Page 1

Regulator Adjustment Guide

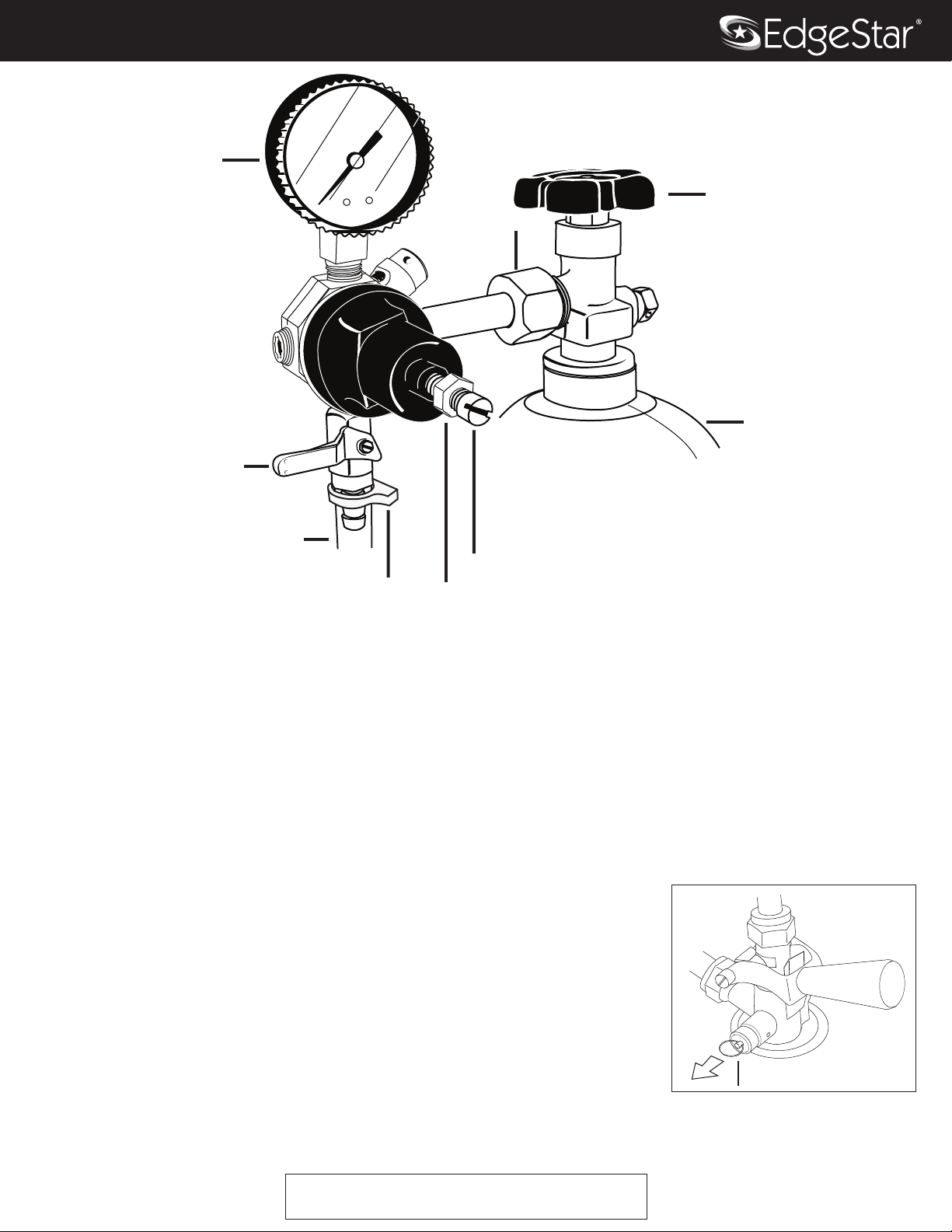

Figure A

Pressure Gauge

Gold Regulator Nut

1. Shut-o Valve

2. Cylinder Valve

CO2 Cylinder

Tube

CO

2

Snap-On Clamp

This Regulator Adjustment Guide will help you with those final steps in assuring that your EdgeStar Full Size Kegerator / Keg Beer Cooler provides you with

the highest quality tasting beer by walking you step by step through the regulator adjustment process.

This guide assumes that your CO2 regulator is firmly and properly attached to the CO2 Cylinder and that you are using the single gauge regulator that your

Kegerator came with. However, any regulator that can be used on CO2 cylinder with a CGA-320 valve will work.

1). Make sure that the brass shut-off valve on the regulator (1) is closed (as shown in Figure A), and open the valve (2) on the gas cylinder completely.

2). Loosen the regulator adjustment nut (3) by slowly turning the nut counterclockwise until the screw becomes loose. Now with a flat head screw driver

turn the adjustment screw (4) clockwise until the desired pressure is shown on the output pressure gauge. We recommend setting the regulator at 12 psi.

NOTE: On regulators designed for draft beer, turning clockwise will increase the output pressure, and turning counter-clockwise will decrease the output

pressure. Under normal circumstances we recommend setting the regulator at 12 psi. Other conditions, such as altitude or special beer type, may require

some adjustment. Consult your keg distributor for recommend psi settings.

3). Make sure the Keg Coupler (Figure B) is locked in the downward position. Open the shut-off valve (1) on the regulator (Figure A) to allow CO2 gas to flow

from the regulator to the keg coupler.

NOTE: You will hear the keg pressurizing. The output needle on the regulator should drop momentarily until the pressure has equalized. Then the needle

will return to the previously set pressure.

4). The keg coupler is designed with a pressure relief valve (PRV) (5). Pull the ring on the PRV briefly to allow

gas to vent.

NOTE: This will help gas flow through the regulator and help obtain a more accurate reading on the output

pressure gauge.

5). Re-check the output pressure on the regulator, and if necessary re-adjust using step #2 until the desired

pressure is shown.

4. Adjustment Screw

3. Adjustment Nut

Figure B Keg Coupler

NOTE: It is always wise to follow up any adjustment to the regulator with a brief pull of the PRV ring to

ensure an accurate pressure reading.

6). Check to make sure that beer pours properly out of the faucet. The beer should dispense at a normal pace.

If beer is wild, cloudy, or off tasting check the owner’s manual for tips on how to remedy common dispensing

issues.

NOTE: To check for CO2 leaks, drip some soapy water over the CO2 cylinder and regulator connection. If

soapy bubbles form, you may need to tighten or re-attach the gold regulator nut connection to the CO2

cylinder.

Warning

CO2 can be dangerous! CO2 cylinders contain high-pressured gas, which

can be hazardous if handled improperly. Please handle with care.

5. Pressure Release Valve (PRV)

Loading...

Loading...