG

AP061600

600

61

59

6 AWG

AP071600

600

71

69

4 AWG

AP102600

600

102

99

1 AWG

AP130600

600

130

130

1 AWG

AP150600

600

150

145

1/0

A green terminal (or a wire connector marked “G”, “GR, “Ground”, or “GROUNDING”) is provided within

the control box. To reduce the risk of electric shock, connect this terminal or connector to the grounding

terminal of the electric service or supply panel with a continuous copper wire in accordance with your

local electrical code.

7

PLUMBING HOOKUP

CAUTION

Never use pipe dope when making plumbing connections to this heater. Follow

standard industry practice with careful application of Teflon tape. Do not allow Teflon

tape to get into the heater.

CAUTION

Never solder any pipe connections while attached to this heater – damage to the

heater will result. Doing this will void the warranty.

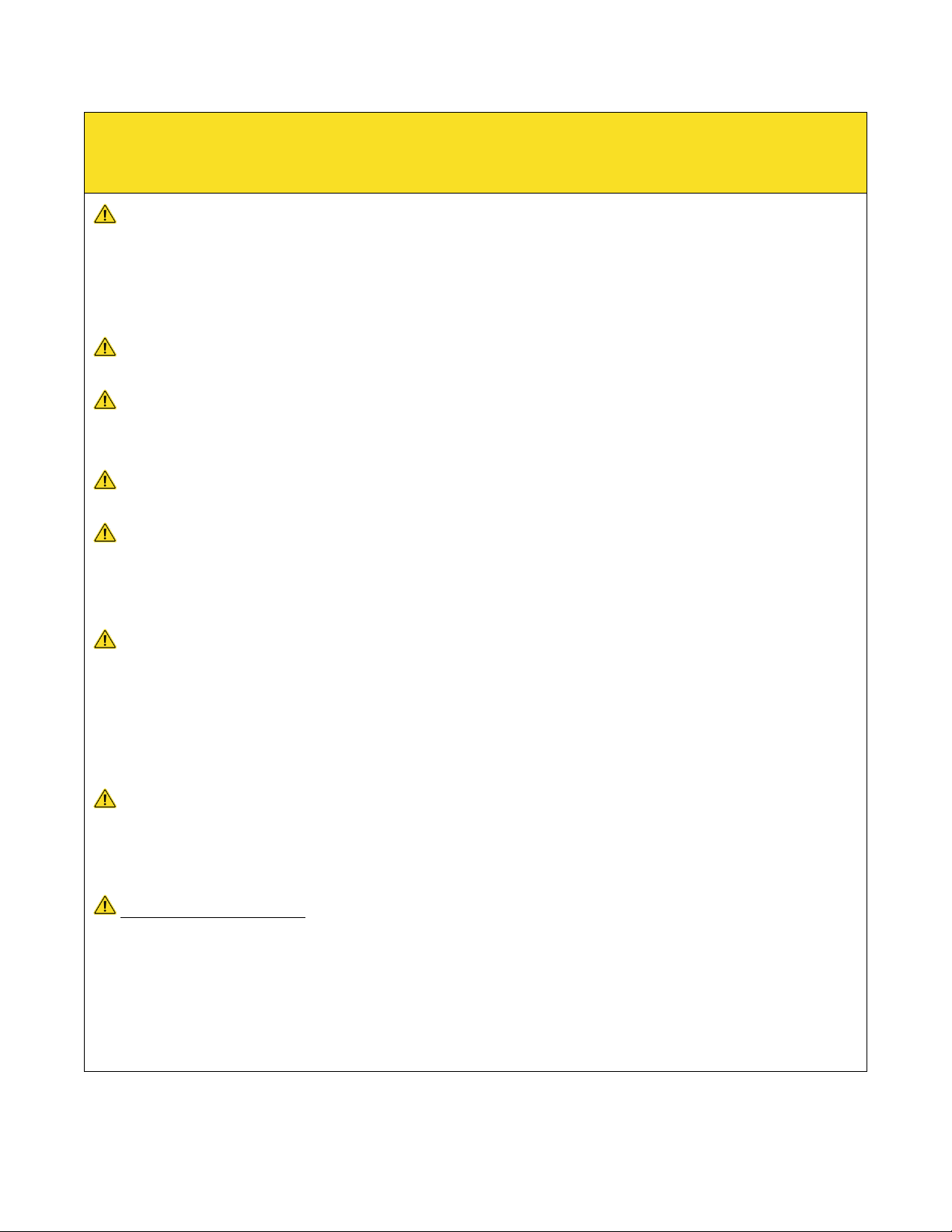

PRV VENT LOCATION. The PRV Vent is not a code

compliant pressure relief valve. Check local codes to

see if a code compliant T&P Relief Valve is required

in your installation.

HOT

WATER

OUT

COLD

WATER

IN

MUST FLUSH LINE A MINIMUM 5 MINUTES, AT A MINIMUM 15 GPM ON INITIAL START UP

The heater is equipped with NPT brass fittings.

Make sure ONLY NPT fittings are used for connection to this heater.

Connect the cold water line with the inlet connection

(RIGHT fitting)

Connect the outlet pipe with the outlet fitting

(LEFT fitting)

Do not reverse connections.

8

WARNING

MUST FLUSH OUT WATER HEATER FOR MINIMUM 5 MINUTES AT A MINIMUM 15

GPM ON INITIAL START UP OR AFTER ANY SERVICE WORK HAS BEEN PERFORMED.

CLOSE AND OPEN DRAIN VALVE 3 TIMES TO REMOVE ANY LODGED AIR BUBBLES.

FAILURE TO DO SO MAY DAMAGE THE HEATER.

MINIMUM INLET WATER PRESSURE 35 PSI DYNAMIC.

MAXIMUM WATER PRESSURE NOT TO EXCEED 150 PSI. RECOMMENDED

OPERATING PRESSURE 60 – 90 PSI.

USE OF A PRESSURE REGULATOR RECOMMENDED.

Water supply inlet piping must be a minimum 1 ¼” pipe diameter and it must be a

dedicated supply line. 2 ½” minimum pipe diameter on trunk main when part of a

branch system.

THE USE OF DI-ELECTRIC UNIONS MUST BE USED ON THE INLET AND OUTLET

PORTS OF THE WATER HEATER. RECOMMENDED 40 MESH Y STRAINER BE INSTALLED

IN COLD WATER INLET TO PREVENT DEBRIS FROM ENTERING THE WATER CHAMBERS.

BLOCKAGE CAUSED BY DEBRIS MAY CAUSE ELEMENT FAILURE. ISOLATION VALVES

RECOMMENDED FOR SERVICING

In applications where a long duty cycle is needed (more than 3 hours continuous

run time), or a short duty cycle (less than 30 sec. on time with less than minute off

time) please contact applications department. 1-800-543-6163

HAMMER ARRESTOR: SYSTEMS WITH A LARGE WATER VOLUME, OR LONG

LENGTHS OF PIPING CAN BE SUSCEPTIBLE TO WATER HAMMER. THE USE OF SLOW

ACTING VALVES ALONG WITH THE INSTALLATION OF A WATER HAMMER ARRESTOR IS

HIGHLY RECOMMENDED ON ALL UNITS. FAILURE TO INSTALL A WATER HAMMER

ARRESTOR CAN CAUSE DAMAGE TO WATER HEATER AND VOID WARRANTY- Refer to

manufacturer’s installation manual for proper size and installation location.

9

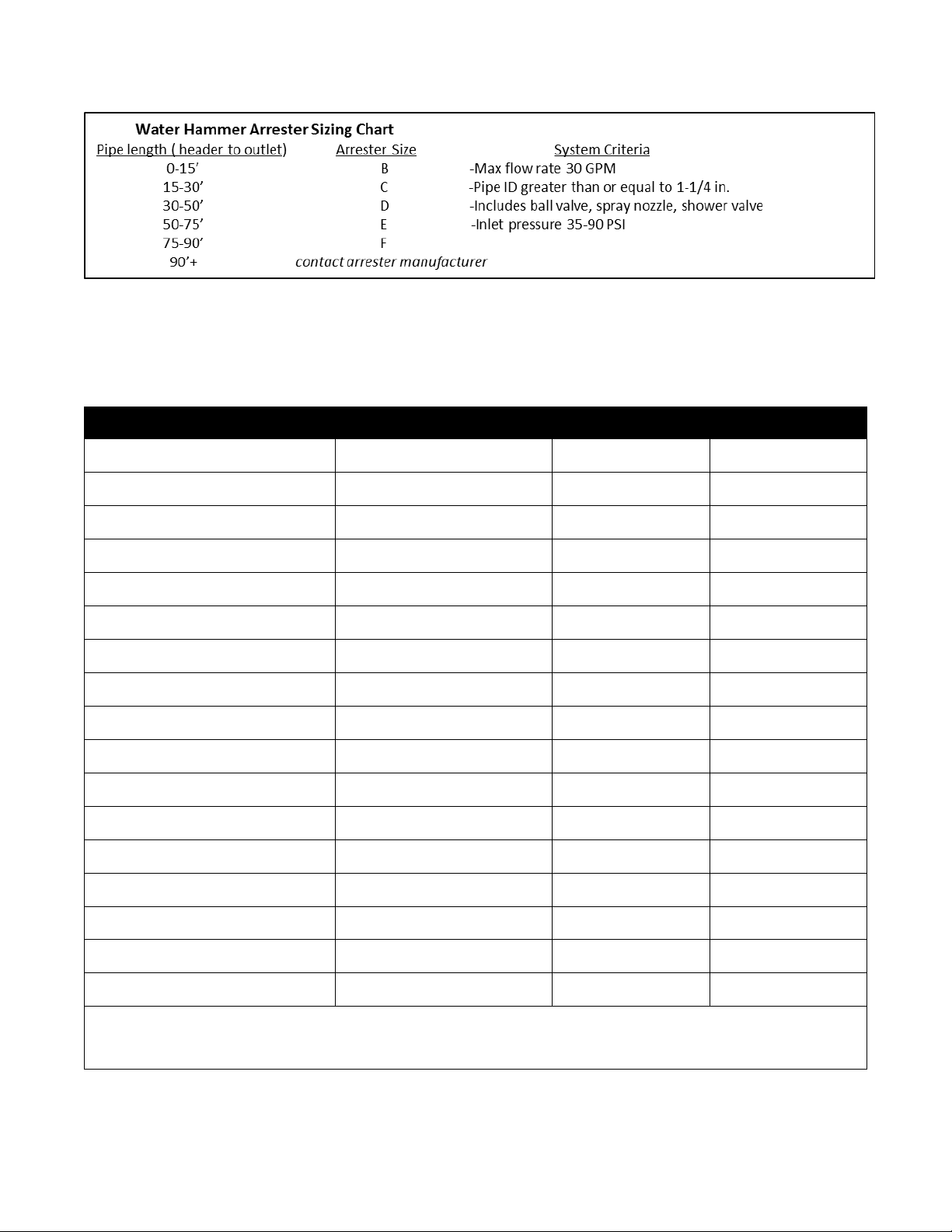

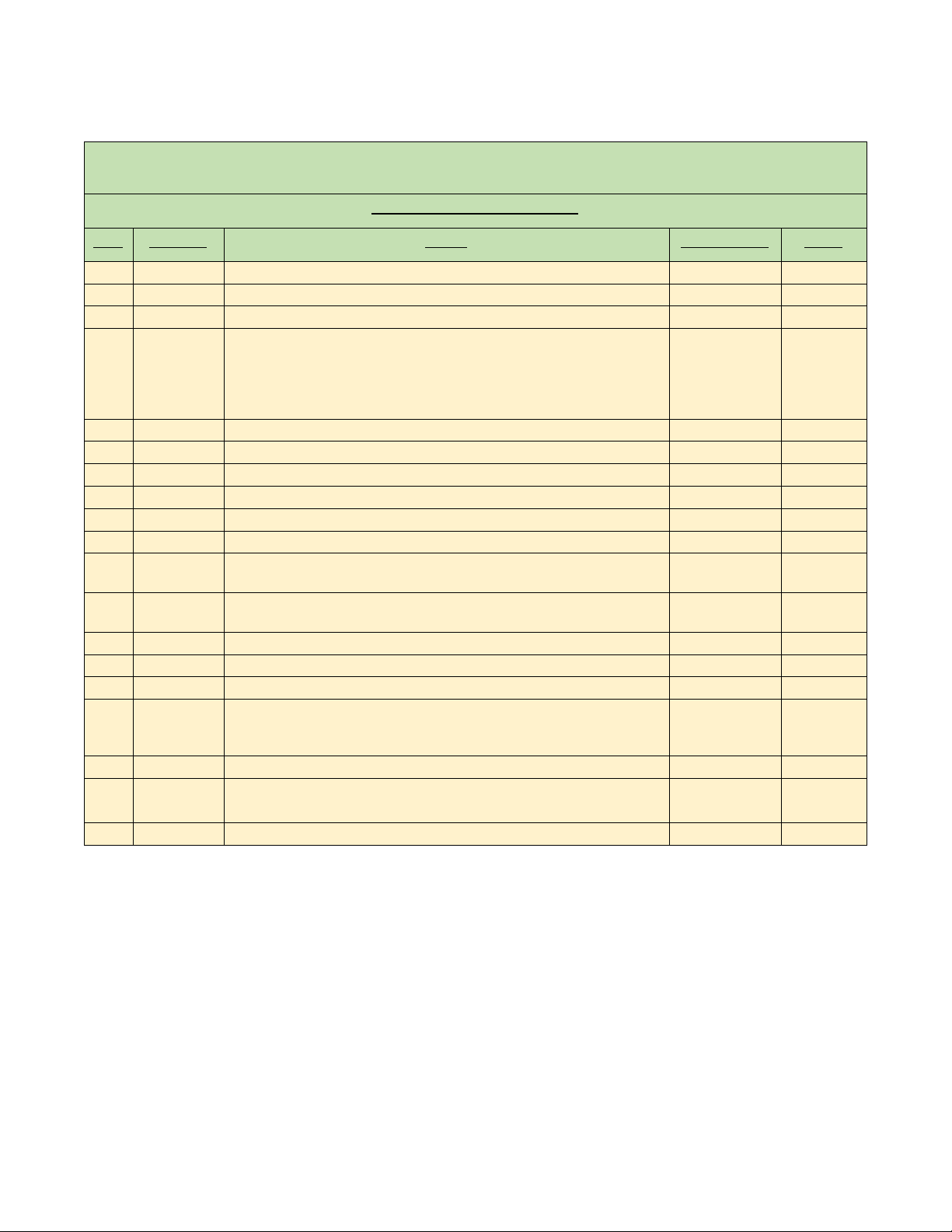

CONSTITUENT (MG/L)

MINIMUM REQUIREMENT

BETTER

BEST

Alkalinity

50

25

10

Calcium

25

5

0.5

Carbon Dioxide

0

0

0

Chlorine

100

15

1

Free Chlorine 1 1

0.05

Iron

0.2

0.1

0.01

Magnesium as Mg

0.5

0.1

0.1

Magnesium as Mn

0.1

0.1

0.1

Nitrate

25

25

10

Oxygen 2 1

0.1

Silica

15

10

1

Sodium

50

10

1

Sulfate

25

25

1

TDS*

200

100

5**

Total Hardness

25

10

1

pH

6.5 – 8.5

6.5 – 8.5

6.5 – 8.5

Turbidity (NTU)

5

5

1

* NOTE: Total dissolved solids

** NOTE: Do not reduce the TDS beyond this amount or the water will be too aggressive

Proper water conditions must be maintained to prevent damage to the water heater.

10

COMMISSIONING THE WATER HEATER

CAUTION

BEFORE SWITCHING THE ELECTRICAL BREAKER “ON”, MAKE SURE THE INLET AND

OUTLET BALL VALVES ARE FULLY OPEN AND WATER IS FLOWING THROUGH ALL

POINTS OF USE FOR A MINIMUM OF 5 MINUTES AT A MINIMUM 15 GPM. Open and

close drain valve 3 times while purging to remove any lodged air bubbles. DO NOT

SWITCH THE BREAKER “ON” IF THERE IS ANY POSSIBILITY THE WATER IN THE HEATER

IS FROZEN.

After verifying the heater has been purged of air (see above)

turn the circuit breaker/disconnect “ON” and observe the

start-up sequence on the display. The LCD screen will display

the SETPOINT TEMPERATURE in degrees F.

Below the display are 4 push buttons that are used to control

the function of the heater. Press the UP or DOWN buttons to

establish your desired temperature. Refer to the CONTROL

FEATURES section of this manual for additional information.

SETPOINT

TEMP 120F

11

Startup Process

Important - Read and fully understand all steps outlined below before proceeding. Failure to do so may damage the

water heater and void any warranty. Technical support is available at 1 (800) 543-6163

Plumbing Installation Checklist

Step

Category

Action

Confirmed By

Notes

1

Water

Heater is supplied with clean potable water

2

Water

Plumbing orientation is correct – water connections on the bottom - inlet on

the right, outlet on the left

3

Water

Ensure piping connections are not causing stress or torque on the inlet and

outlet fittings

4

Water

No leaks at water connection or in plumbing network

5 Water

Water pressure is between 40-90 PSI (min 35psi)

6

Water

Long pipe runs, high flow rates and valves closing can cause pressure spikes

(water hammer) above 1000 PSI. Consult piping schematic to ensure

arrestors and regulators are properly sized and located.

7

Water

(with power off) Open supply valves to water heater - run water through

fixtures to purge all air and debris in system. With water flowing, visually

inspect the clear element tubes between the inlet and outlet manifold to

ensure no air bubbles are present. (this may take several minutes)

8

Water

Using a flashlight, visually inspect heating chamber for any signs of leakage

9 Water

Ensure Water Heater will not freeze

10

Water

Ensure all local plumbing codes are met

11

Water

Plumbing installation correct and complete

Important - Read and fully understand all steps outlined below before proceeding. Failure to do so may damage the

water heater and void any warranty. Technical support is available at 1 (800) 543-6163

Electrical Installation Checklist

Step

Category

Action

Confirmed By

Notes

12

Power

(with power off) - Breaker and disconnect are of proper size and correctly

installed

13

Power

(with power off) - Wiring and conduit are of proper size and correctly

installed.

14

Power

(with power off) - Wiring connections at terminals are correct orientation,

tight, with no stray wire strands or pinched sheathing

15

Power

(with power off) - Proper ground,(not neutral) is clean, and tight

16

Power

(no water flowing, do not turn it on, close outlet water shut off valve if

uncontrolled environment-left hand side) Apply power - ensure voltage

and phasing is according to model rating

17

Power

Disengage power after voltage and phasing is confirmed (open outlet

shutoff valve if closed during step 14)

18

Power

Ensure all local electrical codes are met

19

Power

Electrical Installation correct and complete

Plumbing Installation Checklist MUST BE FILLED OUT AND LEFT WITH WATER HEATER. MUST FLUSH WATER HEATER

FOR MINIMUM 5 MINUTES AT A MINIMUM.

Eemax Installation Checklist and Startup Procedure for SafeAdvantage and SpecAdvantage Water Heaters

12

Important - Read and fully understand all steps outlined below before proceeding. Failure to do so may damage the

water heater and void any warranty. Technical support is available at 1 (800) 543-6163

Startup Procedure and Checklist

Step

Category

Action

Confirmed By

Notes

20

Startup

Water requirements (Steps 1-11) are confirmed

21

Startup

Electrical requirements (Steps 12-19) are confirmed

22

Startup

Plumbing Codes and Electrical Codes are met and confirmed

23

Startup

(with power off) Open supply valves to water heater - run water through

fixtures to purge all air and debris in system. With water flowing, visually

inspect the clear element tubes between the inlet and outlet manifold to

ensure no air bubbles are present. (this may take several minutes)

Chugging or burping of water is also an indication of air

24

Startup

Turn off water flow at all fixtures, keeping water heater supply valves open

25

Startup

Apply power to water heater

26

Startup

Turn water flow on at fixtures

27

Startup

LCD display board is illuminated

28

Startup

Contactors engaged (audible click)

29

Startup

No error codes

30

Startup

Scroll through display (If display is locked, consult manual for unlock

procedure)

31

Startup

Adjust settings if needed. Note - Keep temperature setting as low as

possible for scald potential and minimizing abuse on the heater.

32

Startup

Confirm TURN-ON setting meets fixture flow rate

33

Startup

Confirm SETPOINT setting on display

34

Startup

Confirm ACTUAL TEMP output on display

35

Startup

If SETPOINT does not match ACTUAL TEMP then use the TEMPERATURE

RISE CHART in manual along with LOAD%, INLET TEMP and FLOW RATE on

display to determine the maximum theoretical output.

36

Startup

Shut water flow off at fixture

37

Startup

Power disengaged (audible)

38

Startup

Repeat startup steps 25-28 to ensure proper activation and performance

39

Startup

Water heater installed correctly and operating as designed

After all steps are completed, the heater is fully installed and ready for use.

13

Shutdown Process (Normal, Emergency, and Long Term)

Important - Read and fully understand all steps outlined below before proceeding. Failure to do so may damage

the water heater and void any warranty. Technical support is available at 1 (800) 543-6163

Step

Category

Action

Confirmed By

Notes

Normal Shut Down Procedure

1

Normal

Shut power off to unit in order of sequence - In-door (on-door)

disconnect (if applicable) local disconnect, main breaker - perform

lock out procedure per facilities requirements

2

Normal

Close applicable water valves - Inlet and outlet (water heater will

not be drained)

Emergency Shut Down Procedure

1

Emergency

Shut power off to unit In-door (on door) disconnect (if applicable) or

local disconnect

2

Emergency

Shut water valves off - inlet and outlet (water heater will not be

drained)

3

Emergency

Complete lock out procedures per facilities requirements

4

Emergency

Notify all parties involved that water heaters are shut down

Long Term Shut Down Procedure

1

Long Term

Shut power off to unit in order of sequence - Indoor disconnect (if

applicable) local disconnect, main breaker - perform lock out

procedure per facilities requirements

2

Long Term

Close applicable water valves - Inlet and outlet (water heater will

not be drained)

3

Long Term

Drain water heater through plumbing network, run compressed air

through the water heater to ensure the heater is completely

drained

4

Long Term

Lock out all applicable water valves per facilities procedures

Shut Down Procedure

14

MONITORING & PREVENT IVE MAINTENANCE

Recommended routine instrument readings and operation checking: Please note the instrument readings are

performed during water heater operation. No readings are required when the unit is not being used. Check the

following readings on the Remote display and ensure proper performance:

Inlet temperature

Temperature set point

Actual outlet temperature

Actual GPM

Error codes

Early warning signs of developing operational or equipment problems:

Based on the readings of 3A above water heater unit appears to be performing properly however there are

error codes.

Actual GPM appears to be lower than desired

Procedures for handling non-routine problems such as alarms, power failure, and component failure:

No alarms are built into the unit

Power failure will result in a non-operable system – restore power and startup unit per Start up process (2C)

Component failure will result in repeat error codes. Refer to manual page 16 for error codes and corrective

action

Preventative maintenance requirements: (PMR) Preventive maintenance requirements may impact other items of the

installation such as electrical supply and wiring, water piping and associated valves and controls.

Eemax water heaters are very low maintenance.

Ensure that the water heater is supplied with a clean potable, consistent water supply as outlined in the O+M.

Check filter screen or associated y-strainer or other pre-filters to ensure clear water supply within listed water pressure.

Ensure proper electrical supply as outlined within the O+M.

Perform PMR per site requirements not to exceed 90 days.

Maintenance inspection program: (MIP) Eemax water heaters are very low maintenance. Ensure PMR is completed

every 90 days.

Disable power to the unit via external disconnect or local disconnects. Per site lockout procedures open cabinet door

and visually inspect components for sings of damage associated with possible water leaks, excessive heat or external

factors that could impact the water heater and associated components.

Perform MIP per site requirements not to exceed 90 days.

15

CONTROL FEATURES

CAUTION

BEFORE USING THIS CONTROL, make sure all prior installation steps have been

properly completed, electrical power is on and water is present in the heater.

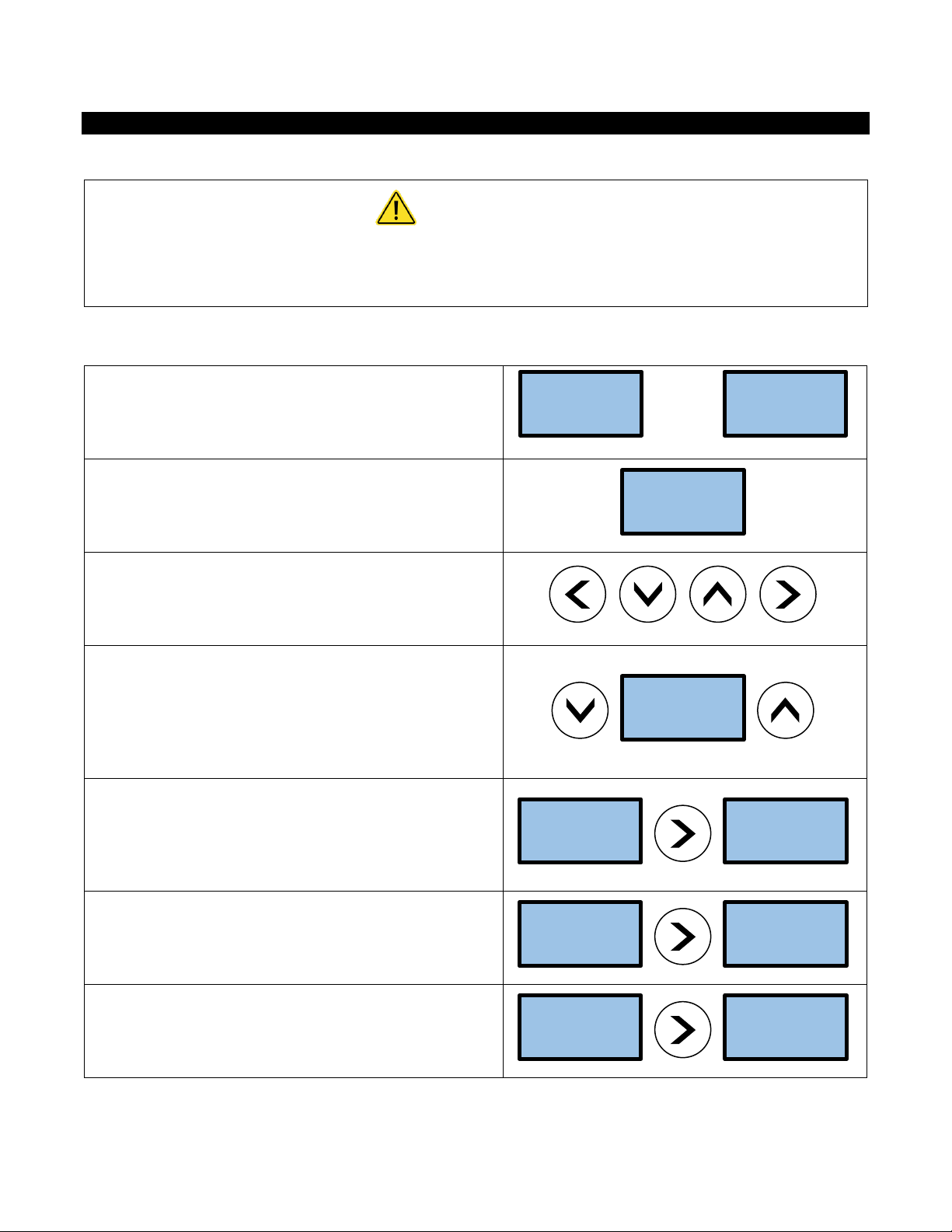

1) The SETPOINT TEMP or ACTUAL TEMP screen can be

selected for display as the home screen. Either of these

screens will remain on the display when the backlight timer

expires.

OR

2) There is a 5-minute time delay built into the control.

Regardless of which screen is being displayed, after 5

minutes of inactivity, the display will revert to the SETPOINT

TEMP screen.

3) The 4 push buttons are used to control the operation of

the heater. The LEFT and RIGHT buttons shift the display

from one screen to another. The DOWN and UP buttons may

change the values within selected screens.

4) As an example, when the screen displays SETPOINT TEMP,

the desired hot water temperature will increase 1 degree for

each press of the UP button and decrease 1 degree for each

press of the DOWN button. Note that minimum and

maximum set point temperatures are established at the

factory.

5) The LEFT and RIGHT buttons shift the display from one

screen to another. From the INLET TEMP screen, one press

of the RIGHT button will shift the display to the SETPOINT

TEMP screen. INLET TEMP shows the actual temperature of

the water entering the heater.

6) From the SETPOINT TEMP screen, one press of the RIGHT

button will shift the display to the ACTUAL TEMP screen. This

shows the actual temperature of the water leaving the

heater.

7) Form the ACTUAL TEMP screen, one press of the RIGHT

button will shift the display to the LOAD PCT screen. This

shows the electrical power consumption as a percentage of

full power.

ACTUAL

TEMP 75F

SETPOINT

TEMP120F

SETPOINT

TEMP120F

SETPOINT

TEMP120F

SETPOINT

TEMP120F

INLET

TEMP 75F

ACTUAL

TEMP 75F

SETPOINT

TEMP120F

LOAD PCT

0% PWR

ACTUAL

TEMP 75F

Push Button Flow Chart

16

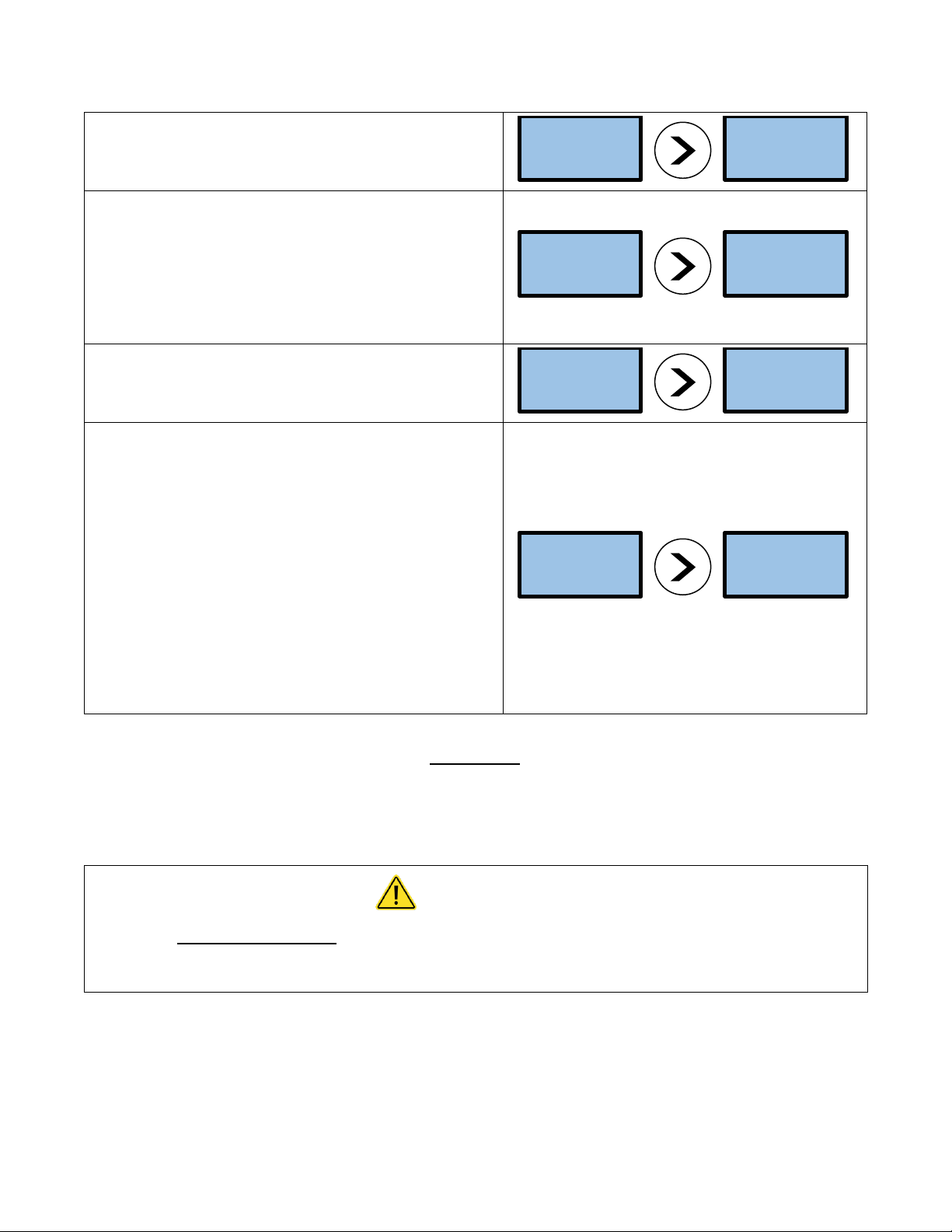

8) From the LOAD PCT screen, one press of the RIGHT button

will shift the display to the FLOWRATE screen. This shows the

rate of flow of water through the heater.

9) From the FLOWRATE screen, one press of the RIGHT

button will shift the display to the UNITS screen. This shows

the units of measure in either the ENGLISH or METRIC

systems. ENGLISH units are degrees Fahrenheit and gallons

per minute. METRIC units are degrees Celsius and liters per

second. Use the UP and DOWN buttons to select the desired

units of measure.

10) From the UNITS screen, one press of the RIGHT button

will shift the display to the SOFTWARE REVISION screen. This

shows the revision level of the software in the control.

11) From the SOFTWARE REVISION SCREEN, one press of the

right button will shift the display to the ERRORS screen. This

shows the error history of the heater. “0 ERRORS” means

that no errors have occurred.

If the heater has an error history of 4 errors: this history will

be displayed on the screen as shown. “CODE 1:E0” refers to

the first error and indicates it to be an E0 error. One press of

the UP button will show the second error as “CODE 2:E0”

error.

Continued pressing of the UP or DOWN buttons will scroll

through each of the errors in the history (in this case a total

of 4). ERRORS indicate an undesirable condition but will not

shut down the operation of the heater

CAUTION

Keep the INLET BALL VALVE fully “OPEN”. NEVER RESTRICT THE WATER FLOW USING

THE INLET VALVE.

FLOWRATE

??? GPM

LOAD PCT

0% PWR

UNITS

ENGLISH

FLOWRATE

??? GPM

SOFTWARE

20131218

UNITS

ENGLISH

1 ERROR

CODE1:F0

SOFTWARE

20131218

Error Codes

E0: Excessive water flow detected

Corrective action: Using the OUTLET BALL VALVE, slowly reduce water flow until the desired temperature is achieved.

The temperature is proportional to the flow through the heater; the lower the flow, the higher the temperature and

vice versa.

E1: Inlet temperature too hot to generate heat

17

12) FAULTS are communicated through the LCD display. The

display will switch from the SETPOINT screen to the FAULT

screen and back again every 3 seconds. FAULTS indicate an

undesirable condition and will immediately shut down the

operation of the heater. If faults are appearing on your heater

call Eemax Technical Support for assistance.

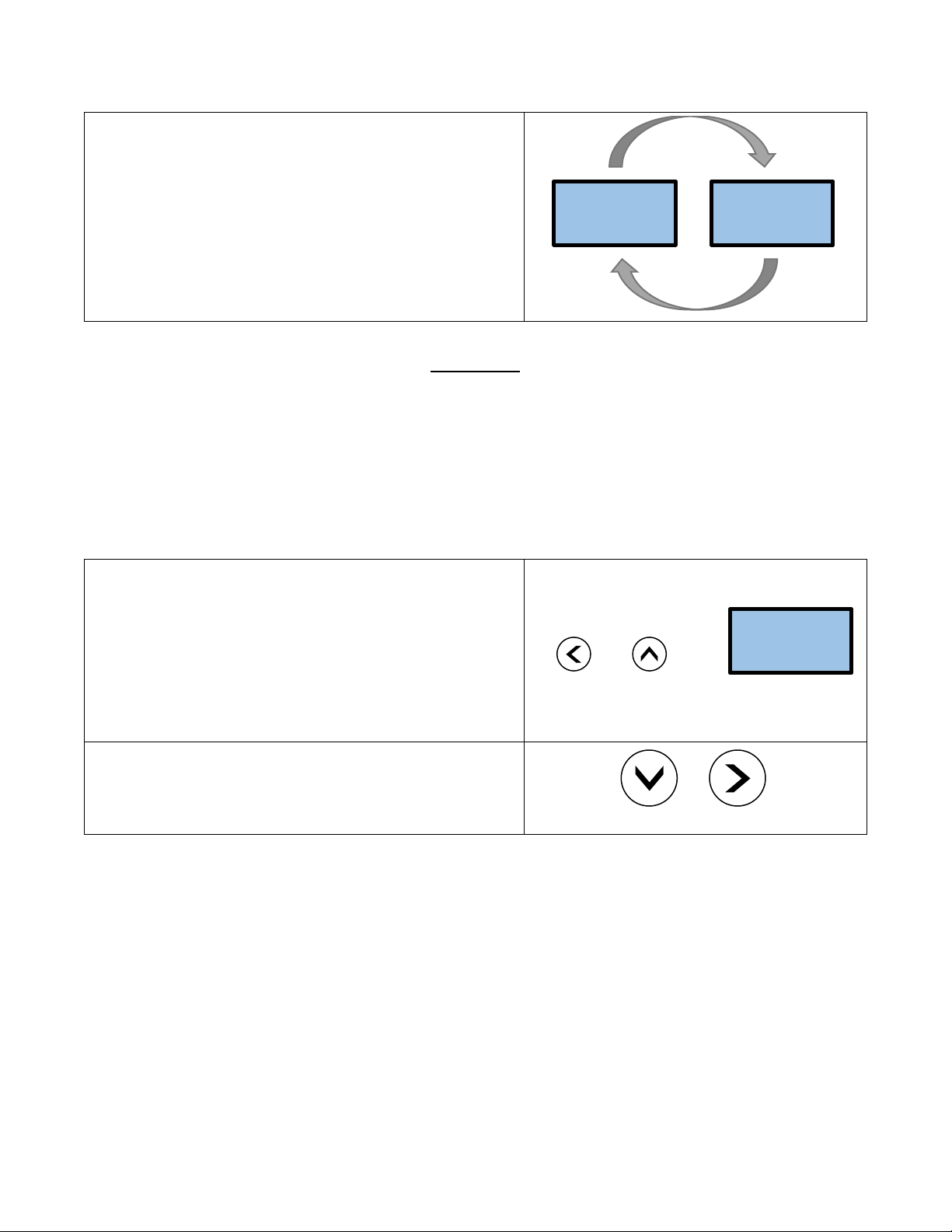

13) The security of the heater settings is provided by pressing

and holding the LEFT and UP buttons for 3 seconds to lock the

buttons. Once locked, the buttons have no function. Press and

hold the same LEFT and UP buttons for 3 seconds to unlock the

buttons.

The security status can be checked at any time by pressing any

one button. If the system is locked, the screen will display

“BUTTONS LOCKED”.

[ + ] =

14) The display can be turned off or on. Press and hold the

DOWN and RIGHT buttons for 3 seconds. If the display is off, it

can be turned on by pressing and holding the same DOWN and

RIGHT buttons for 3 seconds.

+

1 ERROR

CODE1:F0

SOFTWARE

20131218

BUTTONS

LOCKED

F0: Outlet thermistor out of range

F1: No change in water temperature detected

F2: Dry fire detected - Optical Sensor Tripped

F3: Excessive dry fire occurrences detected

F4: Inlet thermistor out of range

Fault Codes

Loading...

Loading...