Page 1

Edwards SAPIEN 3 Transcatheter Heart Valve

with the Edwards Commander Delivery System

Instructions for Use

CAUTION: Federal (USA) law restricts these devices to sale by or on the order of a physician.

Implantation of the transcatheter heart valve should be performed only by physicians who have

received Edwards Lifesciences training. The implanting physician should be e xperienced in

balloon aortic valvuloplasty.

Please verify that you have the latest version of the instructions for use prior to u sing the device

by visiting http://THVIFU.edwards.com or by calling 1.800.822.9837. In order to access the

instructions for use, an IFU Code will be required.

STERILE: The valve is supplied sterilized with glutar aldehyde solution. The delivery system,

eSheath introducer set, and crimper are supplied sterilized with ethylene oxide gas.

Edwards, Edwards Lifesciences, the stylized E logo, Carpentier-Edwards, EDWARDS COMMANDER,

Edwards eSheath, Edwards SAPIEN, Edwards SAPIEN 3, eSheath, PARTNER, PART N ER I I, Qualcrimp,

SAPIEN, SAPIEN 3, TFX, and ThermaFix are trademarks of Edwards Lifesciences Corporation. All other

trademarks are the property of their respective owners.

1

Page 2

1.0 Device Description

• Edwards SAPIEN 3 Transcatheter Heart Valve- Model 9600TFX (Figure 1)

The Edwards SAPIEN 3 Transcatheter Heart Valve is comprised of a balloon-expandable, radiopaque,

cobalt-chromium frame, trileaflet bovine pericardial tissue valve, and polyethylene terephthalate (PET)

fabric skirt. The leaflets are treated according to the Carpentier-Edwards ThermaFix process.

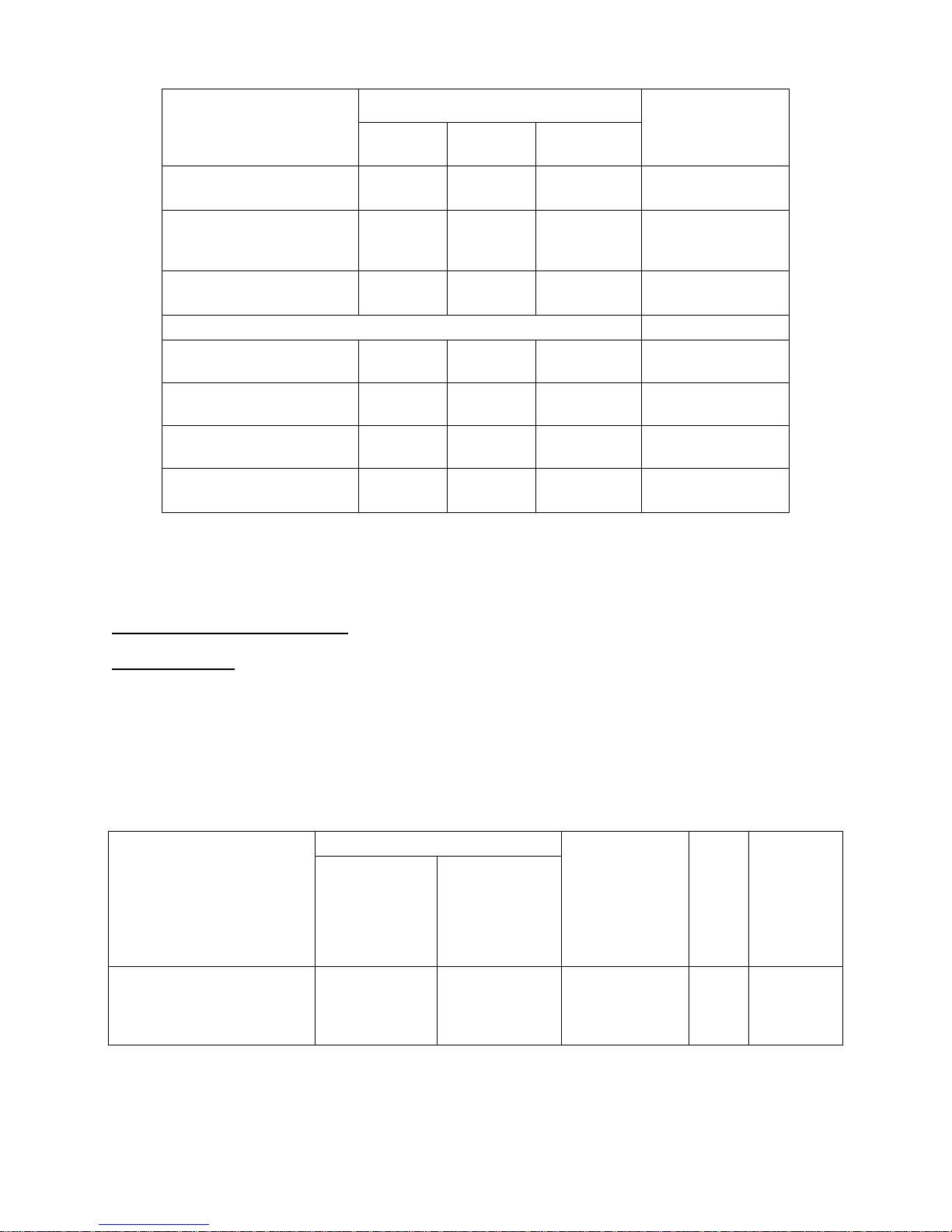

Table 1

Valve Size Height

20 mm 15.5 mm

23 mm 18 mm

26 mm 20 mm

29 mm 22.5 mm

Table 2

Native Valve Annulus Size

Native Valve Annulus Size

(TEE)

16-19 mm 273 – 345 mm2 18.6-21 mm 20 mm

18-22 mm 338 – 430 mm

21-25 mm 430 – 546 mm

24-28 mm 540 – 683 mm

Valve size recommendations are based on native valve annulus size, as measured by transesophageal

echocardiography (TEE) or computed tomography (CT). Patient anatomical factors and multiple imaging

modalities should be considered during valve size selection. Note: Risks associated with undersizing and

oversizing should be considered.

Area

(CT)

Area Derived

Diameter

2

20.7-23.4 mm 23 mm

2

23.4-26.4 mm 26 mm

2

26.2-29.5 mm 29 mm

Valve Size

• Edwards Commander Delivery System (Figure 2)

The Edwards Commander delivery system is used for delivery of the Edwards SAPIEN 3 transcatheter

heart valve and consists of a Flex Catheter to aid in valve alignment to the balloon, tracking, and

positioning of the valve. The delivery system includes a tapered tip to facilitate crossing of the native

valve. The handle contains a Flex Wheel to control flexing of the Flex Catheter, and a Balloon Lock and

Fine Adjustment Wheel to facilitate valve alignment and positioning of the valve within the native annulus.

A stylet is included within the guidewire lumen of the delivery system. The Balloon Catheter has

radiopaque Valve Alignment Markers defining the working length of the balloon. A radiopaque Center

Marker in the balloon is provided to help with valve positioning. A radiopaque Triple Marker proximal to

the balloon indicates the Flex Catheter position during deployment. The inflation parameters for valve

deployment are:

Table 3

Model

9600LDS20 20 mm 11 mL 7 atm

9600LDS23 23 mm 17 mL 7 atm

9600LDS26 26 mm 23 mL 7 atm

9600LDS29 29 mm 33 mL 7 atm

Nominal

Balloon

Diameter

Nominal

Inflation

Volume

Rated Burst

Pressure

(RBP)

2

Page 3

Figure 2: Edwards Commander Delivery System

• Qualcrimp Crimping Accessory

The Qualcrimp crimping accessory (packaged with the Edwards Commander delivery system) is used

during crimping of the valve.

• Edwards eSheath Introducer Set

Refer to the Edwards eSheath Introducer Set instructions for use for device description.

• Edwards Crimper

Refer to the Edwards Crimper instructions for use for device description.

2.0 Indications

The Edwards SAPIEN 3 transcatheter heart valve, Model 9600TFX, and accessories are indicated for

relief of aortic stenosis in patients with symptomatic heart disease due to severe native calcific aortic

stenosis who are judged by a Heart Team, including a cardiac surgeon, to be at intermediate or greater

risk for open surgical therapy (i.e., predicted risk of surgical mortality ≥ 3% at 30 days, based on the

Society of Thoracic Surgeons (STS) risk score and other clinical co-morbidities unmeasured by the STS

risk calculator).

3.0 Contraindications

The valve and delivery systems are contraindicated in patients who cannot tolerate an

anticoagulation/anti pla tel et r egim en or who have active bacterial endocarditis or other active infections.

4.0 Warnings

• Observation of the pacing lead throughout the procedure is essential to avoid the potential risk of

pacing lead perforation.

• There ma y be an increased risk of stroke in transcatheter aortic valve replacement procedures, as

compared to balloon aortic valvuloplasty or other standard treatments in high or greater risk patients.

• The devices are designed, intended, and distributed for single use only. Do not resterilize or reuse

the devices. There are no data to support the sterility, nonpyrogenicity, and functionality of the

devices after reprocessing.

• Incorrect sizing of the valve may lead to paravalvular leak, migration, embolization and/or annul ar

rupture.

• Accelerated deterioration of the valve may occur in patients with an altered calcium metabolism.

• Prior to delivery, the valve must remain hydrated at all times and cannot be exposed to solutions

other than its shipping storage solution and sterile physiologic rinsing solution. Valve leaflets

3

Page 4

mishandled or damaged during any part of the procedure will require replacement of the valve.

• Caution should be exercised in implanting a valve in patients with clinically significant coronary artery

disease.

• Patients with pre-existing mitral valve devices should be carefully assessed prior to implantation of

the valve to ensure proper valve positioning and deployment.

• Do not use the valve if the tamper evident seal is broken, the storage solution does not completely

cover the valve, the temperature indicator has been activated, the valve is damaged, or the expiration

date has elapsed.

• Do not mishandle the delivery system or use it if the packaging or any components are not sterile,

have been opened or are damaged (e.g. kinked or stretched), or the expiration date has elapsed.

• Use of excessive contrast media may lead to renal failure. Measure the patient’s creatinine level prior

to the procedure. Contrast media usage should be monitored.

• Patient injury could occur if the delivery system is not un-flexed prior to removal.

• Care should be exercised in patients with hypersensitivities to cobalt, nickel, chromium, molybdenum,

titanium, manganese, silicon, and/or polymeric materials.

• The procedure should be conducted under fluoroscopic guidance. Some fluoroscopically guided

procedures are associated with a risk of radiation injury to the skin. These injuries may be painful,

disfiguring, and long-lasting.

• Valve recipients should be maintained on anticoagulant/antiplatelet therapy, except when

contraindicated, as determined by their physician. This device has not been tested for use without

anticoagulation.

• Do not add or apply antibiotics to the storage solution, rinse solutions, or to the valve.

5.0 Precautions

• Long-term durability has not been established for the valve. Regular medical follow-up is advised to

evaluate valve performance.

• Glutaraldehyde may cause irritation of the skin, eyes, nose and throat. Avoid prolonged or repeated

exposure to, or breathing of, the solution. Use only with adequate ventilation. If skin contact occurs,

immediately flush the affected area with water; in the event of contact with eyes, seek immediate

medical attention. For more information about glutaraldehyde exposure, refer to the Mater ia l Safet y

Data Sheet available from Edwards Lifesciences.

• To maintain proper valve leaflet coaptation, do not overinflate the deployment balloon.

• Appropriate antibiotic prophylaxis is recommended post-procedure in patients at risk for prosthetic

valve infection and endocar ditis .

• Safety, effectiveness, and durability have not been established for valve-in-valve procedures.

• Safety and effectiveness have not been established for patients with the following

characteristics/comorbidities:

o Non-calcified aortic annulus

o Severe ventricular dysfunction with ejection fraction < 20%

o Congenital unicuspid or congenital bicuspid aortic valve

o Mixed aortic valve disease (aortic stenosis and aortic regurgitation with predominant aortic

regurgitation > 3+)

o Pre-existing prosthetic heart valve or prosthetic ring in any position

o Severe mitral annular calcification (MAC), severe (> 3+) mitral insufficiency, or Gorlin

syndrome

4

Page 5

o Blood dyscrasias defined as: leukopenia (WBC < 3000 cells/mL), acute anemia

(Hb < 9 g/dL), thrombocytopenia (platelet count < 50,000 cells/mL), or history of

bleeding diathesis or coagulopathy

o Hypertrophic cardiomyopathy with or without obstruction (HOCM)

o Echocardiographic evidence of intracardiac mass, thrombus, or vegetation

o A known hypersensitivity or contraindication to aspirin, heparin, ticlopidine (Ticlid™), or

clopidogrel (Plavix™), or sensitivity to contrast media, which cannot be adequately premedicate d

o Significant aortic disease, including abdominal aortic or thoracic aneurysm defined as maximal

luminal diameter 5 cm or greater; marked tortuosity (hyperacute bend), aortic arch atheroma

(especially if thick [> 5 mm], protruding, or ulcerated) or narrowing (especially with calcification

and surface irregularities) of the abdominal or thoracic aorta, severe “unfolding” and tortuosity of

the thoracic aorta

o Access characteristics that would preclude safe placement of 14F or 16F Edwards eSheath

Introducer Set, such as severe obstructive calcification or severe tortuosity

o Bulky calcified aortic valve leaflets in close proximity to coronary ostia

6.0 Potential Adverse Events

Potential risks associated with the overall proc e dur e including potential access complications associated

with standard cardiac catheterization, balloon valvuloplasty, the potential risks of conscious sedation

and/or general anesthesia, and the use of angiography:

• Death

• Stroke/transient ischemic attack, clusters or neurological deficit

• Paralysis

• Permanent disability

• Respiratory insufficiency or respiratory failure

• Hemorrhage requiring transfusion or intervention

• Cardiovascular injury including perforation or dissection of vessels, ventricle, myocardium or valvular

structures that may require intervention

• Pericardial effusion or cardiac tamponade

• Embolization including air, calcific valve m ater ial or thr ombus

• Infection including septicemia and endocarditis

• Heart failure

• M yocar dial inf ar ction

• Renal insufficiency or renal failure

• Conduction system defect which may require a permanent pacemaker

• Arrhythmia

• Retroperitoneal bleed

• AV fistula or pseudoaneurysm

• Reoperation

• Ischemia or nerve injury

• Restenosis

• Pulm onary edema

• Pleural effusion

5

Page 6

• Bleeding

• Anemia

• Abnormal lab values (including electrolyte imbalance)

• Hypertension or hypotension

• Allergic reaction to anesthesia, contrast media, or device materials

• Hematoma

• Syncope

• Pain or changes at the access site

• Exercise intolerance or weakness

• Inflammation

• Angina

• Heart murmur

• Fever

Additional potential risks associated with the use of the valve, delivery system, and/or accessories

include:

• Cardiac arrest

• Cardiogenic shock

• Emergency cardiac surgery

• Cardiac failure or low cardiac output

• Coronary flow obstruction/transvalvular flow disturbance

• Device thrombosis requiring intervention

• Valve thrombosis

• Device embolization

• Device migration or malposition requiring intervention

• Valve deployment in unintended location

• Valve stenosis

• Structural valve deterioration (wear, fracture, calcification, leaflet tear/tearing from the stent posts,

leaflet retraction, suture line disruption of components of a prosthetic valve, thickening, stenosis)

• Device degeneration

• Paravalvular or transvalvular leak

• Valve regurgitation

• Hemolysis

• Device explants

• Nonstructural dysfunction

• Mechanical failure of delivery system, and/or accessories

• Non-emergent reoperation

6

Page 7

7.0 Directions for Use

Model

Edwards SAPIEN 3

Valve

Edwards Commander

Delivery System*

Edwards Balloon

Catheter

* Includes the Qualcrimp Crimping Accessory,2-piece Crimp Stopper and loader

** Or other compatible sheath provided by Edwards Lifesciences

7.1 Required Equipment

Product Name

20 mm System

(9600CM20A)

Table 4:

23 mm System

(9600CM23A)

26 mm System

(9600CM26A)

29 mm System

(9600CM29A)

Transcatheter Heart

Edwards eSheath

Introducer Set**

Edwards Crimper 9600CR

9600TFX (20 mm) 9600TFX (23 mm) 9600TFX (26 mm) 9600TFX (29 mm)

9600LDS20 9600LDS23 9600LDS26 9600LDS29

914ES 914ES 914ES 916ES

9350BC16 9350BC20 9350BC23 9350BC25

Inflation devices provided by Edwards Lifesciences

Additional Equipment:

• 20 cc syringe or larger (x2)

• 50 cc syringe or larger

• High-pressure 3-way stopcock (x2)

• Standard cardiac catheterization lab equipment

• Fluoroscopy (fixed, mobile or semi-mobile fluoroscopy systems appropriate for use in percutaneous

coronary interventions)

• Transesophageal or transthoracic echocardiography capabilities

• Exchange length 0.035 inch (0.89 mm) extra-stiff guidewire

• Temporary pacemaker (PM) and pacing lead

• Sterile rinsing basins, physiological saline, heparinized saline, 15% diluted radiopaque contrast

medium

• Sterile table for valve and device preparation

7.2 Valve Handling and Preparation

Follow sterile technique during device preparation and im plantat ion.

7.2.1 Valve Rinsing Procedure

Before opening the valve jar, carefully examine for evidence of damage (e.g. a cracked jar or lid, leakage,

or broken or missing seals).

CAUTION: Valves from containers f oun d t o be da ma ged, lea ki ng, with o ut adequate steril an t, or

missing intact se als m us t n ot be us ed for im pl antation.

7

Page 8

Step Procedure

1

2

Set up two (2) sterile bowls with at least 500 mL of sterile physiological saline to thoroughly rinse the

glutaraldehyde sterilant from the valve.

Carefully remove the valve/holder assembly from the jar without touching the tissue. Verify the valve

serial identification number with the number on the jar lid and record in the patient information

documents. Inspect the valve for any signs of damage to the frame or tissue.

Rinse the valve as follows: Place the valve in the first bowl of sterile, physiological saline. Be sure

the saline solution completely covers the valve and holder. With the valve and holder submerged,

slowly agitate (to gently swirl the valve and holder) back and forth for a minimum of 1 minute.

Transfer the valve and holder to the second rinsing bowl of sterile physiological sal ine and g ently

agitate for at least one more minute. Ensure the rinse solution in the first bowl is not used. The

3

valve should be left in the final rinse solution until needed to prevent the tissue from drying.

CAUTION: Do not allow the valve to come into contact with the bottom or sides of the rinse bowl

during agitation or swirling in the rinse solution. Direct contact between the identification tag and

valve is also to be avoided during the rinse procedure. No other objects should be placed in the

rinse bowls. The valve should be kept hydrated to prevent the tissue from drying.

7.2.2 Prepare the Com p o n ents

Refer to the Edwards eSheath Introducer Set, Edwards Crimper and Edwards Balloon Catheter

instructions for use for device preparation.

Step Procedure

Visually inspect all components for damage. Ensure the Edwards Commander delivery system is fully

unflexed and the balloon catheter is fully advanced in the flex catheter.

1

WARNING: To prevent possible damage to the balloon shaft, ensure that the proximal end of the

balloon shaft is not subjected to bending.

2 Flush the flex catheter.

3 Carefully remove the distal balloon cover from the delivery system.

Remove the stylet from the distal end of the guidewire lumen and set aside. Flush the guidewire

4

5

6

7

8

9

10

lumen with heparinized saline and insert the stylet back into the distal end of the guidewire lumen.

Note: Failure to insert the stylet back into the guidewire lumen may result in damage to the lumen

during crimping process.

Place the delivery system into the default position and make sure that the flex catheter tip is covered

by the proximal balloon cover. Unscrew the loader cap from the loader tube and flush the lo ader cap.

Place the loader cap over the proximal balloon cover and onto the flex catheter with the inside of the

cap oriented towards the distal tip.

Fully advance the balloon catheter in the flex catheter.

Peel off the proximal balloon cover over the blue section of the balloon shaft.

Attach a 3-way stopcock to the balloon inflation port. Partially fill a 50 cc or larger syringe with

15-20 mL diluted contrast medium and attach to the 3-way stopcock.

Fill the inflation device provided by Edwards Lifesciences with excess volume relative to the indicated

inflation volume. Lock the inflation device and attach to the 3-way stopcock.

Close the 3-way stopcock to the Inflation device provided by Edwards Lifesciences and de-air the

system using the 50 cc or larger syringe. Slowly release the plunger and leave zero-pressure in the

system.

Close the stopcock to the delivery system. By rotating the knob of the inflation device provided by

Edwards Lifesciences, transfer the contrast medium into the syringe to achieve the appropriate

volume required to deploy the valve.

8

Page 9

Step Procedure

Close the stopcock to the 50 cc or larger syringe. Remove the syringe. Verify that the inflation volu me

11

is correct and lock the Inflation device provided by Edwards Lifesciences.

CAUTION: Maintain the Inflation device provided by Edwards Lifesciences in the locked

position until valve deployment.

7.2.3 Mount and Crimp the Valve on the Delivery System

Step Procedure

1

2

3 Remove the valve from the holder and remove the ID tag.

4 Attach the 2-piece crimp stopper to the base of the crimper and click into place.

5

6

7

8 Crimp the valve until it reaches the Qualcrimp Stop located on the 2-piece Crimp Stopper.

9

10

Set up two (2) additional sterile bowls with at least 100 mL of sterile physiological saline to thoroughly

rinse the Qualcrimp crimping accessory.

Completely submerge the Qualcrimp crimping accessory in the first bowl and gently compress it to

ensure complete saline absorption. Slowly swirl the Qualcrimp crimping accessory for a minimum of

1 minute. Repeat this process in the second bowl.

With the crimper in the open position, gently place the valve into the crimper aperture. Gradually

crimp the valve until it fits into the Qualcrimp crimping accessory.

Place the Qualcrimp crimping accessory over the valve making sure the valve is parallel to the edge

of the Qualcrimp crimping accessory.

Place the valve and Qualcrimp crimping accessory in crimper aperture. Insert the delivery system

coaxially within the valve on the Valve Crimp Section (2-3 mm distal to the balloon shaft) with the

inflow (outer skirt) end of th e valve towards the distal end of the delivery system.

Gently remove the Qualcrimp crimping accessory from the valve. Remove the Qualcrimp Stop from

the Final Stop, leaving the Final Stop in place.

Fully crimp the valve until it reaches the Final Stop.

NOTE: Ensure that the Valve Crimp Section remains coaxial within the valve.

11 Repeat the full crimp of the valve two more times for a total of three full crimps.

12 Pull the balloon shaft and lock in the default position.

Flush the loader with heparinized saline. Immediately advance the valve into the loader until the

13

14

tapered tip of the delivery system is exposed.

CAUTION: To prevent possible leaflet damage, the valve should not remain fully crimped

and/or in the loader for over 15 minutes.

Attach the loader cap to the loader, re-flush the delivery system through the flush port and close the

stopcock to the delivery system.

Remove the stylet and flush the guidewire lumen of the delivery system.

CAUTION: Keep the valve hydrated until ready for implantation.

CAUTION: The physician must verify correct orientation of the valve prior to its implantation;

its inflow (outer skirt) end should be oriented distally towards the tapered tip.

7.3 Valvuloplasty and Valve Delivery

Valvuloplasty and valve delivery should be performed under conscious sedation and/or general

anesthesia with hemodynamic monitoring in a catheterization lab/hybrid operating room with fluoroscopic

and echocardiographic imaging capabilities.

Administer heparin to maintain the ACT at ≥ 250 sec during the procedure.

CAUTION: Use of excessive contrast media may lead to renal failure. Measure the patient’s

creatinine level prior to the procedure. Contrast media usage should be monitored.

CAUTION: Procedure may require an arterial cut-down with surgical closure of the puncture si te

due to the size of the arteriotomy.

9

Page 10

7.3.1 Baseline Parameters

Step Procedure

1 Per form a supra-aortic angiogram with fluorosc opic view perpendicular to the aortic valve.

2

3 Introduce a pacemaker (PM) lead until its distal end is positioned in the right ventricle.

4 Set the stimulation parameters to obtain 1:1 capture, and test pacing.

Evaluate the distance of the left and right coronary ostia from the aortic annulus in relation to the valve

frame height.

7.3.2 Valvuloplasty

Refer to Edwards Balloon Catheter Instructions for Use (IFU) for information on device

preparation and handling.

Note: Rapid ventricular pacing s h o u ld be performed when using the Edwards Balloon Catheter for

valvuloplasty prior to aortic transcatheter valve implantation.

After placement of the balloon at the intended site, begin rapid ventricular pacing. Once the systolic blood

pressure has decreased to 50 mmHg or below, balloon inflation can commence.

CAUTION: Valve implantation should no t b e carried out if the balloon canno t be ful ly inflated

during valvuloplasty.

7.3.3 Valve Delivery

Step Procedure

1

2 Insert the loader into the sheath until the loader stops.

3

Prepare and insert the Edwards eSheath Introducer Set. Refer to the Edwards eSheath Introducer

Set IFU for information on device preparation and handling.

Advance the Edwards Commander delivery system, with the Edwards logo facing up, through the

sheath until the valve exits the sheath. Retract the loader to the proximal end of the delivery system.

NOTE: Maintain the proper orientation of the flex catheter (with the Edwards logo facing up)

throughout the procedure.

CAUTION: If accessing femorally or via the iliac, the valve should not be advanced through

the sheath if the sheath tip is not past the aortic bifurcation.

CAUTION: To prevent possible leaflet damage, the valve should not remain in the sheath for

over 5 minutes.

In a straight section of the aorta, initiate valve alignment by disengaging the Balloon Lock and pulling

the balloon catheter straight back until part of the Warning Marker is visible. Do not pull past the

Warning Marker.

WARNING: To prevent possible damage to the balloon shaft, ensure that the proximal end of

the balloon shaft is not subjected to bending.

4

5

6

Engage the Balloon Lock.

Use the Fine Adjustment Wheel to position the valve between the valve alignment markers.

CAUTION: Do not turn the Fine Adjustment Wheel if the Balloon Lock is not engaged.

WARNING: Do not position the valve past the distal Valve Alignment Marker. This will prevent

proper valve deployment.

CAUTION: Maintain guidewire position in the left ventricle during valve alignment.

Advance the catheter and use the flex wheel, if needed, and cross the aortic valve.

NOTE: Verify the Edwards logo is facing up. The delivery system articula tes in a direction

opposite from the flush port.

If additional working length is needed, remove the loader by unscrewing the loader cap and peeling

the loader tubing from the delivery system.

10

Page 11

Step Procedure

Disengage the Balloon Lock and retract the tip of the Flex Catheter to the center of the Triple Marker.

blood pressure has decreased to 50 mmHg or below, balloon

7

8 Verify the correct position of the valve with respect to the aortic annulus.

9

10

11

Engage the Balloon Lock.

As necessary, utilize the Flex Wheel to adjust the co-axiality of the valve and the Fine Adjustment

Wheel to adjust the position of the valve.

Before deployment, ensure that the valve is correctly positioned between the Valve Alignment

Markers and the Flex Catheter tip is over the Triple Marker.

Begin valve deployment:

• Unlock the Inflation device provided by Edwards Lifesciences.

• Begin rapid pacing; once systolic

inflation can commence.

• Deploy the valve by inflating the balloon with the entire volume in the Inflation device provided by

Edwards Lifesciences, hold for 3 seconds and confirm that the barrel of the inflation device is

empty to ensure complete inflation of the balloon.

• Deflate the balloon. When the balloon catheter has been completely deflated, turn off the

pacemaker.

7.3.4 System Removal

Step Procedure

Unflex the delivery system while retracting the device, if needed. Verify that the Flex Catheter tip is

1

locked over the Triple Marker and remove the delivery system from the sheath.

CAUTION: Patient injury could occur if the delivery system is not unflexed prior to removal.

2

3

Remove all devices when the ACT level is appropriate. Refer to the Edwards eSheath Introducer Set

instructions for use for device removal.

Close the access site.

8.0 How Supplied

STERILE: The valve is supplied sterilized with glutaraldehyde solution. The delivery system is supplied

sterilized with ethylene oxide gas.

8.1 Storage

The valve must be stored at 10 °C to 25 °C (50 °F to 77 °F). Each jar is shipped in an enclosure

containing a temperature indicator to detect exposure of the valve to extreme temperature.

The delivery system should be stored in a cool, dry place.

9.0 MR Safety

MR Conditional

Non-clinical testing has demonstrated that the Edwards SAPIEN 3 transcatheter heart valve is MR

Conditional. A patient with this device can be scanned safely, immediately after placement of this device

under the following conditions:

• Static magnetic field of 1.5 tesla or 3 tesla

• Maximum spatial gradient field of 2500 gauss/cm (25 T/m) or less

• Maximum MR system reported, whole body averaged specific absorption rate (SAR) of 2 W/kg

(Normal Operating Mode)

Under the scan conditions defined above, the SAPIEN 3 transcatheter heart valve is expected to produce

a maximum temperature rise of 3.0 ºC after 15 minutes of continuous scanning.

11

Page 12

In non-clinical testing, the image artifact caused by the device extends as far as 14.5 mm from the implant

for spin echo images and 30 mm for gradient echo images when scanned in a 3.0T MRI system. The

artifact obscures the device lumen in gradient echo images.

The implant has not been evaluated in MR systems other than 1.5 or 3.0T.

10.0 Patient Information

Patient education brochures are provided to each site and should be given to the patient to inform them of

the risks and benefits of the procedure and alternatives in adequate time before the procedure to be read

and discussed with their physician. A copy of this brochure may also be obtained from Edwards

Lifesciences by calling 1.800.822.9837. A patient implant card request form is provided with each

transcatheter heart valve. After implantation, all requested information should be completed on this form.

The serial number may be found on the package and on the identification tag att ached to the t ranscathete r

heart valve. The original form should be returned to the Edwards Lifesciences address indicated on the form

and upon receipt, Edwards Lifesciences will provide an identification card to the patient.

11.0 Recovered Valve and Device Disposal

The explanted valve should be placed into a suitable histological fixative such as 10% formalin or 2%

glutaraldehyde and returned to the company. Refrigeration is not necessary under these circumstances.

Contact Edwards Lifesciences to request an Explant Kit.

Used delivery system may be disposed of in the same manner that hospital waste and biohazard ous

materials are handled. There are no special risks related to the disposal of these devices.

12.0 Clinical Studies

SUMMARY OF PRIMARY CLINICAL STUDY

The PARTNER II Trial Overview, SAPIEN 3 Valve

SAPIEN 3 High Risk and Inoperable Cohort: The SAPIEN 3 High Risk and Inoperable Cohort of the

PARTNER II trial (PIIS3HR) was a single arm, non-randomized, historical-controlled study to compare the

third generation Edwards SAPIEN 3 valve system with the first generation Edwards SAPIEN valve system

in patients who either have high risk for surgery or cannot undergo surgery (inoperable). The valve sizes

used in the PIIS3HR trial included only the 23, 26 and 29 mm sizes. The 20 mm valve size was

introduced into the trial after enrollment was completed with the three larger sizes, thus a separate nested

registry, NR7, with identical inclusion/exclusion criteria as the PIIS3HR Cohort except for the aortic

annulus diameter, was created to collect data for the 20 mm valve. Data from the PIIS3HR cohort and

NR7 are pooled for the statistical analyses. For convenience, this combined cohort is referred to as

“PIIS3HR” hereafter.

The database included 583 eligible patients enrolled at 29 investigational sites in the U.S.

The study used an independent Data Safety Monitoring Board (DSMB) that was instructed to notify

Edwards Lifesciences of any safety or compliance issues, a Clinical Events Committee (CEC) that was

responsible for adjudicating endpoint related events reported during the trial per a priori established

VARC 2 definitions

[1]

, an ECG core laboratory for independent analysis of rhythm, and an

echocardiographic core laboratory for independently analyzing all echocardiograms.

SAPIEN 3 Intermediate Risk Cohort: The PIIS3i Cohort of the PARTNER II trial was a single arm, non-

randomized, historical-controlled study to compare TAVR with the Edwards SAPIEN 3 valve system to the

surgical aortic valve replacement (SAVR) arm from the previous PARTNER II trial Cohort A (PIIA-SAVR)

in patients who were judged by a heart team to be at intermediate risk for open surgical therapy. The

valve sizes used in the PIIS3i study included the 20, 23, 26, and 29 mm sizes.

Patients in PIIS3i were treated between February 2014 and September 2014. Patients in PIIA-SAVR

were treated between January 2012 and November 2013. The database reflected data collected through

December 10, 2015 and included 1,078 patients in PIIS3i enrolled at 51 investigational sites in the U.S

and 1,021 patients in PIIA-SAVR enrolled at 57 investigational sites in the U.S.

12

Page 13

The PIIS3i study used an independent Data Safety Monitoring Board (DSMB) that was instructed to notify

SAP IEN 3

Access

Eligible Patient

Population (EPP)

Valve Implant

(VI) Population

Eligible Patient Population (EPP) consists of all enrolled patients who received

laboratory/hybrid suite.

Edwards Lifesciences of any safety or compliance issues and a Clinical Events Committee (CEC) that

was responsible for adjudicating endpoint related events reported during the trial in accordance with the

pre-specified, primarily Valve Academic Research Consortium-2 VARC-2 definitions

[1]

, with the following

exceptions:

• Prosthetic valve dysf uncti o n was adj udic at ed per VAR C -1

• Aortic valve reintervention was adjudicated per protocol definition

• Rehospitalization for symptoms of aortic stenosis and/or complications of the valve procedure

were adjudicated using the protocol and VARC-2 definitions as guidelines

The events in the PIIA-SAVR cohort were adjudicated by the CEC in accordance with the pre-specified,

primarily VARC-1 definitions, with the following exceptions:

• Acute Kidney Injury (AKI) was adjudicated with a modified VARC-1 definition in which the CEC

applied the 72-hour staging window to any AKI event that occurred within 30-days

• Aortic valve reintervention wer e adju dicat ed per the protocol definition

• Rehospitalization for symptoms of AS and/or complications of the valve procedure were

adjudicated using the protocol and VARC-1 as guidelines

• Bleeding events were adjudicated irrespective of whether there was an identifiable, overt source

of bleeding

An electrocardiogram (ECG) core laboratory was used for independent analysis of rhythm, an

echocardiographic core laboratory for echocardiograms, and a computerized tomography (CT) core

laboratory for baseline CTs for annulus dimensions.

PARTNER II SAPIEN 3 HIGH-RISK/INOPERABLE COHORT

Accountability

All 583 eligible patients were successfully implanted with a SAPIEN 3 valve, which constitutes the Valve

Implant (VI) population. Among the VI population, 491 patients were implanted via the transfemoral (TF)

access route, and 92 patients via the transapical (TA) or transaortic (TAo) access route.

Table 5:

Patient Accountability

SAP IEN 3

Valve

Overall

583 491 92

583 491 92

treatment assignment from the database and entered into the catheterization

laboratory/hybrid suite and who remained eligible to receive the implant.

Valve Implant (VI) Population consists of all enrolled patients who received a

SAPIEN 3 valve, and retained the valve upon leaving the catheterization

Study Populatio n Dem o gr a phic s a nd Bas el i ne Pa ra mete rs

The demographics of the study population are summarized in Table 6, which are typical of a TAVR study

performed in the U.S.

13

SAP IEN 3

Valve

Transfemoral

Access

Valve

Non-

Transfemoral

Page 14

Transfemoral

SAP IEN 3

Transfemoral

(N= 92)

Age, yr

82.6 ± 8.1

82.8 ± 8.2

81.7 ± 7.5

Male sex, no. (%)

338 (58.0%)

277 (56.4%)

61 (66.3%)

STS score

8.6 ± 3.7

8.4 ± 3.5

10.0 ± 4.3

New York Heart Association (NYHA) class, no. (%):

I/II

58 (9.9%)

51 (10.4%)

7 (7.6%)

III/IV

525 (90.1%)

440 (89.6%)

85 (92.4%)

Coronary artery disease, no. (%)

444 (76.2%)

360 (73.3%)

84 (91.3%)

Previous myocardial infarction, no. (%)

117 (20.1%)

87 (17.7%)

30 (32.6%)

Previous intervention, no. (%)

Coronary-artery bypass gr af ting (C ABG)

193 (33.1%)

145 (29.5%)

48 (52.2%)

Percutaneous coronary intervention (PCI)

199 (34.1%)

163 (33.2%)

36 (39.1%)

Prior aortic valvuloplasty

62 (10.6%)

49 (10.0%)

13 (14.1%)

Cerebral vascular accident ( CVA), no. (%)

64 (11.0%)

53 (10.8%)

11 (12.0%)

Peripheral vascular disease, no. (%)

205 (35.2%)

155 (31.6%)

50 (54.3%)

Chronic obstructive pulmonary disease (COPD),

no. (%):

Any

259 (44.6%)

216 (44.1%)

43 (47.3%)

Oxygen-dependent

68 (11.8%)

58 (11.9%)

10 (11.0%)

Atrial fibrillation, no. (%)

255 (43.7%)

212 (43.2%)

43 (46.7%)

Permanent pacemaker, no. (%)

95 (16.3%)

78 (15.9%)

17 (18.5%)

Severe pulmonary hypertension, no. (%)

30 (5.1%)

24 (4.9%)

6 (6.5%)

Frailty, no. (%)

180 (30.9%)

162 (33.0%)

18 (19.6%)

Chest deformities that preclude an open chest

procedure, no. (%)

4 (0.7%)

3 (0.6%)

1 (1.1%)

Cirrhosis, no. (%)

11 (1.9%)

9 (1.8%)

2 (2.2%)

Echocardiographic findings

Effective Orifice Area (EOA), cm2

0.7 ± 0.2

0.7 ± 0.2

0.7 ± 0.1

Mean aortic-valve gradient, mmHg

45.5 ± 14.3

45.7 ± 14.4

44.0 ± 13.2

Mean left ventricular ejection fraction (LVEF), %

56.4 ± 14.8

57.0 ± 14.5

53.2 ± 15.9

Moderate or severe mitral regurgitation, no./total

no. (%)

69/541

(12.8%)

63/461

(13.7%)

6/80

(7.5%)

Table 6:

Patient Demographics and Baseline Characteristics –

PIIS3HR VI Population

Characteristic

SAP IEN 3

Valve

Overall

(N= 583)

SAP IEN 3

Valve

Access

(N= 491)

Valve

Non-

Access

Safety and Effectiveness Results

Primary Endpoint

The composite rate of all-cause mortality, all stroke, and AI ≥ moderate at 30 days was 6.7% in the

SAPIEN 3 cohort and 15.6% in the SAPIEN cohort, as shown in Table 7. The resulting proportion

difference in the average treatment effect on the treated (ATT; [2]) was -6.9% (90% CI: [-13.3%, -0.5%]).

Since the upper limit of the CI was < 7.5%, the non–inferiority was met.

14

Page 15

Table 7:

Weighted Proportion

on the Treated (ATT)

Composite of Death, Stroke

and AI ≥ Moderate)

6.7%

[5.1%, 8.6%]1

15.6%

[12.6%, 19.5%]1

-6.9%

[-13.3%, -0.5%]2

1

For each individual study, the two-sided 90% stratified Wilson confidence interval was provided.

SAP IEN 3 Valve

(N = 583)

SAPIEN Valve

(N = 326)

No. Pts with

K-M Estimated

(95% CI)

No. Pts with

M Estimated Event

2.2%

([1.3%, 3.8%])

4.6%

([2.8%, 7.5%])

Cardiac

Death

1.4%

([0.7%, 2.7%])

3.1%

([1.7%, 5.7%])

1.6%

([0.8%, 3.0%])

4.3%

([2.6%, 7.2%])

1

Kaplan-Meier (K-M) estimates at 30 days used time to first event for each patient. Events occurring after 30 days

were not included in this analysis.

Primary Endpoint Analysis –

Non-Inferiority Test SAPIEN 3 Valve (PIIS3HR VI Population) vs. SAPIEN Valve

SAP IEN 3

Event at 30 days

Valve

(N = 583)

2

The Wald-type two-sided 90% confidence interval using weighted mean and SD is provided

SAPIEN

Valve

(N = 326)

Difference in Average

Treatment Effect

The Kaplan-Meier (K-M) estimates for all-cause mortality, cardiac mortality, and all stroke at 30 days for

the SAPIEN 3 cohort and the SAPIEN cohort are provided in Table 8.

Table 8:

Death and Stroke at 30 Days –

SAP IEN 3 Valve vs. SAPIEN Valve (VI Population)

Event at 30

Days

Death 13 13

All Stroke 9 9

No.

Events

8 8

Events

Event Rate1

No.

Events

15 15

10 10

14 14

Events

K-

Rate (95% CI)

Secondary Endpoints

Aortic insufficiency by visit is provided in Figure 3.

15

Page 16

Figure 3:

Aortic Insufficiency by V isit –

SAP IEN 3 Valve (PIIS3HR VI Population) vs. SAPIEN Valve

Weighted Proportion

Treated (ATT)

1

95% Clopper-Pearson Exact confidence interval.

The proportion of patients with AI ≥ moderate at 30 days was 3.0% in the SAPIEN 3 cohort and 14.3% in

the SAPIEN cohort, which were found to be statistically significantly different (p=0.0051; Table 9).

Table 9:

Aortic Insufficiency at 30 Days

(SAPIEN 3 Valve vs. SAPIEN Valve VI Population)

SAP IEN 3

Event at 30 Days

Valve

(N = 583)

AI ≥Moderate, n/Total

no. (%) [95% CI]

16/532

(3.0%)

[1.7%, 4.8%]

2

The Wald-type two-sided 90% confidence interval using weighted mean and SD is provided

SAPIEN Valve

(N = 326 )

1

40/280

(14.3%)

[10.4%,

18.9%]

1

Difference in Average

Treatment Effect on the

-13.1%

[-22.2%, -3.9%]

2

P-value

0.0051

The rate of major vascular complications at 30 days post implantation is shown in Figure 4. The rate was

5.0% for the SAPIEN 3 cohort and 10.1% for the SAPIEN cohort, which were foun d to be not statistically

significantly different (p=0.0578; Table 10).

16

Page 17

Figure 4:

Major Vascular Complications at 30 Days –

SAP IEN 3 Valve vs. SAPIEN Valve (VI Population)

Weighted

reatment

Treated (ATT)

Major Vascular

(%) [95% CI]

29/583

[3.4% , 7.1%]

33/326

[7.1% , 13.9%]1

1

95% Clopper-Pearson Exact confidence interval.

2

Table 10:

Major Vascular Complications at 30 Days –

SAP IEN 3 Valve vs. SAPIEN Valve (VI Population)

SAP IEN 3

Event at 30 Day

Valve

(N = 583)

Complications, n/Total no.

The Wald-type two-sided 90% confidence interval using weighted mean and SD is provided.

(5.0%)

SAPIEN

Valve

(N = 326)

(10.1%)

Proportion

Difference in

Average T

Effect on the

-8.0%

[-16.2%, 0.3%]2

P-value

0.0578

Table 11 lists the hypothesis testing of the two secondary endpoints conducted with p-values in

descending order for the Hochberg multiplicity adjustment steps. The largest p-value (p=0.0578 from

major vascular complications) was greater than 0.05. As such, the null hypothesis was not rejected for the

testing of major vascular complications at 30 days. The subsequent testing of AI ≥ moderate at 30 days

had a p-value of 0.0051, which was less than 0.025. As such, the null hypothesis was rejected for

AI ≥ moderate at 30 days, indicating that the SAPIEN 3 cohort was superior over the SAPIEN cohort in

regards to AI ≥ moderate at 30 days.

17

Page 18

Table 11:

Original

p-value

Major Vascular

Days

> 0.05; reject the alternative

testing

AI at 30 Days

0.0051

< 0.025; claim superiority

SAP IEN 3

Access

Composite Event Rate of Death, All Stroke and

AI ≥ Moderate, n/N (%)

Secondary Endpoints for Labeling –

SAP IEN 3 Valve vs. SAPIEN Valve (VI Population)

Endpoints

Complications at 30

0.0578

hypothesis. Proceed to the rest of

Inference

Adverse Events

The key CEC adjudicated adverse events at 30 days are presented in Table 12.

Table 12:

CEC Adjudicated Adverse Events at 30 Days

(PIIS3HR VI Population)

30 Day Adverse Events

SAPIEN 3 Valve

Overall

SAPIEN 3 Valve

Transfemoral

Access

TF

Valve

Non-

Transfemoral

37/545 (6.8 %) 27/463 (5.8 %) 10/82 (12.2 %)

Death

From Any cause, n/N (%) 13/583 (2.2%) 8/491 (1.6%) 5/92 (5.4%)

From cardiovascular cause, n/N (%) 8/583 (1.4%) 5/491 (1.0%) 3/92 (3.3%)

Stroke, n/N (%) 9/583 (1.5%) 8/491 (1.6%) 1/92 (1.1%)

AI ≥ moderate, n/N (%) 16/532 (3.0%) 12/455 (2.6%) 4 /77 (5.2%)

Myocardial Infarction, n/N (%) 3/583 (0.5%) 2/491 (0.4%) 1/92 (1.1%)

Major Vascular Complications, n/N (%) 29/583 (5.0%) 26/491 (5.3%) 3/92 (3.3%)

Acute Kidney Injury, Stage III, n/N (%) 6/583 (1.0%) 4/491 (0.8%) 2/92 (2.2%)

Disabling Bleeding Event, n/N (%) 37/583 (6.3%) 27/491 (5.5%) 10/92 (10.9%)

Aortic Valve Re-Intervention, n/N (%) 6/583 (1.0%) 4/491 (0.8%) 2/92 (2.2%)

Endocarditis, n/N (%) 1/583 (0.2%) 1/491 (0.2%) 0/92 (0.0%)

Conduction Disturbance Requiring Permanent

Pacemaker,

n/N (%)

Other Results

Procedural Information

Overall, the mean duration in the catheterization laboratory/hybrid suite was 192.8 ± 59.3 min, the mean

total procedure time was 86.3 ± 44.2 min, and the mean total anesthesia time was 193.7 ± 62.9 min.

These duration times were slightly shorter in the TF patients. General anesthesia was used in the vast

majority of cases; 15.9% of the TF patients had conscious sedation. Correct positioning of the valve was

achieved in 99.1% of the patients. Five patients (0.9%; including 3 TF patients) were implanted with a

second valve. One patient (0.2%) experienced valve embolization following rupture of the delivery balloon

on annular calcium. This patient was converted to surgical aortic valve replacement and later died from

aortic dissection.

76/583 (13.0%) 65/ 491 (13.2%) 11/ 92 (12.0%)

18

Page 19

Figure 5:

(PIIS3HR VI Population)

Figure 6:

(PIIS3HR VI Population)

Doppler Velocity Index

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Baseline 30 Day

0.7

1.6

Mean Gradient (mmHg)

0

10

20

30

40

50

60

70

80

90

100

110

Baseline 30 Day

45.5

11.1

Valve Performance

The mean EOA increased from 0.7 ± 0.2 cm2 at baseline to 1.6 ± 0.4 cm2 at 30 days, as shown in

Figure 5.

Effective Orifice Area

The average mean gradient decreased from 45.5 ± 14.3 mmHg at baseline to 11.1 ± 4.5 mmHg at 30

days, as show n in Figure 6.

Mean Gradient

19

Page 20

Figure 7:

(PIIS3HR VI Population)

Figure 8:

(PIIS3HR VI Population)

Peak Gradient (mmHg)

0

10

20

30

40

50

60

70

80

90

100

110

Baseline 30 Day

75.8

21.2

None Trace Mild

Mild-Moderate Moderate Moderate-Severe

Severe

Percentage

0

20

40

60

80

100

Baseline 30 Day

16%

30%

32%

32%

34%

27%

10%

8%

6%

The mean peak gradient decreased from 75.8 ± 22.6 mmHg at baseline to 21.2 ± 8.5 mmHg at 30 days,

as shown in Figure 7.

Peak Gradient

The proportion of patients with AI ≥ moderate was 7.3% at baseline and 3.0% at 30 days, as shown in

Figure 8.

Aortic Insufficiency

20

Page 21

Figure 9:

(PIIS3HR VI Population)

Figure 10:

(PIIS3HR VI Population)

None

Trace Mild

Mild-Moderate Moderate Moderate-Severe

Severe

Percentage

0

20

40

60

80

100

30 Day

33%

29%

28%

8%

1 2

3 4

Percent

0

20

40

60

80

100

All Patients Transapical/Transaortic Transfemoral

Baseline 30 Day Baseline 30 Day

Baseline 30 Day

10%

60%

30%

45%

42%

11%

8%

64%

28%

36%

45%

14%

5%

10%

59%

31%

46%

42%

11%

The proportion of patients with aortic paravalvular leak (PVL) ≥ moderate was 2.9% at 30 days, as shown

in Figure 9.

Aortic Paravalvular Leak

NYHA

The NYHA class by visit is shown in Figure 10. For all patients, the mean NYHA class was 3.2 ± 0.6 at

baseline and 1.7 ± 0.7 at 30 days.

NYHA Class by Visit

21

Page 22

Six Minute Walk Test (6MWT)

The improvement in mean 6MWT distance was 38.5 ± 110.2 meters from baseline to 30 days for all

patients, 42.6 ± 107.8 meters for all TF patients, and 15.9 ± 121.2 meters for all TA/TAo patients.

Length of Stay (LoS)

The overall mean LoS was 6.8 ± 4.8 days, which included 3.0 ± 2.7 days in the ICU. The mean LoS was

6.1 ± 4.3 days (including 2.7 ± 2.3 days in the ICU) for the TF patients a nd 10.4 ± 5.4 days (including

4.8 ± 3.9 days in the ICU) for the TA/TAo patients.

Quality of Life (QoL)

QoL was measured using the visual analog scale (VAS) of the EuroQoL (EQ-5D) measure. The VAS is a

self-assessment in which patients rate their well-being on a scale from 0 to 100 where 0 is the worst state

they can imagine and 100 is the best state. During the trial, the mean improvement in VAS scale from

baseline to 30 days was 14.6 ± 22.2 for all patients, 15.1 ± 21.5 for the TF patients, and 11.5 ± 25.7 for

the TA/TAo patients.

Additional QoL instruments

The mean overall Kansas City Cardiomyopathy Questionnaire (KCCQ) summary score was 46.9 ± 22.6 at

baseline, and 67.5 ± 22.6 at 30 days for the entire VI population. Except for self-efficacy which showed a

small improvement, moderate to large improvements were observed in all other subscores at 30 days. In

general, improvements in the TF patients were slightly larger compared to those observed in the TA/TAo

patients.

Using the SF-36 norm based questionnaire, the physical component score for all patients improved from

32.0 ± 8.9 at baseline to 37.1 ± 9.7 at 30 days, and the mental component score improved from

46.9 ± 12.8 at baseline to 50.0 ± 12.5 at 30 days. In the TF patients, the physical component score

improved from 31.8 ± 8.7 at baseline to 37.3 ± 9.8 at 30 days, and the mental component score improved

from 46.8 ± 13.1 at baseline to 50.5 ± 12.2 at 30 days. In the TA/TAo patients, the physical component

score improved from 32.9 ± 10.0 at baseline to 35.9 ± 9.4 at 30 days, and the mental component scores

were 47.2 ± 11.1 at baseline and 47.2 ± 14.0 at 30 days.

SUMMARY OF SUPPLEMENTAL CLINICAL INFORMATION

Supplemental Clinical Study Design

Supplemental clinical data came from a study (referred to as “S3OUS” hereafter) conducted in Europe

and Canada.

The S3OUS study was a non-randomized, prospective, multi-center study in inoperable, high surgical

risk, and intermediate surgical risk patients who underwent implantation of the 23, 26, or 29 mm

SAPIEN 3 valve.

Except the intermediate surgical risk patients, the inclusion/exclusion criteria of the S3OUS trial were

largely similar to those of the PIIS3HR trial. The S3OUS study had a minimum age requirement

(≥ 75 years) and the upper limit for AVA was higher (< 1 cm

2

instead of ≤ 0.80 cm2). Additionally, the

S3OUS study included BAV within 30 days of the procedure (unless BAV was a bridge to procedure),

patients with planned concomitant surgical or transcatheter ablation for atrial fibrillation, hemodynamic or

respiratory instability requiring inotropic support, mechanical ventilation or mechanical heart assistance

within 30 days of screening; and the need for emergency surgery for any reason. Furthermore, the

exclusion criteria in the S3OUS study excluded senile dementia and any neurologic disease which

severely affected the ability to walk or perform everyday activities, and shortened the time interval

regarding confirmed stroke or TIA (within 3 months instead of 6 month of the procedure). The follow-up

periods were discharge or 7 days, whichever comes first, 30 days, 1 year, and annually thereafter to a

minimum of 5 years post procedure.

22

Page 23

SAPIEN 3 Valve

Overall

SAPIEN 3 Valve

Transfemoral Access

SAPIEN 3 Valve

Non-Transfemoral Access

All Treated

Population

Valve Implant

Population

All Treated

Population

All Treated

Population

102

101

57

56

45

45

All Treated (AT) Population consists of all patients who were enrolled in the trial and for whom the study

retained the valve upon leaving the catheterization laboratory/hybrid suite.

Table 14:

(S3OUS AT Population)

SAP IEN 3

(N = 102)

SAPIEN 3 Valve

(N = 57)

SAPIEN 3 Valve

(N = 45)

Age, yr

84.1 ± 5.0

85.1 ± 4.6

83.0 ± 5.3

Male sex, no.(%)

40 (39.2%)

23 (40.4%)

17 (37.8%)

STS score

8.0 ± 4.7

8.2 ± 4.2

7.9 ± 5.2

Logistic EuroSCORE

24.1 ± 13.0

22.3 ± 11.3

26.4 ± 14.7

New York Heart Association (NYHA)

class, no.(%):

I/II

11 (10.8%)

6 (10.5%)

5 (11.1%)

III/IV

91 (89.2%)

51 (89.5%)

40 (88.9%)

Coronary artery disease, no.(%)

68 (66.7%)

36 (63.2%)

32 (71.1%)

Previous myocardial infarction, no.(%)

20 (19.6%)

7 (12.3%)

13 (28.9%)

Previous intervention, no.(%)

Accountability of the S 3O US Coho rt

Patients were treated at 14 investigational sites. Note that the intermediate risk patients enrolled in the

S3OUS study were excluded from the analysis presented herein. The database included 102 “all treated”

(AT) inoperable and high surgical risk patients. “All treated” population is defined to include all patients

who were enrolled in the trial and for whom the study valve implantation procedures were started (i.e., the

anesthesia was started).

One patient was excluded from the VI population. This patient experienced an aortic root rupture caused

by displacement of a large lump of calcium with sharp edges through the native aortic annulus following

balloon expansion of the SAPIEN 3 valve. The patient was subsequently converted to SAVR. After the

patient was weaned off cardio-pulmonary bypass, bleeding in the region of the dorsal root occurred, and

the patient died on the operating table.

A total of 56 patients were successfully implanted with a SAPIEN 3 valve via the transf em or al acces s

route, and 45 via the transapical/transaortic access route, as shown in Table 13.

Table 13:

Patient Accountability (S3OUS)

(AT)

valve implantation procedures were started (i.e., anesthesia was started).

Valve Implant (VI) Population consists of all enrolled patients who received a SAPIEN 3 valve, and

(VI)

(AT)

Valve Implant

(VI) Population

(AT)

Study Populatio n Dem o gr a phic s a nd Bas el i ne Pa ra mete rs

The demographics of the S3OUS study population are shown in Table 14.

Patient Demographics and Baseline Characteristics

Demographics and Baseline

Characteristics

Valve

Overall

Transfemoral

Access

Valve Implant

(VI) Population

Non-Transfemoral

Access

23

Page 24

Table 14:

Patient Demographics and Baseline Characteristics

(S3OUS AT Population)

SAP IEN 3

(N = 102)

SAPIEN 3 Valve

(N = 57)

SAPIEN 3 Valve

(N = 45)

Coronary-artery bypass grafting

(CABG)

24 (23.5%)

10 (17.5%)

14 (31.1%)

Percutaneous coronary intervention

(PCI)

34 (33.3%)

16 (28.1%)

18 (40.0%)

Prior aortic valvuloplasty

10 (9.8%)

8 (14.0%)

2 (4.4%)

Stroke, no.(%)

7 (6.9%)

4 (7.0%)

3 (6.7%)

Peripheral vascular disease, no.(%)

27 (26.5%)

10 (17.5%)

17 (37.8%)

Chronic obstructive pulmonary disease

(COPD), no.(%):

Any

25 (24.5%)

13 (22.8%)

12 (26.7%)

Oxygen-dependent

1 (1.0%)

1 (1.8%)

0 (0%)

Atrial fibrillation, no.(%)

48 (47.1%)

22 (38.6%)

26 (57.8%)

Permanent pacemaker, no.(%)

15 (14.7%)

7 (12.3%)

8 (17.8%)

Severe pulmonary hypertension, no.(%)

10 (9.8%)

6 (10.5%)

4 (8.9%)

Severe liver disease / Cirrhosis, no.(%)

1 (1.0%)

1 (1.8%)

0 (0%)

Echocardiographic findings

Effective Orifice Area (EOA), cm2

0.6 ± 0.2

0.6 ± 0.2

0.6 ± 0.1

Mean aortic-valve gradie nt, mmHg

44.8 ± 15.3

45.2 ± 14.7

44.2 ± 16.1

Mean left ventricular ejection

fraction (LVEF), %

56.7 ± 9.1

57.7 ± 9.3

55.3 ± 8.7

Moderate or severe mitral

regurgitation, no./total no. (%)

23/85

(27.1%)

9/48

(18.8%)

14/37

(37.8%)

Plus–minus values are means ± SD.

Table 15:

(S3OUS AT Population)

SAPIEN 3

Access

SAPIEN 3

Transfemoral

Composite Event

n/N (%)

Death

Demographics and Baseline

Characteristics

Valve

Overall

Transfemoral

Access

Non-Transfemoral

Access

Safety and Effectiveness Results

Key Adverse Events

Key adverse events as adjudicated b y the CEC are presented in Table 15.

30 Day 1 Year

SAPIEN 3

Outcomes

Rate of Death, All

Stroke and AI ≥

Moderate,

Valve

Overall

13/88

(14.8%)

CEC Adjudicated Adverse Events at 1 Year

SAPIEN 3

Valve

Transfemoral

Access

3/50

(6.0%)

Valve

Non-

Transfemoral

10/38

(26.3%)

Valve

Overall

25/82

(30.5%)

24

SAPIEN 3

Valve

Access

9/47

(19.1%)

SAPIEN 3 Valve

Non-

Transfemoral

Access

16/35

(45.7%)

Page 25

Table 15:

CEC Adjudicated Adverse Events at 1 Year

(S3OUS AT Population)

30 Day

1 Year

SAPIEN 3

Access

SAPIEN 3

Transfemoral

From any

death, n/N (%)

8/102

(7.8%)

2/57

(3.5%)

6/45

(13.3%)

20/102

(19.6%)

7/57

(12.3%)

13/45

(28.9%)

From

cause, n/N (%)

3/102

(2.9%)

1/57

(1.8%)

2/45

(4.4%)

5/102

(4.9%)

2/57

(3.5%)

3/45

(6.7%)

Aortic

n/N (%)

Disabling Str oke,

n/N (%)

0/102

(0.0%)

0/57

(0.0%)

0/45

(0.0%)

1/102

(1.0%)

1/57

(1.8%)

0/45

(0.0%)

Myocardial

n/N (%)

Major Vascular

n/N (%)

Acute Kidney

n/N (%)

Disabling

n/N (%)

Valve Dysfunction

n/N (%)

Prosthetic Valve

n/N (%)

Conduction

n/N (%)

Outcomes

cardiovascular

Stroke, n/N (%)

Insufficiency (AI)

≥ Moderate,

Infarction,

Complications,

Injury - Stage III,

SAPIEN 3

Valve

Overall

7/102

(6.9%)

3/81

(3.7%)

2/102

(2.0%)

5/102

(4.9%)

0/102

(0.0%)

SAPIEN 3

Valve

Transfemoral

Access

2/57

(3.5%)

1/49

(2.0%)

2/57

(3.5%)

1/57

(1.8%)

0/57

(0.0%)

Valve

Non-

Transfemoral

5/45

(11.1%)

2/32

(6.3%)

0/45

(0.0%)

4/45

(8.9%)

0/45

(0.0%)

Valve

Overall

9/102

(8.8%)

1/62

(1.6%)

3/102

(2.9%)

SAPIEN 3

Valve

Access

2/57

(3.5%)

1/40

(2.5%)

2/57

(3.5%)

SAPIEN 3 Valve

Non-

Transfemoral

Access

7/45

(15.6%)

0/22

(0.0%)

1/45

(2.2%)

N/A N/A N/A

N/A N/A N/A

Bleeding Event,

Requiring

Intervention,

Endocarditis,

Abnormality

Requiring

Pacemaker,

6/102

(5.9%)

0/102

(0.0%)

0/102

(0.0%)

14/102

(13.7%)

3/57

(5.3%)

0/57

(0.0%)

0/57

(0.0%)

7/57

(12.3%)

3/45

(6.7%)

0/45

(0.0%)

0/45

(0.0%)

7/45

(15.6%)

N/A N/A N/A

N/A N/A N/A

1/102

(1.0%)

14/102

(13.7%)

0/57

(0.0%)

7/57

(12.3%)

(15.6%)

1/45

(2.2%)

7/45

The composite adverse event rate involving all-cause mortality, all stroke, and AI ≥ moderate at 30 days

for all patients is higher in the S3OUS cohort than PIIS3HR cohort (14.8% vs. 6.8%). This disparity is due

to the composition of the study populations, specifically the S3OUS cohort comprises 44.1% TA/TAo

patients vs. 15.8% TA/TAo patients in the PIIS3HR cohort. Note, the composite adverse event rate at 30

days for TF patients was similar, specifically, 6.0% in the S3OUS cohort and 5.8% in the PIIS3HR cohort.

The K-M estimates for all-cause mortality for all patients, the TF patients, and the TA/TAo patients are

shown in Figure 11.

25

Page 26

Figure 11:

All-Cause Mortality at 1 Year

(S3OUS AT Population)

Note: The confidence intervals are calculated without multiplicity adjustment. The

adjusted confidence intervals could be wider than presented here. As such, confidence

intervals are provided to illustrate the variability only and should not be used to draw

any statistical conclusion.

The K-M estimates for the stroke rate for all patients, the TF patients, and the TA/TAo patients are

shown in Figure 12.

26

Page 27

Figure 12:

(S3OUS AT Population)

any statistical conclusion.

Figure 13:

(S3OUS VI Population)

Effective Orifice Area (EOA)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

Baseline 30 Day 1 Year

0.6 0.6 0.6

1.5 1.5 1.5

1.4

1.4 1.4

All Stroke at 1 Year

Note: The confidence intervals are calculated without multiplicity adjustment. The

adjusted confidence intervals could be wider than presented here. As such, confidence

intervals are provided to illustrate the variability only and should not be used to draw

Valve Performance

The mean EOA increased from 0.6 ± 0.2 cm

1 year, as shown in Figure 13.

Effective Orifice Area

2

at baseline to 1.5 ± 0.4 cm2 at 30 days and 1.4 ± 0.4 cm2 at

27

Page 28

The average mean gradient decreased from 44.8 ± 15.4 mmHg at baseline to 10.4 ± 4.1 mmHg at 30

Figure 14:

(S3OUS VI Population)

Figure 15:

(S3OUS VI Population)

Mean Gradient (mmHg)

0

10

20

30

40

50

60

70

80

90

100

110

Baseline 30 Day 1 Year

44.8 44.8 44.8

10.4 10.4 10.4

10.7 10.7 10.7

Peak Gradient (mmHg)

0

10

20

30

40

50

60

70

80

90

100

110

Baseline 30 Day 1 Year

77.5 77.5 77.5

21.0 21.0 21.0

21.5 21.5 21.5

days and maintained at 10.7 ± 4.1 mmHg at 1 year, as shown in Figure 14.

Mean Gradient

The mean peak gradient decreased from 77.5 ± 24.9 mmHg at baseline to 21.0 ± 7.7 mmHg at 30 days,

and maintained at 21.5 ± 8.2 mmHg at 1 year, as shown in Figure 15.

The proportion of patients with aortic insufficiency ≥ moderate was 9.8% at baseline, 3.7% at 30 days,

and 1.6% at 1 year, as shown in Figure 16.

Peak Gradient

28

Page 29

Figure 16:

Aortic Insufficiency

(S3OUS VI Population)

Figure 17:

(S3OUS VI Population)

None

Trace

Mild

Mild-Moderate

Moderate

Moderate-Severe

Severe

Percentage

0

20

40

60

80

100

Baseline

30 Day 1 Year

13%

37%

55%

37%

44%

32%

35%

12%

8%

5%

9%

None Trace Mild

Mild-Moderate Moderate Moderate-Severe

Severe

Percentage

0

20

40

60

80

100

30 Day 1 Year

40%

56%

42%

31%

12%

6%

5%

The proportion of patients with aortic PVL ≥ moderate was 3.7% at 30 days, and 1.6% at 1 year, as

shown in Figure 17.

Aortic Paravalvular Leak

NYHA

The NYHA class by visit is sho wn in Figure 18. For all patients, the mean NYHA class decreased from 3.0

± 0.5 at baseline to 1.6 ± 0.7 at 30 days and 1.8 ± 0.6 at 1 year.

29

Page 30

Figure 18:

NYHA Class by Visit

(S3OUS AT Population)

Patients

Population†

(VI)Population‡

†. Eligible Patient (EP) Population consists of all enrolled patients who were determined eligible after

the assigned valve, and retained the valve upon leaving the catheterization laboratory.

1 2 3

4

Percent

0

20

40

60

80

100

All Patients

Transapical/Transaortic Transfemoral

Baseline 30 Day 1 Year Baseline

30 Day 1 Year Baseline 30 Day 1 Year

11%

78%

11%

46%

47%

6%

33%

58%

8%

11%

73%

16%

34%

54%

9%

25%

64%

7%

11%

82%

7%

54%

43%

38%

54%

8%

PARTNER II SAPIEN 3 INTERMEDIATE RISK COHORT

Accountability

Table 16 presents patient accountability in the PIIS3i and PIIA-SAVR cohorts. Of the 1,074 eligible

patients (Eligible Pati ent or EP Population) in PIIS3i, 1,069 were successfully implanted with a SAPIEN 3

valve and constitute the PIIS3i Valve Implant (VI) population. Among the VI population, 943 patients were

implanted via the transfemoral (TF) access route, and 126 patients via a non-transfemoral (non-TF;

mainly transapical and trans aortic ) access route. Of the 938 eligible patients in the PIIA-SAVR cohort,

936 were successfully implanted with a surgical valve and constitute the PIIA-SAVR VI population.

Table 16: Patient Accountability

Eligible Patient (EP)

Valve Implant

SAPIEN 3 Cohort 1078 1074 1069

TF 952 948 943

Non-TF 126 126 126

All Enrolled

PIIA SAVR 1021 938 936

screening, entered into the catheterization laboratory and remained eligible to receive the assigned implant.

‡. Valve Implant (VI) Population is a subset of the EP Population who received

30

Page 31

Study Populatio n Dem o gr a phic s a nd Bas el i ne Pa ra mete rs

Table 17: Patient Demographics and Baseline Characteristics of the EP Population

514/938

225/937

712/937

623/938

166/938

45/938

96/938

301/938

279/932

326/938

113/938

15/938

The demographics of the PIIS3i and PIIA-SAVR EP populations are summarized in Table 17.

Demographics &

Characteristics

Overall

(N = 1074)

TF Only

(N = 948)

Non-TF Only

(N=126)

PIIA-SAVR

(N=938)

Age - years 81.9 ± 6.60 82.1 ± 6.57 80.7 ± 6.69 81.6±6.73

SAP IEN 3 Valve

Male sex 662/1074

(61.6%)

Society of Thoracic

5.3 ± 1.29 5.3 ± 1.29 5.6 ± 1.28 5.8±1.92

577/948

(60.9%)

85/126

(67.5%)

(54.8%)

Surgeons (STS) score

New York Heart Association (NYHA) class

I/II 294/1074

(27.4%)

III/IV 780/1074

(72.6%)

Coronary artery disease 748/1074

(69.6%)

Previous myocardial

infarction

172/1074

(16.0%)

262/948

(27.6%)

686/948

(72.4%)

652/948

(68.8%)

133/948

(14.0%)

32/126

(25.4%)

94/126

(74.6%)

96/126

(76.2%)

39/126

(31.0%)

(24.0%)

(76.0%)

(66.4%)

(17.7%)

Previous intervention

Coronary artery

bypass grafting

(CABG)

Percutaneous

coronary intervention

(PCI)

Prior aortic

valvuloplasty

Cerebral vascular accident

(CVA)

Peripheral vascular

disease

301/1074

(28.0%)

344/1074

(32.0%)

55/1074

(5.1%)

97/1074

(9.0%)

304/1074

(28.3%)

248/948

(26.2%)

299/948

(31.5%)

51/948

(5.4%)

81/948

(8.5%)

231/948

(24.4%)

53/126

(42.1%)

45/126

(35.7%)

4/126 (3.2%)

16/126

(12.7%)

73/126

(57.9%)

241/938

(25.7%)

254/938

(27.1%)

(4.8%)

(10.2%)

(32.1%)

Chronic obstructive pulmonary disease (COPD)

Any 321/1072

(29.9%)

Oxygen-dependent 53/1067

(5.0%)

Atrial fibrillation 385/1074

(35.8%)

Permanent pacemaker 142/1074

(13.2%)

Severe pulmonary

hypertension

25/1074

(2.3%)

Frailty 92/1074

(8.6%)

270/946

(28.5%)

46/942

(4.9%)

342/948

(36.1%)

121/948

(12.8%)

19/948

(2.0%)

86/948

(9.1%)

51/126

(40.5%)

7/125 (5.6%)

43/126

(34.1%)

21/126

(16.7%)

6/126 (4.8%)

6/126 (4.8%)

(29.9%)

26/925

(2.8%)

(34.8%)

(12.0%)

N/A

(1.6%)

31

Page 32

Table 17: Patient Demographics and Baseline Characteristics of the EP Population

Demographics &

0/938

(0.0%)

procedure

4/938

(EOA) - cm2

153/841

Continuous measures - Mean ± SD; Categorical measures – n/total no. (%)

Observed Event rate

[90% CI]†

Conclusion

Characteristics

Overall

(N = 1074)

Porcelain aorta 1/1074

(0.1%)

SAP IEN 3 Valve

TF Only

Non-TF Only

(N = 948)

1/948

0/126 (0.0%)

(0.1%)

PIIA-SAVR

(N=938)

(N=126)

Chest deformities that

preclude an open chest

Cirrhosis 4/1074

1/1074

(0.1%)

(0.4%)

1/948

(0.1%)

4/948

(0.4%)

0/126 (0.0%)

0/126 (0.0%)

0/938

(0.0%)

(0.4%)

Echocardiographic findings (Valve Implant Population)

Effective orifice area

Mean aortic-valve gradient

- mmHg

Mean left ventricular

ejection fraction (LVEF) %

Moderate or severe mitral

regurgitation

0.7 ± 0.17 0.7 ± 0.16 0.7 ± 0.18

46.1 ±

12.63

58.5 ±

13.36

91/1033

(8.8%)

46.1 ±

12.66

58.8 ±

13.24

87/909

(9.6%)

45.8 ± 12.47

56.0 ± 14.05

4/124 (3.2%)

0.7±0.20

44.7±12.55

55.4±11.75

(18.2%)

Safety and Effectiveness Results

Primary Endpoints

The primary endpoint was a composite of all-cause death, stroke, and AI ≥ moderate at 1 year. The

weighted proportion dif f erenc e of the prim ary endpoint was -9.2% (90% CI: [-12.4%, -6.0%]) using the

average treatment effect on the treated (ATT) method

[2]

, as shown in Table 18 and Figure 19. Since the

upper limit of the CI was < 7.5%, non–inferiority was met.

Table 18:

Primary Endpoint Non-Inferiority Test

(VI Population)

Propensity

Score Quintile

Pooled

SAP IEN 3

(N=1069)

PIIA-SAVR

(N=936)

Proportion

Difference(ATT

Margin

Method*)

for Non-

Inferiority

Test

Composite of all-cause

death, all stroke, and aortic

insufficiency (AI) ≥ moderate

13.0% 23.2%

[-12.4%, -6.0%]

at 1 year

* ATT: average treatment effect on the treated

†

Two-sided 90% Wald-type confidence interval

Figure 19: Forest Plot – Composite of All Death, All Stroke and AI ≥ Moderate (VI Population)

32

-9.2%

7.5% Pass

Page 33

(N= 1069)

(N = 936)

Estimate

Error

Estimate

Error

*

Events

†

The Kaplan-Meier (KM) estimates for all-cause death and all stroke at 1 year for the PIIS3i cohort and the

PIIA-SAVR cohort are provided in Table 19, as well as Figures 20 and 21, respectively.

Endpoints

All-cause death

at 1 year

Table 19:

All-Cause Death and All Stroke at 1 Year

(VI Population)

SAP IEN 3 Valve

Observed

Event Rate

Kaplan-Meier Event

Point

Rate

Standard

*

Observed

Event Rate

PIIA-SAVR

Kaplan-Meier Event Rate

Point

Standard

*

Proportion Difference

7.0% 7.1% 0.79% 12.4% 12.6% 1.09% -5.2%

Propensity Score

Quintile Pooled

(ATT Method†)

All stroke at 1

year

Kaplan-Meier estimates were calculated at 365 days and i ncluded only the first event for each patient.

occurring after 365 days were not included in this analysis.

ATT: average treatment effect on the treated

4.5% 4.6% 0.65% 7.9% 8.1% 0.91% -3.5%

33

Page 34

Figure 20: All-Cause Death through 1 Year (VI Population)

Figure 21: All Stroke through 1 Year

(VI Population)

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, the confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical conclusion.

Note: The confidence intervals were calculated without multiplicity adjustment. The adjusted

confidence intervals could be wider than presented here. As such, the confidence intervals are

provided to illustrate the variability only and should not be used to draw any statistical conclusion.

The proportion of patients with AI ≥ moderate at 1 year was 1.6% for the PIIS3i cohort and 0.3%

for the PIIA-SAVR cohort, as shown in Table 20.

34

Page 35

Table 20: Aortic Insufficiency (AI) ≥ Moderate at 1 Year (VI Population)

Observed Event Rate

Propensity Score

(ATT Method*)

Conclusion

bleeding through

Quintile Pooled

SAP IEN 3 Valve

(N= 1069)

SAVR

(N= 936)

Proportion

Difference

Aortic insufficiency (AI) ≥ moderate 1.6% 0.3% 1.2%

* ATT: average treatment effect on the treated

Secondary Endpoints

The secondary endpoints were examined in a pre-specified order adjusted for the propensity quintiles

using the ATT method. Table 21 summarizes the statistical conclusions on the non-inferiority hypothesis

testing of the five secondary endpoints for labeling that were evaluated using a gatek eeping/ hi erar chic a l

multiplicity adjustment procedure to control the overall type I error to 0.05. For each second ary endpoint,

the upper limit of the confidence interval was less than the respective non-inferiority margin. Therefore,

for each of the secondary endpoints for labeling, the SAPIEN 3 valve was non-inferior to SAVR.

Table 21: Secondary Endpoints for Labeling – Gatekeeping/Hierarchical Method

(VI Population)

Weighted

Proportion

Difference in

Average

Treatment

Effect on the

Treated

[90% CI]

†

Margin