Page 1

Instruction Manual

Active Digital Controller

D395-90-880

Issue E

Description Item Number

Active Digital Controller - Standard Version D395-90-000

Active Digital Controller - Enhanced Version D395-91-500

Page 2

Declaration of Conformity

We, Edwards Limited,

Crawley Business Quarter,

Manor Royal,

Crawley,

West Sussex, RH10 9LW, UK

declare under our sole responsibility, as manufacturer and person within the EU authorised

to assemble the technical file, that the product(s)

Active Digital Controller – Standard version D395-90-000

Active Digital Controller – Enhanced version D395-91-500

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

EN61010-1: 2010 Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use. General Requirements

EN61326-1:2013 Electrical equipment for measurement, control and laboratory

(Class B Emissions, Use. EMC requirements. General requirements

Industrial Immunity)

EN50581:2012 Technical Documentation for the Assessment of Electrical and

Electronic Products with respect to the Restriction of Hazardous

Substances

Following the provisions of

2014/35/EU Low Voltage Directive

2014/30/EU Electromagnetic Compatibility (EMC) Directive

2012/19/EU Waste from Electrical and Electronic Equipment (WEEE) Directive

2011/65/EU Restriction of Certain Hazardous Substances (RoHS) Directive

Note: This declaration covers all product serial numbers from the date this Declaration was

signed onwards.

16.07.2015, Eastbourne

Larry Marini, Senior Technical Manager Date and Place

This product has been manufactured under a quality management system certified to ISO 9001:2008

P200-03-720 Issue F

Page 3

D395-90-880 Issue E

Contents

Section Page

1 Introduction .......................................................................................1

1.1 Scope and definitions ................................................................................................... 1

1.2 Product description ...................................................................................................... 1

2 Technical data ....................................................................................3

2.1 Electrical data ............................................................................................................ 3

2.2 Operating and storage data ............................................................................................ 3

2.3 Mechanical data .......................................................................................................... 3

2.4 Display .....................................................................................................................3

2.5 Connections ............................................................................................................... 4

2.5.1 Active gauge connectors ................................................................................................ 4

2.5.2 Analogue / relay connector (enhanced only) ........................................................................ 5

2.5.3 Serial communications (enhanced only) .............................................................................. 6

3 INSTALLATION ..................................................................................... 7

Contents

3.1 Unpack and inspect ...................................................................................................... 7

3.2 Fitting the controller .................................................................................................... 7

3.2.1 Bench-top mounting .....................................................................................................7

3.2.2 Panel mounting .......................................................................................................... 8

3.3 Rear panel description ..................................................................................................9

3.3.1 Connecting the electrical supply ...................................................................................... 9

3.3.2 Connecting active gauges ............................................................................................... 9

3.3.3 Connecting the analogue / relay connector (enhanced only) ...................................................10

3.3.4 Connecting the serial interface (enhanced only) ..................................................................10

4 OPERATION ...................................................................................... 11

4.1 Front panel description ................................................................................................11

4.2 Power up .................................................................................................................11

4.2.1 Return to Factory Defaults ............................................................................................11

4.3 Gauge identification ....................................................................................................12

4.4 Gauge display (standard) ..............................................................................................12

4.5 Menu structure (enhanced) ...........................................................................................13

4.5.1 Gauge pressure display ................................................................................................13

4.5.2 Set-point and link threshold adjustment ............................................................................13

4.5.3 Set-point 2 controlling gauge .........................................................................................14

4.5.4 Gauge calibration .......................................................................................................14

4.5.5 Units selection ..........................................................................................................14

4.6 RS232 operation (enhanced only) ....................................................................................15

4.6.1 Message basics ..........................................................................................................15

4.6.2 Commands ...............................................................................................................15

4.6.3 Queries ...................................................................................................................15

4.6.4 Responses ................................................................................................................ 16

4.7 Linking two ADCs (enhanced only) ...................................................................................16

4.7.1 Using two ADCs ..........................................................................................................16

4.7.2 Using one ADC ...........................................................................................................16

5 MAINTENANCE ................................................................................... 17

5.1 Safety ..................................................................................................................... 17

5.2 Fault finding guide ......................................................................................................17

5.3 Cleaning the controller ................................................................................................18

gea/0066/12/09

© Edwards Limited 2010. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 4

D395-90-880 Issue E

Contents

5.4 Software upgrade .......................................................................................................18

5.5 Calibration service ......................................................................................................18

6 STORAGE AND DISPOSAL ....................................................................... 19

6.1 Storage ...................................................................................................................19

6.2 Disposal ...................................................................................................................19

7 SPARES AND ACCESSORIES ..................................................................... 21

7.1 Introduction .............................................................................................................21

7.2 Accessories ............................................................................................................... 2 1

Appendix A Error Numbers ............................................................................ 23

Appendix B RS232 Commands ........................................................................ 25

Appendix C RS232 Queries ............................................................................ 27

Index ........................................................... ................................... 29

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 Pin connections for an 8-way FCC/RJ45 ............................................................................. 4

2 Pin connections and pin-out for the analogue / relay connector ................................................ 5

3 Pin connections for the serial comms connector ...................................................................6

4 Bench mounted dimensions (mm) ..................................................................................... 7

5 Panel cut-out required .................................................................................................. 8

6 Panel mounting the ADC ................................................................................................ 8

7 Rear panel connections .................................................................................................9

8 IBM PC RS232 interface - 9-way ......................................................................................10

9 IBM PC RS232 interface - 25-way .....................................................................................10

10 Front panel displays ....................................................................................................11

Page ii © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 5

D395-90-880 Issue E

Tables

Table Page

1 Compatible gauges for the ADC ....................................................................................... 1

2 Gauge connector pin-out ............................................................................................... 4

3 Pin connections and pin-out for the analogue / relay connector ................................................ 5

4 Pin connections for the serial comms connector ...................................................................6

5 Component checklist ....................................................................................................7

6 Front panel symbols and their functions ............................................................................11

7 Gauge ID numbers ......................................................................................................12

8 Menu items ...............................................................................................................13

9 RS232 commands ........................................................................................................15

10 RS232 queries ............................................................................................................16

11 Fault finding guide ......................................................................................................17

12 Accessories ............................................................................................................... 21

A1 ADC error numbers .....................................................................................................23

Trademark credits

Contents

Barocel™ is a registered trademark of Edwards.

© Edwards Limited 2010. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

D395-90-880 Issue E

This page has been intentionally left blank.

Page iv © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

D395-90-880 Issue E

1Introduction

1.1 Scope and definitions

This manual provides installation, operation and maintenance instructions for the Edwards Active Digital Controller.

You must use the Controller as specified in this manual. Read this man ual before you install and operate the Edwards

Active Digital Controller. Important safety information is highlighted as WARNING and CAUTION instructions; you

must obey these instructions. The use of WARNINGS and CAUTIONS is defined below.

WARNING

Warnings are given where failure to observe the instruction could result in injury or death to

people.

CAUTION

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process.

The following IEC warning label appears on the Active Digital Controller:

Introduction

Warning - refer to accompanying documentation.

From August 2005, Edwards will offer European customers a recycling service.

1.2 Product description

WARNING

Improper use of the equi pment could cause damage to it or injury to people. The user is

responsible for the safe operation and maintenance of the equipment.

The ADC (Active Digital Controller) is us ed for d isplayi ng pres sures mea sured by Ed wa rd s Acti ve Ga uges. The ADC is

available in two versions. The Standard version provides a large clear LED display for a single gauge, and the Enhanced

version has additional features: 2 gauge inputs, 2 set-point relays, analogue outputs for data recording and an RS232

interface for control and data monitoring on a remote PC.

Throughout this manual, certain sections are applicable only to the Standard or Enhanced versions. These section s

are marked "Standard only" or "Enhanced only". The compatible gauges that can be used with the Active Digital

Controller are listed in Table 1.

Table 1 - Compatible gauges for the ADC

ADC version Compatible gauges

Standard APG100-XM, APG100-XLC, APG-L, APG-M, APG-MP,

APGX-H, APGX-L, APGX-M, APGX-MP and WRG

Enhanced As above, plus AIM-S, AIM-X and ASG

© Edwards Limited 2010. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

D395-90-880 Issue E

This page has been intentionally left blank.

Page 2 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

D395-90-880 Issue E

2Technical data

2.1 Electrical data

Connector type CEE/IEC 320

Electrical supply 100 to 240 V a.c. 47 to 63 Hz

Power consumption 15 W maximum

Peak inrush current 20 A at 110 V a.c.

40 A at 240 V a.c.

Fuse The unit is protected by an internal fuse.

This fuse is not user replaceable.

2.2 Operating and storage data

o

Ambient operating temperature range 0

Ambient storage temperature range -30

Maximum ambient operating humidity Max 90% RH non condensing at 40 oC

Maximum operating altitude 2000 m max

IP rating IP20. IP40 when panel mounted. For indoor use only.

C to 40 oC

o

C to 70 oC

Technical data

2.3 Mechanical data

Mass 0.33 kg

Dimensions (w x h x d) 96 x 48 x 165 mm

Panel cut-out 92

Panel thickness 1.5 mm minimum

+0.8

x 45

+0.6

mm to DIN43700

2.4 Display

Type High brightness green LED 7-segment display

LED enunciators for units and display mode

Update rate 300 ms

© Edwards Limited 2010. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

D395-90-880 Issue E

Technical data

2.5 Connections

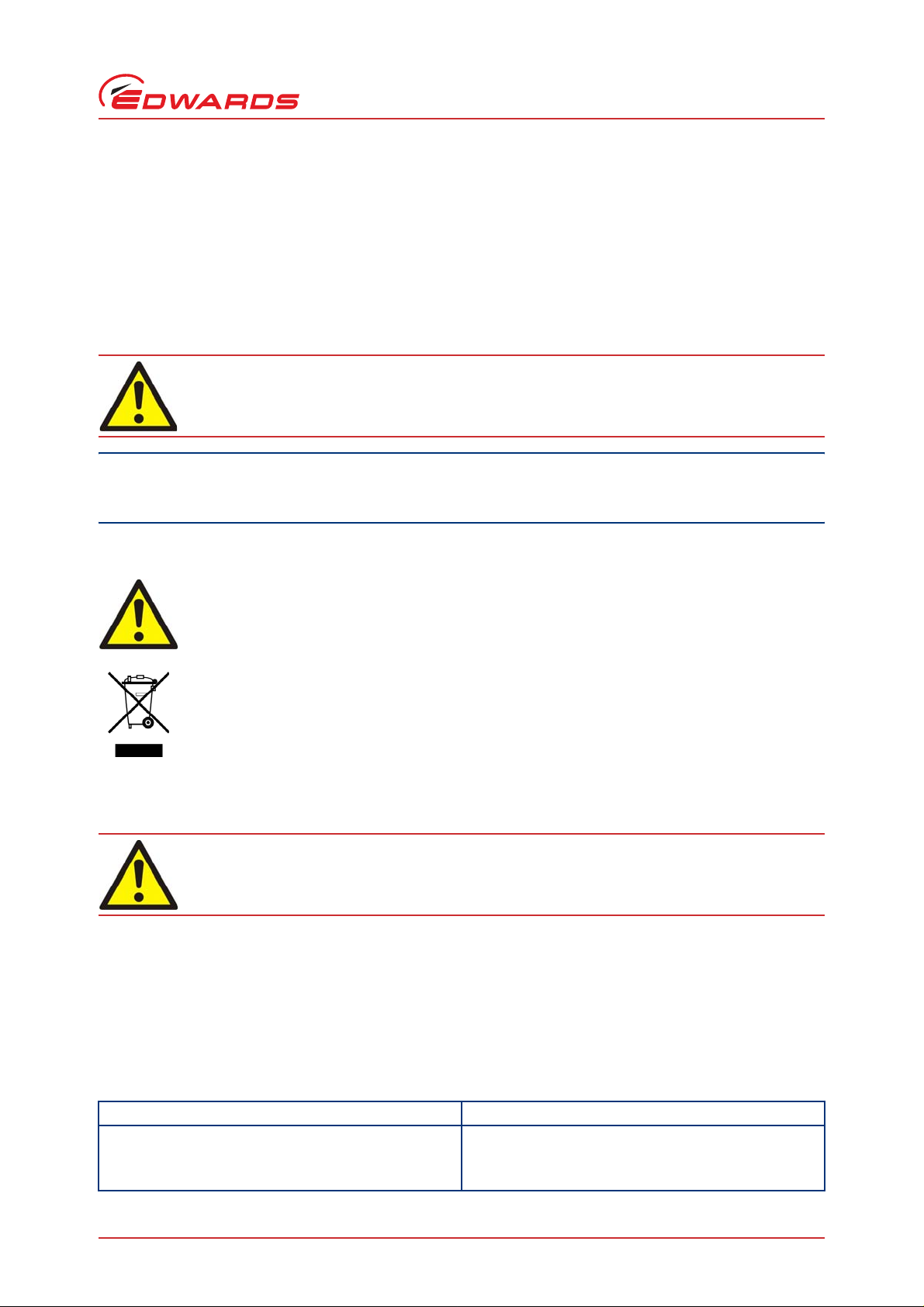

2.5.1 Active gauge connectors

Connector type RJ45, 8-way (refer to Figure 1)

Power supply 24 V d.c. nominal

Maximum power rating 4 W total

Figure 1 - Pin connections for an 8-way FCC/RJ45

Table 2 - Gauge connector pin-out

Pin Allocation

1 Power supply positive

2 Power supply common

3Signal input

4 Identification

5 Signal common

6Control line 1

7Control line 2

8N/C

Page 4 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

D395-90-880 Issue E

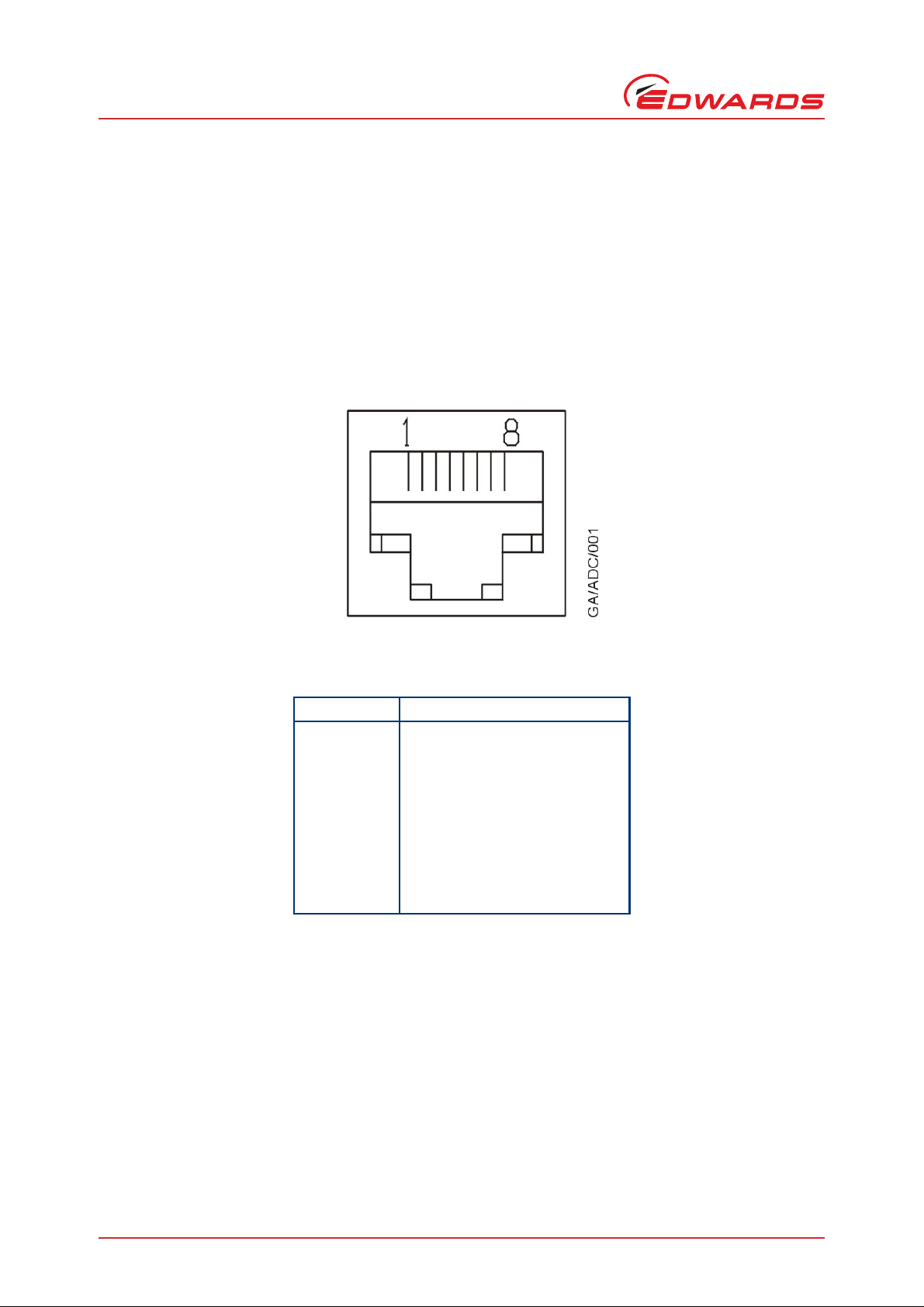

2.5.2 Analogue / relay connector (enhanced only)

Connector type 9-way sub-miniature 'D' type plug (refer to Figure 2)

Relays:

Relay type Volt-free single pole change-over

Relay voltage 48 V max

Relay current 1A @ 48 V d.c.

2A @ 24 V d.c.

Analogue outputs:

Output voltage 0 to 10 V

Minimum load impedance 10 kΩ

Maximum current 1 mA

Accuracy ±2% ±10 mV

Figure 2 - Pin connections and pin-out for the analogue / relay connector

Technical data

Table 3 - Pin connections and pin-out for the analogue / relay connector

Pin Allocation

1 Analogue output common

2 Analogue output signal 1

3 Relay 2 common

4 Relay 1 normally - Closed

5 Relay 1 normally - Open

6 Analogue output signal 2

7 Relay 2 normally - Closed

8 Relay 2 normally - Open

9 Relay 1 common

© Edwards Limited 2010. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

D395-90-880 Issue E

Technical data

2.5.3 Serial communications (enhanced only)

Connector type 9-way sub-miniature 'D' type socket (refer to Figure 3)

RS232 transmit mark: < -5 V (I

space: > +5 V (I

RS232 receive mark: < +0.8 V

space: > +2.4 V

input resistance: 5 kΩ

Maximum input ±25 V

RS232 protocol 9600 baud, 1 stop bit, 8 data bits, no parity

Maximum cable length 10 m

Message rate 3 per second maximum

Figure 3 - Pin connections for the serial comms connector

max: -1.5 mA)

out

max: +1.5 mA)

out

Table 4 - Pin connections for the serial comms connector

Pin Allocation

1N/C

2RS232 transmit

3RS232 received

4N/C

5RS232 common

6N/C

7N/C

8N/C

9N/C

Page 6 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

D395-90-880 Issue E

3 INSTALLATION

3.1 Unpack and inspect

Remove all of the packaging material and ch eck the ADC. If the Controller is damaged, follow the Edwards return of

equipment procedures that are laid out in the back of this manual. Do not use the Controller if it is damaged.

Check that your package contains the items that are listed in Table 5. If any of these items are missing, notify your

supplier in writing within three days. If the Controller is not to be used immediately, store the Controller in suitable

conditions as described in Section 6.1.

Table 5 - Component checklist

Quantity Description Check (3)

1 Active Digital Controller

2 Panel mounting clamps

4Non-slip feet

3.2 Fitting the controller

INSTALLATION

WARNING

Ensure that all wiring is safely secured so that people cannot trip on them.

CAUTION

Ensure that the unit is installed where fluids cannot enter into the Controller. The Controller is IP20 rated, and

therefore has no protection against fluid ingress.

3.2.1 Bench-top mounting

The ADC can be used on a bench-top. Figure 4 shows the dimensions of the Controller that are required for bench

top use. The self-adhesive non-slip feet may be fitted to the bottom of the Controller if required.

Figure 4 - Bench mounted dimensions (mm)

© Edwards Limited 2010. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

D395-90-880 Issue E

INSTALLATION

3.2.2 Panel mounting

If the Controller is to be panel mounted, follow the directions given in Figure 5 and Figure 6 below.

CAUTION

Allow 150 mm at the rear for cables. Allow 50 mm top and bottom and 15 mm to the sides for sufficient air

circulation.

Figure 5 - Panel cut-out required

Figure 6 - Panel mounting the ADC

z Make a cut-out in the panel according to Figure 5. The minimum panel thickness should be 1.5 mm.

z Fit the panel mount clamps to the case, by placing into the recesses and sliding towards the rear of the case.

Use both the left and right or the top and bottom mounting positions.

z Slide the Controller into the panel from the front. The Controller is a push fit and will be retained by the

spring clamps.

Page 8 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

3.3 Rear panel description

Figure 7 - Rear panel connections

ADC standard rear panel ADC enhanced rear panel

3.3.1 Connecting the electrical supply

D395-90-880 Issue E

INSTALLATION

WARNING

Ensure that the Controller is earthed (grounded) via the electrical supply cable and observe all

appropriate safety precautions for the safe installation and handling of electrical equipment. High

voltages exist in the Controller when it is operating.

WARNING

If access to the IEC connector is restricted an additional isolation device should be provided, that

will be easily accessible by an operator.

Connect the electrical supply to the Controller with an appropriate supply cable fitted with an IEC plug. Suitable

cables are available from Edwards.

3.3.2 Connecting active gauges

CAUTION

Do not connect Barocel™ capacitance manometers to the ADC. Doing so will result in damage to the gauge and

will invalidate the warranty.

One or two (depending on version) compatible Active Gauges can be connected to the gauge connectors on the rear

panel. Connect the gauges using Edwards Active Gauge cables. These are available ready-made in different lengths,

see Section 7.2.

© Edwards Limited 2010. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

D395-90-880 Issue E

INSTALLATION

3.3.3 Connecting the analogue / relay connector (enhanced only)

The analogue / relay connector provides two relays for control of your own equipment, and analogue outputs which

can be used for recording the gauge signals.

3.3.3.1 Using relays

WARNING

Do not connect the relays to voltages greater than 48 V d.c.

Do not use the relay outputs for safety purposes.

The two relays are volt-free single pole change-over types. Relay 1 is controlled by gauge 1, and relay 2 is controlled

by gauge 1 or gauge 2. The relays are energised when the indicated pressure of the relevant gauge falls below the

set-point low threshold, and de-energise d when the pre ssure rises above t he set-point high threshold. The th reshold

values are independently set using the front pa nel keys (see Section 4.5.3). The LED indicators on the front panel are

lit when the relays are energised.

3.3.3.2 Using analogue outputs

Two analogue outputs provide the gauge signal voltage for monitoring or recording purposes. These can be connected

to a chart recorder or other similar equipment. The outputs are buffered to prevent disturbance of the gauge signal,

and will follow the gauge signal to within the accuracy specified in Section 2.5.2.

3.3.4 Connecting the serial interface (enhanced only)

The ADC has an RS232 interface built in, which allows a host PC to control the ADC.

The ADC is fitted with a 9-way 'D' type socket on the rear panel. The interface uses two lines for data transfers and

an additional line as a signal common. Hardware handshaking is not implemented.

If connecting to an IBM compatible PC fitted with a 9-way D' type socket then a 'straight through' male-female 9-way

extension cable can be used to connect the ADC to the computer as shown in Figure 8. Connection to an IBM PC fitted

with a 25-way serial connector should be made as shown in Figure 9.

Use shielded cable for the interface to reduce interference problems and limit the length of the RS232 link to less

than 10 metres. For longer links, install line drivers.

Figure 8 - IBM PC RS232 interface - 9-way

Figure 9 - IBM PC RS232 interface - 25-way

Page 10 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

4OPERATION

4.1 Front panel description

Figure 10 - Front panel displays

ADC standard front panel ADC enhanced front panel

Table 6 - Front panel symbols and their functions

D395-90-880 Issue E

OPERATION

Symbol Name Function

UP

DOWN

ENTER

Move to previous selection.

Cycle selected numerical values up.

Move to next selection.

Cycle selected numerical values down.

Turn the selected gauge on or off.

Edit the selected numerical item.

Move to the next digit of a numerical value.

4.2 Power up

When you apply power to the ADC, all LEDs in the display will light for 2 seconds to confirm operation. The software

version will then be displayed for a further 2 seconds, in the format "AdCxx". If you need to contact Edwards for

support regarding the ADC, please have this softw a re ve rsi o n nu mb er available.

4.2.1 Return to Factory Defaults

The ADC can be reset to factory defaults by holding the “UP” key before you apply power to the ADC, and continuing

to hold it throughout the startup process. The startup screens will be displayed and then “Err01” will be shown to

confirm successful reset. Disconnect all connected gauges and power cycle to clear this message.

© Edwards Limited 2010. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

D395-90-880 Issue E

OPERATION

4.3 Gauge identification

When a gauge is connected to the ADC, the display mode will change to display the reading from that gauge. An

identification message consisting of "ID" followed by a number will be displayed for 3 seconds to show that the ADC

has identified the new gauge. The ID numbers and corresponding gauges are shown in Table 7.

Table 7 - Gauge ID numbers

ID number Gauge

ID 04 APG-M / APG-MP

ID 05 APG-L

ID 06 APGX-H

ID 11 AIM-S

ID 15 ASG

ID 19 AIM-X

ID 20 WRG

ID 21 APGX-L / APGX-M / APGX-MP /

APG100-XM / APG100-XLC

If a gauge cannot be identified or is of a type which is not supported by the Controller, then the message "???" will be

displayed.

Where an ASG is used, you need to select the full-scale range of the gauge. This can only be done when the gauge is

first connected. After the iden tification message "ID15", the display will sh ow 1.0

You can change this to 2.03 for a 2000 mbar ASG using the UP and DOWN keys ( / ). When the required value is

showing on the display, press the ENTER key ( ).

3

, representing a 1000 mbar ASG.

4.4 Gauge display (standard)

The ADC will continuously display the pressure measured by an Active Gauge. The display is in exponential format.

The pressure units are shown by the LEDs on the right of the display. Use the DOWN key ( ) to change the pressure

units. The units mbar, Torr and Pascal will be selected in turn. A further press of the DOWN key ( ) will select

voltage mode, in which the output voltage of the Active Gauge will be displayed, and the LED enunciators will

extinguish. To return to pressure display, press the DOWN key ( ) again.

If an error condition is detected by the gauge or by the controller, then the display will show an error message of the

form "Err" followed by a number. Refer to Appendix A for a list of error numbers and suggested remedies. To clear

the error message from the display press the DOWN key ( ). If the error originated in a gauge it may be necessary

to disconnect the gauge and correct the fault before the error message can be cleared.

If a gauge is not connected then the display will show "- - -".

Page 12 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 19

D395-90-880 Issue E

4.5 Menu structure (enhanced)

The LEDs along the top of the ADC indicate which item is currently being shown on the num eric display. To select the

next item press the DOWN key ( ), and to select the previous item press the UP key ( ). The available items are

listed in order in Table 8.

Table 8 - Menu items

Gauge 1 pressure display

Gauge 2 pressure display

Set-point 1 high threshold

Set-point 1 low threshold

Set-point 2 high threshold

Set-point 2 low threshold

Set-point 2 controlling gauge

G1-G2 link high threshold

G1-G2 link low threshold

Gauge 1 calibrate

Gauge 2 calibrate

Units select

OPERATION

4.5.1 Gauge pressure display

When gauge 1 is selected (G1 LED lit) the pressure measured by gauge 1 is displayed. The display is in exponential

format. The units are shown by the LEDs on the right of the display. If gauge 1 is a controllable gauge (for example

an AIM gauge), then you can turn it on and off by pressing the ENTER key ( ). Controllable gauges default to off,

and the display shows "OFF". When the gauge is turn ed on the display will show "Str " whilst the gauge is starting up,

and will then display pressure.

When gauge 2 is selected (G2 LED lit) gauge 2 is displayed and can be controlled similarly.

If either gauge 1 or gauge 2 is displayed, the status of the set-point relays is indicated by the SP1 and SP2 LEDs. The

relays are energised and the LEDs are lit when the measured pressure is below the set-point threshold.

If an error condition is detected by the gauge or by the controller, then the display will show an error message of the

form "Err" followed by a number. Refer to Appendix A for a list of error numbers and suggested remedies. To clear

the error message from the display press the ENTER key ( ). If the error originated in a gauge it may b e necessary

to disconnect the gauge and correct the fault before the error message can be cleared.

If a gauge is not connected then the display will show "- - -".

4.5.2 Set-point and link threshold adjustment

The set-point and link thresholds are adjusted using the front panel keys. Thresholds are entered and displayed as

pressures, using the currently selected units.

To make an adjustment, first select the required threshold using the UP and DOWN keys ( / ). The LEDs are lit

in combination to show which threshold is selected. For example: if SP1 and Hi LEDs are lit together, then the di splay

is showing the set-point 1 high threshold. If G1, G2 and Hi LEDs are lit together, then th e display is showi ng the link

high threshold.

To change the value press the ENTER key ( ). The first digit on the display w ill flash and can be changed using the

UP and DOWN keys ( / ). When you have selected the required value, press the ENTER key ( ) again to select

the next digit. Repeat this process for the second digit and then the exponent. Note that the complete exponent is

© Edwards Limited 2010. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

D395-90-880 Issue E

OPERATION

adjusted as one number from -10 to +6. When the ENTER key ( ) is pressed after adjusting the exponent, the

complete number will be entered and the new threshold will become effective.

For each set-point, or link threshold, the low threshold must always be lower than or equal to the high threshold. If

you enter a low threshold which is higher than the high threshold (or vice versa), then both thresholds will be set to

the value that you have just entered.

If you set the high and low thresholds to the same value then there will be no hysteresis, and the relay may switch

on and off several times as the pressure changes through the set-point threshold. It is recommended that some

hysteresis is always used.

Note: The set-point or link thresholds can be set to any value in the range 1.0 x 10

thresholds to a pressure which cannot be measured by the gauge which you are using, then the set-points

or link will not operate.

4.5.3 Set-point 2 controlling gauge

The set-point 2 relay can be controlled by gauge 1 or gauge 2. To select which gauge is controlling the relay, first

select the menu option using the UP and DOWN ke ys ( / ). When this option is selected, the numeric display will

be blank and the SP2 LED will be lit. Either the G1 or G2 LED will flash to show the currently selected controlling

gauge. To change between gauge 1 and gauge 2, press the ENTER key ( ). When the required controlling gauge

is flashing, press the UP or DOWN key ( / ) to move to a different menu option.

-10

to 9.9 x 106. If you set the

4.5.4 Gauge calibration

If gauge 1 or gauge 2 is a type which supports remote calibration (for example APG-X or WRG) then the calibration

options will be available. To calibrate gauge 1, select G1 and CAL LEDs together using the UP and DOWN keys

( / ), and then press the ENTER key ( ). The message "CAL'd" will be displayed for 3 seconds to show that the

calibration command has been sent to the gauge. To calibrate gauge 2, first select G2 and CAL LED's.

Where an ASG is used, the calibration functions as a zero offset adjustment. You can cancel the calibration by

pressing the ENTER key ( ) again. The message "OFF" will be displayed to confirm that the offset adjustment has

been removed.

Please refer to the instruction manual of the specific gauge which you are using for details of the correct calibration

procedure.

4.5.5 Units selection

You can change the pressure units for the display by selecting the units menu option. When this option is selected,

the numeric display will be blank, and the currently selected units will flash. To change the units, press the ENTER

key ( ). The units enunciator will move between mbar, Torr and Pa with each press of ENTER. A further press of

the ENTER key ( ) will select voltage mode, when the LED enunciators will extinguish and '0.000' will flash on the

display. Pressing ENTER key ( ) again will return to mbar. When the required units are flashing, press the UP or

DOWN keys ( / ) to move to a different menu option.

When the units are changed, the set-point values will be converted to the new units. For example, if a set-point

threshold is entered as 1.0 x10

7.5 x 10-4Torr.

-3

mbar and the units are changed to Torr, then the value will be displayed as

Page 14 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

D395-90-880 Issue E

4.6 RS232 operation (enhanced only)

WARNING

The data received from this unit should not be used for safety purposes.

4.6.1 Message basics

The communications to the ADC work on a master / slave principle. The ADC is the slave and will only transmit a

message in response to one sent to it. The master, a PC for example, must always start the conversation.

A conversation consists of a message to the ADC and it's response back. Having sent a message to the ADC, wait for

the reply before continuing. When the ADC receives a message a reply is always sent. If the message cannot be

understood or if the syntax is wrong, an error message of the form "Err n" will be returned. Refer to Appendix A for

a list of error numbers.

All messages consist of ASCII coded characters. Messages to the ADC start with either a "!" or a "?" character. All

messages end with a carriage return (cr). Characters not enclosed by start (!?) and end (cr) characters will be ignored.

Incomplete messages will be ignored if a new start character is received. Responses from the ADC end with a carriage

return (cr).

OPERATION

There are two basic types of message sent to the ADC:

z Commands sending information to the ADC (starting with "!").

z Queries requesting information from the ADC (starting with "?").

4.6.2 Commands

Commands send information to the ADC. These can be literal commands such as 'tu rn gauge on' or values to be stored

by the ADC such as 'set-point 1 high threshold'. A summary of available commands is shown in Table 9. Full details of

the commands are given in Appendix B.

Table 9 - RS232 commands

Mnemonic Meaning

!CH Set-point high threshold

!CL Set-point low threshold

!GA Accept gauge error

!GW Switch gauge on/off

!RC Relay controlling gauge

!TH Link high threshold

!TL Link low threshold

!US Units

4.6.3 Queries

Queries request information from the ADC. These can be direct queries of the value of a parameter such as gauge

pressure, or reading a value currently stored in the ADC. A summary of available queries is shown in Table 10. Full

details of the queries and the corresponding response from the ADC are given in Appendix C.

© Edwards Limited 2010. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

D395-90-880 Issue E

OPERATION

Table 10 - RS232 queries

Mnemonic Meaning Reply

?CH Set-point high threshold {pressure}

?CL Set-point low threshold {pressure}

?GA Gauge pressure {pressure}

?GV Gauge version {nn}

?RC Relay controlling gauge {1..2}

?TH Link high threshold {pressure}

?TL Link low threshold {pressure}

?US Units {0..3}

?VL Voltage {voltage}

4.6.4 Responses

Responses to commands will always be a message of the form "Errn". If the command syntax was correct t he response

will be "Err0", confirming that there is no error.

Responses to queries will usually be a string containing the requested data. If the syntax is not correct an error

message of the form "Errn" will be returned. Refer to Appendix A for a list of error numbers.

4.7 Linking two ADCs (enhanced only)

4.7.1 Using two ADCs

Two ADCs may be linked together to allow automatic switching of one gauge by another, for example using an APG

gauge to switch an AIM gauge on and off.

z Connect the controlling gauge (APG) to the Gauge 1 connector of the first ADC.

z Set the set-point 1 thresholds to the required pressures.

z Connect the controlled gauge (AIM) to the Gauge 1 connector of the second ADC.

z Connect the two Gauge 2 connectors of the two ADCs together using a standard Active Gauge cable.

The ADCs will automatically recognise the linking cable, and the AIM gauge on the second ADC will switch on and off

at the pressures defined by the set point 1 thresholds of the first ADC.

4.7.2 Using one ADC

Two gauges may be linked together to allow automatic switching of one gauge by another.

z Connect a controlling gauge to the ADC. (APG, APG100 and APGX Gauges)

z Connect a controlled gauge to the ADC. (AIM-S and AIM-X Gauges)

z Set the link threshold on the link menu.

The ADC will automatically recognise the two gauges as being a controlling/controlled pair and switch the controlled

gauge on and off at the pressures defined by the link thresholds.

The link thresholds default to above the operating range of controlling gauges, and will not trigger the controlled

gauge to turn on or off until the link thresholds are set within the operating range of the controlling gauge.

The controlled gauge can be manually turned on or off within the “ON” range defined by the link thres holds. Wh en

the controlling gauge is above the high link threshold, manual operation of the controlled gauge is blocked un til the

controlling gauge drops below the low link threshold again.

Page 16 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 23

D395-90-880 Issue E

5 MAINTENANCE

The ADC requires no regular maintenance. The uni t is factory calibrated and will remain in calibration throughout it's

lifetime. Maintenance is limited to fault finding and software upgrades if required.

5.1 Safety

WARNING

Hazardous voltages are present inside the Controller. Qualified personnel only should carry out

servicing.

5.2 Fault finding guide

Table 11 - Fault finding guide

Symptom Possib le cause Remedy

Display blank

(no LEDs lit)

Display shows "ERR" An error has been detected by

Display shows "???" A gauge has not been

Unable to turn on

AIM gauge

Electrical supply defective Check electrical supply cable and external fuses.

Connect the electrical supply cable to any other device to

confirm that the supply is good.

Short circuit or overload on

connections

Internal fuse blown Measure the voltage present between pins 1 and 2 of the

the Controller or by a

connected gauge

recognised by the ADC

2 ADCs connected and Link

blocking manual operation via

comms

2 ADCs connected and Link set

point set below operating range

Controlling and cont rolled

gauges connected and Link

Thresholds blocking manual

operation or operation via

comms

Controlling and cont rolled

gauges connected and Link

Thresholds set below operating

range

Remove all connectors except the electrical supply and

re-check. If display now lights, there is a fault in one of

the external leads or devices. Re-connect one at a time

until the fault is pinpointed.

RJ-45 gauge connector. This should be about 23V. If there

is no voltage present then the internal fuse could be

blown. This fuse is not replaceable and will only blow in

the event of a major malfunction.

Refer to Appendix A for a description of error numbers.

Press the ENTER key ( ) to clear the message.

Check that the gauge is a type listed in Table 1, and is

supported by the ADC version which you have.

Adjust set-point 1 on controlling ADC above or within

operating range of controlling gauge. See Section 4.5.2.

Adjust Link Thresholds above or within operating range of

controlling gauge. See Section 4.5.2. If problems persist

then reset the ADC to Factory Defaults. See Section 4.2.1.

MAINTENANCE

© Edwards Limited 2010. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 24

D395-90-880 Issue E

MAINTENANCE

Table 11 - Fault finding guide (continued)

Symptom Possib le cause Remedy

Chart recorder

output voltage not

as expected

Relays chattering Insufficient hysteresis Adjust the set-point low threshold lower or adjust the set-

RS232 no response Cable wiring incorrect Check that the wiring agrees with Figure 8 or 9.

RS232 erratic Message rate too fast Ensure that the master is not sending more than

5.3 Cleaning the controller

Excessive loading on output Set the ADC into voltage display mode (see Section 4.5.5)

and compare the displayed voltage with the output

voltage. If they are different then the loading may be

incorrect. Check the connections and compare with the

specification in Section 2.5.2.

point high threshold higher. See Section 4.2.1.

Protocol on master does not

match ADC

Handshaking selected at master Check that no handshaking is selected. ADC does not

Check that the master is set to 9600 baud, 8 data bits,

1 stop bit, and no parity.

support CTS/RTS and Xon /Xoff.

3 messages per second. Wait for reply from the ADC

before sending another message.

If necessary, use a soft dry cloth to clean the exterior of the Controller. Do not clean with harsh abrasives or liquids.

5.4 Software upgrade

As new compatible gauges are released, a software upgrade for the ADC might be necessary. If you have purchased

a new gauge which is not listed in Table 1, and the display shows "???" when the gauge is connected, then you may

need an upgrade. Please contact Edwards for details, quoting the serial number and the software version number of

the ADC. The software version number is shown on the display during power-up, in the form "AdCxx".

5.5 Calibration service

A calibration service is available for all Edwards Controllers and gauges. If you require a calibration certificate for

your ADC, please contact Edwards.

Page 18 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 25

D395-90-880 Issue E

6 STORAGE AND DISPOSAL

6.1 Storage

Store the ADC in clean dry conditions in accordance with the technical specifications. Refer to Section 2.2.

6.2 Disposal

Dispose of the Controller and any components safely in accordance with all local and national safety and

environmental requirements.

Alternatively, you may be able to recycle the ADC and/or cables; contact Edwards or your supplier for advice (also

see below).

The ADC and associated cables are within the scope of the European Directive on Waste Electrical and Electronic

Equipment, 2002/96/EC. From August 2005, Edwards will offer European customers a recycling service for the ADC/

cables at the end of the product’s life. Contact Edwards for advice on how to return the ADC/cables for recycling.

The plastic enclosure of the ADC in made from >PPO+PS< material.

STORAGE AND DISPOSAL

WARNING

Do not incinerate the Controller. If the Controller is heated to very high temperatures, dangerous

gases may be emitted and internal components may explode.

© Edwards Limited 2010. All rights reserved. Page 19

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 26

D395-90-880 Issue E

This page has been intentionally left blank.

Page 20 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 27

D395-90-880 Issue E

7 SPARES AND ACCESSORIES

7.1 Introduction

Edwards products, spares and accessories are available from Edwards compani es in Belgium, Brazil, Canada, France,

Germany, Hong Kong, Italy, Japan, Korea, Switzerland, United Kingdom, U.S.A. and a world-wide network of

distributors. The majority of these centres employ Service Engineers who have undergone comprehensive Edwards

training courses.

Order spare parts and accessories from your nearest Edwards company o r di st ri buto r. When you order, pleas e state

for each part required:

z Model and Item Number of your equipment

z Serial number (if any)

z Item Number and description of the part.

7.2 Accessories

Table 12 shows the range of accessories that can be purchased.

SPARES AND ACCESSORIES

Table 12 - Accessories

Product Description Ordering Information

Active Digital Controllers

Active Digital Controllers - Standard version

Active Digital Controllers - Enhanced version

Gauges

APG100-XM, APG100-XLC Ranges

APG-L, APG-M, APG-MP Ranges

APGX-L, APGX-M, APGX-MP, APGX-H Ranges

AIM-S, AIM-SL, AIM-X, AIM-XL Ranges

WRG-S and WRG-SL

ASG

Active Gauge Cables (including RJ45 connectors at both ends)

0.5 m active gauge cable D400-01-005

1 m active gauge cable D400-01-010

3 m active gauge cable D400-01-030

5 m active gauge cable D400-01-050

10 m active gauge cable D400-01-100

15 m active gauge cable D400-01-150

25 m active gauge cable D400-01-250

50 m active gauge cable D400-01-500

100 m active gauge cable D400-01-999

Interface cable

2 m RS232 interface cable D397-00-834

Mains cables

2 m UK plug D400-13-025

2 m USA plug D400-13-120

2 m Northern European plug D400-13-030

D395-90-000

D395-91-500

© Edwards Limited 2010. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 28

D395-90-880 Issue E

This page has been intentionally left blank.

Page 22 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 29

D395-90-880 Issue E

Appendix A Error Numbers

The table below lists all ADC error numbers, together with likely causes and suggested remedies. The error numbers

apply both to errors appearing on the display and to error messages sent over the RS232 link.

Table A1 - ADC error numbers

Appendix A

ERR

number

0 No error RS232 message in response to a correctly formatted

1 EEPROM error The internal EEPROM checksum has failed. Some stored

2 ID reference error The reference used for identifying gauges is incorrect. Please

11 Gauge voltage too high The voltage from a gauge is too high. The gauge may be

12 Gauge voltage too low The voltage from a gauge is too low. The gauge may be

13 AIM Gauge not striking The voltage from a gauge is too low. The gauge may be

21 WRG Pirani failure Errors specific to WRG. Please refer to the WRG manual for

22 WRG magnetron short

23 WRG striker fail

24 WRG magnetron not struck

25 APGX filament failure Errors specific to APGX. Please refer to the APGX manual for

26 APGX cal err

27 APGXH tube not fitted

Meaning Possible cause / remedy

Controller errors

command, indicating no error.

values such as set-point thresholds will revert to the factory

default.

remove all gauge connection, turn the electrical supply off

and on, and wait for 30 seconds before connecting gauges.

Gauge errors

defective.

defective.

defective.

details.

details.

RS232 errors

51 Not a valid query or command word The ADC did not recognise the mnemonic in a message.

Check that the message is as specified in Appendix B

and Appendix C.

52 Message incomplete The mnemonic was recognised but additional characters

were expected. Check that a command (!) was not used in

place of a query (?).

53 Message too long The mnemonic was recognised by had extra characters at

end of message. Check format of command message in

Appendix B.

54 Incorrect gauge number Queries and commands are only valid for gauges 1 and 2.

57 Incorrect number format A command had an invalid number. Check range of valid

numbers in Appendix B.

© Edwards Limited 2010. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 30

D395-90-880 Issue E

Appendix A

Table A1 - ADC error numbers (continued)

ERR

number

58 Incorrect pressure format A command had a wrongly formatted pressure. Check format

81 No gauge connected An attempt was made to read or control a gauge when it was

82 Unknown gauge type A gauge is connected that cannot be recognised. Check that

83 Gauge not reading pressure An attempt was made to read a gauge which was switched

84 AIM gauge striking An attempt was made to read a gauge which was striking.

90 Incorrect gauge type, query/command

91 Gauge turn-on is inhibited by link A "GW1=1" command has been sent when 2 ADCs are linked,

Meaning Possible cause / remedy

specified in Appendix B.

not connected. Check that gauge number is correct.

the gauge is a type listed in Table 1. If not, a software

upgrade may be needed. See Section 5.4.

off. Check that the gauge is switched on. Use the command

!GW if necessary.

Wait until the gauge has struck and try again.

The command or query is not supported by the particular

not appropriate

gauge e.g. an attempt was made to switch an APG on or off.

and the pressure is too high to allow the controlled gauge to

turn on.

Page 24 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 31

D395-90-880 Issue E

Appendix B RS232 Commands

In the lists that follow:

x refers to gauge channel and is in the range 1..2

y refers to a single digit number

pressure is in exponential format which must be m.mEsee where m is the mantissa with 1 decimal place,

s the sign (+ or -) and e is the exponent (2 digits).

!CH x=pressure

Set the set-point high thresho ld fo r re la y x as a pressu re using the currently selected units. If you set the threshold

to a pressure which cannot be measured by the gauge which you are using then the set point will not operate.

Example: !CH2=1.3E-03

!CL x=pressure

Set the set-point low threshold for relay x as a pressure using the currently selected units. If you set the threshold

to a pressure which cannot be measured by the gauge which you are using then the set point will not operate.

Example: !CL1=1.0E+01

!GA x

Accept an error being reported for the gauge channel x. This is equivalent to pressing the ENTER key ( ) on the

front panel to clear an error message. If the error originated in a gauge it may be necessary to disconnect the gauge

and correct the fault before the error message can be cleared.

Appendix B

Example: !GA1

!GW x=y

Turn the gauge on channel x to on or off. If the gauge type cannot be switched on and off (for example APG), then

an error message is returned. The value of y is 0 = off, 1 = on.

Example: !GW2=1

!RCx=y

Set relay control for relay x to gauge y. Only relay 2 can be configured, any other value will produce an error message.

The set-point thresholds for relay 2 aare configured using !CH2 and !CL2 even if the relay is controlled by gauge 1.

Example: !RC2=1

!TH=pressure

Set the link high threshold as a pressure using the currently selected units. If you set the threshold to a pressure

which cannot be measured by the gauge which you are using then the link will not operate.

Example: !TH=1.3E03

!TL=pressure

Set the link low threshold as a pressure using the currently selected units. If you set the threshold to a pressure

which cannot be measured by the gauge which you are using then the link will not operate.

Example: !TL=1.0E-03

!USy

Set the pressure units. The value of y is:

0 = volts

1 = mbar

2 = Pa

3 = Torr

Example: !US2

© Edwards Limited 2010. All rights reserved. Page 25

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 32

D395-90-880 Issue E

This page has been intentionally left blank.

Page 26 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 33

D395-90-880 Issue E

Appendix C RS232 Queries

In the lists that follow:

x refers to gauge channel and is in the range 1..2

pressure is in exponential format m.mmEsee where m is the mantissa,

s the sign (+ or -) and e is the exponent (2 digits).

?CH x

Returns the set point high threshold for relay x as a pressure in the currently selected units.

Example: ?CH1

Reply: 5.50E-03

?CL x

Returns low set point the threshold for relay x as a pressure in the currently selected units.

Example: ?CL2

Reply: 1.00E+02

?GA x

Returns the current pressure reading for gauge channel x. If the current units are volts then the voltage will be

returned. If the gauge is switched off or has an error then an error number will be returned. Refer to Appendix A for

a description of error numbers.

Appendix C

Example: ?GA1

Reply: 3.20E-05

?GV x

Returns the gauge version for channel x, as a number. The number is the same as the ID number indicated on the

display when a gauge is first connected.

Example: ?GV1

Reply: 00 = No gauge

04 = APG-M

05 = APG-L

06 = APGX-H

11 = AIM-S

15 = ASG

19 = AIM-X

20 = WRG

21 = APGX-M / APGX-L

?RCx

Returns the gauge number currently assigned to relay x. Only relay 2 can be configured, any other value will produce

an error message.

Example: ?RC2

Reply: 1

?TH

Returns the link high threshold as a pressure in the currently seleted units.

Example: ?TH

Reply: 1.3E-03

?TL

Returns the link low threshold as a pressure in the currently seleted units.

Example: ?TL

Reply: 1.0E-03

© Edwards Limited 2010. All rights reserved. Page 27

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 34

D395-90-880 Issue E

Appendix C

?US

Returns the current units setting.

Example: ?US

Reply: 0 = volts

1 = mbar

2 = Pascal

3 = Torr

?VL x

Returns the gauge voltage reading for channel x as a number of the form vv.vvv

Example: ?VL2

Reply: 5.324

Page 28 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 35

Index

D395-90-880 Issue E

Index

A

Accessories ............................................... 21

Active gauge connectors ..................................4

ADC error numbers ...................................... 23

Analogue / relay connector (enhanced only) ..........5

Appendix A ................................................ 23

Appendix B ................................................ 25

Appendix C ................................................ 27

B

Bench mounted dimensions (mm) .......................7

Bench-top mounting .......................................7

C

Calibration service ...................................... 18

Checklist of components .................................7

Cleaning the controller ................................. 18

Commands ................................................ 15

Compatible gauges for the ADC .........................1

Component checklist ......................................7

Connecting active gauges ................................9

Connecting the analogue / relay connector

(enhanced only) .......................................... 10

Connecting the electrical supply ........................9

Connecting the serial interface (enhanced only) ... 10

Connections .................................................4

D

Dimensions of a bench mounted TIC (mm) ............7

Display .......................................................3

Disposal ................................................... 19

E

Electrical data .............................................3

Error Numbers ............................................ 23

F

Fault finding guide ...................................... 17

Fitting the controller ......................................7

Front panel description ................................. 11

Front panel display ......................................11

Front panel symbols and their functions ............. 11

Fuse ..........................................................3

G

Gauge ........................................................4

Gauge calibration ........................................ 14

Gauge connector pin-out .................................4

Gauge display (standard) ...............................12

Gauge ID numbers ....................................... 12

Gauge identification .................................... 12

Gauge pressure display ................................. 13

I

IBM PC RS232 interface - 9-way ....................... 10

Installation ..................................................7

Introduction ...........................................1, 21

L

Linking two ADCs (enhanced only) ....................16

M

Maintenance .............................................. 17

Mechanical data ............................................3

Menu items ............................................... 13

Menu structure (enhanced) ............................ 13

Message basics ........................................... 15

O

Operating and storage data .............................. 3

Operation ..................................................11

P

Panel cut-out required ..................................8

Panel mounting ...........................................8

Panel mounting the ADC .................................8

Pin connections and pin-out for the analogue /

relay connector ...........................................5

Pin connections for an 8-way FCC/RJ45 ..............4

Pin connections for the serial comms connector ....6

Power up ................................................. 11

Product description ......................................1

Pump set up ............................................. 14

Q

Queries ................................................... 15

R

Rear panel connections ..................................9

Rear panel description ...................................9

Responses ................................................ 16

RS232 commands ...................................15, 25

RS232 operation (Enhanced only) .................... 15

RS232 queries .......................................16, 27

S

Safety .................................................... 17

Scope and definitions ....................................1

Serial communications (enhanced only) ..............6

Set-point 2 controlling gauge ......................... 14

Set-point adjustment .................................. 13

Set-point an link threshold adjustment ............. 13

Software upgrade ....................................... 18

Spares and accessories ................................ 21

Storage ................................................... 19

Storage and disposal ................................... 19

T

Technical data ............................................3

U

Units selection .......................................... 14

Unpack and inspect ......................................7

Using analogue outputs ................................ 10

Using relays .............................................. 10

Using two ADCs ......................................... 16

© Edwards Limited 2010. All rights reserved. Page 29

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 36

D395-90-880 Issue E

Index

Page 30 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Loading...

Loading...