Page 1

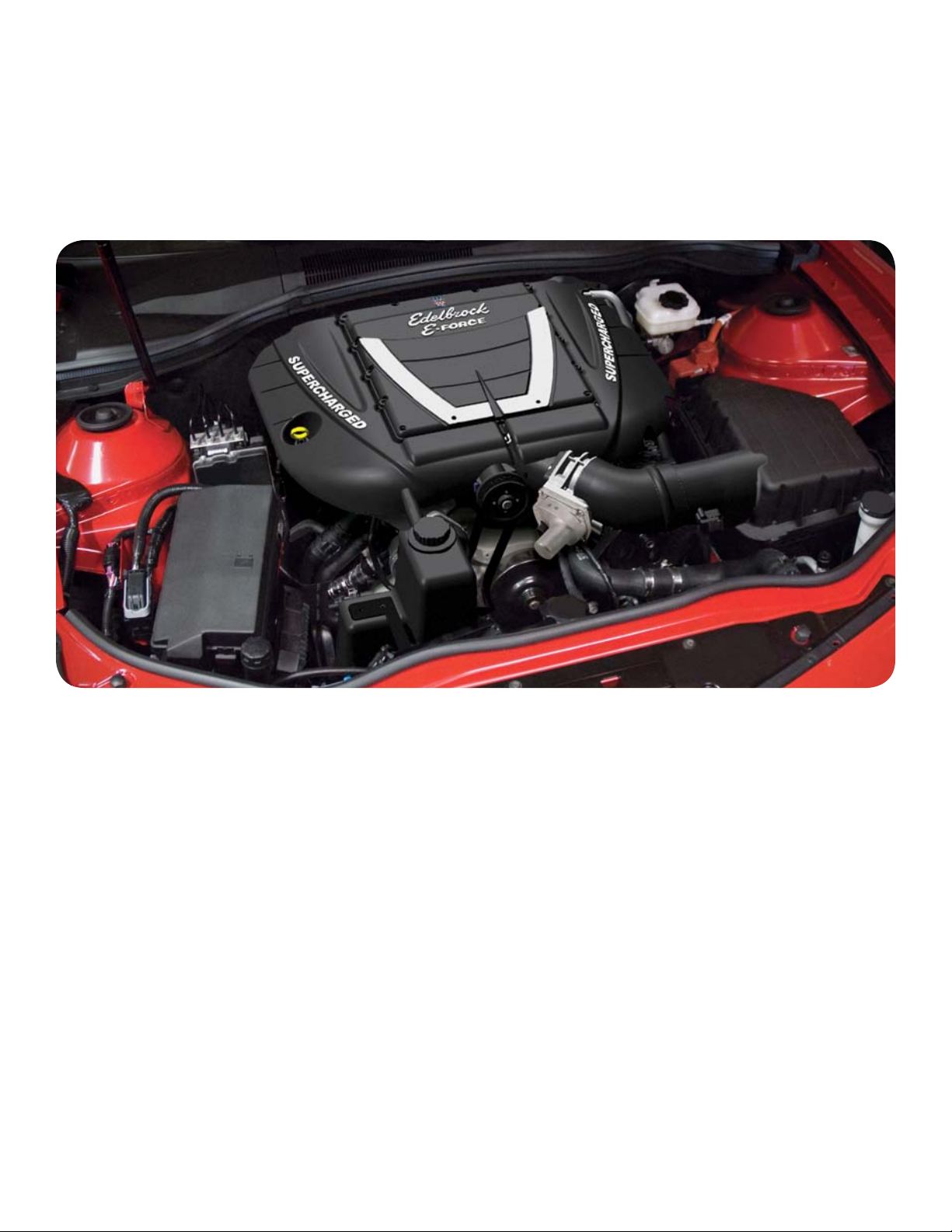

Edelbrock 2010-2013 Camaro SS

Supercharger

Part #’s: 1596, 1597, 1598, 1599, 15997

Page 2

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

INTRODUCTION

Thank you for purchasing the Edelbrock 6.2L GM Supercharger System for the 2010-13 Chevy Camaro. The Edelbrock

E-Force Supercharger System for the Camaro SS utilizes Eaton’s new Gen VI TVS Supercharger rotors, featuring a four

lobe design with a full 160 deg. of twist for maximum flow, minimum temperature rise, quiet operation, and the reliability

for which Eaton is known. The Edelbrock Supercharger is a complete system that maximizes efficiency and performance

by minimizing air restriction into, and out of, the supercharger. This results in maximum airflow, with minimal temperature

rise and power consumption. The supercharger housing itself is integrated into the intake manifold for a seamless design

with minimal components, eliminating the possibility of vacuum leaks between gasket surfaces. The system also utilizes

a front drive, front inlet configuration giving it the shortest, least restrictive inlet path on the market. The supercharger

is inverted, expelling the air upward. Air pressure then builds in the plenum, before being drawn down through each

of two intercooler cores, oriented horizontally, next to, and below the supercharger outlet. After passing through the

intercooler cores, the air travels through the long 12” individual intake runners, which route underneath the supercharger

housing to the cylinder head ports, in a horizontal, nested configuration. The upper plenum area is enclosed by a top

cover that has been designed to provide an appealing and distinctive under-hood appearance. This configuration allows

for a compact package that can fit under the stock hood and cowl of the Camaro, without sacrificing runner length, or

intercooler area. The E-Force supercharger features a uniquely styled plenum, and includes matching side covers. The

Edelbrock supercharger provides neck snapping performance that is safe to operate on a completely stock engine. It

is 50-state emissions legal, and can be had with an optional 5-year 100,000 mile warranty so that there are no worries

when installing it on a brand new car.

TOOLS REQUIRED

l Jack and Jack Stands

OR Service Lift

l Panel Puller

l Ratchet and Socket Set including: 7mm, 8mm, 10mm

(standard, deep and universal), 12mm (deep), 13mm,

15mm (deep), 18mm, 21mm (deep), 24mm

l Wrenches including: 8mm, 13mm, 16mm, 18mm,

13/16”, 3/4”

l Crescent Wrench

l 12” Ratchet Extension Bar

l 1/2” Breaker Bar

l Flat Blade & Phillips Screwdrivers

l Compressed Air

l Torx-20 Driver

l Allen Wrenches including: 6mm, 8mm

Edelbrock LLC, 2700 California Street, Torrance, CA 90503

Toll-Free Tech Line: 1-800-416-8628 Office/Sales Line: 310-781-2222

l 3/8” Fuel Line Removal Tool

l Torque Wrench

l Needle Nose Pliers

l Pliers

OR Hose Clamp Removal Tool

l Pneumatic or Power Drill

l 1-1/8” or larger Uni-bit

l Impact Wrench

l Red & Blue Loctite or equivalent

l O-ring Lube

l Thread Sealing Compound

l Anti-seize

l Masking Tape

l J-42386-A Flywheel Holding Tool

l Soldering Iron

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 1

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 3

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

IMPORTANT WARNINGS

Before beginning installation, use the enclosed checklist to verify that all

components are present in the box, then inspect each component for damage

that may have occurred in transit. If any parts are missing or damaged, contact

Edelbrock Technical Support (800-416-8628), not your parts distributor.

WARNING: Installation of this supercharger will result in a significant change to the

performance characteristics of your vehicle. It is highly recommended that you take

some time to familiarize yourself with the added power, and how it is delivered, in a

controlled environment. Take extra care on wet and slippery roads, as the rear tires

will be more likely to lose traction, with the added power. It is never recommended

to turn off your vehicles traction control system.

Proper installation is the responsibility of the installer. Improper installation will void all

manufacture’s standard warranties and may result in poor performance and engine or vehicle

damage.

Due to the complexity of the Edelbrock E-Force Supercharging system, it is recommended that this system only

be installed by a qualified professional with access to a service lift, pneumatic tools, and a strong familiarity with

automotive service procedures. To qualify for the optional supplemental warranty, it is necessary to have this

system installed by a Certified ASE Technician at a licensed business, GM Dealership, or an Authorized Edelbrock

Installer. Failure to do so will void and/or disqualify any and all optional supplemental warranties offered with this

system. Please contact the Edelbrock Technical Support department if you have any questions regarding this

system and/or how your installer of choice will affect any warranty coverage for which your vehicle may qualify.

Please see warranty contract for all details and restrictions.

Any previously installed aftermarket tuning equipment must be removed and the vehicle returned

to an as stock condition before installing the supercharger.

Any equipment that directly modifies the fuel mixture or ignition timing of the engine can cause severe engine

damage if used in conjunction with the Edelbrock E-Force Supercharger System. This includes, but is not limited

to: OBDII programmers, MAF sensors, adapters and any other device that modifies signals to and/or from the

ECU. Aftermarket bolt-on equipment such as underdrive pulleys or air intake kits will also conflict with the

operation of the supercharger and must be removed prior to installation. Use of any of these products with the

E-Force Supercharger could result in severe engine damage.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 2

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 4

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

IMPORTANT WARNINGS (CONTINUE)

Edelbrock periodically releases improved versions of the calibration file found on the supplied

handheld programmer. Check the website to ensure you have the latest version, as described in

Step #165.

It is also recommended that you check the Edelbrock Tech Center Website for any updates to this

installation manual. Please refer to the lower right hand footer to verify that you have the

latest revision of this installation manual before beginning the installation.

Tech Center: http://www.edelbrock.com/automotive_new/misc/tech_center/install/index.php

91 octane or higher gasoline is required at all times. If your vehicle

has been filled with anything less, it must be run until almost dry and

refilled with 91 or higher octane gasoline twice prior to installation.

Failure to use the required 91 octane gasoline or higher could

permanently damage your engine. Any failures associated with not

using premium 91 octane gasoline or higher, will be ineligible for

warranty repairs.

Edelbrock Authorized Installer Disclaimer

Authorized installers of Edelbrock products are independent companies over which Edelbrock has no right of control. Edelbrock LLC makes

no claims regarding the abilities, expertise or competency of individual employees of any authorized installer. Each authorized installer is

an independent company and makes its own independent judgments. Edelbrock LLC specifically disclaims any responsibility to any party

including third parties for the actions, or the failure to act, of individuals, agents or a company authorized in the installation of Edelbrock LLC

products.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 3

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 5

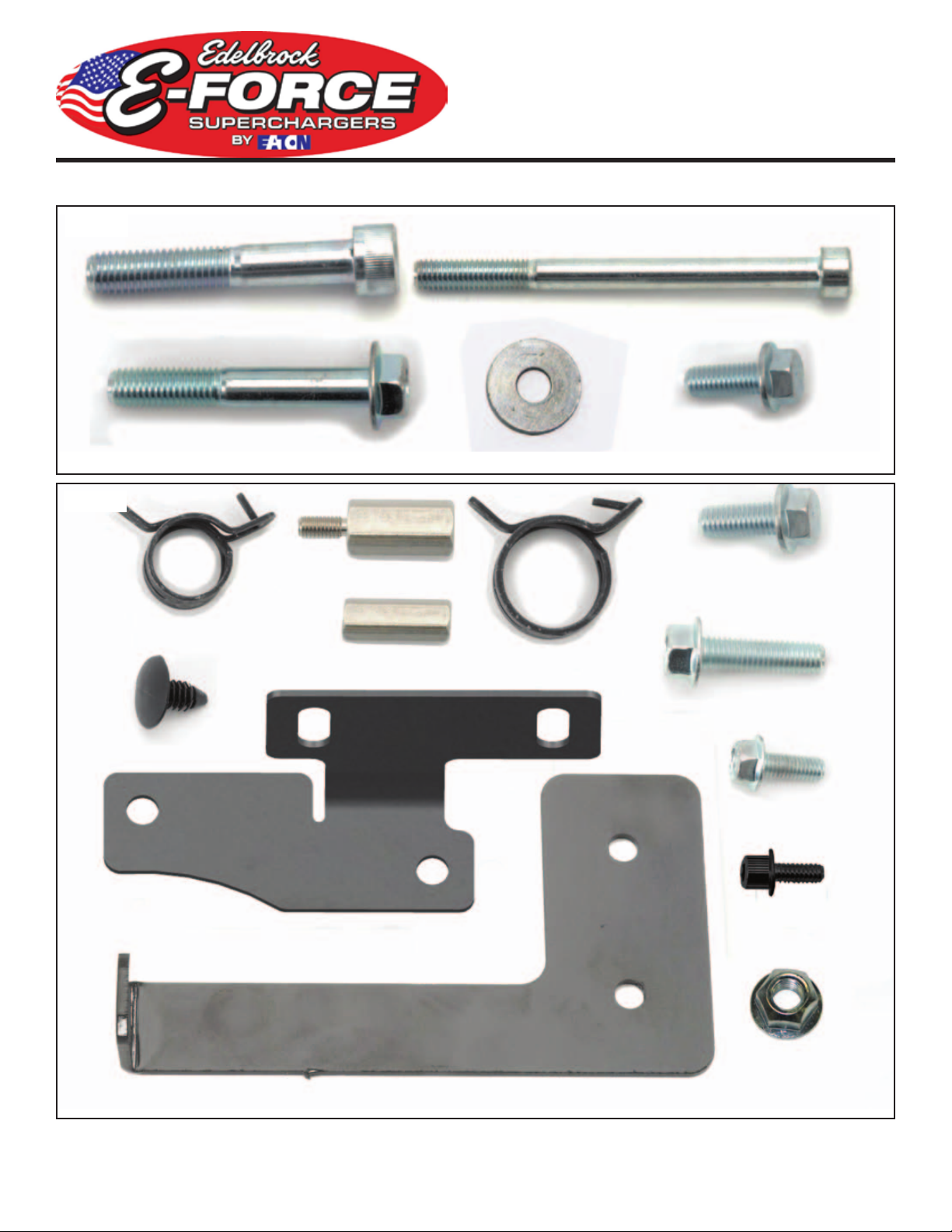

Bag #1

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

INSTALLATION HARDWARE IDENTIFICATION GUIDE

(1x) - M10 x 1.5 x 65mm Socket Head Bolt

(1x) - M10 x 1.5 x 75mm Hex Flange Bolt

Bag #2

(1x) - M6 x 1 x 25mm

(2x) - 1/2” Hose Clamp

(1x) - M5 X .8 X 25mm

(2x) - Nylon Body Pin

Hex Stand-Off

Hex Stand-Off

(3x) - M8 x 1.25 x 100mm Socket Head Bolt

(2x) - M8 Washer

(7x) - 3/4” Hose Clamp

(3x) - M8 x 1.25 x 20mm

Hex Flange Bolt

(4x) - M8 x 1.25 x 20mm

Hex Flange Bolt

(1x) - M8 x 1.25 x 30mm

Hex Flange Bolt

(1x) - Lower Intercooler Reservoir Bracket

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

(1x) - Upper Intercooler Reservoir Bracket

Page 4

(4x) - M6 x 1 x 16mm

Hex Flange Bolt

(1x) M5 X .8 X10mm

Socket Head Bolt

(4x) - M8 x 1.25

Hex Flange Nut

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 6

Bag #3

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

(11x) - M8 x 1.25 x 25mm

Countersunk Socket Head Bolt

Bag #4

(1x) - GM Factory Harmonic Balancer Bolt

(1x) - M16 x 2 x 120mm Hex Bolt

(8x) - M6 x 1 x 45mm

Hex Flange Bolt

(4x) - M6 x 1 x 12mm

Socket Head Bolt

Drill Hole

(1x) - Crank Pinning Drill Guide

(2x) - M6 x 1 x 16mm

Button Head Bolt

Bolt Hole

Ream Hole

(1x) - 1/4” x 3/4”

Steel Dowel

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

(1x) - 15/64” High Speed Steel Drill Bit

(1x) - .2500” Reamer

Page 5

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 7

Bag #5

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

(4x) - Coil Cover Bracket

(4x) - Coil Cover Standoff

(1x) - Coil Cover

(4x) - Coil Cover Bracket Grommet

Dipstick Grommet

(4x) - Coil Cover Retainer Stud

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 6

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 8

Intercooler Water

Pump to Heat

Exchanger Hose

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

HOSE IDENTIFICATION GUIDE

Heater Core

Hose Assembly

Fuel Rail Inlet

Fuel Rail Crossover

Intercooler

Reservoir to Water

Pump Hose

Manifold to EVAP

Solenoid Hose (18”)

Brake Booster to

Manifold Hose

EVAP Solenoid

to Fender Fitting

Hose (21”)

Intercooler Hose

Assembly

Passenger Side Manifold to

Intercooler Reservoir Hose

Driver Side PCV Hose (22”)

Passenger Side

PCV Hose (24”)

Driver Side Manifold to

Intercooler Reservoir Hose

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 7

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 9

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

Test Flash Procedure

Use the supplied programmer to flash the ECU and verify

its compatibility.

• Original Equipment Manufacturers often release updates

to the computer programming for your vehicle. Edelbrock

highly recommends that you verify, with your new car

dealer, that your vehicle is equipped with the latest software

version from your vehicle manufacturer, before attempting

to load the Edelbrock tune.”

• Confirm that you have the latest calibration by checking

the Edelbrock website

(http://www.edelbrock.com/automotive_new/mc/

superchargers/software-tech.shtml ) and entering your

serial number in the search field.( Your 4 digit supercharger

serial number is written on your kit checklist paperwork,

and is also stamped on the front bolt bosses of your

supercharger-first 2 digits on RH bolt boss, 2nd 2 digits on

LH bolt boss.) Once you have found the latest tune on the

site, power on the programmer, press the left arrow and

select the Device Info option. Scroll down to Tune Version

and compare that number to the one on the site. If they

are different, download the new calibration as instructed

on the website.

• Use directional pad to highlight your vehicle and

transmission combination then press Select.

• Use directional pad to highlight Begin Program then press

Select.

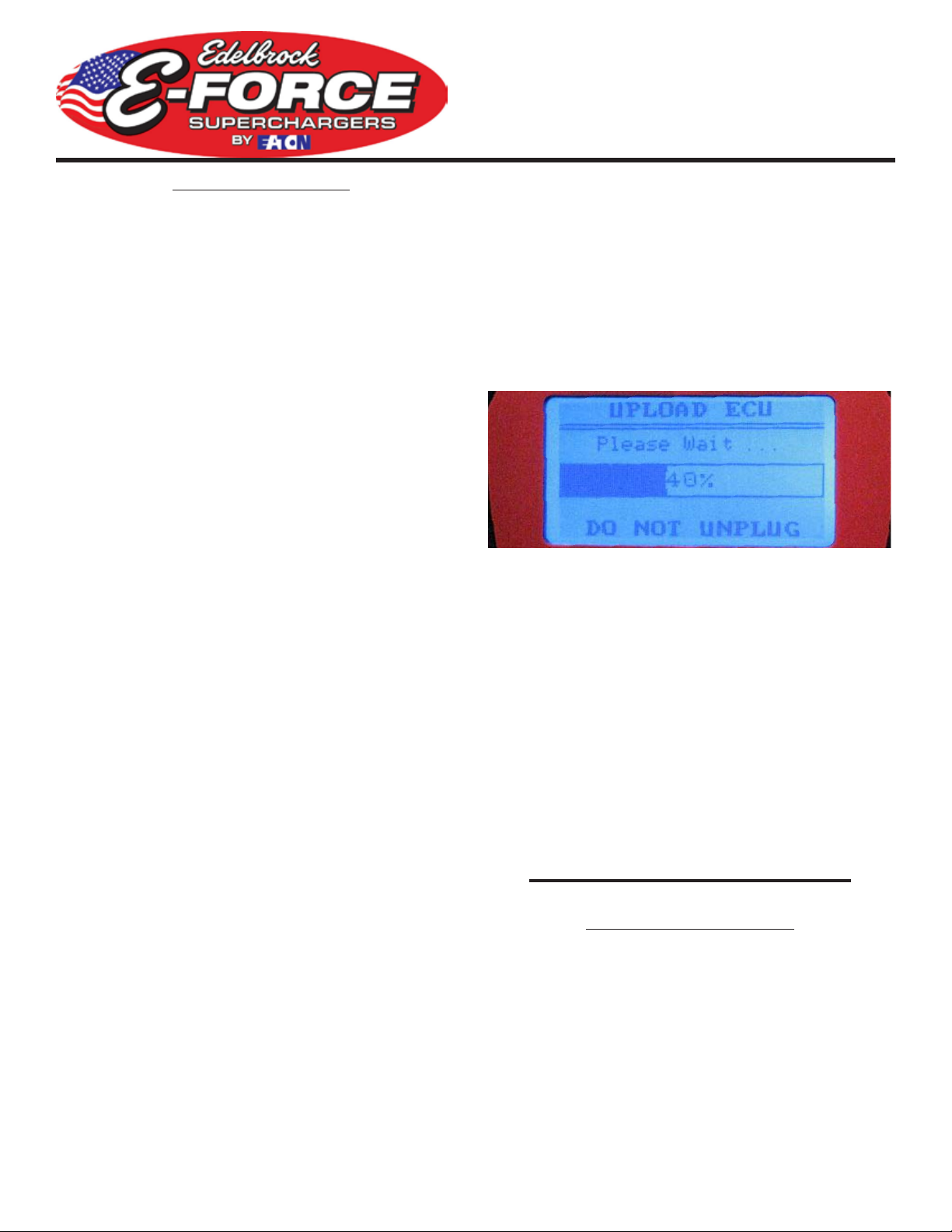

• Depending on your specific drivetrain configuration,

several separate operations may take place during this

step. Completion of each operation will cause the progress

bar to reset to zero.

DO NOT unplug the programmer until prompted.

• Turn the car off when prompted to do so by the handheld

programmer.

• Read parting message from programmer then press

Select to continue.

• Unplug the programmer cable from the OBD-II port.

• Put the car into Acc mode, but don’t start the vehicle.

• Connect the supplied PCM cable to the OBD-II connector.

• Use directional pad to highlight Program Vehicle option

and press Select button.

• Use directional pad to highlight Preprogrammed Tune

option and press Select button.

• Read disclaimer then press Select to continue.

• Verify ignition is in the ‘Key On’ position but that the

engine is not running then press Select.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 8

In the rare occurrence that you encounter an error message

during the test flash procedure, please refer to pg. 27, titled

Email Edelbrock Your Stock PCM Calibration.

Post Successful Test Flash

If you are ready to install the supercharger, proceed to Step

1 of the Supercharger Installation

OR

If you wish to return the ECU back to the factory calibration,

such that the vehicle can still be driven until you are ready

to begin the installation, then:

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 10

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

• Put the car into Acc mode, but don’t start the vehicle.

• Connect the supplied PCM cable to the OBD-II connector.

• Use directional pad to highlight Program Vehicle option

and press Select button.

• Use directional pad to highlight Return To Stock option

and press Select button.

• Follow the on screen instructions. Turn the car off when

prompted to do so by the handheld programmer.

• Read parting message from programmer then press

Select to continue.

• Unplug the programmer cable from the OBD-II port.

• When you are ready to Install the supercharger, proceed

with Step 1 and you will be prompted to re-flash the ECU

towards the end of the installation procedure.

4. Lift and support the front end of the vehicle using a

service lift or jack and appropriately load rated jack stands

then loosen and remove the lug nuts from both front wheels.

Remove the wheels and set them aside.

5. Use a T20 Torx wrench to remove the three bolts on each

side holding the front and the two holding the rear of the

front wheel fender liners. Use a panel puller to remove the

five body pins on each side that retain the inner fender wells

then remove them and set them aside.

Supercharger Installation

1. Open trunk and lift trunk liner to access plastic hold down.

Unscrew plastic hold down then remove air compressor and

foam support.

2. Use a 10mm socket to loosen and remove the negative

battery terminal.

3. Lift the protective cover then use a 10mm socket to

loosen and remove the positive battery terminal.

6. Reach in through the wheel wells with a 10mm socket to

remove the four bolts at the front of each side of the fascia

then use a 7mm socket to remove the two bolts on each

side of the front fascia.

7. Disconnect the fog lamp electrical connectors and the

fascia wiring harness connector on the passenger side.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 9

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 11

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

8. Use a 10mm socket to remove the two bolts retaining

the bottom of the fascia.

9. Use a panel puller to remove the six body pins holding

the top of the fascia then use a 10mm socket to remove the

bolt at each end of the top of the fascia.

14. Disconnect the passenger side PCV tube from the valve

cover then use a flat head screwdriver to loosen the worm

clamp retaining the air intake tube to the throttle body.

Remove the air intake tube and PCV hose.

15. Use a 15mm socket and a breaker bar to loosen the

tensioner and remove the serpentine belt.

16. Disconnect the throttle body control connector on the

passenger side of the throttle body.

10. The front fascia can now be removed by pulling it

forward off the vehicle. Set front fascia aside.

11. Remove the oil fill cap and remove the plastic engine

cover. Reinstall the oil fill cap.

12. Disconnect the Mass Airflow Sensor connector.

13. Use a flat head screwdriver to loosen the worm clamp

holding the inlet tube to the air box lid then remove the air

box lid by pushing the lock tabs back.

17. Use a 10mm socket to remove the four bolts retaining

the throttle body and set it aside.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 10

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 12

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

18. Push down the white tab on the front EVAP hose fittings

and disconnect them from the manifold and the EVAP

solenoid.

19. Disconnect the Manifold Air Pressure sensor and EVAP

solenoid electrical connectors.

NOTE: 2013 model years disregard Step 20 and proceed

to Step 21.

20. Disconnect the PCV tube from the engine valley cover.

22. Use a 3/8” Fuel Line Removal Tool to disconnect the

fuel line from the fuel rails and from the passenger side

fender fitting. Use a shop rag to absorb any excess fuel.

23. Use a 10mm socket to remove the nut holding down

the fuel line clamp then remove the fuel line and clamp.

24. Disconnect the two ignition harness connectors, the

eight spark plug wires from the ignition coils and the eight

fuel injector electrical connectors.

25. Use a 10mm deep socket to remove the five studs

retaining each of the ignition coil brackets to the valve

covers. Lift and remove the coil brackets as an assembly.

NOTE: Step 21 only pertains to 2013 model years. Please

disregard otherwise.

21. Remove the driver side PCV on the rear of the diverside

valve cover and on the passenger side of the throttle body.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 11

26. Disconnect the EVAP hose from the EVAP Solenoid and

the passenger side fender fitting.

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 13

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

27. Use a 10mm socket to remove the nut on the driver

side and remove the plastic manifold webbing.

28. Use an 8mm socket to remove the manifold bolt on the

driver side retaining the fuel rail bracket.

29. Use a 10mm deep socket to remove the four fuel rail

studs. Remove the fuel rail bracket then remove the rails

by lifting the injectors straight up out of their provisions then

work the rails forward and set them aside.

31. Use a pair of hose clamp pliers to loosen the clamp

retaining the vacuum hose to the brake booster fitting and

disconnect the hose. It will be removed with the manifold.

32. Lift the rear of the manifold and pull it forward to

remove. Remove the o-ring seals from the manifold flanges

and set them aside as they will be reused.

33. Use a clean shop rag to wipe down the intake flange of

both cylinder heads then put a small strip of masking tape

over each port to prevent debris from entering.

34. Unplug the oil pressure sensor connector. Use a

crescent wrench to remove the oil pressure sensor from the

engine valley plate.

30. Use an 8mm socket to remove the nine remaining

manifold bolts. Note that the rearmost passenger side bolt

will come out with the manifold and that it is necessary to

rotate the manifold towards the passenger side to remove

the rearmost driver side bolt and the bracket it retains.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 12

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 14

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

NOTE: Steps 36-42 outline the procedure for disabling

the Active Fuel Management system found in Camaros

equipped with an automatic transmission. Manual vehicles

need to disregard Steps 36-42 and proceed to Step 43.

WARNING: AUTOMATIC CAMAROS EQUIPPED WITH

STANDARD, NON-AFM LIFTERS MUST USE THE MANUAL

VALLEY COVER PLATE. FAILURE TO DO SO WILL RESULT

IN ENGINE DAMAGE.

35. Use a 13mm socket to remove the eleven bolts retaining

the engine valley plate and remove the plate.

36. Use a T-20 Torx driver to remove the four bolts retaining

the plastic solenoid bracket, then pry open the clip at the

rear of the plate to remove the bracket.

40. Trim the two tabs projecting from the gasket to the base

of their tapers. Use a file to remove any burrs then install

the gasket in the new valley plate.

41. Install the new valley plate with the gasket in place onto

the engine and proceed to Step #46.

NOTE: Steps 43-45 are for vehicles without Active fuel

Management. Disregard otherwise.

42. Use a 13mm socket to remove the eleven bolts retaining

the engine valley plate and remove the plate. The metal

and rubber gasket beneath it will be reused and should be

left in place.

43. Use a flathead screwdriver to remove the eight o-ring

seals from the underside of the valley plate.

37. Rotate each solenoid 90° and remove them.

38. Use a T-30 Torx driver to remove the twenty bolts

holding the steel sandwich in place and remove it.

39. Remove the plastic and rubber gasket from the valley

tray using great care not to damage the seal.

44. Inspect each seal for damage and replace any that have

been compromised then install the seals into the supplied

valley plate.

45. Install the new valley plate on the engine carefully so as

not to dislodge the o-rings and line up the bolt holes.

46. Apply anti-seize to the underside of the heads of the

eleven countersunk bolts from Bag #3 then use a 5mm

Allen tool to install them in the plate. Torque them to 18

ft-lbs from the center out.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 13

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 15

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

47. Apply thread sealant to the threads of the oil pressure

sensor then use a crescent wrench to install the sensor in

the new valley plate. Reconnect the oil pressure sensor

electrical connector.

48. Use a 15mm socket to remove the two bolts retaining

the belt tensioner.

NOTE: Steps 49-52 will demonstrate how to install the

Edelbrock heater hoses included with this kit. This

procedure is optional on 2013 model years as the factory

heater hoses are adequate.

49. Place a drain pan below the radiator petcock on the

driver side. Remove the radiator cap then loosen the

petcock to drain the engine coolant.

52. Install the supplied Heater Core Hose Assembly to the

firewall fittings using the supplied hose clamps. Route the

lines between the engine oil dipstick and the fuse box to the

fittings on the water pump and secure them with the

supplied hose clamps. Note that the hose closer to the

passenger side of the firewall will be routed to the fitting

closer to the front of the vehicle and vice versa.

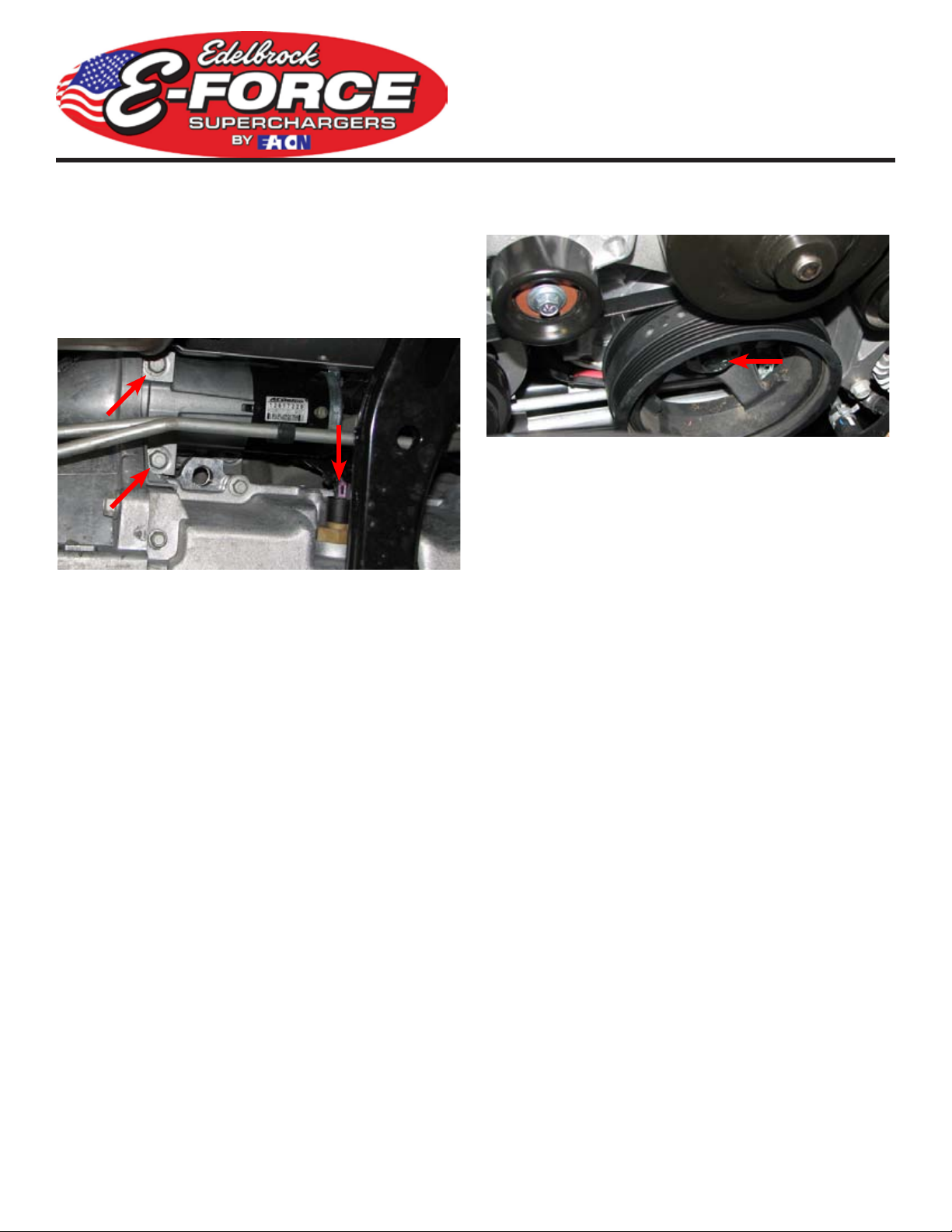

53. Apply Blue Loctite, or equivalent, to the threads of the

M8 x 20mm bolt supplied in Bag #1 then use a 12mm

socket and washer to install the smaller supplied idler pulley

onto the supplied idler bracket.

50. Disconnect the two heater hoses from the firewall using

a shop rag to absorb any excess coolant.

51. Disconnect the two heater hoses from the water pump

using a shop rag to absorb any excess coolant.

54. Use a 10mm socket to remove the three water pump

bolts indicated.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 14

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 16

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

55. Apply blue Loctite, or equivalent, to the threads of the

M8 x 100mm bolts supplied in Bag #1 then use a 6mm

Allen tool to install the idler bracket onto the water pump.

56. Use a 15mm socket to remove the nut retaining the

ground strap on the passenger side cylinder head then use

a 15mm deep socket to remove the ground strap stud.

59. Apply blue Loctite, or equivalent, to the threads of an

M8 x 20mm bolt supplied in Bag #1 then use the supplied

washer and a 12mm socket to install the supplied idler

pulley onto the tensioner bracket.

60. Apply blue Loctite, or equivalent, to the threads of the

M10 x 75mm bolt supplied in Bag #1 then use a 15mm

socket to install the supplied tensioner onto the tensioner

bracket.

57. Apply blue Loctite, or equivalent, to the threads of the

stock tensioner bolts then use a 15mm socket to install the

supplied tensioner bracket to the water pump.

58. Apply blue Loctite, or equivalent, to the threads of the

M10 x 65mm bolt supplied in Bag #1 then use an 8mm

allen to install it in the countersunk bolt hole of the tensioner

bracket.

61. Use a 12mm socket and an M8 x 20mm bolt supplied

in Bag #1 to secure the ground strap to the back side of the

tensioner bracket.

NOTE: If not already done so, it’s recommended to drain the

coolant by removing the petcock to avoid coolant spillage.

62. Use pliers to loosen the hose clamps and disconnect

the two small upper radiator hoses. Use caution when

removing and reinstalling hoses onto plastic fittings.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 15

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 17

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

63. Use a 13mm socket (10mm on 2013 model years) to

remove the two bolts holding the fan assembly to the top of

the radiator then disconnect the electrical connector on the

passenger side of the fan assembly and remove the radiator

fans.

64. Disconnect the oil level sensor electrical connector from

the passenger side of the oil pan.

65. Use a 10mm socket to remove the starter support

bracket bolt.

72. Use a breaker bar and a 24mm socket to loosen and

remove the crank bolt. A long pipe slid over the breaker bar

can be helpful for increasing leverage.

73. Install the drill guide and the M16 x 120mm bolt supplied

in Bag #4 onto the end of the crankshaft.

74. Measure 1.7” from the tip of the 15/64” drill bit supplied

in Bag #4 and mark the position with a piece of masking

tape then drill into the crank through the hole in the guide

that has a bushing in it until the tape mark reaches the drill

guide.

66. Use a 13mm socket to remove the two starter bolts.

67. Use an 8mm wrench to remove the three bolts retaining

the starter heat shield.

68. Disconnect electrical connector at top of starter.

69. Use a 13mm socket to remove the nuts retaining power

wires to the starter.

70. Remove and set aside the starter and bracket.

71. Install GM Flywheel Holding Tool #J-42386-A to prevent

the crank from rotating while loosening the balancer bolt

and torque the bolts holding it to 37 ft/lbs.

75. Loosen the bolt holding the drill guide and rotate it until

the second hole lines up with the hole drilled in the crank.

Use the back side of the ream tool to verify the guide is

correctly aligned.

76. Tighten the guide bolt then use compressed air to clean

out any metal flakes in the drill hole.

77. Insert the supplied ream tool through the hole and ream

the full depth of the hole.

78. Use compressed air to clean out any metal flakes then

loosen the bolt and remove the drill guide.

79. Apply red Loctite retaining compound to the supplied

crank pin and tap it into the reamed hole until it is flush with

the crank snout.

80. Install the crank bolt supplied in Bag #4 and torque it to

37 ft-lbs then rotate it an additional 140°.

81. Remove GM Flywheel Holding Tool #J-42386-A.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 16

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 18

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

82. Lift the starter support bracket and starter into place

then use a 13mm wrench to reinstall the power wire onto

the starter.

83. Reconnect the starter solenoid electrical connector.

84. Use an 8mm wrench to reinstall the three bolts that

hold the starter heat shield in place.

85. Use a 13mm socket to install the two starter bolts.

86. Use a 10mm socket to reinstall the starter support

bracket bolt.

87. Lower the fan assembly back into place, reconnect

the passenger side electrical connector then use a 13mm

socket to reinstall the stock fan assembly bolt on the driver

side only, the passenger side will be installed later.

88. Use a panel puller to remove the two body pins from the

top of the lower radiator shroud.

NOTE: Convertible models are equipped with a brace that

connects the frame extensions, this brace will need to

be removed and replaced with the Edelbrock Convertible

Brace (Part #15956, Sold Separately) as it interferes with

the installation of the Edelbrock heat exchanger.

89. Install the supplied heat exchanger behind the bumper

so that the lower bracket holes line up with those in the

radiator shroud.

90. Secure the top of the heat exchanger with the two M8

x 20mm bolts supplied in Bag #2 and tighten them with a

12mm socket.

91. Install the M8 nuts and M8 x 20mm bolts supplied in

Bag #2 into the holes in the lower heat exchanger brackets

then use a 12mm wrench and socket to tighten them.

92. Install the intercooler water pump bracket on the studs

located on the back of the passenger side of the bumper.

Secure it in place with the M8 nuts supplied in Bag #2 and

tighten them with a 12mm wrench.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 17

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 19

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

93. Install the water pump to heat exchanger hose on the

passenger side inlet fitting of the heat exchanger and clock

it until it contacts the lower radiator shroud. Secure the

fitting with a 3/4” hose clamp supplied in Bag #2.

94. Slide the strap over the body of the water pump and

install it in the water pump bracket. Rotate the water pump

and slide it in and out until it roughly lines up with the

position of the hose on the other side of the lower radiator

shroud.

96. Use the supplied bolt and a 13mm socket to secure the

water pump by tightening the strap to the bracket.

97. Slide the hose onto the water pump outlet and secure

it with a 3/4” hose clamp supplied in Bag #2.

98. Install the Intercooler Hose Assembly by sliding it down

between the radiator fan assembly and the engine. Note

that the short hose section will go around the radiator to the

outlet of the heat exchanger.

95. Use a uni-bit to drill a 1-1/8” hole in the lower radiator

shroud to allow the hose to slide onto the water pump outlet

fitting.

99. Use a unibit to drill a 1-1/8” hole in the radiator

shroud on the driver side directly across from the heat

exchanger outlet.

100. Slide the short section of the Intercooler Hose

Assembly through the hole and onto the heat exchanger

outlet. Secure it with a 3/4” hose clamp supplied in Bag

#2.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 18

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 20

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

101. Mount the brackets, supplied in Bag #2, to the

intercooler reservoir with the M6 x 16mm bolts located in

Bag #2. Refer to figures 2a & 2b for the specific orientation

of the lower bracket for each model year.

Figure - 1

102. FOR 2010-‘11 MODEL YEARS ONLY Use a 10mm

socket to remove the upper-outside bolt from the backpassenger side of the radiator fan; retain the bolt as it will

be re-used.

103. FOR 2012-‘13 MODEL YEARS ONLY Use a 13mm

wrench to install the standoff stud supplied in Bag #2 in

place of the bolt which was just removed. See Figure 3a.

2010-’11

Figure - 3a

2010-’11

104. FOR 2012 - ‘13 MODEL YEARS ONLY Use a 10mm

wrench to install the standoff, supplied in Bag #2, to the

stud located on the back of the radiator fan. See Figure 3b

2012-’13

Figure - 2a

2012-’13

Figure - 3b

Figure - 2b

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 19

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 21

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

105. Install the intercooler reservoir - water pump hose

onto the outlet of the intercooler reservoir so that the other

end will extend down to the inlet of the intercooler water

pump. Secure the hose to the reservoir fitting with a

supplied hose clamp. See Figure 4.

To passenger side manifold

To driver side manifold

To water pump

Figure 4

106. Lower the intercooler reservoir and its attached hose

down into the passenger side of the engine bay so that the

lower bracket will line up with the mounting hole (Refer

to the Figure that corresponds to your model year;“3a” or

“3b”), the upper bracket will line up with the passenger

side radiator fan assembly bolt and the hose will mate up

to the intercooler water pump.

108. FOR 2010-‘11 MODEL YEARS ONLY Secure the

lower intercooler reservoir bracket to the back of the fan by

using a 10mm socket to re-install the stock bolt onto the

standoff stud.(Refer to Figure “3a”).

109. FOR 2012-’13 MODEL YEARS ONLY Secure the

lower intercooler reservoir bracket to the back of the fan by

using a 4mm allen to install the M5 X 10mm bolt, supplied

in bag 2, onto the spacer.(Refer to Figure“3b”).

110. Secure the intercooler reservoir to water pump hose

to the inlet of the water pump with a supplied hose clamp.

111. Install the factory o-ring intake seals into the machined

grooves of the supercharger flanges.

112. Two of the stock manifold bolt hole provisions in

the cylinder heads break into the crankcase and are not

used with this supercharger. These must be plugged by

installing two button head bolts supplied in Bag #3 in

the front passenger side and rear driver side bolt holes

to ensure a good seal.

107. Use a 13mm (10mm for 2012-’13 Models) socket to

reinstall the stock radiator fan assembly bolt through the

upper reservoir bracket.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 20

113. Remove the tape covering the intake ports.

114. Connect the TMAP harness to the TMAP sensor at the

rear of the supercharger manifold. Bundle the harness up

and wrap over the top of the manifold to avoid damage

during installation of the supercharger.

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 22

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

115. With the assistance of one or more people, lift the

supercharger assembly onto the engine. Use a 10mm

universal socket to install the M6 x 45mm intake manifold

bolts supplied in Bag #3 and torque them to 89 in/lbs in the

sequence shown below.

NOTE: 2010-’12 Vehicles use belt #4061065 (106.5”).

2013 vehicles use belt #4060102 (102”).

116. Route the supplied serpentine belt according to the

diagram below, except for the idler pulley adjacent to the

tensioner. Use a 15mm wrench to push the tensioner in

enough for the belt to slip on the idler pulley then inspect

the belt installation to make sure it is properly aligned.

118. Apply o-ring lube to the upper seals of the supplied

fuel injectors and install them into the supplied fuel rails

so that the electrical connectors are oriented towards the

rounded side of the rails.

119. Lower the passenger fuel rail assembly onto the

manifold lining up the injectors with their provisions on the

manifold. Gently, push down on the rails until the injectors

are fully seated. Secure fuel rail using a 5mm Hex tool and

two (2) M6 x 12mm bolts from Bag #3.

120. Install the supplied Fuel Rail Inlet between the fender

fitting and fuel rail fitting on the passenger side. DO NOT

install this fuel input line onto the smaller 8mm barb meant

for the EVAP.

TENS

S/C

IDLER

IDLER IDLER

WATER

PUMP

CRANK

SHAFT

ALT

P/S

PUMP

or

IDLER

117. Apply o-ring lube to the seals of each of the fuel rail

fittings. Use a 13/16” wrench to install the plug in the rear

of the driver side rail and a 3/4” wrench to install the

crossover fittings in both rails as well as the inlet fitting at

the rear of the passenger side rail. Clock the inlet fitting to

the rounded side of the fuel rail.

121. Install the supplied Brake Booster to Manifold Hose

onto the brake booster fitting and secure it with the 3/4”

hose clamp supplied in Bag #2. Then connect the other

end of the brake booster hose to the fitting on the driver

side of the supercharger air inlet and secure it with another

3/4” hose clamp supplied in Bag #2.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 21

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 23

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

122. Connect the supplied Fuel Rail Crossover line with the

90° fittings to the passenger side fuel rail. Route the

crossover line below the hub snout and air inlet of the

supercharger and over to the front of the driver side rail.

Clip the Fuel Rail Crossover line onto the driver side fuel rail

fitting.

123. Reattach the fuel injector electrical connectors.

124. Install the Manifold to EVAP Solenoid Hose to the

fitting directly below the supercharger hub snout. Connect

the other end of the hose to the bottom fitting on the EVAP

solenoid, opposite of the EVAP connector.

128. Connect the Driver Side PCV Hose to the straight

fitting on the driver side air inlet. Route the PCV to the

vacuum fitting at the rear of the driver side valve cover and

clip it into place.

129. Use a small flat blade screwdriver to remove the wire

loom covers from the back of the ignition coil brackets.

125. Connect the EVAP Solenoid to Fender Fitting Hose to

the EVAP Solenoid (side with connector). Route the hose

back over the passenger side coils onto the 8mm EVAP

hard line. Slide the connector onto the appropriate barb

fitting. DO NOT confuse the 10mm fuel output line with

the EVAP.

126. Use a 10mm wrench to remove the valve cover ball

stud from the driver side valve cover (if applicable).

127. Use a pair of pliers to remove the vacuum cap from

the rear of the driver side valve cover (if applicable).

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 22

130. Use a 10mm socket to reinstall the coil brackets

using the five stock studs on each side then reconnect the

ignition coil harness electrical connectors and the spark

plug wires to the ignition coils.

131. Use a 10mm socket to remove the two bolts holding

the ignition coils for cylinders #2, #3, #6 & #7.

132. Install the supplied rubber grommets into the supplied

coil cover brackets. Instal the coil cover brackets on top of

the ignition coils then reinstall the ignition coil bolts.

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 24

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

133. Install the Passenger Side Manifold to Intercooler

Reservoir Hose between the manifold and reservoir then

secure the reservoir fitting with a hose clamp supplied in

Bag #2. Refer to figure 4 on page 20.

134. Install Driver Side Manifold to Intercooler Reservoir

Hose between the manifold and reservoir then secure the

reservoir fitting with a hose clamp supplied in Bag #2.

Refer to figure 4 on page 20.

135. Connect the Intercooler Hose Assembly to the rear

facing driver side fitting and the side facing passenger side

fitting. Push each hose end on until it clicks into place.

136. Use a 16mm wrench to install the coil cover standoffs

on the valve covers.

139. Route the TMAP wiring harness below the supercharger

hub snout towards the driver side using care to secure it

well away from the serpentine belt.

140. Connect the throttle body connector extension harness

to the stock throttle body connector and route the extension

harness so that it will clear the serpentine belt and connect

it to the throttle body connector on the throttle body.

141. Use a T20 Torx bit to remove the MAF sensor from

the stock air box cover and install it in the supplied air box

cover. The arrow on the side of the sensor should point

back towards the supercharger.

137. Install the factory throttle body O-ring into the

machined groove on the supercharger air inlet.

138. Use a 10mm socket, the four stock bolts and the stock

O-ring gasket to install the throttle body on the supercharger

air inlet flange.

142. Replace the stock air filter with the one supplied.

143. Slide the supplied worm clamps over each end of the

supplied silicone tube then slide the tube onto the outlet of

the supplied air box cover. Install the cover by sliding the

tabs into the holes on the driver side of the air box while

sliding the silicone tube onto the throttle body. Push down

on the cover until the tabs snap into place.

144. Use a flathead screwdriver to tighten the worm

clamps on each end of the silicone tube.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 23

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 25

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

145. Connect the stock MAP & MAF sensor wiring harness

connectors into the supplied TMAP wiring harness then

connect the TMAP harness to the MAF sensor.

146. Use a 13mm socket to remove the nut from the power

stud at the front of the fuse box. Slide the ring connector

at the end of the orange wire on the relay harness over the

power stud then reinstall the stock nut.

147. Install the relay on the tab on the passenger side of

the fuse box and the fuse housing on the brace directly in

front of the fuse box using the body pins supplied in Bag #2.

149. Use a 10mm socket to remove the passenger side

fender bolt, install the ground strap ring connector

underneath it, then reinstall the bolt.

150. Disconnect the stock EVAP solenoid electrical

connector and plug it into the color matched receptacle on

the relay harness.

148. Route the intercooler water pump connector attached

to the relay down to the water pump and plug it in.

151. Clip the supplied EVAP solenoid electrical connector

on the relay harness into the EVAP solenoid.

152. Connect the passenger side pcv hose to the fitting on

the passenger side valve cover and carefully route the hose

to the fitting on the underside of the silicone air inlet tube

so as to avoid contact with the serpentine belt or any

pulleys.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 24

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 26

153. Use a 10mm deep socket to install the supplied ball

studs into the new coil covers.

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

If you have yet to flash your ECU, then proceed with

steps 163 - 176, otherwise disregard them.

163. It is recommended that you check the Edelbrock

website (http://www.edelbrock.com/automotive_new/mc/

superchargers/fuel_injected_soft-tech.shtml) to confirm

that you have the latest calibration. Once you have found

the latest tune on the site, power on the programmer, press

the left arrow and select the Device Info option. Scroll down

to Tune Version and compare that number to the one on the

site. If they are different, download the new calibration with

the supplied USB cable.

154. Install the grommet supplied in Bag #6 in the hole on

the passenger side coil cover.

155. Slide the front fascia back into place and secure it by

reinstalling the stock fasteners, reversing the disassembly

process.

156. Reconnect the fog light electrical connectors and the

fascia wiring harness connector on the passenger side.

157. Use a 10mm socket to reconnect the positive battery

terminal.

158. Use a 10mm socket to reconnect the negative battery

terminal.

159. Remove intercooler reservoir cap and fill intercooler

system with a 50/50 blend of water and coolant.

160. Reconnect petcock and fill the engine coolant system

with a 50/50 blend of water and coolant (if applicable).

161. Reinstall and secure the front inner fender wells with

the stock fasteners.

162. Reinstall the front wheels and snug the lug nuts.

Lower the vehicle to the ground then torque the lug nuts in

a crossing pattern to 100 ft/lbs.

164. Turn the key to the On position, but do not start it.

165. Connect the PCM cable from the supplied downloader

to the OBD-II connector located below the steering wheel in

the passenger compartment.

166. Use the directional pad to highlight the Program

Vehicle option and press the Select button.

167. Use the directional pad to highlight the Preprogrammed

Tune option and press the Select button.

168. Read disclaimer then press Select to continue.

169. Verify ignition is in the ‘Key On’ position but that the

engine is not running then press Select.

170. Use directional pad to highlight your vehicle and

transmission combination then press Select.

171. Use directional pad to highlight your vehicle and

transmission combination then press Select, again.

172. Use directional pad to highlight Begin Program then

press Select.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 25

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 27

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

173. Vehicles equipped with a manual transmission will

have three separate operations take place during this step,

while vehicles with an automatic transmission will have

five. Completion of each operation will cause the progress

bar to reset to zero.

DO NOT unplug the programmer until prompted.

174. Turn the car off when prompted to do so by the

handheld programmer.

175. Read parting message from programmer then press

Select to continue.

176. Unplug the programmer cable from the OBD-II port.

181. Install the driver side coil cover by sliding it into place

and pressing the ball studs into bracket grommets.

Congratulations on the installation of your new Edelbrock

E-Force Supercharger System. If you have any questions,

please call our Technical Support hotline and one of our

technicians will be happy to assist you.

177. Start the car and allow it to idle while closely

inspecting the engine bay for any fuel or coolant leaks.

Repair any leaks before operating vehicle!

178. Remove the engine oil dipstick.

179. Lubricate the grommet on the passenger side coil

cover then install it by sliding the grommet down and

around the dipstick tube and pressing the ball studs into the

bracket grommets.

180. Return the dipstick to the dipstick tube.

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 26

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Page 28

Edelbrock E-Force Supercharger System for

the 2010-2013 Camaro SS

Installation Instructions

E-mail Edelbrock Your Stock Vehicle Calibration

In the rare occurrence that you encounter an error message that reads “Calibration not supported” during

the test flash procedure on page 8, you will need to e-mail Edlecbrock your stock vehicle calibration to

Calibration@edelbrock.com. Otherwise, disregard this step.

• Begin by downloading the SCT device updater software to your computer; it can be downloaded from: http://www.

sctflash.com/software/SCTDeviceUpdater.exe

• Put the car into Acc mode but do not start it.

• Connect the supplied PCM cable from the tuner to the OBD-II connector.

• Select PROGRAM VEHICLE, arrow over to UPLOAD STOCK, press SELECT and follow the prompts on the

screen.

• If the upload fails, you will be asked to AUTO DETECT, press SELECT and follow the prompts on the screen. If the auto

detect fail, then please contact Edelbrock Tech support @ 800-416-8628

• Once the stock calibration has loaded, disconnect the programmer from the OBD-II connector and connect it to your PC

using the supplied USB cable.

• Open the SCT software and select the button on the lower left hand side that reads GET STOCK FILE FROM DEVICE.

Follow the instructions on the screen.

• Once the download is complete e-mail your file to Calibration@edelbrock.com or call 1-800-416-8628 and our tech

support staff will assist you in e-mailing the file. NOTE: The subject line of your e-mail should be “file update needed”,

The file will automatically be labeled using your VIN # followed by “.sul “ (XXXXXXXXXXXXX.sul)

• Once we have this file we can update the tune to work with your application, then we will e- mail you the custom tune

which you may use until the release version is available. (This process can usually be completed within 1 to 2 business

days)

• Download the new tune to the programmer using the directions received with the custom tune.

• Re-try the test flash procedure using the custom tune

©2013 Edelbrock LLC

Part #1596, 1597, 1598, 1599

Page 27

Brochure #63-1598

Rev. 3/25/13 - QT/mc

Loading...

Loading...