Page 1

Instruction Manual

TIC and Scientific Profibus Module

D397-54-880

Issue A Original

Description

TIC Profibus Module D397-54-000 Scientific Profibus Module D397-55-000

Item

Number

Original Instructions

Description

Item

Number

Page 2

This product has been manufactured under a quality management system certified to ISO 9001:2008

P200-03-180 Issue F

Declaration of Conformity

We, Edwards,

Innovation Drive,

Burgess Hill,

West Sussex,

RH15 9TW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised

to assemble the technical file, that the product(s)

TIC Profibus Module D397-54-000

Scientific Profibus Module D397-55-000

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61326-1:2013 Electrical equipment for measurement, control and laboratory

(Class B Emissions, Use. EMC requirements. General requirements

Industrial Immunity)

and fulfils all the relevant provisions of

2014/30/EU Electromagnetic Compatibility (EMC) Directive

2012/19/EU Waste from Electrical and Electronic Equipment (WEEE) Directive

2011/65/EU Restriction of Certain Hazardous Substances (RoHS) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

06.07.2017, Eastbou r n e

Larry Marini, Senior Technical Manager Date and Place

Page 3

P200-10-088

This product cont ain s h azardous substance s in at

26572 as detailed in t h e declaration table b elow.

材料成分声明

Hazardous Substance s

(Cr VI)

(PBDE)

Assembly (PCA)

Cable/wire/connector

Mechanical Components

this part is above th e l imit requirement of GB/T26572.

Lead

lead

Lead

Lead

lead

Lead

Cadmium

Lead

Lead

Issue B

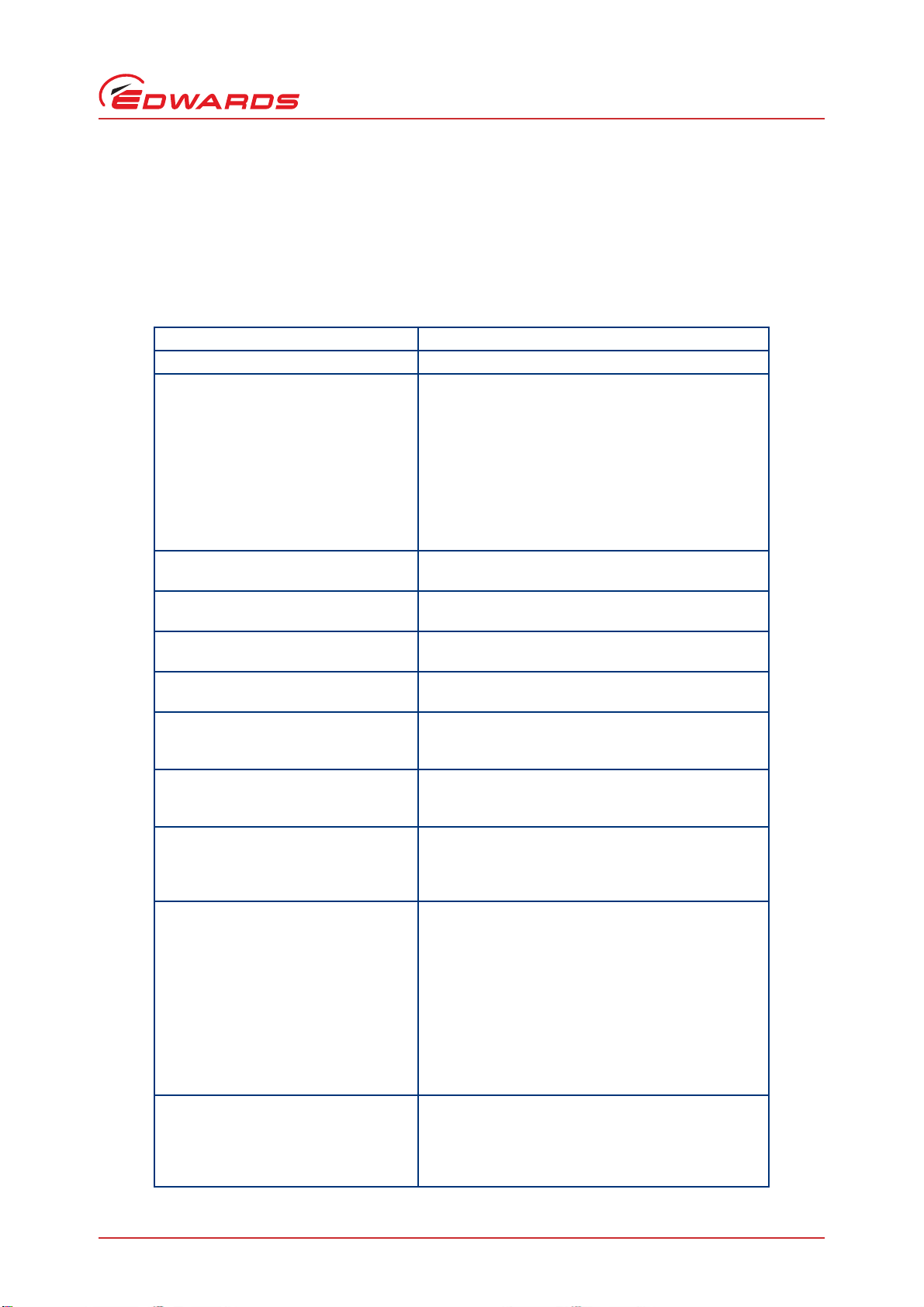

Material Declaration

In accordance with the requirements of the Chinese regulatory requirement on the Management Methods for the

Restriction of the U se of Hazardous Substances in Electric al and Electronic Product s Order N o. 32 (also known as

‘China RoHS2’) and SJ/T 11364 Marking for the R estrict ed Use of Hazard ous Subst ance s in Ele ctronic an d Elect rical

Products:

Product Product Label Meaning

least one of the hom ogeneous materials used

D39754000 TIC Profibus Module

D39755000 Scientific Profibus Module

Materials Content Declaration

which are above the limit requirement in GB/T

These parts can safe ly b e used for the

environmental protection use per iod as

indicated.

有害物质

部件名称

Part name

印刷电路组件 (PCA)

Printed Circuit

电缆/电线/连接器

机械部件

铅

Lead

(Pb)

汞

Mercury

(Hg)

Cadmium

X O X

X O

X O

镉

(Cd)

O O O O

O O O O

六价铬

Hexavalent

Chromium

多溴联苯

Polybrominated

biphenyls (PBB)

O O O

多溴二苯醚

Polybrominated

diphenyl ethers

O: 表示该有害物质在该部件的所有均质材料中的含量低于 GB/T 26572 标准规定的限量要求。

O: Indicates that the hazardous substance contained in all of the homog eneous materials for this part is

below the limit requirement in GB/T 26572.

X: 表示该有害物质在该部件的至少一种均质材料中的含量超出 GB/T26572 标准规定的限量要求。

X: Indicates that the hazardou s substance cont ained in at least one of th e homogeneou s materials use d for

NOTE: These products are EU RoHS compliant, the following Exemptions apply:

6(b)

as an alloying element in aluminium containing up to 0.4% by weight

6(c) Copper alloy containing up to 4%

7(a)

in in high melting temperature type solder (i.e. lead based alloys containing 85% by or more)

7(b)

in solders for servers, storage and storage array systems, network infrastructure equipment for switching, signalling,

by weight

transmission, and network management for telecommunications

7(c) I Electrical and electronic components containing

in a glass or ceramic other than dielectric ceramic in capacitors, e.g.

piezoelectronic devices, or in a glass or ceramic matrix compound

7(c) II

in dielectric ceramic in capacitors for a rated voltage of 125 V AC or 250 V DC or higher

8(b)

15

and its compounds in electrical contacts

in solders to complete a viable electrical connection between semiconductor die and carrier within integrated circuit flip

chip packages

34

in cermet-based trimmer potentiometer elements

Page 4

This page has been intentionally left blank.

Page 5

D397-54-880 Issue B

Contents

Section Page

1 Introduction ....................................................................................... 1

1.1 Scope and definitions ................................................................................................... 1

1.2 Product description ...................................................................................................... 2

2 Technical data .................................................................................... 3

2.1 Electrical data ............................................................................................................ 3

2.2 Operating and storage data ............................................................................................ 4

2.3 Mechanical data .......................................................................................................... 4

2.4 Connections ............................................................................................................... 4

2.4.1 Profibus connector ...................................................................................................... 4

2.4.2 D.C. Power connector ................................................................................................... 5

2.4.3 RS232 Connector (TIC Version only) .................................................................................. 5

2.4.4 DX/nEXT/nXDS Pump Connector (Scientific version only) ......................................................... 6

2.4.5 Front panel USB connector ............................................................................................. 7

Contents

3 Installation ........................................................................................ 9

3.1 Unpack and inspect ...................................................................................................... 9

3.2 Fitting the Module ....................................................................................................... 9

3.2.1 Rack mounting .......................................................................................................... 10

3.2.2 Panel mounting ......................................................................................................... 11

3.2.3 DIN rail mounting .......................................................................................................11

3.3 Electrical connections ..................................................................................................12

3.3.1 TIC Profibus module rear connections ............................................................................... 12

3.3.2 Scientific Profibus module rear connections .......................................................................12

3.4 Bus termination .........................................................................................................12

4 Operation ........................................................................................ 13

4.1 Profibus system information ..........................................................................................13

4.2 Start up sequence ...................................................................................................... 13

4.2.1 Simple set up instructions for the TIC version .....................................................................14

4.2.2 Simple set up instructions for the Scientific version ..............................................................14

4.3 Front panel display .....................................................................................................15

4.4 Address set-up ........................................................................................................... 16

4.5 Baud-rate ................................................................................................................18

4.6 Software format ........................................................................................................18

4.6.1 Parameterisation ........................................................................................................18

4.6.2 Configuration ............................................................................................................19

4.6.3 Configuration failure ...................................................................................................19

4.6.4 Parameterisation failure ............................................................................................... 19

4.6.5 Diagnostics description ................................................................................................ 20

4.7 Details of DX/nEXT/nXDS pump software modules ................................................................20

4.7.1 Software module 802 - nXDS Pump Control ......................................................................... 21

4.7.2 Software module 803 - nXDS Pump Speed Demand ................................................................ 21

4.7.3 Software module 808 - nXDS Pump Temperatures .................................................................22

4.7.4 Software module 809 - nXDS Pump Power ..........................................................................22

4.7.5 Software module 810 - nXDS Pump Run Time ......................................................................22

4.7.6 Software module 811 - nXDS Pump Cycles .......................................................................... 23

4.7.7 Software module 813 - nXDS Drive Run Time ....................................................................... 23

4.7.8 Software module 814 - nXDS Tip Seal Run Time ...................................................................23

4.7.9 Software module 815 - nXDS Bearing Run Time ....................................................................24

4.7.10 Software module 852 - DX/nEXT Pump Control ....................................................................24

gea/042/01/11

© Edwards Limited 2017. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

D397-54-880 Issue B

Contents

4.7.11 Software module 853 - DX/nEXT Pump Set-up .....................................................................25

4.7.12 Software module 859 - DX/nEXT Pump Temperatures ............................................................26

4.7.13 Software module 860 - DX/nEXT Pump Power ..................................................................... 26

4.7.14 Software module 864 - nEXT85 Pump Vent Option 2 .............................................................. 26

4.7.15 Software module 865 - nEXT85 Only Pump Temperatures .......................................................27

4.7.16 Software module 869 - DX/nEXT Pump Speed Demand ...........................................................27

4.7.17 Software module 875 - DX/nEXT Vent Valve close ................................................................ 27

4.7.18 Software module 880 - nEXT Service Set-up ........................................................................ 28

4.7.19 Software module 881 - nEXT Service Status ........................................................................28

4.7.20 Software module 882 - nEXT Controller Run Time ................................................................ 29

4.7.21 Software module 883 - nEXT Pump Run Time ......................................................................29

4.7.22 Software module 884 - nEXT Pump Cycles .......................................................................... 29

4.7.23 Software module 885 - nEXT Bearing Run Time .................................................................... 30

4.7.24 Software module 886 - nEXT Oil Cartridge Run Time .............................................................30

4.7.25 Software module 902 - Scientific Profibus module Software Version ........................................... 30

4.8 Details of TIC Software modules ..................................................................................... 31

4.8.1 Front panel lock ......................................................................................................... 33

4.8.2 Software module 853 - DX/nEXT Pump Set-up .....................................................................33

4.8.3 Software module 859 - DX/nEXT Pump Temperatures ............................................................34

4.8.4 Software module 860 - DX/nEXT Pump Power ..................................................................... 34

4.8.5 Software module 864 - nEXT85 Pump Vent Option 2 .............................................................. 35

4.8.6 Software module 865 - nEXT85 Only Pump Temperatures ....................................................... 35

4.8.7 Software module 869 - DX/nEXT Pump Speed Set-up .............................................................35

4.8.8 Software module 875 - DX/nEXT Vent Valve close ................................................................ 36

4.8.9 Software module 880 - nEXT Service Set-up ........................................................................ 36

4.8.10 Software module 881 - nEXT Service Status ........................................................................37

4.8.11 Software module 882 - nEXT Controller Run Time ................................................................ 37

4.8.12 Software module 883 - nEXT Pump Run Time ......................................................................38

4.8.13 Software module 884 - nEXT Pump Cycles .......................................................................... 38

4.8.14 Software module 885 - nEXT Bearing Run Time .................................................................... 38

4.8.15 Software module 886 - nEXT Oil Cartridge Run Time .............................................................39

4.8.16 Software module 803 - nXDS Pump Speed Demand ................................................................ 39

4.8.17 Software module 808 - nXDS Pump Temperatures ................................................................. 39

4.8.18 Software module 809 - nXDS Pump Power ..........................................................................40

4.8.19 Software module 810 - nXDS Pump Run Time ......................................................................40

4.8.20 Software module 811 - nXDS Pump Cycles ..........................................................................40

4.8.21 Software module 813 - nXDS Drive Run Time ....................................................................... 40

4.8.22 Software module 814 - nXDS Tip Seal Run Time ...................................................................41

4.8.23 Software module 815 - nXDS Bearing Run Time ....................................................................41

4.8.24 Software module 902 - TIC Software Version ....................................................................... 41

4.8.25 Software module 904 - Turbo Pump control ........................................................................ 42

4.8.26 Software module 905 - Turbo Pump Speed .........................................................................43

4.8.27 Software module 906 - Turbo Pump Power .........................................................................43

4.8.28 Software module 907 - Turbo Normal ...............................................................................44

4.8.29 Software module 908 - Turbo Standby .............................................................................. 44

4.8.30 Software module 909 - Turbo Cycle Time ...........................................................................44

4.8.31 Software module 910 - Backing pump control ......................................................................45

4.8.32 Software module 911 - Backing pump speed .......................................................................45

4.8.33 Software module 912 - Backing pump power .......................................................................46

4.8.34 Linking gauges and pumps .............................................................................................46

4.8.35 Software module 913 - Gauge 1 ......................................................................................47

4.8.36 Software module 914 - Gauge 2 ......................................................................................48

4.8.37 Software module 915 - Gauge 3 ......................................................................................48

4.8.38 Linking Relay set point outputs ....................................................................................... 48

4.8.39 Software module 916 - Relay 1 .......................................................................................49

4.8.40 Software module 917 - Relay 2 .......................................................................................49

4.8.41 Software module 918 - Relay 3 .......................................................................................49

4.8.42 Software module 919 - TIC Power supply temperature ........................................................... 50

4.8.43 Software module 920 - TIC internal temperature ................................................................. 50

4.8.44 Software module 921 - Analogue output ............................................................................51

Page ii © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

D397-54-880 Issue B

4.8.45 Software module 922 - TIC Vent valve ..............................................................................51

4.8.46 Software module 923 - Heater band .................................................................................52

4.8.47 Software module 924 - Air Cooler (Fan) .............................................................................52

4.8.48 Software module 933 - System ....................................................................................... 53

4.8.49 Software module 934 - Gauge 4 ......................................................................................53

4.8.50 Software module 935 - Gauge 5 ......................................................................................54

4.8.51 Software module 936 - Gauge 6 ......................................................................................55

4.8.52 Software module 937 - Relay 4 .......................................................................................55

4.8.53 Software module 938 - Relay 5 .......................................................................................55

4.8.54 Software module 939 - Relay 6 .......................................................................................55

4.9 Response time calculations & Measurements ...................................................................... 55

5 Maintenance ..................................................................................... 57

5.1 Fault finding .............................................................................................................57

5.2 Factory defaults ......................................................................................................... 58

5.3 Fuse replacement (Scientific version only) .........................................................................63

6 Storage and Disposal ........................................................................... 65

6.1 Storage ...................................................................................................................65

6.2 Disposal ................................................................................................................... 65

7 Spares and Accessories ........................................................................ 67

Contents

7.1 Introduction .............................................................................................................67

7.2 Spares ..................................................................................................................... 67

7.3 Accessories ...............................................................................................................67

Appendix A1 TIC Full Pump States .................................................................... 69

Appendix A2 Alert ID .................................................................................... 70

Appendix A3 Priority .................................................................................... 71

Appendix A4 Command List ............................................................................ 72

Appendix A5 Active Gauge States ..................................................................... 73

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Pin connections for 9-way sub-miniature ‘D’ type socket ......................................................... 4

2 Pin connections for the 2-way Power Connector ................................................................... 5

3 Pin connections for 9-way sub-miniature ‘D’ type plug ........................................................... 6

4 Pin connections for 15-way sub-miniature ‘D’ type socket ....................................................... 7

5 Dimensions of the Profibus module (mm) ............................................................................ 9

6 Rack mounting the Module ............................................................................................10

7 Panel mounting the Module ...........................................................................................11

8 DIN rail mounting the Module ......................................................................................... 11

9 TIC Profibus module rear connections ............................................................................... 12

10 Scientific Profibus module rear connections .......................................................................12

11 Profibus front panel display ...........................................................................................15

© Edwards Limited 2017. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

D397-54-880 Issue B

Contents

Tables

Table Page

1 Electrical data ............................................................................................................ 3

2 Operating and storage data ............................................................................................ 4

3 Mechanical data .......................................................................................................... 4

4 Profibus connector ...................................................................................................... 4

5 Pin connections for 9-way sub-miniature ‘D’ type socket ......................................................... 5

6 D.C. power connector ................................................................................................... 5

7 RS232 connector (TIC version only) ................................................................................... 5

8 Pin connections for 9-way sub-miniature ‘D’ type plug ........................................................... 6

9 DX/nEXT/nXDS pump connector (Scientific version only) ......................................................... 6

10 Pin connections for 15-way sub-miniature ‘D’ type socket ....................................................... 7

11 Front panel USB connector ............................................................................................. 7

12 Component checklist .................................................................................................... 9

13 Front panel symbols and their functions ............................................................................ 15

14 Address switch settings ................................................................................................16

15 DX/nEXT/nXDS pump module summary .............................................................................20

16 DX/nEXT status flags ...................................................................................................25

17 Converting the value to binary .......................................................................................28

18 TIC Controller Module summary ......................................................................................31

19 Converting the value to binary .......................................................................................37

20 Fault finding guide ......................................................................................................57

21 Profibus Module default set-up values (Scientific version) ....................................................... 58

22 Profibus Module default set-up values (TIC version) ..............................................................58

Page iv © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

D397-54-880 Issue B

CAUTION

WARNING

1Introduction

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards Turbo Instrument

Controller (TIC) Profibus Module and the Edwards Scientific Profibus Module. You must use the Controller as specified

in this manual.

Read this manual before you install and operate your Controller. Important safety information is highlighted as

WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is defined

below.

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

Introduction

Throughout this manual, page, figure or title numbers are sequential.

The following labels appear on the Controller:

Warning - refer to accompanying documentation.

Edwards offer European customers a recycling service.

The units used throughout this manual conform to the SI international system of units of measurement.

© Edwards Limited 2017. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

D397-54-880 Issue B

WARNING

WARNING

WARNING

Introduction

1.2 Product description

Improper use of the equipment may impair the protection provided and could cause damage to it.

The equipment is used to remotely control other equipment that could be hazardous if used

inappropriately. The responsibility for the safe operation and maintenance of the equipment

being controlled is with the user.

The data received from this unit should not be used for safety purposes.

There are two variants of the Profibus Module, both of which are provided with a standard Profibus connection, DC

power input connection and connection to the Edwards equipment. The TIC Profibus Module is provided with a short

serial cable to connect the module to the TIC serial comms port. The Scientific Profibus Module is provided with a

15 way connector. The 15 way flying lead or extension cable attached to the DX/nEXT/nXDS pump can be directly

connected for both power and control.

This manual explains how to control and monitor the TIC and Scientific modules with a Profibus system. Please refer

to the following manuals for operation of TIC controllers and DX/nEXT/nXDS pumps:

D397-01-880 TIC Instrument Controller - 6 Gauge

D397-12-880 Turbo Controller

D397-21-880 Instrument Controller

D397-22-880 Turbo Instrument controller

D397-30-880 TIC serial comms manual

B722-40-880 DX Pumps

B800-00-880 nEXT Pumps

B8G0-00-880 nEXT85 Pump

A735-01-880 nXDS Scroll Pump

A735-01-860 nXDS Serial Comms Interface

Page 2 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

D397-54-880 Issue B

WARNING

WARNING

2Technical data

2.1 Electrical data

Table 1 - Electrical data

Power connector type 2 Way cable-mount Terminal Block (supplied)

Suitable parts include: Phoenix MSTB 2.5/2-ST-5.08;

Weidmuller BLZ 5.08/2; Amp 796634-2; IMO 21.950/2

Electrical supply

TIC Profibus Module

Scientific Profibus Module for

EXT75DX, EXT255DX, nEXT85, 240, 300, 400 *

Power consumption 5W maximum

Fuse

TIC Profibus Module

Scientific Profibus Module

9 V d.c. min to 52 V d.c. max

21.6 V d.c. min to 25.2 V d.c. max

Switch on surge 500 mA max.

Note: Scientific Profibus Modules also supply power to

the pump. Additional supply requirement: 6 A

for EXT75DX, 10 A for EXT255DX and nEXT.

Refer to manuals for other DX/nEXT Turbo

Pumps.*

No internal fuse

Fitted with 10 A internal fuse. Suitable fuses available

from Edwards (Part No. D39751830).

Technical data

* nXDS does not require an electrical supply on the Profibus Module.

(Scientific version only)

Incorporate a suitable isolation device in the electrical supply. Locate the switch in an easily

accessible position and mark it as the disconnecting device for the DX/nEXT pump. If you do not,

you will not be able to switch off the DX/nEXT pump in an emergency.

Do not exceed the maximum supply voltage. Excessive supply voltage will cause permanent

damage to the control electronics and may result in a mechanical hazard in some failure

conditions.

Profibus cable Should be screened and comply with EN50170

RS232 cable (TIC version only) 25 m max. Screening not required.

DX/nEXT/nXDS pump cable (Scientific pump version

only)

Use (1 m) cable supplied with DX/nEXT pump only or

Edwards DX/nEXT/nXDS pump extension cables.

© Edwards Limited 2017. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

D397-54-880 Issue B

Technical data

2.2 Operating and storage data

Table 2 - Operating and storage data

Ambient operating temperature range 0 °C to 40 °C

Ambient storage temperature range -30 °C to 70 °C

Maximum ambient operating humidity Max 90% RH non condensing

Maximum operating altitude 2000 m max

IP rating IP30 - indoor use only

2.3 Mechanical data

Table 3 - Mechanical data

Weight 0.28 kg

Dimensions See Section 3.2

2.4 Connections

2.4.1 Profibus connector

Table 4 - Profibus connector

Connector type 9-way sub-miniature ‘D’ type socket (refer to Figure 1)

Profibus Data signals Electrically compliant with RS485 specification.

Isolated from chassis.

Profibus Power Supply 10 ma supply (protected) for external terminator

resistors if required.

Chassis For Profibus cable screen connection

Repeater control sign Digital signal, nominally 0-5 V but with series 340 ohm

resistor. High = module transmitting. Low = Receiving

or Idle.

Figure 1 - Pin connections for 9-way sub-miniature ‘D’ type socket

Page 4 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

Table 5 - Pin connections for 9-way sub-miniature ‘D’ type socket

Pin Allocation

1 Chassis (box)

2 Not connected

3Profibus Data + (B)

4 Control Signal for Repeater

5 Profibus Data reference (Isolated)

6 Profibus 5 V output (Isolated)

7 Not connected

8 Profibus Data - (A)

9 Not connected

Shell Chassis (box)

2.4.2 D.C. Power connector

D397-54-880 Issue B

Technical data

Table 6 - D.C. power connector

Connector type 2 Way Receptacle. Mating part is cable-mount Terminal

Block (supplied).

Suitable parts include: Phoenix MSTBV 2.5/2-G-5.08;

Weidmuller BLZ 5.08/2; Amp 796634-2; IMO 21.950/2

(Refer to Figure 2).

Requirements See Section 2.1

Figure 2 - Pin connections for the 2-way Power Connector

2.4.3 RS232 Connector (TIC Version only)

Table 7 - RS232 connector (TIC version only)

Connector type 9-way sub-miniature ’D’ type Plug (refer to Figure 3)

For connection to serial comms port of Turbo Instrument

Controller only.

RS232 protocol 9600 baud, 1 stop bit, 8 data bits, no parity

© Edwards Limited 2017. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

D397-54-880 Issue B

CAUTION

Technical data

Figure 3 - Pin connections for 9-way sub-miniature ‘D’ type plug

Table 8 - Pin connections for 9-way sub-miniature ‘D’ type plug

Pin Allocation

1 Not connected

2RS232 receive

3RS232 transmit

4 Not connected

5 RS232 common

6 Not connected

7 Not connected

8 Not connected

9 Not connected

Shell Chassis (box)

2.4.4 DX/nEXT/nXDS Pump Connector (Scientific version only)

Table 9 - DX/nEXT/nXDS pump connector (Scientific version only)

Connector type 15-way sub-miniature ‘D’ type Socket (refer to Figure 4)

Cable type Connection must be either direct to the DX/nEXT pump

flying lead or an Edwards DX/nEXT/nXDS pump

extension cable. Refer to the specification in the DX

pump manual B722-40-880, nEXT pump manual B800-00880, nEXT85 pump manual B8G0-00-880 and nXDS pump

manual A735-01-880 for further information.

Power connections Refer to caution below

When connecting the DX/nEXT/nXDS pump to the power supply, ensure that all 3 pins for the 24 V connection

and all 3 pins for the 0 V connection on your connector mating half are connected to the power supply.

RS232 protocol 9600 baud, 1 stop bit, 8 data bits, no parity.

Page 6 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

Figure 4 - Pin connections for 15-way sub-miniature ‘D’ type socket

Table 10 - Pin connections for 15-way sub-miniature ‘D’ type socket

Pin Allocation

1+24 V d.c. power output (Connect all three 24 V pins)

2 Not connected

3 Not connected

4RS232 Transmit

5 Serial enable link (Resistor to 0 V)

6+24 V d.c. power output

7RS232 Receive

80 V power (Connect all three 0 V pins)

9+24 V d.c. power output (Connect all three 24 V pins)

10 Chassis (box)

11 +24 V d.c. power output (Connect all three 24 V pins)

12 Not connected

13 0 V power (Connect all three 0 V pins)

14 0 V power (Connect all three 0 V pins)

15 Not connected

Shell Chassis (box)

D397-54-880 Issue B

Technical data

2.4.5 Front panel USB connector

Table 11 - Front panel USB connector

Connector type USB Micro-B socket

Function Software upgrade by Edwards service personnel only

© Edwards Limited 2017. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

D397-54-880 Issue B

This page has been intentionally left blank.

Page 8 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

D397-54-880 Issue B

WARNING

3 Installation

3.1 Unpack and inspect

Remove all of the packaging material and check the Module. If the Module is damaged, follow the Edwards return of

equipment procedures that are laid out in the back of this manual. Do not use the Module if it is damaged.

Check that your package contains the items that are listed in Table 12. If any of these items are missing, notify your

supplier in writing within three days. If the Module is not to be used immediately, store the Module in suitable

conditions as described in Section 6.1.

Table 12 - Component checklist

Installation

Quantity Description Check ( )

1Module

1 Quick Guide and Health and Safety Information

1 Profibus Module CD (includes main manual, GSD files)

1 DC Power Connector

2 DIN Rail clips

2 Mounting screws

1 Serial cable (TIC version only)

1 Spare Fuse (Scientific version only)

4Rubber feet

3.2 Fitting the Module

If access to the DC power connector is restricted an additional isolation device should be provided

which will be easily accessible by an operator.

The Module can be fitted in a rack or DIN-rail mounted. If either of these methods are not used, the module should

be laid with one of it's largest faces down, to ensure stability. Figure 5 shows the dimensions of the Profibus module.

Figure 5 - Dimensions of the Profibus module (mm)

© Edwards Limited 2017. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

D397-54-880 Issue B

CAUTION

CAUTION

WARNING

Installation

Ensure that all electrical wiring is safely secured so that people cannot trip on them.

Sufficient space must be provided at the rear of the unit for the cables. For this reason it is suggested that the

customer uses a straight Profibus connection. If a right-angled connection is to be used space will be required above

the height on the module.

Do not "Hot-swap" the DX/nEXT pump connection. Power must be removed before connecting or disconnecting

a turbo pump.

The unit is IP30 rated. Please ensure that the unit is not installed where fluids can enter into the Controller.

3.2.1 Rack mounting

For Rack mounting the unit should fit in a 6HP wide, 3U High space using the 2-off M2.5 screws provided, as shown

in Figure 6.

Figure 6 - Rack mounting the Module

Page 10 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 19

D397-54-880 Issue B

3.2.2 Panel mounting

For panel mounting cut the aperture in the panel using the dimensions shown in Figure 7. The module can be fixed

into the panel with the 2-off M2.5 screws.

Figure 7 - Panel mounting the Module

Installation

3.2.3 DIN rail mounting

For DIN rail mounting the 2 clips should be attached to the module using 2-off M3 screws provided (one in the centre

of each clip), as shown in Figure 8. The clips should then be roughly aligned with the box sides. The clips can then

be fitted to a suitable DIN-rail, as shown in Figure 8.

It is recommended to use end stops on a DIN rail system.

Figure 8 - DIN rail mounting the Module

© Edwards Limited 2017. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

D397-54-880 Issue B

Installation

3.3 Electrical connections

Fit the electrical connections as specified in Section 2.

3.3.1 TIC Profibus module rear connections

Figure 9 - TIC Profibus module rear connections

3.3.2 Scientific Profibus module rear connections

Figure 10 - Scientific Profibus module rear connections

3.4 Bus termination

Bus-termination is not supplied with the module, but must be used as for a normal Profibus DP system. Bus

termination must be used at both ends of the Profibus trunk and not anywhere else. If the module is placed at one

end of the trunk a connector containing the standard termination resistors should be used. The appropriate 5 V and

0 V signals are supplied on the standard pins for this purpose.

Page 12 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

D397-54-880 Issue B

4 Operation

4.1 Profibus system information

The Edwards Profibus Modules are for connection to a Profibus DP network and operate as V0 slaves only. The

required performance is described in standard EN50170.

The Profibus master requires a GSD file for each slave and these are provided on the CD included with the unit. The

TIC and Scientific versions require different GSD files so please ensure the relevant file (only) is installed. The ''ident''

numbers are unique for each type, and are registered with the Profibus association. The numbers are:

TIC 0D25 (GSD file for TIC version)

DX 0D26 (GSD file for Scientific version)

Note: If the wrong GSD file is selected it will not operate the module. The GSD files must not be altered.

4.2 Start up sequence

The diagram below provides an overview of how the TIC Profibus module and the Scientific Profibus module fit within

a Profibus Fieldbus system.

Operation

© Edwards Limited 2017. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

D397-54-880 Issue B

Operation

4.2.1 Simple set up instructions for the TIC version

1. Make all the connections to the TIC as appropriate to the system needs and as defined in the TIC instruction

manual.

2. Ensure the TIC protocol is set to ’RS232’ (not RS485) and the ’comms address’ is set to ’00’ which is the TIC’s

factory default. This can be done from the TIC’s parameters/units menu.

3. Connect the short serial cable provided between the TIC and Profibus module.

4. Connect the Profibus cable (provided by customer) to the Profibus connection.

5. Set address switches.

6. Load the GSD file into the Profibus system configurator (provided by customer).

7. Select module 904 to provide on and off control of a turbo pump connected to the TIC and select modules 913915 to provide gauge control.

Note: The TIC controller is provided with factory set defaults, which are suitable for basic operation of the

controller.

8. Connect the 24V power supply to the Profibus module.

9. Connect the mains supply to the TIC, and turn the TIC on.

10. The TIC controller is available for basic operation within a Profibus Fieldbus system.

4.2.2 Simple set up instructions for the Scientific version

1. Connect the 15 way flying lead or extension cable from the DX/nEXT/nXDS pump to the Profibus module.

2. Connect the Profibus cable (provided by customer) to the Profibus connection.

3. Set address switches.

4. Load the GSD file into the Profibus system configurator (provided by customer).

5. Select module 852 to provide on and off control.

Note: The DX/nEXT/nXDS pump is provided with factory set defaults, which are suitable for basic operation of

the pump.

6. Connect the 24V power supply to the Profibus module.

7. The DX/nEXT/nXDS pump is available for basic operation within a Profibus Fieldbus system.

Page 14 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 23

4.3 Front panel display

Figure 11 - Profibus front panel display

D397-54-880 Issue B

Operation

Table 13 - Front panel symbols and their functions

Symbol Name Function

Data exchange Module is in data exchange as defined by the Profibus standard.

Off-line Module is not in data exchange as defined by the Profibus

standard.

Error ON at the same time as Offline LED = Configuration or

parameterisation error.

Flashing at 1 Hz = Invalid address selected.

Power Internal 5 V supply is operating.

Upper address

switch

Lower address

switch

Sets value of upper nibble of address (Hexadecimal).

Sets value of lower nibble of address (Hexadecimal).

© Edwards Limited 2017. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 24

D397-54-880 Issue B

Operation

4.4 Address set-up

The module address can be set from 1 to 125 using the two hexadecimal rotary switches on the front panel. The lower

switch defines the lower half of the address byte (nibble) and the upper switch defines the upper half of the address

byte. Each node on a Profibus network must have a unique address. The address switches will only be read by the

unit at power-up. Any change of address setting after power-up will be ignored until next power-up.

The following table may assist.

Table 14 - Address switch settings

Upper switch

setting

Address in

Decimal

000633F

1016440

2026541

3036642

4046743

5056844

6066945

7077046

8087147

9097248

10 0 A 73 4 9

11 0 B 74 4 A

12 0 C 75 4 B

13 0 D 76 4 C

14 0 E 77 4 D

15 0 F 78 4 E

16 1 0 79 4 F

17 1 1 80 5 0

18 1 2 81 5 1

19 1 3 82 5 2

20 1 4 83 5 3

21 1 5 84 5 4

22 1 6 85 5 5

23 1 7 86 5 6

24 1 8 87 5 7

25 1 9 88 5 8

26 1 A 89 5 9

27 1 B 90 5 A

28 1 C 91 5 B

29 1 D 92 5 C

Lower switch

setting

Address in

Decimal

Upper switch

setting

Lower switch

setting

Page 16 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 25

D397-54-880 Issue B

Operation

Upper switch

setting

Address in

Decimal

30 1 E 93 5 D

31 1 F 94 5 E

32 2 0 95 5 F

33 2 1 96 6 0

34 2 2 97 6 1

35 2 3 98 6 2

36 2 4 99 6 3

37 2 5 100 6 4

38 2 6 101 6 5

39 2 7 102 6 6

40 2 8 103 6 7

41 2 9 104 6 8

42 2 A 105 6 9

43 2 B 106 6 A

44 2 C 107 6 B

45 2 D 108 6 C

46 2 E 109 6 D

47 2 F 110 6 E

48 3 0 111 6 F

49 3 1 112 7 0

50 3 2 113 7 1

51 3 3 114 7 2

52 3 4 115 7 3

53 3 5 116 7 4

54 3 6 117 7 5

55 3 7 118 7 6

56 3 8 119 7 7

57 3 9 120 7 8

58 3 A 121 7 9

59 3 B 122 7 A

60 3 C 123 7 B

61 3 D 124 7 C

62 3 E 125 7 D

Lower switch

setting

Upper switch

setting

Address in

Decimal

Lower switch

setting

Note: If the address is set to a value greater than 125 (decimal) or 0 the RED error LED will flash at around 1 Hz

and the module will not go on-line. If this occurs either, change the address and cycle the power or remove

power and change the address.

© Edwards Limited 2017. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 26

D397-54-880 Issue B

Operation

4.5 Baud-rate

All 10 standard DP baud-rates are supported. These are: 9.6Kbd; 19.2Kbd; 45.45Kbd; 93.75Kbd; 187.5Kbd; 500Kbd;

1.5Mbd; 3Mbd; 6Mbd; 12Mbd. The unit has no facility for adjusting baud-rate as detection is automatic, and it will

therefore respond to the baud-rate chosen by the master.

4.6 Software format

The Slave software is based upon a modular configurable architecture so the user has considerable control of the

contents of the Data exchange messages.

The software modules (defined in the GSD files) generally follow the TIC and DX/nEXT/nXDS pump serial

communications objects. In terms of the TIC/DX/nEXT/nXDS serial comms the Profibus input data is provided by ?V,

output data is sent by !C and parameterisation by !S. The unit uses ?S to check that parameterisation has succeeded

but this data is not returned over the Profibus network as there is no equivalent Profibus message.

Wh e n t h e u n i t i s linked onto the Profibus it will be parameterised and then configured before entering data exchange.

The parameterisation and configuration choices are in the GSD file and its comments describe the data content of

the input, output and parameterisation bytes. These choices will often be made using a third party configurator such

as SyCon that presents an user-friendlier interface.

16-bit values are transmitted with the MSB first and the LSB last.

4.6.1 Parameterisation

The TIC version has one common parameterisation - front panel lock/unlock. The other parameters are modular and

will only be sent when a module is selected in the configuration. The TIC and the DX/nEXT/nXDS remember the

parameterisation during power down so if it is required to alter a parameterisation you must send it (include it in the

configuration list). Parameter settings do not go to default during a power down. On the TIC if a module is in the

parameterisation do not alter its settings from the front panel. Conversely if a module is not in the parameterisation

then you could sensibly set up from the TIC front panel.

In order to speed up the true data exchange rate (the serial comms information transfer is relatively slow or very

slow compared to Profibus) the configuration list might not include all modules and therefore those modules left out

will not be parameterised. As the TIC and DX/nEXT/nXDS remember their settings during power down this will not

normally cause a problem once the TIC or DX/nEXT/nXDS has been initially set up. However, if the TIC or DX/nEXT/

nXDS is replaced with a different one it wil l not be fully set up by the parameterisation and the user must takes steps

to correct this by either setting up the missing modules using the front panel or temporarily adding the modules to

the configuration.

The TIC and DX/nEXT/nXDS come with factory default settings that suit simple operation, it is not necessary to alter

these settings to simply turn a pump on/off or read a gauge, see their respective manuals for further details. In

general the GSD defaults match the TIC and DX/nEXT/nXDS factory defaults.

Page 18 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 27

D397-54-880 Issue B

4.6.2 Configuration

During configuration the user can define what modules are required and in which order the data is transferred. The

unit simply adds the input and output data bytes to the message maps in the order that they are defined in the

configuration message.

A module must only be defined once in the list. If a module is declared more than once it may cause a

parameterisation/configuration failure or may not update the data content correctly.

Example:

Module = Mod_A 3 bytes in (Ai1, Ai2, Ai3), 1 byte out (Ao1)

Module = Mod_B 2 bytes in (Bi1, Bi2), 2 bytes out (Bo1, Bo2)

A) Configure Mod_A, Mod_B gives

Output map: -

Byte1 Byte 2 Byte 3

Ao1 Bo1 Bo2

Input map: -

Operation

Byte1 Byte 2 Byte 3 Byte 4 Byte 5

Ai1 Ai2 Ai3 Bi1 Bi2

B) Configure Mod_B, Mod_A gives

Output map: -

Byte1 Byte 2 Byte 3

Bo1 Bo2 Ao1

Input map: -

Byte1 Byte 2 Byte 3 Byte 4 Byte 5

Bi1 Bi2 Ai1 Ai2 Ai3

Data is always referred to the Master so output data is Control data from Master to Slave and Input data is feedback

data from Slave to Master.

There are many software modules, (TIC has over 30), and many bytes of data (TIC has over 100 input bytes), care

must be taken in correctly selecting and aligning the data into your system.

Configuration may take up to 5 seconds to occur. During this period the Profibus Slave will signal to the Master that

is is "not-ready" for data exchange.

4.6.3 Configuration failure

Some variants of the TIC do not have all functional items present and the modules related to these items will not be

valid. An inappropriate configuration will lead to parameterisation or configuration failure and the slave will not

enter data exchange. The number of the first failed module will be placed in the extended diagnostic data. See GSD

or Section 4.6.5 for description of the extended diagnostics.

4.6.4 Parameterisation failure

Some parameterisation will not be valid in particular combinations. The TIC and/or DX/nEXT/nXDS will determine

this and the Slave will not enter data exchange. The number of the first failed module will be placed in the extended

diagnostic data. As per current recommendations this is not flagged as a critical diagnostic in the mandatory

diagnostics (octet 1 bit 3).

© Edwards Limited 2017. All rights reserved. Page 19

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 28

D397-54-880 Issue B

Operation

4.6.5 Diagnostics description

The modules use extended diagnostics in the format below.

Max_Diag_Data_Len = 12

Bytes 1-6 7 8 and 9 10 and 11

Description Mandatory No of bytes of

extended

diagnostics (6)

Note: An appropriately configured software module will be shown as a parameterisation failure if that module

contains parameterisation data as the Profibus standard is for parameterisation to occur before

configuration. If there is more than one bad parameterisation or configuration entry, the module number

will be the first bad module in the order of configuration.

Module failed

parameterisation,

MSB in 8, LSB in 9

Module failed

configuration,

MSB in 10, LSB in

11

12

Serial comms

lost (0=OK,

1=lost).

4.7 Details of DX/nEXT/nXDS pump software modules

Introduction

This section applies only to the Scientific Profibus module. The table below provides a summary of the modules.

Table 15 - DX/nEXT/nXDS pump module summary

Module No Module description Compatibility

802 nXDS pump nXDS 1 9 None

803 nXDS pump speed demand nXDS 1 None 4

No of output

bytes

No of input

bytes

No of

Parameter

bytes

808 nXDS temperatures nXDS None 4 None

809 nXDS power nXDS None 2 None

811 nXDS pump cycles nXDS None 4 None

813 nXDS drive run time nXDS None 8 None

814 nXDS tip seal run time nXDS None 8 None

815 nXDS bearing run time nXDS None 8 None

852 DX/nEXT pump control 75DX, 255DX/nEXT 1 6 None

853 DX/nEXT pump set-up 75DX only None 1 (Dummy) 7

853 DX/nEXT pump set-up 255DX/nEXT None 1 (Dummy) 7

859 DX/nEXT pump temperature 75DX, 255DX/nEXT None 2 None

860 DX/nEXT pump power 75DX, 255DX/nEXT None 2 None

864 nEXT85 vent opt2 ONLY setup nEXT85 None 1 (Dummy) 2

865 nEXT85 ONLY temps nEXT85 None 3 None

869 DX/nEXT pump speed demand 75DX,255DX/nEXT 1 None 4

875 DX/nEXT vent valve close 75DX or 255DX/nEXT with a

TIC controller supporting

turbo controller

1 None None

Page 20 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 29

D397-54-880 Issue B

Operation

Module No Module description Compatibility

880 Service set-up nEXT None 1 (Dummy) 3

881 Service Status nEXT None 4 None

882 Controller Run Time nEXT None 8 None

883 Pump run time nEXT None 8 None

884 Pump cycles nEXT None 4 None

885 Bearing run time nEXT None 8 None

886 Oil cartridge run time nEXT None 8 None

902 Scientific Profibus module

Software Version

Scientific Profibus Module None 2 None

No of output

bytes

No of input

bytes

4.7.1 Software module 802 - nXDS Pump Control

General Description

Main nXDS Pump control and monitoring module. This module must be selected for pump control.

No of

Parameter

bytes

Output bytes (from Master)

1st Stop if value 0. Run if value 1.

Input bytes (to Master)

1st

2nd - 3rd Form a 64-bit system status word. To decode the status first

4th - 5th

6th - 7th

8th - 9th

Associated Parameter options

None.

Form an 8-bit number, which is the motor speed in Revolutions per

Second (0-255).

convert the value to binary. Refer to nXDS manual to interpret

each bit.

4.7.2 Software module 803 - nXDS Pump Speed Demand

General Description

Controls nXDS Pump speed demand (value).

Output bytes (from Master)

1st Speed demand (if pump started) is full speed if value 0, and

standby speed if value 1.

Input bytes (to Master)

None.

© Edwards Limited 2017. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 30

D397-54-880 Issue B

Operation

Associated Parameter options

Bytes Parameter Option Description of Parameter

1st Module number Cannot be changed.

2nd

3rd Normal speed indication The value as a percentage of the full speed to define normal

speed indication. (50-100%).

4th Standby speed The value as a percentage of the full speed to define standby

speed. (66-100%).

4.7.3 Software module 808 - nXDS Pump Temperatures

General Description

Read nXDS Pump controller and motor temperatures.

Output bytes (from Master)

None.

Input bytes (to Master)

1st, 2nd Motor temperature in °C.

3rd, 4th Controller temperature in °C.

Associated Parameter options

None.

4.7.4 Software module 809 - nXDS Pump Power

General Description

Read nXDS Pump motor power consumption.

Output bytes (from Master)

None.

Input bytes (to Master)

1st, 2nd

Associated Parameter options

None.

Forms a 16-bit (signed) number, which is the motor power in 10th’s

of Watts.

4.7.5 Software module 810 - nXDS Pump Run Time

General Description

Read Hours run by pump.

Output bytes (from Master)

None.

Input bytes (to Master

1st,2nd,3rd

and 4th

Associated Parameter options

None.

Page 22 © Edwards Limited 2017. All rights reserved.

Hours run by pump 0..999999

)

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 31

4.7.6 Software module 811 - nXDS Pump Cycles

General Description

Read cycles run by pump.

Output bytes (from Master)

None.

D397-54-880 Issue B

Operation

Input bytes (to Master

1st, 2nd, 3rd

and 4th

Associated Parameter options

None.

Cycles run by pump 0..65535

)

4.7.7 Software module 813 - nXDS Drive Run Time

General Description

Read Hours run by drive and Hours until drive service.

Output bytes (from Master)

None.

Input bytes (to Master

1st,2nd,3rd

and 4th

5th, 6th, 7th

and 8th

Associated Parameter options

None.

Hours until drive service 0..999999

Hours run by drive 0..999999

)

4.7.8 Software module 814 - nXDS Tip Seal Run Time

General Description

Read Hours run by tip seal and Hours until tip seal service.

Output bytes (from Master)

None.

Input bytes (to Master

1st,2nd,3rd

and 4th

5th, 6th, 7th

and 8th

Associated Parameter options

None.

Hours until tip seal service 0..999999

Hours run by tip seal 0..999999

)

© Edwards Limited 2017. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 32

D397-54-880 Issue B

Operation

4.7.9 Software module 815 - nXDS Bearing Run Time

General Description

Read Hours run by bearing and Hours until bearing service.

Output bytes (from Master)

None.

Input bytes (to Master

1st,2nd,3rd

and 4th

5th, 6th, 7th

and 8th

Associated Parameter options

None.

Hours until bearing service 0..999999

Hours run by bearing 0..999999

)

4.7.10 Software module 852 - DX/nEXT Pump Control

General Description

Main DX/nEXT Pump control and monitoring module. This module must be selected for pump control.

Output bytes (from Master)

1st Stop if value 0. Run if value 1.

Input bytes (to Master)

1st Form a 16-bit number, which is the motor speed in Revolutions per

2nd

3rd Form a 32-bit system status word. The Upper two bytes (3rd and

4th

5th

6th

Second (0-1800).

4th) are reserved. Each bit of lower 2 bytes is a flag. To decode

the status first convert the value to binary. Refer to Table 16 to

interpret each bit.

Associated Parameter options

None.

Page 24 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 33

Table 16 - DX/nEXT status flags

Bit No. Status Flag Name Meaning if Flag 0 Meaning if Flag 1

0 Fail Not failed Failure condition

1 Stopped Speed Pump in motion Pump at rest

2 Normal Speed Below normal speed Above normal speed

3 Vent valve Valve output not powered Valve output powered

4 Start Not commanded to start Commanded to start

5 Serial Enable Serial control disabled Serial control enabled

6 Standby Standby not commanded Standby commanded

7 50% speed Below 50% speed Above 50% speed

8 Parallel control Not in Parallel control mode In Parallel control mode

9 Serial control Not in Serial control mode In Serial control mode

10 Software Compatibility Podule software not mis-matched Invalid Podule software

11 Software Completion Podule upload complete Podule Config or Cal failed

12 Timer State Timer duration not exceeded Timer (for 50% speed) expired

13 Hardware Trip No trip Overspeed or Overcurrent trip

14 Thermistor Error Internal temp system good Internal temp system failed

15 Serial Interlock Serial enable good Serial enable bad

D397-54-880 Issue B

Operation

Note: There are slight differences in the status between the DX and nEXT. For example, DX clears faults on a stop

command and nEXT clears faults on the start command (a stop command should be sent first). The TIC

attempts to hide these differences in its returned data (objects 900+).

4.7.11 Software module 853 - DX/nEXT Pump Set-up

There are two versions of this module for the two ranges of pumps - 75DX and 255DX/nEXT. The software modules

have different power limit values. The correct module for the pump in use must be selected.

General Description

DX/nEXT Pump set-up and configuration.

Output bytes (from Master)

None.

Input bytes (to Master)

1st Dummy byte (always zero).

Associated Parameter options

Bytes Parameter Option Description of Parameter

1st Module number Cannot be changed.

2nd

3rd Vent options 8 options with textual descriptions. More information

available on each option from the DX/nEXT pump manual.

4th Ramp and droop timer

setting

5th Power limit Sets the maximum power that the DX/nEXT pump motor will

6th Effect if speed drops below

50%

7th Brake use Whether Electronic braking is enabled or disabled.

Value of the timeout period for both initial speed ramp-up and

if the speed drops below 50%. Value is in minutes (1-30).

be allowed to consume (in Watts). The range is different for

the two pump ranges.

Options are stop immediately or stop if timing period

exceeded.

© Edwards Limited 2017. All rights reserved. Page 25

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 34

D397-54-880 Issue B

Operation

4.7.12 Software module 859 - DX/nEXT Pump Temperatures

General Description

Read DX/nEXT Pump controller and motor temperatures.

Output bytes (from Master)

None.

Input bytes (to Master)

1st Motor temperature in °C.

2nd Controller temperature in °C.

Associated Parameter options

None.

4.7.13 Software module 860 - DX/nEXT Pump Power

General Description

Read DX/nEXT Pump motor power consumption.

Output bytes (from Master)

None.

Input bytes (to Master)

1st Forms a 16-bit (signed) number, which is the motor power in 10th’s

2nd

Associated Parameter options

None.

of Watts.

4.7.14 Software module 864 - nEXT85 Pump Vent Option 2

General Description

Controls nEXT85 Pump Vent Option 2 (value).

Output bytes (from Master)

None.

Input bytes (to Master)

1st Dummy byte (always 0)

Associated Parameter options

Bytes Parameter Option Description of Parameter

1st Module number Cannot be changed.

2nd

3rd Vent options 8 options with textual descriptions. More information

available on each option from the nEXT85 pump manual.

Page 26 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 35

4.7.15 Software module 865 - nEXT85 Only Pump Temperatures

General Description

Read nEXT85 Pump motor, controller and rotor temperatures.

Output bytes (from Master)

None.

Input bytes (to Master)

1st Motor temperature in °C.

2nd Controller temperature in °C.

3rd Motor temperature in °C.

Associated Parameter options

None.

4.7.16 Software module 869 - DX/nEXT Pump Speed Demand

General Description

Controls DX/nEXT Pump speed demand (value).

D397-54-880 Issue B

Operation

Output bytes (from Master)

1st Speed demand (if pump started) is full speed if value 0, and

standby speed if value 1.

Input bytes (to Master)

None.

Associated Parameter options

Bytes Parameter Option Description of Parameter

1st Module number Cannot be changed.

2nd

3rd Normal speed indication The value as a percentage of the full speed to define normal

speed indication. (50-100%).

4th Standby speed The value as a percentage of the full speed to define standby

speed. (55-100%).

4.7.17 Software module 875 - DX/nEXT Vent Valve close

General Description

Forces vent valve closed (by powering it) regardless of vent valve control set-up.

Output bytes (from Master

1st Not forced closed if value 0. Forced closed if value 1.

)

Note: Once a "forced close" command has been sent it can only be cleared in the DX/nEXT pump podule by

demanding the pump to stop (using software module 852).

Input bytes (to Master)

None.

Associated Parameter options

None.

© Edwards Limited 2017. All rights reserved. Page 27

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 36

D397-54-880 Issue B

Operation

4.7.18 Software module 880 - nEXT Service Set-up

This module must only be selected if there is a nEXT pump connected to the TIC.

General Description

Set-up how a service alert is communicated.

Output bytes (from Master)

None.

Input bytes (to Master

1st Dummy byte (always 0)

Associated Parameter options

Bytes Parameter Option Description of Parameter

1st and 2nd Module number Cannot be changed.

3rd Service set-up 0: Service indication on Status LED

)

1: Service indication on Status LED and FAIL line

2: No service indication on Status LED or FAIL line

3: Service indication on FAIL line

4.7.19 Software module 881 - nEXT Service Status

This module must only be selected if there is a nEXT pump connected to the TIC.

General Description

Overall service status.

Output bytes (from Master)

None.

Input bytes (to Master

)

1st,2nd,3rd,

4th

Bit Number Status flag Active flag means

Associated Parameter options

None.

From a 32-bit system status word. The Upper three bytes (2nd, 3rd and 4th) are reserved. Each

bit of the lower byte is a flag. To decode the status first convert the value to binary. Refer to

Ta bl e 1 7 to interpret each bit.

Table 17 - Converting the value to binary

0 Oil cartridge service due Set when hours until oil cartridge service due = 0

1 Bearing service due Set when hours until bearing service due = 0

2 Pump service due Set when hours until pump service due = 0

or cycles until pump service due = 0

3 Controller service due Set when hours until controller service due = 0

4Reserved -

5Reserved -

6Reserved -

7 Service due Service operation required may be determined by

checking the bits above

8 - 31 Reserved -

Page 28 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 37

4.7.20 Software module 882 - nEXT Controller Run Time

This module must only be selected if there is a nEXT pump connected to the TIC.

General Description

Read Hours run by controller and Hours until controller service.

Output bytes (from Master)

None.

D397-54-880 Issue B

Operation

Input bytes (to Master

1st,2nd,3rd

and 4th

5th, 6th, 7th

and 8th

Associated Parameter options

None.

Hours until controller service 0..999999

Hours run by controller 0..999999

)

4.7.21 Software module 883 - nEXT Pump Run Time

This module must only be selected if there is a nEXT pump connected to the TIC.

General Description

Read Hours run by pump and Hours until pump service.

Output bytes (from Master)

None.

Input bytes (to Master

1st,2nd,3rd

and 4th

5th, 6th, 7th

and 8th

Hours until pump service 0..999999

Hours run by pump 0..999999

)

Associated Parameter options

None.

4.7.22 Software module 884 - nEXT Pump Cycles

This module must only be selected if there is a nEXT pump connected to the TIC.

General Description

Read cycles run by pump and cycles until pump service.

Output bytes (from Master)

None.

Input bytes (to Master

1st and 2nd Cycles until pump service 0..65535

3rd and 4th Cycles run by pump 0..65535

Associated Parameter options

None.

)

© Edwards Limited 2017. All rights reserved. Page 29

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 38

D397-54-880 Issue B

Operation

4.7.23 Software module 885 - nEXT Bearing Run Time

This module must only be selected if there is a nEXT pump connected to the TIC.

General Description

Read Hours run by bearing and Hours until bearing service.

Output bytes (from Master)

None.

Input bytes (to Master

1st,2nd,3rd

and 4th

5th, 6th, 7th

and 8th

Associated Parameter options

None.

Hours until bearing service 0..999999

Hours run by bearing 0..999999

)

4.7.24 Software module 886 - nEXT Oil Cartridge Run Time

This module must only be selected if there is a nEXT pump connected to the TIC.

General Description

Read Hours run by oil cartridge and Hours until oil cartridge service.

Output bytes (from Master)

None.

Input bytes (to Master

1st,2nd,3rd

and 4th

5th, 6th, 7th

and 8th

Hours until oil cartridge service 0..999999

Hours run by oil cartridge 0..999999

)

Associated Parameter options

None.

4.7.25 Software module 902 - Scientific Profibus module Software Version

General Description

Module used in Scientific Profibus unit to read the software version it contains. This would normally only be

used during setup or test; as it can't alter during data exchange it would not normally be present.

Output bytes (from Master)

None.

Input bytes (to Master)

1st Release state of software in ASCII, should be '4' for production.

e.g.ASCII ’4’ = 34 h.

2nd Version letter of software in ASCII, normally A to Z.

e.g.ASCII ’A’ = 41 h.

Associated Parameter options

None.

Page 30 © Edwards Limited 2017. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 39

D397-54-880 Issue B

4.8 Details of TIC Software modules

This section applies only to the TIC controllers' Profibus module. The table below provides a summary of the modules

that can be configured.

Table 18 - TIC Controller Module summary

Operation

Module No. Module description Compatibility

853 DX/nEXT pump set-up 75DX with a TIC controller

supporting turbo control

853 DX/nEXT pump set-up 255DX/nEXT with a TIC

controller supporting turbo

control

859 DX/nEXT pump

temperature

860 DX/nEXT pump power 75DX or 255DX/nEXT with a

864 nEXT85 Vent Opt2 ONLY

Setup

865 nEXT85 ONLY Temps nEXT85 with a TIC

869 DX/nEXT pump speed set up75DX or 255DX/nEXT with a

875 DX/nEXT vent valve close 75DX or 255DX/nEXT with a

880 Service set-up nEXT with a TIC controller

881 Service Status nEXT with a TIC controller

882 Controller Run Time nEXT with a TIC controller

883 Pump run time nEXT with a TIC controller

884 Pump cycles nEXT with a TIC controller

885 Bearing run time nEXT with a TIC controller

886 Oil cartridge run time nEXT with a TIC controller

803 nXDS Pump Speed Demand nXDS with a TIC controller

808 nXDS Temperature nXDS with a TIC controller

75DX, 255DX/nEXT with a

TIC controller supporting

turbo control

TIC controller supporting

turbo control

nEXT85 with a TIC

controller supporting turbo

control

controller supporting turbo

control

TIC controller supporting

turbo control

TIC controller supporting

turbo control

supporting turbo control

supporting turbo control

supporting turbo control

supporting turbo control

supporting turbo control

supporting turbo control

supporting turbo control

supporting backing control

supporting backing control

No of output

bytes

None 1 (Dummy) 7

None 1 (Dummy) 7

None 2 None

None 2 None

None 1 (Dummy) 2

None 3 None

1None4

1 None None

None 1 (Dummy) 3

None 4 None

None 8 None

None 8 None

None 4 None

None 8 None

None 8 None

1None4

None 4 None

No of input

bytes

No of

Parameter

bytes

© Edwards Limited 2017. All rights reserved. Page 31

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 40

D397-54-880 Issue B

Operation

Module No. Module description Compatibility

809 nXDS Power nXDS with a TIC controller

supporting backing control

811 nXDS Pump cycles nXDS with a TIC controller

supporting backing control

813 nXDS Drive run time nXDS with a TIC controller

supporting backing control

814 nXDS Tip seal run time nXDS with a TIC controller

supporting backing control

815 nXDS Bearing run time nXDS with a TIC controller

supporting backing control

902 TIC Profibus module

Software Version

904 Turbo pump control Any TIC controller with

905 Turbo pump speed Any TIC controller with

906 Turbo pump power Any TIC controller with

907 Turbo normal Any TIC controller with

908 Turbo standby Any TIC controller with

909 Turbo cycle time Any TIC controller with

910 Backing pump control Any TIC controller with

911 Backing pump speed

(Reserved)

912 Backing pump power Any TIC controller with

913 Gauge1 Any TIC controller with

914 Gauge2 Any TIC controller with

914 Gauge3 Any TIC controller with

916 Relay 1 Any TIC controller 1 3 14

917 Relay 2 Any TIC controller 1 3 14