Page 1

Instruction Manual

Drypump Profibus Module

D397-52-880

Issue D

Description

Drypump Profibus Module D397-52-000

Item

Number

Original Instructions

Description

Item

Number

Page 2

Declaration of Conformity

We, Edwards Limited,

Crawley Business Quarter,

Manor Royal,

Crawley,

West Sussex, RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU

authorised to assemble the technical file, that the product(s)

Drypump Profibus Module D397-52-000

to which this declaration relates is in conformity with the followin g standard(s) or

other normative document(s)

EN61326-1:2013 Electrical equipment for measurement, control and

(Class B Emissions, laboratory Use. EMC requirements. General requirements

Industrial Immunity)

and fulfils all the relevant provisions of

2014/30/EU Electromagnetic Compatibility (EMC) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

16.07.2015, Eastbourne

Larry Marini, Senior Technical Manager Date and Place

This product has been manufactured under a quality management system certified to ISO 9001:2008

P200-02-820 Issue C

Page 3

P200-10-085

Issue A

Material Declaration

In accordance with the requirements of the Chinese regulatory requirement on the Ma nagement Methods for the

Restriction of the Use of Hazardous Substances in Electrical and Electronic Products Order No. 32 (also known as

‘China RoHS2’) and SJ/T 11364 Marking for the Restricted Use of Hazardous Substances in Electronic and Electrical

Products:

Product Product Label Meaning

This product contains hazardous substances in at

least one of the homogeneous materials used

which are above the limit requirement in GB/T

D39752000 Drypump Profibus Module

部件名称

Part name

印刷电路组件 (PCA)

Printed Circuit

Assembly (PCA)

电缆/电线/连接器

Cable/wire/connector

机械部件

Mechanical Components

铅

Lead

(Pb)

Mercury

(Hg)

X O X

X O

X O

材料成分声明

Materials Content Declaration

Hazardous Substances

汞

镉

Cadmium

(Cd)

O O O O

O O O O

26572 as detailed in the declaration table below.

These parts can safely be used for the

environmental protection use period as

indicated.

有害物质

六价铬

Hexavalent

Chromium

(Cr VI)

多溴联苯

Polybrominated

biphenyls (PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

O O O

O: 表示该有害物质在该部件的所有均质材料中的含量低于 GB/T 26572 标准规定的限量要求。

O: Indicates that the hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement in GB/T 26572.

X: 表示该有害物质在该部件的至少一种均质材料中的含量超出 GB/T26572 标准规定的限量要求。

X: Indicates that the hazardous substance contained in at least one of the homogeneous materials used for

this part is above the limit requirement of GB/T26572.

NOTE:TheseproductsareEURoHScompliant,thefollowingExemptionsapply:

6(b)Leadasanalloyingelementinaluminiumcontainingupto0.4%byweight

6(c)Copperalloycontainingupto4%leadbyweight

7(a)Leadininhighmeltingtemperaturetypesolder(i.e.leadbasedalloyscontaining85%byormore)

7(b) Leadin solders for servers, storage andstorage array systems, network infrastructureequipmentfor switching, signalling,

transmission,andnetworkmanagementfortelecommunications

7(c)I Electrical andelectronic componentscontaining leadina glassor ceramic otherthandielectric ceramicin capacitors, e.g.

piezoelectronicdevices,orina

glassorceramicmatrixcompound

7(c)IILeadindielectricceramicincapacitorsforaratedvoltageof125VACor250VDCorhigher

8(b)Cadmiumanditscompoundsinelectricalcontacts

15Leadinsolderstocompleteaviableelectricalconnectionbetween semiconductordieandcarrierwithinintegratedcircuitflip

chippackages

34Leadincermet‐basedtrimmerpotentiometerelements

Page 4

This page has been intentionally left blank.

Page 5

D397-52-880 Issue D

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ...................................................................................................1

1.2 Outline description ...................................................................................................... 2

2 Technical data ....................................................................................3

2.1 Mechanical data .......................................................................................................... 3

2.2 Operating and storage data ............................................................................................ 3

2.3 Electrical data ............................................................................................................ 3

2.3.1 D.C. Power connector ................................................................................................... 3

2.3.2 Profibus connector ...................................................................................................... 4

2.3.3 RS232 Connector ......................................................................................................... 5

2.3.4 Front panel USB Connector ............................................................................................. 5

3 Installation ............................................... ................................... .......6

3.1 Unpack and inspect ...................................................................................................... 6

3.2 Fitting the module .......................................................................................................6

3.2.1 Rack mounting ........................................................................................................... 7

3.2.2 Panel mounting .......................................................................................................... 7

3.2.3 DIN rail mounting ........................................................................................................ 7

3.3 Electrical connections ................................................................................................... 8

3.3.1 Connection to a PDT Port only ......................................................................................... 9

3.3.2 Connection to a PDT Port and a LON Port ........................................................................... 9

3.4 Profibus network connection .......................................................................................... 9

Contents

4 Operation ........................................................................................ 10

4.1 Profibus system information ..........................................................................................10

4.2 Quick start set up instructions ........................................................................................10

4.3 Front panel display .....................................................................................................10

4.4 Address set-up ...........................................................................................................11

4.5 Baud-rate ................................................................................................................13

4.6 Software format ........................................................................................................13

4.6.1 Parameterisation ........................................................................................................14

4.6.2 Configuration ............................................................................................................14

4.6.3 Diagnostics description ................................................................................................15

4.6.4 Data exchange values ..................................................................................................15

4.7 Software modules .......................................................................................................16

4.7.1 Module 990 - Pump Family ............................................................................................17

4.7.2 Module 991 - Pump Serial Number ...................................................................................17

4.7.3 Module 110 - Remote/Local state ....................................................................................18

4.7.4 Module 992 - Alert Status ..............................................................................................18

4.7.5 Module 11 - Pump Control .............................................................................................19

4.7.6 Module 14 - DP Run Hours .............................................................................................19

4.7.7 Module 20 - DP Number of Starts .....................................................................................19

4.7.8 Module 21 - DP Time to Stop ..........................................................................................19

4.7.9 Module 3 - DP Current ..................................................................................................19

4.7.10 Module 4 - DP Power ...................................................................................................19

4.7.11 Module 184 - DP Speed Absolute .....................................................................................20

4.7.12 Module 994 - DP Speed Relative ......................................................................................20

4.7.13 Module 699 - DP Speed Demand ......................................................................................20

4.7.14 Module 55 - DP Body Temperature ...................................................................................20

4.7.15 Module 57 - DP End Cover Temperature ............................................................................20

gea/0029/09/16

4.7.16 Module 70 - DP Body Temperature 2 .................................................................................20

© Edwards Limited 2016. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

D397-52-880 Issue D

Contents

4.7.17 Module 63 - Pump Internal Temperature ...........................................................................21

4.7.18 Module 12 - MB Override ...............................................................................................21

4.7.19 Module 7 - MB Current .................................................................................................21

4.7.20 Module 8 - MB Power ...................................................................................................21

4.7.21 Module 174 - MB Speed Absolute .....................................................................................21

4.7.22 Module 995 - MB Speed Relative ......................................................................................21

4.7.23 Module 698 - MB Speed Demand ......................................................................................22

4.7.24 Module 54 - MB Body Temperature ...................................................................................22

4.7.25 Module 62 - MB End Cover Temperature ............................................................................22

4.7.26 Module 812 - PB Override ..............................................................................................22

4.7.27 Module 817 - PB Run Hours ............................................................................................22

4.7.28 Module 818 - PB Number of Starts ...................................................................................23

4.7.29 Module 820 - PB Current ...............................................................................................23

4.7.30 Module 821 - PB Power .................................................................................................23

4.7.31 Module 823 - PB Speed Absolute .....................................................................................23

4.7.32 Module 996 - PB Speed Relative ......................................................................................23

4.7.33 Module 697 - PB Speed Demand ......................................................................................23

4.7.34 Module 813 - PB Body Temperature ..................................................................................23

4.7.35 Module 814 - PB En d Cover Temperatu re ...........................................................................24

4.7.36 Module 35 - Nitrogen Flow Rate ......................................................................................24

4.7.37 Module 68 - Active Utility Control ....................................................................................24

4.7.38 Module 39 - Exhaust Pressure .........................................................................................24

4.7.39 Module 56 - Exhaust Gas Temperature ..............................................................................24

4.7.40 Module 84 - Exhaust Pipe Temperature .............................................................................24

4.7.41 Module 52 - Water Flow Rate .........................................................................................25

4.7.42 Module 161 - Gate Valve ...............................................................................................25

4.7.43 Module 53 - Active Gauge .............................................................................................25

4.7.44 Module 993 - Profibus Software Version .............................................................................25

5 Maintenance ..................................................................................... 26

5.1 Fault finding .............................................................................................................26

6 Storage and disposal .............................. ..... ..... ..... ..... ......................... 27

6.1 Storage ...................................................................................................................27

6.2 Disposal ...................................................................................................................27

7 Spares and accessories ......................................................................... 28

7.1 Introduction .............................................................................................................28

7.2 Accessories ............................................................................................................... 2 8

Index ........................................................... ................................... 29

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Pin connections for the 2-way power connector .................................................................... 3

2 Pin connections for 9-way ‘D’ type socket ........................................................................... 4

3 Pin connections for 9-way ‘D’ type plug ............................................................................. 5

4 Dimensions of the Profibus module (mm) ............................................................................6

5 Panel mounting the module (mm) .................................................................................... 7

6 DIN rail mounting the module ......................................................................................... 8

7 Profibus module rear connections .................................................................................... 9

8 Profibus front panel display ...........................................................................................10

Page ii © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

D397-52-880 Issue D

Tables

Table Page

1 Pin connections for 9-way ‘D’ type socket ........................................................................... 4

2 Pin connections for 9-way ‘D’ type plug ............................................................................. 5

3 Component checklist .................................................................................................... 6

4 Drypump connections ................................................................................................... 8

5 Front panel symbols and their functions ............................................................................11

6 Address switch settings ................................................................................................11

7 Summary of software modules ........................................................................................16

8 Fault finding guide ......................................................................................................26

Contents

© Edwards Limited 2016. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

D397-52-880 Issue D

This page has been intentionally left blank.

Page iv © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

D397-52-880 Issue D

CAUTION

WARNING

1Introduction

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards Drypump Profibus Module.

You must use the Module as specified in this manual.

Read this manual before you install and operate the Module. Important safety information is highlighted as WARNING

and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is defined below.

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

Introduction

Throughout this manual, page, figure or title numbers are sequential.

The following labels appear on the module:

Warning - refer to accompanying documentation.

Edwards offer European customers a recycling service.

© Edwards Limited 2016. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

D397-52-880 Issue D

WARNING

WARNING

WARNING

Introduction

1.2 Outline description

Edwards take no responsibility for damage or injury caused by improper use of the equipment.

This equipment provides remote control of an Edwards Drypump. You must refer to the safety

information in the Drypump instruction manual.

This unit should not be relied upon for safety related functions.

The Drypump Profibus Module p rovides a Profibus DP V0 slave interface for Edwards drypumps with a PDT (Pump

Display Terminal) port. This does not include older pumps with a PDM (Pump Display Module) port. The module

communicates with the pump using the RS232 interface. Commands received from the Profibus network are relayed

to the pump. Data from the pump is stored in the module and transmitted over the Profibus network when requested.

Most drypumps provide the DC power for the module. The front panel of the module has four L EDs which indicate the

status of the module and the Profibus network. he Profibus slave address is set using ro tary switches. The ba ck panel

of the module has a 9-way 'D' connector for the Profibus network, a 9-way 'D' connector for the RS232 link to the

drypump and a power connector.

Page 2 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

2Technical data

WARNING

2.1 Mechanical data

Weight 0.28 kg

Dimensions 129 x 30.5 x 117 mm

Refer to Section 3.2 for installed dimensions and panel cut-out.

2.2 Operating and storage data

Ambient operating temperature 0 °C to 40 °C

Humidity Maximum 90% RH non-condensing

Maximum altitude 2000 m

IP rating IP30 - indoor use only

Ambient storage temperature -30°C to 70°C

D397-52-880 Issue D

Technical data

2.3 Electrical data

Do not exceed the maximum supply voltage. Excessive supply voltage will cause permanent

damage to the control electronics and may result in a mechanical hazard in some failure

conditions.

Electrical supply 9 V d.c. to 52 V d.c.

Power consumption 5 W maximum Switch on surge 500 mA maximum

Fuse No internal fuse

2.3.1 D.C. Power connector

Connector type 2 Way Receptacle. Mating part is cable-mount

Terminal Block. Suitable parts inclu de: Phoenix MSTB

2.5/2-G-5.08; Weidmuller BLZ 5.08/2; Amp 796634-2;

IMO 21.950/2 (Refer to Figure 1).

Figure 1 - Pin connections for the 2-way power connector

© Edwards Limited 2016. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

D397-52-880 Issue D

Technical data

2.3.2 Profibus connector

Connector type 9-way ‘D’ type socket (Refer to Figure 2)

Profibus Data signals Electrically compliant with RS485 specification.

Profibus Power Supply 10 mA supply (protected) for external terminator

Chassis For Profibus cable screen connection

Repeater control signal Digital signal, nominally 0-5 V but with series 340 ohm

Figure 2 - Pin connections for 9-way ‘D’ type socket

Isolated from chassis.

resistors if required.

resistor. High = module transmitting. Low = Receiving

or Idle.

Table 1 - Pin connections for 9-way ‘D’ type socket

Pin Allocation

1

2

3

4

5

6

7

8

9

Shell

Chassis (box)

Not connected

Profibus Data + (B)

Control Signal for Repeater

Profibus Data reference (isolated)

Profibus 5V output (isolated)

Not connected

Profibus Data - (A)

Not connected

Chassis (box)

Page 4 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

2.3.3 RS232 Connector

Connector type 9-way ‘D’ type plug (Refer to Figure 3)

For connection to serial comms port of SCU-750/1500

controller only.

RS232 protocol 9600 baud, 1 stop bit, 8 data bits, no parity

Figure 3 - Pin connections for 9-way ‘D’ type plug

Table 2 - Pin connections for 9-way ‘D’ type plug

D397-52-880 Issue D

Technical data

Pin Allocation

1

2

3

4

5

6

7

8

9

Shell

Not connected

RS232 receive

RS232 transmit

Not connected

RS232 common

Not connected

Not connected

Not connected

Not connected

Chassis (box)

2.3.4 Front panel USB Connector

Connector type USB Micro-B socket

Function Software upgrade by Edwards service personnel only

© Edwards Limited 2016. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

D397-52-880 Issue D

CAUTION

Installation

3 Installation

3.1 Unpack and inspect

Remove all of the packaging material and check the module . If the module is damaged, follow the Edwards return of

equipment procedures that are laid out in the back of this manual. Do not use the module if it is damaged.

Check that your package contains the items that are listed in Table 3. If any of the s e it ems are missing, notify your

supplier in writing within three days. If the module is not to be used immediately, store the module in suitable

conditions as described in Section 6.1.

Table 3 - Component checklist

?

)

Quantity Description Check(

1Module

1 Instruction manual

1 Cable for connection between pump PDT port and Profibus

module

2DIN rail clips

2 Mounting screws

4 Rubber feet

1 CD (includes GSD file)

3.2 Fitting the module

The unit is IP30 rated. Please ensure that the unit is not installed where fluids can enter into the module.

The module can be rack mounted, panel mounted, DIN rail mounted or free-standing. Sufficient space must be

provided at the rear of the unit for the cables. If right-angled connectors are used additional space will be requ ired.

If the unit is to be used free-standing it should be laid flat to ensure stability. The four self-adhesive rubber feet can

be used to prevent sliding. Figure 4 shows the dimensions of the module with the rubber feet attached.

Figure 4 - Dimensions of the Profibus module (mm)

Page 6 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

D397-52-880 Issue D

3.2.1 Rack mounting

For rack mounting the unit should be fitted in a space 6HP wide x 3U high, using the 2-off M2.5 screws provided.

3.2.2 Panel mounting

For panel mounting cut the aperture in the panel using the dimensions shown in Figure 5. The module can be fixed

into the panel with the 2-off M2.5 screws.

Figure 5 - Panel mounting the module (mm)

Installation

3.2.3 DIN rail mounting

For DIN rail mounting the 2 clips should be attached to the module using 2-off M3 screws provided (one in the centre

of each clip), as shown in Figure 6. The clips should then be roughly aligned with the box sides. The clips can then

be fitted to a suitable DIN-rail, as shown in Figure 6.

It is recommended to use end stops on a DIN rail system.

© Edwards Limited 2016. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

D397-52-880 Issue D

WARNING

Installation

3.3 Electrical connections

Figure 6 - DIN rail mounting the module

When installing the module ensure that the cables are laid out and secured in a manner that will

not create a trip hazard.

The Profibus module should not be connected to a Drypump when the pump or tool are "On Process".

The Profibus module uses a Drypump's PDT port (normally a 5-way XLR socket) for communication with the Drypump.

It is not possible to connect any other devices to the same PDT port when that port is used by the Profibus module,

for example a PDT.

Some PDT connectors are not able to supply enough power to operate the Profibus modu le . However for mos t pump

types an alternative power source will be available. See Table 4 below.

Table 4 - Drypump connections

Drypump Type PDT Port Position Drypump Connection Ports

iXH Front Use rear PDT port only

iXH Rear PDT port only (see Section 3.3.1)

iXL (Large) Front Use rear PDT port only

iXL (Large) Rear PDT port only (see Section 3.3.1)

pXH Front Use rear PDT port only

pXH Rear PDT port only (see Section 3.3.1)

iGX Remote Front PDT port only (see Section 3.3.1)

iGX Remote Rear PDT + LON for power (see Section 3.3.2)

iGX Systemable Either External power required - Contact Edwards for advice

pHMB Upper PDT port only (see Section 3.3.1)

pHMB Lower PDT + LON for power (or upper PDT only)

iH Front PDT + LON for power (see Section 3.3.2)

iF Front PDT + LON for power (see Section 3.3.2)

If the pump has several accessories at tached, guidance should be so ught from Edward s to ensure the pump is ab le to

provide enough power.

Page 8 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

D397-52-880 Issue D

3.3.1 Connection to a PDT Port only

If connecting to a PDT port capable of powering the Profibus module then either use the cable provided in the kit

(5m long) or cable length may be increased using 5-way XLR extension cables. See Section 7.2.

Connect the 9-way D-type free socket and the DC power connector to the Profibus module. Connect the 5-way XLR

plug to the Drypump PDT port.

3.3.2 Connection to a PDT Port and a LON Port

Where connections to both a PDT socket and a LON socket is required the LON/PDT power/RS-232 splitter cable mu st

be used. See Section 7.2. This is to be used with the cable provided in this kit. The 5-way XLR plug of the long cable

should be connected to the 5-way XLR socket of the short splitter cable to make one cable assemb ly. The XLR plugs

can then be connected to the pump and the 9-way D-type and power connector connected to the Profibus module.

Cable length may be increased using 5-way XLR extension cables. See Section 7.2.

Figure 7 - Profibus module rear connections

Installation

3.4 Profibus network connection

Standard Profibus network cables and connectors compliant to EN50170 should be used to connect the Edwards

Drypump Profibus module to your system.

Bus-termination is not supplied with the module, but must be used as for a normal Profibus DP system. Bus

termination must be used at both end s of th e Prof ibus tr unk and not anywhere else. If the module is placed at one

end of the trunk a connector containing the standard termination resistors should be used. The appropriate 5 V and

0 V signals are supplied on the standard pins for this purpose.

© Edwards Limited 2016. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

D397-52-880 Issue D

Operation

4 Operation

4.1 Profibus system information

The Profibus module is for connection to a Profibus DP network and operates as a V0 slave only.

The Profibus master requires a GSD file for each slave. The GSD file for this slave is contained on the CD supplied

with the unit and has the file name "EDW0BC2.GSD", which is registered with the Profibus association.

When configuring your system the "ID" number will be 0BC2 and the unit's description will be “Edwards Drypump”.

Note: The GSD file should not be altered.

4.2 Quick start set up instructions

1. Install the module and connect the cables as described in Section 3.

2. Set the address switches on the Profibus module. See Section 4.4.

3. Apply power (or power cycle the Profibus module, for example by disconnecting then reconnecting the power

connector).

4. Load the GSD file into your Profibus system configurator.

5. Select "Edwards Drypump" as a slave and set the address to match the address switches.

6. Select Module 11 to provide on and off control of the Drypump and select Module 992 to monitor pump alert

state. Add other Profibus software modules as required.

4.3 Front panel display

Figure 8 - Profibus front panel display

Page 10 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 19

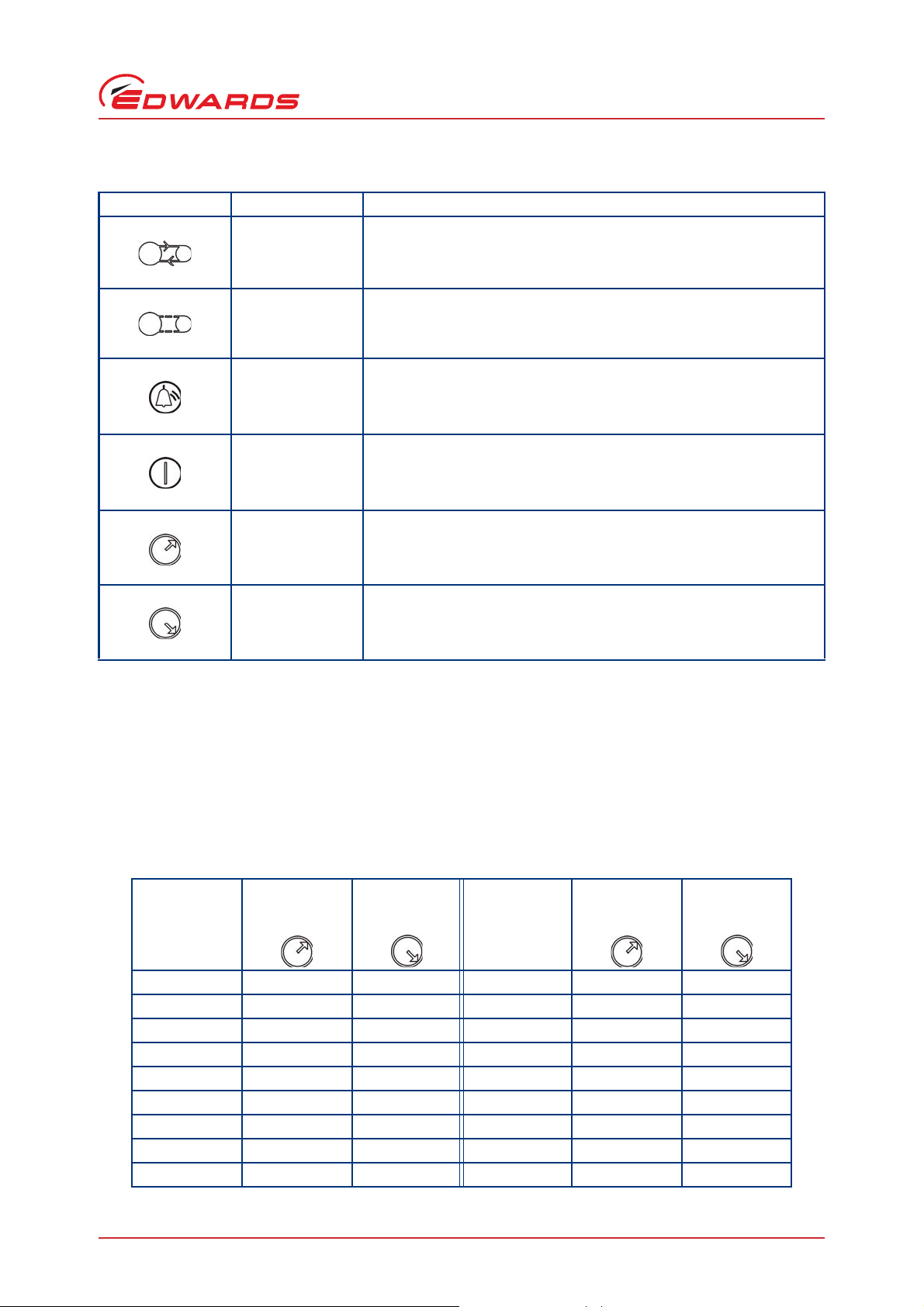

Table 5 - Front panel symbols and their functions

Symbol Name Function

Data exchange Module is in data exchange as defined by the Profibus standard.

Off-line Module is not in data exchange as defined by the Profibus standard.

Error ON at the same as Offline LED = Configuration or parameterisation

error:

Flashing at 1 Hz = Invalid address selected.

Power Internal 5 V supply is operating.

D397-52-880 Issue D

Operation

Upper address

switch

Lower address

switch

Sets value of upper nibble of address (Hexadecimal).

Sets value of lower nibble of address (Hexadecimal).

4.4 Address set-up

The module address can be set from 1 to 125 using the two hexadecimal rotary switches on the front panel. The lower

switch defines the lower half of the address byte (nibble) and the uppe r switch defines the upper half of the address

byte. Each node on a Profibus network must have a unique address. The address swi tches will only be read by the

unit at power-up. Any change of address setting after power-up will be ignored until next power-up.

The following table may assist.

Table 6 - Address switch settings

Address in

Decimal

Upper switch

setting

Lower switch

setting

Address in

Decimal

Upper switch

setting

Lower switch

setting

000633F

1016440

2026541

3036642

4046743

5056844

6066945

7077046

8087147

© Edwards Limited 2016. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

D397-52-880 Issue D

Operation

Table 6 - Address switch settings (continued)

Upper switch

Address in

Decimal

9097248

10 0 A 73 4 9

11 0 B 74 4 A

12 0 C 75 4 B

13 0 D 76 4 C

14 0 E 77 4 D

150F784E

16 1 0 79 4 F

17 1 1 80 5 0

18 1 2 81 5 1

19 1 3 82 5 2

20 1 4 83 5 3

21 1 5 84 5 4

22 1 6 85 5 5

23 1 7 86 5 6

24 1 8 87 5 7

25 1 9 88 5 8

26 1 A 89 5 9

27 1 B 90 5 A

28 1 C 91 5 B

29 1 D 92 5 C

30 1 E 93 5 D

311F945E

32 2 0 95 5 F

33 2 1 96 6 0

34 2 2 97 6 1

35 2 3 98 6 2

36 2 4 99 6 3

37 2 5 100 6 4

38 2 6 101 6 5

39 2 7 102 6 6

40 2 8 103 6 7

41 2 9 104 6 8

42 2 A 105 6 9

43 2 B 106 6 A

44 2 C 107 6 B

45 2 D 108 6 C

setting

Lower switch

setting

Address in

Decimal

Upper switch

setting

Lower switch

setting

Page 12 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

Table 6 - Address switch settings (continued)

D397-52-880 Issue D

Operation

Upper switch

Address in

Decimal

46 2 E 109 6 D

47 2 F 110 6 E

48 3 0 111 6 F

49 3 1 112 7 0

50 3 2 113 7 1

51 3 3 114 7 2

52 3 4 115 7 3

53 3 5 116 7 4

54 3 6 117 7 5

55 3 7 118 7 6

56 3 8 119 7 7

57 3 9 120 7 8

58 3 A 121 7 9

59 3 B 122 7 A

60 3 C 123 7 B

61 3 D 124 7 C

62 3 E 125 7 D

setting

Lower switch

setting

Address in

Decimal

Upper switch

setting

Lower switch

setting

Note: If the address is set to a value greater than 125 (decimal) or 0, the RED error LED will flash at 1 Hz and the

module will go online. If this occurs either, change the address and cycle the power or remove power and

change the address.

4.5 Baud-rate

All 10 standard DP baud-rates are supported. These are: 9.6kBd; 19.2kBd; 45.45kBd; 93.75kBd; 187.5kBd; 500kBd;

1.5MBd; 3MBd; 6MBd; 12MBd. The unit has no facility for adjusting baud-rate as detection is automatic, and it will

therefore respond to the baud-rate chosen by the master.

4.6 Software format

The Slave software is based upon a modular configurab le architecture so the us er has considerable cont rol of the

contents of the data exchange messages.

The software modules (defined in the GSD files) relate to the controller serial communications objects.

When the unit is linked onto the Profibus it will be parameterised and then configured before entering data exchange.

The configuration choices ar e in the GSD file and it s comments describe th e data content of the input and output

bytes. These choices will often be made using a third party configurator such as SyCon that presents a user-friendlier

interface.

16-bit values are transmitted with the MSB first and the LSB last.

© Edwards Limited 2016. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

D397-52-880 Issue D

Operation

4.6.1 Parameterisation

Only the Profibus mandatory 7 bytes of parameterisat ion data are used by the Dryp ump Profibus slave. None of these

values can be adjusted by the user.

4.6.2 Configuration

During configuration the user can define what modules are required and in which order the data is transferred. The

unit adds the input and output data bytes to the message maps in the order that they are de fined in the configuration

message.

Example:

Module = Mod_A 3 bytes in (Ai1, Ai2, Ai3), 1 byte out (Ao1)

Module = Mod_B 2 bytes in (Bi1, Bi2), 2 bytes out (Bo1, Bo2)

A) Configure Mod_A, Mod_B gives

Output map: -

Byte1 Byte2 Byte3

Ao1 Bo1 B02

Input map:-

Byte1 Byte2 Byte3 Byte4 Byte5

Ai1 Ai2 Ai3 Bi1 Bi2

B) Configure Mod_B, Mod_A gives

Output map:-

Byte1 Byte2 Byte3

Bo1 Bo2 Ao1

Input map:-

Byte1 Byte2 Byte3 Byte4 Byte5

Bi1 Bi2 Ai1 Ai2 Ai3

Data is always referred to the Master so outp ut is control data from Mas ter to Slave a nd input da ta is feed ba ck from

Slave to Master. There are many software modules a nd many bytes of da ta. Care must be tak en in correctly selecting

and aligning the data into your system.

Modules should have no more than one entry in the configuration list. For reliable operation do not exceed the

maximum number of configuration items.

Configuration item Maximum number

Modules 40

Input and output bytes added together 116

Page 14 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 23

D397-52-880 Issue D

4.6.3 Diagnostics description

The modules use extended diagnostics in the format below.

Max_Diag_Data_Len = 12

Bytes 1-6 7 8 and 9 10 and 11 12

Mandatory No of bytes of

Description

A configuration error will be signalled if the number of modules co nfigured exceeds the maximum number allowed

by the Profibus module.

Loss of serial comms may take up to 20 seconds to be signalled. If this occurs the Slave will signal the Master with a

‘Data High’ flag in the Frame Control byte but will continue to be in data exchange with the data values all set to

zero. The extended diagnostics message will be available to the Master.

If RS232 communications are restored the Slave will again signal the Master with a ‘Data High’ flag in the Frame

Control byte and will return to ‘good’ data exchange values. Again the extended diagnostics message will be available

to the Master.

extended

diagnostics (6)

Not used (values

always zero)

Module failed

configuration,

MSB in 10, LSB

in 11

Serial comms

lost (0=OK,

1=lost)

Operation

4.6.4 Data exchange values

The Edwards Drypump GSD file has been designed to control all types of Edwards Drypumps with a PDT port. This

includes:

Many different pump families (for example iH, iGX, iXH).

Different pump types (standard Drypumps, mechanical boosters and proximity boosters).

Variations of which accessories are fitted (for example gas modules, exhaust and water sensors).

Due to the many possible hardware variations some of the GSD file modules will not be applicable or suitable for a

particular pump.

Rather than attempting to define the exact pump configuration before data exchange (a process that would take

several minutes) and signal a configuration error for an inappropriate Profibus configur ation select ion, the module

will accept any configuration and enter data exchange very quickly. However at the start of data exchange this means

almost no data will actually be available to the Profibus unit and thus not to the Profibus user. Instead a "CONDITION

BYTE" is appended to most of the configurable modules. The condition byte indicates whether the data in that module

is both present and valid. The condition byte uses bits as st atus flags. Flags are use d for 'Valid Object No.' and 'Valid

Reading'. A valid object number indicates the pump has messages for that object number. A valid reading indicates

that the object number does not have its "No Reading" flag set. These flags will show condition as invalid (flag bit

value of 0) until known to be valid. Thus data exchange will start with the Condition byte status flags set to invalid.

The user should ignore all other (preceding) data within that software module until both status flags indicate data is

valid.

The condition byte also provides Alarm and Warning bit flags. See below.

Bit No. Function Meaning of 0 Meaning of 1

7 Reserved

6 Reserved

5 Alarm No Alarm Alarm

4 Warning No Warning Warning

3 Reserved

2 Reserved

1 Valid Reading Invalid Valid Reading

0 Valid Object No. Invalid Valid Object

© Edwards Limited 2016. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 24

D397-52-880 Issue D

Operation

Thus a good condition byte will have the value 03 (hex). Data is not valid (should be ignored) u nless both valid flags

are set.

The Warning and Alarm flags may be inhibited in the Drypump setup. In this case a Warning or Alarm will not be

indicated over Profib us.

The update rate (latency) varies significantly for different parameters, typically between a second and a minute. In

addition a Drypump takes up to 15 seconds from power-up before it starts to communicate with peripherals.

4.7 Software modules

Terminology: DP=DryPump; MB=Mechnical Booster; PB=Proximity Booster.

Table 7 - Summary of software modules

Module No. Module Name No. of Output bytes No. of Input bytes Units

990 Pump Family 0 2 991 Pump Serial Number 0 17 110 Remote/Local State 0 3 992 Alert Status 0 4 -

11 Pump Control 1 2 14 DP Run Hours 0 3 hrs

20 DP Number of Starts 0 3 21 DP Time to Stop 0 3 s

3 DP Current 0 3 0.1A

4DP Power 0 3 0.1kW

184 DP Speed Absolute 0 3 0.1Hz

994 DP Speed Relative 0 3 0.1%

699 DP Speed Demand 2 0 0.1%

55 DP Body Temperature 0 3 °C

57 DP End Cover Temperature 0 3 °C

70 DP Body Temperature 2 0 3 °C

63 Pump Internal Temperature 0 3 °C

12 MB Override 1 2 -

7MB Current 0 3 0.1A

8MB Power 0 3 0.1kW

174 MB Speed Absolute 0 3 0.1Hz

995 MB Speed R elative 0 3 0.1%

698 MB Speed Demand 2 0 0.1%

54 MB Body Temperature 0 3 °C

62 MB End Cover Temperature 0 3 °C

812 PB Override 1 2 817 PB Run Hours 0 3 hrs

818 PB Number of Starts 0 3 820 PB Current 0 3 0.1A

821 PB Power 0 3 0.1kW

Page 16 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 25

D397-52-880 Issue D

Table 7 - Summary of software modules (continued)

Module No. Module Name No. of Output bytes No. of Input bytes Units

823 PB Speed Absolute 0 3 0.1Hz

996 PB Speed Relative 0 3 0.1%

697 PB Speed Demand 2 0 0.1%

813 PB Body Temperature 0 3 °C

814 PB End Cover Temperature 0 3 °C

35 Nitrogen Flow Rate 0 3 slm

68 Active Utility Control 1 2 -

39 Exhaust Pressure 0 3 0.1kPa

56 Exhaust Gas Temperature 0 3 °C

84 Exhaust Pipe Temperature 0 3 °C

52 Water Flow Rate 0 3 0.1L/min

161 Gate Valve 1 2 -

53 Active Gauge 0 6 993 Profibus Software Version 0 2 -

Operation

4.7.1 Module 990 - Pump Family

Output bytes:None

Input bytes: Byte 1 is pump type. See table below for example values.

V alue (in decimal) Pump Family

1iH

2iL

4iF

15 EPX

18 iGX

19 pHMB

20 System Controlle r

22 GX

25 iXH

26 iXL120

27 pXH

28 iXL (Large)

Byte 2 is condition byte (see Section 4.6.4).

4.7.2 Module 991 - Pump Serial Number

Output bytes: None

Input bytes: Bytes 1-16 are ASCII characters for Pump serial number

Byte 17 is condition byte (see Section 4.6.4).

© Edwards Limited 2016. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 26

D397-52-880 Issue D

Operation

4.7.3 Module 110 - Remote/Local state

Drypumps have more than one control device that in principle can control the pump. The Drypump will only let one

control device have control at a time. This is indicated by this module. At power-up no control device has control.

To start a pump, or turn ON any item like a valve, a control device (e.g. Profibus, PDT) must take control. That

control device must release control before another control device can turn ON any item. However, in some cases a

control device can turn OFF an item without having control. The Profibus module only takes control of the pump

when it receives a run command from the tool using Module 11 and no other control device has control.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigne d number which is the object number of the unit which has control

of the pumping system. Example values (decimal): 0=No Control; 61=Drypump Front Panel;

101=PDM1; 102=PDM2; 103=PDT Front; 104=PDT Rear; 110=Profibus in Control; 221=Micro-TIM.

Byte 3 is condition byte (see Section 4.6.4).

4.7.4 Module 992 - Alert Status

This module is a summary of all the warnings and alarms from the pump (except those inhibited by the Drypump

internal setting). It does not just sign al alarms and warnings from configured Profibus modules but signals all rece ived

alarms and warnings including from functions that cannot be configured through Profibus.

The four input bytes are bit flags. If a flag value is 0 that function has no alert. If the exact caus e of a warning is

unclear it is recommended the user investigate the pump locally using a PDT.

Output bytes: None

Input bytes: Byte 1 Bit 7 = Alarm - EMS system

Byte 1 Bit 6 = Alarm - Drypump drive

Byte 1 Bit 5 = Alarm - Mechanical booster drive

Byte 1 Bit 4 = Alarm - Proximity booster drive

Byte 1 Bit 3 = Alarm - Drypump temperature

Byte 1 Bit 2 = Alarm - Mechanical booster temperature

Byte 1 Bit 1 = Alarm - Proximity booster temperature

Byte 1 Bit 0 = Alarm - Exhaust temperature

Byte 2 Bit 7 = Alarm - Exhaust pressure

Byte 2 Bit 6 = Alarm - Gas

Byte 2 Bit 5 = Alarm - Gate valve

Byte 2 Bit 4 = Alarm - Water flow

Byte 2 Bit 3 = Alarm - Service due

Byte 2 Bit 2 = Alarm - System controller - system

Byte 2 Bit 1 = Alarm - System controller - device

Byte 2 Bit 0 = Alarm - other (any alarm not in categories above).

Byte 3 Bit 7 = Warning - EMS system

Byte 3 Bit 6 = Warning - Drypump drive

Byte 3 Bit 5 = Warning - Mechanical booster drive

Byte 3 Bit 4 = Warning - Proximity booster drive

Byte 3 Bit 3 = Warning - Drypump temperature

Byte 3 Bit 2 = Warning - Mechanical booster temperature

Byte 3 Bit 1 = Warning - Proximity booster temperature

Byte 3 Bit 0 = Warning - Exhaust temperature

Byte 4 Bit 7 = Warning - Exhaust pressure

Byte 4 Bit 6 = Warning - Gas

Byte 4 Bit 5 = Warning - Gate valve

Byte 4 Bit 4 = Warning - Water flow

Byte 4 Bit 3 = Warning - Service due

Byte 4 Bit 2 = Warning - System controller - system

Byte 4 Bit 1 = Warning - System controller - device

Byte 4 Bit 0 = Warning - other (any warning not in categories above).

For example input bytes 00 80 00 E0 would indicate an exhaust pressure alarm + warn ings for exhaust

pressure, gas and gate valve.

To start the pump after the pump has stopped due to an alarm, the tool controller must send a Stop command

followed by a Start command. See Section 4.7.5.

Page 18 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 27

D397-52-880 Issue D

4.7.5 Module 11 - Pump Control

This is the main control software module. It is used to start and stop ALL connected pump s in sequence. The general

start sequence is DP(s) then MB(s) then PB(s). The shut down sequence is the reverse.

Output byte: Single byte is pump control.

Values: 1=On

2=Fast shut down,

3=Auto shut down (slow),

Other values - ignored.

Note: The value is only sent from the Profibus module to the pump on change of demand state (to prevent rapid

cycling if the pump had an alarm state). Thus if the demand state is on, but the pump has been stopped by

something other than the Profibus module, it will be necessary to demand an Off and then an On to restart

the pump.

Input bytes: Byte 1 reports the state (feedback) specifically of the DP.

Values: 0=Off

1=Off going On (starting)

2=On going off fast (stopping fast)

3=On going off slow (stopping slow)

4=On.

2nd input byte is condition byte (see Section 4.6.4).

Operation

4.7.6 Module 14 - DP Run Hours

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for DP run time in hours.

Byte 3 is condition byte (see Section 4.6.4).

4.7.7 Module 20 - DP Number of Starts

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number which is the number of times the DP has been

started.

Byte 3 is condition byte (see Section 4.6.4).

4.7.8 Module 21 - DP Time to Stop

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for number of seconds it will take the pump to stop.

If pump is not in the process of stopping the value will be zero.

Byte 3 is condition byte (see Section 4.6.4).

4.7.9 Module 3 - DP Current

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit signed number for DP current in 0.1A.

Byte 3 is condition byte (see Section 4.6.4).

4.7.10 Module 4 - DP Power

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for DP power in 0.1kW.

Byte 3 is condition byte (see Section 4.6.4).

© Edwards Limited 2016. All rights reserved. Page 19

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 28

D397-52-880 Issue D

Operation

4.7.11 Module 184 - DP Speed Absolute

This module will only be valid on inverter driven pumps.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for actual DP speed in 0.1Hz.

Byte 3 is condition byte (see Section 4.6.4).

4.7.12 Module 994 - DP Speed Relative

This module will only be valid on inverter driven pumps.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for actual DP speed in 0.1% of configured full speed.

Byte 3 is condition byte (see Section 4.6.4).

4.7.13 Module 699 - DP Speed Demand

This module should only be used on inverter driven pumps.

Output bytes: 2 Bytes which are a 16-bit unsigned number for DP speed demand in 0.1% of configured full speed.

Input bytes: None

4.7.14 Module 55 - DP Body Temperature

The actual meaning and measurement location of this temperature measurement will vary between pump families

and pump types, even if a valid temperature reading is indicated by the condition byte.

For iXH parameter is DP body temperature

For iGX parameter is DP body temperature

For iH/iF/iL parameter is DP motor temperature

Output bytes: None

Input bytes: Bytes 1 and 2 are a 16-bit signed number for DP temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

4.7.15 Module 57 - DP End Cover Temperature

The actual meaning and measurement location of this temperature measurement will vary between pump families

and pump types, even if a valid temperature reading is indicated by the condition byte.

For iXH parameter is DP end cover temperature

For iGX parameter is DP motor temperature

For iH/iF/iL parameter is DP body temperature

Output bytes: None

Input bytes: Bytes 1 and 2 are a 16-bit signed number for DP temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

4.7.16 Module 70 - DP Body Temperature 2

The actual meaning and measurement location of this temperature measurement will vary between pump families

and pump types, even if a valid temperature reading is indicated by the condition byte.

For iXH parameter is DP body temperature 2 (but not fitted to most pumps)

For iGX parameter is Not used

For iH/iF/iL parameter is DP High Vacuum Stage (but only fitted to the largest pumps)

Output bytes: None

Input bytes: Bytes 1 and 2 are a 16-bit signed number for DP temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

Page 20 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 29

D397-52-880 Issue D

4.7.17 Module 63 - Pump Internal Temperature

The actual meaning and measurement location of this temperature measurement will vary between pump families

and pump types, even if a valid temperature reading is indicated by the condition byte.

For iXH parameter is DP internal temperature

For iGX parameter is Not used

For iH/iF/iL parameter is Not used

Output bytes: None

Input bytes: Bytes 1 and 2 are a 16-bit signed number for temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

4.7.18 Module 12 - MB Override

This module provides MB state feedback. It can als o be used to override the control of Mod ule 11 (as normally MB

operation would follow DP) to stop a booster. It can fu rther start a booster, but only if the Profibus module has

control of the pump. (See Section 4.7.3). Use this command with caution as if the Profibus module does not have

control it will be possible to stop the booster but not restart it. It is also not recommended to run the MB with the

DP stopped.

Output byte: Single byte is MB override.

Values: 1=On

2=Off

Other values - ignored.

Operation

Note: Demand value is only sent from the Profibus module to the pump on change of state.

Input bytes: Byte 1 reports the state (feedback) specifically of the booster.

Values: 0=Off

1=Off going on

2=On going off fast

3=On going off slow

4=on.

2nd input byte is condition byte (see Section 4.6.4).

4.7.19 Module 7 - MB Current

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit signed number for MB curre nt in 0.1A.

Byte 3 is condition byte (see Section 4.6.4).

4.7.20 Module 8 - MB Power

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for MB Power in 0.1kW.

Byte 3 is condition byte (see Section 4.6.4).

4.7.21 Module 174 - MB Speed Absolute

This module will only be valid on inverter driven pumps.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for actual MB speed in 0.1Hz.

Byte 3 is condition byte (see Section 4.6.4).

4.7.22 Module 995 - MB Speed Relative

This module will only be valid on inverter driven pumps.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for actual MB speed in 0.1% of configured full speed.

Byte 3 is condition byte (see Section 4.6.4).

© Edwards Limited 2016. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 30

D397-52-880 Issue D

Operation

4.7.23 Module 698 - MB Speed Demand

This module should only be used on inverter driven pumps.

Output bytes: 2 Bytes which are a 16-bit unsigned number for MB speed demand in 0.1% of configured full speed.

Input bytes: None

4.7.24 Module 54 - MB Body Temperature

The actual meaning and measurement location of this temperature measurement will vary between pump families

and pump types, even if a valid temperature reading is indicated by the condition byte.

For iXH parameter is MB body temperature

For iGX parameter is MB body temperature

For iH/iF/iL parameter is MB body temperature

Output bytes: None

Input bytes: Bytes 1 and 2 are a 16-bit signed number for MB temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

4.7.25 Module 62 - MB End Cover Temperature

The actual meaning and measurement location of this temperature measurement will vary between pump families

and pump types, even if a valid temperature reading is indicated by the condition byte.

For iXH parameter is MB end cover temperature

For iGX parameter is MB motor temperature

For iH/iF/iL parameter is Not Used.

Output bytes: None

Input bytes: Bytes 1 and 2 are a 16-bit signed number for MB temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

4.7.26 Module 812 - PB Override

This module provides PB state feedback. It can also be used to override the control of Module 11 (as normally PB

operation would follow DP) to stop a booster. It can fu rther start a booster, but only if the Profibus module has

control of the pump. (See Section 4.7.3). Use this command with caution as if the Profibus module does not have

control it may be possible to stop the booster but not restart it. It is al so not recom mended to run t he PB with the

DP stopped.

Output byte: Single byte is MB override.

Values: 1=On

2=Off

Other values - ignored.

Note: Demand value is only sent from the Profibus module to the pump on change of state.

Input bytes: Byte 1 reports the state (feedback) specifically of the booster.

Values: 0=Off

1=Off going on

2=On going off fast

3=On going off slow

4=On.

2nd input byte is condition byte (see Section 4.6.4).

4.7.27 Module 817 - PB Run Hours

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for PB run time in hours.

Byte 3 is condition byte (see Section 4.6.4).

Page 22 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 31

D397-52-880 Issue D

4.7.28 Module 818 - PB Number of Starts

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number which is the number of times the booster has been

started.

Byte 3 is condition byte (see Section 4.6.4).

4.7.29 Module 820 - PB Current

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit signed number for PB current in 0.1A.

Byte 3 is condition byte (see Section 4.6.4).

4.7.30 Module 821 - PB Power

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for PB Power in 0.1kW.

Byte 3 is condition byte (see Section 4.6.4).

4.7.31 Module 823 - PB Speed Absolute

Operation

This module will only be valid on inverter driven pumps.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for actual PB speed in 0.1Hz.

Byte 3 is condition byte (see Section 4.6.4).

4.7.32 Module 996 - PB Speed Relative

This module will only be valid on inverter driven pumps.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for actual PB speed in 0.1% of configured full speed.

Byte 3 is condition byte (see Section 4.6.4).

4.7.33 Module 697 - PB Speed Demand

This module should only be used on inverter driven pumps.

Output bytes: 2 bytes which are a 16-bit unsigned number for PB speed demand in 0.1% of configured full speed.

Input bytes: None

4.7.34 Module 813 - PB Body Temperature

The actual meaning and measurement location of this temperature measurement will vary between pump families

and pump types, even if a valid temperature reading is indicated by the condition byte.

For iXH parameter is PB body temperature

For pHMB parameter is PB body temperature

For iH/iF/iL parameter is Not Used

Output bytes: None

Input bytes: Bytes 1 and 2 are a 16-bit signed number for PB temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

© Edwards Limited 2016. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 32

D397-52-880 Issue D

Operation

4.7.35 Module 814 - PB End Cover Temperature

The actual meaning and measurement location of this temperature measurement will vary between pump families

and pump types, even if a valid temperature reading is indicated by the condition byte.

For iXH parameter is PB end cover temperature

For pHMB parameter is PB motor temperature

For iH/iF/iL parameter is Not Used

Output bytes: None

Input bytes: Bytes 1 and 2 are a 16-bit signed number for PB temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

4.7.36 Module 35 - Nitrogen Flow Rate

Requires gas module with this feature.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for Nitrogen flow rate in slm (Standard litres per

minute).

Byte 3 is condition byte (see Section 4.6.4).

4.7.37 Module 68 - Active Utility Control

Active Utility Control is used to reduce pump speed (saving energy) and nitrogen flow, when the chamber is not

processing. The Drypump may need to be set up to operate in this mode. The Profibus module must have control of

the pump to turn AUC on or off. (See Section 4.7.3).

Output byte: Single byte is AUC control. Values: 1=On (speed and flow reduced); 2=Off (speed and flow normal);

Other values - ignored.

Note: Demand value is only sent from the Profibus module to the pump on change of state.

Input Bytes: Byte1 AUC state

Values: 0=Off (normal)

1=Off going On

2=On going off fast

3=On going off slow

4=On (reduced).

2nd input byte is condition byte (see Section 4.6.4).

4.7.38 Module 39 - Exhaust Pressure

Requires gas module with this feature.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit signed number for exhaust pressure in 0.1 kPa.

Byte 3 is condition byte (see Section 4.6.4).

4.7.39 Module 56 - Exhaust Gas Temperature

Requires exhaust gas temperature sensor to be fitted.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit signed number for exhaust gas temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

4.7.40 Module 84 - Exhaust Pipe Temperature

Requires exhaust pipe temperature sensor to be fitted.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit signed number for exhaust pipe temperature in °C.

Byte 3 is condition byte (see Section 4.6.4).

Page 24 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 33

D397-52-880 Issue D

4.7.41 Module 52 - Water Flow Rate

Requires water flow sensor to be fitted.

Output bytes: None

Input bytes: Bytes 1 and 2 form a 16-bit unsigned number for water flow rate in 0.1 l/min.

Byte 3 is condition byte (see Section 4.6.4).

4.7.42 Module 161 - Gate Valve

This module provides gate valve control and demand status if a gate valve is fitted to the pump. It can be used to

turn off the valve, however, it can only turn on the valve if the Profibus module has control of the pump. (See

Section 4.7.3). Use this command with caution as if the Profibus module does not have control it may be possible to

turn off the valve but not turn it back on.

Output byte: Single byte is gate valve control.

Values: 1=On

2=Off

Other values - ignored.

Note: Demand value is only sent from the Profibus module to the pump on change of state.

Input bytes: Byte1 valve demand state

Values: 0=Off

1=Off going On

2=On going off fast

3=On going off slow

4=On.

2nd input byte is condition byte (see Section 4.6.4).

Operation

Note: If demand status is not the same as actual state, a warning will be raised in Module 992.

4.7.43 Module 53 - Active Gauge

Requires active gauge to be fitted.

Output bytes: None

Input bytes: Bytes 1-4 are 32-bit IEEE754 format floating point value.

Byte 5 is units (59=Pascals, 66=volts).

Byte 6 is condition byte (see Section 4.6.4).

4.7.44 Module 993 - Profibus Software Version

Output bytes: None

Input bytes: Input bytes are Profibus code version in ASCII

1st character is s/w type e.g. 0x50 = P (Production)

2nd character is revision letter e.g. 0x41 = A.

© Edwards Limited 2016. All rights reserved. Page 25

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 34

D397-52-880 Issue D

CAUTION

Maintenance

5Maintenance

5.1 Fault finding

In the event of a Profibus module failing to respond check the following:

Table 8 - Fault finding guide

Symptom Fault

Power LED not lit No DC supply or internal regulator faulty.

Off-line not lit and Error LED flashing. Address selection is above 125 (decimal) or 0,

Off-line LED is lit and Error LED is lit. Unsuitable parameterisation or configuration,

Off-line LED is lit and Error LED is not lit. Check unit’s address matches that being used

Power LED is lit and all other LED’s are not lit. Serial connection to controller disconnected or

Data exchange LED is lit but data is not

changing.

correct the address and re-power unit.

check extended diagnostics for module number.

by the master. Check Profibus cable connected.

Check Profibus master is on-line.

faulty or controller not powered on.

Serial connection has become faulty after

entering data exchange. Check extended

diagnostics for serial comms lost indication.

The Profibus module contains no user serviceable parts. Do not disassemble the module.

Page 26 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 35

D397-52-880 Issue D

6 Storage and disposal

6.1 Storage

Store the Profibus module in clean dry conditions until required. When required for us e, install the Profibus module

as described in Section 3.

6.2 Disposal

Dispose of the Profibus module and any components safely in accordance with all local and national safety and

environmental requirements.

Alternatively, you may be able to recycle the Profibus module and/or cables; contact Edwards or your supplier for

advice (also see below).

The Profibus module and associated cables are within the scope of the European Directive on Waste Electrical and

Electronic Equipment, 2002/96/EC. Edwards offer European customers a recycling service for the Profibus module/

cables at the end of the product’s life. Edwards' Registration Number as a UK producer of electrical and electronic

products is WEE/BF0054TQ. Contact Edwards for advice on how to return the Profibus module/cables for recycling.

Storage and disposal

© Edwards Limited 2016. All rights reserved. Page 27

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 36

D397-52-880 Issue D

Spares and accessories

7 Spares and accessories

7.1 Introduction

Edwards products, spares and accessories are available from Edwards companie s in Belgium, Brazil, Canada, France ,

Germany, Hong Kong, Italy, Japan, Korea, Switzerland, United Kingdom, U.S.A. and a world-wide network of

distributors. The majority of thes e centres employ Service Engineers w ho have undergone co mprehensive Edwa rds

training courses.

Order spare parts and accessories from your nearest Edwards company or distributor. When you order, please state

for each part required:

Model and Item Number of your equipment

Serial number (if any)

Item Number and description of the part.

7.2 Accessories

CABLE LON/PDT POWER/RS232 D397-52-016

5 WAY XLR EXTENSION CABLE 3M D373-70-591

5 WAY XLR EXTENSION CABLE 5M D373-70-592

5 WAY XLR EXTENSION CABLE 10M D373-70-595

5 WAY XLR EXTENSION CABLE 15M D373-70-596

5 WAY XLR EXTENSION CABLE 25M D373-70-597

PDT ADAPTOR, RJ12 PLUG/5 WAY XLR SOCKET D373-70-726

Page 28 © Edwards Limited 2016. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Loading...

Loading...