Page 1

Specifications

Installation Instructions for Catalog Series 48

AdaptaBeacon

Signals

Catalog Electrical Lamp

Number Rating Ratings

48SIN(*)-E1 12V DC 188 Lumens

1.0A 1,520 hr.

48SIN(*)-G1-20WH 24V DC 226 Lumens

0.80A 20,000 hr.

48SIN(*)-G5-20WH 24V 50/60 Hz 226 Lumens

0.80A 20,000 hr.

48SIN(*)-N5-25WH 120V 50/60 Hz 175 Lumens

0.20A 20,000 hr.

48SLED(**)-G1 24V DC 100,000 hr.

†

‡

†

‡

†

‡

†

‡

‡

0.062A

48SLED(**)-N5 120V 50/60 Hz 100,000 hr.

‡

0.022A

48FIN(*)-E1 12V DC 188 Lumens

1.0A 1,520 hr.

48FIN(*)-G1-20WH 24V DC 226 Lumens

0.80A 25,000 hr.

48FIN(*)-G5-20WH 24V 50/60 Hz 226 Lumens

0.80A 25,000 hr.

48FIN(*)-N5-25WH 120V 50/60 Hz 175 Lumens

0.20A 25,000 hr.

48FLED(**)-G1 24V DC 100,000 hr.

†

‡

†

‡

†

‡

†

‡

‡

0.062A

48FLED(**)-N5 120V 50/60 Hz 100,000 hr.

‡

0.022A

*Specify color of lens by adding one of the following letters to the cat.

number: A-amber, B-blue, C-clear, G-green, M-magenta, or R-red.

**Specify color of lens by adding one of the following letters to the cat.

number: A-amber, B-blue, G-green, or R-red.

†

Bulb manufacturer's Lumen rating.

‡

Projected lamp life based on manufacturer's calculated lamp life at 65

fpm and 50% duty cycle.

Description

The Catalog Series 48 Adaptabeacon signal is a UL and cUL listed

signaling appliance in a NEMA 4X enclosure. The signals are

suitable for indoor or outdoor (weatherproof) installation and are

available in AC and DC models as listed above.

Table 1. PLC Compatibility

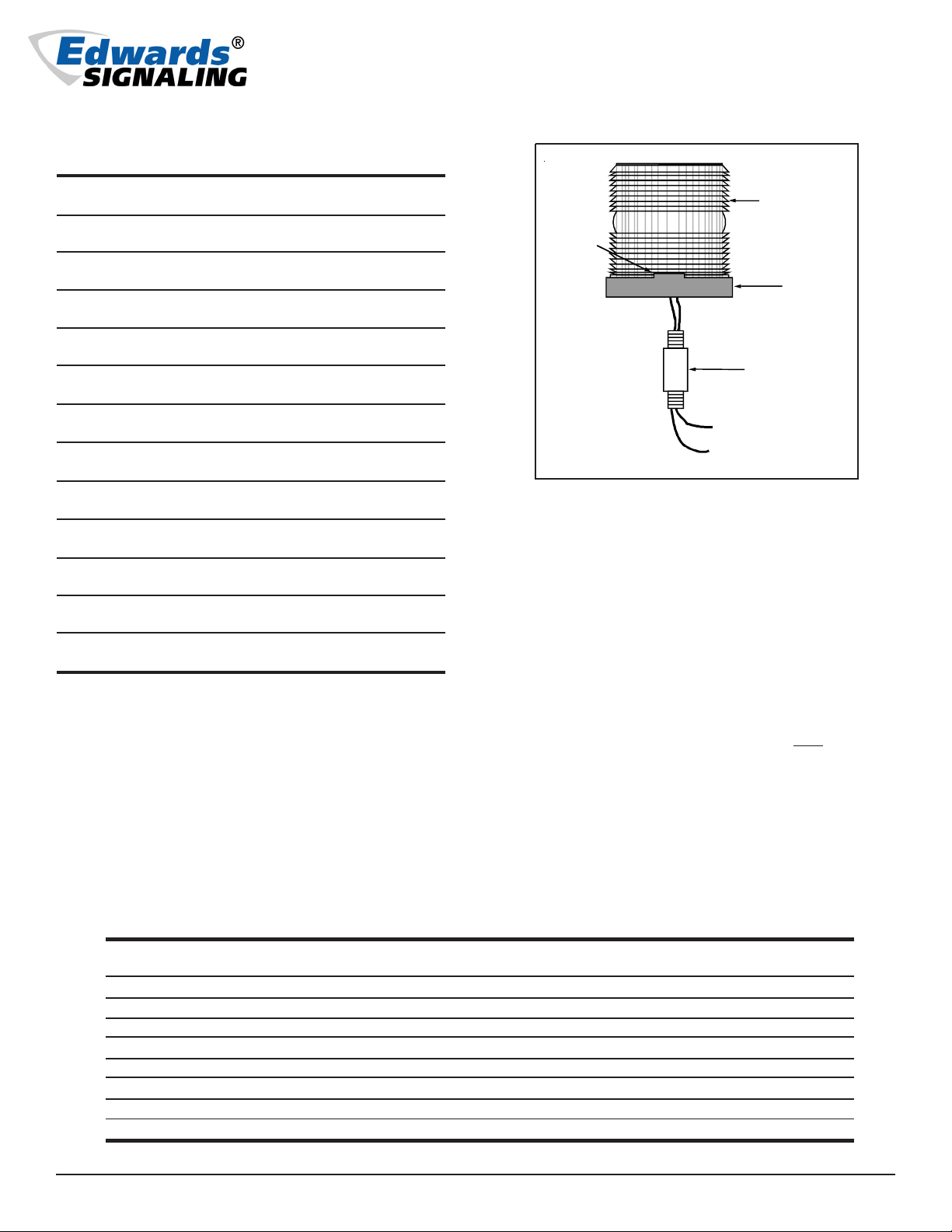

Lens

Locking

Mechanism

Mounting base

and lamp

support plate

1/2“ (13mm)

NPT conduit

(not supplied)

To field wiring

Figure 1. Conduit Mounting

Edwards halogen models, 48SIN and 48FIN, are designed for use

where increased light output is required. The 20 watt halogen

bulbs are rated by the manufacturer at 226 lumens. The 25 watt

halogen bulbs are rated at 175 lumens.

Edwards 48FLED long life, flashing LED models are effective in

high noise level areas, especially where ear protection must be

worn and a visual status indicator is required. Edwards 48SLED

long life, steady-on LED models are suited for light duty applications where a continuous steady-on status indicator is required

and where ambient noise makes audible signals difficult to hear.

The 48 series signals can be mounted on 1/2" (13mm) NPT conduit (indoor or outdoor) or direct surface mounted (indoor). For

outdoor (weatherproof) installation, the signals must be conduit

mounted with their lens facing directly up. When installing indoors, these signals can be mounted in any position.

PLC Compatibility

The electrical input load requirements for PLC compatible signaling devices are listed in Table 1. Signaling devices may be

directly connected to output cards that meet these requirements.

Operating Maximum off state Continuous on Surge (inrush/duration)

Cat. No. voltage* leakage current (mA) current (mA) (A/ms**)

48SIN( )-G1-20WH 24V DC 25 800 0.9/1

48SIN( )-N5-25WH 120V AC 25 200 0.8/8

48SLED( )-G1 24V DC 4 65 0.07/1

48SLED( )-N5 120V AC 5 25 0.09/8

48FIN( )-G1-20WH 24V DC 25 800 2.2/100

48FIN( )-N5-25WH 120V AC 25 200 1.3/8

48FLED( )-G1 24V DC 4 65 0.07/1

48FLED( )-N5 120V AC 5 25 0.09/8

*All AC volts at 60 Hz

**Amps/milliseconds

P-047550-1448 ISSUE 10 © 2003

Page 2

Installation

WARNING

To prevent electrical shock, ensure that power is

disconnected before installing the signals.

Install in accordance with the latest edition of the National Electrical Code and local regulations. Install the signals using one of

the following applicable mounting procedures.

Conduit Mounting (Indoor or Outdoor) - Figure 1

WARNING

To prevent leakage and a potential shock hazard,

when mounting outdoor s the signal m ust be

installed with the lens or dome facing directl y up.

1. Route the signal's wire leads through 1/2" (13mm) NPT

conduit (not supplied) and thread the conduit into the signal

mounting base.

2. Connect the field wiring to the signal wire leads as described

in the Wiring Section.

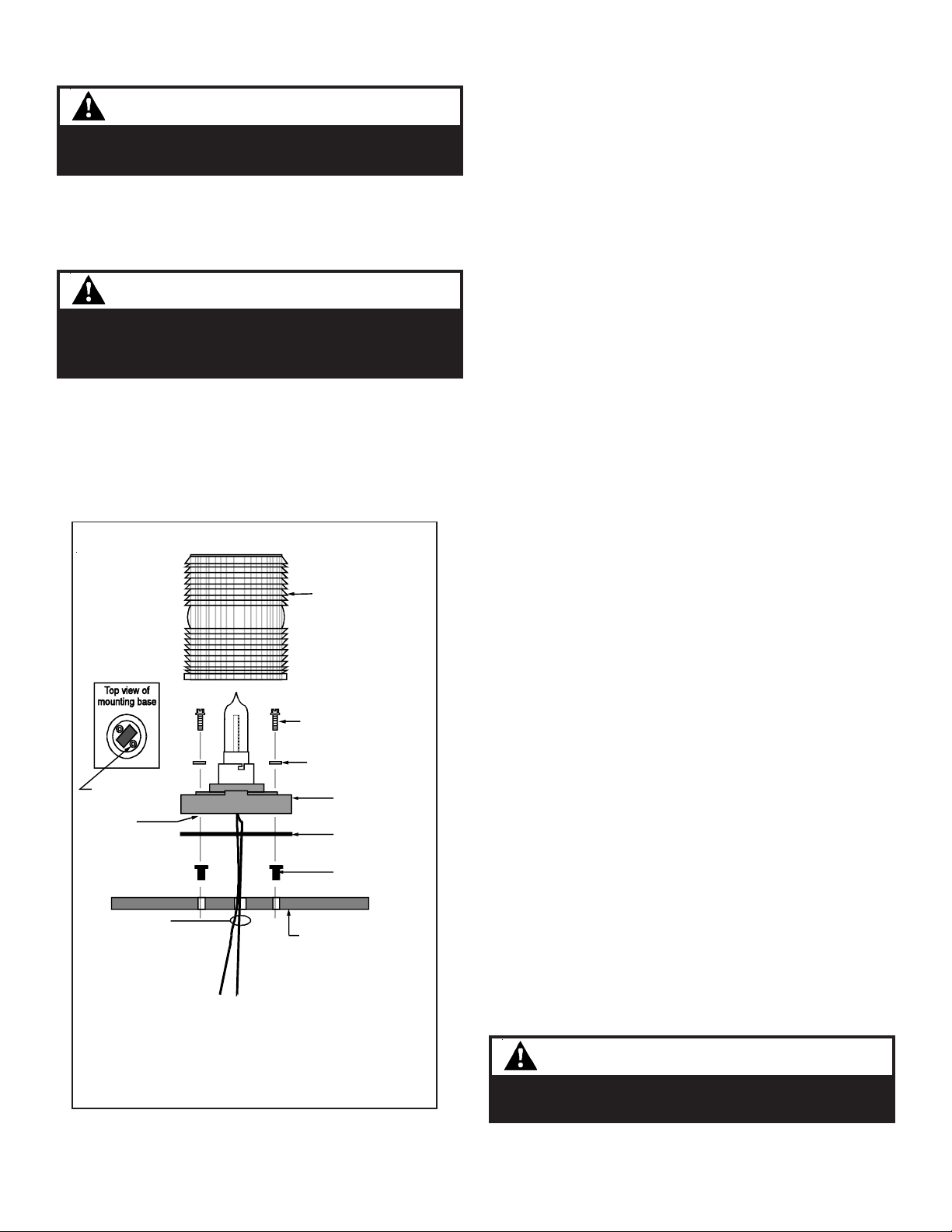

Direct Surface Mounting (Indoor Only) - Figure 2

NOTE: AC signals may be direct surface mounted but are not

supplied with a direct surface mounting kit. The

installer should use suitable hardware appropriate for

the installation.

1. Insert a small flat blade screwdriver between the locking

mechanism and the lens. Gently push down and then pry up,

unseating the lens. Pull the lens up and off of the signal

mounting base, being careful not to damage the lamp.

2. Remove the two knockouts for mounting screws from the

signal base. Place the 3-3/4" (95mm) mounting gasket

provided in the direct surface mounting kit (DC models only)

on the mounting surface and mark the center of the three

holes in the gasket on the mounting surface. Remove the

gasket and drill a 3/8" (10mm) hole at each of the marked

positions.

3. Install the two rubber expansion plugs provided in the

hardware kit (DC models only) into the two outer holes in

the mounting surface.

4. Route the wire leads from the signal base through the center

hole in both the mounting gasket and surface. The wiring

should be run through an approved raceway or conduit

connected between the bottom of the signal base and an

approved junction box (not supplied). Bring wire leads into

the junction box. Refer to the signal's label for voltage rating.

One of two

knockouts for

direct surface

mounting

Enclose in

Raceway

Lens

(2) Mounting

screws (supplied with

DC models)

(2) Lockwashers (supplied

with DC models)

Mounting base

and lamp

support plate

Mounting gasket

(supplied with DC

models)

(2) Rubber expansion

plugs (supplied with

DC models)

Mounting surface

5. Align the outer holes in the mounting gasket with the holes

in the surface. Insert two screws with lockwashers through

the two outer holes in the signal base and align the screws

with the rubber expansion plugs as shown in Figure 2. Press

the signal base firmly against the mounting surface and tighten

the screws.

6. Connect the field wiring to the signal wire leads as described

in the Wiring Section.

Wiring

1. For AC models, use wire nuts (not supplied) and connect the

signal's black and white wire leads to the power source wires.

Polarity is not important.

2. For DC models, connect the signal's red wire to the positive

power source wire and connect the signal's black wire to the

negative power source using appropriate connectors (not

supplied). Polarity must be observed.

Troubleshooting

If the signal light fails to operate, make sure there is power to the

signal. If there is power and the light still fails to operate, replace

the lamp as directed in the "lamp replacement" section.

To field wiring

NOTE: Enclose wiring within an approved raceway

interconnecting the appliance and junction

box in accordance with governing codes,

standards and regulations.

Figure 2. Direct Surface Mounting of the 48 Series

Signals

P-047550-1448 ISSUE 10

Maintenance

Cleaning

CAUTION

To prevent damage to the lens, do not use abrasive

materials or cleaners.

Periodically clean the Adaptabeacon lens surface with a soft cloth

or sponge and water or a mild detergent solution to maintain op-

Page 3

timum light visibility. Ensure that the lens is completely dry

before assembling the signal.

Lamp Replacement (non-LED models onl y)

WARNINGS

To prevent injury, do not remove or insert lamp

when unit is ener gized.

To prevent leakage and potential electrical shoc k,

use care when disassembling the signals to

prevent tearing of the weatherproof gaskets.

Refer to the "Replacement Parts" section, for the required type of

lamp. After disconnecting power, replace the lamp as follows:

Refer to Figure 3.

CAUTION

To prevent property damage and injury,

touch glass with bare fingers. Grasp glass with a

soft, clean cloth or with packaging supplied with

the replacement lamp.

1. Insert a small flat blade screwdriver between the locking

mechanism and the lens. Gently push down and then pry up,

unseating the lens. Pull the lens up and off of the signal

mounting base.

2. Gently push down on the lamp, twist and pull up to remove

the lamp from its socket. Install the new lamp by aligning

the connector on the base of the tube with its mating socket,

then carefully press down into the socket. Assemble the

signal.

3. Apply power to the signal and verify that the signal operates

properly.

do not

Figure 3. Lamp Replacement

Replacement Parts

Component Catalog or Part Number

Halogen Lamp - 48SIN(*)-N5-25WH, 48FIN(*)-N5-25WH 50LMP-25WH or

Industry Trade No. 15T7DC**

Halogen Lamp - 48SIN(*)-G1-20WH, 48SIN(*)-G5-20WH, 50LMP-20WH or

48FIN(*)-G1-20WH, 48FIN(*)-G5-20WH Industry Trade No. 1692**

Incandescent Lamp - 48SIN(*)-E1, 48FIN(*)-E1 Industry Trade No. 94

Lens (Amber, Blue, Clear, Green, Magenta or Red) - 48FIN and 96-L(*)

48SIN Series

Lens (Amber, Blue, Green, Red) - 48FLED and 48SLED Series 96-L(*)

*Specify color of lens by adding one of the following letters to the catalog number: A-amber, B-blue,

C-clear, G-green, M-magenta, or R-red. Example: A red lens for the 48SIN series signal is 96-LR.

**The non-halogen bulb listed may be used in the halogen bulb models.

P-047550-1448 ISSUE 10

Loading...

Loading...