Edsyn Soldapullt ZD500DX-230, Soldapullt ZD500DX Instruction Manual

ZD500DX-230

®

Deluxe Hot Tip

Desoldering Station

(self-contained)

Instruction manual

• COMPLIES WITH MIL-S-45743E, MIL-STD-2000-1B, WS6536E AND

ESD SPEC, DOD-STD-1686, DOD-HDBK-263

MADE

IN

U.S.A.

EMC Directive 89/336/EEC

ZD500DX-230

®

Deluxe Hot Tip

Desoldering Station

Contents at a Glance

Page 3 - 4 Features & Specications

Page 5 Operation

Page 6 - 8 Tip Usage & Replacement

Page 9 Maintenance

Page 10 Trouble Shooting & Maintenance

Page 11 Calibration

Page 11 - 13 Spare Parts List for Power Supply

Page 14 - 15 Spare Parts List for Hand Tool

Page 2

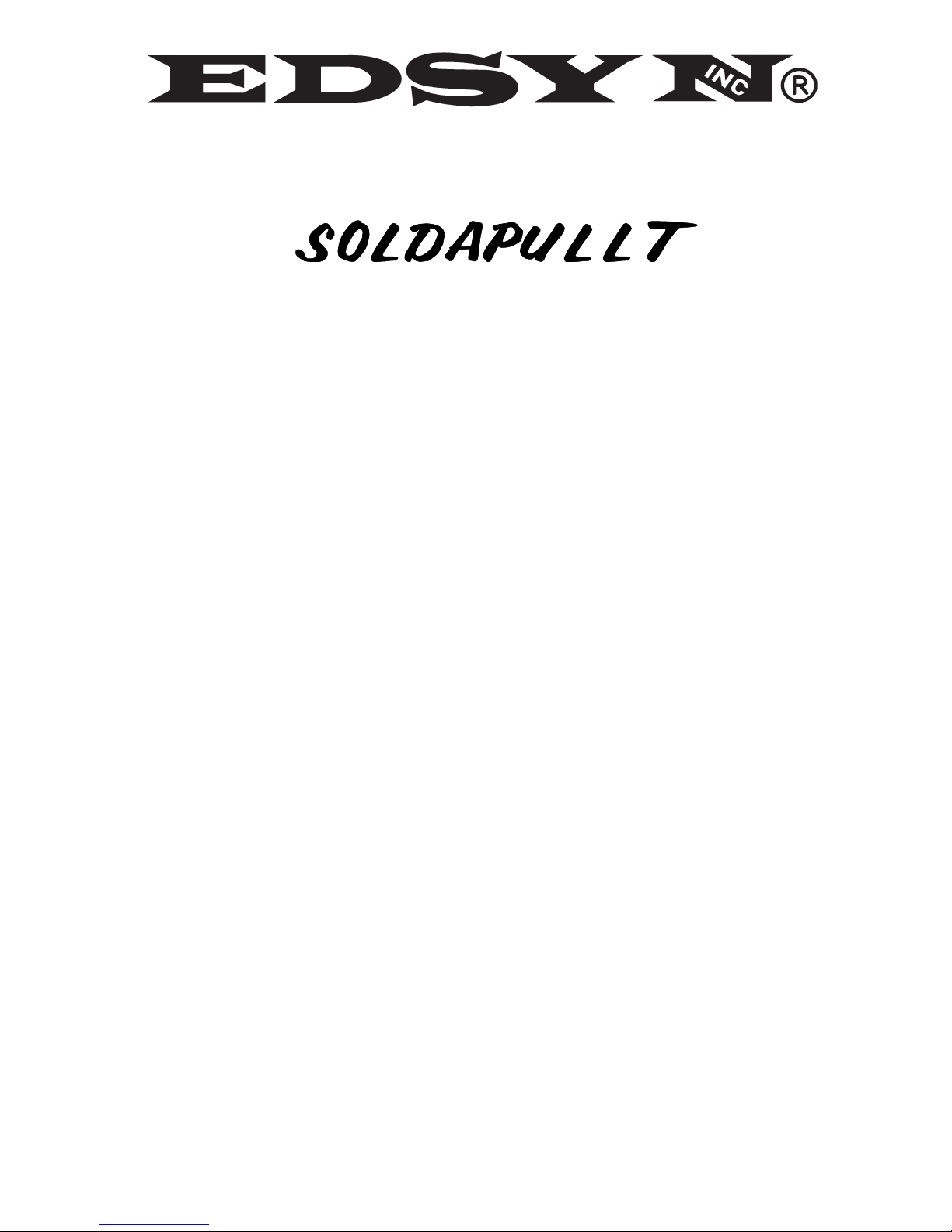

FEATURES

Static Safe

POWER SUPPLY

K

A) Tool Pod, equipped with micro-switch to activate pump.

B) Power Switch, to activate WorkStation.

C) Temp. Control Knob

D) Pump LED

E) Heater LED

F) SH232 Sponge Holder, with cleaning sponge.

G) Power output, 24V, controlled

H) AF110 Filter, (note ow direction)

I) External Calibration

J) Pump

K) WT623 Tip Wrench

L) WT619 Tip Wrench

A

B

C

E

F

D

G

J

H

I

H

L

SPECIFICATIONS

• 230V, 50/60 Hz, 150W Power Supply

• 24V, 50/60 Hz, 70W Hand Tool

• Weight; Power Supply: 5 lbs. 12 ozs. (2.6 kg)

Hand Tool: 11 ozs. (312 g)

• Temperature range of 400°F to 800°F (205°C-425°C)

• Voltage leakage from tip to ground, less than 2 MV

• Tip to ground resistance, less than 2 ohms

• COMPLIES WITH MIL-S-45743E, DOD-STD-2000-1B, WS-6536E and

ESD SPEC, DOD-STD-1686, DOD-HDBK-263

Page 3

DISTINGUISHING FEATURES

For ZD500DX-230 For ZD500DX-230P

POWER CORD WIRING

BROWN to LINE

BLUE to NEUTRAL

GRN/YEL to GROUND

For ZD500DX-230B

3A Fuse inside

For ZD500DX-230I

Not CE Approved

Power Cord

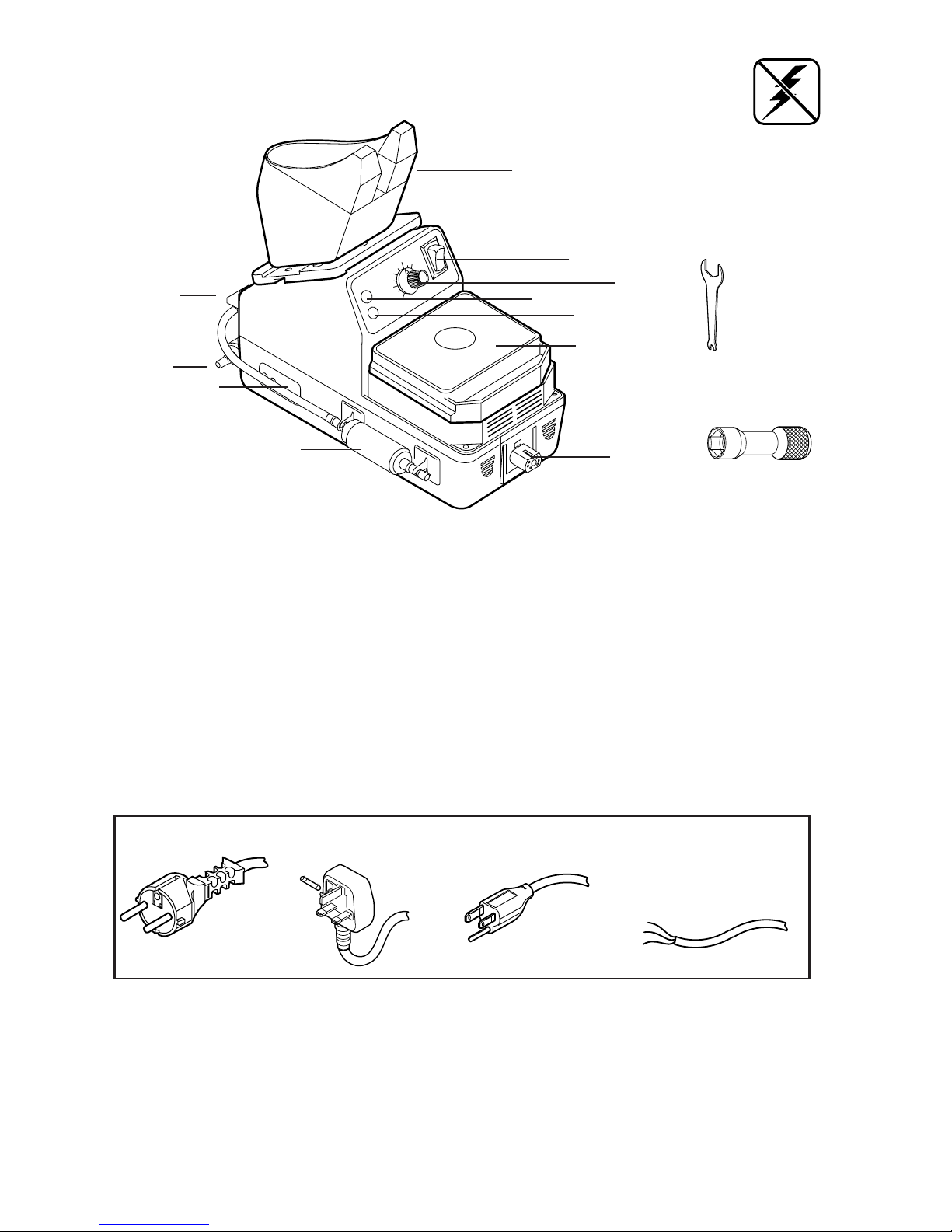

A) Head Assembly- Includes the primary

ltering system and solder debri chamber.

B) Hot Tip Desoldering Tip- Wide range of

desoldering Tips applicable.

C) Head Shaft- Allows 4-point rotation of

Head Assembly.

D) Trigger- Activates vacuum suction.

E) Vacuum Hose- Low Static silicone hose.

Connects to vacuum source.

F) Connector- To 24 V controlled output.

(for HT500) (for HT500-2)

G) Cleaning Shaft- For cleaning Desoldering

Tip orice: .05 (1.3 mm) and .025 (0.6

mm)

HT500/-1/-2

®

Hot Tip Desoldering Tool

D

A

F (for HT500-1)

E

B

C

ESD Safe

FEATURES

HOT TIP DESOLDERING TOOL

1. Insert nut into the slot of adapter plate on both sides.

2. Screw PA233 on the adapter plate.

PA233 Dovetail Extension Bracket allows

you to install additional Tool Pods.

OPTIONS

FC641 Large Filter Cartridge Assembly

Replaces FC640. For use in applications

that require heavy use, or where No-Clean

solder/ux is used at high temperature.

Page 4

ADJUSTMENTS

The HT500 Head assembly can be adjusted into varying positions to suit the operator.

While Tool is in the Pod, push handle

down and twist handle until it locks

into 1 of it's 4 positions. Twisting

counter-clockwise will permit a 1800

turn. Twisting clockwise will permit

a 900 turn.

Note: Head Assembly does not make a full 3600 turn

To tilt the Head assembly, loosen (2)

Adjustment Screws. Tilt the Head assembly to de s ired positio n. Ret i ghten

Screws.

adjustment

screws

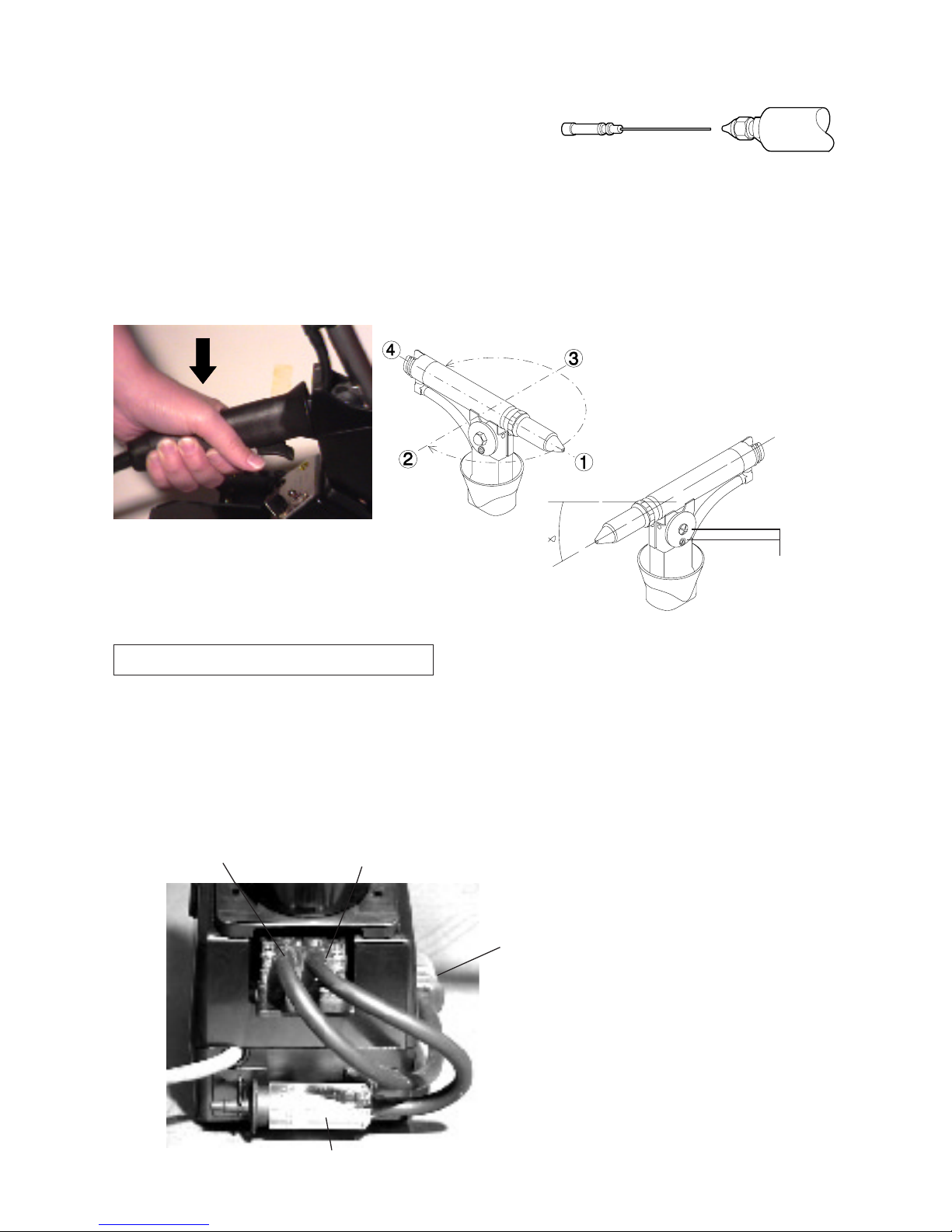

Air out

Vacuum

Air out

Vacuum

AIR FLOW DIRECTION

Hoses must be clean and not

kinked or cracked

For Factory repair:

Specify the problem and ship the

unit to EDSYN INC.

Customer Service

15958 Arminta Street

Van Nuys, CA 91406-1896

NOTE: When Tip orice is blocked,

use a correct size Cleaning Shaft

while pressing the Trigger to clear the

obstruction.

CS468 is .05 in. dia.

CS468-1 is .025 in. dia.

OPERATION

1. Connect HT500 to 24V power supply and vacuum source.

2. Press trigger to activate vacuum.

3. Always clean the Tip with wet sponge and

always re-tin (add fresh solder) during and after each

operation.

Page 5

Loading...

Loading...