Page 1

Instruction Manual

nXDS Serial Comms Interface

A735-01-860

Issue A Original

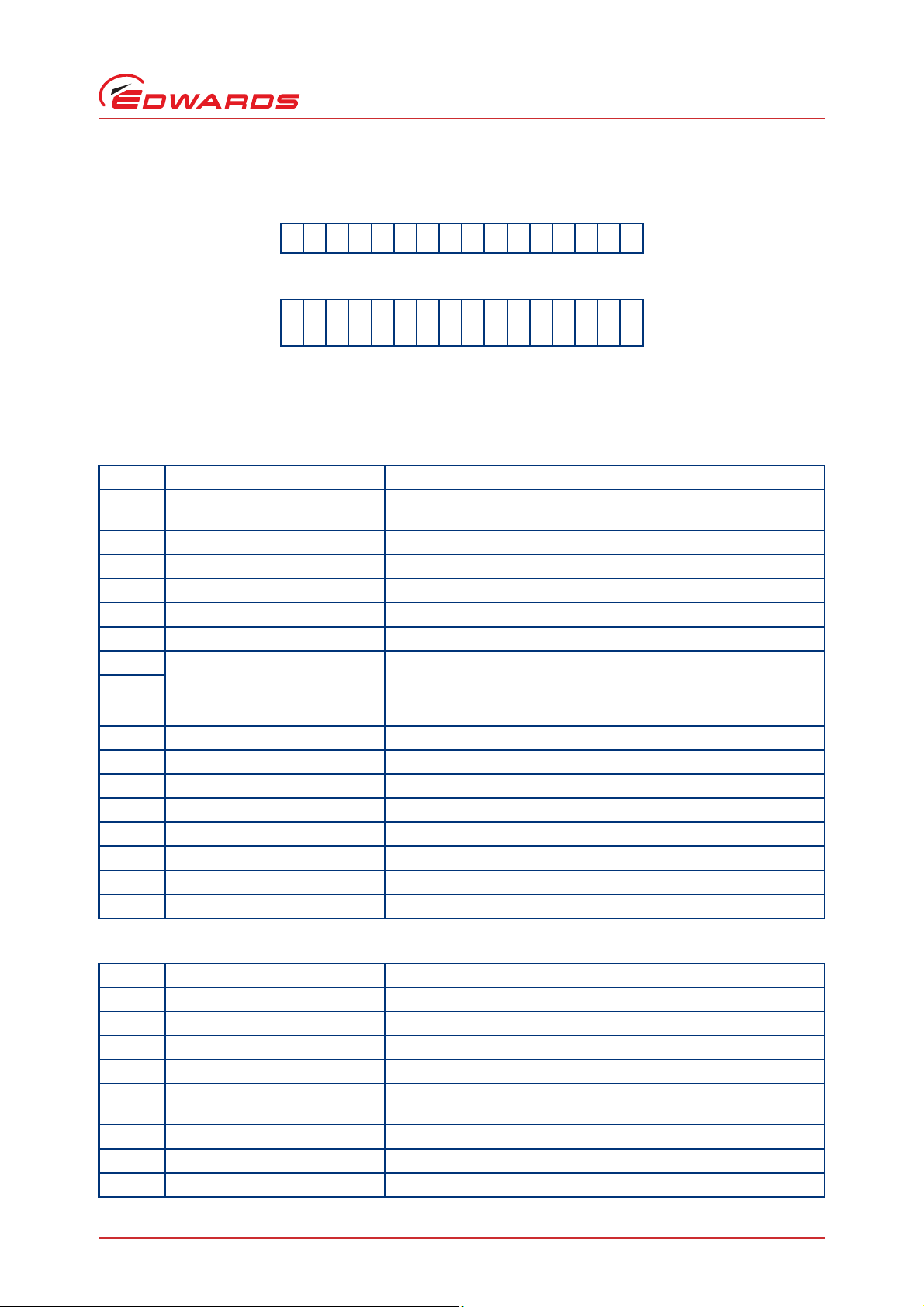

Description Item Number

nXDS6i A735-01-983

nXDS10i A736-01-983

nXDS15i A737-01-983

nXDS20i A738-01-983

nXDS6iC A735-02-983

nXDS10iC A736-02-983

nXDS15iC A737-02-983

nXDS20iC A738-02-983

nXDS6iR A735-03-983

nXDS10iR A736-03-983

nXDS15iR A737-03-983

nXDS20iR A738-03-983

Page 2

This page has been intentionally left blank.

Page 3

A735-01-860 Issue A

Contents

Section Page

1 Introduction ........................................................................................1

1.1 Scope of this manual.................................................................................................... 1

1.2 Description................................................................................................................ 1

2 Technical data .....................................................................................3

2.1 Logic interface........................................................................................................... 3

3 Connection for serial control and monitoring.................................................5

3.1 Serial connection ........................................................................................................ 5

3.2 Serial enable ............................................................................................................. 6

3.3 Serial protocol ........................................................................................................... 6

3.4 Message structure ....................................................................................................... 7

3.5 Command set............................................................................................................. 7

3.6 Operating the nXDS pump............................................................................................. 12

3.6.1 Start the pump.......................................................................................................... 12

3.6.2 Standby speed........................................................................................................... 12

3.6.3 Stop the pump .......................................................................................................... 12

3.7 Multi-drop operation................................................................................................... 13

3.7.1 Assigning a multi-drop address ....................................................................................... 14

3.8 Mixed parallel and serial operation.................................................................................. 15

3.9 Decoding status words................................................................................................. 16

3.9.1 Decoding system status word......................................................................................... 16

3.9.2 Decoding service status word......................................................................................... 19

Contents

For return of equipment, complete the HS Forms at the end of this manual.

gea/0207/06/12

© Edwards Limited 2012. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 4

A735-01-860 Issue A

Contents

Illustrations

Figure Page

1 Start / Stop Control Diagram ........................................................................................... 1

2 nXDS scroll pump ......................................................................................................... 2

3 Logic interface connections - RS232 serial control.................................................................. 5

4 Logic interface connections - RS485 serial control.................................................................. 6

5 RS485 multi-drop connections.........................................................................................13

6 Logic interface connection - mixed parallel and serial operation ...............................................15

Tables

Table Page

1 Logic interface connection pins........................................................................................ 3

2 Logic interface technical data.......................................................................................... 4

3 Summary of the commands that can be sent to the nXDS pump.................................................. 8

4 Command abbreviations................................................................................................11

5 Error codes ...............................................................................................................11

6 Hexadecimal conversion table.........................................................................................16

7 System status register 1 flags..........................................................................................17

8 System status register 2 flags..........................................................................................17

9 Warning register 2 flags ................................................................................................18

10 Fault register flags ......................................................................................................19

11 Service flags..............................................................................................................20

Associated publications

Publication title Publication number

Vacuum Pump and Vacuum System Safety P400-40-100

nXDS Scroll Pump Instruction Manual A735-01-880

Page ii © Edwards Limited 2012. All ri ghts reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 5

A735-01-860 Issue A

1Introduction

1.1 Scope of this manual

This manual provides operational instructions for the Edwards nXDS pump serial communication protocol. Read this

manual before you attempt to operate your nXDS pump using serial communica tion protocol.

For safety and operating information for the nXDS range of pumps, please refer to the nXDS Scroll Pump Instruction

Manual (A735-01-880).

1.2 Description

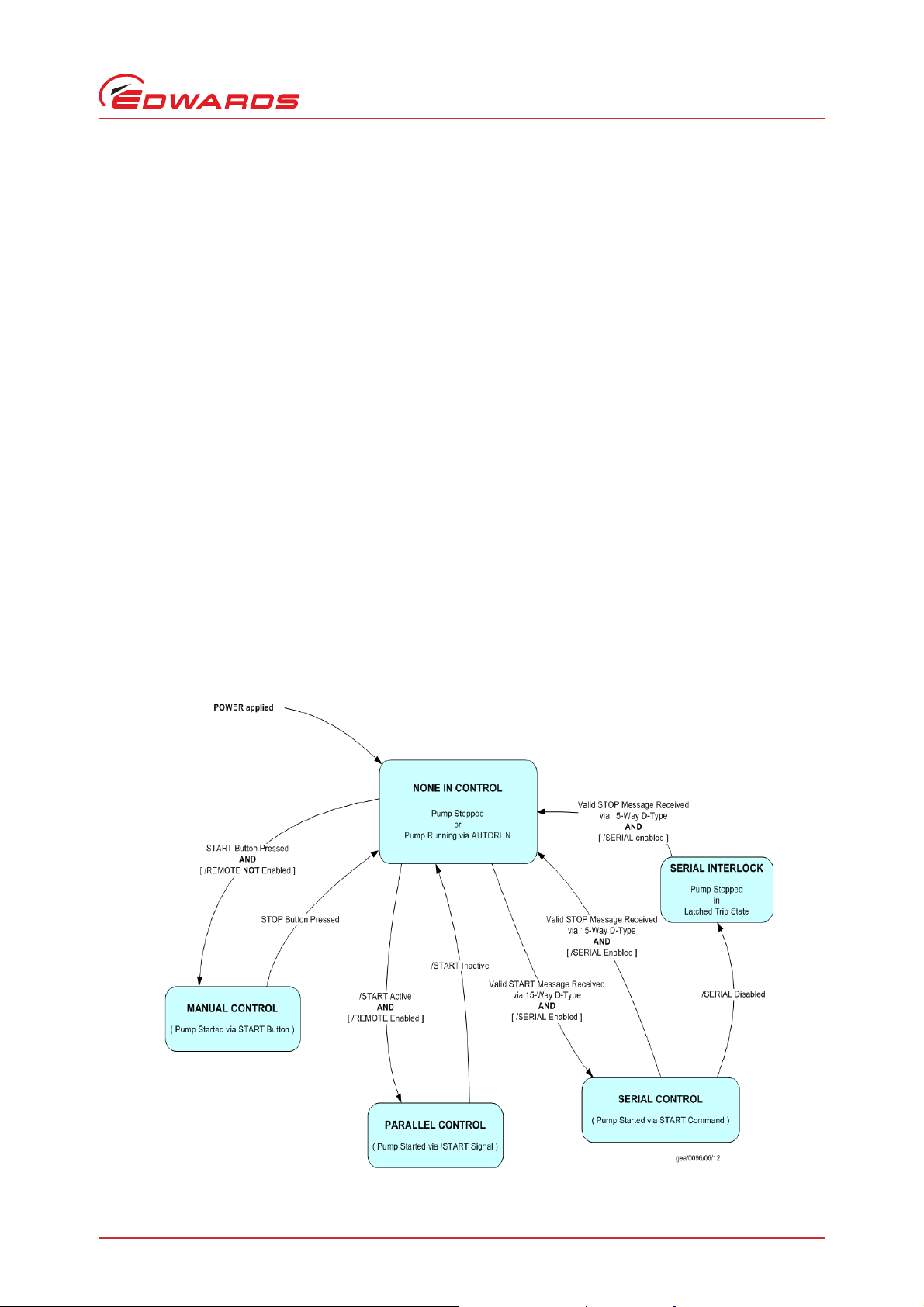

The nXDS pump can be operated in four control modes:

None in Control Mode - Inactive control mode

Manual Control Mode - Active control mode

Parallel Control Mode - Act ive control mode

Introduction

Serial Control Mode (including Serial Interlock) - Active control mode

The control mode is determined by the way the nXDS pump is started. All the control mo des, and transitions between

them, are defined in Figure 1.

Once started the nXDS pump can only be stopped by the mode in which it was started.

Figure 1 - Start / Stop Control Diagram

© Edwards Limited 2012. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

A735-01-860 Issue A

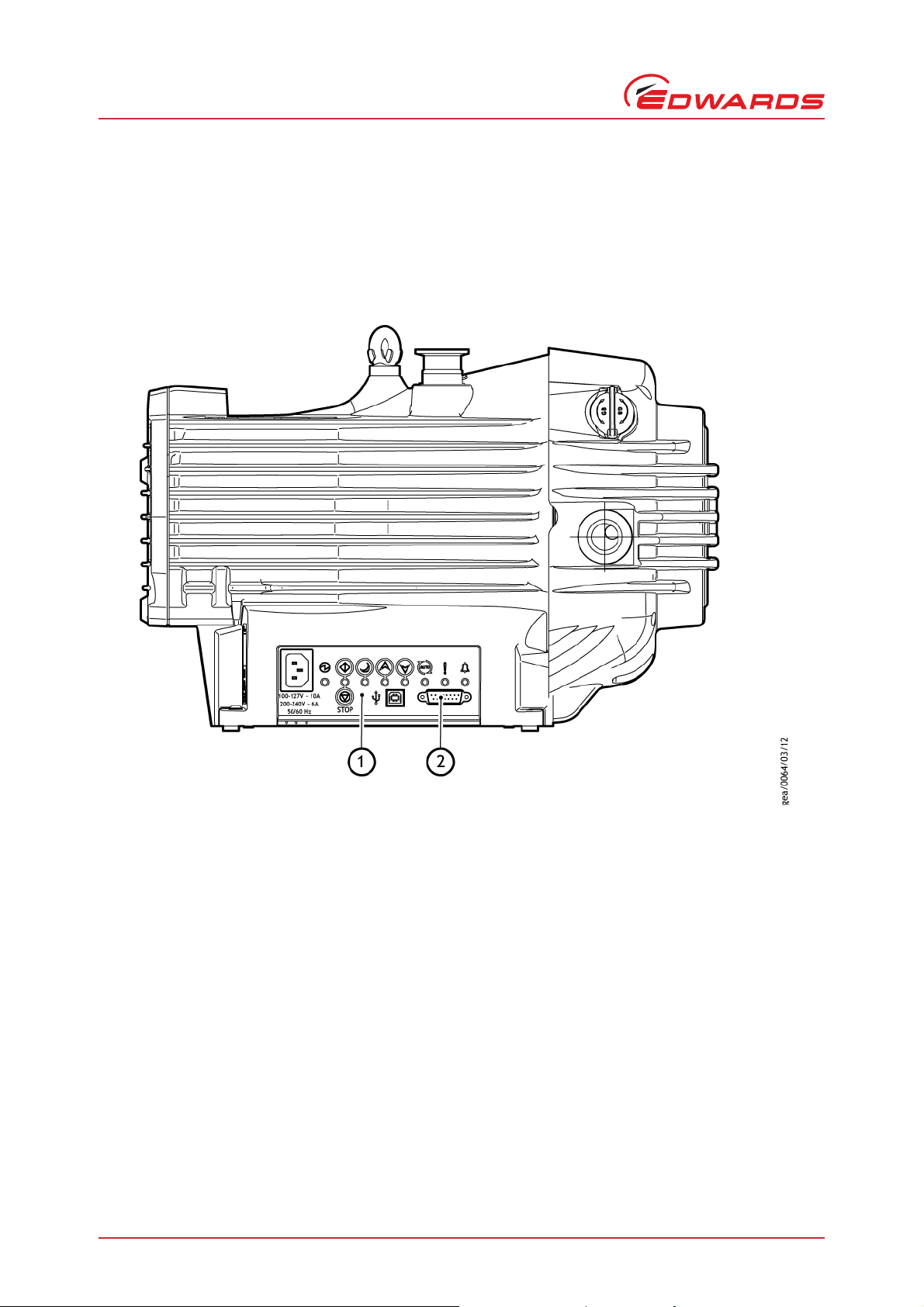

1. User interface panel

2. 15-way logic interface connection

Introduction

This instruction manual details the connection and operation of the nXDS pump in its serial control mode. The

parallel, manual and none in control modes are detailed in the nXDS Scroll Pump Instruction Manual (A735-01-880).

The nXDS pump can be connected directly to the RS485 or RS232 serial input on your control equipment or a PC, using

a suitable connector mating half (not supplied). Full serial control is realised by using the following two signa l lines:

serial enable and RS232 / RS485 control inputs.

Figure 2 - nXDS scroll pump

Page 2 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

A735-01-860 Issue A

2Technical data

2.1 Logic interface

nXDS pumps have a male 15-way D-type logic interface connector located on the user interface panel (Figure 2, Item

2). The logic interface connector can be plugged directly into your control equipment or a PC using a suitable

connector mating half (not supplied). Refer to Table 1 for the logic interface pins for the electrical connections and

Table 2 for the interface technical data.

Table 1 - Logic interface connection pins

Pin Number Signal Use

1 Analogue Speed Enable-control Input Connect to Pin 2 (0 V) to enable analogue speed control via

Pin 9.

2 0 V Control Reference 0 V reference for ALL control and status signals listed within

this table.

3 START / STOP – Control Input Connect to Pin 2 (0 V) to START the nXDS pump system.

4STANDBY – Control Input /

RS232 Rx / RS485 A5 Serial Enable – Control Input Connect to Pin 2 (0 V) to enable serial communications.

6 RS232 / RS485 – Control Input Default configuration is RS232 with Pin 6 unconnected.

7 FAIL – Status Output /

RS232 Tx / RS485 B+

8 0 V Control Reference 0 V reference for ALL control and status signals listed within

9 Analogue Speed – Control Input 0-10 V Analogue Input: 0 V = 0% Speed; +10 V = 100% Speed

10 Chassis / Screen Screen

11 +10 V Analogue Reference – Control

Output

12 Chassis / Screen Screen

13 Not Connected Unused control pin.

14 REMOTE – Control Input Connect to Pin 2 (0 V) to enable remote operation via Parallel

15 NORMAL – Status output Logic LOW when the pump rotational speed is at normal

Connect to Pin 2 (0 V) to enable STANDBY speed when the

SERIAL ENABLE control input is inac tive.

Connect to Pin 2 (0 V) to enable RS485 serial

communications.

Logic HIGH when a fail / fault condition exists and the SERI AL

ENABLE control input is inactive.

this table.

+10 V analogue voltage reference output: 5 mA;

uni-polar output, diode protected.

control mode.

speed or above.

Technical data

© Edwards Limited 2012. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

A735-01-860 Issue A

Technical data

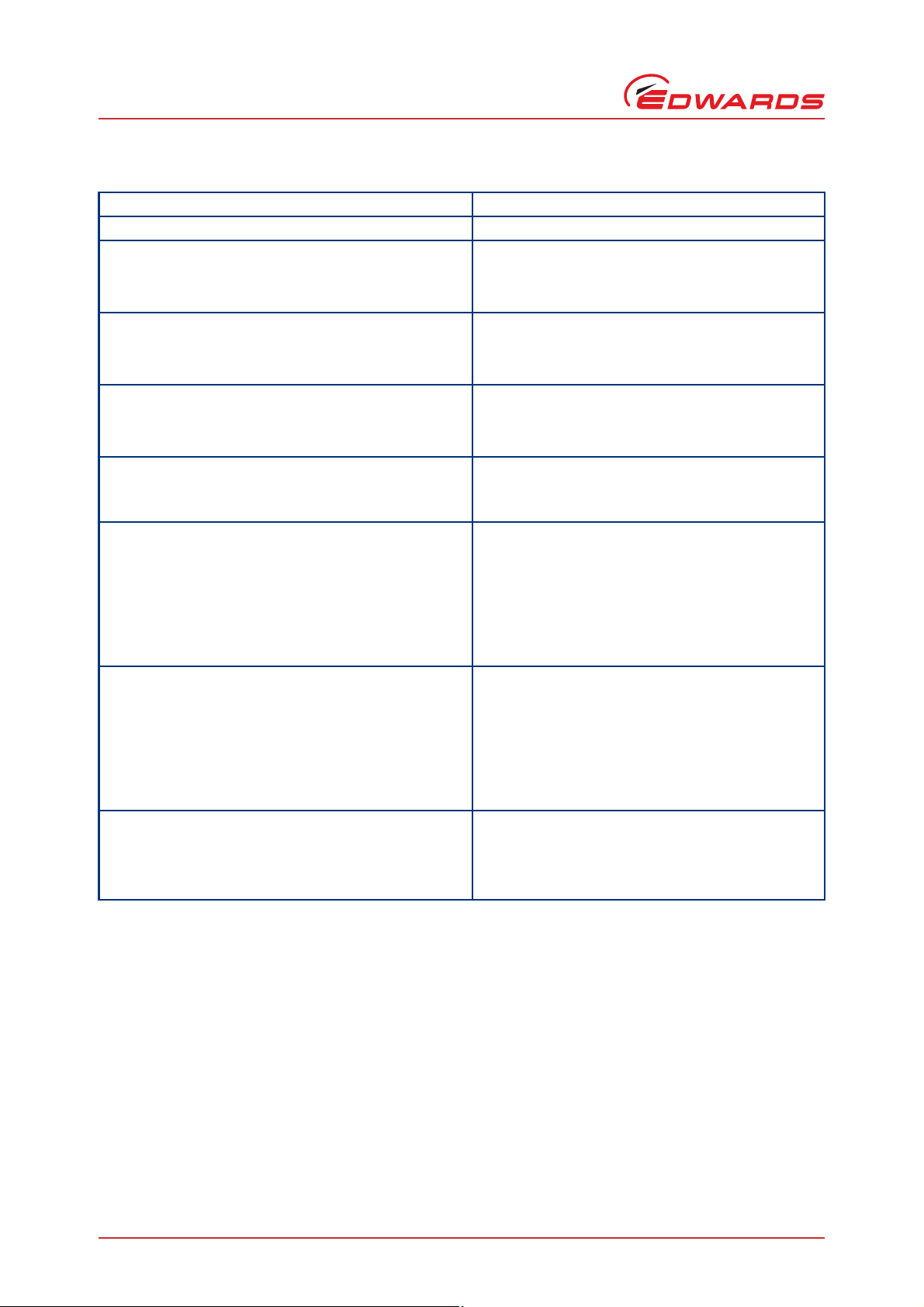

Table 2 - Logic interface technical data

Logic interface description

Connector

Start, serial enable and remote enable:

Standby control input:

Analogue and RS485 enable control inputs:

Analogue speed input

Speed set accuracy ± 5% full scale

NORMAL status output:

FAIL status output:

Analogue 10 V reference

Voltage accuracy ± 2%

Output current ≤ 5 mA for specified accuracy

*

Mating half of connector not supplied

*

Enable control voltage: low (closed) 0 to 0.8 V d.c. (l

Disable control voltage: high (open) 4 to 26.4 V d.c. (Internal pull up to 6.4 V nominal)

Enable control voltage: low (closed) 0 to 0.8 V d.c. (l

Disable control voltage: high (open) 4 to 26.4 V d.c. (Internal pull up to 3.2 V nominal)

Enable control voltage: low (closed) 0 to 0.8 V d.c. (l

Disable control voltage: high (open) 4 to 52.8 V d.c. (Internal pull up to 6.4 V nominal)

Type Open collector transistor plus pull up resistor.

< Normal speed (default 80%) OFF (4.7 k pull up + diode to 12 V d.c.)

≥ Normal speed ON (< 0.8 V d.c. sinking 10 mA)

Maximum current rating 10 mA

Maximum voltage rating 28.8 V d.c.

Type Open collector transistor plus pull up resistor.

Fail OFF (4.7 k pull up + diode to 12 V d.c.)

OK ON (< 0.8 V d.c. sinking 10 mA)

Maximum current rating 10 mA

Maximum voltage rating 28.8 V d.c.

15-way D-type (male)

0 to 10 V d.c. directly proportional to the motor speed

e.g. 0 V = 0 Hz, 10 V = 30 Hz

+ 10 V d.c. analogue voltage reference

Unipolar output with diode protection

= 0.55 mA nominal)

OUT

= 0.3 mA nominal)

OUT

= 0.55 mA nominal)

OUT

Page 4 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

A735-01-860 Issue A

1. RS232 interface on control equipment or PC

2. nXDS pump logic interface

3 Connection for serial control and

monitoring

The serial interface allows you to control the nXDS pump and to interrogate its operational status using a number of

serial commands. There is also a multi-drop mode that allows you to connect more than one nXDS pump to a single

serial port on your control system.

3.1 Serial connection

The nXDS pump can connect directly to the RS485 or RS232 serial input on your control equipment or a PC as shown

in Figure 3 and 4. In this configuration the PC is the serial link master and the nXDS pump is the slave. The RS232

serial link is capable of operating reliably at distances up to 6m. The RS485 serial link is recommended to maintain

reliable serial communications at distances greater than 6m. Alternatively an interface circuit, external to the nXDS

pump, may be required to communicate using the RS232 serial link over longer distances.

The software in the nXDS pump is capable of operating with several pumps connected to a single serial link master.

This is referred to as multi-drop mode (refer to Section 3.7). The RS485 option is recommended for multi-drop mode.

To enable the RS485 option, link the RS485 input signal to the 0 V Control Reference (pin 6 to pin 2) of your logic

interface mating half.

Connection for serial control and monitoring

Figure 3 - Logic interface connections - RS232 serial control

© Edwards Limited 2012. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

A735-01-860 Issue A

1. RS485 interface on control equipment or PC

2. nXDS pump logic interface

Connection for serial control and monitoring

Figure 4 - Logic interface connections - RS485 serial control

3.2 Serial enable

To send a serial message you mus t first activate serial enab le. This is achieved by linking the serial enable inpu t signal

(pin 5) to pin 2 of your logic interface mating half. We recommend that you incorporate this link into your serial

communications cable so that the serial enable is only activated when the serial cable is connected. When you

subsequently remove the cable, serial enable will become inactive.

Serial enable acts as an interlock for start commands sent over the serial interface. If the nXDS pump is running in

serial control mode (having been sent a serial start command) and the serial enable subsequently becomes inactive,

the nXDS pump will trigger a fail condition and will decelerate to rest. To clear this fail condition, you must reactivate the serial enable and send a serial stop command.

3.3 Serial protocol

The serial interface link is set to 9600 Baud, 8 bits, 1 stop, no parity with no handshaking. The commands are made

up from printable ASCII characters. The maximum message size you can send is 80 characters , including start and end

characters.

All alphabetical characters must be sent in upper case format. Response may contain lower case characters.

Every complete command message you send will receive a response - either a status code or a data return. The n XDS

pump can only deal with one message at a time. It will only accept a new message once the res ponse to the previous

message has been returned.

If the nXDS pump receives characters that are not framed inside start and stop characters, it will ignore them.

Messages with the stop character missing will be discarded with no response when a new start character is received.

If the nXDS pump receives an unrecognisable message between the start and stop characters, it will re turn an

appropriate error message.

Page 6 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

A735-01-860 Issue A

3.4 Message structure

The message structure and command set are the same for RS485 and RS232 options. To communicate a message to

the nXDS pump you must send the characters in a specific order. If the message does not conform to the correct

structure it will be ignored and no reply will be sent.

There are two basic types of message sent to the nXDS pump:

A command sending information to the nXDS pump; this is prefixed with a '!' character

A query requesting information from the nXDS pump; this is prefixed with a '?' character

Data is stored and accessed via two memory types within the nXDS Pump:

Non-volatile memory - this provides access to persistent data which is restored after power-cycling; the

prefix 'S' indicates persistent data.

Volatile me mory - this provides access to non-persiste nt data which is NOT restored after power-cycling; the

prefixes 'C' and 'V' indicate non-persistent data.

The correct structure to use is as follows:

a valid start character, either a '!' character for a store operation or a '?' character for a query operation,

followed by

a command, which will be an upper case alphabetical character, followed by

Connection for serial control and monitoring

an object number, comprising three decimal digits, followed by

for some commands only, a data field, comprising a sequence of characters separated from the object

number by a space, followed by

a terminating carriage return, as the stop character

An extended message protocol is used in multi-drop mode, refer to Section 3.7.

3.5 Command set

Table 3 shows a summary of the full set of commands available for controlling and monitoring the nXDS pump.

Table 4 shows the abbreviations that are used to define commands in the following sections and Table 5 shows the

error codes that might be returned.

© Edwards Limited 2012. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

A735-01-860 Issue A

Connection for serial control and monitoring

Table 3 - Summary of the commands that can be sent to the nXDS pump

Object name Command

Identification ?S0 - - - -

Node

Pump type ?S801

Pump control

Speed control !C803

Normal speed

threshold

Standby speed

setting

Auto-run

?S800

!S800

!C802

?V802

?S804

!S804

?S805

!S805

!C805

?S806

!S806

Parameter

range

0..98 0 Decimal

[1..8] - String

[1..11] - String

1..255 - String Hz

0-Decimal-Stop the pump

1 - Decimal Start the pump

0..255 - Decimal Hz Reported motor frequency

64-bits

encoded as

four

16-bit words:

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>

0-Decimal-Use full speed

1 - Decimal Use standby speed

50..100 80 Decimal %

66..100 70 Decimal %

0

1

Factory

setting

-

0 Decimal -

Data type Units Comments

Hexadeci-

mal

Slave

Address

ASCII

Characters

ASCII

Characters

Acts as wildcard object number to identify

instrument.

Reply identical to ?S801

Multi-drop address (RS485)

0 = disable multi-drop mode;

Pump type (nXDS)

Motor-Control Software

Version number (Dxxxxxxxx Y)

(where Dxxxxxxxx is the

drawing number and Y is the

revision)

Design frequency (= Nominal

mechanical frequency of the

pump)

System status:

System status register 1;

-

System status register 2;

Warning register and Fault

register

Normal speed status output

trigger level:

Percentage (%) of selected

speed

Standby speed of pump:

Percentage (%) of full

mechanical speed (see 801)

!S stores standby speed to

non-volatile memory

(use !C805 for real-time

speed control, faster

execution and extended nonvolatile memory life)

!C retains value in volatile

memory only

Run the nXDS Pump-System

from power-on:

Enable = 1

Disable = 0

*

Page 8 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

A735-01-860 Issue A

Table 3 - Summary of the commands that can be sent to the nXDS pump (continued)

Connection for serial control and monitoring

Object name Command

Temperature

readings

Link parameter

readings

Run hours ?V810

Pump cycles ?V811 0..99999 - Decimal Cycles

Drive run time ?V813

Time run since

last tip seal

service

Run time to

tip seal

service

indicator

Service

indicator reset

Time run since

last bearing

service

Run time to

bearing service

indicator

Bearing service

indicator reset

Fault history 1 ?V816

?V808

?V809

?V814

!C814 1 - Decimal -

?V815

!C815 1 - Decimal -

Parameter

range

0..150 - Decimal °C Measured pump temperature

0..150 - Decimal °C

0..5000 - Decimal 0.1V Measured link voltage

±0..300 - Decimal 0.1A Measured motor current

±0..15000 - Decimal 0.1W Measured motor power

0..99999

~11 years

0..99999

~11 years

0..99999

~11 years

0..99999

~11 years

0..99999

~11 years

0..99999

~11 years

0..99999

~11 years

0..99999

64-bits

encoded as

four 16-bit

words:

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>

Factory

setting

- Decimal Hours

- Decimal Hours

- Decimal Hours

- Decimal Hours

- Decimal Hours

- Decimal Hours

- Decimal Hours

-

Data type Units Comments

Decimal

Hexidecimal

Hours

-

Measured pump-controller

temperature

Total run hours - time pump

has run

Total number of start/stop

cycles

Total run hours - time pumpcontroller has run

Hours until recommended

controller replacement

Number of pump running

hours since last tip seal

service

Number of pump running

hours left until tip seal

service due. Decreases until

due at zero

Command to reset service

indicators, 'time since' to

zero and 'time to' to service

interval

Number of pump running

hours since last bearing

service

Number of pump running

hours left until bearing

service due. Decreases until

due at zero

Command to reset service

indicators, 'time since' to

zero and 'time to' to service

interval

Fault history at last trip:

nXDS pump-controller

powered time (hours)

system status register 01;

system status register 02;

warning register 01 and fault

register 01

†

*

†

© Edwards Limited 2012. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

A735-01-860 Issue A

Connection for serial control and monitoring

Table 3 - Summary of the commands that can be sent to the nXDS pump (continued)

Object name Command

Fault history 2 ?V817

Fault history 3 ?V818

Fault history 4 ?V819

Customer

interface

software version

Factory

settings

Motor-control

boot-loader

version

Customer

interface

boot-loader

version

?S820 [1..11] - String

!C821 1 - Decimal -

?S822 [1..11] - String

?S823 1..11] - String

Parameter

range

0..99999

64-bits

encoded as

four 16-bit

words:

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>

0..99999

64-bits

encoded as

four 16-bit

words:

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>

0..99999

64-bits

encoded as

four 16-bit

words:

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>

Factory

setting

-

-

-

Data type Units Comments

Fault history at 2nd last trip:

Decimal

Hexidecimal

Decimal

Hexidecimal

Decimal

Hexidecimal

Hours

-

Hours

-

Hours

-

ASCII

Characters

ASCII

Characters

ASCII

Characters

nXDS pump-controller

powered time (hours)

system status register 01;

system status register 02;

warning register 01 and fault

register 01

Fault history at 3rd last trip:

nXDS pump-controller

powered time (hours)

system status register 01;

system status register 02;

warning register 01 and fault

register 01

Fault history at 4th last trip:

nXDS pump-controller

powered time (hours)

system status register 01;

system status register 02;

warning register 01 and fault

register 01

Customer interface software

version number (Dxxxxxxxx Y)

(where Dxxxxxxxx is the

drawing number and Y is the

revision)

Reset all configuration

options and parameters to

factory settings

Motor-control boot-loader

version number

(Dxxxxxxxx Y)

(where Dxxxxxxxx is the

drawing number and Y is the

revision)

Customer interface bootloader version number

(Dxxxxxxxx Y)

(where Dxxxxxxxx is the

drawing number and

Y is the revision)

*

*

*

Page 10 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

A735-01-860 Issue A

Table 3 - Summary of the commands that can be sent to the nXDS pump (continued)

Connection for serial control and monitoring

Object name Command

Service setting

Service status ?V826

Service ?S835

*

See Section 3.9.1 for status word decoding

†

If either returned value is ‘-200’, then this means that this temperature is not utilised within the product

‡

See Section 3.9.2 for service word decoding

!S825

?S825

Parameter

range

0..3 0 Decimal -

One 16-bit

word:

<0000..FFFF>

[1..30] - String

[1..36] - String

Table 4 - Command abbreviations

Factory

setting

- Hexidecimal -

Data type Units Comments

ASCII

Characters

ASCII

Characters

0: Service indication on

Service LED

1: Service indication on

Service LED and FAIL line

2: No service indication on

Service LED or FAIL line

3: Service indication on FAIL

line

Service status word –

Contact Edwards for more

information

Serial numbers:

pump; drive-module and

power/control PCA

(fixed at manufacture, 9

characters each)

Pump type and build

‡

Abbreviation Meaning

cr carriage return character

chars characters

d decimal ASCII character

Note: Fields showing multiple d characters are to indicate typical length. All

h hexadecimal ASCII character

r Returned error code - refer to Table 5

sp space character

string may have several ASCII characters

X Multi-drop decimal ASCII character

Note: Fields showing multiple X characters are to indicate maximum length and

Returned error code Meaning

0 No error

1 Invalid command for object ID

2 Invalid Query/Command

3Missing parameter

4 Parameter out of range

5 Invalid command in current state - e.g. serial command to start/stop when in par-

allel control mode

data fields have a maximum of 5 decimal characters (prefixed by a minus

number for negative numbers).

not fixed length.

Table 5 - Error codes

© Edwards Limited 2012. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

A735-01-860 Issue A

Connection for serial control and monitoring

3.6 Operating the nXDS pump

3.6.1 Start the pump

To start the pump, send the following command over the serial communications link:

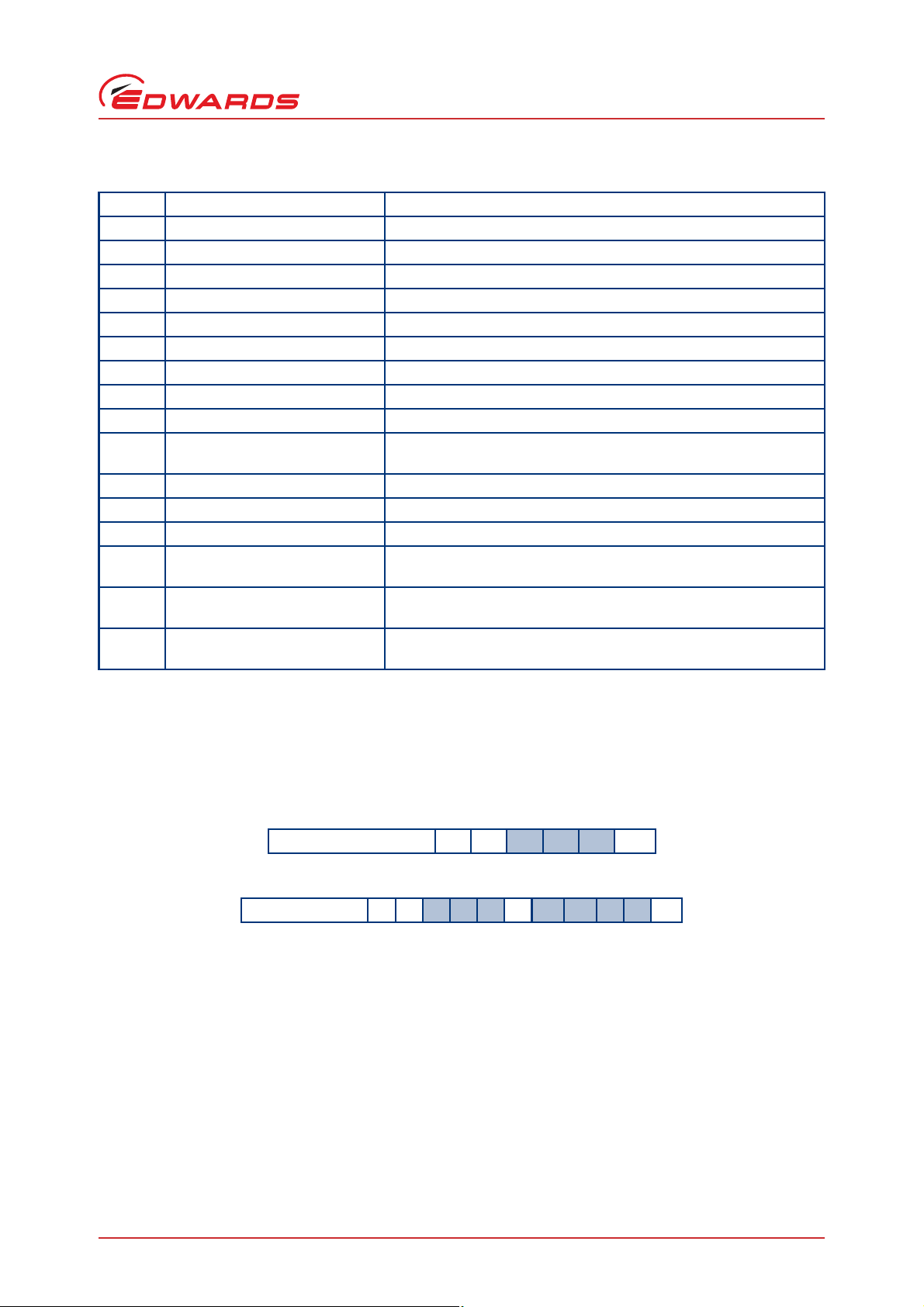

Command ! C 8 0 2sp1cr

The reply you receive will be in the following format:

Reply *

The pump will then accelerate up to the target speed and the green run LED will flash whilst it is doing so. When the

pump reaches its target speed, the green run LED will remain illuminated.

C 8 0 2sp rcr

3.6.2 Standby speed

To run the nXDS pump at standby speed, send the following command over the serial communications link:

Command !

The reply you receive will be as follows:

Reply * C 8 0 3sp rcr

If the pump is currently below standby speed then it will accelerate until it reaches s tandby speed. If it is running

faster than standby speed, it will decelerate until standby speed is reached.

To return the pump to full speed, send the following command:

Command ! C 8 0 3sp0cr

The reply you receive will be as follows:

Reply *

C 8 0 3sp1cr

C 8 0 3sp rcr

3.6.3 Stop the pump

To stop the nXDS pump, send the following command over the serial communications link:

Command !

The reply you receive will be in the following format:

Reply * C 8 0 2sp rcr

On successful receipt of the stop command, the pump will decelerate to rest.

Page 12 © Edwards Limited 2012. All rights reserved.

C 8 0 2sp0cr

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

A735-01-860 Issue A

1. RS485 interface on control equipment or PC

2. nXDS pump logic interface

3.7 Multi-drop operation

Using multi-drop mode, a single computer system can communicate with more than one nXDS pump. Each nXDS pump

must be assigned its own individual address, or node, before it can be fitted into a multi-drop system. The command

to assign the multi-drop addres s is sent in standard nXDS message format and is detailed in Section 3.7.1 below.

The message protocol in multi-drop mode is marginally different to that des cribed for serial messages in single pump

systems (Section 3.4). The main differences in multi-drop message protocol are detailed below:

All multi-drop commands, queries or replies have the start character #.

All multi-drop commands, queries and replies include a header, which contains the address of the node that

the message is to, followed by the address of the node that the message is from.

There is a delimiter character ':' (colon) which separates the two multi-drop addresses in the header.

The remainder of the message (command, query or reply) follows the same protocol as already de scribed for

single pump systems.

The wild card address 99 means 'any' node.

After a nXDS pump has been assigned a multi-drop address, it w ill ignore any messages in the format for single pumps.

An individual nXDS pump will remain silent and ignore all command messages unless the multi-drop address matches

its own address.

Connection for serial control and monitoring

Figure 5 shows a schematic diagram of an example multi-drop connection system, which can be expanded to

accommodate multiple pumps.

Figure 5 - RS485 multi-drop connections

© Edwards Limited 2012. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

A735-01-860 Issue A

Connection for serial control and monitoring

3.7.1 Assigning a multi-drop address

When you receive your nXDS pump it will have multi-drop mode disabled by default. Each individual pump must be

programmed with its own multi-drop address, via a point-to-point connection, before introduction into a multi-drop

network.

Send the following command to assign a multi-drop address (where the 'd' characters represent the address):

Command ! S

Note: The address can be any decimal number from 1 to 98. The address number 0 is used to disable multi-drop

mode. The address number 99 is reserved as a wild card and is used in the query set up detailed later.

The reply you receive will be as follows:

Reply * S 8 0 0sprcr

The multi-drop address is stored within the nXDS pump.

You can also send a query to the pump to find out whether it already has a multi-drop address. Send the following

command:

Reply ? S

If you receive the reply shown below, your pump has mu lti-drop mode disabled:

Reply = S

If your pump already has a multi-drop address you will receive no reply and you must then communicate with your

pump in multi-drop message protocol.

Use the following query (using wild card address 99 which means ‘any’ node) to find out the multi-drop ad dress of

the nXDS pump:

Command # 9 9:9 9? S8 0 0cr

8 0 0spd dcr

8 0 0cr

8 0 0sp0cr

The reply you receive will be as follows, where dd denotes the multi-drop address of the pump:

Reply #

You can disable multi-drop mode by assigning the pump an address 0. To do this, send the following command (where

dd denotes the multi-drop address of the pump and xx denotes the address of the node that is sending the command):

Command #

The reply you receive will be as follows:

Reply #

Once multi-drop mode is disabled, the pump will no longer respond to multi-drop commands.

9 9:9 9= S8 0 0spd dcr

d d:x x! S8 0 0sp0cr

x x:d d* S8 0 0sp0cr

Page 14 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 19

A735-01-860 Issue A

1. RS232 interface on control equipment or PC

2. nXDS pump logic interface

3. Start / Stop switch

4. Optional LED indicator - normal speed

5. Current limit resistor for LED

3.8 Mixed parallel and serial operation

You can control the nXDS pump using the parallel interface control inputs and at the same time monitor various pump

parameters using the serial interface. Alternatively you can control the nXDS pump using commands sent over the

serial interface and at the same time monitor the normal signal using the parallel interface. Figure 6 shows a

schematic diagram of an example mixed operation system that would allow you to do this. Many of the individual

functions available in either parallel or serial operations are also available in mixed parallel and serial operation; but

note that whilst serial enable is active, the parallel standby and fail signals are not available.

The following functions can also be used in conjunction with mixed parallel and serial operation:

Multi-drop operation; described in Section 3.7.

Analogue speed control; described in the nXDS Scroll Pump Instruction Manual (A735-01-880)

For more information on the parallel control and monitoring, please refer to the nXDS Scroll Pump Instruction Manual

(A735-01-880).

Figure 6 - Logic interface connection - mixed parallel and serial operation

Connection for serial control and monitoring

You cannot control the nXDS pump using both the parallel and serial interfaces simultaneously. For example, if you

start the pump by sending a start command over the serial interface, you cannot then stop the pump by using the

parallel interface; you must stop the pump by sending a stop command over the serial interface. Similarly, if you

start the pump by using the start / stop switch on the parallel interface, you cannot then stop the pump by using the

serial interface; you must stop the pump by using the start / stop switch on the parallel interface.

© Edwards Limited 2012. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

A735-01-860 Issue A

Connection for serial control and monitoring

3.9 Decoding sta tus words

3.9.1 Decoding system status word

If you are using the serial communications link you will be able to access further information that may be useful for

fault finding. When you send a query to monitor measured motor speed, the pump also returns a s ystem status wo rd.

The send command is as follows:

Command ?

You will receive the following reply, where the first returned number refers to motor rotational speed in revolutions

per second (Hz):

Reply =

The system status word returned is made up of 4 separate status words, each made up of 4 hexadecimal digits and

are separated by a semi-colon ';'. The first status word is 'System status register 1', then 'System status register 2',

then 'Warning register' and the final status word is 'Fault register'. To decode each indivi dua l status w ord, you mu st

convert each hexadecimal digit into a 4-digit binary number. (Table 6 is provided as an aid.) Follow the example

below:

V 8 0 2spd d d;h h h h;h h h h;h h h h;h h h hcr

2283

0010001010000011

Table 6 - Hexadecimal conversion table

Hexadecimal Binary Decimal

000000

100011

200102

300113

401004

501015

601106

701117

810008

910019

A101010

B101111

C110012

D110113

E111014

F111115

V 8 0 2cr

Page 16 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

A735-01-860 Issue A

Each binary digit (bit) represents a flag that is either active (state 1) or not active (state 0). To help decode each of

the system status words, each bit is numbered (starting with 0 for the least significant to 15 for the most significant),

as shown below:

0000000000100010

Connection for serial control and monitoring

15141312111

The following 4 tables each contain a list of the 16 status flags that will be used for decoding the status or fault

finding for the nXDS pump. Table 7 contains the 16 flags used to decode the 'System status register 1', Table 8

contains the 16 flags used to decode the 'System status register 2', Table 9 contains the 16 flags used to decode the

'Warning register' and Table 10 contains the 16 flags used to decode the 'Fault register'.

Table 7 - System status register 1 flags

Bit Status Flag Active Flat Meas

0 (lsb) Deceleration Stop command received and pump-controller is in the de celeration/

1 Acceleration/running Accelerating or running

2 Standby speed Standby active

3 Normal speed Above normal speed

4 Above ramp speed Operating above the ramp speed threshold

5 Above overload speed Operating above the overload speed threshold

6 Control mode Bits 6, 7 and 13 indicate which control mode the pump-controller is

7

8Reserved-

9Reserved10 Serial enable Serial enable active

11 Reserved 12 Reserved 13 Control mode Used in conjunction with bits 6 and 7 above

14 Reserved -

15 (msb) Reserved -

System status regis

Table 8 - System status register 2 flags

9876543210

0

ramp down process

operating in (bit 13; bit 7; bit 6).

000=none; 001=serial; 010=parallel; 011=manual

100...111=reserved

Bit Status Flag Active Flat Meas

0 (lsb) Upper power regulator active Power limit is active - i.e. pump operating on power limit

1 Lower power regulator active Acceleration is limited to manage link voltage

2 Upper voltage regulator active Deceleration is limited to manage link voltage

3Reserved-

4 Service due Service is due - See hours counters to identify what needs replacing

or use command ?V826

5Reserved6 Warning Warning condition - See 'Warning register' for detail

7 Alarm Fault condition - See 'Fault register' for detail

© Edwards Limited 2012. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

A735-01-860 Issue A

Connection for serial control and monitoring

Table 8 - System status register 2 flags (continued)

Bit Status Flag Active Flat Meas

8Reserved9Reserved-

10 Reserved 11 Reserved 12 Reserved 13 Reserved 14 Reserved -

15 (msb) Reserved -

Table 9 - Warning register 2 flags

Bit Status Flag Active Flat Meas

0 (lsb) Reserved -

1 Low pump-controller

temperature

2Reserved3Reserved4Reserved5Reserved6 Pump-controller temperature

regulator active

7Reserved8Reserved9Reserved-

10 High pump-controller

temperature

11 Reserved 12 Reserved 13 Reserved 14 Reserved -

15 (msb) Self test warning Non-critical problem with EEPROM or other internal function

Pump-controller temperature is below the minimum measurable

value

Output current is being restricted due to high pump-controller

temperature

Pump-controller temperature is above the maximum measurable

value

Page 18 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 23

A735-01-860 Issue A

Table 10 - Fault register flags

Bit Status Flag Active Flat Meas

0 (lsb) Reserved -

1 Over voltage trip Fault due to excessive link voltage

2 Over current trip Fault due to excessive motor current

3 Over temperature trip Fault due to excessive pump-controller temperature

4 Under temperature trip Pump-controller temperature sensor failure

5 Power stage fault Power stage failure

6Reserved7Reserved8 H/W fault latch set Hardware fault latch active, see bits 0-7 for detail

9 EEPROM fault Fault due to a critical EEPROM problem (e.g. Parameter upload

incomplete)

10 Reserved 11 No parameter set Parameter set upload required

12 Self test fault Self test fault (e.g. Invalid software code)

13 Serial control mode interlock Fault because the serial enable input went inactive whilst operating

with a serial start command

14 Overload time out Fault because the output frequency fell below the threshold for

more than the allowable time (with an active start command)

15 (msb) Acceleration time out Fault because the output frequency did not reach the threshold in

the allowable time (following a start command)

Connection for serial control and monitoring

3.9.2 Decoding service status word

The service status may be accessed directly via the seri al link. Thi s method of acces sin g service s tatu s will give the

most complete picture of current and future service requirements and will allow preventative maintenance activities

to be scheduled.

A summary of the current pending service status is provided in response to the service status command:

Command ?

You will receive the following reply:

Reply = V

The service status word is made up of 4 hexadecimal digits. To decode this word, you must convert each hexadecimal

digit into a 4-digit binary number as described in Section 3.9.1.

Each binary digit (bit) represents a flag that is either active (state 1) or not active (state 0). To help decode the

service status word, each bit is numbered (starting with 0 for the least significant to 15 for the most significant) as

shown in Section 3.9.1. The meaning of each bit in the service status word is given in Table 11.

8 2 6sph h h hcr

V 8 2 6cr

© Edwards Limited 2012. All rights reserved. Page 19

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 24

A735-01-860 Issue A

Connection for serial control and monitoring

Table 11 - Service flags

Bit number Status flag Active flag means

0 Tip seal service due Set when hours until tip seal service due = 0

1 Bearing service due Set when hours until bearing service due = 0

2Reserved -

3 Controller service due Set when hours until controller service due = 0

4Reserved -

5Reserved -

6Reserved -

7 Service due Service is due. Specific operation required should be

determined by checking the bits above

8 - 15 Reserved -

Page 20 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Loading...

Loading...