Page 1

Instruction Manual

EXTPX Split Flow

B760-60-880

Issue A Original

Description Item Number

24 Volt EXT400/200PX Split flow compound Turbomolecular Vacuum Pump B760-61-991

24 Volt EXT400/200PX Split flow compound Turbomolecular Vacuum Pump B760-62-991

24 Volt EXT400/200/30iPX Split flow compound Interstage Turbomolecular Vacuum Pump B760-67-991

24 Volt EXT400/200/30iPX Split flow compound Cartridge Interstage Turbomolecular Vacuum Pump B760-53-991

Page 2

@o*,"Fttrt=.

Declaration

We, Edwards,

l"lanor

Royal,

Crawtey,

West Sussex RH10 9LW, UK

declare under our sote responsibility

DffPX Compound Turbomotecutar

Dfi40020030iPX cartridge interstage 8760-53-991'

Dfi400200PX

ECT400200PX

Dff40020030iPX short chamber + end

to which

normative

this dectardtion retates is in conformity with the fottowing standard(s) or other

document(s)

EN(|5O)12100-2: 2003 Safety of l,lachinery - B6ic Concepts, Generat Principtes for Design.

EN1012-2t 1997 Compr6sors and Vacuum

EN610'l0-1: 2001t Safety

EN6t326: 1997 Eectrical equipment for measurement, control and laboratory use

(immunity,

Cla5s B Emissions)

C22.2 No 61010.1-04F

UL6101O-1

'

pumps

The

manuat supplied

"

24V Pumps onty compty with the Canadian Standard Authority and UnderwriteB laboratory

when used with D(DC 24V famitv of controtlers.

'optiport'

'optiport'

(2'd

Edition;# safety requirements for etectricat equipment for medurement,

compty with EN61010-1 when instatled in accordance with the instruction

+

Technicat Principats,

laboratory use.

E IC requirements,

Safety requirements for

Controt and taboratory use, Part 1: General requirements

Controt ard taboratory use, Part 1!

with

the

that the

port

end

requirements for

pump.

of Conformity

product(s)

pump:

8760-61-991

8760-62-991

oott 8760-67-991

pumps,

etectricat equipment

electricat

Safety Requirements. Vacuum Pumps.

equipment ior measurement,

Generat

for meaiurement controt and

requirements

following the

2006t95tEC

2@4t't08tEc

98tX7tEC

provisions

of

Vottage Directive.

Low

ElectrorEgnetic

^,lachirErv Directive

e.ca----t^',

B, D, Brewster,

&)rge5s Hill

Technical hlanager

PrducE

product

This

has been manufactured

Compatibitity Directive

zL?t<^

9,)d,a\e59

Date and Place

quality

under a

system

O.l€

registered to |SO9W1

>',r

a

t

Lr.-

Z'cxlr

c

-

s

Page 3

l?nwa,FrD=

Declaration

We,

Edwards,

Manor Royat,

Crdwtey,

West Sussex RH10 9LW, UK

declare under our sote rGponsibitity that the madfne(s)

Description

EXT40020030iPX Cartridge inGrstage

to which this dectaration relates is intended to be incorporated into other equipment and not

function independentty. The machine(s) is in conformity with the fottowing standard(s)

normative

document(5)

(l5O)12100-2:

EN

EN1012-2: 1997 Compressors and Vacuum

EN61010-l: 2001.

EN61326: 1997

(immunity,

2003 Safety of Machinery - Basic Concepts, General Principtes for

Design. Technicat Principals.

PumDs.

Safety requirements for electrical equipment for measurement

control and laboratory use.

EtectricaI equipment for measurement, control and [abordtory use

EMC requi rements.

of Incorporation

Item number

8760-53-991

or other

pumps.

safety Requirements. Vacuum

Ctass B Emissions)

C22.2 No 61010.1-04 Safety requirements for electrical equipment for measurement,

Ut6101o-1

*

The

manual supptied with the

'

24V Pumps onty compty with the Canadian Standard Authority and

when used

(2"d

Edition)' safety requirements for etectricat equipment for measurement,

pumps

compty with EN61010-1 when instatled in accordance

with

Controt and laboratory

Controt and laboratory

pump.

24V famity of controtleB.

ExDc

use, Part 1: General requirements

use, Part

General requirements

1:

with tJle instruction

underwriteE Labontory

to

The machine(s) must not be

has been brought into

conformity with the fottowing

2006t95tEC

20ut108tEc

98t17 tEC

Brewster, Technlcat Manager

B. D.

Burgess Hitt Product5

This

product

has been monufoctured

put

Lo

Etectromagnetic

service untit the equipment into

into

,

Vottage Directive.

compatibitity Directive

Machinery Directive

under o

provisions

2-t++.'_

Go

quality

|y6tem

which

it is incorporated

<)

c-xG!=-,,- 2-c,-?

rz<<ZS9 At

Dak ahd Place

registered to lSOgNl

rL-

Page 4

This page has been intentionally left blank.

Page 5

B760-60-880 Issue A

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

2 Technical data ....................................................................................3

2.1 General .................................................................................................................... 3

2.2 Pumping media ........................................................................................................... 5

2.3 Vent gas specification and vent control data ....................................................................... 7

2.4 Purge gas specification and data ...................................................................................... 7

2.5 Materials exposed to gases pumped .................................................................................. 7

3 Installation .................................................... ................................... 13

3.1 Unpack and inspect .....................................................................................................13

3.2 Typical installation .....................................................................................................14

3.3 Connection to the vacuum system ...................................................................................16

3.3.1 Mechanical fixing .......................................................................................................16

3.3.2 Inlet screens .............................................................................................................16

3.3.3 Inlet connection and pump orientation .............................................................................17

3.3.4 Backing-port connection ...............................................................................................20

3.3.5 Booster port connection ...............................................................................................20

3.4 Vent options, vent-valve connection and control .................................................................20

3.5 Purge gas connection ...................................................................................................21

3.6 Electrical installation ..................................................................................................21

3.6.1 EXDC drive module .....................................................................................................22

3.6.2 TIC controller ............................................................................................................22

3.7 Cooling ...................................................................................................................22

3.7.1 Introduction .............................................................................................................22

3.7.2 Forced-air cooling ......................................................................................................22

3.7.3 Water-cooling ...........................................................................................................22

3.8 Magnetic fields ..........................................................................................................23

Contents

4 Operation ........................................................................................ 25

4.1 Start-up ..................................................................................................................25

4.2 Shut-down ................................................................................................................26

4.3 Safety interlocks and control system ................................................................................26

4.3.1 EXDC drive module .....................................................................................................26

4.3.2 TIC controller ............................................................................................................26

4.4 Bakeout ...................................................................................................................26

5 Maintenance ..................................................................................... 27

5.1 Introduction .............................................................................................................27

5.2 Bearing maintenance ...................................................................................................27

5.3 Rotor life .................................................................................................................27

5.4 Cleaning the pump ......................................................................................................27

5.5 Fault finding .............................................................................................................28

6 Storage and disposal ...... .... ..... ..... ..... ..... ..... ..... ................................... 31

6.1 Storage ...................................................................................................................31

6.2 Disposal ...................................................................................................................31

7 Service, spares and accessories .............................................................. 33

dcs/7784/01/08

© Edwards Limited 2007. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

B760-60-880 Issue A

Contents

7.1 Introduction .............................................................................................................33

7.2 Service ....................................................................................................................33

7.3 Spares kits ...............................................................................................................33

7.3.1 Inlet screens .............................................................................................................33

7.3.2 Inlet strainer .............................................................................................................33

7.3.3 Inlet-flange seal .........................................................................................................33

7.4 Accessories ...............................................................................................................34

7.4.1 Installation ...............................................................................................................34

7.4.2 EXDC drive module .....................................................................................................34

7.4.3 TIC controller ............................................................................................................34

7.4.4 TAV vent-valve and vent port adaptor ..............................................................................34

7.4.5 VRX vent-restrictor .....................................................................................................35

7.4.6 PRX purge-restrictor ....................................................................................................35

7.4.7 ACX air-cooler ...........................................................................................................35

7.4.8 WCX water-cooler ......................................................................................................35

Index ................................................................ .............................. 37

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Booster port performance with lines of constant backing pressure ............................................. 5

2 Dimensions of B76061991 EXT400/200PX split flow pump - large main and side ports (units in mm) ...... 8

3 Dimensions of B76062991 EXT400/200PX split flow pump -

large main and side ports plus end port (units in mm) ............................................................ 9

4 Dimensions of B76067991 EXT400/200/30iPX -

large side port and end port plus interstage port (units in mm) ................................................10

5 Dimensions of B76053991 EXT400/200/30iPX -

interstage cartridge pump with main, side ports plus interstage port (units in mm) ........................11

6 Schematic of a typical EXTPX split flow system ...................................................................15

7 Correct installation of inlet screen ..................................................................................17

8 Correct mounting attitude of the EXTPX split flow pump ........................................................19

9 Installation of optional accessories ..................................................................................36

Page ii © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

B760-60-880 Issue A

Tables

Table Page

1 General data .............................................................................................................. 3

2 Technical data ........................................................................................................... 3

3 Vent gas and vent control data ........................................................................................ 7

4 Purge gas specification ................................................................................................. 7

5 List of items supplied ..................................................................................................13

6 Vent-restrictor orifice diameter (with atmospheric pressure at the inlet of the vent-valve) ..............21

7 Water-cooling block supply requirements ..........................................................................23

8 Fault finding .............................................................................................................28

9 Spares kits ...............................................................................................................33

10 EXDC drive module .....................................................................................................34

11 TIC controller ............................................................................................................34

12 TAV vent-valve and vent port adaptor ..............................................................................34

13 VRX vent restrictor .....................................................................................................35

14 PRX purge restrictor ....................................................................................................35

15 ACX air-cooler ...........................................................................................................35

16 WCX water-cooler ......................................................................................................35

Contents

Associated publications

Publication title Publication number

EXDC Turbomolecular pump drive module D396-45-880

TIC (100 W and 200 W) manual D397-22-880

TIC range CD D397-00-879

EXT pump accessories manual B580-65-880

© Edwards Limited 2007. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

B760-60-880 Issue A

This page has been intentionally left blank.

Page iv © Edwards Limited 2007 . All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

B760-60-880 Issue A

CAUTION

WARNING

1Introduction

1.1 Scope and definitions

This manual provides installation, operation, maintenance and storage instructions for the range of Edwards

EXT400/200PX and EXT400/200/30iPX split f low com pound t urbomo lecular vacuum pu mps, he reaf ter re ferred to as

EXTPX split flow pumps. Please read and follow all instructions in this manual.

The EXTPX split flow pump is designed for use with an Edwards 24 V EXDC160 drive module unless using Argon (please

refer to Section 2.2) when an EXDC80 drive module may be recommended. Read this manual and the instruction

manual supplied with your EXDC before you attempt to install or operate the equipment. The EXDC drive module

manual contains details of electrical installation.

Important safety information in this manual is highlighted as WARNING and CAUTION instructions; please obey these

instructions. The use of WARNINGS and CAUTIONS is defined below.

Warnings are given where failure to observe the instruction could result in injury to or death of

people.

Introduction

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

In accordance with the recommendations of EN61010, the following warning symbols may appear on the p ump or its

accessories:

Warning - refer to accompanying documentation.

Warning - risk of electric shock.

Warning - hot surfaces.

The units used throughout this manual conform to the SI international system of units of measurement.

Also throughout this manual, wherever flow rates are specified, the abbreviation 'sccm' is used to mean standard

3

cm

min-1: this is a flow of 1 cm3 min-1 at an ambient temperature of 0 °C and a pressure of 1013 mbar

5

(1.013 x 10

Pa).

© Edwards Limited 2007. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

B760-60-880 Issue A

This page has been intentionally left blank.

Page 2 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

B760-60-880 Issue A

2Technical data

2.1 General

Table 1 - General data

General items Reference data

Performance Refer to Table 2

Dimensions Refer to Table 2 and Figure 2 to 5

Maximum inlet-flange temperature 70 °C

Maximum radial and axial magnetic field 3.5 mT

Installation category EN61010 part 1, Category 1

Pollution degree EN61010 part 1, Category 2

Table 2 - Technical data

Parameter EXTPX split flow pump Notes

Mass 12 kg or less Weight dependent on specific

variant.

Main inlet port Refer to Figure 2 to 5

Side inlet port Refer to Figure 2 to 5

Interstage port Refer to Figure 2 to 5

Booster port DN 25NW

Exhaust port DN 25NW

Vent port 1/8 inch BSPP

Purge port 1/8 inch BSPP

Peak end inlet pumping speed

-1 *

N

2

He 320 l s

H

2

Peak main inlet pumping sp eed

N

2

He 310 l s

H

2

Peak side inlet pumping speed

N

2

He 200 l s

H

2

Peak interstage inlet pumping speed

N

2

He 27 l s

H

2

320 l s

-1

-1

280 l s

-1 *

310 l s

-1

-1

270 l s

-1 *

200 l s

-1

-1

150 l s

-1 *

27 l s

-1

-1

27 l s

Technical data

© Edwards Limited 2007. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

B760-60-880 Issue A

Technical data

Table 2 - Technical data (continued)

Parameter EXTPX split flow pump Notes

Peak booster port pumping speed N

using XDS10 24 m3 h-1 (6.7 l s-1)

using RV12 26 m3 h-1 (7.2 l s-1)

Peak compression ratio from the

backing-port to the main inlet

, He and H

N

2

2

Peak compression ratio from the side

inlet to the main inlet

, He and H

N

2

2

Maximum booster port pressure- N

Maximum backing pressure- N

Recommended backing-pump Application dependent Please consult Edwards.

Maximum single continuous

inlet pressure

Main inlet 1.2 x 10

Side inlet 4.1 x 10

Interstage inlet (where fitted) 2.2 x 10 -1 mbar

Operating attitude Refer to Figure 8

Nominal rotational speed 60,000 rpm

Starting time to 90% speed

Using an EXDC 160

Cooling method Forced air/ water-cooling Refer to Section 3.7.

Ambient air temperature

(forced air-cooling)

Water-cooling supply temperature 10- 20°C

Noise level at 1 metre < 45 dBA

Recommended controller EXDC 160 W 24 V D396-46-000

Recommended controller (Argon) EXDC 80 24 V D396-45-000 also refer to

EXDC160 maximum VA output 250 VA

Quiescent power 25-40 W P ower at ultimate pressure with

*

All pumping speeds are peak valu es for a horizontal envelope pump without inlet screen. Inlet screens may

reduce performance by up to 15%. Actual pumpin g speed for different envelope variants will be dependent

on inlet geometry and flow distribution between ports.

2

N2 > 1 x 10

He 1 x 10

H2 2 x 10

N2 1 x 10

8

6

5

4

*

He 100

H2 35

2

4.5 mbar Air cooled at 25 °C ambient with

RV12 backing-pump (1400 sccm flow)

and with no flow through other inlet

ports, and no strainer fitted.

2

17 mbar Air cooled at 25 °C ambient, with no

flow through other inlet ports.

-2

mbar Air at 35 °C ambient- with RV12

-2

mbar

backing-pump.

285 seconds With zero gas load, and XDS10

backing-pump.

0- 35°C

Section 2.2.

-2

mbar backing pressure.

10

Page 4 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

B760-60-880 Issue A

WARNING

WARNING

WARNING

WARNING

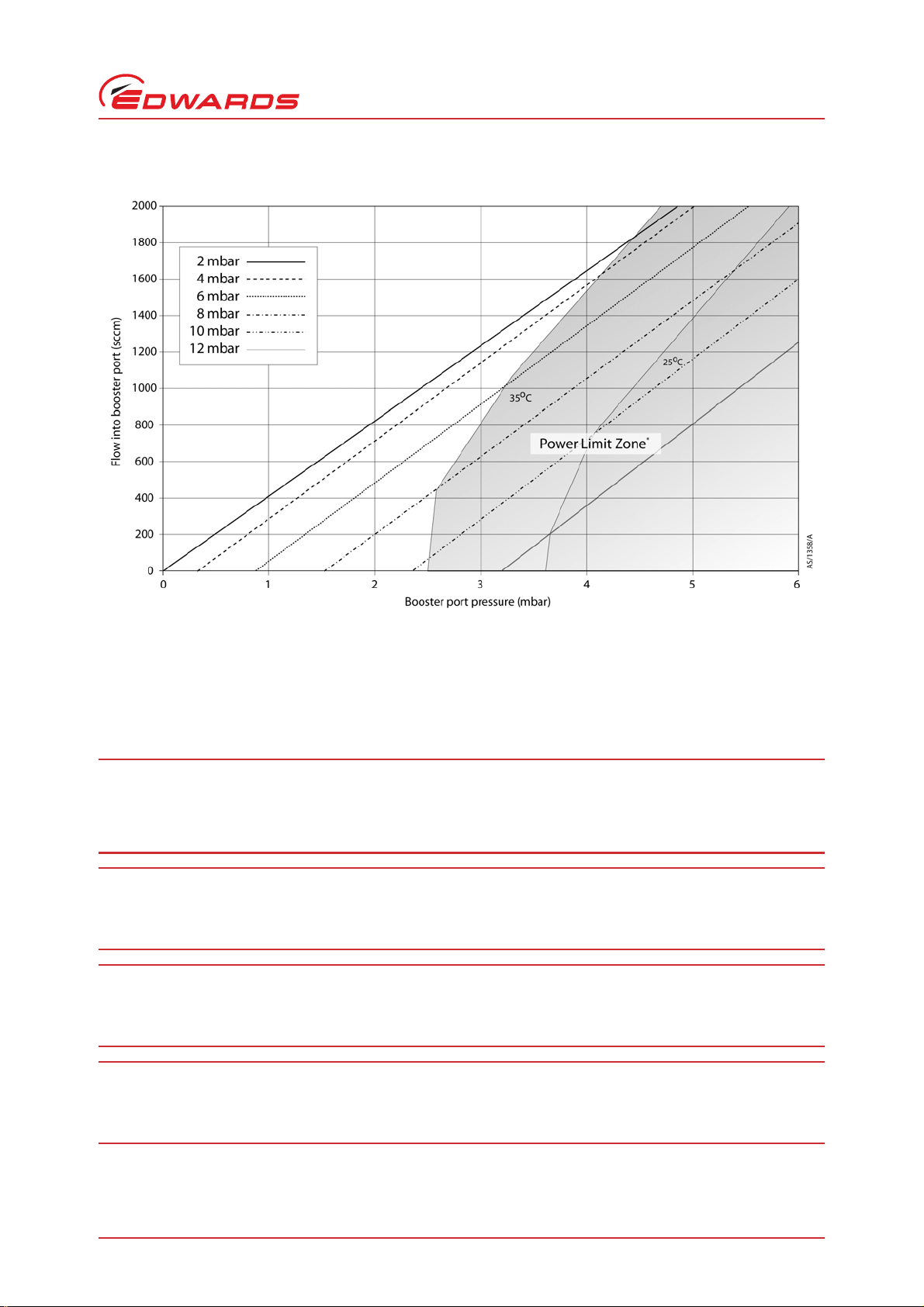

Figure 1 - Booster port performance with lines of constant backing pressure

Technical data

*

Power Limit Zone: The temperatures shown are pump local ambients. The tests were performed with a single

radial fan cooling the pump. If extra cooling is added, extra performance can be obtained. Exact limits will be

based on application requirements, cooling metho d and pump configuration; please consult Edwards to ensure

suitability. Also refer to Section 3.7 and 7.4 for cooling requirements and accessories.

2.2 Pumping med ia

If pumping hazardous gases or vapours, the customer must observe the safety recommendations

of the supplier of the gas or vapour. Vent hazardous gases and gas mixtures safely. Do not expose

people to these gases.

Do not pump explosive gas mixtures through the EXTPX split flow pump as the pump is not suitable

for this purpose.

If pyrophoric gases are pumped then the customer must supply adequate dilution with an inert gas.

It is the customers' responsibility to leak check their system to ensure that the process gases will

not escape to the atmosphere where this would cause a hazard.

© Edwards Limited 2007. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

B760-60-880 Issue A

CAUTION

CAUTION

CAUTION

WARNING

Technical data

Gases entering from different pump inlets may combine to cause dangerous mixtures.

An EXDC160 drive module is recommended for most applications. However, when pumpi ng high concentrations

of Argon (over 50% of gas mixture) an EXDC80 drive module is recommended to protect the pump against

overheating. If in any doubt, please contact your local Edwards Vacuum Representative.

Do not use the EXTPX split flow pump to pump particulates or condensable media. Deposition may occur within

the pump which will degrade pump performance and reduce the pump life.

Do not use the EXTPX split flow pump to pump gases containing more than 20% oxygen. If you do, the lubricant

will polymerise and the pump will fail prematurely.

Note: Concentrations of gases may be modified by the compression of the pump.

The pump is designed to pump the following residual gases normally used in high-vacuum systems:

z Air z Nitrogen z Carbon Dioxide

z Carbon Monoxide z Krypton z Helium

z Neon z Argon z Hydrogen

z Ethane z Propane z Butane

z Methane

You can use the pump to pump oxygen and water vapour, subject to the following conditions:

z Oxygen - The oxygen concentration must be less than 20% by volume; also refer to Section 2.4.

z Water vapour - You must ensure that vapour does not condense inside the pump.

If you wish to pump a gas not in the list above, co ntact your supplier for advice. If you do not contact your supplier,

you may invalidate the warranty on the pump. The pump is not suitable for pumping aggressive or corrosive gases.

Page 6 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

B760-60-880 Issue A

2.3 Vent gas specification and vent control data

Although the pump may be vented to atmosphere, high relative humidity of the air may greatly increase the

subsequent pump-down time. To reduce pump-down times you should vent the pump with dry, clean gases. Refer to

Table 3.

Table 3 - Vent gas and vent control data

Vent items Reference data

Vent gas Dry air, nitrogen, argon or other inert gases

Maximum dew point at atmospheric pressure -22°C

Maximum size of particulate 1

Maximum concentration of oil 0.1 parts per million

Time for rotational speed to reduce to 50% ≥15 seconds

Maximum purge gas pressure < 0.5 bar gauge (7 psig, 0.5 x 10

*

If you wish to use vent pressures in excess of this value, please consult Edwards.

µm

5

Pa gauge)

*

2.4 Purge gas specification and data

Technical data

When purged with an inert gas, the pumps can be used to pump oxygen in concentrations above 20% by volume.

Table 4 - Purge gas specification

Purge gas system items Reference data

Purge gas Dry nitrogen, argon or other inert gas

Maximum dew point at atmospheric pressure -22°C

Maximum size of particulate 1

Maximum concentration of oil 0.1 parts per million

Allowable purge gas flow (when required) 20- 150 sccm (0.33- 2.5 mbar l s

Recommended purge gas flow 25 sccm minimum (0.42 mbar l s-1, 42 pa l s-1)

Maximum allowable purge gas supply pressure 0.5 bar gauge (7 psig, 0.5 x 105 Pa)

*

If you wish to use pressures in excess of this value, plea se consult Edwards.

µm

-1

, 33- 250 Pa l s-1)

*

2.5 Materials exposed to gases pumped

The following materials and component types are exposed to the gases pumped: aluminium alloys, steels, stainless

steels, fluoroelastomer and nitrile O-rings, hydrocarbon lubricant, felt, rare earth magnets, silicon nitride, phenolic

resin, and carbon-fibre reinforced epoxy resin.

© Edwards Limited 2007. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

B760-60-880 Issue A

1. Fan-mounting holes

2. Base mounting holes (remove feet)

3. Purge port

4. Booster port

5. Backing-pump port

6. Earth screw

7. Electrical connector

8. Side port

9. Main port

10.Vent port

Technical data

Figure 2 - Dimensions of B76061991 EXT400/200PX split flow pump - large main and side ports (units in mm)

Page 8 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

B760-60-880 Issue A

1. Fan-mounting holes

2. Base mounting holes (remove feet)

3. Purge port

4. Booster port

5. Backing-pump port

6. Earth screw

7. Electrical connector

8. Side port

9. Main port

10.Vent port

11.End port

Figure 3 - Dimensions of B76062991 EXT400/200PX split flow pump - large main and side ports plus end port

(units in mm)

Technical data

© Edwards Limited 2007. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

B760-60-880 Issue A

1. Fan-mounting holes

2. Base mounting holes (remove feet)

3. Purge port

4. Booster port

5. Backing-pump port

6. Earth screw

7. Electrical connector

8. Interstage port

9. Side port

10.Vent port

11.End port

Technical data

Figure 4 - Dimensions of B76067991 EXT400/200/30iPX - large side port and end port plus interstage port

(units in mm)

Page 10 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 19

B760-60-880 Issue A

1. Jacking point (M6 thread)

2. Purge port

3. Booster port

4. Backing-pump port

5. Earth screw

6. Electrical connector

7. Base mounting holes

8. Flange-mounting holes

9. Fan-mounting holes

10.Main port

11.Interstage port

12.Side port

13.Vent port

Figure 5 - Dimensions of B76053991 EXT400/200/30iPX - interstage cartridge pump with main, side ports plus

interstage port (units in mm)

Technical data

© Edwards Limited 2007. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

B760-60-880 Issue A

This page has been intentionally left blank.

Page 12 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

B760-60-880 Issue A

WARNING

3 Installation

3.1 Unpack and inspect

The pump weighs up to 12 kg (26 lbs). Appropriate care should be taken when lifting and moving

the pump to avoid injury.

Take care when unpacking the pump to avoid excessive sh ocks which co uld damage the beari ngs and re duce th e life

of the pump. The pump is supplied with the inlets and outlet sealed to prevent entry of dust and vapour. Do not

remove these seals until you are ready to install the pump on your vacuum system.

Open the cardboard box from the top. Once the box lid is open, remove the upper piece(s) of foam and cut open the

bag.

If the pump is damaged, notify your supplier and the carrier in writing within three days; state the Item Number of

the pump together with your order number and your supplier's invoice number. Retain all packing materials for

inspection. Do not use the pump if it is damaged.

Check that your package contains the items listed in Table 5. If any of these items are missing, notify your supplier

in writing within three days.

Installation

If the pump is not to be used immediately, store in suitable conditions as described in Section 6.1.

It is advised to retain all packing materials for use, should you return the pump for service.

Table 5 - List of items supplied

Quantity per pump

Description

EXTPX split flow pump 1111

Main (large) inlet screens (supplied fitted)2210

Interstage (small) inlet screens (supplied

fitted)

ISO160 inlet screen (supplied fitted) 0001

Inlet protection strips (supplied fitted)0002

Booster port O-ring and inlet strainer

(fitted)

Inlet O-ring seals (supplied loose) 2333

Covers 1221

B760-

61-991

0010

1111

B760-

62-991

B760-

67-991

B760-

53-991

Check (9)

© Edwards Limited 2007. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

B760-60-880 Issue A

CAUTION

Installation

3.2 Typical installation

Local legislation concerning the impact of the pump on the environment must be followed when installing and

removing the pump.

A typical pumping system with an EXTPX split flow pump is shown in Figure 6.

Page 14 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 23

Figure 6 - Schematic of a typical EXTPX split flow system

1. Vacuum system

2. Alternative position for

vent-valve

3. High vacuum gauge

4. Inlet screens

5. EXTPX split flow pump

6. Interstage port

7. Booster port

8. Booster port valve

9. PRX10 purge restrictor

10.Regulated purge gas supply

11.EXDC drive module

12.vent-valve

13.Controller (for example TIC)

*

14.Cooling fan (s)

15.Flexible bellows

16.Backing valve

17.Vacuum gauge

18.Foreli ne tra p (for OSRVP)

†

19.Backing-pump

20.Mist filter (for OSRVP)

*

TIC = Turbo and Instrument

Controller

†

OSRVP = Oil Sealed Rotary Vane

Pump

B760-60-880 Issue A

Installation

The accessories available for the EXTPX split flow pump are detailed in Section 7.4 and are shown in Figure 9.

© Edwards Limited 2007. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 24

B760-60-880 Issue A

WARNING

WARNING

WARNING

WARNING

WARNING

Installation

3.3 Connection to the vacuum system

Install the pump in the vacuum system before you connect the controller to the power supply. This

will ensure that the pump cannot operate and injure people during installation.

Under no circumstances must any part of the human body be exposed to a vacuum.

Carefully remove the pump from the packaging media and connect to the vacuum system.

3.3.1 Mechanical fixing

Ensure the EXTPX split flow pump is either securely fixed to the vacuum system via its inlet-flange

using all available mounting points, or that it is securely restrained to a fixed point. If the pump

were to seize when not securely mounted or restrained, the stored energy of the rotor (approx

20 kJ) could cause rapid movement of the pump, which may cause further damage and injury to

personnel.

If you wish to base-mount your pump, you will need to remove the 3 feet that are supplied fitted to the base of the

pump before mounting with qty. 5 M8 bolts. Refer also to the warning in Section 3.3.3.

3.3.2 Inlet screens

Inlet screens are supplied fitted to the pump.

The impeller blades on an EXTPX split flow pump are very sharp. The absence or removal of inlet

screens or strainers exposes the risk of injury from sharp edges or moving parts. Care should be

taken when handling the pump not to dislodge or damage the protective inlet screens.

For B76062991 and B76067991 only: There is no inlet screen fitted to the end of the chamber

pump and the blades of the turbo-pump are visible and accessible through the pump envelope at

this point. These blades represent a rotational safety hazard when the pump is operational and a

sharp edged hazard when the pump is stationary. Retain plastic transport covers over inlets until

ready to install in order to minimize any risk of injury.

Care must be taken to avoid foreign objects entering the pump when installing equipment to the

chambers.

Do not remove the inlet screens unless you can be sure that there is no danger that debris can fall into the pump.

To remove an inlet screen, carefully extract it from the inlet-flange using a bent wire hook. Once removed, a screen

is not reusable. Spares are available (refer to Section 7).

Page 16 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 25

B760-60-880 Issue A

CAUTION

WARNING

WARNING

1. Inlet screen

2. Inlet-flange

In the unlikely event of a pump fracture, it is possible that the inlet screen may not trap all debris

within the pump. Ensure that the system can contain any debris that may escape from the pump.

Figure 7 - Correct installation of inlet screen

Installation

3.3.3 Inlet connection and pump orientation

It is important that the pump is correctly orientated. Incorrect orientation may lead to premature pump failure.

Do not store or orientate the pump such that the pump inlets face towards the ground, nor store the pump such

that the end of the envelope faces towards the ground (with the pump body - containing electrical connector facing directly upwards). In either of these orientations it could be possible for oil used to lubricate the lower

bearing to escape from a reservoir at the base of the pump into the pump mechanism or vacuum system. This

may reduce performance and bearing life.

For base-mounting, use qty. 5 x M8 bolts tightened to a minimum torque of 10 Nm (7.5 lb ft) to

attach to the mounting. Use ISO898-1 material property class 12.9 or greater.

3.3.3.1 Inlet connection and pump orientation (non-cartridge pumps)

It is recommended that the pump is f lange mounte d. However, if this is not the case, please obs erve the warning in

Section 3.3.1. The exhaust port must not be tilted at more than 60° from the vertical position, (refer to Figure 8)

otherwise oil may leak into the pumping mechanism; refer to the Caution above.

Make sure that the pump inlets and all components fitted to the pump-inlets are clean and dust-free. If the pump-

inlets are not kept clean, the pump-down time may be increased or HV chamber pressures may not be achieved.

Use the O-rings supplied with the pump and use four M8 bolts tightened to a torque of 20 Nm (15 lb ft) to connect

the inlet-flange of the pump to the vacuum system.

© Edwards Limited 2007. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 26

B760-60-880 Issue A

WARNING

Installation

3.3.3.2 Inlet connection and pump orientation (cartridge pumps)

Use 6 x M8 fixing screws of appropriate length to attach the pum p to the vacuum chamber. Ensure

the chamber is robust enough to restrain the pump in the highly unlikely event of a rotor burst

where a peak torque of approximately 13,000 Nm may be transmitted to the chamber for a very

short time. It is the responsibility of the user to ensure that the vacuum system is capable of

containing the rotor fragments in the event of a catastrophic failure. Contact Edwards for further

information if required.

O-rings included with the cartridge pump must be fitted to the grooves before installing the cartridge pump into its

system. To ensure a proper seal between the inlets these should be untwisted, undamaged, dry, clean and dust-free.

Please refer to Edwards for recommended housing sizes.

Page 18 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 27

Figure 8 - Correct mounting attitude of the EXTPX split flow pump

B760-60-880 Issue A

Installation

© Edwards Limited 2007. All rights reserved. Page 19

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 28

B760-60-880 Issue A

CAUTION

CAUTION

WARNING

WARNING

Installation

3.3.4 Backing-port connection

The customer must ensure safe ducting of the backing-line if oil mist or hazardous substances are

present.

The EXTPX split flow pump must not be operated, or vented from a positive pressure gas supply,

with a restricted / blocked backing-line.

Do not use the EXTPX split flow pump with a backing pressure below 5 x 10-4 mbar (5 x 10-2 Pa). Lower backing

pressures will increase the evaporation rate of the lubricating oil reducing the bearing life.

Use suitable vacuum tubing and connectors to connect the NW25 flange of the backing-port to your backing-pump.

If necessary, use flexible pipe or bellows to reduce the transmission of vibration from the backing-pump to the EXTPX

split flow pump.

The EXTPX split flow pump is suitable for use with Edwards Rotary Vane, Scroll or diaphragm backing-pumps. The

system performance may depend upon which pump is used, hence we recommend that you consult Edwards to help

select an appropriate backing-pump for your application.

3.3.5 Booster port connection

During operation the booster port must either be connected to the vacuum system or have a blanking flange attached.

Use suitable vacuum tubing and connectors to connect the NW25 flange of the booster port to your vacuum system

in the first instance. The strainer fitted is to prevent foreign object ingress. Refer also to the first Warning in

Section 3.3.2.

3.4 Vent options, vent-valve connection and control

To maintain the cleanliness of your vacuum system, we recommend that you vent the pump (or vacuum system)

whenever you switch the pump off.

If you manually vent the pump when it is at full rotational speed and the rate of pressure rise is too high, the

pump life may be reduced. When using the manual vent-valve supplied, we recommend that you either limit the

vent or only open the vent-valve after the EXTPX split flow pump speed has fallen to 50% of full rotational speed.

Do not vent from the backing-line, this may lead to contamination. If you vent into your vacuum system, and

use an oil-sealed rotary vane backing-pump, select a point upstream of the pump, to prevent oil back-streaming

from the backing-line.

Table 6 gives an indication of the appropriate orifice size to be fitted to the vent-valve for given vacuum system

volumes in order that the vent rate is kept within the limits given in Section 2.3.

Venting may be accomplished by one of the following means and by using the procedure below:

z Use a TAV5 or TAV6 solenoid vent-valve accessory (refer to Section 7) in the manual vent-valve position.

z Use a TAV5 or TAV6 solenoid vent-valve connected to a convenient flange on your vacuum system.

z Use an alternative valve, with an appropriate restriction, connected to your vacuum system. For further

details contact Edwards.

Page 20 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 29

B760-60-880 Issue A

WARNING

WARNING

WARNING

WARNING

1. Turn off the EXTPX split flow pump, but keep the backing-pump on.

2. When speed has fallen to 50%, open the vent-valve.

3. When the EXTPX split flow pump reaches standstill, the vent-valve may be closed.

Table 6 - Vent-restrictor orifice diameter (with atmospheric pressure at the inlet of the vent-valve)

Vacuum system volume (l) Orifice diameter (mm)

< 20 < 1.0

< 10 < 0.7

< 5 < 0.5

< 2 < 0.35

3.5 Purge gas connection

If you want to supply a purge gas to the pump, fit a vent port adaptor (refer to Section 7) in place of the blank plug

(refer to Figure 2 to 5). Connect your gas supply to the purge p ort . Your purge gas must comply with the limits/

specification given in Section 2.4. To limit the flow rate, use a fl ow controller or a pressure regulator and calibrated

flow restrictor. The PRX10 purge restrictor accessory ( refer to Section 7) is suitable for this purpose. Adjust the PRX10

as described in the instruction manual supplied with it.

Installation

3.6 Electrical installation

This product requires a separate power supply (not included). The power supply should be

adequately protected against a hazardous live condition (for example in case of a short circuit).

The customer must ensure that any electrical circuits are protected from dripping water caused

by condensation on cold surfaces.

It is the responsibility of the customer to ensure that the power supply used is correctly rated /

protected.

The customer must ensure appropriate routing of cables and pipe work to avoid slip/ trip hazards.

It is recommended that you fit a separate earth (ground) conductor to earth the EXTPX split flow pump and

accessories: use an uninsulated braid or a separate insulated green/yellow conductor, and use the M5 x 10 screw and

shake proof washer supplied (fitted in the earth hole on the pump) to secure the ea rth conductor to th e EXTPX split

flow pump and accessories.

For external protective earth systems: the installation should be permanent and use the same earth system as the

EXDC drive module; the impedance between the pump-body and earth connection point must be less than 0.1 Ohms.

Refer to the instruction manual supplied with the controller to complete the electrical installation.

© Edwards Limited 2007. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 30

B760-60-880 Issue A

CAUTION

CAUTION

CAUTION

WARNING

Installation

3.6.1 EXDC drive module

The customer must provide an emergency stop circuit to turn off power to the EXDC drive module.

Allow the pump to stop before removing the EXDC drive module.

An EXDC drive module requires connection to a suitably rated power supply. The EXDC drive module is designed to

allow a pumping system to operate in a fully automatic system.

3.6.2 TIC controller

The TIC controller can be used to provide the electrical supply to the EXDC (please refer to Section 7.4.3 for details).

The EXDC drive module connects to the back of the TIC via a 15 pin D-type connector.

The TIC controller is designed to allow a pumping system to be configured in a variety of ways, from a basic manuallyoperated system to a fully automatic system with remote control; refer to the TIC instruction manual.

3.7 Cooling

3.7.1 Introduction

The pump must be cooled either by forced-air or through a water-cooling accessory to prevent pump damage

and to maximize pump performance.

If you are using forced-air cooling to cool the pump you must ensure that there is an adequate supply of cooling-air

to the pump (refer to Section 3.7.2). During operation, if the tempera ture of any surface of the pump is hi gher than

60 °C, the cooling is inadequate and should be increased.

3.7.2 Forced-air cooling

Air-cooler accessories are available for the EXTPX split flow pu mp (refer to Section 7). Fit the air-cooler as described

in the instruction manual supplied with it (also refer to Figure 9). If you wish to use an alternative fa n for air-cooling,

ensure that the flow rate is above 80 m

module.

Pump performance may be affected if you do not cool the pump adequately.

3.7.3 Water-cooling

3h-1

(47 cfm) and is directed across the pump (base) and the EXDC drive

In the event of coolant failure, the pump must be allowed to cool down (to ambient temperature) before

restarting.

An accessory is available to enable the EXTPX split flow pump to be water cooled (refer to Section 7). Fit the

water-cooler as described in the instruction manual supplied with it. Ensure that the water supply is constant and

within the quality, temperature and flow rate limits detailed in Table 7.

Page 22 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 31

B760-60-880 Issue A

WARNING

Table 7 - Water-cooling block supply requirements

Parameter Specification

Quality Mechanically and optically clean with no deposits or

turbidity

pH Value 6.0 to 8.0

Maximum calcium carbonate concentration 75 parts per million

Maximum chloride concentration 100 parts per million

Minimum oxygen concentration 4 parts per million

Minimum water-cooling flo w rate (at 15 °C) 15 l h

Water temperature 10 to 20 °C

Maximum water pressure 5 bar (gauge), 72.5 psig, 5 x 105 Pa (gauge)

Materials exposed to cooling-water Nickel plated brass

-1

3.8 Magnetic fields

Installation

If you wish to use the pump in or near magnetic fields please consult Edwards.

© Edwards Limited 2007. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 32

B760-60-880 Issue A

This page has been intentionally left blank.

Page 24 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 33

4 Operation

WARNING

WARNING

WARNING

WARNING

WARNING

Do not operate the EXTPX split flow pump unless it is connected to your vacuum system. If you do,

the pump-rotor can cause injury. The pump-rotor rotates at very high speeds and the rotating

blades might not be visible.

Do not move the pump whilst it is running. The gyroscopic forces generated by this movement can

cause excessive use of the back-up bearing and may result in catastrophic failure of the pump.

When power is restored following a power cut, the pump may restart automatically depending

upon the electrical configuration. The pump must remain connected to the vacuum system to

prevent risk of injury.

B760-60-880 Issue A

Operation

After power to the pump has been switched off, either through emergency or as a requirement,

the rotor will continue to spin at very high speeds. The rotor possesses considerable mechanical

energy until it slows down/ stops.

Do not remove the EXDC cable from the pump until the pump is completely at rest. If the pump is

still rotating when the cable is removed, the pump operator could be exposed to hazardous voltage

and potentially damage the EXDC drive module.

4.1 Start-up

Use the procedure below to start up a basic, manually-controlled pumping system with a manual vent-valve and an

EXDC drive module. Refer to the EXDC instruction manual.

1. Ensure any vent-valves are closed (including the manual vent-valve on the pump body).

2. Switch on the power to the air-cooler.

3. Start the backing-pump.

4. When the vacuum system pressure is approximately 10 mbar or less, start the E XTP X spli t f low pump . Fo r fas te r

ramp-up times, this pressure should be well below this figure.

5. The pump will then accelerate to full operating speed. The normal-speed LED on the EXDC drive module will

illuminate once nominal operating speed is reached.

Note: Refer to the controller manual if using the TIC controller.

© Edwards Limited 2007. All rights reserved. Page 25

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 34

B760-60-880 Issue A

CAUTION

Operation

4.2 Shut-down

Note: In an emergency only, open the vent-valve quickly to decelerate the pump-rotor in the shortest possible

time.

Use the procedure below to shut down a basic, manually-controlled pumping system with a manual vent-valve and a

TIC controller.

1. Close the valve in the backing-line connecting the EXTPX split flow pump to the backing-pump.

2. Switch off/ deactivate the start command to the EXTPX split flow pump.

3. When the EXTPX split flow pump rotational speed has fallen to below 50% of full rotational speed, turn the

manual vent-valve anti-clockwise slowly to open it. Refer to Section 3.4 for the venting procedure.

4.3 Safety interlocks and control system

The pump protection and safety interlock features are listed below. Refer to the instruction manual supplied with

the controller for a full description of these features.

4.3.1 EXDC drive module

The EXDC drive module monitors the temperature of the EXTPX split flow pump and the electrical power con sumption

of the pump. If the EXDC drive module detects excessive power consumption or temperature, the rotational speed

of the pump motor is reduced until the power and temperature return to normal.

4.3.2 TIC controller

The TIC controller monitors the pump rotational speed. If the EXDC drive module detects excessive power

consumption or temperature of the EXTPX split flow pump, it will reduce the operational speed of the unit. If this

speed is reduced to below 50% for a user-defined period of time, the TIC controller will automatically disconnect the

power supply. An error diagnostic message will then be displayed on the TIC controller. If the error message

‘Droop timeout’ is displayed on the TIC controller, switch off the backing-pump immediately and vent the EXTPX split

flow pump. Once the pump has stopped, rectify the cause of the failure and restart the pump. If the pump is hot,

allow sufficient time for it to cool before restarting.

4.4 Bakeout

Bakeout of envelopes would lead to damage of this product - do not bake.

Page 26 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 35

B760-60-880 Issue A

CAUTION

WARNING

WARNING

WARNING

WARNING

5Maintenance

The EXTPX split flow pump is not to be serviced by the customer. Pumps requiring servicing should

be returned to Edwards or serviced by a qualified Edwards engineer.

Allow the pump-rotor to stop, then disconnect the controller before you remove the pump from

your vacuum system for maintenance or fault finding procedures.

5.1 Introduction

The maintenance operations for the EXTPX split flow pump are described in the following sections. The inlet screens

and inlet-flange seals are available as spares (refer to Section 7). Fit the inlet screens as shown in Figure 7.

5.2 Bearing maintenance

Maintenance

The bearings will need to be replaced at the recommended service interval. This is typically more than 20,000 hours,

but may be less; this depends on the type of pumping duty on which the pump is used.

When the bearings need replacement, we recommend that you exchange your pump for a factory reconditioned

replacement. Alternatively, you can send your own pump to an Edwards Service Centre to have the bearings replaced.

Lubricants can contain toxic substances from the pumping media. The oil felt cartridge must be

disposed of in accordance with relevant regulations.

When you return the EXTPX split flow pump to an Edwards Service Centre please use the procedure included at the

end of this manual. Please note that the instruction to drain all fluids does not apply to the lubricant in the EXTPX

split flow pump oil-reservoir.

5.3 Rotor life

The fatigue life of the EXTPX split flow rotor is typically 40,000 to 50,000 cycles of acceleration fr om rest to full

speed and then back to rest. As a precautionary measure, Edwards recommends that pumps are returned for a

major service (rotor replacement) after 20,000 cycles or ten years, whichever occurs first.

5.4 Cleaning the pump

Clean the external surfaces of the EXTPX split flow pump in a well-ventilated location. When you

use cleaning solutions and solvents to clean the pump, observe all precautions specified by the

manufacturer. Avoid inhalation of any particulates which may be present in the pump.

© Edwards Limited 2007. All rights reserved. Page 27

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 36

B760-60-880 Issue A

CAUTION

Maintenance

Do not attempt to clean any parts of the EXTPX split flow pump other than external surfaces. Organic solvents

may damage internal pump components. Do not use abrasive materials to clean any part of the pump.

If the inside of the EXTPX split flow pump is contaminated, it may not be possible to achieve the specified ultimate

vacuum performance, or pump-down times may increase. In these circumstances the pump must be returned to an

Edwards Service Centre, where the pump will be dismantled and cleaned. Use the procedure given in the forms at

the end of this manual to return the pump.

You can use any organic solvent to clean the external surfaces of the EXTPX s plit flow pump. Edwards recommends

the use of non-CFC solvents such as isopropanol or ethanol. Use a cleaning solution which is suitable for the

contaminants on the pump surfaces.

For environmental reasons, keep wastage of cleaning solutions and solvents to a minimum.

5.5 Fault finding

Refer to Table 8 for the possible causes of faults and for the recommended actions to rectify faults. Table 8 is

applicable to a basic, manually controlled pumping system with an EXDC drive module.

Table 8 - Fault finding

Symptom Check Action

The impeller does not rotate after

giving a start signal.

‘Droop timeout’ displayed on th e

TIC.

Are the three red phase LEDs on the

EXDC drive module lit?

Is the EXDC correctly connected to

the EXTPX split flow pump?

Is the start signal being given

across the correct pins of the

EXDC logic interface plug?

None of the above. If all the above checks are OK but

Refer to Section 4.3.2. Refer to Section 4.3.2.

If not, check that power is supplied

to the EXDC.

If power is supplied but one or more

of the LEDs are not lit, then the

EXDC drive module may be faulty;

change the EXDC and try to start the

pump.

If the problem persists then the

EXTPX split flow pump may be faulty.

Consult Edwards or your supplier.

If the red LEDs are all lit, check that

the EXDC is properly connected to

the pump.

Refer to Section 3.4 of the EXDC

instruction manual for electrical

connections.

the impeller still does not rotate,

the EXTPX split flow pump may be

faulty; consult Edwards or your

supplier.

Page 28 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 37

Table 8 - Fault finding (continued)

Symptom Check Action

System operating pressure cannot be

reached.

The EXTPX split flow pump is very

noisy or there is excessive vibration,

or there is both.

Are any of the vacuum gauges

contaminated?

Is the pumping speed insufficient

owing to poor conductance between

pump and chamber/gauge, or too

large a chamber?

Is the backing pressure too high?

(refer to Table 2).

Is the high vacuum area of the

system contaminated?

Is the EXTPX split flow pump and/or

the EXDC drive module too hot?

Check the system for leaks and

contamination.

Are the booster and backing-ports

connected the right way round?

Is the pumps' rotational speed the

same as the resonant frequency of

the attached system?

Is the vibration being transmitted

from the backing-pump?

Is the noise irregular and getting

progressively worse?

If so, clean and replace them.

If so, increase the conductance or

reduce the volume.

Check for backing-line leaks. If the

backing pressure is too high, you may

need a larger backing-pump.

If so, clean the system.

If so, the pump and/or EXDC may

have gone into thermal limit;

increase the cooling to the pump

and/ or EXDC.

Clean any contaminated areas and

repair leaks.

Reconnect the ports correctly

(marked on the side of the body).

If so, change the resonant frequency

of the system.

If so, fit flexible bellows or a

vibration isolator in the backing-line.

If so, the bearing may be defective.

Consult Edwards or your supplier.

B760-60-880 Issue A

Maintenance

Is the EXTPX split flow pump making

a constant high-pitched noise?

None of the above. Consult Edwards or your supplier.

If so, the rotor may be out of

balance. Consult Edwards or your

supplier.

© Edwards Limited 2007. All rights reserved. Page 29

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 38

B760-60-880 Issue A

This page has been intentionally left blank.

Page 30 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 39

B760-60-880 Issue A

WARNING

6 Storage and disposal

6.1 Storage

Use the following procedure to store the pump.

1. Place protective covers over all ports, the main inlet, side inlet, booster port, exhaust, purge and vent ports.

2. Place the pump in its packing materials. For fastest pump-down when the pump is put back into service, seal the

pump inside a plastic bag together with a suitable desiccant.

3. Store the pump in cool, dry conditions, preferably not exposed to atmospheric air until required for use. When

required, prepare and install the pump as described in Section 3.

4. Keep the pump upright at all times to prevent the drainage of oil from the bearing reservoir.

5. Avoid long-term storage if possible. W hen long-term storage is necessary, the pump should be set up and run for

at least eight hours every six months.

6.2 Disposal

Storage and disposal

In the unlikely event of a failure of the pump-rotor, dust can be generated from the carbon fibre

reinforced components. In this event, use appropriate Personal Protective Equipment when

handling and disposing of the pump, and ensure that all pump inlets and outlets are capped off

before disposal.

Take appropriate action to avoid inhalation of any particles which may be present in the pump. Do

not incinerate the pump. The pump contains phenolic and fluorosilicone materials which can

decompose to very dangerous substances when heated to high temperatures.

Be aware that any hazardous gases may remain in the system after it has been switched off.

Dispose of the EXTPX split flow pump and any components and accessories safely in accordance with all local and

national safety and environmental requirements.

Particular care must be taken with any components which have been contaminated with dangerous process

substances.

© Edwards Limited 2007. All rights reserved. Page 31

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 40

B760-60-880 Issue A

This page has been intentionally left blank.

Page 32 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 41

B760-60-880 Issue A

7 Service, spares and accessories

7.1 Introduction

Edwards products, spares and accessories are avai lable from Edwards com panies in Belgium, Brazil, C anada, Peoples

Republic of China, France, Germany, Hong Kong, India, Israel, Italy, Japan, Korea, Singapore, Taiwan, United

Kingdom, USA and a worldwide network of distributors. The majority of these employ service engineers who have

undergone comprehensive Edwards training courses.

Order spare parts and accessories from your nearest Edwards company o r dist ri but or. When you order, p lease state

for each part required:

z Model and item number of your equipment.

z Serial number (if any).

z Item number and description of the part.

7.2 Service

Edwards products are supported by a worldwide network of Edwards Service Centres. Each Service Cent re offers a

wide range of options including: equipment decontamination; service exchange; repair; rebuild and testing to factory

specifications. Equipment which has been serviced, repaired or rebuilt is returned with a full warranty.

Service, spares and accessories

Your local Service Centre can also provide Edwards engineers to support on-site maintenance, service or repair of

your equipment.

For more information about service options, contact your nearest Service Centre or other Edwards company.

7.3 Spares kits

7.3.1 Inlet screens

Inlet screens are fitted to your pump as supplied to prevent damage from the entry of debris into the pump. The Item

Number of replacement inlet screens is given in Table 9.

7.3.2 Inlet strainer

An inlet strainer is supplied fitted into the booster port. The Item Number for replacement strainers is given in

Table 9.

7.3.3 Inlet-flange seal

The EXTPX split flow pump is supplied with inlet seals. The Item Number of replacement seals is given in Table 9.

Table 9 - Spares kits

Description Flange version Item Number

Chamber inlet screen spares kit

Cartridge inlet strip spares kit

Inlet strainer spares kit NW25 ISO-K A223-05-067

Chamber inlet O-ring spares kit

Cartridge inlet O-ring spares kit

B760-61-991, B760-62-991, B760-67-991

B760-53-991

B760-61-991, B760-62-991, B760-67-991

B760-53-991

B760-61-812

B760-53-812

B760-61-810

B760-53-810

© Edwards Limited 2007. All rights reserved. Page 33

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 42

B760-60-880 Issue A

Service, spares and accessories

7.4 Accessories

7.4.1 Installation

The accessories available for use with the EXTPX split flow pump are described in the following sections. Figure 9

shows how the accessories are fitted to an EXTPX split flow pump.

7.4.2 EXDC drive module

The Item Numbers of the EXDC drive modules are shown in Table 10.

Table 10 - EXDC drive module

Drive Module Item Number

EXDC 160 24 V D396-46-000

EXDC 80 24 V D396-45-000

7.4.3 TIC controller

A TIC controller can be used to supp ly p ower t o t he EXDC driv e modu le . Ref er to Table 11. To minimise pump ramp

up time and to maximise the pump performance the 200 W TIC controller is recommended.

Table 11 - TIC controller

Controller Voltage Item Number

TIC 200 W (Turbo controller) 90 - 264 V a.c. 47 to 63 Hz D397-12-000

TIC 200 W (Turbo and Instruments controller) 90 - 264 V a.c. 47 to 63 Hz D397-22-000

7.4.4 TAV vent-valve and vent port adaptor

Two solenoid-operated vent-valves are available for system venting. The valves are 24 V d.c., normally-open, and

can be driven automatically from the TIC controller. The solenoid-valve is fitted in place of the manual-valve , or

alternatively can be fitted with an adaptor (supplied with th e valve) and be used with any suitable NW10 flanged port

on your vacuum system. The vent port adaptor allows the vent port or the purge port to be used with any suitable

NW10 fitting. Refer to Table 12.

Table 12 - TAV vent-valve and vent port adaptor

Product Item Number Orifice diameter Vac system (litres)

TAV5 vent-valve B580-66-010 0.5 mm <5

TAV6 vent-valve B580-66-020 1.0 mm <20

NW10-1/8 inch BSP male adaptor B580-66-011

Page 34 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 43

B760-60-880 Issue A

7.4.5 VRX vent-restrictor

Use a VRX fixed orifice vent-restrictor to restrict the flow of vent gas into the EXTPX split flow pump. Refer to Table 6

for information on the selection of the correct VRX vent-restrictor. Also refer to Table 13.

Table 13 - VRX vent restrictor

Vent-restrictor Orifice diameter Item number

VRX10 0.1 mm B580-66-021

VRX20 0.2 mm B580-66-022

VRX30 0.3 mm B580-66-023

VRX50 0.5 mm B580-66-024

VRX70 0.7 mm B580-66-025

7.4.6 PRX purge-restrictor

A modified DN10NW centering-ring is available to filter the purge gas and restrict its flow rate to the recommended

flow of 25 sccm. The restrictor is suitable for all EXTPX split flow pumps fitted with a purge port. Refer to Table 14.

Table 14 - PRX purge restrictor

Service, spares and accessories

Purge-restrictor Flange size Item number

PRX10 NW10 B580-65-001

7.4.7 ACX air-cooler

A choice of ACX air-coolers can be fitted to the EXTPX split flow pump. Please refer to Section 3.7 to check the

suitability of air-cooling in a particular application. Both radial and axial air-coolers may be used simultaneously if

so desired and space allows. TICs can be used to provide power for one fan. Refer to Table 15.

Table 15 - ACX air-cooler

Air-cooler Item Number

ACX400 - axial air-cooler kit B580-53-405

ACX400 - radial air-cooler kit B580-53-455

7.4.8 WCX water-cooler

A water-cooler can be fitted to the EXTPX split flow pump. Please refer to Section 3.7.3 to check the suitability of

the water-cooling supply.

Table 16 - WCX water-cooler

Water-cooler Item Number

WCX250 B735-01-164

© Edwards Limited 2007. All rights reserved. Page 35

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 44

B760-60-880 Issue A

1. ACX400 axial air cooling accessory

2. ACX400 radial air cooling accessory

3. DN10NW adaptor

4. VRX vent restrictor

5. Manual vent-valve (fitted)

6. TAV solenoid vent-va lve

7. Purge plug (fitted)

8. PRX purge restrictor

9. DN10W adaptor

10.WCX water-cooler

11.EXDC drive module

Service, spares and accessories

Figure 9 - Installation of optional accessories

Page 36 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 45

Index

B760-60-880 Issue A

Index

A

Accessories ............................................... 34

ACX air-cooler ............................................ 35

B

Backing-port connection ............................... 20

Bakeout ................................................... 26

Bearing maintenance

Booster port connection

................................... 27

................................ 20

C

Cleaning the pump ...................................... 27

Connection to the vacuum system

Cooling

.................................................... 22

.................... 16

D

Disposal ................................................... 31

E

Electrical installation ................................... 21

EXDC drive module ............................22, 26, 34

F

Fault finding ..............................................28

Forced-air cooling ....................................... 22

I

Inlet connection and pump orientation .............. 17

Inlet connection and pump orientation

(cartridge pumps)

Inlet connection and pump orientation

(non-cartridge pumps)

Inlet screens

Inlet strainer .............................................33

Inlet-flange seal

Installation

.......................................18

.................................. 17

.........................................16, 33

.........................................33

............................................... 13

M

Magnetic fields ...........................................23

Maintenance

Materials exposed to gases pumped ....................7

Mechanical fixing ........................................ 16

.............................................. 27

P

PRX purge-restrictor .................................... 35

Pumping media ............................................5

Purge gas connection

Purge gas specification and data .......................7

................................... 21

R

Rotor life ................................................. 27

S

Safety interlocks and control system ................ 26

Scope and definitions .....................................1

.................................................... 33

Service

Service, spares and accessories

Shut-down ................................................ 26

Spares kits ................................................ 33

Start-up

Storage .................................................... 31

Storage and disposal .................................... 31

................................................... 25

....................... 33

T

TAV vent-valve and vent port adaptor ............... 34

Technical data .............................................3

TIC controller

Typical installation ...................................... 14

..................................22, 26, 34

U

Unpack and inspect ..................................... 13

V

Vent gas specification and vent control data .........7

Vent options, vent-valve connection and control

VRX vent-restrictor ..................................... 35

.. 20

W

Water-cooling ............................................ 22

WCX water-cooler

....................................... 35

O

Operation ................................................. 25

© Edwards Limited 2007. All rights reserved. Page 37

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 46

B760-60-880 Issue A

This page has been intentionally left blank.

Page 38 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Loading...

Loading...