Page 1

Instruction Manual

FL20K Foreline Trap

Description Item Number

FL20K A133-05-000

A133-99-880

Issue E Original

Page 2

This page has been intentionally left blank.

Page 3

A133-99-880 Issue E

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 General Description ..................................................................................................... 1

2 Technical Data ....................................................................................3

2.1 Operating conditions .................................................................................................... 3

2.2 Performance .............................................................................................................. 3

2.3 Mechanical data .......................................................................................................... 3

3 Installation ............................................... ................................... .......4

3.1 Unpack and inspect ...................................................................................................... 4

3.2 Install the FL20K ......................................................................................................... 4

3.3 Fill the FL20K with sorbent ............................................................................................. 4

4 Operation .......................................................................................... 6

Contents

5 Maintenance ....................................................................................... 7

5.1 Replace the sorbent charge ............................................................................................7

6 Storage and disposal ....................................................... ......................8

6.1 Storage .................................................................................................................... 8

6.2 Disposal ....................................................................................................................8

7 Spare and accessories ............................................................................9

7.1 Introduction .............................................................................................................. 9

7.2 Spares ......................................................................................................................9

7.3 Accessories ................................................................................................................ 9

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Component parts of the FL20K ........................................................................................ 2

2 Dimensions (mm) ........................................................................................................ 3

3 Component parts of the basket assembly ............................................................................ 5

cg/7590/02/13

© Edwards Limited 2013. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 4

A133-99-880 Issue E

Contents

Tables

Table Page

1 Checklist of items ........................................................................................................ 4

Associated publications

Publication title Publication number

Vacuum pump and vacuum system safety P400-40-100

Page ii © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 5

A133-99-880 Issue E

CAUTION

WARNING

1Introduction

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Ed wards FL20K Foreline Trap. Yo u

must use the FL20K as specified in this manual.

Read this manual before you install and operate the FL20K. Important safety information is highlighted as WARNING

and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is defined below.

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process

Introduction

The units used throughout this manual conform to the SI international system of units of measurement.

1.2 General Description

The FL20K has been developed for use in clean pumping systems to prevent the back-migration of rotary pump oil

vapour into the systems; we particularly recommend that you use an FL20K with two-stage rotary pumps.

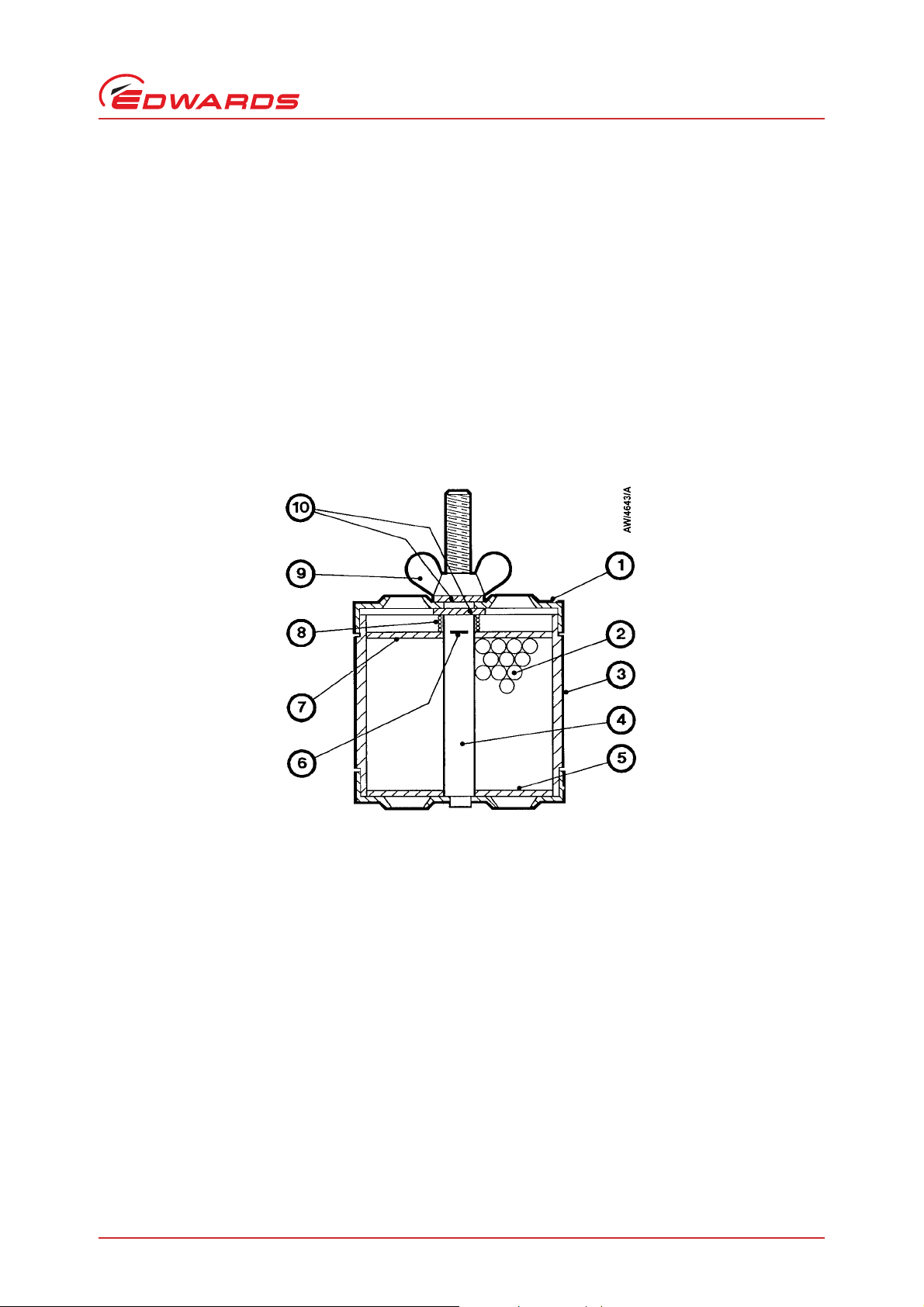

The component parts of the FL20K are illustrated in Figure 1. The FL20K consists of a metal basket (4) located within

a cast aluminium body (3), the metal basket is secured in place by a knurled nut (1), lid (6) and spring (5).

A sorbent is contained in the metal basket to absorb any oil which back-migrates from the pump. The sorbent

material used is activated alumina which has exceptional trapping properties for oil vapour. It has a long life (up to

six months) before it becomes saturated and has to be renewed.

© Edwards Limited 2013. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

A133-99-880 Issue E

1. Nut

2. Wing nut

3. Body

4. Basket

5. Compression spring

6. Lid

7. O-ring

A. Clearance required for removal of basket (4)

Introduction

Figure 1 - Component parts of the FL20K

Page 2 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

2Technical Data

2.1 Operating conditions

Ambient operating temperature range 0 to 50 °C

2.2 Performance

A133-99-880 Issue E

Technical Data

Leak tightness (1 bar (1 x 10

Maximum internal pressure 1 bar absolute, 1 x 105 Pa

5

Pa) differential) 1 x 10-6 mbar ls-1, 1 x 10-4 Pa ls

2.3 Mechanical data

Dimensions See Figure 2

Mass 1 kg

Sorbent charge 0.07 kg

Figure 2 - Dimensions (mm)

-1

© Edwards Limited 2013. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

A133-99-880 Issue E

CAUTION

WARNING

Installation

3 Installation

3.1 Unpack and inspect

Remove all packing materials and check th e FL20K. If the FL20K is damaged, notify your supplier and carrier in writing

within three days; state the item number of the FL20K together with your orde r num ber a nd your su pplier’s inv oice

number. Retain all packaging materials for inspection. Do not use the FL20K if it is damaged.

Check that your package contains the items shown in Table 1. If any one of these items is missing, notify your supplier

in writing within three days.

Table 1 - Checklist of items

Qty Description Check ()

1FL20K Valve

1 Tin of activated alumina

If the FL20K is not to be used immediately, return it to it’s protective packaging.

3.2 Install the FL20K

We recommend that you mount the FL20K horizontally, as shown in Figure 1. If necessary, however, you can mount

the FL20K in any orientation, as the sorbent is securely retained in the basket. The mass of the FL20K will be

adequately supported by the pipeline connections and you can connect either port to the rotary vacuum pump.

However, we recommend that you mount the FL20K as close to the vacuum system and as far from th e rotary pump

as possible, to maximise the useful life of the sorbent. When you mount the FL20K, ensure that you leave adequate

clearance to enable the sorbent basket to be removed.

Use the standard KF coupling components (that is, NW clamping rings, centring rings and O-rings) to connect the

FL20K to the pump and the vacuum syst em.

3.3 Fill the FL20K with sorbent

Activated alumina is a desiccant and will absorb materials from your process system. You must ta ke

suitable precautions to protect people from the harmful effects of any noxious materials released

if you bake the spent alumina to reactivate it. Avoid inhalation of its dust, eye contact and

unnecessary skin contact.

Do not overfill the basket with sorbent, If you do, crushed sorbent could be sucked into the rotary pump and

damage the pump.

1. Refer to Figure 1; unscrew and remove the nut (1) and the lid (6).

2. Remove the basket (4) and spring (5) from the trap body (3).

3. Refer to Figure 3. Remove the wing nut (9) and end cap (1) from the basket (3). Remove the washer (10),

compression spring (8) and perforated disk(7).

4. Fill the basket with sorbant; when full, the end disk (7) should align with the marker (6) on the spindle:

Page 4 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

A133-99-880 Issue E

1. End cap

2. Activated alumina

3. Basket

4. Spindle

5. End disk

6. Alignment marker

7. End disk

8. Compression spring

9. Wing nut

10.Washer (M6)

Fill the basket with alumina balls so that the top of the sorbent charge is approximately level wi th the

marker (6).

Tap the basket gently to settle the sorbent, then add more alumina balls if necessary.

5. Place the perforated end disk (7) on top of the alumina balls and slide the spring (8) over the spindle (4) so that

it rests on the end disk (7). Ensure that both end disk s (5 and 7) have their smooth s ide i n contact wi th the balls .

6. Refit the washer (10) and end cap (1) over the spindle.

7. Refit the second washer (10) and wing nut (9) over the spindle (4) and tighten the wing nut (9). To ease

tightening of the wing nut, push the lid down gently

8. Position the charged basket in the trap, ensuring that it is fully located on the bottom O-ring seal.

9. Refer to Figure 1 and replace the spring (5), lid (6) and nut (1).

Figure 3 - Component parts of the basket assembly

Installation

© Edwards Limited 2013. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

A133-99-880 Issue E

WARNING

Operation

4 Operation

Activated alumina is a desiccant and will absorb materials from your process system. You must ta ke

suitable precautions to protect people from the harmful effects of any noxious materials released

if you bake the spent alumina to reactivate it. Avoid inhalation of its dust, eye contact and

unnecessary skin contact.

Take note of the following information:

In common with other types of sorbent, activated alumina absorbs moisture. This will not affect its oil

vapour trapping properties but may tend to prolong rough pumping on successive pumping cycles. Regular

regeneration by baking the trap or renewal of the sorbent will be necessary for rapid pump-down.

If the FL20K has been open to atmosphere for a long period of time, it may be necessary to carry out

prolonged pumping with a gas-ballasted rotary pump to remove the absorbed moisture. Alternatively,

remove the basket from the FL20K and bake it at 250°C to 300°C for two hours.

Use a valved by-pass line to minimise vapour absorption during pump-down.

Page 6 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

A133-99-880 Issue E

WARNING

5Maintenance

5.1 Replace the sorbent charge

Activated alumina is a desiccant and will absorb materials from your process system. You must ta ke

suitable precautions to protect people from the harmful effects of any noxious materials released

if you bake the spent alumina to reactivate it. Avoid inhalation of its dust, eye contact and

unnecessary skin contact.

During normal use, the sorbent material nearest to the port connected to the rotary pump will become brown in

colour. When the discolouration reaches the sorbent layer furthest from the port, you must change the sorbent

charge. The time taken for this to occur depends on the frequency of use and the location of the trap in relation to

the rotary pump. A typical charge life is six months, although Edwards recommends that you change the charge every

three months as a routine maintenance procedure.

1. Refer to Figure 1. Unscrew and remove the nut (1) and the lid (6).

2. Remove the basket (4) and spring (5) from the trap body (3).

Maintenance

3. Refer to Figure 3. Remove the wing nut (9) and end cap (1) from the basket (3). Remove the washer (10),

compression spring (8) and perforated end disk (7).

4. If the trap body interior appears oily or dirty, wash it out with isopropyl or et hyl alcohol and then dry it

thoroughly.

5. Fill the basket (3) with sorbent: refer to steps 4 to 9 of Section 3.3.

© Edwards Limited 2013. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

A133-99-880 Issue E

Storage and disposal

6 Storage and disposal

6.1 Storage

1. Return the FL20K to its protective packaging.

2. Store the FL20K in clean dry conditions, away from direct sources of heat and sunlight.

6.2 Disposal

Dispose of the FL20K safely and in accordance with all local and national safety and environmental requirements.

Page 8 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

A133-99-880 Issue E

7 Spare and accessories

7.1 Introduction

Edwards products, spares and accessories are available from Edwards companies around th e wo rld . The majority of

these centres employ people who have undergone comprehensive Edwards training courses.

Order spare parts and accessories from your nearest Edwards company o r di st ri buto r. When you order, pleas e state

for each part required:

Model and Item Number of your equipment

Serial Number (if any)

Item Number and description of part

7.2 Spares

Description Item Number

0.45 kg activated alumina H026-00-050

Spare and accessories

7.3 Accessories

Description Item Number

Stainless steel clamping ring - NW20/25 C105-14-401

Polymer clamp - NW20/25 C105-14-403

Centring ring and O-ring - NW25 (polymer with nitrile O-ring) C105-14-393

Centring ring and O-ring - NW25 (stainless steel with nitrile O-ring) C105-14-396

Centring ring and O-ring - NW25 (polymer with fluoroelastomer O-ring) C105-14-394

Centring ring and O-ring - NW25 (stainless steel with fluoroelastomer O-ring) C105-14-395

© Edwards Limited 2013. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

A133-99-880 Issue E

This page has been intentionally left blank.

Page 10 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Loading...

Loading...