Page 1

LIFE SAFETY & INCIDENT MANAGEMENT

Intelligent 3D

Multisensor

Detector

SIGA-PHS

EDWARDS Catalog u Intelligent Initiating

Overview

The Signature Series Model SIGA-PHS Intelligent 3D Multisensor

Detector gathers analog information from each of its two fire sensing elements (photoelectric and heat) and converts it into digital

signals. The detector’s on-board microprocessor measures and

analyzes these signals separately with respect to a third element

- Time. We call this technology 3D. It compares the information to

historical readings, time patterns, and several known fire characteristics to make an alarm decision. Digital filters remove signal

patterns that are not typical of fires. Unwanted alarms are virtually

eliminated.

Standard Features

• Integrates photoelectric smoke and 135 º F (57 º C) fixed-temperature heat sensing technologies

• Non-volatile memory

• Automatic device mapping

• Electronic addressing

• Environmental compensation

• Integral microprocessor - intelligent detector

• Wide 0.67% to 3.77%/ft. sensitivity range

• Twenty pre-alarm sensitivity values, set in 5% increments

• Identification of dirty or defective detectors

• Automatic day/night sensitivity adjustment

• Twin RED/GREEN status LEDs

• Standard, relay, fault isolator, and audible mounting bases

• Designed and manufactured to ISO 9001 standards

Note: Some features described here may not be supported by all control

systems. Check your control panel’s Installation and Operation Guide for

details.

MEA

7272-1657:

0126

S853

Signature Series Overview

The microprocessor in each detector provides four additional

benefits - Self-diagnostics and History Log, Automatic Device

Mapping, and Fast, Stable Communication.

Self-diagnostics and History Log - Each Signature Series

detector constantly runs self-checks to provide important maintenance information. The results of the self-check are automatically

updated and permanently stored in the detector’s non-volatile

memory. This information is accessible for review any time at the

control panel, PC, or by using the SIGA-PRO Signature Program/

Service Tool.

Automatic Device Mapping - The loop controller learns where

each device’s serial number address is installed relative to other

devices on the circuit. This mapping feature provides supervision

of each device’s installed location to prevent a detector from being

reinstalled (after cleaning etc.) in a different location from where it

was originally. The history log for the detector remains relevant and

intact regardless of its new location.

The Signature Series Data Entry Program also uses the mapping

feature. With interactive menus and graphic support, the wired circuits between each device can be examined. Layout or “as-built”

drawing information showing wire branches (T-taps), device types

and their address are stored on disk for printing hard copy. This

takes the mystery out of the installation. The preparation of as-built

drawings is fast and efficient.

Page 1 of 4 DATA SHEET E85001-0247

Not to be used for installation purposes. Issue 1

Page 2

Fast Stable Communication - On-board intelligence means less

information needs to be sent between the detector and the loop

controller. Other than regular supervisory polling response, the detector only needs to communicate with the loop controller when it

has something new to report. This provides very fast control panel

response time and allows a lower baud rate (speed) to be used for

communication on the circuit.

Environmental Compensation - Detection sensitivity for the

SIGA-PHS is virtually independent of its installed environment and

its physical condition. Environmental compensation means each

sensing element adapts to long-term changes caused by dirt,

humidity, temperature, aging etc. It even compensates for small

amounts of normal ambient smoke.

Sensitivity Range - The SIGA-PHS has a sensitivity range or

window of 0.67 - 3.70% obscuration per foot. The installer selects

the detector’s ALARM sensitivity level. Five settings ranging from

the least sensitive at 3.5% obscuration/ft to the most sensitive at

1.0% obscuration/ft are available.

Automatic Day/Night Sensitivity Selection - Signature Series

detectors may be programmed for different sensitivities during day

and night periods. This allows the detector to be more sensitive

during unoccupied periods when lower ambient background conditions are expected.

Stability - The 3D detector’s sensitivity remains stable in wind

velocities up to 500 ft/min (2.53 m/sec). Ambient temperature has

very little affect on the detector. The detector may be installed in

rooms with ambient temperatures up to 100oF (38oC).

Electronic Addressing - The loop controller electronically ad-

dresses each detector, saving valuable time during system commissioning. Setting complicated switches or dials is not required. Each

detector has its own unique serial number stored in its on-board

memory. The loop controller identifies each device on the circuit and

assigns a “soft” address to that device’s serial number. If desired,

detectors can be addressed using the SIGA-PRO Signature Program/Service Tool.

Testing & Maintenance

Each detector automatically identifies when it is dirty or defective

and causes a “dirty detector” message. The detector’s sensitivity measurement can also be transmitted to the loop controller. A

sensitivity report can be printed to satisfy NFPA sensitivity measurements which must be conducted at the end of the first year

and every two years thereafter.

The user-friendly maintenance program shows the current state

of each detector and other pertinent messages. Single detectors

may be turned off temporarily, from the control panel. Availability of

maintenance features is dependent on the fire alarm system used.

Scheduled maintenance (Regular or Selected) for proper detector operation should be planned to meet the requirements of the

Authority Having Jurisdiction (AHJ). Refer to current NFPA 72 and

ULC CAN/ULC 536 standards.

Installation

Signature Series detectors mount to North American 1-gang

boxes, 3-1/2 inch or 4 inch octagon boxes, and to 4 inch square

electrical boxes 1-1/2 inches (38 mm) deep. They mount to European BESA and 1-gang boxes with 60.3 mm fixing centers.

Compatibility

The SIGA-PHS detectors are compatible only with the Signature

Loop Controller.

Application

Although photoelectric detectors have a wide range of fire sensing capabilities they are best suited for detecting slow, smoldering

fires. The table below shows six standard test fires used to rate

the sensitivity of smoke and heat detectors. The table indicates

SIGA-HRS and

Test Fire SIGA-PS Photo

Open Wood unsuitable optimum very suitable optimum

Wood Pyrolysis optimum unsuitable optimum optimum

Smouldering Cotton optimum unsuitable optimum optimum

Poly Urethane Foam very suitable suitable very suitable optimum

n-Heptane very suitable very suitable optimum optimum

Liquid Fire without

Smoke

unsuitable optimum very suitable very suitable

SIGA-HFS Rate-ofRise/ Fixed Temp.

that no single sensing element is suited for all test fires.

EDWARDS recommends that this detector be installed according

to latest recognized edition of national and local fire alarm codes.

SIGA-PHS

Photo Heat 3D

SIGA-IPHS

Ion/Photo/Heat 4D

Page 2 of 4 DATA SHEET E85001-0247

Not to be used for installation purposes. Issue 1

Page 3

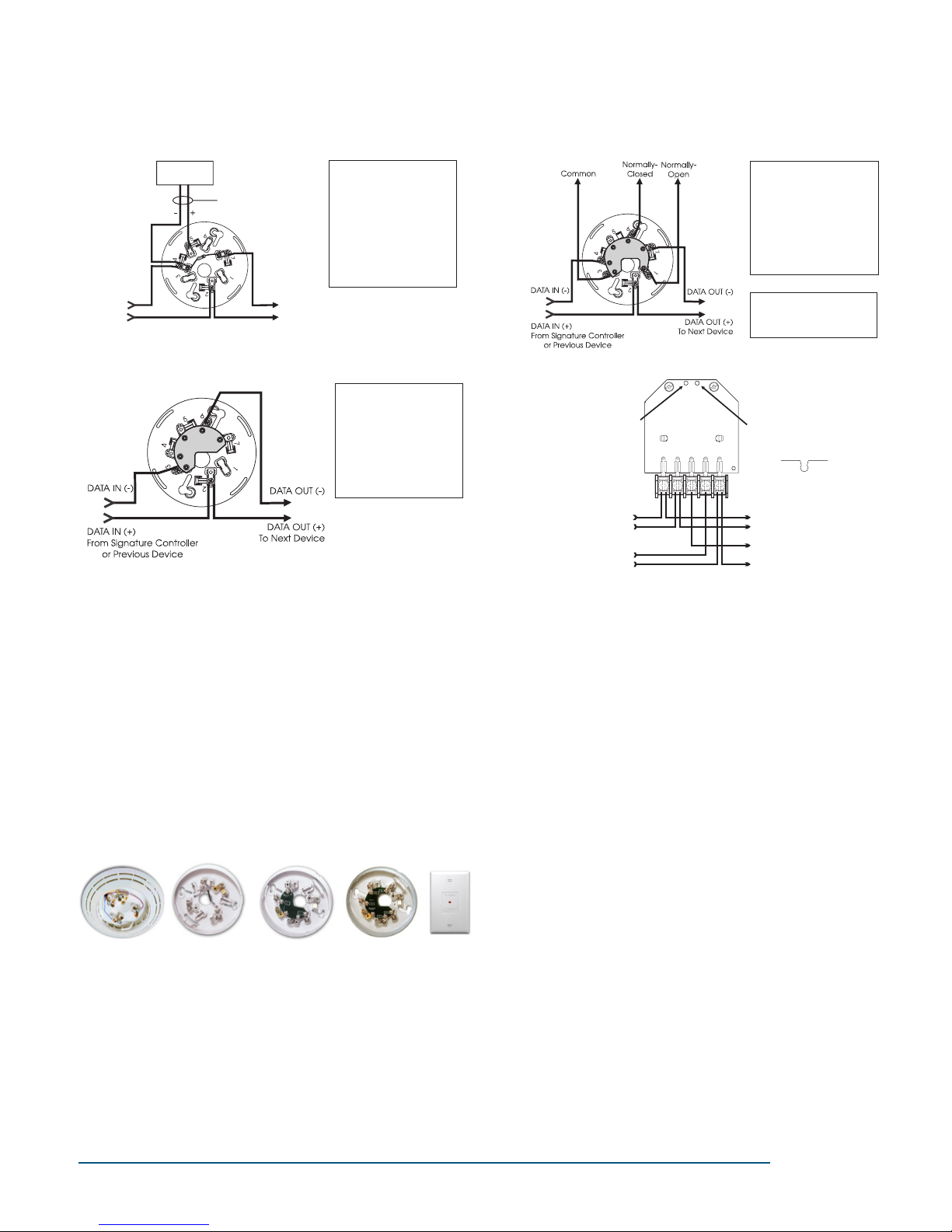

Typical Wiring

Max resistance

per wire

must not exceed

10 Ohms

DATA IN (-)

DATA IN (+)

From Signature Controller

DATA OUT (-)

DATA OUT (+)

To Next Device

Remote LED

The detector mounting bases accept #18 AWG (0.75mm2), #16 (1.0mm2), #14 AWG (1.5mm2), and #12 AWG (2.5mm²) wire sizes.

Note: Sizes #16 AWG (1.0mm2) and #18 AWG (0.75mm2) are preferred for ease of installation. See Signature Loop Controller catalog

sheet for detailed wiring requirement specifications.

Standard Detector Base, SIGA-SB, SIGA-SB4

Term Description

1 Not Used

2 DATA IN/OUT (+)

3 Not Used

4 DATA IN (-)

4 Remote LED (-)

5 Remote LED (+)

6 Not Used

7 DATA OUT (-)

Relay Detector Base, SIGA-RB, SIGA-RB4

Term Description

1 Normally-Open

2 DATA IN/OUT (+)

3 Common

4 DATA IN (-)

5 Not Used

6 Normally-Closed

7 DATA OUT (-)

CONTACT RATING

1.0 Amp @ 30 VDC

(Pilot Duty)

Isolator Detector Base, SIGA-IB, SIGA-IB4

Term Description

1 Not Used

2 DATA IN/OUT (+)

3 DATA IN (-)

4 Not Used

5 Not Used

6 DATA OUT (-)

7 Not Used

Accessories

All detector mounting bases have wiring terminals that are accessible from the “room-side” after mounting the base to the electrical

box. The bases mount to North American 1-gang boxes and to 3½

inch or 4 inch octagon boxes, 1½ inches (38 mm) deep. They also

mount to European BESA and 1-gang boxes with 60.3 mm fixing

centers. The SIGA-SB4, SIGA-RB4, and SIGA-IB4 mount to North

American 4 inch square electrical boxes in addition to the above

boxes. They include the SIGA-TS4 Trim Skirt which is used to cover

the “mounting ears” on the base. The SIGA-AB4G mounts to a 4”

sqare box only.

Standard Base SIGA-SB, SIGA-SB4 - This is the basic mount-

ing base for EDWARDS Signature Series detectors. The SIGA-LED

Remote LED is supported by the Standard Base.

Relay Base SIGA-RB, SIGA-RB4 - This base includes a relay.

SIGA-AB4G

Audible Base

SIGA-SB

Standard Base

SIGA-IB

Isolator Base

Normally open or closed operation is selected during installation.

The dry contact is rated for one amp (pilot duty) @ 30 Vdc. The

relay’s position is supervised to avoid accidentally jarring it out of

position. The SIGA-RB can be operated as a control relay if programmed to do so at the control panel (EST3 V. 2 only). The relay

base does not support the SIGA-LED Remote LED.

Audible Base SIGA-AB4G - This base is designed for use where

localized or group alarm signaling is required. When the detector

senses an alarm condition, the audible base emits a local alarm

signal. The optional SIGA-CRR Polarity Reversal Relay can be

SIGA-RB

Relay Base

SIGA-LED

Remote LED

Audible Detector Base, SIGA-AB4G

Volume setting

Default=High volume

Cut for low volume

24 Vdc in

From power supply or

previous base

From Signature controller or

Datain

previous device

DATA-

DATA-INDATA+

OUT

SIG+ SIG-

-

+

-

+

Tone setting

Default =Temporal pattern

Cut for steady tone

IN/OUT

-

+

-

+

To configure output volume

or tone, cut the circuit board

as shown.

24 Vdc out

To next base or EOL relay

Data out

To next Signature device

used for sounding to other audible bases on the same 24 Vdc

circuit.

Relay and Audible Bases operate as follows:

- at system power-up or reset, the relay is de-energized

- when a detector is installed in the base with the power on, the

relay energizes for four seconds, then de-energizes

- when a detector is removed from a base with the power on,

the relay is de-energized

- when the detector enters the alarm state, the relay is energized.

Isolator Base SIGA-IB, SIGA-IB4 - This base includes a built-in line

fault isolator for use on Class A circuits. A detector must be installed

for it to operate. The isolator base does not support the SIGA-LED

Remote LED.

The isolator operates as follows:

- a short on the line causes all isolators to open within 23 msec.

- at 10 msec intervals, beginning on one side of the Class A

circuit nearest the loop controller, the isolators close to provide

the next isolator down the line with power.

- when the isolator next to the short closes, it reopens within

10 msec.

The process repeats beginning on the other side of the loop controller.

Remote LED SIGA-LED - The remote LED connects to the

SIGA-SB or SIGA-SB4 Standard Base only. It features a North

American size 1-gang plastic faceplate with a white finish and red

alarm LED.

SIGA-TS4 Trim Skirt - Supplied with 4 inch bases, it can also

be ordered separately to use with the other bases to help hide

surface imperfections not covered by the smaller bases.

Page 3 of 4 DATA SHEET E85001-0247

Not to be used for installation purposes. Issue 1

Page 4

LIFE SAFETY & INCIDENT MANAGEMENT

Contact us...

Email: edwards.fire@fs.utc.com

Web: Edwards-fire.com

Warnings & Cautions

This detector will not operate without electrical power. As fires frequently cause power

interruption, we suggest you discuss further safeguards with your fire protection specialist.

This detector will NOT sense fires that start in areas where smoke or heat cannot reach

the detector. Smoke from fires in walls, roofs, or on the opposite side of closed doors may

not reach the detector to alarm it. The heat sensor in this device only provides a source

of information to supplement the information provided by the photoelectric smoke sensor.

The heat sensor by itself does NOT protect life against fire and smoke.

EDWARDS is a UTC brand.

1016 Corporate Park Drive

Mebane, NC 27302

© 2016 United Technologies Corporation.

All rights reserved.

Specifications

Smoke Sensing

Element

Heat Sensing Element Fixed Temperature Alarms at 135ºF (57ºC) Ambient

Operating and Storage

Environment

Sensitivity Range ULI/ULC - 0.67% to 3.77%

User Selected Alarm

Sensitivity Settings

Pre-alarm Sensitivity 5% increments, allowing up to 20 pre-alarm settings

Operating Voltage 15.2 to 19.95 Vdc (19 Vdc nominal)

Operating Current Quiescent: 45µA @ 19 V. Alarm: 45µA @ 19 V. Pulse Current: 100 µA

Construction & Finish High Impact Engineering Polymer - White

Compatible Mounting

Bases

LED Operation On-board Green LED - Flashes when polled On-board Red LED -

Compatibility Use With: Signature Loop Controller

Address Requirements Uses one Device Address

Agency Listings UL, ULC, CSFM, MEA

UL Listed Spacing 30 ft

Photoelectric - Light Scattering Principle

Operating Temp: 32ºF to 100ºF (0ºC to 38ºC) Storage Temp: -4ºF to

140ºF (-20ºC to 60ºC) Humidity: 0 to 93% RH, Non-Condensing

Most Sensitive: 1.0%/ft. More Sensitive: 2.0%/ft. Normal: 2.5%/ft. Less

Sensitive: 3.0%/ft. Least Sensitive: 3.5%/ft.

(100 msec). During Communication: 9 mA maximum.

SIGA-SB Standard Base, SIGA-RB Relay Base, SIGA-IB Isolator Base,

SIGA-AB4, SIGA-AB4G Audible Bases

Flashes when in alarm. Compatible Remote Red LED (model SIGALED) Flashes when in alarm

Ordering Information

Catalog

Number

SIGA-PHS Intelligent 3D Multisensor Detector - UL/ULC Listed .5 (.23)

Accessories

SIGA-SB Detector Mounting Base

SIGA-SB4 4-inch Detector Mounting Base c/w SIGA-TS4 Trim Skirt

SIGA-RB Detector Mounting Base w/Relay

SIGA-RB4 4-inch Detector Mounting Base w/ Relay c/w SIGA-TS4 Trim Skirt

SIGA-IB Detector Mounting Base w/Fault Isolator

SIGA-IB4 4-inch Detector Mounting Base w/Fault Isolator c/w SIGA-TS4 Trim Skirt

SIGA-LED Remote Alarm LED

SIGA-

AB4G

SIGA-TS4 Trim Skirt (supplied with 4-inch bases) 0.1 (.04)

Page 4 of 4 DATA SHEET E85001-0247

Not to be used for installation purposes. Issue 1

Description Ship Wt.

Audible (Sounder) Base 0.3

lbs (kg)

0.2 (.09)

(0.15)

10-27-16

Loading...

Loading...