Page 1

Instruction Manual

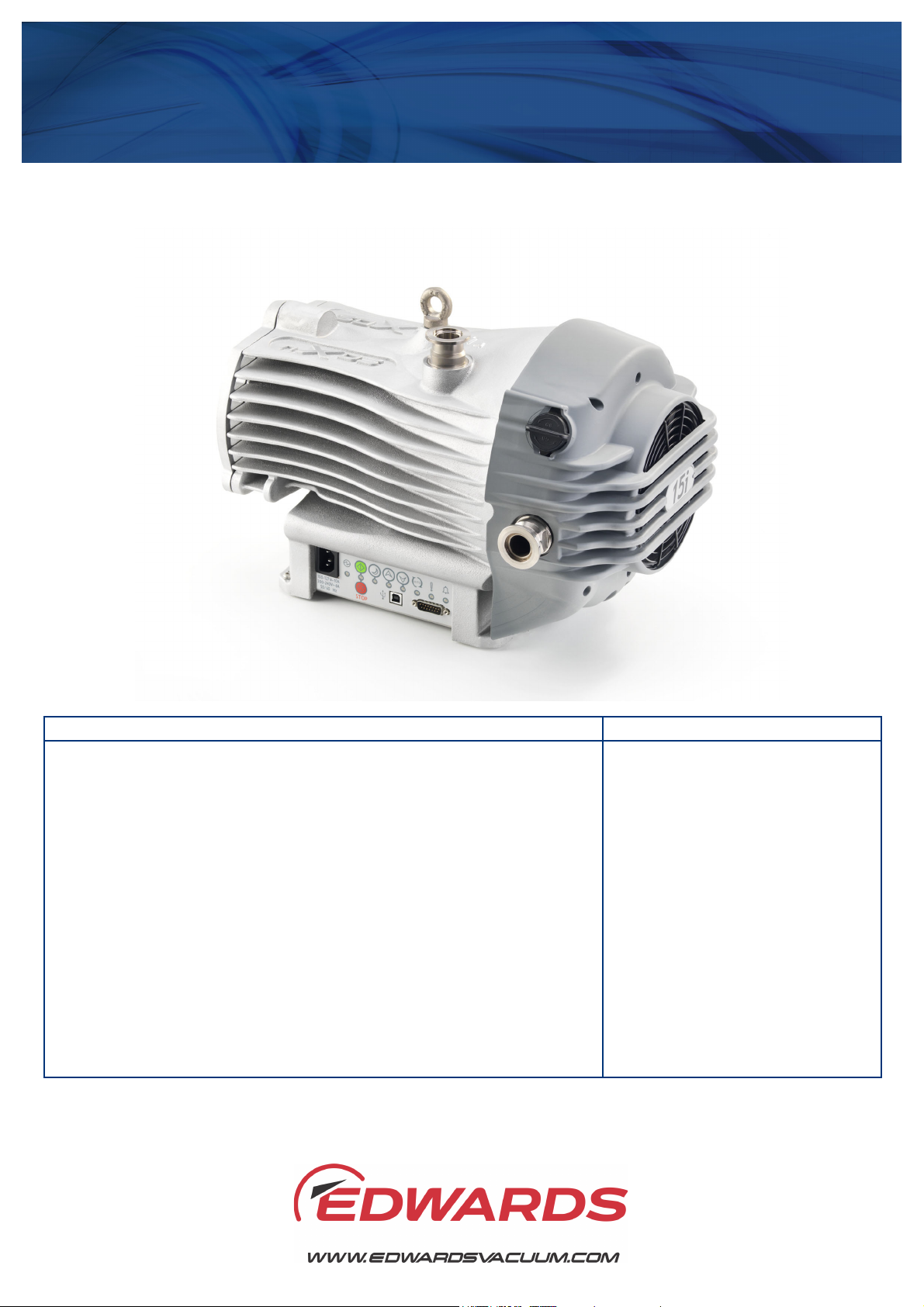

nXDS Scroll Pump

A735-01-880

Issue F

Description Item Number

nXDS6i A735-01-983

nXDS10i A736-01-983

nXDS15i A737-01-983

nXDS20i A738-01-983

nXDS6iC A735-02-983

nXDS10iC A736-02-983

nXDS15iC A737-02-983

nXDS20iC A738-02-983

nXDS6iR A735-03-983

nXDS10iR A736-03-983

nXDS15iR A737-03-983

nXDS20iR A738-03-983

Original Instructions

Page 2

This product has been manufactured under a quality management system certified to ISO 9001:2015.

P200-06-720-F

2006/42/EC

Machinery directive

2014/35/EU

Low voltage directive

2014/30/EU

Electromagnetic compatibility (EMC) directive

2014/34/EU

ATEX directive on use in potentially explosive atmospheres

II 3 G Ex h IIB T4 Gc Internal Atmospheres Only, Tech File ref 209

2011/65/EU

Restriction of certain hazardous substances (RoHS) directive

EN 1012-2:1996

+A1:2009

Compressors and vacuum pumps. Safety requirements. Vacuum pumps

BS EN ISO 8007936:2016

Non-electrical equipment for explosive atmospheres. Basic method and requirement

BS EN ISO 8007937:2016

Non-electrical equipment for explosive atmospheres. Non-electrical type of

constructional safety ‘c’

EN 61010-1:2010

Safety requirements for electrical equipment for measurement, control and

laboratory use. General requirements

EN 61326-1:2013

Electrical equipment for measurement, control and laboratory use. EMC

Class A Emissions, Industrial Immunity

CSA-C22.2

No.61010-1-12

Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

UL61010-1

3rd Edition

Safety requirements for electrical equipment for measurement, control and

laboratory use – Part 1: General requirements

Mr Ian Keech

Date and Place

Declaration of Conformity

Edwards Ltd,

Innovation Drive,

Burgess Hill,

West Sussex, RH15 9TW, UK

The following products:

nXDS6i scroll pump 100-127/200-240V, 50/60Hz A735-01-983

nXDS10i scroll pump 100-127/200-240V, 50/60Hz A736-01-983

nXDS15i scroll pump 100-127/200-240V, 50/60Hz A737-01-983

nXDS20i scroll pump 100-127/200-240V, 50/60Hz A738-01-983

nXDS6iC scroll pump 100-127/200-240V, 50/60Hz A735-02-983

nXDS10iC scroll pump 100-127/200-240V, 50/60Hz A736-02-983

nXDS15iC scroll pump 100-127/200-240V, 50/60Hz A737-02-983

nXDS20iC scroll pump 100-127/200-240V, 50/60Hz A738-02-983

nXDS6iR scroll pump 100-127/200-240V, 50/60Hz A735-03-983

nXDS10iR scroll pump 100-127/200-240V, 50/60Hz A736-03-983

nXDS15iR scroll pump 100-127/200-240V, 50/60Hz A737-03-983

nXDS20iR scroll pump 100-127/200-240V, 50/60Hz A738-03-983

Is in conformity with the relevant requirements of European CE legislation:

Based on the relevant requirements of harmonised standards:

requirements. General requirements

The product also complies with the following:

This covers all product serial numbers from the date of this declaration onwards.

19.10.2018, Burgess Hill

Vice President Engineering, High Vacuum Division

This declaration is based on the requirements of EN ISO 17050-1 and the relevant directives.

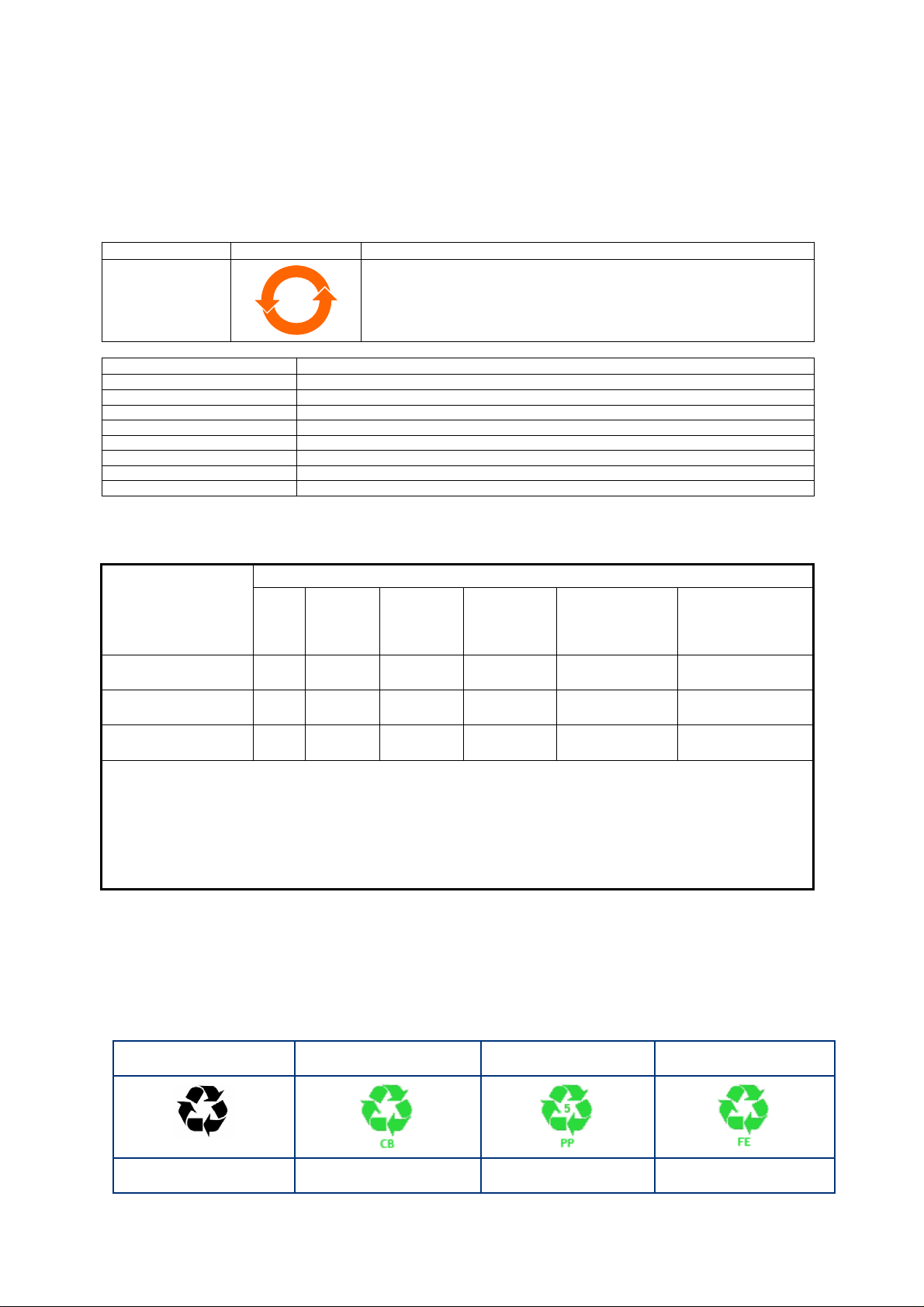

Page 3

P200-10-019

Issue D

Material Declaration

In accordance with the requirements of the Chinese regulatory requirement on the Ma nagement Methods for the

Restriction of the Use of Hazardous Substances in Electrical and Electronic Products Order No. 32 (also known as

‘China RoHS2’) and SJ/T 11364 Marking for the Restricted Use of Hazardous Substances in Electronic and Electrical

Products:

Product Labels

Product Product Label Meaning

This product contains hazardous substances in at least one of the

All pumps in the

list below

Pump Type Pump Size

RV Pumps RV3,5,8,12, E Lab, nRVi

EM Small Pumps E2M0.7, 1.5, E1M18, E2M18, 28, 30, nE2M40i

nEXT Pumps nEXT 85, 240, 300, 400, Splitflow

nXDS pumps nXDS 6, 10, 15, 20

EXT pumps EXT75DX

XDS pumps XDS35, 46, 100

Diaphragm XDD 1, D lab

Turbo Pump Carts T station, nEXPT, nEXT station

部件名称

Part name

铸铝

Cast Aluminium

铜管管件

Brass pipe Fittings

铜接头

Brass Connectors

2020

铅

Lead

(Pb)

Mercury

X O O O O O

X O O O O O

X O O O O O

homogeneous materials used which are above the limit requirement

in GB/T 26572 as detailed in the declaration table below.

These parts can safely be used for the environmental protection use

period as indicated.

材料成分声明

Materials Content Declaration

质

汞

(Hg)

镉

Cadmium

(Cd)

危险物

六价铬

Hexavalent

Chromium

(Cr VI)

多溴联苯

Polybrominated

biphenyls (PBB)

Polybrominated

diphenyl ethers

多溴二苯醚

(PBDE)

O: 表示该有害物质在该部件的所有均质材料中的含量低于 GB/T 26572 标准规定的限量要求。

O: Indicates that the hazardous substance contained in all of the homogeneous materials for this part is below

the limit requirement in GB/T 26572.

X: 表示该有害物质在该部件的至少一种均质材料中的含量超出 GB/T26572 标准规定的限量要求。

X: Indicates that the hazardous substance contained in at least one of the homogeneous materials used for

this part is above the limit requirement of GB/T26572.

NOTES: These products are EU RoHS compliant, the following Exemptions apply:

6(b) Lead as an alloying element in aluminium containing up to 0.4% by weight.

6(c) Copper alloy containing up to 4% lead by weight

Packaging Information

Pallet Over-shipper Protection Pieces Support Braces

NWNW

Recyclable Natural Wood Recyclable Cardboard Recyclable Polypropylene Recyclable Mild Steel

Page 4

This page has been intentionally left blank.

Page 5

A735-01-880 Issue F

Contents

Section Page

1 Introduction ........................................................................................ 1

1.1 Scope of this manual .................................................................................................... 1

1.2 ATEX directive implication ............................................................................................. 2

1.3 General description ..................................................................................................... 2

1.4 Pump controller.......................................................................................................... 3

1.5 Logic interface ........................................................................................................... 4

1.6 Gas ballast control ...................................................................................................... 4

2 Technical data ..................................................................................... 7

2.1 Operating and storage conditions ..................................................................................... 7

2.2 Performance.............................................................................................................. 7

2.2.1 General.................................................................................................................... 7

2.2.2 Pumping media........................................................................................................... 8

2.2.3 Performance characteristics ........................................................................................... 8

2.3 Mechanical data ........................................................................................................ 11

2.3.1 General................................................................................................................... 11

2.3.2 Sound and vibration data.............................................................................................. 11

2.3.3 Construction............................................................................................................. 11

2.4 Electrical data .......................................................................................................... 11

2.4.1 Electrical cables ........................................................................................................ 12

2.5 Logic interface data.................................................................................................... 12

2.6 LED indicators ........................................................................................................... 14

Contents

3 Installation ....................................................................................... 15

3.1 Safety..................................................................................................................... 15

3.2 System design considerations......................................................................................... 15

3.3 Unpack and inspect .................................................................................................... 17

3.4 Position the pump ...................................................................................................... 17

3.4.1 Mechanical fixing ....................................................................................................... 17

3.5 Connect to the vacuum system....................................................................................... 17

3.6 Electrical installation .................................................................................................. 18

3.6.1 Fuses and circuit breakers ............................................................................................ 18

3.6.2 Electrical supply connection .......................................................................................... 19

3.6.3 Disconnect the pump from the electrical supply .................................................................. 19

3.7 Connection for remote control and monitoring.................................................................... 19

3.7.1 Connect the logic interface to the control equipment ........................................................... 19

4 Operation ......................................................................................... 21

4.1 Operational modes ..................................................................................................... 21

4.2 Manual operation ....................................................................................................... 21

4.2.1 Start and stop ........................................................................................................... 22

4.2.2 Standby................................................................................................................... 22

4.3 Parallel control and monitoring ...................................................................................... 23

4.4 Analogue speed control................................................................................................ 24

4.4.1 Hardware configuration ............................................................................................... 25

4.4.2 Operation ................................................................................................................ 25

4.5 Auto-run.................................................................................................................. 26

4.6 Use of gas ballast control ............................................................................................. 26

4.6.1 Gas ballast control ..................................................................................................... 26

4.7 Start up procedure ..................................................................................................... 26

4.8 To achieve ultimate vacuum.......................................................................................... 27

gp/0281/01/18

4.9 To pump condensable vapours ....................................................................................... 27

© Edwards Limited 2018. All rights reserved. Page i

Page 6

A735-01-880 Issue F

Contents

4.10 Shut down................................................................................................................ 27

5 Maintenance...................................................................................... 29

5.1 Safety information...................................................................................................... 29

5.2 Maintenance plan....................................................................................................... 30

5.3 Inspect and clean the inlet strainer ................................................................................. 30

5.4 Clean the external fan cover ......................................................................................... 30

5.5 Check the pump performance (service indicator) ................................................................. 30

5.6 Replace the tip-seals................................................................................................... 31

5.7 Replace the pump bearings (service indicator) .................................................................... 31

5.8 Replace the pump controller (service indicator) .................................................................. 31

5.9 Electrical safety check................................................................................................. 31

5.10 Service indicator codes ................................................................................................ 32

5.11 Fault finding............................................................................................................. 32

5.11.1 The pump has failed to start or has stopped ....................................................................... 32

5.11.2 The pump has failed to achieve the required performance ..................................................... 32

5.11.3 The pump has poor ultimate vacuum................................................................................ 33

5.11.4 The pump is noisy ...................................................................................................... 33

5.11.5 The pump surface temperature is high ............................................................................. 33

5.11.6 Alarm indicator codes.................................................................................................. 34

6 Storage and disposal ............................................................................ 37

6.1 Storage ................................................................................................................... 37

6.2 Disposal .................................................................................................................. 37

7 Spares and accessories ......................................................................... 39

7.1 Introduction ............................................................................................................. 39

7.2 Accessories .............................................................................................................. 40

7.2.1 Silencer................................................................................................................... 41

7.2.2 Gas ballast adaptor..................................................................................................... 41

7.2.3 Gas ballast adaptor blank ............................................................................................. 41

7.2.4 Vibration isolators ...................................................................................................... 41

7.2.5 Inlet/exhaust filter..................................................................................................... 41

7.2.6 Exhaust nozzle .......................................................................................................... 42

7.2.7 Chemical resistance conversion kit .................................................................................. 42

7.2.8 Electrical cables ........................................................................................................ 42

7.2.9 Pump-to-controller cable ............................................................................................. 42

7.3 Spares .................................................................................................................... 43

7.3.1 Tip-seal kit (Youtube video https://www.youtube.com/watch?v=vKnh9dxOyhE) ........................... 43

7.3.2 Cooling fan............................................................................................................... 43

7.3.3 Gas ballast knob ........................................................................................................ 43

7.3.4 Silencer spares kit ...................................................................................................... 43

7.3.5 Inlet/exhaust filter spares ............................................................................................ 43

7.3.6 Bearing replacement kit (not field serviceable) ................................................................... 44

7.3.7 Exhaust and ballast valve kit ......................................................................................... 44

For return of equipment, complete the HS Forms at the end of this manual.

Page ii © Edwards Limited 2018. All rights reserved.

Page 7

A735-01-880 Issue F

Illustrations

Figure Page

1 nXDS scroll pump ......................................................................................................... 3

2 Quick start guide (manual control mode)............................................................................. 5

3 nXDS6i Performance characteristics ................................................................................... 9

4 nXDS10i Performance characteristics ................................................................................. 9

5 nXDS15i Performance characteristics ................................................................................ 10

6 nXDS20i Performance characteristics ................................................................................ 10

7 LED indicators ............................................................................................................ 14

8 Installation drawing ..................................................................................................... 16

9 User interface panel ....................................................................................................22

10 Logic interface connections - parallel control ......................................................................23

11 Logic interface connections - analogue speed control............................................................. 24

12 Analogue speed control................................................................................................. 25

13 Poor ultimate vacuum flow chart .....................................................................................33

14 Noisy pump flow chart .................................................................................................. 34

15 nXDS accessories.........................................................................................................40

Contents

Tables

Table Page

1 nXDS Control modes...................................................................................................... 6

2 Operating and storage conditions ...................................................................................... 7

3 Environmental conditions ............................................................................................... 7

4 General characteristics .................................................................................................. 7

5 Performance characteristics ............................................................................................ 8

6 General mechanical data............................................................................................... 11

7 Sound and vibration data...............................................................................................11

8 Electrical ratings for continuous operation.......................................................................... 11

9 Recommended regional supply protection...........................................................................11

10 Recommended cord sets................................................................................................12

11 Logic interface technical data......................................................................................... 12

12 Logic interface connector pins ........................................................................................13

13 LED indicators ............................................................................................................ 14

14 Maintenance plan........................................................................................................30

15 Flashing service codes ..................................................................................................32

16 Flashing error codes..................................................................................................... 35

17 Silencer....................................................................................................................41

18 Gas ballast adaptor...................................................................................................... 41

19 Gas ballast blank adaptor ..............................................................................................41

20 Vibration isolators .......................................................................................................41

21 Inlet/exhaust filter......................................................................................................41

22 Exhaust nozzle ...........................................................................................................42

23 Chemical resistance conversion kit ...................................................................................42

24 Electrical cables .........................................................................................................42

25 Pump-to-controller cables .............................................................................................42

26 Tip-seal kit................................................................................................................43

27 Cooling fan................................................................................................................43

28 Gas ballast knob .........................................................................................................43

© Edwards Limited 2018. All rights reserved. Page iii

Page 8

A735-01-880 Issue F

Contents

29 Silencer spares kit .......................................................................................................43

30 Inlet/exhaust filter spares .............................................................................................43

31 Bearing replacement kit................................................................................................44

32 Exhaust and ballast valve kit ..........................................................................................44

Associated publications

Publication title Publication number

Vacuum Pump and Vacuum System Safety P400-40-100

nXDS Serial Comms Interface Instruction Manual A735-01-860

Trademark credits

Edwards and the Edwards logo are trademarks of Edwards Limited, Innovation Drive, Burgess Hill,

West Sussex, RH15 9TW, UK.

Page iv © Edwards Limited 2018. All rights reserved.

Page 9

A735-01-880 Issue F

CAUTION

WARNING

1Introduction

1.1 Scope of this manual

This manual provides installation, operation and maintenance instructions for the Edwards nXDS series of scroll

pump. The pump must be used as specified in this manual or the protection provided by the equipment may be

impaired. Read this manual before installing and operating the pump.

Important safety information is highlighted as WARNING and CAUTION instructions; these instructions must be

obeyed. The use of WARNINGS and CAUTIONS is defined below.

Warnings are given where failure to observe the instruction could result in injury or death to

people. The actual symbol shown varies according to the hazard.

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

Introduction

Pressures are stated as absolute pressures unless otherwise stated.

The units used throughout this manual conform to the SI international system of units of measurement. The following

warning labels may be present on the pump and used throughout the product documentation.

Warning – an appropriate safety instruction should be followed or a caution to a potential hazard exists.

Warning – dangerous voltage. Indicates hazards arising from dangerous voltages.

Warning – hot surfaces. To indicate that the marked item can be hot and should not be touched without

taking precautions.

Warning – risk of explosion. Indicates the potential risk of explosion.

Warning – heavy object. Indicates the potential risk of physical injury and requires suitable lifting

equipment to move.

© Edwards Limited 2018. All rights reserved. Page 1

Page 10

A735-01-880 Issue F

Introduction

1.2 ATEX directive implication

This equipment is designed to meet the requirements of Group II Category 3G in respects to ignition sources internal

to the pump. This classification is in accordance with Directive 2014/34/EU.

The pumping mechanism and its mechanical components exposed to the “INTERNAL ATMOSPHERES” within the nXDS

pump system is defined as: equipment group II; equipment category 3 – in accordance with the ATEX directive. This

designation ONLY applies to the mechanical pumping mechanism, which is hermetically sealed from the external

pump system and its operating environment. An ATEX category has not been assigned in respect of potential ignition

sources on the outside of the equipment as the equipment has not been designed for use where there is an external

potentially explosive atmosphere.

There is no potential source of ignition within the pump during normal operation but there may be potential sources

of ignition under conditions of rare or unexpected malfunction as defined in the Directive. As a result of this, it is

necessary to consider the potential consequences of ignition sources occurring under rare or expected malfunction.

(Ref ATEX137 1992/92/EC).

When flammable materials are present within the equipment you must:

Not allow air to enter the equipment.

Ensure the system is leak tight.

Use an inert gas purge (for example, nitrogen) to dilute any flammable gasses or vapours entering the pump

inlet, and/or use an inert gas purge to reduce the concentration of flammable gases or vapours in the pump

and in the exhaust pipeline, to less than one quarter of the gases published Lower Explosion Limits (LEL).

Do not pump pyrophoric materials, process debris could produce an ignition source on the scroll surface.

Do not locate the pump in an ATEX zoned area, the ATEX specification is not applicable for external atmospheres.

When planning to pump hazardous substances with this pump, read the related chapters in the Safety Booklet and in

these Operating Instructions first.

Further details can be obtained by contacting Edwards.

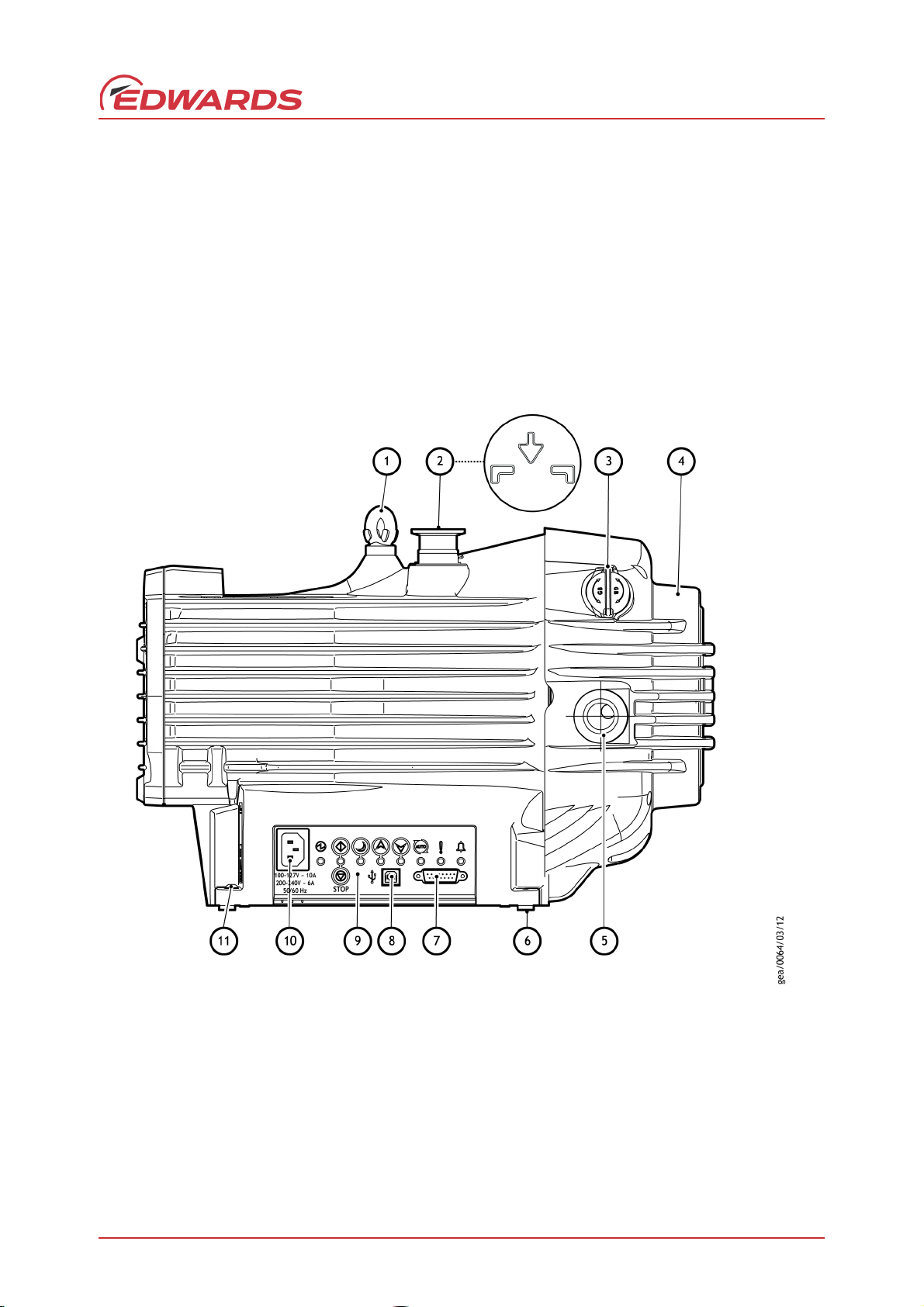

1.3 General description

The nXDS pump is shown in Figure 1.

The nXDS pump is a truly dry vacuum pump as all the bearings, with their hydrocarbon lubricant, are isolated from

the vacuum space. The nXDS pump is suitable for use on vapour handling processes, and may be used for some

pumping applications involving corrosive substances. For information on pumping flammable gases, contact Edwards.

The body of the pump includes a fixed scroll and an orbiting scroll. The orbiting scroll is controlled by an electric

motor through an eccentric cam on the motor drive shaft. The movement of the orbiting scroll, meshed with the

fixed scroll, forms successive crescent shaped volumes in the pump. Gas that enters the pump through the inlet is

compressed by the movement of the orbiting scroll and swept towards the centre of the fixed scroll. The compressed

gas enters the exhaust port near the centre of the fixed scroll and is exhausted from the pump through the outlet.

Refer to Section 2.1 for details of operating conditions.

Page 2 © Edwards Limited 2018. All rights reserved.

Page 11

A735-01-880 Issue F

1. Lifting eye

2. NW25 inlet port

3. Gas ballast control

4. Cooling fan

5. NW25 exhaust port

6. Rubber feet

7. 15-way D-type connector

8. USB port (service mode only)

9. User interface panel

10. Mains power connector

11. Secondary earth bond point

1.4 Pump controller

The integral pump controller manages the supply of current to a three-phase electric motor in accordance with

operating conditions. The controller monitors power and temperature, and will protect the pump in the event of

operation under sustained high load or under fault conditions.

The controller provides the user interface (refer to Figure 1). The pump may be operated in these modes:

Manually, using the buttons on the interface panel. Refer to Figures 2 and 9.

Remotely via serial communications or digital and analogue process control (parallel), via the 15-way D-type

logic interface connector. Refer to Section 1.5.

Figure 1 - nXDS scroll pump

Introduction

© Edwards Limited 2018. All rights reserved. Page 3

Page 12

A735-01-880 Issue F

Introduction

1.5 Logic interface

The pump controller can be operated via the 15-way D-type logic interface connector. The signals on the logic

interface are of the following types:

Control inputs: these are switch-type and analogue signals that are used to control the pump

Status outputs: these outputs identify the status of the system Tab

The logic interface has been designed to support both serial control, parallel control and monitoring, operating

though one connector. For serial control either RS232 or RS485 can be selected.

For Control Modes refer to Table 1.

For Logic interface data refer to Section 2.5.

1.6 Gas ballast control

To pump high vapour loads, gas ballast can be delivered into the pump to prevent condensation of the vapour carried

by the pumped gases.

Air can be introduced to the low vacuum stages through the gas ballast control (Figure 1, item 3). Alternatively, an

inert gas such as nitrogen can be supplied through a suitable external valve and by using the appropriate adaptor,

available as an accessory. Refer to Section 7.

Page 4 © Edwards Limited 2018. All rights reserved.

Page 13

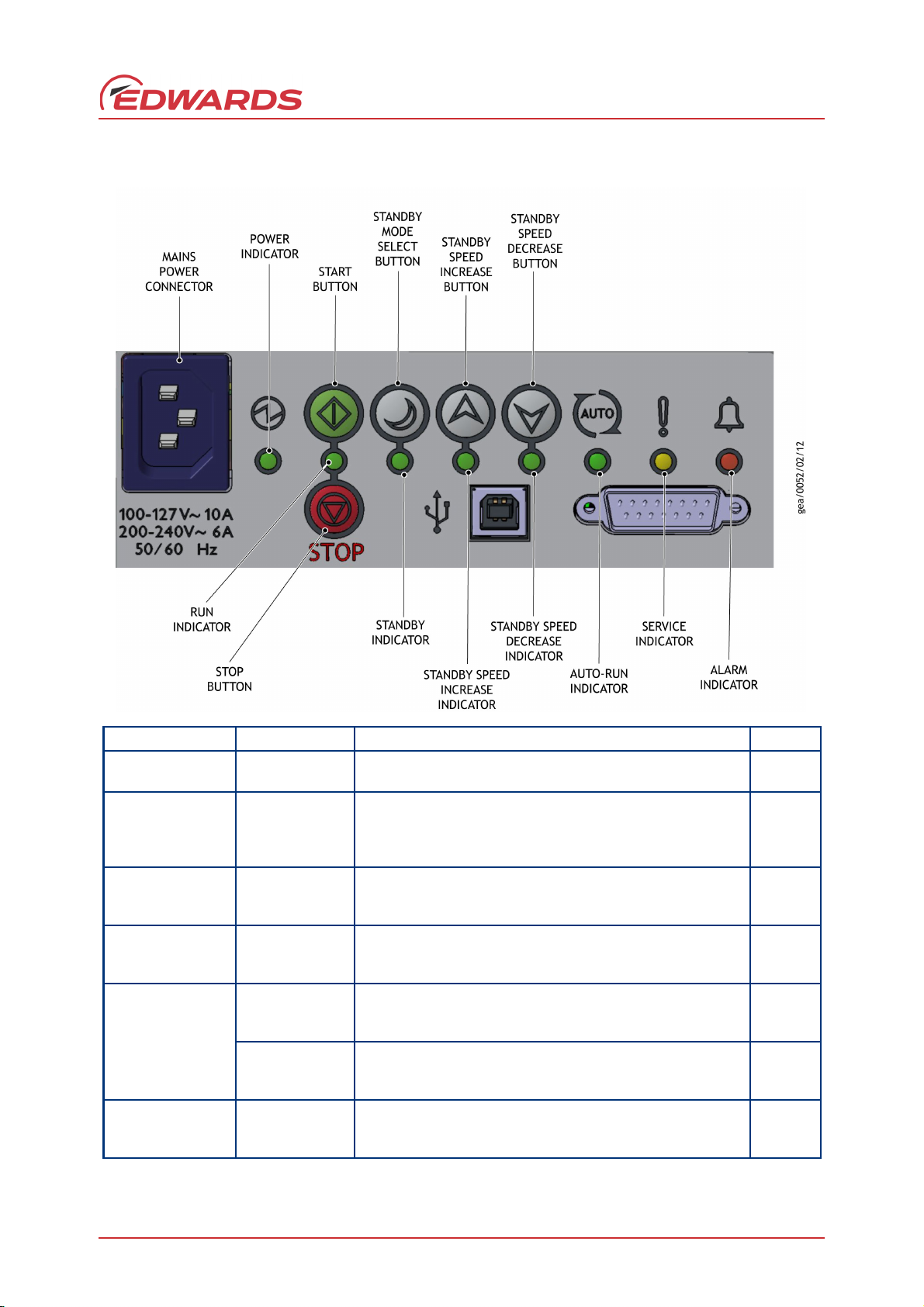

Figure 2 - Quick start guide (manual control mode)

OPERATION SELECT STATUS SECTION

Apply power

MAINS

POWER

The pump will remain off (factory default).

The POWER INDICATOR will illuminate.

3.6.2

Start the pump

START

BUTTON

The pump will accelerate up to full running speed.

*

The RUN INDICATOR will flash while accelerating.

The RUN INDICATOR will remain on when the pump reaches

full speed.

*

The pump is set to 30 Hz rotational full speed (factory default)

4.2.1

Stop the pump STOP BUTTON

The pump will decelerate and stop running.

The RUN INDICATOR will flash while decelerating.

The RUN INDICATOR will go off when the pump has stopped.

4.2.1

Select and deselect

the standby speed

STANDBY MODE

SELECT BUTTON

When engaged, the STANDBY INDICATOR will illuminate and

the pump will run at the standby speed setting. Factory

default is 70% of full speed.

4.2.2

Increase or

decrease the pump

speed when in

standby mode

STANDBY SPEED

INCREASE

BUTTON

The pump speed will increase.

The INCREASE STANDBY INDICATOR will remain illuminated

when the pump reaches a maximum of 100% of full speed.

4.2.2

STANDBY SPEED

DECREASE

BUTTON

The pump speed will decrease.

The DECREASE STANDBY INDICATOR will remain illuminated

when the pump reaches a minimum of 67% of full speed.

4.2.2

Select and deselect

the Auto-run

function

START or STOP

BUTTON (>8 sec)

When engaged, the AUTO-RUN INDI CATOR will illuminate.

The pump will re-start automatically after the power has

been restored.

4.5

A735-01-880 Issue F

Introduction

© Edwards Limited 2018. All rights reserved. Page 5

Page 14

A735-01-880 Issue F

Introduction

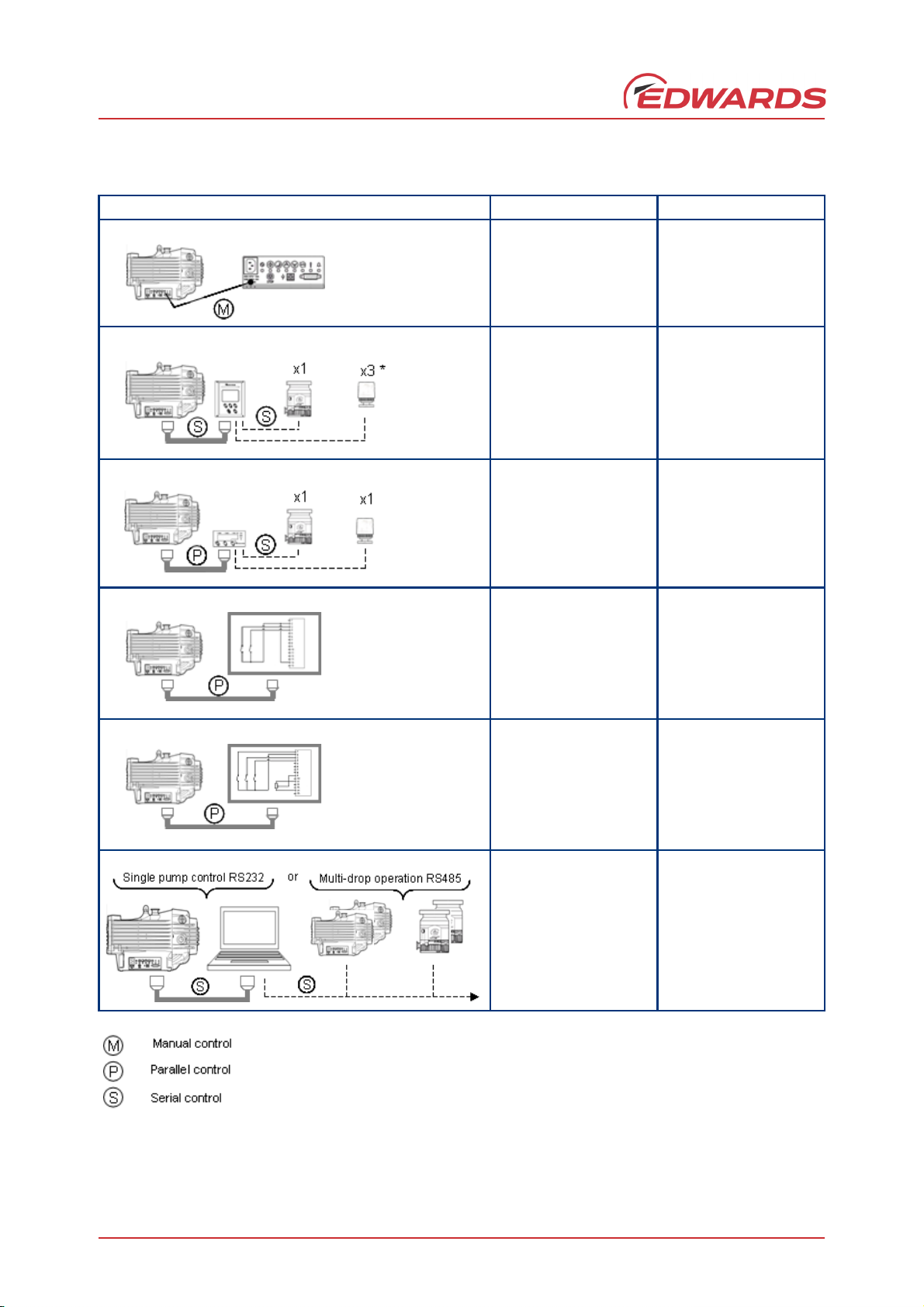

Table 1 - nXDS Control modes

Configuration Control mode Manual/Section

Manual control

via

nXDS user interface

Serial control

via (TIC)

*Turbo Instrument

Controller or

Tu r b o C o n t r o l l e r

Parallel control

via (TAG)

Turbo & Active Gauge

Controller

Parallel control

via Digital I/O

e.g. PLC control

Section 1

Figure 2

in this manual

Manual

D397-22-880

Manual

D395-92-880

Section 1.4

in this manual

Parallel control

via Digital I/O and

Analogue speed

control source

Serial control

via RS232 or

RS485 Comms

Interface

Note: Table 1 shows additional Edwards products, such as DX / nEXT Turbo pumps and active gauges that can be

controlled at the same time using the various control methods displayed above.

Section 4.4

Figure 11

Manual

A735-01-860

Page 6 © Edwards Limited 2018. All rights reserved.

Page 15

A735-01-880 Issue F

WARNING

2Technical data

If the nXDS pump is operated outside the specified limits, the pump housing may become hot.

2.1 Operating and storage conditions

Table 2 - Operating and storage conditions

Operating and storage conditions nXDS

Ambient temperature range (storage) –30 °C to +70 °C

Ambient temperature range (operation) +5 °C to +40 °C

Maximum humidity (storage in original packaging) 95% RH

Maximum humidity (operation) 90% RH

Table 3 - Environmental conditions

Environmental conditions

Pollution Pollution degree 2

Installation Installation category II

Altitude restriction Max 2000 m

Area of use Indoor

*

The product can be used up to an altitude of 3000 m. However, the product is only ETL certified for use up

to 2000 m.

*

Technical data

2.2 Performance

2.2.1 General

Tab l e 4 - G en e ra l ch ara c t e ri s t i cs

Description nXDS6i nXDS10i nXDS15i nXDS20i

3h-1

Peak pumping speed (m

Maximum permitted continuous inlet pressure (mbar)

Maximum permitted exhaust pressure (bar gauge)

Maximum permitted gas ballast inlet pressure (bar gauge) 0.5 0.5 0.5 0.5

Maximum recommended chamber volume to pump down

from atmospheric pressure (litres)

Maximum pressure rise when stopped, with no inlet or gas

ballast flow (mbar)

Leak tightness (mbar ls

*

These pumps are designed to pump down from atmospheric pressure, but prolonged operation at inlet

pressures higher than specified may reduce bearing life.

†

These pumps are intended to exhaust to atmospheric pressure. High exhaust pressure may reduce tip-seal

life.

‡

Larger volumes may be pumped, but prolonged operation at inlet pressures higher than specified may

reduce bearing life. The nXDS20i is optimised for constant throughput and is not recommended for cyclic

duty.

) 6.2 11.4 15.1 22.0

*

†

‡

-1

)1 x 10

200 200 200 50

1111

25 50 75 75

7777

-6

1 x 10

-6

1 x 10

-6

1 x 10

-6

© Edwards Limited 2018. All rights reserved. Page 7

Page 16

A735-01-880 Issue F

WARNING

Technical data

Note: If the pump is operated outside the specified limits, then the pump housing may become hot; the controller

may reduce the motor speed; and tip seal wear rate will be increased.

2.2.2 Pumping media

Do not use the nXDS pump to pump pyrophoric materials or dust.

The pump is designed to pump the following gases:

Air

Carbon dioxide

Helium

Carbon monoxide

Nitrogen

Argon

Oxygen (O

)

2

The pump can be used to pump water vapour. Caution must be taken to ensure that vapour does not condense inside

the pump. Refer to Section 4.6.1 on how to prevent condensation of water vapour in the pump.

If pumping a vapour or gas not in the list above, contact Edwards for advice.

2.2.3 Performance characteristics

The position of the gas ballast control defines the performance characteristics of the pump. These performance

characteristics are listed in Table 5.

Table 5 - Performance characteristics

Description nXDS6i nXDS10i nXDS15i nXDS20i

Pump ultimate

(mbar)

Gas ballast flow

(l min-1)

Gas ballast position 0 2 x10

Gas ballast position 1 5 x 10

-2

-2

Gas ballast position 1 12 16 31 24

7 x 10

4 x 10

-3

-2

7 x 10

4 x 10

-3

-2

3 x 10

6 x 10

-2

-2

Page 8 © Edwards Limited 2018. All rights reserved.

Page 17

Figure 3 - nXDS6i Performance characteristics

A735-01-880 Issue F

Technical data

Figure 4 - nXDS10i Performance characteristics

© Edwards Limited 2018. All rights reserved. Page 9

Page 18

A735-01-880 Issue F

Technical data

Figure 5 - nXDS15i Performance characteristics

Figure 6 - nXDS20i Performance characteristics

Page 10 © Edwards Limited 2018. All rights reserved.

Page 19

2.3 Mechanical data

2.3.1 General

A735-01-880 Issue F

Technical data

Parameter nXDS

Overall dimensions (L x W x H) 432 x 282 x 302 mm

Maximum tilt angle 10 degrees

Nominal rotational speed 1800 rpm (30 Hz)

Mass (maximum) 6i - 26.2 kg

Inlet connection NW25

Outlet connection NW25

Table 6 - General mechanical data

10i - 25.8 kg

15i - 25.2 kg

20i - 25.6 kg

2.3.2 Sound and vibration data

Parameter nXDS

Sound pressure, measured at ultimate vacuum 1 metre from the end of the pump

to ISO 3744

Vibration: measured at the inlet port (ISO 3744) Class 1C…< 4.5 mms

Table 7 - Sound and vibration data

52.0 dB (A) ± 2.5

Declared dual number noise

emission values according

with ISO 4871

radial)

–1

(rms

2.3.3 Construction

All surfaces of the pump which are exposed to the pumped gases are free from copper, zinc and cadmium. Exposed

components include: anodised aluminium scrolls, aluminium housing, nickel-plated inlet and exhaust ports, PTFE

composite tip-seals, various stainless steel parts and fluorocarbon elastomer seals.

Other materials of construction include steel, copper, hydrocarbon lubricant and chemically resistant polymers.

2.4 Electrical data

Table 8 - Electrical ratings for continuous operation

Pump Supply (Vac rms) Phase Frequency (Hz) Input current (A rms)

All variants

Area Voltage Rating

Europe 230 V 10 A, 250 V a.c. rms

Japan 100 V 10 A, 250 V a.c. rms

100 - 127 ± 10% Single 50/60 10

200 - 240 ± 10% Single 50/60 6

Table 9 - Recommended regional supply protection

UK 230 V 10 A, 250 V a.c. rms

US 120 V 10 A, 250 V a.c. rms

© Edwards Limited 2018. All rights reserved. Page 11

Page 20

A735-01-880 Issue F

Technical data

2.4.1 Electrical cables

Recommended cord sets and fuses for regional requirements.

Table 10 - Recommended cord sets

Description Rating Coupler type Item number

2

Cord set assembly, UK Cable Style = H05VV-F, 3 x 1.0 mm

70 °C, maximum length of 2.0 metres Straight entry A50505000

Plug Type = BS1363 UK plug

Appliance Coupler = IEC60320 style C14

Fuse Type = BS1363 10 Amp fuse, to an

IEC60320 style

Cord set assembly, Europe Cable Style = H05VV-F, 3 x 1.0 mm

70 °C, maximum length of 2.0 metres Straight entry A50506000

Plug Type = European Schuko VDE approved,

16 A 250 V rated with dual earthing contact

Appliance Coupler = IEC60320 style C14 N/A

Cord set assembly,

USA/Canada

Cable style = SJT, 3 x 18 AWG, 300 V, 70 °C,

VW-1 maximum length of 2 metres Straight entry A50507000

Plug Type = NEMA, 5-15P plug

Appliance Coupler = IEC 60320 style C14

, 300 V,

2

, 300 V,

2.5 Logic interface data

The pumps have a 15-way D-type logic interface connector located on the user interface panel (Figure 1, item 7).

The logic interface connector can be plugged directly into the Edwards 200W Turbo Instrument Controller (TIC) or

turbo controller, or Turbo and Active Gauge controller (TAG). A suitable connector mating half must be used (not

supplied) to connect the nXDS pump to the customer control system. Refer to Table 11 for the interface technical

data and Table 12 for the logic interface pins for the electrical connections.

Table 11 - Logic interface technical data

Logic interface description

Connector

Start, serial enable and remote enable:

Standby control input:

Analogue and RS485 enable control inputs:

Analogue speed input

Voltage accuracy ± 5% full scale

*

Enable control voltage: low (closed) 0 to 0.8 V d.c. (l

Disable control voltage: high (open) 4 to 26.4 V d.c. (Internal pull up to 6.4 V nominal)

Enable control voltage: low (closed) 0 to 0.8 V d.c. (l

Disable control voltage: high (open) 4 to 26.4 V d.c. (Internal pull up to 3.2 V nominal)

Enable control voltage: low (closed) 0 to 0.8 V d.c. (l

Disable control voltage: high (open) 4 to 52.8 V d.c. (Internal pull up to 6.4 V nominal)

15-way D-type (male)

= 0.55 mA nominal)

OUT

= 0.3 mA nominal)

OUT

= 0.55 mA nominal)

OUT

0 to 10 V d.c. directly proportional to the motor speed

e.g. 0 V = 0 Hz, 10 V = 30 Hz

Page 12 © Edwards Limited 2018. All rights reserved.

Page 21

Table 11 - Logic interface technical data (continued)

Logic interface description

NORMAL status output:

Type Open collector transistor plus pull up resistor.

< Normal speed (default 80%) OFF (4.7 k pull up + diode to 12 V d.c.)

Normal speed ON (< 0.8 V d.c. sinking 10 mA)

Maximum current rating 10 mA

Maximum voltage rating 28.8 V d.c.

FAIL status output:

Type Open collector transistor plus pull up resistor.

Fail OFF (4.7 k pull up + diode to 12 V d.c.)

OK ON (< 0.8 V d.c. sinking 10 mA)

Maximum current rating 10 mA

Maximum voltage rating 28.8 V d.c.

Analogue 10 V reference

Voltage accuracy ± 2% full scale

Output current 5 mA for specified accuracy

*

Mating half of connector not supplied

+ 10 V d.c. analogue voltage reference

Unipolar output with diode protection

A735-01-880 Issue F

Technical data

Table 12 - Logic interface connector pins

Pin Number Signal Polarity Use

1 Analogue Speed Enable-

control Input

2 0 V Control Reference - 0 V reference for ALL control and status signals listed within

3 START / STOP – Control

Input

4STANDBY – Control Input /

Serial-RX / RS-485 A-

5 Serial Enable – Control

Input

6 RS-232 / RS-485 – Control

Input

7 FAIL – Status Output /

Serial-TX / RS-485 B+

8 0 V Control Reference - 0 V reference for ALL control and status signals listed within

9 Analogue Speed – Control

Input

10 Chassis / Screen - Screen

11 +10 V Analogue Reference

– Control Output

12 Chassis / Screen - Screen

- Connect to Pin 2 (0 V) to enable analogue speed control via

Pin 9.

this table.

- Connect to Pin 2 (0 V) to START the nXDS pump system.

- Connect to Pin 2 (0 V) to enable STANDBY speed when the

SERIAL ENABLE control input is inactive.

- Connect to Pin 2 (0 V) to enable serial communications.

- Default configuration is RS-232 with Pin 6 unconnected.

Connect to Pin 2 (0 V) to enable RS-485 serial

communications.

- Logic HIGH when a fail / fault condition exists and the SERIAL

ENABLE control input is inactive.

this table.

- 0-10 V Analogue Input: 0 V = 0% Speed; +10 V = 100% Speed

Positive +10 V analogue voltage reference output: 5 mA;

uni-polar output, diode protected.

© Edwards Limited 2018. All rights reserved. Page 13

Page 22

A735-01-880 Issue F

Technical data

Table 12 - Logic interface connector pins (continued)

Pin Number Signal Polarity Use

13 Not Connected - Unused control pin.

14 REMOTE – Control Input - Connect to Pin 2 (0 V) to enable remote control via Parallel or

15 NORMAL – Status output - Logic LOW when the pump rotational speed is at normal

2.6 LED indicators

Serial control modes.

speed or above.

Figure 7 - LED indicators

The nXDS pump has eight indicator LED’s

Table 13 - LED indicators

LED Description Details

1 Power indicator Indicates that electrical mains supply to the pump is ON

2 Run indicator Indicates that the pump is running. Refer to Section 4.2.1.

3 Standby mode indicator

Standby speed increase

4

indicator

Standby speed decrease

5

indicator

6 Auto-run indicator

7 Service indicator

8 Alarm indicator Indicates an Alarm has been triggered. Refer to Section 5.11.6.

Indicates that the Standby mode has been selected. Refer to

Section 4.2.2.

The indicator will blink with every short push of the Standby speed

increase button. The indicator will remain ON when maximum standby

speed has been reached. Refer to Section 4.2.2.

The indicator will blink with every short push of the Standby speed

decrease button. The indicator will remain ON when minimum standby

speed has been reached. Refer to Section 4.2.2.

Indicates that the Auto-run mode has been selected. Refer to

Section 4.3.

Indicates that a service interval has been reached. Refer to

Section 5.10.

Page 14 © Edwards Limited 2018. All rights reserved.

Page 23

A735-01-880 Issue F

WARNING

3 Installation

3.1 Safety

Obey the safety instructions in this section and take note of appropriate precautions. If not, injury

to people and damage to equipment can result.

Prevent any part of the human body coming into contact with the vacuum.

The Edwards nXDS pump is not intended for pumping explosive gases continuously (refer to

Section 1.2).

Ensure that the pump is suitable for the application. If in doubt, refer to the Edwards guidelines on vacuum pump

and vacuum system safety (see associated publications at the end of the contents list at the front of this manual),

or contact Edwards for advice.

A suitably trained and supervised technician must perform the installation of the pump. Obey the safety instructions

listed below, especially when connecting the pump into an existing system. Details of the specific safety precautions

are given at the appropriate point in the instructions.

Installation

Wear the appropriate safety clothing if contact with contaminated components is anticipated. Dismantle and

clean contaminated components inside a fume cupboard.

Vent and purge the vacuum system before starting installation work.

Ensure that the installation technician is familiar with the safety procedures that relate to the products

handled by the pumping system.

Disconnect the other components in the pumping system from the electrical supply to prevent accidental

operation.

3.2 System design considerations

Consider the following points when designing the pumping system:

Edwards recommend the use of a foreline vacuum isolation valve to allow the pump to warm up before pumping

condensible vapours or if a vacuum needs to be maintained when the pump is not running.

Use a suitable valve to isolate the pump from the vacuum system if the pump needs to warm up before pumping

condensable vapours or if vacuum needs to be maintained when the pump is switched off.

Avoid high levels of heat input into the pump from the process gases, otherwise the pump may overheat and cause

the thermal protection system to operate.

Ensure that the exhaust pipeline cannot become blocked. If an exhaust isolation valve is installed, ensure that the

pump cannot be operated with the valve closed. Refer to Section 3.5.

Provide for a purge of inert gas when the pumping system is shut down, to dilute dangerous gases to safe

concentrations. Contact the Edwards Application team for further advice on dilution requirements if required.

© Edwards Limited 2018. All rights reserved. Page 15

Page 24

A735-01-880 Issue F

Installation

Figure 8 - Installation drawing

Note: All dimensions in mm. External dimensions are the same for all variants.

Page 16 © Edwards Limited 2018. All rights reserved.

Page 25

A735-01-880 Issue F

WARNING

WARNING

WARNING

3.3 Unpack and inspect

Use suitable lifting equipment to move the nXDS pump. The maximum pump mass is 27 kg.

Mechanical lifting equipment should be attached to the lifting eye; loose slings should not

be used.

Take care when moving the pump into position. Its mass may make it difficult to slide. The

fan cowl is shaped to provide a handhold for positioning; the pump must not be lifted using

this handhold.

Remove all packing materials, remove the pump from its packing box, remove the protective covers from the inlet

and outlet ports and inspect the pump. If the pump is damaged, notify the supplier and carrier in writing; state the

item number of the pump together with the order number and supplier's invoice number. Retain all the packing

materials for inspection. Do not use the pump if it is damaged. If the pump is not to be used immediately, replace

the protective covers. Store the pump in the conditions described in Section 6.1. Refer to Section 6.2 for disposal of

materials.

3.4 Position the pump

Installation

If the pump is to be used on the floor of a work area, position the power lead and the exhaust and

inlet hoses with care. Ensure that personnel in the area are aware of any obstructions around the

pump.

Provide a firm, level platform for the pump. Locate the pump so that the gas ballast control and the user controls

are accessible.

If the pump will be located inside an enclosure, ensure that there is adequate ventilation at both ends of the pump,

so that the ambient temperature around the pump does not exceed 40 °C. There must be a minimum space of 25 mm

between the pump and the enclosure walls.

3.4.1 Mechanical fixing

Note: The pump can be secured by using the four holes located on each corner of the pump base. Edwards

recommends using M8 bolts.

3.5 Connect to the vacuum system

If pumping dangerous gases or vapours, connect the exhaust to a suitable treatment plant to

prevent the discharge of dangerous gases and vapours to the surrounding atmosphere.

If the pump is operated with the exhaust line blocked, high pressure may be generated in the

exhaust line pipework.

Refer to Figure 1. Before connecting the pump to the vacuum system, remove the plastic cap from the inlet and

exhaust, and ensure that the inlet strainer is fitted to the pump inlet port. Use appropriate NW25 vacuum fittings for

connection to the system.

© Edwards Limited 2018. All rights reserved. Page 17

Page 26

A735-01-880 Issue F

CAUTION

WARNING

Installation

Take note of the following information when connecting the pump to the vacuum system:

To minimise noise and exhaust emissions, it is recommended that the pump is connected to an exhaust line

or a silencer (refer to Section 7).

For optimum pumping speeds, ensure that the pipeline connected to the pump inlet is as short as possible

and has a suitable internal diameter.

Support the vacuum pipeline to prevent loading of the coupling joints.

A pressure of 3 barg may be generated in the exhaust pipework if the pump is operated with the exhaust line

blocked. Connect the pump using appropriate pipework and fittings.

If necessary, incorporate flexible bellows in the system pipelines to reduce the transmission of vibration and

to prevent loading of the coupling joints. If using flexible bellows, ensure that bellows have a maximum

pressure rating which is greater than the highest pressure that can be generated in the system. Edwards

bellows are recommended.

Incorporate an inlet isolation valve in the pipeline from the vacuum system to the pump to isolate the

vacuum system from the pump when it is switched off and prevent suck-back of process gases and debris into

the vacuum system.

Ensure that the sealing surfaces are clean and scratch-free.

Edwards recommends using an exhaust extraction system suitable for use with all process gases that will be pumped.

Ensure that the exhaust extraction system cannot become blocked or obstructed when the pump is operating.

A small amount of tip seal wear product may collect in the exhaust duct of the pump. The dust may be blown out

with the initial burst of air after the pump has been vented. This is quite common and the amount of dust seen will

reduce over time.

Leak test the system and seal any leaks found after pump installation.

3.6 Electrical installation

3.6.1 Fuses and circuit breakers

Ensure that the electrical installation of the pump conforms to local and national safety

requirements. The pump must be connected to a suitably fused and protected electrical supply

with a suitable earth point. For recommended fuse ratings and cord sets refer to Section 2.4.

Ensure that access to the pump electrical supply cable is not obstructed when locating the pump.

If using an earth leakage device, for example, a Residual Current Device (RCD), use a 30 mA (minimum) rated

unit to avoid trip during start up.

The live conductor is fused inside the pump controller whilst the neutral conductor is not. An external RCD

should be installed to guard against damage in the event of a short circuit between neutral and earth.

For recommended protection ratings, refer to Table 9 in Section 2.4.

Page 18 © Edwards Limited 2018. All rights reserved.

Page 27

A735-01-880 Issue F

3.6.2 Electrical supply connection

Use an IEC60320 connector (C13) and cable that meets local electrical standards when connecting to the pump. The

pump must be earthed via the earth conductor of the IEC60320 connector. A list of cable specifications is available

in Section 2.4 of this manual.

Edwards recommends fitting a separate earth to the pump using a non-insulated braid or a separate insulated green/

yellow conductor. The conductor must be a minimum of 14 AWG. Use the M5 x 10 screw and shake proof washer

located on the rear of the pump housing (refer to Figure 1) to secure the earth conductor to the pump.

3.6.3 Disconnect the pump from the electrical supply

Before removing the physical electrical supply connection to the pump, via the IEC60320 cable (C13), isolate the

Mains supply (refer to Figure 1).

3.7 Connection for remote control and monitoring

To operate the pump using parallel or serial control, use the 15-way D-type connector on the user interface panel

(refer to Figure 1, item 7). Refer to Table 12 for full details of the logic interface pins.

3.7.1 Connect the logic interface to the control equipment

Installation

The pump can be controlled using a hardware parallel control interface and/or via commands sent over a serial

interface.

To control the pump using the hardware parallel interface, refer to Section 4.3 for more information. To use the

serial interface or to work with a mixture of parallel and serial control, refer to manual A735-01-860.

© Edwards Limited 2018. All rights reserved. Page 19

Page 28

A735-01-880 Issue F

This page has been intentionally left blank.

Page 20 © Edwards Limited 2018. All rights reserved.

Page 29

A735-01-880 Issue F

CAUTION

WARNING

4 Operation

Ensure that the system design does not allow the exhaust pipeline to become blocked.

A fine dust may be emitted from the exhaust of the scroll pump during start up, particularly when the pump is

new or if new tip seals are fitted.

4.1 Operational modes

The nXDS pump implements three control modes:

Manual Control Mode - using buttons on user interface panel

Parallel Control Mode - via 15-way D-type logic interface connector on user interface panel

Operation

Serial Control Mode (including Serial Interlock) - via 15-way D-type logic interface connector on user

interface panel

The Control Mode is determined by the way the pump is started. Once started, the pump can only be stopped by the

mode in which it was started, unless the power is cycled by isolation from the electrical supply.

4.2 Manual operation

The pump control functions of the user interface panel are detailed in Figure 9.

© Edwards Limited 2018. All rights reserved. Page 21

Page 30

A735-01-880 Issue F

1. Mains power connector

2. Power connected indicator

3. Start button with indicator

4. Standby button with indicator

5. Increase standby speed button with indicator

6. Decrease standby speed button with indicator

7. Auto-run enabled indicator

8. Service indicator

9. Alarm indicator

10. 15-way D-type connector

11. USB port (Service mode only)

12. Stop button

Operation

Figure 9 - User interface panel

4.2.1 Start and stop

Use the buttons (Figure 9, items 3 and 12) to start and stop the pump. Note that the stop command does not isolate

the pump from the electrical supply.

4.2.2 Standby

Operation at reduced speed will further improve tip seal and bearing service life. Vacuum performance will be

reduced when operating at standby speed.

Press the Standby button to select standby mode. The pump will initially run at factory default standby speed (70%

of full speed). The speed can be adjusted using the increase and decrease standby speed buttons. The maximum

standby speed is 100% of the default run speed and the minimum standby speed is 67% of the default run speed. A

single short push will change the speed by 1% of the default run speed, holding the button will change the speed by

1%/sec. Once adjusted, the pump will return to this new user-defined speed each time standby speed is selected.

The Standby button must be pressed to return to normal run speed.

Page 22 © Edwards Limited 2018. All rights reserved.

Page 31

4.3 Parallel control and monitoring

CAUTION

1. Start switch

2. Standby switch (optional)

3. nXDS pump logic interface

Figure 10 - Logic interface connections - parallel control

A735-01-880 Issue F

Operation

If using the normal and fail lines to drive the coils of d.c. relays, include a back EMF suppression diode in parallel

with each relay coil to protect the pump.

Connect the control equipment to the control input pins of the logic interface mating half. Refer to Table 11 to

identify the logic interface connector pins. The control inputs are as follows:

Start

Standby speed

Analogue speed

To activate any of these control inputs, connect the relevant control input (pin 14) to the 0 V control reference.

To monitor the normal status output, connect the control equipment to the Normal status output (pin 15) and to pin

2 of the logic interface mating half. The output can be used to control other devices in the pumping system. The

output can drive a low power relay of up to 24 V coil rating (up to 10 mA).

To monitor the fail status output, connect the control equipment to the fail output (pin 7) and to pin 2 of the logic

interface mating half. The output can be used to control other devices in the pumping system. The output can drive

a low power relay of up to 24 V coil rating (up to 10 mA).

© Edwards Limited 2018. All rights reserved. Page 23

Page 32

A735-01-880 Issue F

1. Start switch

2. Analogue control switch

3. nXDS pump logic interface

Operation

4.4 Analogue speed control

The Analogue Speed input is a process control source which enables the nXDS Scroll pump to run at variable operating

speeds. This speed control source is an alternative to standby speed control.

Figure 11 - Logic interface connections - analogue speed control

Note: 0.1 V

Page 24 © Edwards Limited 2018. All rights reserved.

1% of Default Run Speed

Page 33

Figure 12 - Analogue speed control

A735-01-880 Issue F

Operation

Note: Voltages below 6.7 V will result in a clamped speed of 67% of full speed.

4.4.1 Hardware configuration

Using the 15-way D-type connector (Figure 1, item 7) apply the following signal configurations to enable the Analogue

Speed Control source (refer to Table 12):

Connect the Analogue Speed Enable control input (pin 1) to the 0 V Control Reference (pin 2).

Connect a suitably calibrated analogue voltage source (0 to +10 V), for example, (DAC) to the analogue speed control

input (pin 9). Alternatively connect the output of a potentiometer referenced to the pump reference voltage (pin 11)

to the analogue speed control input (pin 9). Refer to Figure 11. The 0 V rail of the external voltage source must be

connected to the 0 V Control Reference (pin 2) of the pump controller.

4.4.2 Operation

A +10 V input equates to a mechanical running speed which is equal to: 100% of the default run speed, that

is, 30 Hz.

The minimum running speed provided by the Analogue Speed control source, is clamped at the minimum

Standby Speed Setting, that is, approximately 67% of the default run speed of 20 Hz.

The maximum running speed provided by the Analogue Speed control source is clamped by the maximum

Standby Speed Setting, that is, 100% of the default run speed of 30 Hz.

© Edwards Limited 2018. All rights reserved. Page 25

Page 34

A735-01-880 Issue F

Operation

4.5 Auto-run

The auto-run setting configures the pump to start at power-up without any customer intervention. This parameter is

customer configurable via serial communications, or using the START / STOP buttons. Holding down either the START

or STOP button, for more than eight seconds, will enable or disable the auto-run setting. The status of the auto-run

setting is visible via the auto-run LED.

The pump can be stopped using either manual, parallel or serial control modes whilst in auto-run.

4.6 Use of gas ballast control

The gas ballast control can be used to optimise the performance of the scroll pump for the application. The

performance characteristics of the pump with gas ballast on are shown in Section 2.2.3. The position of the gas

ballast control can be changed when the pump is either off or operating.

4.6.1 Gas ballast control

Use the gas ballast control to introduce air into the final stage of the pump. Use of gas ballast will reduce the

condensation of vapours in the pump; the condensates would contaminate the pump.

There are only two positions, 0 and 1. The gas ballast control knob will rotate 360° in either direction at 90° intervals.

Gas ballast OFF (position 0). Use this setting to:

achieve ultimate vacuum

pump dry gases.

Gas ballast ON (position 1). Use this setting to:

pump low concentrations of condensable vapours

decontaminate the pump.

4.7 Start up procedure

Use the procedure below to start up the pump:

1. Ensure that any vacuum system isolation valve is closed (if fitted).

2. With the mains supply to the pump isolated, connect a recommended lead to the electrical socket on the pump

(refer to Figure 1).

3. Apply power.

4. Start the pump system using the appropriate control source, that is, using the Start button in manual control

mode (refer to Figure 9); the Start/Stop control input (refer to Tab le 1 2 , pin 3) in parallel control mode or a

Start command in serial control mode.

5. Open the vacuum system isolation valve, if fitted.

Page 26 © Edwards Limited 2018. All rights reserved.

Page 35

A735-01-880 Issue F

4.8 To achieve ultimate vacuum

In order to achieve the best possible vacuum, the pump should be operated with the gas ballast control turned off.

However, if the pump, or elements of the vacuum system it is attached to, are new or have been newly fitted, some

atmospheric moisture may be present. If atmospheric moisture is present, run the pump with gas ballast on for

20 minutes before turning gas ballast off. If moisture is allowed to remain, the performance of the pump will be

impaired.

4.9 To pump condensable vapours

Select gas ballast ON when there is a high proportion of condensable vapours in the process gases. This will assist the

vapours to pass through the pump without condensing and keep the pump performance from degrading.

4.10 Shut down

Use the procedure below to shut down the pump:

1. If shutting the pump down prior to a period of storage, remove any process gases by running on a gas ballast for

at least one hour.

2. Close any vacuum system isolation valves to prevent suck-back into the vacuum system (where fitted).

Operation

3. Stop the pump system using the appropriate control source, that is, using the Stop button in manual control

mode (refer to Figure 9); the Start/Stop control input (refer to Ta b le 1 2, pin 3) in parallel control mode or a Stop

command in serial control mode.

4. Vent the nXDS pump system using the gas ballast control or the valve on the inlet.

5. Isolate the Mains supply.

© Edwards Limited 2018. All rights reserved. Page 27

Page 36

A735-01-880 Issue F

This page has been intentionally left blank.

Page 28 © Edwards Limited 2018. All rights reserved.

Page 37

5Maintenance

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

5.1 Safety information

Obey the safety instructions in this section and take note of appropriate precautions. Failure to

observe these instructions may result in injury to people and damage to equipment.

In order to maintain the ATEX certification, all maintenance work has to be carried

out in accordance with this nXDS instruction manual, the nXDS Replacement Tip Seal

manual and the nXDS maintenance manual, using only genuine Edwards spare parts.

Disconnect the pump and other components from the electrical supply to prevent accidental

operation.

A735-01-880 Issue F

Maintenance

The pump may be contaminated with the process chemicals that have been pumped during

operation. If so, ensure that the pump is decontaminated before maintenance and adequate

precautions taken to protect people from the effects of dangerous substances if contamination has

occurred.

Do not touch or inhale the thermal breakdown products of fluorinated materials which may be

present in the pump if the pump has been heated to 260 °C and above. Fluorinated materials are

safe in normal use but can decompose into very dangerous substances (which may include

hydrofluoric acid) if heated to 260 °C and above. The pump may have overheated if it was misused

or if it was in a fire. Safety Data Sheets for fluorinated materials used in the pump are available on

request; contact the supplier or Edwards.

External surfaces of the pump should be cleaned using a damp cloth. Care must be taken with solvent-based

cleaning fluids as they may remove important information from the product labels.

The pump is designed to require little user maintenance. Observe the following guidelines when carrying out

maintenance on the pump:

Ensure the maintenance is done by a suitably trained and supervised technician. Obey local and national

safety requirements.

Ensure the maintenance technician is familiar with the safety procedures which relate to the products

processed by the pumping system.

Check that all the required parts are available and are of the correct type before starting work.

Isolate the pump and other components from the electrical supply to prevent accidental operation.

Allow the pump to cool for at least 3 hours before starting maintenance work.

© Edwards Limited 2018. All rights reserved. Page 29

Page 38

A735-01-880 Issue F

Maintenance

5.2 Maintenance plan

More frequent maintenance may be required if the pump is used to pump aggressive gases or vapours, such as

solvents, organic substances and acids, or if the pump is operated continuously at the higher end of its operating

temperature.

Table 14 - Maintenance plan

Operation

Inspect and clean the inlet strainer 12 No 5.3

Inspect and clean the external fan cover if required 12 No 5.4

Check the pump performance 30 Yes 5.5

Replace the pump bearings 60 Yes 5.6

Replace the pump controller 120 Yes 5.6

Electrical safety check 60 No 5.8

For service indicator codes, refer to Section 5.10.

Frequency

(months)

Service

indicator

Section

reference

5.3 Inspect and clean the inlet strainer

Whenever the pump is disconnected from the vacuum system, or on an annual basis, Edwards recommends:

Removing the inlet strainer from the pump inlet (refer to Figure 1) and remove any debris that may have

accumulated.

Inspecting the inlet strainer and if necessary, clean it with a cleaning solution suitable for the substances

pumped. Refit the inlet strainer before reconnecting the pump to the vacuum system. Refer to Section 3.5.

5.4 Clean the external fan cover

If the fan cover is not kept clean, the air flow over the pump can be restricted and the pump may overheat.

1. Switch off the pump and disconnect it from the electrical supply.

2. Use a dry cloth and a soft brush to remove dirt and deposits from the fan cover.

5.5 Check the pump performance (service indicator)

The service indicator, (flashing ON 1s / OFF 1s) is triggered as a reminder to check the performance of the pump.

The service indicator will flash to indicate that a tip-seal change may be required (based on typical tip-seal life). If

after checking, the pump is no longer achieving the required performance, Edwards recommends carrying out a tipseal replacement (refer to Section 5.10).

If however the pump performance is still within acceptable limits, or is performing satisfactorily, the tip-seal

replacement can be delayed.

If operating a preventative maintenance plan, depending upon the particular regime, a tip-seal change can be carried

out at this time irrespective of the pump performance.

To reset the service indicator, refer to Section 5.10.

Page 30 © Edwards Limited 2018. All rights reserved.

Page 39

A735-01-880 Issue F

5.6 Replace the tip-seals

This information is applicable to the nXDS replacement tip seal kit that must be fitted. Refer to Section 7.3.1 for

ordering information.

A tip-seal replacement should be carried out to maintain or restore the pumps performance. The frequency for

replacing the pump tip-seals is determine by the following factors:

The pump has reached a service interval. Refer to Sections 5.5 and 5.7.

The pump is no longer achieving the required performance.

If the pump is no longer achieving the required performance prior to a service interval being reached, Edwards

recommends first following the guide lines, refer to Section 5.11.2.

Note: There may be a running-in period after fitting your new tip-seals. The performance should improve over a

period of 24 to 48 hours. If the pump performance does not improve sufficiently after the running-in period,

please contact Edwards for advice.

For information on how to replace the nXDS tip-seals and Health and Safety, refer to the nXDS replacement tip seal

kit instruction manual A735-02-840 which is included on the CD manual. Also refer to Youtube video at

https://www.youtube.com/watch?v=vKnh9dxOyhE.

Maintenance

5.7 Replace the pump bearings (service indicator)

The service indicator, (flashing ON 3s / OFF 1s) is triggered to indicate that a bearing replacement service interval

has been reached. Bearing wear cannot necessarily be detected under normal operating conditions. This service

interval is a recommendation that a bearing replacement is required, this is especially useful if operating a

preventative maintenance plan.

It is possible for an experienced technician, who is suitably trained, to perform maintenance and repair on nXDS

pumps up to and including bearing replacement. Edwards has developed a detailed maintenance manual and

instructional video (Edwards part number A73501713) that will enable an experienced technician to undertake this

work. If required Edwards can also provide face to face training. Please contact Edwards for more information or to

purchase this training.

Note: Failure to replace the pump bearings at this time may subsequently lead to damage of the pumping

mechanism.

Note: A tip-seal change and exhaust and ballast valve change should be carried out at the same time when

performing a bearing replacement. Refer to Section 7.3 for ordering information.

To reset the service indicator, refer to Section 5.10.

5.8 Replace the pump controller (service indicator)

The service indicator, (flashing ON 3s / OFF 3s) is triggered to indicate that the pump controller should be replaced.

Contact Edwards for further details.

To reset the service indicator, refer to Section 5.10.

5.9 Electrical safety check

Test the earth continuity and the insulation resistance of the pump system in accordance with local regulations for

the periodic testing of electrical equipment.

The earth continuity should be less than 0.1 and the DC insulation resistance greater than 1.0 M.

If the pump fails any of these tests, the supplier or Edwards must be contacted.

© Edwards Limited 2018. All rights reserved. Page 31

Page 40

A735-01-880 Issue F

Maintenance

5.10 Service indicator codes

The nXDS controller incorporates a service indicator (refer to Figure 7). The service indicator will flash a specific

code whenever a service interval has been reached. There are three service levels listed in Table 15.

Table 15 - Flashing service codes

Service flash code Comments See section

ON 1s / OFF 1s Pump performance check. 5.5

ON 3s / OFF 1s Pump bearing service. 5.6

ON 3s / OFF 3s Pump-Controller service. 5.7

To reset the service indicator, press and hold the standby speed increase and decrease buttons simultaneously for

more than 5 seconds.

Note: Resetting the pump bearing service indicator will also reset the performance check timer, that is, both

counters will be set to zero.