Page 1

Instruction Manual

Turbo Controller

D397-12-880

Issue J Original

Description Item Number

TIC Turbo Controller 100 W D397-11-000

TIC Turbo Controller 200 W D397-12-000

Page 2

Declaration of Conformity

We, Edwards

Manor Royal,

Crawley,

West Sussex RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised to

assemble the technical file, that the product(s)

TIC Instrument Controller D397-00-000

TIC Instrument Controller 6-Gauge D397-01-000

TIC Instrument Controller 6-Gauge Capacitance Manometer D397-02-000

TIC Turbo Controller 100W D397-11-000

TIC Turbo Controller 200W D397-12-000

TIC Turbo & Instrument Controller 100W D397-21-000

TIC Turbo & Instrument Controller 200W D397-22-000

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61010-1:2001 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use – Part 1: General Requirements.

EN61326-1:2006 Electrical Equipment for Measurement Control and Laboratory

(Industrial location, Use – EMC Requirements.

Class B Emissions)

and fulfils all the relevant provisions of

2006/95/EC Low Voltage Directive.

2004/108/EC Electromagnetic Compatibility Directive.

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

11/06/2010, Eastbourne

Mr L Marini, Technical Manager Date and Place

This product has been manufactured under a quality system registered to ISO9001

P200-03-140 Issue C

Page 3

D397-12-880 Issue J

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 Product description ...................................................................................................... 1

2 Technical data ....................................................................................3

2.1 Electrical data ............................................................................................................ 3

2.2 Operating and storage data ............................................................................................ 3

2.3 Mechanical data .......................................................................................................... 3

2.4 Connections ............................................................................................................... 4

2.4.1 Turbo pump connector .................................................................................................. 4

2.4.2 Backing pump connector ............................................................................................... 5

2.4.3 Auxiliary terminals ...................................................................................................... 6

2.4.4 Logic interface ...........................................................................................................7

2.4.5 Serial communications .................................................................................................. 8

Contents

3 Installation ............................................... ................................... .......9

3.1 Unpack and inspect ...................................................................................................... 9

3.2 Fitting the controller .................................................................................................... 9

3.3 Controller electrical connections ....................................................................................12

3.3.1 Connecting the electrical supply .....................................................................................12

3.3.2 Additional earth bonding ..............................................................................................12

3.3.3 Connecting a turbo pump ..............................................................................................13

3.3.4 Connecting a backing pump ...........................................................................................13

3.3.5 Connecting a vent valve ...............................................................................................13

3.3.6 Connecting an air cooler ...............................................................................................13

3.3.7 Connecting the logic interface .......................................................................................13

3.3.8 Connecting the serial interface .......................................................................................15

4 Operation ........................................................................................ 17

4.1 Front panel description ................................................................................................17

4.2 Menu structure ..........................................................................................................18

4.3 Navigating the menu ...................................................................................................19

4.4 The view screen .........................................................................................................20

4.5 Turning pumps and relays on/off .....................................................................................21

4.6 Changing list items .....................................................................................................21

4.7 Changing numerical values ............................................................................................21

4.8 Turbo set up .............................................................................................................21

4.8.1 Introduction .............................................................................................................21

4.8.2 Default turbo set up options ..........................................................................................22

4.8.3 Additional set up options using a DX or nEXT pump ...............................................................23

4.9 Backing set up ...........................................................................................................25

4.10 Alarms ....................................................................................................................25

4.11 The main menu ..........................................................................................................26

4.12 Turbo status .............................................................................................................26

4.13 Backing status ...........................................................................................................27

4.14 Parameters/units .......................................................................................................28

4.15 Relay setpoint outputs .................................................................................................28

4.16 Service information .....................................................................................................29

4.17 Electrical supply failure ...............................................................................................29

gea/0075/05/10

© Edwards Limited 2013. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 4

D397-12-880 Issue J

Contents

5 Maintenance ..................................................................................... 31

5.1 Safety ..................................................................................................................... 31

5.2 Fault finding .............................................................................................................31

5.3 Cleaning the controller ................................................................................................31

5.4 Software updates .......................................................................................................32

5.5 Factory defaults .........................................................................................................32

6 Storage and disposal ............................................................ ..... ..... ..... 33

6.1 Storage ...................................................................................................................33

6.2 Disposal ...................................................................................................................33

7 Service, spares and accessories .............................................................. 35

7.1 Service ....................................................................................................................35

7.2 Spares .....................................................................................................................35

7.3 Accessories ...............................................................................................................35

Index ........................................................... ................................... 37

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

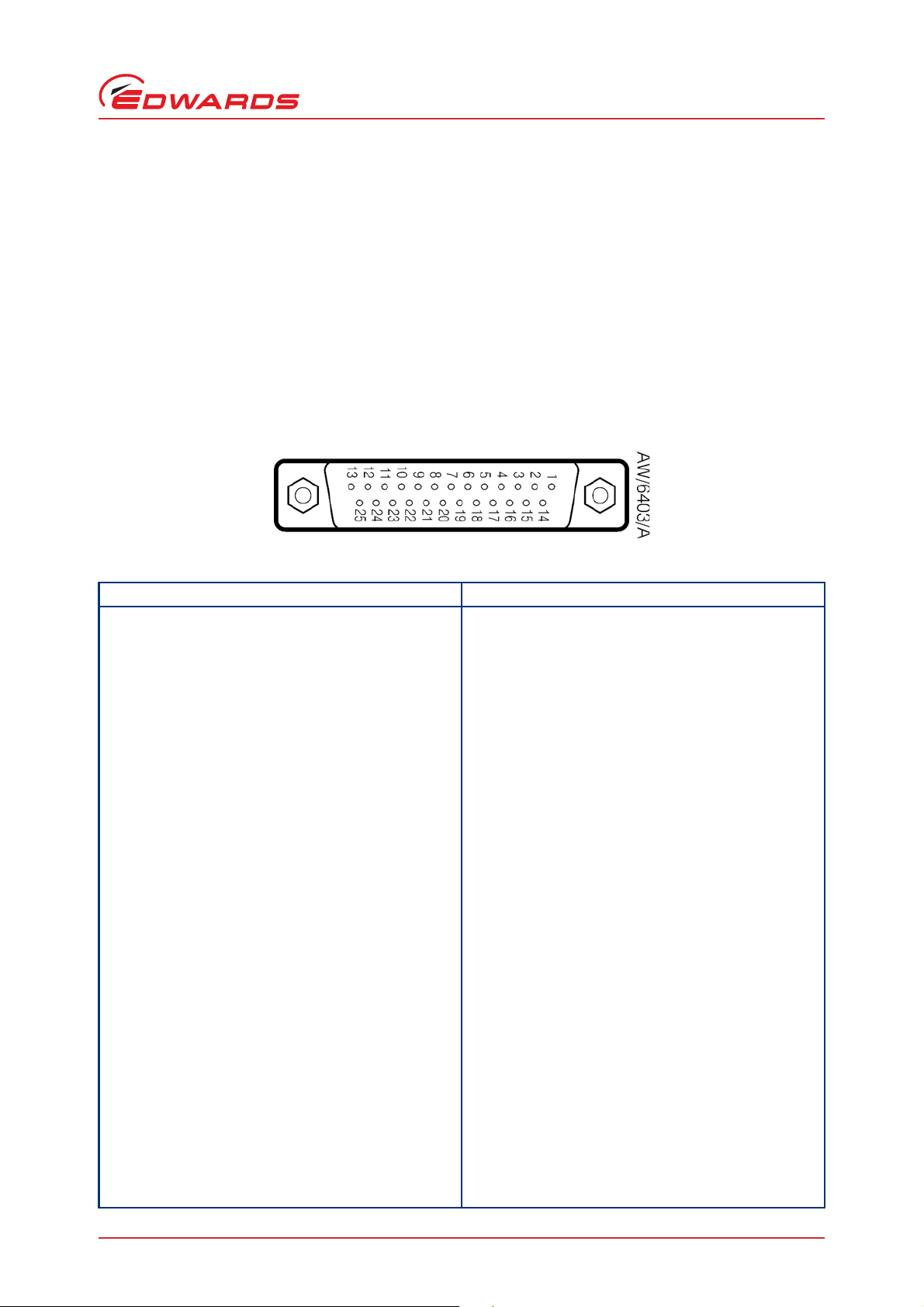

1 Pin connections for a 15-way sub-miniature ‘D’ type socket ..................................................... 4

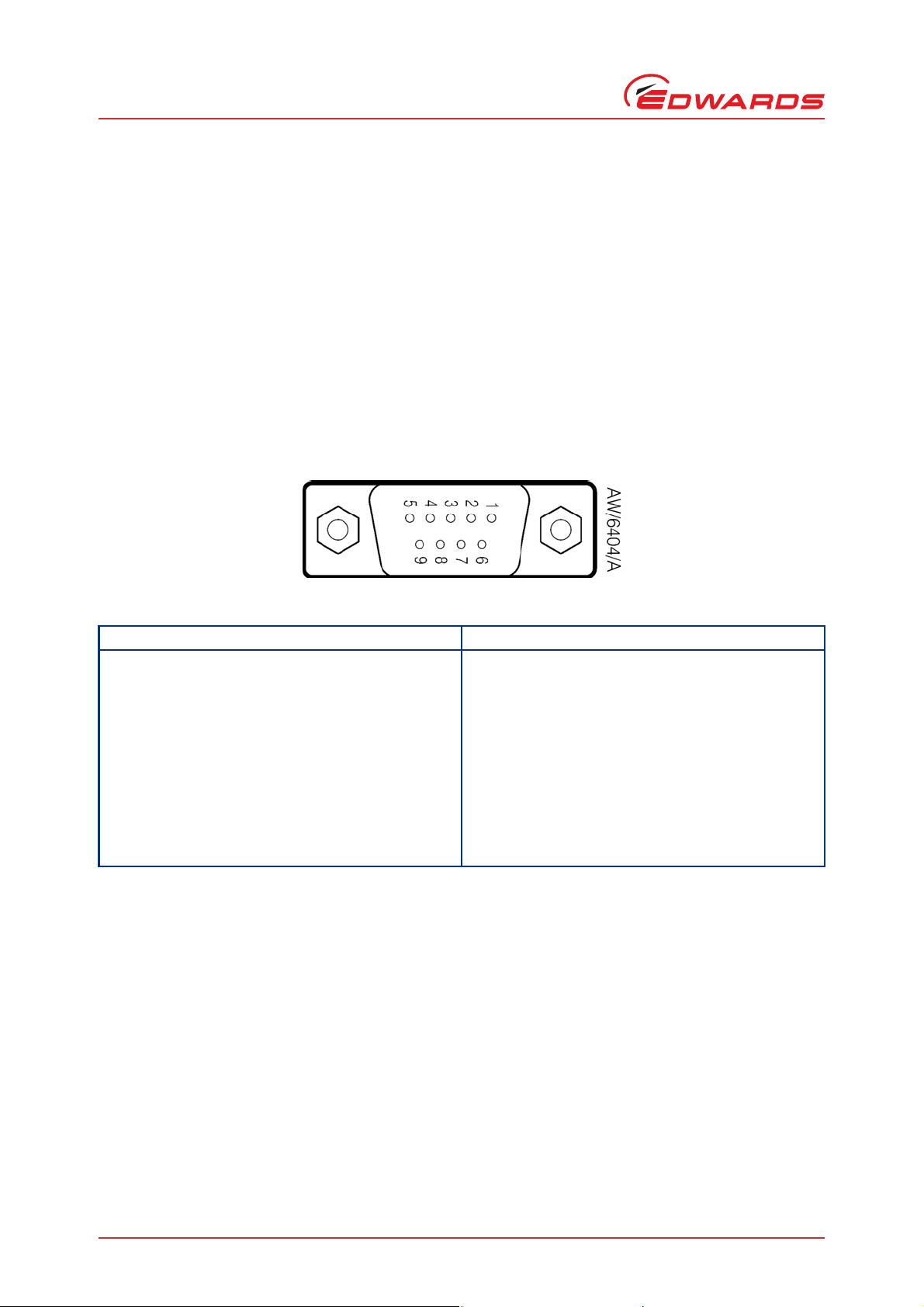

2 Pin connections for a 15-way sub-miniature ‘D’ type socket ..................................................... 5

3 4-way screw terminal block ............................................................................................ 6

4 Pin connections for a 25-way sub-miniature ‘D’ type socket ..................................................... 7

5 Pin connections for a 9-way sub-miniature ‘D’ type socket ...................................................... 8

6 Bench mounted TIC dimensions (mm) ...............................................................................10

7 Front panel removal ....................................................................................................10

8 Rack mounting of a TIC ................................................................................................11

9 Panel cut out drawing ..................................................................................................11

10 Rear panel connections ................................................................................................12

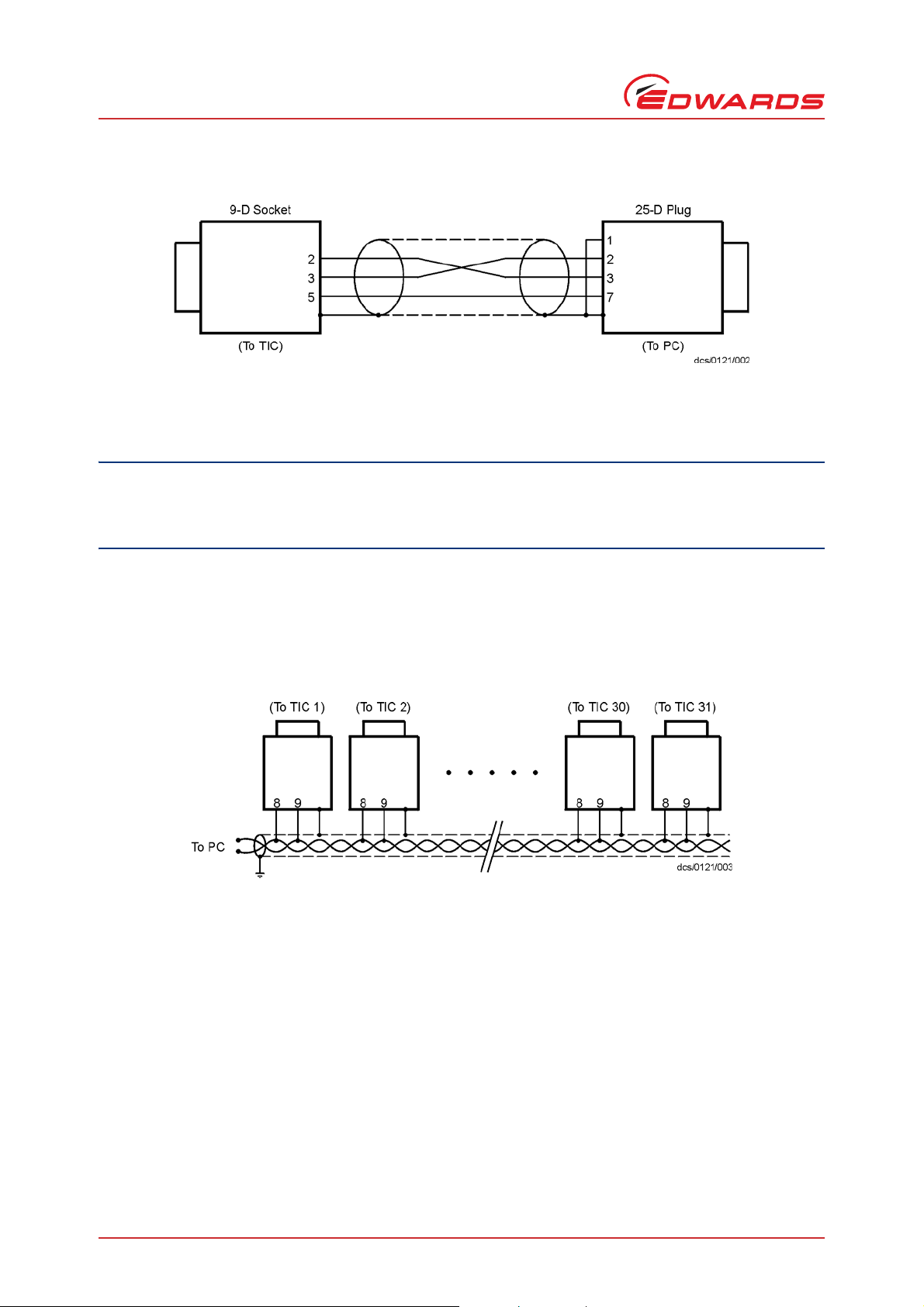

11 IBM PC RS232 interface - 9-way ......................................................................................15

12 IBM PC RS232 interface - 25 way .....................................................................................16

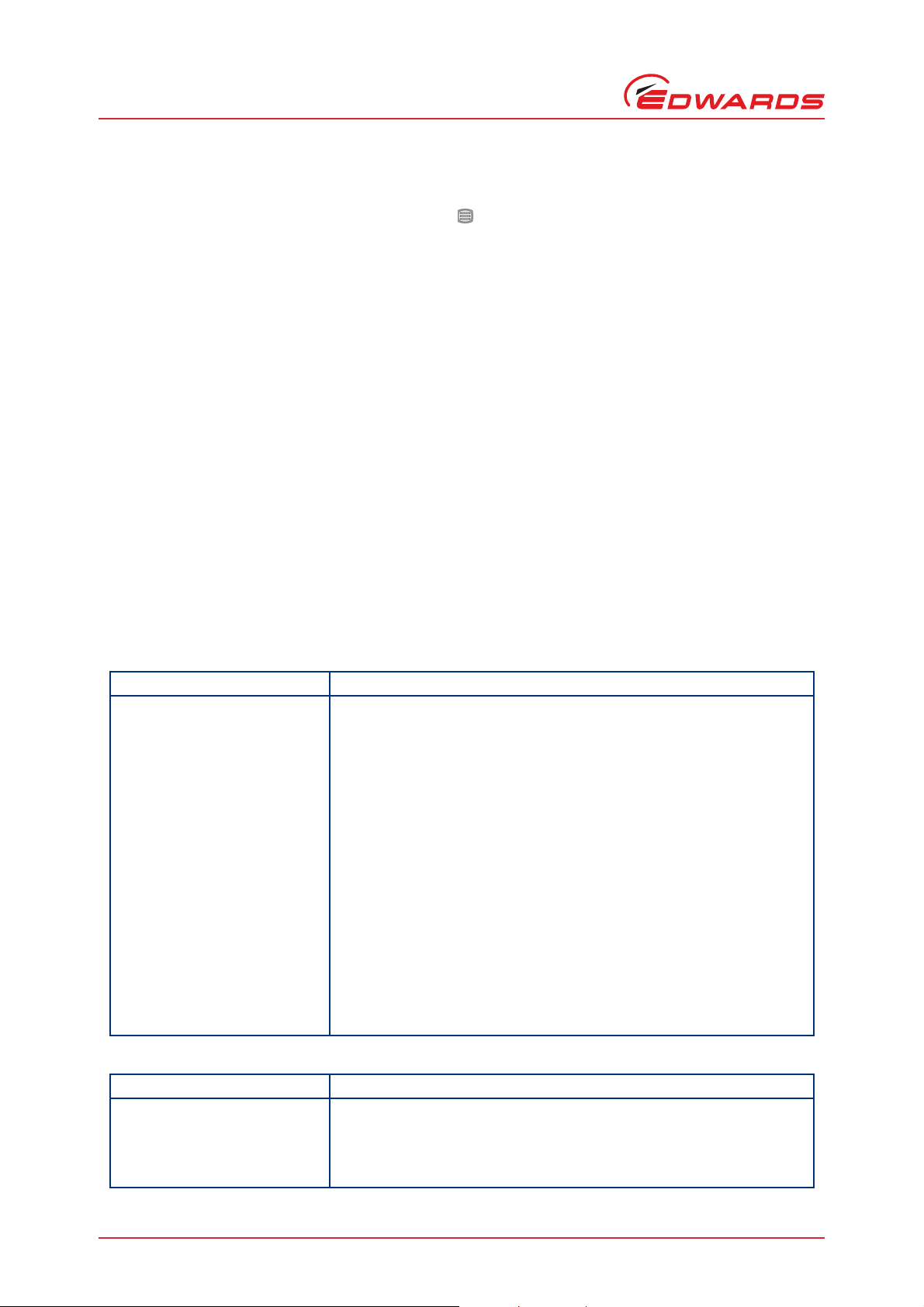

13 RS485 TIC network ......................................................................................................16

14 Front panel display .....................................................................................................17

15 View screen shortcuts ..................................................................................................18

16 Menu structure ..........................................................................................................19

17 Pump status ..............................................................................................................20

18 Changing numerical values ............................................................................................21

19 Turbo set up screen ....................................................................................................22

Page ii © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 5

D397-12-880 Issue J

Tables

Table Page

1 Compatible equipment for the TIC range ............................................................................2

2 Turbo pump connector pin-out ........................................................................................ 4

3 Backing pump connector pin-out ...................................................................................... 5

4 Auxiliary connector pin-out ............................................................................................ 6

5 Logic interface connector pin-out .................................................................................... 7

6 Serial communications connector pin-out ........................................................................... 8

7 Checklist of components ................................................................................................ 9

8 Front panel symbols and their functions ............................................................................17

9 Default turbo setup options ...........................................................................................22

10 Error/diagnostic monitoring, pumps .................................................................................23

11 Turbo pump vent options ..............................................................................................23

12 DX,nEXT and nXDS pump set up options .............................................................................24

13 Error/diagnostic monitoring, DX, nEXT and nXDS pumps .........................................................24

14 Default Backing set up options .......................................................................................25

15 nXDS pump set up options .............................................................................................25

16 nEXT Service Screen ....................................................................................................26

17 nEXT Service Reset Screen ............................................................................................26

18 nXDS Service Screen ....................................................................................................27

19 nXDS Service Reset Screen ............................................................................................27

20 Fault finding .............................................................................................................31

21 Factory default settings ...............................................................................................32

22 Accessories ............................................................................................................... 35

Contents

© Edwards Limited 2013. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

D397-12-880 Issue J

This page has been intentionally left blank.

Page iv © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

D397-12-880 Issue J

CAUTION

WARNING

WARNING

1Introduction

1.1 Scope and definitions

This manual provides Installation, Operation and Maintenance instructions for the Edwards Turbo Controller. You

must use the Controller as specified in this manual.

Read this manual before you install and operate the Edwards Turbo Controller. Important safety information is

highlighted as WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and

CAUTIONS is defined below.

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

Introduction

Throughout this manual, page, figure or table numbers are sequential.

The following IEC warning labels appear on the controller:

Warning - refer to accompanying documentation.

Edwards offer European customers a recycling service.

1.2 Product description

Improper use of the equi pment could cause damage to it or injury to people. The user is

responsible for the safe operation and monitoring of the equipment. Hazardous voltages should not

be connected to this unit except where specified.

There are two variants of the Turbo Controller, both of which are provided with a large clear graphics display, easyto-use control interface via a touch sensitive keypad, an RS232/485 interface for control and data monitoring on a

remote PC and a logic interface for interface with associated system hardware.

The compatible pumps/accessories that can be used with the Turbo Controller are listed in Table 1.

© Edwards Limited 2013. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

D397-12-880 Issue J

Introduction

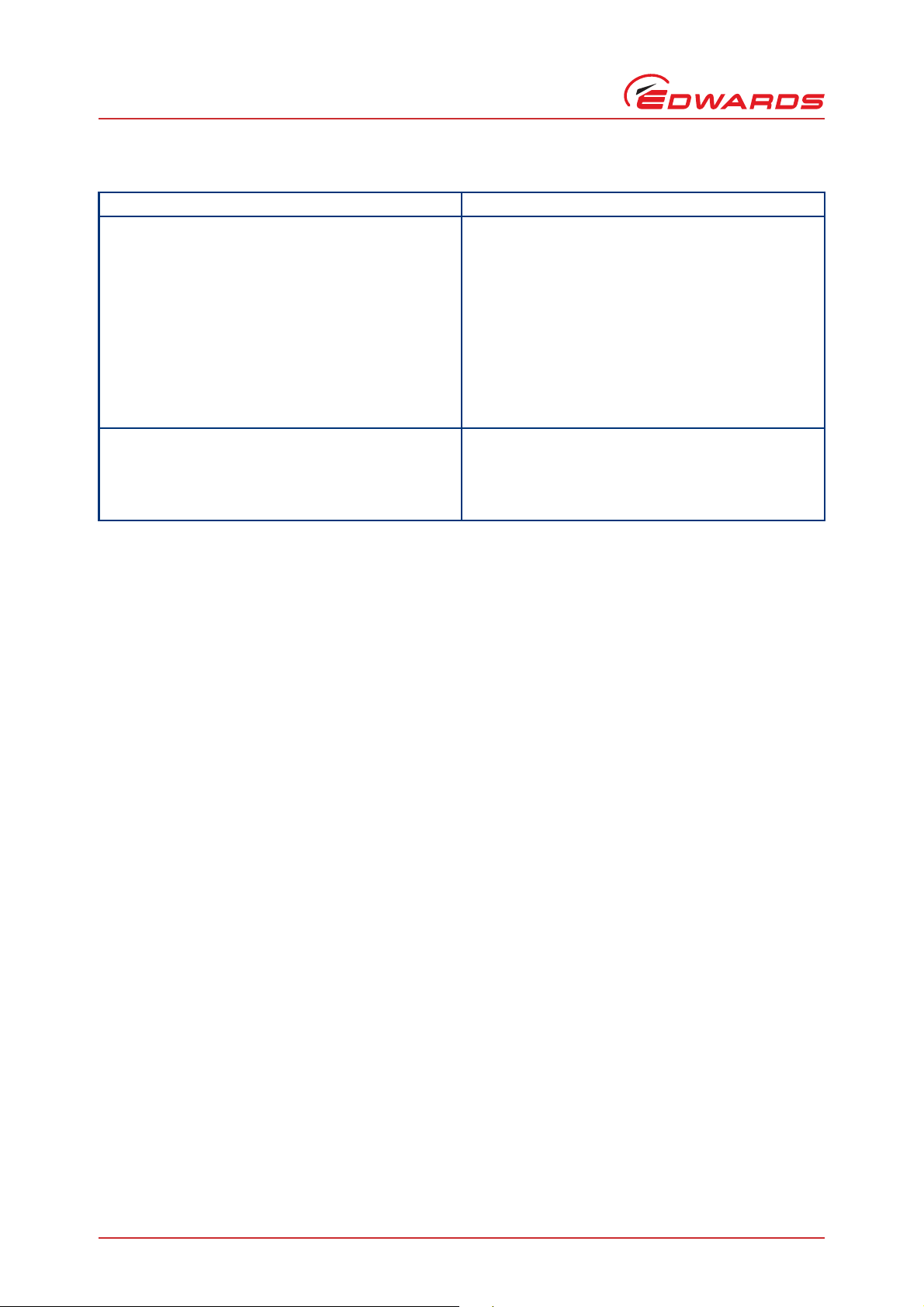

TIC variant Compatibility

TIC Turbo Controller 100 W EXT75DX - fast ramp

TIC Turbo Controller 200 W Same as the 100 W version plus the following:

Table 1 - Compatible equipment for the TIC range

EXT255DX - slow ramp

nEXT-P2 - slow ramp

EXT70H + EXDC80 - fast ramp

EXT255H + EXDC80 - slow ramp

Mains backing pumps, XDS scroll, up to RV 12 (via an

optional relay box)

Air Cooler, ACX70 and ACX250

Vent Valve, TAV5 and TAV6

Bakeout band (via an optional relay box)

24 V backing line valves, LCPV16EKA and LCPV25EKA (via

an optional relay box)

24 V backing pump

EXT255H + EXDC160 - fast ramp

EXT255DX - fast ramp

nEXT-P2 - fast ramp

Page 2 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

2Technical data

2.1 Electrical data

Connector type CEE/IEC 320

Electrical supply 90 to 264 V a.c. 47 to 63 Hz

Power consumption

TIC Turbo Controller 100 W 215 VA maximum (D397-11-000)

TIC Turbo Controller 200 W 350 VA maximum (D397-12-000)

Peak inrush current 11 A at 110 V a.c D397-11-000

23 A at 240 V a.c D397-12-000

Fuse The unit is self-protecting and has no user

replaceable fuse. The unit will recover once any

overload is removed.

Earth Stud M4

2.2 Operating and storage data

D397-12-880 Issue J

Technical data

Ambient operating temperature range 0 °C to 40 °C

Ambient storage temperature range -30 °C to 70 °C

Maximum ambient operating humidity Max 90% RH non condensing at 40 °C

Maximum operating altitude 3000 m max

IP rating 20

2.3 Mechanical data

Weight

TIC Turbo Controller 100 W 1.8 kg

TIC Turbo Controller 200 W 1.9 kg

© Edwards Limited 2013. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

D397-12-880 Issue J

Technical data

2.4 Connections

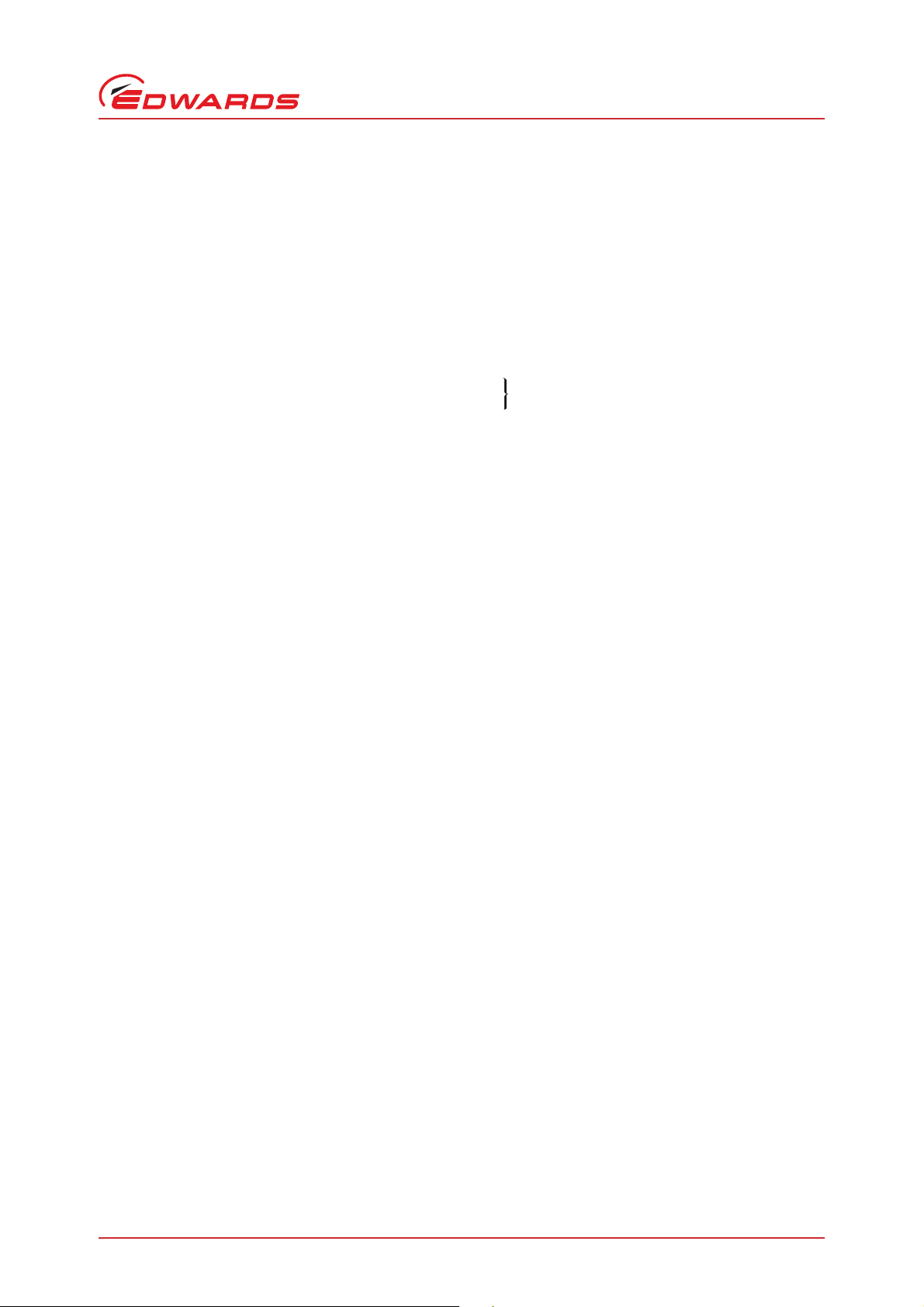

2.4.1 Turbo pump connector

Connector type 15-way sub-miniature ‘D’ type socket (refer to Figure 1)

Power supply 24 V d.c.

Maximum output power 100 W TIC: 80 W continuous, 120 W peak

200 W TIC: 160 W continuous, 240 W peak (combined total power of the

24 V turbo and backing pumps)

Input voltage range -0.5 V to 15 V

Output ID current 33

Control output active: <1.1 V d.c. (I

Control input low: <4.0 V d.c. (I

RS232 transmit disabled: open

RS232 receive mark: <4.0 V d.c. (I

Maximum cable length 7 m

µA, 0 V to 13 V

20 mA max)

out

<0.8 V d.c. (I

inactive: open (<24 V d.c. externally applied)

high: 7.0 V to 24 V d.c. (internally pulled up to 24 V)

enabled: 0: > +8 V (I

1: < -8 V (I

space: 7.0 V to 24 V d.c. (internal pull up to 24 V)

<2 mA)

out

<160 µA)

out

max: 8 mA)

out

max: -8 mA)

out

< 160 µA)

out

Figure 1 - Pin connections for a 15-way sub-miniature ‘D’ type socket

Table 2 - Turbo pump connector pin-out

Pin Allocation

1 Power supply positive

2 Signal common

3 /Start signal output

4RS232 Tx

5 /Serial enable output

6 Power supply positive

7RS232 Rx

8Power supply common

9 Speed signal input

10 Screen

11 Power supply positive

12 Screen

13 Power supply common

14 Power supply common

15 Normal signal input

Page 4 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

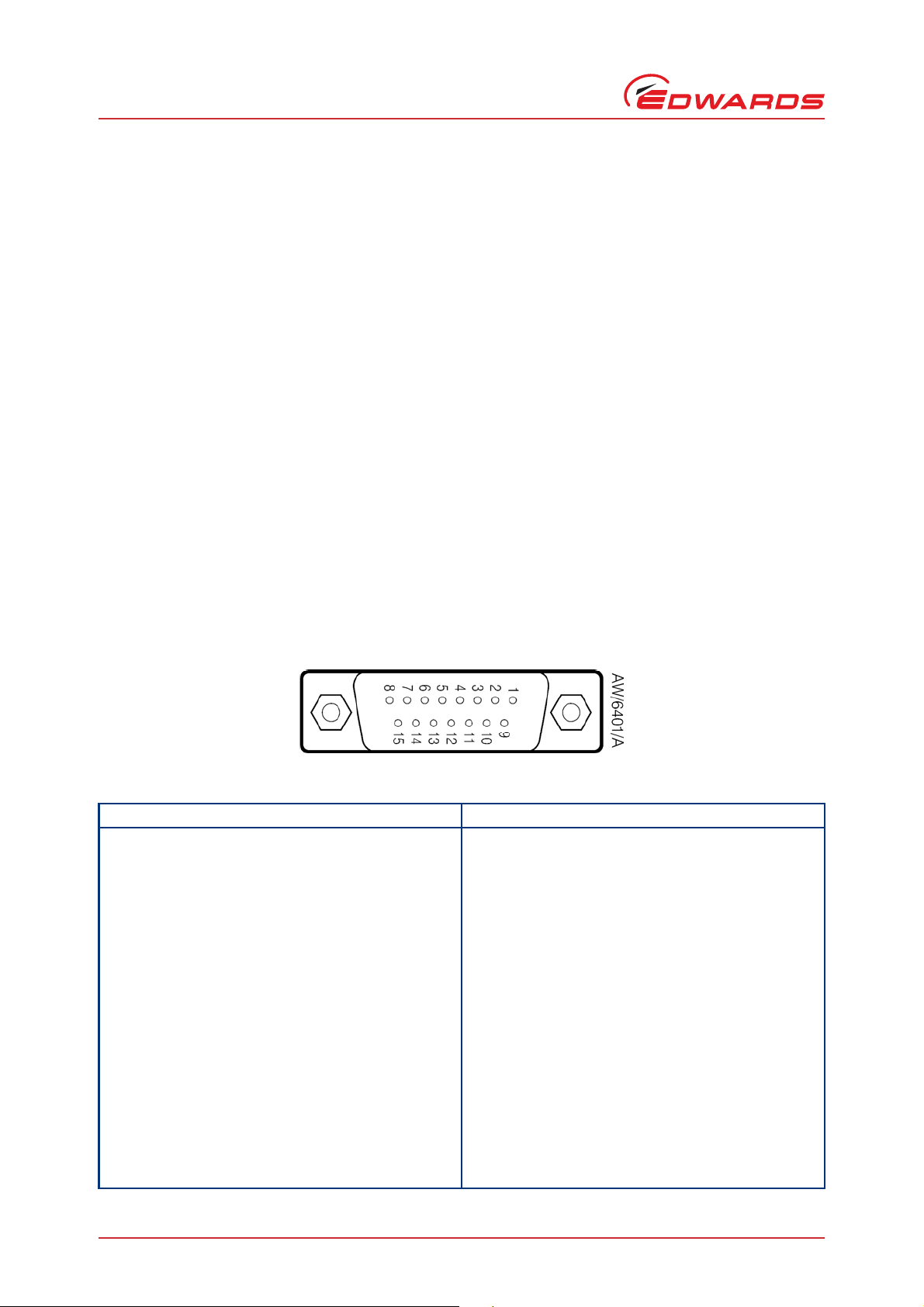

2.4.2 Backing pump connector

Note: Only applicable to the 200 W TIC

Connector type 15-way sub-miniature ‘D’ type socket (refer to Figure 2)

Power supply 24 V d.c.

Maximum output power

160 W continuous, 240 W peak (combined total power of the 24 V turbo

and backing pumps)

Output voltage range Stop = 0 V

Start = 10 V (5 mA maximum)

Output ID current 33

Control output active: <1.1 V d.c. (I

Control input low: <4.0 V d.c. (I

RS232 transmit disabled: open

RS232 receive mark: <4.0 V d.c. (I

Maximum cable length 7 m

µA, 0 V to 13 V

< 20 mA)

out

<0.8 V d.c. (I

inactive: open (<24 V d.c. externally applied)

high: 7.0 to 24 V d.c. (internally pulled up to 24 V)

enabled: 0: > +8 V (I

1: < -8 V (I

space: 7.0 V to 24 V d.c. (internal pull up to 24 V)

< 2 mA)

out

<160 µA)

out

max: 8 mA)

out

max: -8 mA)

out

< 160 µA)

out

D397-12-880 Issue J

Technical data

Figure 2 - Pin connections for a 15-way sub-miniature ‘D’ type socket

Table 3 - Backing pump connector pin-out

Pin Allocation

1 Power supply positive

2 Signal common

3 /Start signal output

4RS232 Tx

5 /Serial enable output

6 Power supply positive

7RS232 Rx

8Power supply common

9 Speed signal input

10 Screen

11 Power supply positive

12 Screen

13 Power supply common

14 Power supply common

15 Normal signal input

© Edwards Limited 2013. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

D397-12-880 Issue J

Technical data

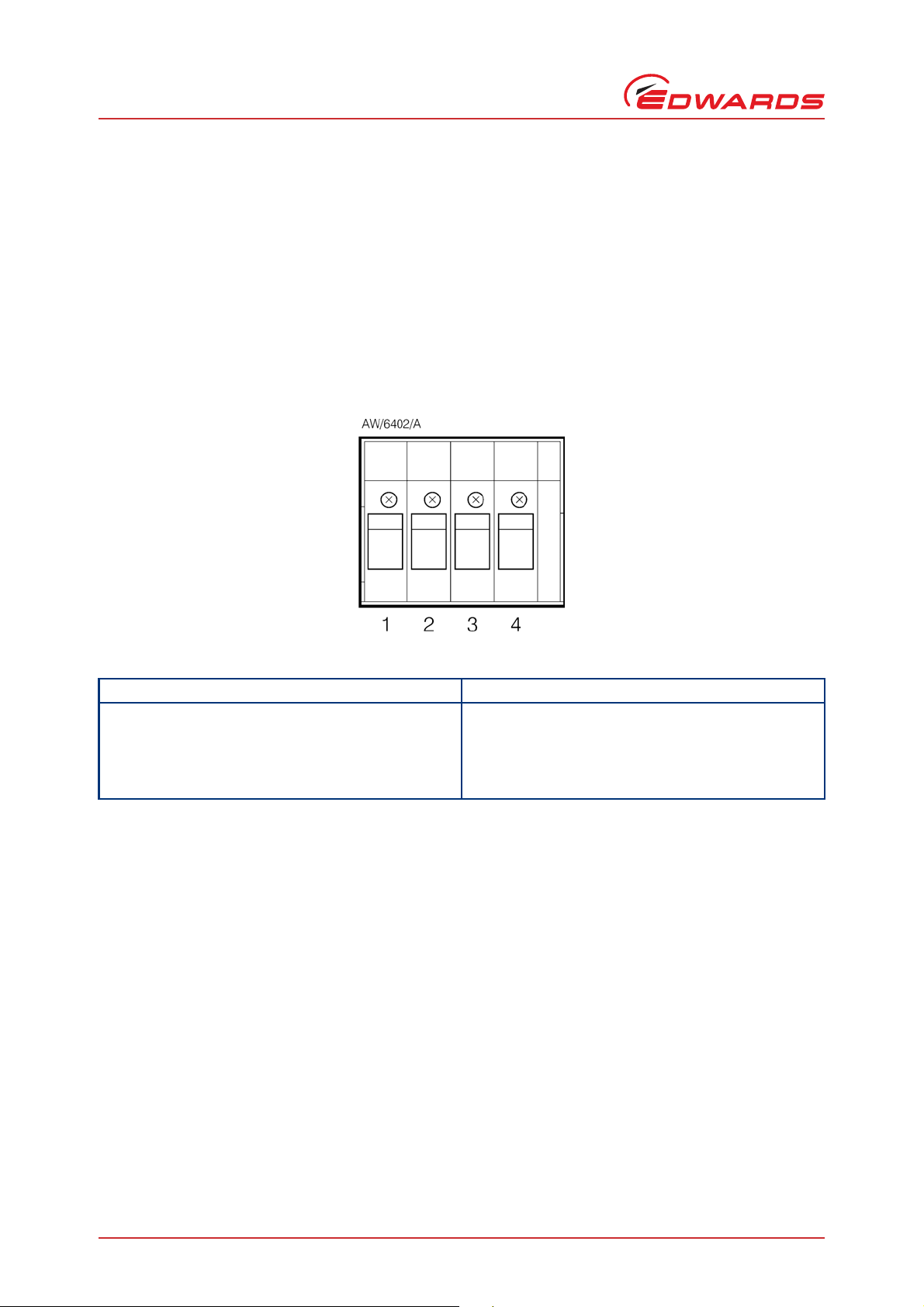

2.4.3 Auxiliary terminals

Connector type 4-way screw terminal block (refer to Figure 3)

Wire size 1.5 mm2 max

Power supply 24 V d.c.

Maximum output power Fan: 3 W max

Vent-valve: 2 W max

Control output active: <1.5 V d.c.

inactive: open

Maximum cable length 10 m

Figure 3 - 4-way screw terminal block

Table 4 - Auxiliary connector pin-out

Pin Allocation

1 Fan control output

2Fan 24 V

3 Vent control output

4Vent 24 V

Page 6 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

2.4.4 Logic interface

Connector type 25-way sub-miniature ‘D’ type socket (refer to Figure 4)

Power supply 24 V d.c.

Maximum output power 5 W

Control output active: <1.1 V d.c. (

<0.8 V d.c. (I

inactive: open (internal pull up to 24 V)

Control input low: <2.0 V d.c. (I

high: 3.5 V to 24 V d.c. (internal pull up to 24 V)

Analogue output 0 to 10 V (5 mA max)

50 mV resolution

Figure 4 - Pin connections for a 25-way sub-miniature ‘D’ type socket

< 20 mA)

Iout

< 2 mA)

Iout

<160 µA)

Iout

D397-12-880 Issue J

Technical data

Table 5 - Logic interface connector pin-out

Pin Allocation

1Screen

2 Analogue output signal

3Setpoint 1 output

4 Vent control output

5 Bakeout band control output

6N/C

7Power supply common

8 Backing pump control output

9N/C

10 Power supply common

11 Power supply positive

12 Power supply common

13 Power supply common

14 Analogue output common

15 Setpoint 2 output

16 Setpoint 3 output

17 Turbo normal output

18 Alarm output

19 Air cooler output

20 N/C

21 N/C

22 Backing pump enable input

23 Turbo stand-by control input

24 Turbo pump enable input

25 System interlock input (SYSI)

© Edwards Limited 2013. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

D397-12-880 Issue J

2.4.5 Serial communications

Connector type 9-way sub-miniature ‘D’ type socket (refer to Figure 5)

RS232 transmit mark: < - 8 V (I

space: > +8 V (I

RS232 receive mark: < +1.0 V (Iin max: -2.0 mA)

space: >+2.0 V (I

maximum input: ±12 V

RS232 protocol 9600 baud, 1 stop bit, 8 data bits, no parity

RS485 Output differential: >1.5 V (I

Input differential threshold: >± 0.2 V (I

Maximum input: -7.0 V to +12 V

Bus load The TIC applies one unit load to the RS485 bus.

Figure 5 - Pin connections for a 9-way sub-miniature ‘D’ type socket

max: -8 mA)

out

max: -8 mA)

out

max: +2.0 mA)

in

max: ± 25 mA)

out

max: ± 1 mA)

in

Table 6 - Serial communications connector pin-out

Pin Allocation

This page has been intentionally left blank.

1N/C

2RS232 transmit

3RS232 receive

4N/C

5RS232 common

6N/C

7N/C

8RS485 data A

9RS485 data B

Page 8 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

D397-12-880 Issue J

CAUTION

WARNING

3 Installation

3.1 Unpack and inspect

Remove all of the packaging material and check the Controller. If the Controller is damaged, follow the Edwards

return of equipment procedures that are laid out in the back of this manual. Do not use the Controller if it is

damaged.

Check that your package contains the items that are listed in Table 7. If any of these items are missing, notify your

supplier in writing within three days. If the Controller is not to be used immediately, store the Controller in suitable

conditions as described in Section 6.1.

Table 7 - Checklist of components

Quantity Description Check ()

1 Controller

1 Quick Guide and Health and Safety Information

1TIC CD

2 Rear non-slip feet

1 Logic interface plug

Installation

3.2 Fitting the controller

If access to the IEC connector is restricted an additional i solation device should be provided, which

will be easily accessible by an operator.

Rubber feet must be fitted (Figure 6, item 1) so that there are correct clearances for air circulation. If you do

not, the performance of the Controller may be affected at high operating temperatures.

The Controller can be used on a bench-top or can be fitted in a rack or cabinet. Figure 6 shows the dimensions of the

TIC that are required for bench top use.

Note: If the interlocks are not used the logic interface adaptor must be fitted to the 25-way connector.

© Edwards Limited 2013. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

D397-12-880 Issue J

CAUTION

CAUTION

CAUTION

WARNING

1. Rubber foot

1. Bench top adaptor

2. Fixing screw and washer

Installation

Ensure that all electrical wiring is safely secured so that people cannot trip on them.

Figure 6 - Bench mounted TIC dimensions (mm)

If a Controller is fitted in a rack, cabinet or panel, follow the directions given in Figure 7, 8 and 9.

Allow 150 mm at the rear for cables. Allow 50 mm top and bottom and 15 mm to the sides for sufficient air

circulation. Do not cover any of the ventilation holes.

This unit is IP20 rated. Please ensure that the unit is not installed where fluids can enter into the controller.

The unit must be supported at the rear.

Figure 7 - Front panel removal

Page 10 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

D397-12-880 Issue J

1. Fixing screw and washer

2. 19" rack guide rails

Remove the bench top adaptor (Figure 7, item 1) by removing the four screws (Figure 7, item 2).

Slide the Controller into the 19" rack or panel cut out. The use of 19" rack guide rails (Figure 8, item 2) and

support at the rear of the Controller is recommended as shown in Figure 8. The panel cut out information is

defined in Figure 9.

Fix the Controller in place using the four screws removed previously (Figure 8, item 1).

Figure 8 - Rack mounting of a TIC

Installation

Figure 9 - Panel cut out drawing

© Edwards Limited 2013. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

D397-12-880 Issue J

WARNING

1. Backing pump (200 W only)

2. Turbo pump connection

3. Logic interface

4. Serial communications port

5. Earth stud

6. Mains input

7. Mains on/off

8. Auxiliary terminals

Installation

3.3 Controller electrical connections

Figure 10 - Rear panel connections

3.3.1 Connecting the electrical supply

High voltages exist in the Controller when it is operating. Ensure that the Controller is earthed and

observe all appropriate safety precautions for the safe installation and handling of electrical

equipment. If you do not, there will be a danger of injury or death to people by electric shock.

Ensure that the electrical supply switch is set to ‘off’ and then connect the Controller to the electrical suppl y with

an appropriate supply cable.

3.3.2 Additional earth bonding

The electrical supply cable normally provides protective earthing for electrical safety. If this is not the case , or if

additional earth bonding is required, then the earth stud on the rear of the Controller (Figure 10, item 5) should be

connected to your vacuum system earth.

The earth connection of any vent valves or air coolers should also be connected to this earth stud to ensure that they

are adequately earthed.

Connect a suitably earthed cable between the two nuts fitted to the earth stud on the rear of the TIC.

Note: Do not remove the bottom nut from the earth stud.

Page 12 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 19

D397-12-880 Issue J

CAUTION

CAUTION

3.3.3 Connecting a turbo pump

Pumps are not hot swap safe unless explicitly stated in their manual. Before connecting or disconnecting a pump

to the TIC turn the power off. Failure to do so may damage the pump.

The TIC will only identify the pump connected at power on.

A suitable turbo pump can be connected to the TIC turbo pump connector on the rear panel.

Connect the pump to the lower of the two 15 way ‘D’ connectors and tighten the locking screws to ensure the

connector cannot come loose.

3.3.4 Connecting a backing pump

Both the 100 W and 200 W TICs can control a mains backi ng pump via the lo gic interfac e. For details o f this, refer t o

Section 3.3.7.3.

The 200 W TIC can also drive a suitable backing pump from it’s second rear panel pump conn ector.

Connect the pump to the upper of the two 15 way ‘D’ connectors and tighten the locking screws to ensure the

connector cannot come loose.

Installation

Note: To control an XDD1 24 V backing pump, the pump must be configured for ‘analogue speed control’. Please

refer to the pump instruction manual for details on how to configure the pump for this operating mode.

3.3.5 Connecting a vent valve

A vent valve can be driven from either the auxiliary terminals on the rear of the TIC, or from the logic interface. For

details of using the logic interface to control a vent valve, see Section 3.3.7.3.

Note: If a DX or nEXT pump is to be used, it is recommended that the vent valve is connected to the pump, not

the TIC Controller. If two vent valves are required, both the DX and TIC vent outputs can be used at the

same time. (Refer to Table 11).

Connect the positive lead of the vent valve to the terminal marked ‘Vent +’, connect the negative lead of the vent

valve to the terminal marked ‘Vent –’, and clamp the earth wire between the earth stud locking nuts on the rear of

the controller. Ensure the screws and the earth terminal locking nut, are all firmly tightened.

3.3.6 Connecting an air cooler

An air cooler can be driven from either the auxiliary terminals on the rear of the TIC , or from the logic interface. For

details of using the logic interface to control an air cooler, refer to Section 3.3.7.3.

Connect the positive lead of the air cooler to the terminal marke d ‘Fan +’, connect the negative lead of the air cooler

to the terminal marked ‘Fan –’, and clamp the earth wire between the earth stud locking nuts on the rear of the

controller. Ensure the screws and the earth terminal locking nut, are all firmly tightened.

3.3.7 Connecting the logic interface

3.3.7.1 Introduction

Note: In most applications it will be preferable not to earth the logic interface powe r supply common to prevent

earth loops inadvertently occurring.

Do not connect voltages greater than 24 V to the logic interface.

The logic interface provides a number of signals that can be used for monitoring the status of your vacuum system,

and for controlling certain aspects of its operation. These signals can be broadly divided into three groups, control

inputs, control outputs and status outputs.

© Edwards Limited 2013. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

D397-12-880 Issue J

CAUTION

WARNING

Installation

3.3.7.2 Using control inputs

Control inputs provide a means of controlling the operation of the TIC and the associ ated vacuum system from

external sources.

Turbo Stand-by:

to full speed, disconnect ‘Turbo Stand-by’ from 0 V. Note only pumps that have stand-by speed capability will respond

to this input.

Turbo Enable:

the turbo pump cannot be started, and will stop if it is running. If turbo enable is connected to 0 V when power is

applied to the TIC, the pump is abl e to start when commanded to do so. If turbo enable is connected to 0 V while

the controller is operating, the turbo pump will start, as long as SYSI and the software configuration allow it to do so.

Backing Pump Enable: The backing pump enable input can be used to control the operation of the backing pump. If

backing pump enable is open, the backing pump cannot start, and will stop if it is running. If backing pump enable

is connected to 0 V when power is applied to the TIC, the pump is able to start when commanded to do so. If backing

pump enable is connected to 0 V while the controller is operating, the backing pump will start, as long as ‘SYSI’ and

the software configuration allow it to do so.

SYSI: The System interlock input can be used to interlock the TIC to a system fail or control signal. When ‘SYSI’ is

open, all pumps will stop and the vent valve will be opened. The TIC will also trip into the fail condition. To clear

the system interlock and allow the pumps and gauges to start, connect ‘SYSI’ to 0 V.

To cause the turbo pump to run at stand-by speed, link ‘Turbo Stand-by’ to 0 V. To return the pump

The turbo enable input can be used to control the operation of the turbo pump . If turbo enable is open,

’SYSI’ is not fail safe and should not be relied upon for safety critical applications.

3.3.7.3 Using control outputs

Control outputs provide a means for the TIC to control external resources.

Vent valve control:

signal will be driven low to energise the valve when required. Connect the positive lead of the vent valve to ‘24 V’

and the negative lead to ‘Vent Valve Control’. The vent valve earth lead must be connected to ‘Screen’ or a suitable

alternative earth point.

The vent valve output on the logic interface will not be maintained in the event of a power failure. If venting of

your turbo pump while it is running at high speed is undesirable, use the vent valve output from the auxiliary

terminals. This output will be maintained during a power failure.

Bakeout band control:

relay box has a relay built in for this purpose and provides connectors to allow power to be applied to the bakeout

band. Refer to the relay box instruction manual for further information on driving a bakeout band.

To drive a relay without a relay box, connect the coil of a suitable 24 V d.c. relay between ‘Bakeout Band Control

Output’ (negative) and ‘Power Supply Positive’ (positive).

Backing pump control:

backing pump. The relay box has a relay built in for this purpose and provides a connector that will switch th e pump

on and off. Refer to the re lay box instructions for further information on driving a backing pump.

To drive a relay without a relay box, connect the coil of a suitable 24 V d.c. relay between ‘Backing Pump Output’

(negative) and ‘Power Supply Positive’ (positive).

Air cooler:

driven low to energise the cooler when required. Connect the positive lead of the cooler to the power supply positive

and the negative lead to ‘Air Cooler Control’. The air cooler earth lead must be connected to ‘Screen’ or a suitable

alternative earth point.

The air cooler output can be used to control the operation of an air cooler. The air cooler signal will be

The vent valve output can be used to control the operation of a vent valve. The ‘Vent Valve’

The bakeout band control can be used to switch a relay that can apply power to the band. The

The backing pump control can be used to switch a relay that can apply power to a mains

Page 14 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

D397-12-880 Issue J

3.3.7.4 Using status outputs

Status outputs provide a means for external systems to react based upon the current state of the TIC.

Installation

Analogue output:

pressure, pump speed etc. Refer to Section 4.8 for how to configure this output.

To connect this output to an external system, connect the ‘Analogue Output Signal’ to the positive input of your

system and ‘Analogue Output Common’ to the negative side.

Relay setpoint:

output can be configured in software to activate at pump speed. Refer to Section 4.15 of the main manual for how

to configure these outputs. Each relay can be manually controlled. Refer to Section 4.5.

The relay box has built in relays that can switch external loads and provides a connector to interface to an external

system. Refer to the rela y box instructions for further information on using the setpoint outputs.

To drive a relay without a relay box, connect the coil of a suitable 24 V d.c. relay between ‘Setpoint Output’

(negative) and ‘Power Supply Positive’ (positive).

Turbo normal speed:

This output is normally inactive and will become active when the turbo pump has reached its defined ‘Normal’ speed.

To drive a relay, connect the coil of a suitable 24 V d.c. relay between ‘Turbo Normal Output’ (negative) and ‘Power

Supply Positive’ (positive).

Alarm:

Alarm can be used to interface to external logic or can be used to drive a relay. This output is normally active

and will become inactive in the event of an alarm condition.

To drive a relay, connect the coil of a suitable 24 V d.c. relay between ‘Alarm Output’ (ne gative) and ‘Power Supply

Positive’ (positive).

The analogue output provides a 0 V to 10 V signal that can be configured to represent system

The setpoint outputs can be used to interface to external logic or can be used to drive relays. Each

Turbo normal speed can be used to interface to external logic or can be used to drive a relay.

3.3.8 Connecting the serial interface

The TIC has two serial communications protocols built in, RS232 and RS485. RS232 is the simple st interface and can

be used to allow a host PC to control the TIC. RS485 allows a host PC to control a small network of TICs.

3.3.8.1 Connecting RS232

The TIC is fitted with a 9-way ‘D’ type socket on th e rear pan el. The interface uses tw o li nes fo r da ta tra nsfers a nd

an additional line as a signal common. Hardware handshaking is not implemented.

If connecting to an IBM compatible PC fitted with a 9-way ‘D’ type socket then a ‘straight through’ male-female

9-way extension cable can be used to connect the TIC to the computer as shown in Figure 11. Connection to an IBM

PC fitted with a 25-way serial connector should be made as shown in Figure 12.

Use shielded cable for the interface to reduce interference problems and limit the length of the RS232 link to less

than 10 metres. For longer links, either install line drivers or use RS485.

Figure 11 - IBM PC RS232 interface - 9-way

© Edwards Limited 2013. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

D397-12-880 Issue J

CAUTION

Installation

Figure 12 - IBM PC RS232 interface - 25 way

3.3.8.2 Connecting RS485

RS485 provides the TIC with the capability to be networked with other TICs and a host PC as shown in Figure 13.

All of the ground connections are tied together. If differences exist in the local ground voltage, damage could

occur. If the TICs being networked are liable to experience different ground potentials, a suitable RS 485 isolator

should be connected between them.

Use shielded cable for the interface to reduce interference problems and limit the length of the RS485 link to less

than 1000 metres.

Long links may require the addition of 120 Ω terminating resistors at each end of the link to improve communications

reliability.

Figure 13 - RS485 TIC network

Page 16 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 23

4 Operation

4.1 Front panel description

Figure 14 - Front panel display

D397-12-880 Issue J

Operation

Table 8 - Front panel symbols and their functions

Symbol Name Function

Move up through a menu.

UP

DOWN

SELECT

MENU

CYCLE Turn a highlighted gauge on or off.

Cycle selected numerical values up.

Cycle a selected list item upwards.

Move down through a menu.

Cycle selected numerical values down.

Cycle a selected list item downwards.

Enter the highlighted sub-menu.

Edit the highlighted list or numerical item.

Move to the next digit of a numerical value.

Jump to the setup screen for the highlighted gauge.

Switch between the default view screen and the main menu.

Exit the current sub-menu or setup screen.

Abort edit of a selected list item.

Move to the previous digit of a numerical value.

© Edwards Limited 2013. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 24

D397-12-880 Issue J

Operation

4.2 Menu structure

Figure 15 and 16 show the view screen shortcuts and menu structure for the TIC. They also give an indication as to

what buttons will take you where within the menu layout.

Figure 15 - View screen shortcuts

Page 18 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 25

Figure 16 - Menu structure

D397-12-880 Issue J

Operation

4.3 Navigating the menu

This section summarises the display navigation method for the TIC. There are 4 buttons for menu navigation and

configuration tasks. A fifth button is used for switching pumps ON and OFF. In most configuration tasks there are no

more than three menu levels.

Refer to Table 8 for a description of the functions that the buttons on the front panel perform.

© Edwards Limited 2013. All rights reserved. Page 19

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 26

D397-12-880 Issue J

Operation

4.4 The view screen

The view screen can be set to various view options. The following, describes the view screen that shows ‘all’. (Refer

to Figure 17).

The top portion of the view screen shows the status of the vacuum pumps; the top line shows the pump speed as a

bar chart. In the top right-hand corner the status of the turbo pump is shown as follows:

Off. The turbo pump is off.

>>>. The turbo pump is accelerating.

<<<. The turbo pump is decelerating.

Run. The turbo pump is above 50% speed.

Norm. The turbo pump is at or above ‘normal

speed’.

Strt. The turbo pump is enabled to start,

but will not run until the start delay

has run down.

Flt. An error has occurred. Select the

alarms screen.

The second line provides the basic status of the turbo pump and backing pump under TIC command.

The status of the setpoint relays is shown at the bottom line of the view screen. Relays that are on are shown in

reverse video.

Figure 17 - Pump status

Page 20 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 27

D397-12-880 Issue J

CAUTION

4.5 Turning pumps and relays on/off

Pressing the ‘Cycle’ ( ) button whilst the turbo/backing status line is highlighted, a menu of switchable items will

appear.

Note: If SYSI is opened during the vacuum cycle, all connected controllable components will be switched OFF.

If the selected item is the relay status line, a list of the relays will appear. Scroll to the required relay, use the ’cycle’

( ) button to switch th e item. When the relay is activa ted the annunciator on the view screen will change to reverse

video.

4.6 Changing list items

To change a list item, scroll to the required line and press the ‘Select’ ( ) button. The list can then be scrolled

using the up and down arrows ( / ).

Pressing the ‘Select’ ( ) button will accept the adjustment and return the highlight to the row item, allowing

another item to be selected for adjustment.

Pressing the ‘Menu’ ( ) button will cancel the adjustment and return the highlight to the row item, allowing

another item to be selected for adjustment.

Operation

4.7 Changing numerical values

To change a numerical item, scroll to the required line and press the ‘Select’ ( ) button. The first number will then

be highlighted and can be changed using the up and down arrows ( / ).

The ‘Select’ ( ) button will move the highlight to the next digit with ea ch successive press, allowing the co mplete

number to be entered. Pressing the ‘Select’ ( ) button with the last digit selected will accept the adjustment and

return the highlight to the row item, allowing another item to be selected for adjustment.

At any time, mistakes can be corrected by pressing the ‘Menu’ ( ) button. This will move the highlight to the

previous digit with each successive button press, allowing co rre c ti ons to be ma de . Pr ess ing the ‘Menu’ ( ) button

with the first digit selected will cancel the adjustment and return the highlight to the row item, allowing another

item to be selected for adjustment.

Figure 18 - Changing numerical values

4.8 Turbo set up

All setups in the TIC are held in non-volatile memory. Non-volatile memory has a limit on the number of times

its content can be changed. Current minimum lifetime is 100,000 changes on a particular section, this equates

to in excess of 1 change per hour every hour for 10 years. If you exceed this number of changes random data

may be stored leading to unexpected system behaviour.

4.8.1 Introduction

The TIC can be used to configure the EXT, DX and nEXT pump ranges. The menu screen shows differing functionality

depending on the pump attached. The TIC will recognise the pump attached, which will be seen on the pump set up

and pump status screen. (Refer to Figure 19).

© Edwards Limited 2013. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 28

D397-12-880 Issue J

Operation

4.8.2 Default turbo set up options

Menu option Description

Ramp Up Timer The user can set the ramp up timer from 1 to 30 minutes. This timer will

Droop Timer The user can set the droop time from 1 to 30 minutes. This timer will generate

Heater time The user can set the time that the heater band bakes out the turb o pump from

Start delay The start delay enables the user to delay the start of the turbo pump from 0 to

System ON Allows the user to define the components of the system that are to be turned

System OFF Allows the user to define the components of the system that are to be turned

Figure 19 - Turbo set up screen

Table 9 - Default turbo setup options

generate an alarm if the pump speed does not rise above 50% speed after the

set time.

an alarm if the pump speed drops below 50% speed for longer than the

specified time.

0 to 35 hrs. The heater will come on for the set time, once the pump reaches

'normal speed'. If the pump drops below 'normal speed', the heater band will

switch off and the timer will be reset.

99 minutes.

on, when the 'system' is cycled on.

off, when the 'system' is cycled off.

Note: The system ON and OFF commands provid e manual control of the items

listed. Where possible it will override set tings such as bac king options

and gauge linking.

Note: If the backing pump option has been set to 50% or on stop, ’seq’ will be

indicated showing the backing pump is sequenced to one of the

options.

Air cooler The user can set when a Edwards air cooler should operate. The air cooler can

be set to 'ON' (on permanently) or 'Turbo' (on when the turbo pump is running).

TIC vent options A vent valve attached to the TIC can be operated in the following ways:

'On stop' to open the vent valve 2 seconds after the stop command, or '50%' to

open the vent valve when the pump slows to 50% speed.

Page 22 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 29

D397-12-880 Issue J

CAUTION

CAUTION

Table 9 - Default turbo setup options (continued)

Menu option Description

Backing pump options A backing pump attached to the TIC or via a relay box can be operated in the

following way:

None: The backing pump is not sequenced to the Turbo

pump

50%: The backing pump will turn off after 2 seconds,

once the turbo speed has dropped to 50% of its

speed. The delay allows detritus to be removed

from the system on stop.

On stop: The backing pump will turn off 4 seconds after the

Turbo off command has been sent. The 4 second

delay allows shutting of a valve and then removal

of detritus from the system.

Please refer to Table 10 for error and diagnostic information for pumps.

If an Edwards 24 V backing pump is connected, it is advised that the overall power used does not exceed the

data specified in Section 2.

Operation

Table 10 - Error/diagnostic monitoring, pumps

Diagnostic messages Description

RampUp Timeout Check whether the pump is too hot or whether the inlet pressure is too high.

Check that the backing pump is operational.

Check your vacuum system for leaks.

Droop Timeout Check whether the pump is too hot or whether the inlet pressure is too high.

Check that the backing pump is operational.

Check your vacuum system for leaks.

4.8.3 Additional set up options using a DX or nEXT pump

The TIC allows the user to set up additional functionality available within a DX, nEXT or nXDS pump.

Read the DX or nEXT pump manual before using the TIC to set up the DX, nEXT or nXDS pump.

Turbo vent options - If a DX, nEXT or nXDS pump is attached, the user can set up one of the Turbo vent options. The

user can set up the Turbo vent, and also the TIC vent to enable two vent valves to be connected to a vacuum system.

(Refer to Table 11).

Table 11 - Turbo pump vent options

On screen Description

50% Vent valve opens fully below 50% full rotational speed for both Stop command or Fail

Note: This is the default factory setting.

50%CvV Controlled venting from 100% - 50% full rotational speed;

Ven t valve opens fully below 50% for both Stop command or Fail

STP50% Vent valve opens fully immediately Stop command is received;

Vent valve opens fully below 50% full rotational speed if Fail

© Edwards Limited 2013. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 30

D397-12-880 Issue J

Operation

On screen Description

STPCnV Vent valve opens fully immediately Stop command is received;

FLT50% Vent valve opens fully immediately if Fail;

FLTCnV Vent valve opens fully immediately if Fail;

STPFLT Vent valve opens fully immediately for both Stop command or Fail

FLTSTP Vent valve opens fully immediately for both Stop command or Fail

FAN Vent is Permanently Enabled, and can be used to provide power to a Edwards air

Menu option Description

Normal The TIC allows ‘normal speed’ to be set as a percentage of full speed.

Standby speed The user can set the standby speed as a percentage of full speed.

Max power The user can set the maximum power a DX pump can use.

Braking Off/Enabled. The user can utilise this function to slow the turbo pump at a quicker

Service opt nEXT service indication options. Podule flashing LED, fail line, both, none.

Table 11 - Turbo pump vent options (continued)

Controlled venting from 100% - 50% full rotational speed then vent valve opens fully

below 50% if Fail

Ven t valve opens fully below 50% full rotational speed if Stop

Controlled venting from 100% - 50% full rotational speed then vent valve opens fully

below 50% if Stop command received

cooler

Table 12 - DX,nEXT and nXDS pump set up options

rate.

Please refer to Table 13 for the error and diagnostic information for DX, nEXT and nXDS pumps.

Table 13 - Error/diagnostic monitoring, DX, nEXT and nXDS pumps

Diagnostic messages Description

Serial ID Fail A DX, nEXT, nXDS or serial pump is connected, however the type has not been

recognised. Please check the leads are connected.

Turbo Fault Review the flashing error codes on the pump podule, and refer to the DX, nEXT or

nXDS instruction manual.

SC Interlock Serial enable to the DX, nEXT or nXDS pump was lost while it was running. This could

be caused by a temporary loss of power or a broken wire. It is recommended to stop

the pump and then restart it. If the alarm does not clear , cycle the controller and then

try again.

Uload Timeout Check that the pump is correctly connected, then try to upload again.

Dload Failed Check that the pump is correctly connected, then try to download again.

nEXT Service due warning One of the nEXT items has exceeded its service interval. See nEXT Service screen for

details. Contact Edwards for a suitable service kit or to arrange a service by Ed wards.

nXDS Service due warning One of the nXDS items has exceeded its service interval. See nXDS Service screen for

details. Contact Edwards for a suitable service kit or to arrange a service by Ed wards.

Page 24 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 31

D397-12-880 Issue J

4.9 Backing set up

Table 14 - Default Backing set up options

Menu option Description

Start delay The start delay enables the user to delay the start of the turbo pump from 0 to 99 minutes.

System ON Allows the user to define the components of the system that are to be turned on, when the

'system' is cycled on.

System OFF Allows th e user to define the components of the system that are to be turned off, when the

'system' is cycled off.

Note: The system ON and OFF commands provide manual control of the items

listed.Where possible it will override settings such as backing options and gauge

linking.

Note: If the backing pump option has been set to 50% or on stop, ’seq’ will be indicated

showing the backing pump is sequenced to one of the options.

Air cooler The user can set when an Edwards air cooler should operate. The air cooler can be set to

'ON' (on permanently) or 'Turbo' (on when the turbo pump is running).

TIC vent options A vent valve attached to the TIC can be operated in the following ways:

'On stop' to open the vent valve 2 seconds after the stop command, or '50%' to open the

vent valve when the pump slows to 50% speed.

Backing pump options A backing pump attached to the TIC or via a relay box can be operated in the following

way:

None: The backing pump is not sequenced to the Turbo pump50%: The backing pump will

turn off after 2 seconds, once the turbo speed has dropped to 50% of its speed. The delay

allows detritus to be removed from the system.

On stop: The backing pump will turn off 4 seconds after the Turbo off command has been

sent. The 4 second delay allows shutting of a valve and then removal of detritus from the

system.

Operation

Table 15 - nXDS pump set up options

Menu option Description

Normal The TIC allows ’normal speed’ of the backing pump to be set as a percen tage of full sp eed .

Standby speed The user can set the standby speed of the backing pump as a percentage of full speed.

Autorun Sets the nXDS to start when power is turned on

Service opt nXDS service indication options. Podule flashing LED, fail line, both, none.

4.10 Alarms

If an Alarm occurs, an ‘Alarms’ warning will begin flashing in the lower half of the view screen. Refer to Figure 17.

The Alarm can then be selected by moving the cursor over it and pressing the ‘Select’ ( ) button. This action will

take you to the Alarms screen. Alternatively the Alarms screen can be accessed through the main menu.

The Alarm will stop flashing when it has been acknowledged and will disappear when the alarm situation no longer

exists. An alarm is acknowledged by pressing the ‘Select’ ( ) button whilst the flashing alarm is highlighted.

To clear an alarm you will need to refer to the fault finding guid e in Section 5 of this instruction manual. This guide

gives information of what the alarm is and the possible solutions for clearing the alarm.

In a similar way a warning can appear. To clear it take the same actions as for alarms above.

© Edwards Limited 2013. All rights reserved. Page 25

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 32

D397-12-880 Issue J

Operation

4.11 The main menu

The main menu can be accessed by pressing the ‘Menu’ ( ) button on the view screen (refer to Figure 14). From

here the following sub-menus can be accessed.

4.12 Turbo status

This screen allows the user to view the current status of the Turbo and Backing pumps. Basic information such as:

Whether the Turbo pump is ON or OFF and a graph of its speed.

The state of the turbo pump that the user has requested.

Whether the Backing pump is ON or OFF.

The power that the Turbo pump is using.

The speed of the Turbo pump as a percentage of full speed.

The temperature of the Turbo drive. (Only on DX and nEXT pumps).

The temperature of the Turbo pump. (Only on DX and nEXT pumps).

The cycle time is the run time of the current cycle. (Only on DX and nEXT pumps).

Whether the TIC vent valve is ‘on/off’.

Service menu - enter, press enter to move to the nEXT Service screen.

Table 16 - nEXT Service Screen

nEXT Service Description

Service due Indicates which service is due - None, Oil, Bearing, Turbo, Controller.

Shows only initial letters if multiple services are due - O B T C.

Oil run Hours run since last service.

Oil until Hours left to run until next service.

Bearing run Hours run since last service.

Bear until Hours left to run until next service.

Turbo run Hours run since last service.

Turbo until Hours left to run until next service.

Contlr run Stress adjusted hours controller has been powere d since last service . Stress

adjustment - hours can advance slower or faster than real time depending

on temperature and load.

Cntlr until Stress adjusted hours controller is powered left until next service.

Turbo cycle Start/stop cycles run since last service.

Cycle until Start/stop cycles left to run until next service.

Reset Service Due ... Press enter to move to the nEXT Service Reset screen.

Table 17 - nEXT Service Reset Screen

nEXT Service Reset Description

Select line below and press enter

after servicing

Reset oil due Press enter key to reset only the oil service due

Reset bearing due Press enter key to reset only the bearing service due

Page 26 © Edwards Limited 2013. All rights reserved.

Instructions to follow

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 33

D397-12-880 Issue J

4.13 Backing status

This screen allows the user to view the current status of the Turbo and Backing pumps. Basic information such as:

Whether the Backing pump is ON or OFF and a graph of its speed.

The state of the turbo pump that the user has requested.

Whether the Backing pump is ON or OFF.

The power that the Backing pump is using.

The speed of the Backing pump as a percentage of full speed.

The temperature of the Backing drive. (Only on nXDS pumps).

The cycle time is the run time of the current cycle. (Only on nXDS pumps).

Whether the TIC vent valve is 'on/off'.

Service menu - enter, press enter to move to the nXDS Service screen.

Table 18 - nXDS Service Screen

nXDS Service Description

Service due Indicates which service is due - None, Tip Seal, Bearing, Backing, Controller. Shows only

initial letters if multiple services are due - O B T C.

TipSeal run Hours run s ince last service.

TipSeal til Hours left to run until next service.

Bearing run Hours run since last service.

Bear until Hours left to run until next service.

Back run Hours run since last service.

Cntlr run Stress adjusted hours controller has been powered since last service.

Stress adjustment - hours can advance slower or faster than real time depending on

temperature and load.

Back cycle Start/stop cycles run since last service.

Reset Service Due ... Press enter to move to the nXDS Service Reset screen.

Operation

Table 19 - nXDS Service Reset Screen

nXDS Service Reset Description

Select line below and press enter after servicing Instructions to follow

Reset Tip Seal due Press enter key to rese t only the oil service due

Reset bearing due Press enter key to reset only the bearing service due

© Edwards Limited 2013. All rights reserved. Page 27

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 34

D397-12-880 Issue J

Operation

4.14 Parameters/units

This screen allows the user to change the units that are displayed and other parameters such as:

Setup lock - When the 3 digit lock code is entered, the lock is enabled and an operator will not be able to

change any of the setups, however the operator is still able to scroll through the menus and start and stop

pumps. The lock is disabled by entering the 3 digit unlock code. Lock - 501, unlock - 147.

Panel Lock - This function completely locks the front panel. An operator will only be able to see the view

screen. Lock - 509, unlock - 824.

The 0 - 10 V analogue output on the logic interface can be set to follow the turbo speed.

Display contrast allows the user to change the contrast of the display.

Protocol shows whether RS232 or RS485 is being used.

Comms address - To set the comms address of the TIC.

TMPI Alert off - To disable/enable the warning when using TMPI line to start the Turbo pump.

BMPI Alert off - To disable/enable the warning when using BMPI line to start the Backing pump.

4.15 Relay setpoint outputs

The relay setpoints option allows the setpoint outputs on the logic interface to be linked to turbo speed. When

selected, a summary of the current setting is displayed. The default setting for the three relays is ‘Not Linked’.

There are four steps to set up the links, proceed as follows:

Select the controlled relay. Scroll to the relay that is to be controlled and press the ‘Select’ ( ) button.

Select the controlling item. The top highlighted line is used to select the controlling item. The controlling item can

either be ‘Not Linked’ or ‘Turbo Speed’ (%). Press the ‘Select’ ( ) button to confirm the choice.

Enter the required setpoint. The ‘On’ and ‘Off’ setpoints can be adjusted to suit the application. For pumps, the unit

used is ‘Turbo Speed’ (%).

Note: For pumps, the ‘Off’ setpoint is less than or equal to the ‘On’ setpoint.

Enable the set point. Once configured, the setpoint should be enabled by changing the bottom ‘Setpoint’ line from

‘OFF’ to ‘ENABLED’.

Page 28 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 35

D397-12-880 Issue J

4.16 Service information

Service information contains the following information:

Software Issue - This is the issue of the currently installed software. This will change when new software is

downloaded to the TIC in the future.

Serial Number - The serial number of the TIC is used when contacting Edwards about the product.

Analogue O/P - The analogue output value (internal units) is used when contacting Edward s about the

product.

PSU Temp - Temperature of PSU.

TIC Temp - Temperature of TIC.

Turbo run - Number of hours the turbo pump has been run (DX and nEXT pumps only).

Upload Turbo - The TIC can store one set of the pump’s configuration. This function will upload the current

configuration from the attached pump (DX and nEXT pump only).

Download Turbo - The TIC can download one set of configurations to DX and nEXT pumps, once a

configuration has been uploaded. This function will download the stored configuration to the attached pump

(DX and nEXT pump only).

Operation

Reset Trbo - Reset the turbo pump to it’s factory defaults (DX and nEXT pumps only).

Reset TIC - Resets the TIC to it’s factory default configuration and can be used to quickly undo all user

settings (relay setpoints, units, etc.).

4.17 Electrical supply failure

If the electrical supply to the controller fails while the turbo pump is rotating at high speed, the pump begins acting

like a generator and will supply power back to the TIC. This power will be used to maintain operation of the vent

valve, and if enough power is available the TIC will maintain operation.

The power returned to the TIC is not made available to the logic interface or the air cooler; all of these will stop

operating until power is restored.

Once the turbo pump speed falls below 50%, the vent valve will open and the TIC will shut down.

© Edwards Limited 2013. All rights reserved. Page 29

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 36

D397-12-880 Issue J

This page has been intentionally left blank.

Page 30 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 37

D397-12-880 Issue J

WARNING

5Maintenance

5.1 Safety

Obey the safety instructions given below and take note of the appropriate precautions. If you do

not, you could cause injury to people or damage to equipment.

There are no serviceable parts on the TIC. Do not open, return to your nearest Edwards service centre for any repairs

that are necessary.

The Edwards return of equipment forms can be found at the rear of this manual.

5.2 Fault finding

Table 20 - Fault finding

Diagnostic messages Description

RampUp Timeout R efer to Table 10

Pump

DX and nEXT

General

Droop Timeout Refer to Table 10

Serial ID Fail Refer to Table 13

Turbo Fault Refer to Table 13

SC Interlock Refer to Table 13

Uload Timeout Refer to Table 13

Dload Failed Refer to Table 13

nEXT Service Due Refer to Table 13

SYSI Inhibit The system interlock has been disconnected. Please check that the logic

interface plug is connected correctly, or check the status of the system

interlocks.

Ext Inhibit Enable lines have been disconnected, please check the Turbo or Backing

pump enable lines.

No Reading An object has not received a value update from its source within a given

time and is flagging that its value is now old. Check connections to

components of system.

No Message

An object has not received a reply to a message it sent within a given time.

Check logic interface connections, are correctly attached to the TIC.

Maintenance

Brownout/Short

Either the loading on the TIC outputs exceeds a certain current level or

there was a brownout of the mains power while a turbo was spinning and

could provide some regen power. Remove the short or high load and then

accept the error, the TIC will re-at tempt to drive the output. If a brownout

wait for it to pass and then accept the error.

5.3 Cleaning the controller

If necessary, use a soft dry clo th to cle an the exterio r of the Controller. Do not clean with harsh abrasives or liquids.

If the interior of the Controller requires cleaning, it is our recommendation that you return the Controller to your

supplier or your nearest Edwards Service Centre.

© Edwards Limited 2013. All rights reserved. Page 31

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 38

D397-12-880 Issue J

Maintenance

5.4 Software updates

The software within the Controller and the TIC PC monitor program will be updated as part of Edwards ongoing

development program. The updates and associated instruction manual can be found by visiting

www.upgrades.edwardsvacuum.com.

5.5 Factory defaults

The following is a list of factory default settings for the TIC:

Table 21 - Factory default settings

Menu option Default

Pump and relay slaving - not slaved

Turbo pump start delay = 0

EXDC Ramp time = 8

EXDC Droop time = 8

Analogue out slaved = NONE

TIC vent = 50%

Heater band = 0 hrs

Air Cooler = Turbo

Setup lock = Off

Panel lock = Off

Display contrast = 5

PC comms = RS232

Multi-drop address = 0

Default screen = All

System On = Backing

System Off = Turbo

Backing option = None

Page 32 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 39

D397-12-880 Issue J

WARNING

6 Storage and disposal

6.1 Storage

Store the Controller in clean dry conditions in accordance with the technical specifications. Refer to Section 6 of the

main manual on CD.

6.2 Disposal

Dispose of the Controller and any components safely in accordance with all-local and national safety and

environmental requirements.

Alternatively, you may be able to recycle the Controller and/or cables; contact Edwards or your supplier for advice

(also see below).

The Controller and associated cables are within the scope of the European Directive on Waste Electrical and

Electronic Equipment, 2002/96/EC. Edwards offer European customers a recycling service for the Controller/cables

at the end of the product’s life. Contact Edwards for advice on how to return the Controller/cables for recycling.

Storage and disposal

Do not incinerate the Controller. If the Controller is heated to very high temperatures, dangerous

gases may be emitted and internal components may explode.

© Edwards Limited 2013. All rights reserved. Page 33

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 40

D397-12-880 Issue J

This page has been intentionally left blank.

Page 34 © Edwards Limited 2013. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 41

D397-12-880 Issue J

7 Service, spares and accessories

7.1 Service

A worldwide network of Edwards Service Centres supports Edward’s products. Each Service Centre offers a wide range

of options including equipment decontamination; service exchange; repair; rebuild and testing to factory

specifications. Equipment, which has been serviced, repaired or rebuilt, is returned with a full warranty.

For more information about service options, contact your nearest Service Centre or other Edwards company.

7.2 Spares

Spare Item Number

TIC Front Bezel Kit D397-00-803

TIC Logic Interface D397-00-850

Front Panel Assembly D397-00-822

Note: This assembly is suitable for customers who have electrical and electronic repair expertise and possess a

portable appliance tester. If the customer is unable to carry out this repair, the Controller should be

returned to Edwards for a full repair and safety re-test.

Service, spares and accessories

7.3 Accessories

Table 22 shows the range of accessories that can be purchased.

Table 22 - Accessories

Product Description Ordering Information

TIC Controllers

TIC Profibus Module D397-50-000

Turbo Pumps and Controllers

EXT70H range

(EXDC80 Control Module required with above Turbo Pumps) D396-45-000

EXT255H range

(EXDC160 Control Module required with above Turbo Pumps) D396-46-000

EXT75DX range

EXT255DX range

nEXT range

Extension Cables DX/EXDC and 24 V backing pumps

1 m DX/EXDC extension cable (16/0.2) D397-00-835

3 m DX/EXDC extension cable (16/0.2) D397-00-836

5 m DX/EXDC extension cable (16/0.2) D397-00-837

Air Cooler

ACX70 B580-53-050

ACX250 B580-53-150

© Edwards Limited 2013. All rights reserved. Page 35

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 42

D397-12-880 Issue J

Service, spares and accessories

Table 22 - Accessories (continued)

Product Description Ordering Information

Vent Valves

TAV5

TAV6

Examples of compatible 24 V backing pumps

XDD1 24 V d.c. Diaphragm pump A746-01-991

Examples of compatible mains backing pumps

XDS10 220-240 V 50 Hz 1-phase A726-01-903

XDS10 115-120 V 60 Hz 1-phase A726-01-906

E2M1.5 220-240 V 50/60 Hz 1-phase A371-22-919

E2M1.5 115-120 V 50/60 Hz 1-phase A371-22-902

RV12 110-120 V 60 Hz or 220-240 V 50 Hz 1-phase A655-01-903

E2M28 220-240 V 50 Hz or 230-240 V 60 Hz 1-phase A373-15-903

E2M28 115/230 V 60 Hz 1-phase A373-15-981

Bakeout band (via optional relay box)

BX70 240 V 30 W (EXT70H & EXT75DX) B580-52-060

BX70 110 V 30 W (EXT70H & EXT75DX) B580-52-040

BX250 240 V 60 W (EXT255H) B580-52-061

BX250 110 V 60 W (EXT255H) B580-52-041

24 V backing line valves (via optional relay box)

LCPV16EKA 24 V a.c./d.c. C417-51-200

LCPV25EKA 24 V a.c./d.c. C417-52-200

Relay Boxes

TIC Relay box 3 x 240 V 3 A D397-00-804

TIC Relay box D397-11-805

TIC Relay box comb D397-21-806

Interface cables

2 m Logic interface cable D397-00-833

2 m RS232 interface cable D397-00-834

Mains cables (Suitable for TIC controllers)

2 m UK plug D400-13-025

2 m USA plug D400-13-120

2 m Northern European plug D400-13-120

Other accessories and supporting products

TIC software upgrade www.upgrades.edwardsvacuum.com

B580-66-010

B580-66-020