Edwards Signaling Series 49 AdaptaBeacon, Series 50 AdaptaBeacon, Series 50SIN AdaptaBeacon, Series 51 AdaptaBeacon, Series 52 AdaptaBeacon Installation Guide

Page 1

Installation Instructions for Catalog Series 49, 50, 50SIN,

51 and 52 AdaptaBeacon

DescriptionDescription

Description

DescriptionDescription

Catalog Series 49, 50, 50SIN, 51 and 52 AdaptaBeacon signals are UL and cUL listed, general purpose visual and

visual/audible signaling appliances. The 49 and 50 series

are flashing lights. The 50SIN is a steady-on light. The 51

series are combination flashing lights with horn. The 51

series come in single and double horn versions; the double

horn version is denoted by a 2H in its catalog number.

The 52 series are rotating lights.

The 49, 50, 50SIN, 51 and 52 series signals are suitable for

indoor or outdoor (weatherproof) installation and utilize a standard base that allows direct surface mounting,

mounting on a 4" (102 mm) octagon box, or mounting

on 1/2" (13 mm) NPT conduit. For outdoor installation,

the signals must be mounted on conduit.

For product specification details see Table 2. Refer to

Table 3 for available replacement lamps, flashers, domes

and lenses.

PLC Compatibility

The electrical input load requirements for PLC compatible signaling devices are listed in Table 1. Signaling

devices may be directly connected to output cards that

meet these input load requirements.

®

Signals

InstallationInstallation

Installation

InstallationInstallation

WARNINGS

To prevent electrical shock, ensure that power is

disconnected before installing the signal.

To prevent electrical shock, use care when

disassembling the signal to pre vent tearing of the

permanently affixed gaskets provided for

weatherproofing.

Install in accordance with the latest edition of the National Electrical Code and local regulations.

1. For the 49, 50, 50SIN, 51 and 52 series signals, remove

the base from the signal using one of the following

applicable procedures.

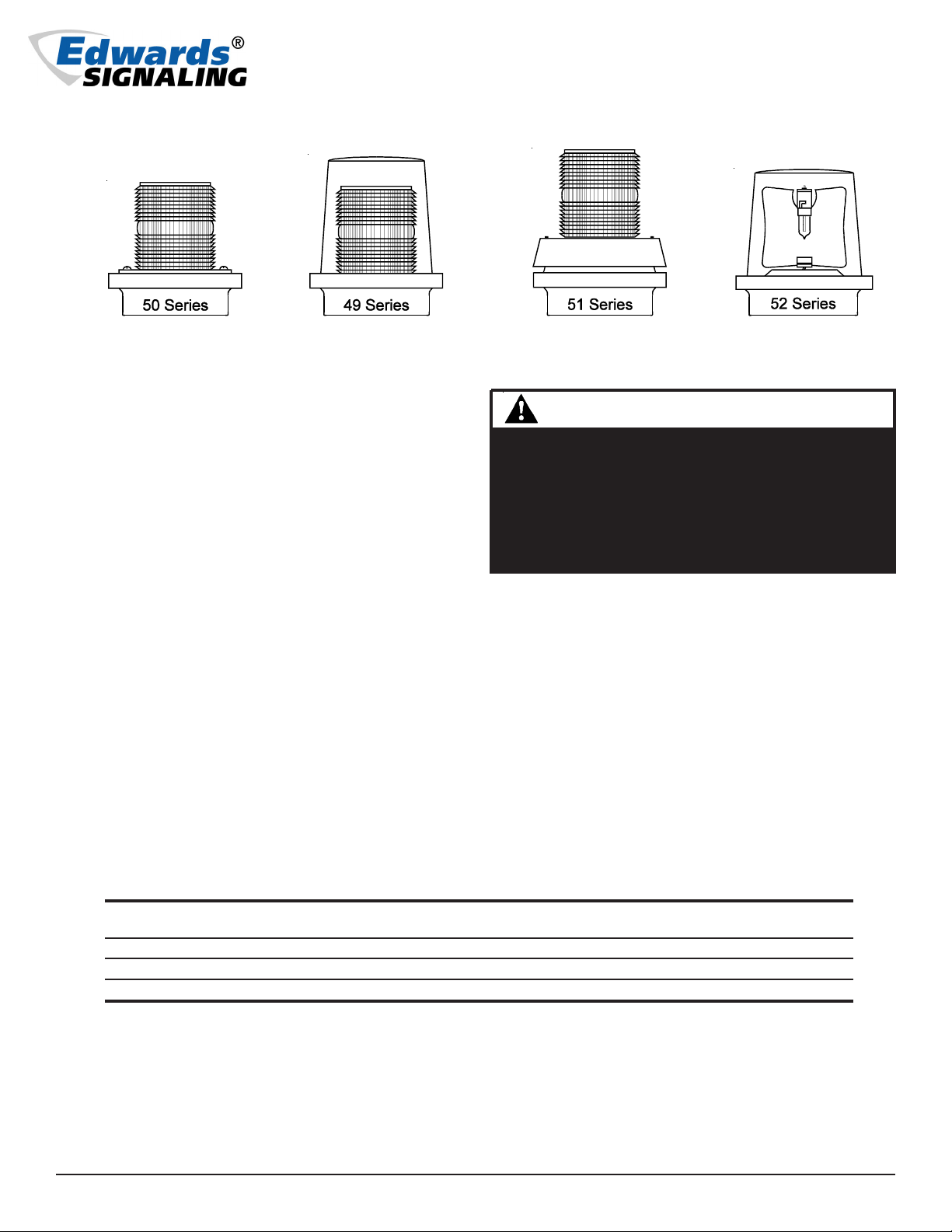

49 Series: See Figure 1. Remove the screw in the

clamp ring, remove the ring, and lift off the dome.

Loosen the three screws in the base of the lens and

turn the lens clockwise to remove. Then remove the

two screws that are partially set into the raised area

of the lamp assembly mounting plate, lift the

assembly off of the base, and pull the wire leads out

of the conduit entrance hole in the base. Proceed to

step 2 for installation of the base.

Table 1. PLC Compatibility

Operating Maximum off state Continuous on Surge (inrush/duration)

Cat. No. voltage* leakage current (mA) current (mA) (A/ms**)

50( )-N5-40WH 120V AC 25 300 2/8

50SIN( )-N5-40WH 120V AC 25 290 0.47/8

51( )-N5-40W 120V AC 25 350 2/8

*All AC volts at 60 Hz

**Amps/milliseconds

P-047550-0541 ISSUE 13 © 2003

Page 2

Figure 1. Catalog Series 49 Flashing Lights

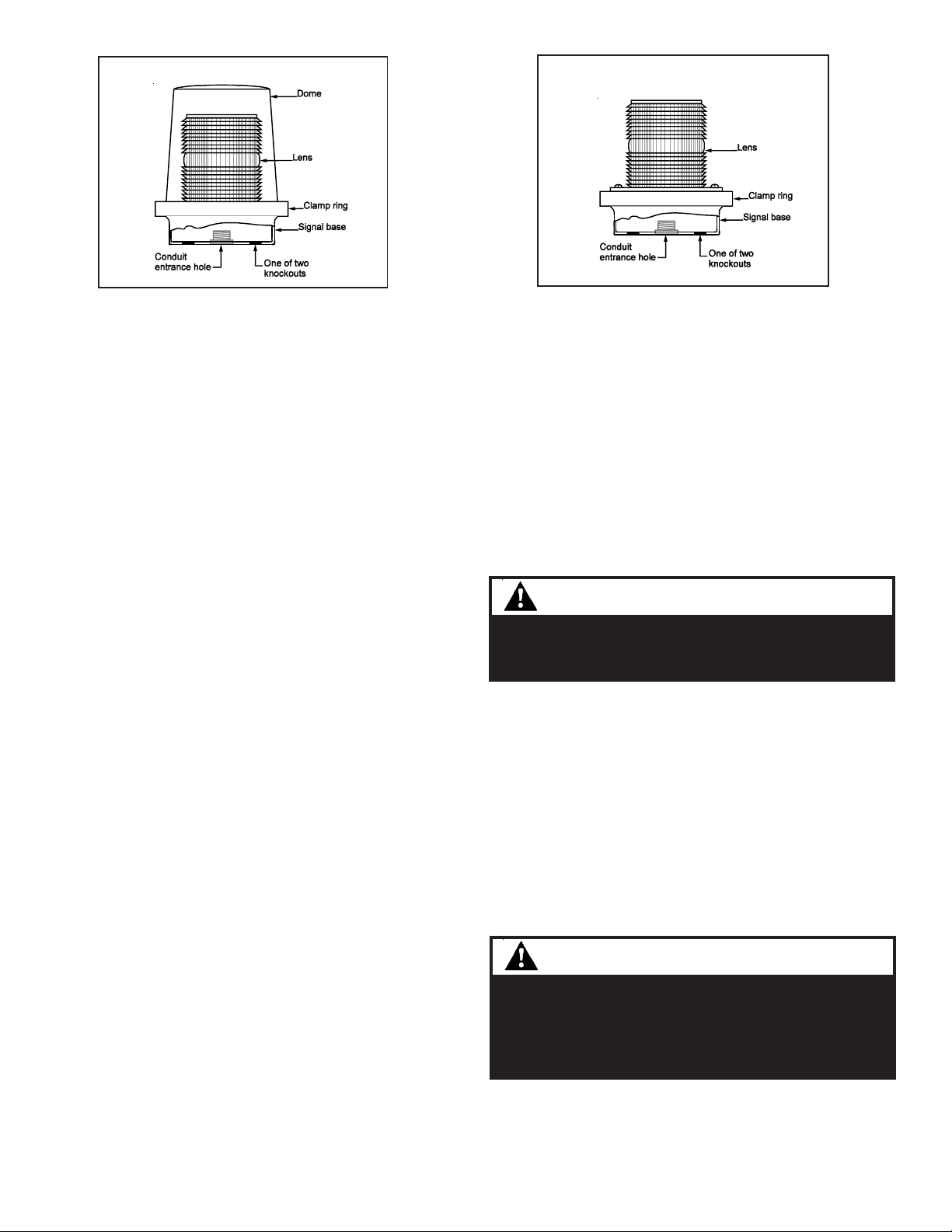

Figure 2. Catalog Series 50 and 50SIN

Flashing Lights

50 and 50SIN Series: See Figure 2. Remove the

screw in the clamp ring, remove the ring, lift the lens/

lamp assembly off of the base, and pull the wire leads

out of the conduit entrance hole in the base. Proceed

to step 2 for installation of the base.

51 Series: See Figure 3. Remove the screw in the

clamp ring, remove the ring, lift the lens/lamp

assembly off of the base, and pull the wire leads out

of the conduit entrance hole in the base. Proceed to

step 2 for installation of the base.

52 Series: See Figure 4. Remove the screw in the

clamp ring, remove the ring, and lift off the dome.

Then remove the two screws in the rotating lamp

assembly mounting plate, lift the assembly off of the

base, and pull the wire leads out of the conduit

entrance hole in the base. Proceed to step 2 for

installation of the base.

2. For indoor installation, the signal may be direct

surface mounted, mounted on a 4" (102 mm) octagon

box, or mounted on 1/2" (13 mm) NPT conduit. For

outdoor (weatherproof) installation, the signal must

be conduit mounted. Install the signal base using

one of the following applicable mounting

procedures.

Direct Surface Mounting (indoor installation only)

NOTE: For proper operation of the 52 series rotating

lights, the signals must be installed with the

dome facing either directly up or directly

down.

Remove the two knockouts for mounting screws from

the bottom of the signal base.

Route the field wiring from the required power source

through the conduit entrance hole in the base. Power

source requirements are in Tables 2 and 3.

Route the field wiring from the required power source

through the conduit entrance hole in the base. Power

source requirements are in Tables 2 and 3.

Fasten the base to the octagon box (not supplied) by

installing the screws supplied with the box through the

knockout holes in the base. Proceed to step 3 for wiring

connections.

Mounting on 1/2" (13 mm) NPT Conduit (indoor or

outdoor installation)

NOTE: For proper operation of the 52 series rotating

lights when mounting indoors, the signals

must be installed with the dome facing either

directly up or directly down.

WARNING

To prevent leakage and potential electrical shoc k

when mounting outdoor s, the signals must be

installed with the dome facing directl y up.

Route the field wiring from the required power source

through the conduit entrance hole in the base. Power

source requirements are in Table 2 located on the last

page of these instructions.

Install the base on the conduit (not supplied). Proceed

to step 3 for wiring connections.

3. Using wire nuts (not supplied), connect the field

wiring to the signal's wire leads. Polarity is not

important. A green ground wire is provided on all

units. Connect the green ground wire lead in

accordance with local codes. Place the connected

wires inside of the base and reassemble the signal

on the base.

Fasten the base to the surface by installing two #10 wood

screws (not supplied) or other suitable hardware through

the knockout holes in the base. Proceed to step 3 for

wiring connections.

Mounting on a 4" (102 mm) Octagon Box (indoor

installation only)

NOTE: For proper operation of the 52 series rotating

lights, the signals must be installed with the

dome facing either directly up or directly

down.

Remove the two knockouts for mounting screws from

the bottom of the signal base.

P-047550-0541 ISSUE 13

WARNINGS

To avoid risk of injur y, do not remove or insert lamp

when unit is ener gized.

To avoid risk of injur y, install lens before energizing

the unit.

4. Turn on power and verify that the signal operates

properly.

Page 3

Figure 3. Catalog Series 51 Flashing Lights

TT

rr

oubleshootingoubleshooting

T

r

oubleshooting

TT

rr

oubleshootingoubleshooting

Should the lamp fail to operate, check that power is on.

If power is on, either the lamp or the solid state flasher

module (the module is not used in the 52 series signals)

requires replacement. Replace the lamp first as directed

in the "Lamp Replacement" section that follows. Should

the replacement lamp also fail to operate, the flasher

module must be replaced. Refer to Table 3 for the required replacement flasher. Instructions for replacing

the flasher are provided with the flasher.

NOTE: Should both the lamp and horn fail to operate

in a 51 Series signal, replace the flasher

module.

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

with Horn

WARNINGS

To avoid risk of injury, do not remove or insert lamp

when unit is ener gized.

To avoid risk of injur y, install lens before energizing

the unit.

Figure 4. Catalog Series 52 Rotating Lights

WARNING

To prevent electrical shock, use care when

disassembling the signal to pre vent tearing of the

permanently affixed gaskets provided for

weatherproofing.

49 Series: See Figure 1. Remove the screw in the clamp

ring, remove the ring, and lift off the dome. Loosen the

three screws in the base of the lens and turn the lens

clockwise to remove. Replace the lamp.

50 and 50SIN Series: See Figure 2. Remove the three

screws from the top of the trim ring and lift off the lens

and ring. Replace the lamp.

51 Series: See Figure 3. Remove the three screws from

the top of the skirt and lift off the lens and skirt. Replace the lamp.

CAUTION

To prevent damage to the lens and/or dome,

use abrasive materials or cleaners.

do not

Lamp Replacement

Refer to Table 3 for the required lamp. After disconnecting power, replace the lamp using one of the following applicable procedures:

WARNING

To prevent electrical shock, ensure that power is

disconnected prior to disassemb ly.

52 Series: See Figure 4. Remove the screw in the clamp

ring, remove the ring, and lift off the dome. Replace

the lamp.

Cleaning

The signal's lens and/or dome should be peridodically

cleaned to maintain optimum light visibility. These items

may be cleaned with a soft cloth or sponge using mild

detergent. Ensure that the lens or dome is completely

dry before replacing.

P-047550-0541 ISSUE 13

Page 4

Table 2. Specifications

Catalog Number Rated Voltage Current

49(*)-R5 240V 50/60 Hz 0.10 amp

50(*)-R5 240V 50/60 Hz 0.10 amp

52(*)-R5 240V 50/60 Hz 0.10 amp

49(*)-N5-40WH 120V 50/60 Hz 0.30 amp

50(*)-N5-40WH 120V 50/60 Hz 0.30 amp

50SIN(*)-N5-40WH 120V 50/60 Hz 0.29 amp

51(*)-N5-40W 120V 50/60 Hz 0.29 amp

52(*)-N5-40WH 120V 50/60 Hz 0.35 amp

50(*)-G5-20WH 24V 50/60 Hz 0.80 amp

51(*)-G5-20W 24V 50/60 Hz 1.1 amp

52(*)-G5-20WH 24V 50/60 Hz 0.80 amp

Table 3. Replacement Parts

Replacement lamps, flashers, lenses and domes for the 49, 50, 50SIN, 51 and 52 series signals may be obtained from your

Edwards distr ibutor. The catalog n umbers or part numbers for these components are as f ollows.

Replacement Component

Signal Catalog Number Replacement Component Part Number

49(*)-N5-40WH, 50(*)-N5-40WH, Lamp - 40 Watt Halogen 50LMP-40WH or 50LMP-40W**

50SIN(*)-N5-40WH, 52(*)-N5-40WH 25T8DC**

51(*)-N5-40W Lamp - 40 Watt 50LMP-40W or 25T8DC

49(*)-R5, 50(*)-R5, 52 (*)-R5 Lamp - 25 Watt P-041917-0039 or

industry trade no. 25T8/240V/DC/CL

50(*)-G5-20WH, 52(*)-G5-20WH Lamp - 20 Watt Halogen 50LMP-20WH or industry trade no. 1638**

51(*)-G5-20W Lamp - 20 Watt 50LMP-20W or industry trade no. 1638

49(*)-N5-40WH, 50(*)-N5-40WH, Solid state flasher module P-041917-0026

51(*)-N5-40W

50(*)-G5-20WH, 51(*)-G5-20W Solid state flasher module P-041917-0029

49(*)-R5, 50(*)-R5 Solid state flasher module P-041917-0038

51(*)-N5-40W Horn 123A-N5

51(*)-G5-20W Horn 123A-G5

49(*)-N5-40WH, 49(*)-R5 Dome (Clear) 52-LC

52(*)-G5-20WH, 52(*)-N5-40WH, Dome 52-L(*)

52(*)-R5 (Amber, Blue, Clear, Green, Magenta or Red)

49(*)-N5-40WH, 49(*)-R5, Lens 92-L(*)

50(*)-N5-40WH, 50(*)-R5, (Amber, Blue, Clear, Green, Magenta or Red)

50(*)-G5-20WH, 50SIN(*)-N5-40WH,

51(*)-G5-20W, 51(*)-N5-40W

*Specify color of item by adding one of the following letters to the catalog number: A - amber, B - blue, C - clear, G - green,

M - magenta, or R - red (e .g., a red dome f or the 52 ser ies signal is 52-LR).

**The listed non-halogen b ulb may be used instead of the halogen b ulb.

P-047550-0541 ISSUE 13

Loading...

Loading...