Edwards D397-00-000, D397-01-000, D397-02-000, D397-11-000, D397-12-000 Instruction Manual

...Page 1

Issue H Original

Note: Laptop PC not included

Instruction Manual

Turbo Instrument Controller (TIC) Serial Communications

D397-30-880

Description Item Number

TIC Instrument Controller D397-00-000

TIC Instrument Controller 6-Gauge D397-01-000

TIC Instrument Controller 6-Gauge Capacitance Manometer D397-02-000

TIC Turbo Controller 100 W D397-11-000

TIC Turbo Controller 200 W D397-12-000

TIC Turbo & Instrument Controller 100 W D397-21-000

TIC Turbo & Instrument Controller 200 W D397-22-000

Page 2

This page intentionally blank.

Page 3

D397-30-880 Issue H

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope ...................................................................................................................... 1

1.2 Message basics ........................................................................................................... 1

1.2.1 Commands ................................................................................................................ 1

1.2.2 Queries .................................................................................................................... 1

1.2.3 Responses .................................................................................................................2

1.2.4 Setup ....................................................................................................................... 2

1.3 DX, nEXT and nXDS pumps .............................................................................................. 2

1.4 Communications timings ................................................................................................ 2

1.5 Object IDs ................................................................................................................. 2

1.6 TIC serial protocol messages ........................................................................................... 3

1.6.1 TIC serial protocol - multi-drop prefix to a message ............................................................... 3

1.6.2 PC serial ................................................................................................................... 3

1.7 Additional information ................................................................................................. 12

1.7.1 Serial comms response codes (*Cnnn x, *S, *V) ....................................................................12

1.7.2 Priority ...................................................................................................................12

1.7.3 Alert ID ...................................................................................................................12

1.7.4 SNVT values ..............................................................................................................14

1.7.5 Command list ............................................................................................................14

1.7.6 State ......................................................................................................................14

1.7.7 Active gauge states .....................................................................................................14

1.7.8 Full pump states ........................................................................................................15

1.7.9 Gas types .................................................................................................................15

1.7.10 Gauge types .............................................................................................................15

1.7.11 Pump types ..............................................................................................................16

Contents

Index ................................................................ .............................. 17

For return of equipment, complete the HS Forms at the end of this manual.

Table

Page

1 Objects accessed via the PC serial comms .......................................................................... 4

2 Abbreviations ............................................................................................................ 11

3 Serial comms response codes .........................................................................................12

gea/0077/05/10

© Edwards Limited 2012. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 4

D397-30-880 Issue H

This page has been intentionally left blank.

Page ii © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 5

D397-30-880 Issue H

CAUTION

1Introduction

1.1 Scope

This manual provides Operation instructions for serial interface communications to the Edwards Turbo Instrument

Controller product range, part numbers:

Description Item Number

TIC Instrument Controller D397-00-000

TIC Instrument Controller 6-Gauge D397-01-000

TIC Instrument Controller 6-Gauge Capacitance Manometer D397-02-000

TIC Turbo Controller 100 W D397-11-000

TIC Turbo Controller 200 W D397-12-000

TIC Turbo & Instrument Controller 100 W D397-21-000

TIC Turbo & Instrument Controller 200 W D397-22-000

Before using these instructions, ensure that you have a good understanding about the operation of the

controller.

Introduction

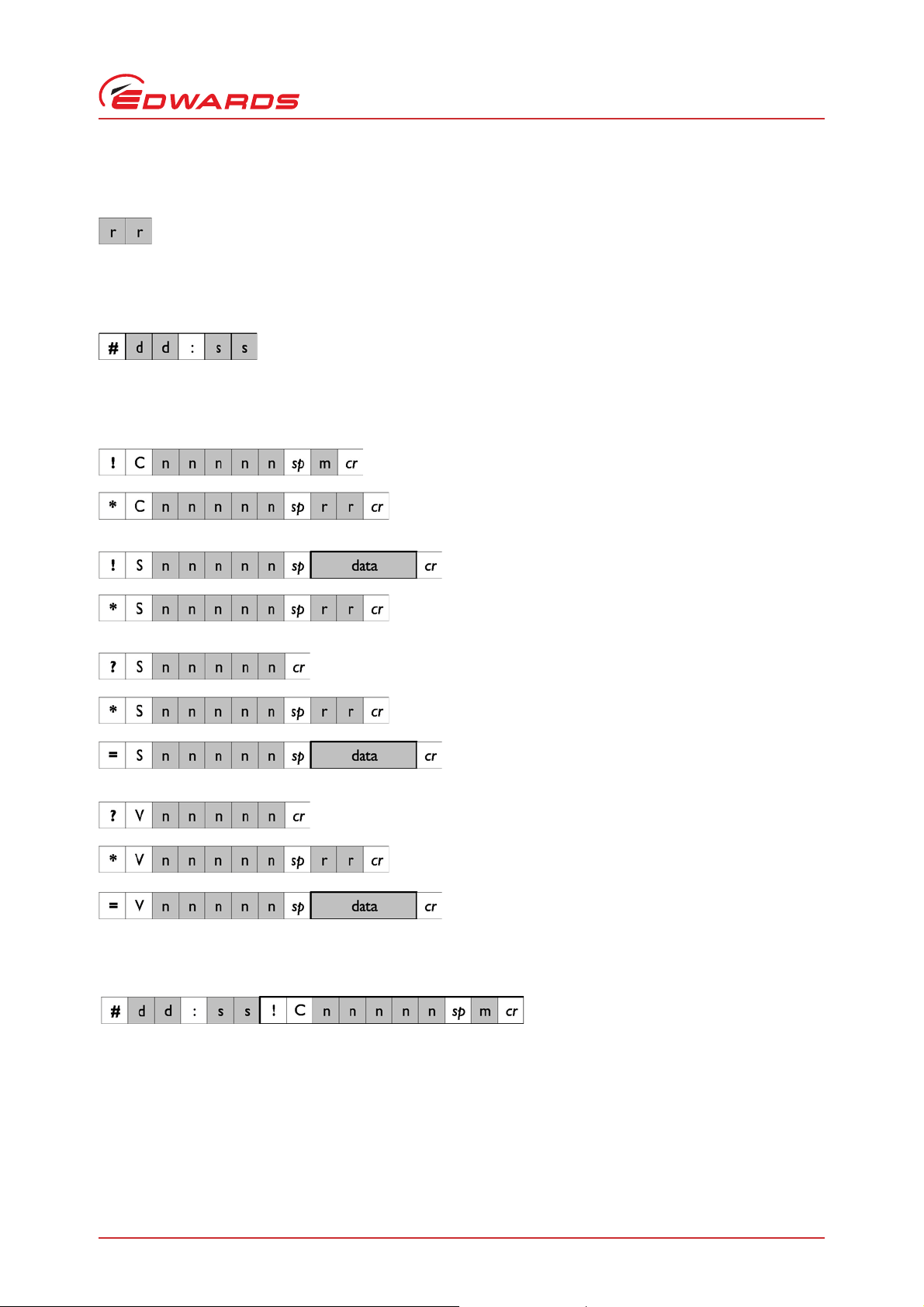

1.2 Message basics

The communications to the TIC work on a master/slave principle. The TIC is the slave and will only transmit a message

in response to one sent to it. The master, a PC for example, must always start the conversation.

A conversation consists of a message to the TIC and its response b ack. Having sent a message to the TIC, wait for the

reply before continuing.

There are two basic types of message sent to the TIC:

Command sending information to the TIC (!).

Query requesting information from the TIC (?).

All messages end with a carriage return.

In multi-drop mode, the ? and ! are preceded by the addressing information.

Characters not enclosed by start (!?) and end (cr) characters will be ignored. Incomplete messages will be ignored if

a new start character is received.

1.2.1 Commands

Commands send information to the TIC. These can be literal commands such as 'turn pump on' or setups to be stored

by the TIC. Setups hold information about how the TIC should behave such as the conditions under which the vent

valve should open.

1.2.2 Queries

Queries request information from the TIC. These can be direct queries of the value of a parameter such as pump

speed, or reading the setup value currently in the TIC.

© Edwards Limited 2012. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

D397-30-880 Issue H

Introduction

1.2.3 Responses

Responses from the TIC contain either the data requested (=) or the status of the command (*). Note that for

commands such as Upload/Download, the action will continue after the response has been received. Also detailed

checking is performed by the objects themselves so a good response only guara ntees that the message was accepted

by the serial communications, correct behaviour must be checked by querying the appropriate attribute. For example

write a setup, read it back and check the updates are as requ ested.

1.2.4 Setup

Some objects have more than one setup, for these objects the config type is sent and returned as the first paramete r

in the data field.

1.3 DX, nEXT and nXDS pumps

The TIC will pass messages to the DX, nEXT or nXDS pump and return the replies. It limits some of the commands that

can be sent directly as the TIC must take account of setups and inputs connected to it. For example, if SYSI is set

into the fail condition; the turbo pump must not run so on/off commands directly to the DX, nEXT or nXDS are always

ignored, use the TIC turbo object instead.

Under a fault condition the DX and nEXT move through their state machines slightly differently. The TIC adjusts the

information from the nEXT so the TIC’s states move like the DX for both pum p types. On fault the TIC shows both

pumps as fault braking until a stop command is issued. At this point the fault is cleared from the pump object 904

and the front panel.

When not using the TIC the main visible difference is that the DX clears its fault bits and fault LED when a stop

command is issued. The nEXT does not clear them until both a stop and then a start command are issued.

1.4 Communications timings

Because of the complexity of the product precise message timings are not defined, however, the following are

provided for guidance:

Basic messages less than 100 mSecs

Messages to DX, nEXT or nXDS (dependent on DX or nEXT behaviour) less than 200 mSecs

Suggested timeout in master 500 mSecs

Upload Turbo (DX/nEXT) less than 2 secs

Download Turbo (DX/nEXT) less than 4 secs

1.5 Object IDs

This sub-section summarises the protocol, based on the use of object IDs, to identify sources and destinations in

messages.

Objects can be physical items such as gauges and pumps, or virtual items such as software modules and data records.

Each object is allocated a unique identification number, although two instances of a particular item will both have

the same ID. In a message, the Object ID consists of 1 - 5 ASCII digits representing a number between 1 - 65535, as

shown below:

Data fields contain command codes, parameter values or response codes, and will vary in length and format according

to the message type. If there is more than one item in the data field, each item is separated by a semi colon(;).

Page 2 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

D397-30-880 Issue H

A returned response code consists of 1 or 2 characters representing a number between 0_99. A code of '0' always

means 'OK'. Other codes can be used to indicate various error conditions:

Where several items are linked together using multiple RS232 lines radiating from a hub, a 'multi-drop' identifier is

prefixed to each message. It is composed of a '#', followed by a 2 character Destination ID, a colon, and a 2 character

Source ID:

1.6 TIC serial protocol messages

GENERAL COMMAND

NORMAL (or ERROR) RESPONSE

Introduction

NORMAL (or ERROR) RESPONSE

1.6.1 TIC serial protocol - multi-drop prefix to a message

SETUP COMMAND

QUERY SETUP

ERROR RESPONSE

NORMAL RESPONSE

QUERY VALUE

ERROR RESPONSE

NORMAL RESPONSE

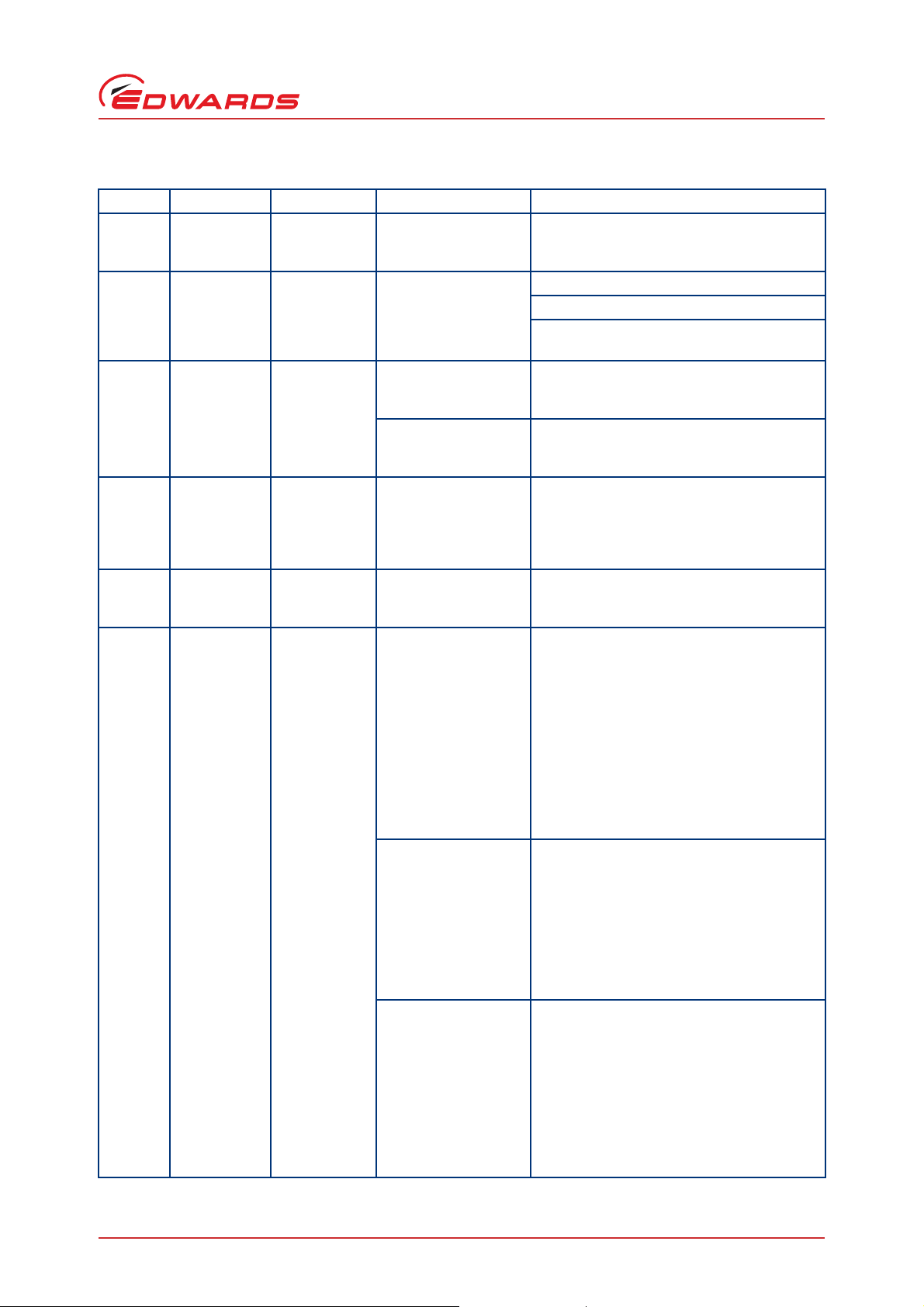

1.6.2 PC serial

This covers operations specific to the PC serial link covering control, monit orin g a n d se tup of all sections of the TIC

and the attached pumps.

Objects in the DX, nEXT or nXDS pump can be read via the TIC at their normal object ID and the TIC will pass the

messages on and return the reply, refer to DX, nEXT or nXDS requirements Section 1.3. Wait for the reply before

sending in another message even if the new message is for the TIC or 'other' pump.

© Edwards Limited 2012. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

D397-30-880 Issue H

Introduction

The following objects can be accessed via the PC serial comms:

Table 1 - Objects accessed via the PC serial comms

Object ID Object Operations Notes

800 + DX, nEXT and

nXDS objects

901 Node ?S

!S

902 TIC Status ?V T – see turbo state

0 – 98 Read multi-drop

B – see backing state

G – see gauge state

R – see relay state

Alert ID of 902

Highest priority level

in system

Routed, refer to DX, nEXT and nXDS pump

manual

Set multi-drop

Config type not needed

System status, depends on unit type –

TC

T;B;R1;R2;R3;Alert ID; priority

TIC

T;B;G1;G2;G3;R1;R2;R3;Alert ID; priority

NB just the state value

is returned between;

?S max 80 chars, typical 40Read system string - TICxxx; SW Ver; Ser

903 Unused

904 Turbo Pump ?V State 0 – 7 - see

Section 1.7.8

Alert – see

Section 1.7.3

Priority – see

Section 1.7.2

!C On =1

Off = 0

?S

!S

905 Turbo speed ?V Value 0.0 – 110.0% Turbo speed – value; alert ID; priority

?S

!S

see pump type list Read pump type

Master – object ID

gauge 1/2/3

Units type – 59, 66 see

snvt list

Setpoint –

volts 0.000 – 9.999,

pressure float.

Enable 1 = on, 0 = off

Delay 0 – 99 mins Read start delay

Times 1 – 30;

0 - 30 mins

IC

G1;G2;G3;R1;R2;R3;Alert ID; priority

IC6

G1;G2;G3;G4;G5;G6;R1;R2;R3;R4;R5;R6;

Alert ID; priority

e.g. TIC

4;4;0;11;0;0;4;0;0;0

Num; PIC SW ver

Config type not needed

Pump status – state; alert ID; priority

Turn pump on/off

Config type = 3

Read slave setup – master; units type; on

setpoint; off setpoint, enable

Write slave setup – master; units type; on

setpoint; off setpoint, enable

Config type = 4

Write start delay

Config type = 21

Read start fail time; droop fail time

Write start fail time; droop fail time

Config type not needed

Page 4 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

D397-30-880 Issue H

Table 1 - Objects accessed via the PC serial comms (continued)

Object ID Object Operations Notes

906 Turbo power ?V Value 0.0 – 300.0 w

(typ)

907 Turbo normal ?V State 0 = no, 4 = yes At normal speed – state; alert ID; priority

908 Turbo standby ?V 4 = in standby

0 = not in standby

!C 1 = set standby

0 = set not standby

909 Turbo cycle

time

910 Backing Pump ?V State 0 – 4 Pump status – state; alert ID; priority

911 Backing speed ?V Value 0.0 – 100.0% Backing speed - value; alert ID; priority

912 Backing power ?V Value 0.0 – 50.0 w

913 Gauge 1 ?V Value – pressure (see

?V V alue - 0-65535 hours Time period turbo has been on - value; state;

!C Turn pump on/off

?S

!S

?S

!S

!C Commands – see

see pump type list Read pump type

None = 0

On stop = 1

On 50% = 2

(typ)

gauge type) or voltage

0.000 to 11.000 volts.

Master – object ID

gauge 1/2/3 and turbo

speed.

Units type – 59, 66, 81

see snvt list.

Setpoints to suit units

type and master.

volts 0.000 – 9.999,

pressure float, pascals

speed 0 – 99.

Gauge type – see gauge

list

Gas type – see gas list.

Filter 1 = on,

0 = off.

0 = 1000

1 = 2000 mbar

Gauge name Read user gauge name - 4 characters 0-9, A-Z

command list

Turbo power – value; alert ID; priority

In standby mode

Set standby mode

alert ID; priority

Config type = 3

Read backing sequence options - none/on

stop/50%

Set backing sequence options

Config type = 70

Backing power - value; alert ID; priority

Gauge reading and state – value; units type;

state; alert ID; priority

Read slave setup – master; units type; on

setpoint; off setpoint, enable

Write slave setup – master; units type; on

setpoint; off setpoint, enable

Config type = 4

Read gauge type – e.g. AIMX

Config type = 5

Read gauge setup - gas type (volt); filter on/

off

Set gauge setup - gas type (volt); filter on/off

Config type = 7

Read ASG range

Set ASG range

Config type = 6

Set user gauge name

Config type = 68

Accept new gauge

On/off

Zero/calibrate/degas

Introduction

© Edwards Limited 2012. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

D397-30-880 Issue H

Introduction

Table 1 - Objects accessed via the PC serial comms (continued)

Object ID Object Operations Notes

914 Gauge 2 ?V

?S

!S

!C

915 Gauge 3 ?V

?S

!S

!C

916 Relay 1 ?V State 0 – 4 Relay state on/off - state; alert ID; priority

?S

!S

!C On = 1

917 Relay 2 ?V

?S

!S

918 Relay 3 ?V

?S

!S

919 PS

Temperature

920 Internal

Temperature

921 Analogue out ?V 0 – 255 Analogue out value - value; alert ID; priority

922 External vent

valve

923 Heater band ?V Value 0-2100 mins

924 External Air

Cooler

?V 273.0 – 400.0 celsius

?V see PS temperature TIC internal temperature value - value; alert

?S

!S

?V State 0 – 4 Vent valve state on/off – value; alert ID;

?S

!S

!C 0 = off, 1 = on On/off Heater band

?S

!S

?V State 0 – 4 Air cooler state on/off - value; alert ID;

?S

!S

see gauge 1 see gauge 1

see gauge 1 see gauge 1

Master – object ID

gauge 1/2/3

Units type – 59, 66, 81

see snvt list

Setpoints to suit units

type

Off = 0

see relay 1 see relay 1

see relay 1 see relay 1

offset by 274

i.e. freezing water =

274

Object ID gauge 1/2/3,

turbo speed

On stop = 0

On 50% = 1

State 0 – 4

Turbo slaved = 1

Permanent = 0

Read slave setup – master; units type; on

setpoint; off setpoint, enable

Set slave setup– master; units type; on

setpoint; off setpoint, enable

Config type not needed

Turn relay on/off

Power supply temperature value - value;

alert ID; priority

ID; priority

Read analogue out source

Set analogue out source

Config type not needed

priority

Read vent options – on stop/50%

Set vent options

Config type not needed

Heater band time, state on/off – value;

state; alert ID; priority

Read on time 0-35 hours

Set on time 0-35 hours

Config type not needed

priority

Read permanently on or turbo slaved

Write permanently on or turbo slaved

Config type not needed

Page 6 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

Table 1 - Objects accessed via the PC serial comms (continued)

Object ID Object Operations Notes

925 Display

contrast

926 Configuration

Operations

928 Lock ?S

929 Pressure Units ?S

930 PC comms ?S

931 Default screen ?S

?S

!S

!C see command list Default TIC

!S

!S

!S

!S

-5 – 15 Read contrast setting

Set contrast setting

Config type not needed

Default Turbo send to DX or nEXT pump

Load config to Turbo (DX or nEXT)

Load config from Turbo (DX or nEXT)

?S-Locked = 1

Released = 0

!S-see config list

?S-Locked = 1

Released = 0

!S-see config list

kPa = 1

mbar = 2

Torr = 3

232 = 0

485 = 1

All = 0

Three gauges = 1

Gauge 1 = 2

Gauge 2 = 3

Gauge 3 = 4

Turbo only = 5

One gauge = 6

Six gauges = 7

Turbo + one gauge = 8

Possible IDs are - 913,

914, 915, 934, 935,

936 and 0 = none

As above Read three gauge order

Lock/release config setup

Lock/release front panel

Read display pressure Units – kPascal/mbar/

Torr

Set display pressure Units – kPascal/mbar/

Torr

Config type not needed

Read PC comms to RS232/RS485

Set PC comms to RS232/RS485

Config type not needed

Read default screen

Set default screen

Config type 15

Options 2,3,4 are only available to

D39700640F and earlier.

Options 6,7 are only available to D397 00640G

and later.

TC - option 5 only

TIC - option 0,1,2,3,4,5,6

IC - options 1,6

IC6 - options 1,6,7

Read one gauge order

Set one gauge order

Config type 71

S931 71;Position 1 ID;Pos 2 ID;Pos 3 ID;

Pos 4 ID; Pos 5 ID;Pos 6 ID

Gauge IDs can be in any order and can be

repeated.

0 (zero) ID entry means don’t show this

position.

Set three gauge order

Config type 72

S931 72;Position 1 ID;Pos 2 ID; Pos 3 ID;

Pos 4 ID;Pos 5 ID;Pos 6 ID

Gauge IDs can be in any order and can be

repeated.

0 (zero) ID entry means don’t show this

position but there must be a minimum of

three non-zero entries.

D397-30-880 Issue H

Introduction

© Edwards Limited 2012. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

D397-30-880 Issue H

Introduction

Table 1 - Objects accessed via the PC serial comms (continued)

Object ID Object Operations Notes

932 Fixed/Float

ASG

933 System (TIC

and TC only)?S!S

?S

!S

Float = 1

Fixed = 0

0 = no

1 = yes

Read Float/fixed display (ASG)

Write Float/fixed display (ASG)

Config type not needed

Read/write System On/Off setup

Config type not needed

The message consists of sections of Object

ID; system on; system off.

Any number of whole sections can be sent up

to the maximum of 12. Invalid object IDs will

be ignored. You can send just the sections

you wish to alter e.g. !S933 915;1;1;910;1;0cr

The actual structures for each kind of unit

are shown below. ?S answers will be in this

order and return all relevant entries.

TIC

Turbo 904;on;off;

Back 910;on;off;

Gauge1 913;on;off;

Gauge2 914;on;off;

Gauge3 915;on;off;

Relay1 916;on;off;

Relay2 917;on;off;

Relay3 918;on;off

e.g. = S933 904;0;1;910;1;0;913;0;0;914;0;

915;0;0;916;1;1;917;0;0;918;0;0cr

TC

Turbo 904;on;off;

Back 910;on;off;

Relay1 916;on;off;

Relay2 917;on;off;

Relay3 918;on;off;

e.g. = S933 904;0;1;910;1;0;916;1;1;917;0;0;

918;0;0cr

Recommend read/modify/write sequence to

reduce errors.

!C 0 = off, 1 = on On/off System

System on will turn on objects marked with a

1 in the setup on field

System off will turn off objects marked with

a 1 in the setup off field

?V State 0 - 4 System status - state; alert ID; priority

Page 8 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

Table 1 - Objects accessed via the PC serial comms (continued)

Object ID Object Operations Notes

934 Gauge 4 ?V Value - pressure (see

gauge type) or voltage

0.000 to 11.000 volts.

?S

!S

Master - object ID

gauge 1/2/3 and turbo

speed.

Units type - 59, 66, 81

see snvt list. Setpoints

to suit units type and

master.

volts 0.000 - 9.999,

pressure float,

speed 0 - 99.

Gauge type - see gauge

list

Gas type - see gas list.

Filter - 1 = on, 0 = off.

0 = 1000

1 = 2000 mbar

Gauge name Read user gauge name - 4 characters 0-9,

0 = 0.05

1 = 0.1

2 = 0.2

3 = 1

....

10 = 2000

Gauge reading and state - value; units type;

state; alert ID; priority

Read slave setup - master; units type; on

setpoint; off setpoint, enable

Write slave setup - master; units type; on

setpoint; off setpoint, enable

Config type = 4

Read gauge type - e.g. AIMX

Config type = 5

Read gauge setup - gas type (volt);

filter on/off

Set gauge setup - gas type (volt);

filter on/off

Config type = 7

Read ASG range

Set ASG range

Config type = 6

A-Z

Set user gauge name

Config type = 68

Read CapMan setup - range;units

Write CapMan setup - range;units

Config type = 73

D397-30-880 Issue H

Introduction

2 = mBar

3 = Torr

© Edwards Limited 2012. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

D397-30-880 Issue H

Introduction

Table 1 - Objects accessed via the PC serial comms (continued)

Object ID Object Operations Notes

934 Gauge 4 ?S

!S

!C Commands - see

935 Gauge 5 See Gauge 4 See Gauge 4

936 Gauge 6 See Gauge 4 See Gauge 4

937 Relay 4 ?V

?S

!S

938 Relay 5 ?V

?S

!S

939 Relay 6 ?V

?S

!S

940 Gauge Values ?V Position 1-6.

Filament

1 = 1

2 = 2

Head

1 = A

2 = B

Emission

0 = Auto

1 = 100uAmp

2 = 1 mAmp

3 = 10 mAmp

Restrike

0 = off

1 = on

Constant1

0.020 to 0.480

Constant2

0.020 to 0.480

command list

See Relay 1 See Relay 1

See Relay 1 See Relay 1

See Relay 1 See Relay 1

Value - pressure (see

gauge type) or voltage

0.000 to 11.000 volts.

Read IGC setup

Write IGC setup

Filament;head;emission;restrike;constant1;

constant2

Config type = 74

e.g.

!S913 74;1;1;0;0;0.1;0.1

Accept new gauge

On/off

Zero/calibrate/degas

For each attached gauge

<Position byte>;<Gauge value>;

Examples

Reply for 1 gauge connected at position 2

=V940 2;3.9441e+02;

Reply for 3 gauges connected at p ositions 2, 3

and 5 with gauge 2 in voltage mode and

gauge 5 not ON (e.g. OFF, error, striking etc)

=V940 2;6.546;3;2.7245e-04;5; 9.9000e+09;

Note: The pump shall accept the wildcard multi-drop address 99.

The pump shall accept the wildcard object ID 0 for a ?S and return information from the TIC Status object

902.

The following are examples of abbreviations and codings, with their meanings, which appear in subsequent

paragraphs.

Page 10 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

Table 2 - Abbreviations

Abbreviation Meaning

r returned error code – see Table 3

String may have several ASCII characters

d decimal ASCII character

h hexadecimal ASCII character

ck checksum (1 byte)

cr carriage return

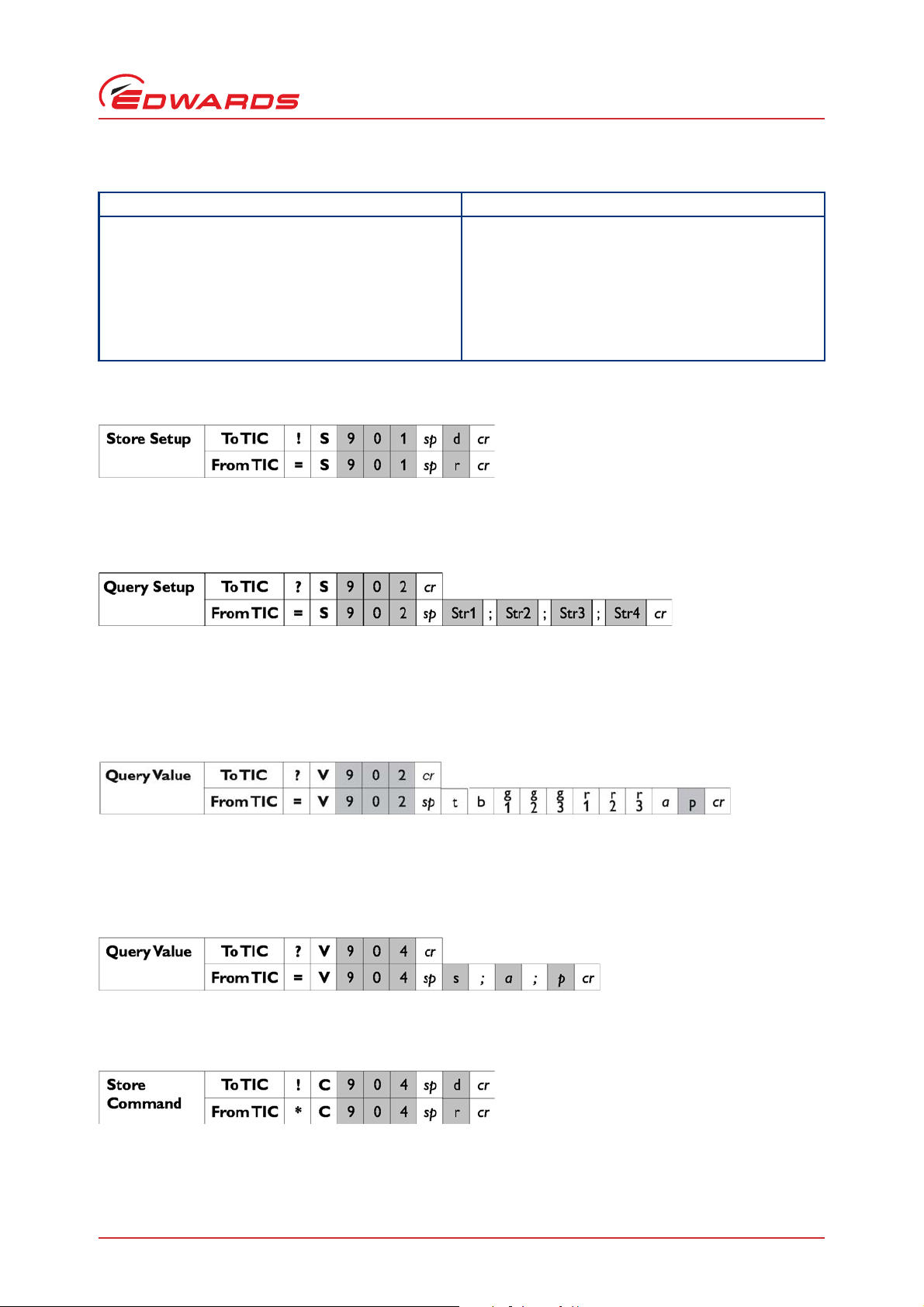

1.6.2.1 Node object 901

where d is the multi-drop address to be stored in EEPROM.

1.6.2.2 Node object 902

D397-30-880 Issue H

Introduction

Query setup returns a data string in the following format:

TIC;Dxxxxxxxx;serial number;PIC s/w ver

where 'TIC' is a fixed string for this pump, Dxxxxxx is the software version number fixed by the software, serial

number is a string loaded during production, PIC s/w ver is the PIC software version.

System state of key items on the TIC, state value from Turbo, backing, gauge 1, gauge 2, gauge 3, relay 1, relay 2,

relay 3, alert ID of object 902 and highest priority on the TIC.

1.6.2.3 Turbo pump object 904

where s is the state of the pump, a is the alert ID and p is the priority. Number of characters per parameter is as

required to represent the value.

where d is 0 = pump off, 1 = pump on.

© Edwards Limited 2012. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

D397-30-880 Issue H

Introduction

where 3 is the config type and p is the pump type.

where 4 is the config type, m is the master object, p is pressure '59' or voltage '66', n is the on setpoint, f is the off

setpoint and e is enabled '1' or disabled '0' e.g.

=S904 913;59;5.1e-2;4.9e-1;1

=S904 914;66;3.62;4.34;1.

1.7 Additional information

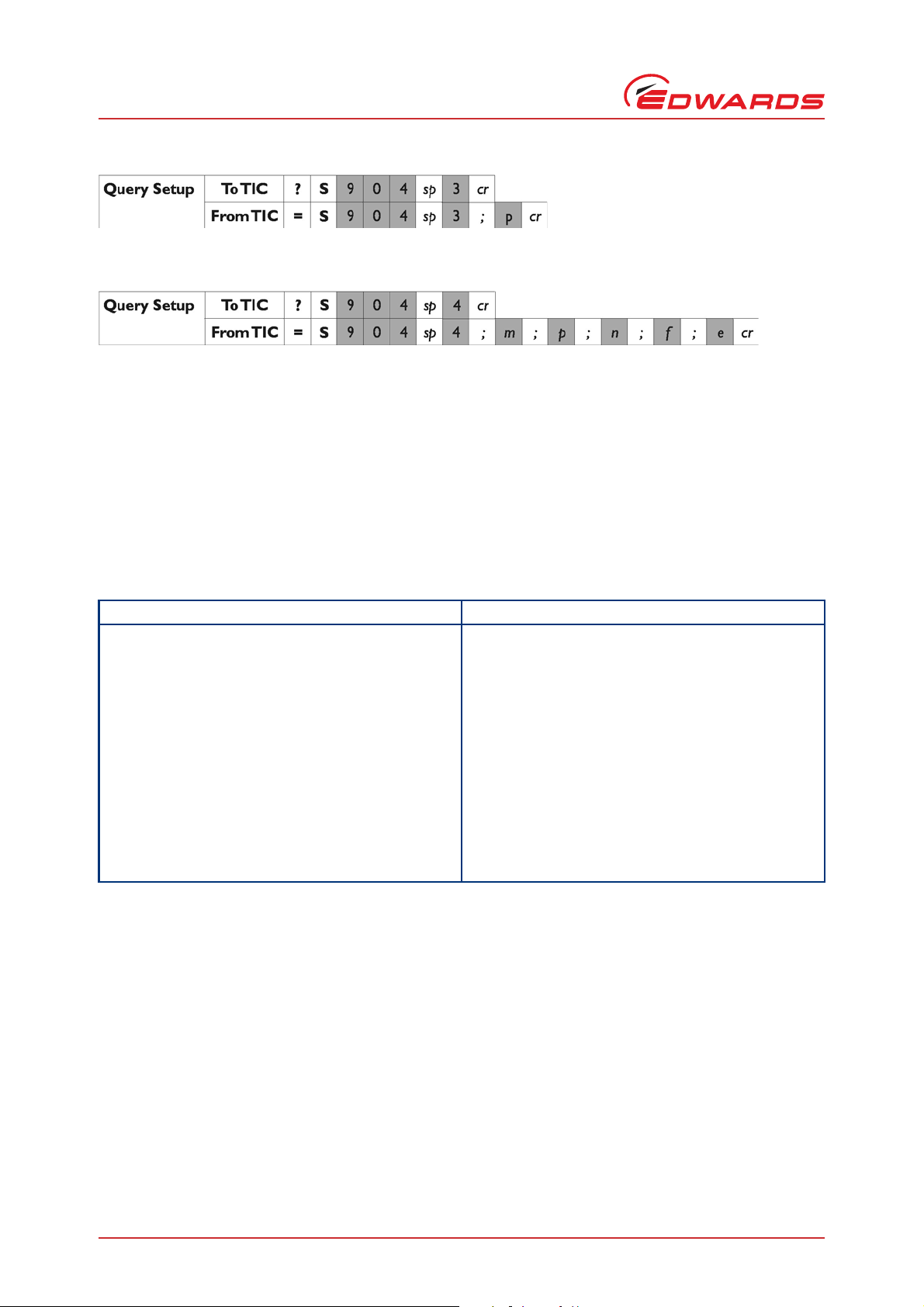

1.7.1 Serial comms response codes (*Cnnn x, *S, *V)

Value Meaning

0 no error

1 Invalid command for object ID

2 Invalid query/command

3 Missing parameter

4 Parameter out of range

5 Invalid command in current state - e.g. serial command

6 Data checksum error

7 EEPROM read or write error

8 Operation took too long

9 Invalid config ID

1.7.2 Priority

OK = 0

warning = 1

alarm = 2/3

Table 3 - Serial comms response codes

to start or stop when in parallel control mode

1.7.3 Alert ID

No Alert = 0

ADC Fault = 1

ADC Not Ready = 2

Page 12 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

Over Range = 3

Under Range = 4

ADC Invalid = 5

No Gauge = 6

Unknown = 7

Not Supported = 8

New ID = 9

Over Range = 10

Under Range = 11

Over Range = 12

Ion Em Timeout = 13

Not Struck = 14

Filament Fail = 15

Mag Fail = 16

Striker Fail = 17

Not Struck = 18

Filament Fail = 19

Cal Error = 20

Initialising = 21

Emission Error = 22

Over Pressure = 23

ASG Cant Zero = 24

D397-30-880 Issue H

Introduction

RampUp Timeout = 25

Droop Timeout = 26

Run Hours High = 27

SC Interlock = 28

ID Volts Error = 29

Serial ID Fail = 30

Upload Active = 31

DX Fault = 32

Temp Alert = 33

SYSI Inhibit = 34

Ext Inhibit = 35

Temp Inhibit = 36

No Reading = 37

No Message = 38

NOV Failure = 39

Upload Timeout = 40

Download Failed = 41

No Tube = 42

Use Gauges 4-6 = 43

Degas Inhibited = 44

IGC Inhibited = 45

Brownout/Short = 46

Service due =47

© Edwards Limited 2012. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

D397-30-880 Issue H

Introduction

1.7.4 SNVT values

VOLTAGE 66 - float

PRESSURE 59 - float (Pascals only)

PERCENT 81

Note: Pressure values used in the configuration setups and in the logging will be in Pascals. They are not stored

or displayed in the selected units.

1.7.5 Command list

Device Off = 0 //general off/on

Device On = 1

Gauge Off = 0

Gauge On = 1

Gauge New_Id = 2

Gauge Zero = 3

Gauge Cal = 4

Gauge Degas = 5

Load Defaults = 576

Upload = 0 //to TIC

Download = 1 //from TIC

1.7.6 State

Off State = 0

Off Going On State = 1

On Going Off Shutdown State = 2

On Going Off Normal State = 3

On State = 4

1.7.7 Active gauge states

Gauge Not connected = 0

Gauge Connected = 1

New Gauge Id = 2

Gauge Change = 3

Gauge In Alert = 4

Off = 5

Striking = 6

Initialising = 7

Calibrating = 8

Zeroing = 9

Degassing = 10

On = 11

Inhibited = 12

Page 14 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 19

1.7.8 Full pump states

TIC’s representation of an attached pump’s state.

Stopped = 0

Starting Delay = 1

Accelerating = 5

Running = 4

Stopping Short Delay = 2

Stopping Normal Delay = 3

Fault Braking = 6

Braking = 7

1.7.9 Gas types

Nitrogen = 0

Helium = 1

Argon = 2

Carbon Dioxide = 3

Neon = 4

Krypton = 5

Voltage = 6

D397-30-880 Issue H

Introduction

1.7.10 Gauge types

Unknown Device = 0

No Device = 1

EXP_CM = 2

EXP_STD = 3

CMAN_S = 4

CMAN_D = 5

TURBO = 6

APGM = 7

APGL = 8

APGXM = 9

APGXH = 10

APGXL = 11

ATCA = 12

ATCD = 13

ATCM = 14

WRG = 15

AIMC = 16

AIMN = 17

AIMS = 18

AIMX = 19

AIGC_I2R = 20

AIGC_2FIL = 21

ION_EB = 22

AIGXS = 23

USER = 24

ASG = 25

© Edwards Limited 2012. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

D397-30-880 Issue H

Introduction

1.7.11 Pump types

No Pump = 0

EXDC Pump = 1

EXT75DX Pump = 3

EXT255DX = 4

Mains Backing Pump = 8

Serial Pump = 9 //temporary until serial comms receives ID from pump

nEXT - 485 = 10 //TIC only supports this in parallel form

nEXT - 232 = 11

nXDS = 12

Not yet identified = 99

Page 16 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

Index

D397-30-880 Issue H

Index

A

Abbreviations ............................................ 11

Active gauge states .....................................14

Additional information

Alert ID .................................................... 12

................................. 12

C

Command list ............................................ 14

Commands

Communications timings

..................................................1

.................................2

D

DX, nEXT and nXDS pumps ...............................2

F

Full pump states .........................................15

G

Gas types .................................................15

Gauge types .............................................. 15

General command .........................................3

I

Introduction ................................................1

Setup command

SNVT values .............................................. 14

State ...................................................... 14

...........................................3

T

TIC serial protocol - multi-drop prefix to a message 3

TIC serial protocol messages ............................3

M

Message basics .............................................1

O

Object IDs ..................................................2

Objects accessed via the PC serial comms

............4

P

PC serial ....................................................3

....................................................12

Priority

Pump types

...............................................16

Q

Queries ......................................................1

Query setup ................................................3

Query value ................................................3

R

Responses ...................................................2

S

Scope ........................................................1

Serial comms response codes (*Cnnn x, *S, *V) ..... 12

........................................................2

Setup

© Edwards Limited 2012. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

D397-30-880 Issue H

This page has been intentionally left blank.

Page 18 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Loading...

Loading...