Edelbrock 1905 User Manual

ostScript Pictur delbrock B/W Logo.ep

Performer Q-Jet Carburetors for Thermo-Quad Applications

Catalog #1905

for non-computer controlled 1972-1985 Chrysler 360, 400 & 440 V8s

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before installing your new carburetor. please call our Carburetor Technical Hotline at: (800) 416-8628 or e-mail us

If you have any questions or problems, at edelbrock@edelbrock.com.

DESCRIPTION

The Edelbrock Performer Q-Jet Carburetor for Thermo-Quad applications is a high quality, all new carburetor designed to replace the original equipment Thermo-Quad that came stock on 360, 400 and 440 Chrysler engines in trucks and motorhomes from 1972 to 1985. This Edelbrock carburetor features all-metal construction for no leaks and no hassles. It includes an electric choke along with a 3/4" 4-hole spacer, throttle lever adapter and fuel line adapter for an easy installation. These carburetors are street legal parts when used on the applications for which they are listed.

Edelbrock Performer Q-Jet Carburetors for Thermo-Quad applications are compatible with all OEM linkage and components for the years listed, and will fit stock intake manifolds. For best performance, they may be used with the matching Performer or Performer EGR intake manifold for those who wish to use a new stock replacement carburetor.

Caution: Check hood clearance due to additional carburetor spacer height.

IMPORTANT NOTES

Before installation of your new carburetor, you must do the following:

1.Replace fuel filter. Dirt found in carburetor voids warranty.

2.Check and replace the air filter if necessary.

3.Check PCV valve and replace if clogged.

4.Check all hoses for leaks or cracks and replace if necessary.

5.Check fuel pump for proper operation and replace if necessary.

6.Check the intake manifold and cylinder head gaskets for leaks and replace if necessary.

7.Check the ignition system: clean and gap or replace spark plugs, plug wires, and adjust ignition timing.

8.Check the vacuum line routing from your original carburetor to determine if each line is “timed vacuum” or “manifold vacuum”. Consult factory manual or underhood vacuum diagram if necessary to determine vacuum line routing on new carburetor.

9.Suggested Procedure: With engine fully warmed up, remove vacuum lines from carburetor one at a time and place your finger over port to feel for vacuum. Timed vacuum ports have little or no vacuum at idle; manifold vacuum ports have full vacuum at idle.

Note that while this carburetor does not appear identical to your old carburetor, it will perform properly on the models it was cataloged to replace. Main Jet: .073; Metering Rods: Primary-50M, Secondary-DR.

CARBURETOR REMOVAL

1. Prior to carburetor removal, make sure that engine is cool. 2. Disconnect negative battery cable from battery.

3. Remove air cleaner. Be sure to carefully disconnect any hoses from the air cleaner and note their location for re-installation. You may want to mark them with masking tape for easy reference.

4.Disconnect throttle linkage, kickdown linkage (certain automatic transmission applications only), cruise control (if equipped) and any return springs if present. NOTE: Check carefully for the precise location of all these linkages and return springs. You may want to mark them with masking tape for easy reference.

5. Disconnect all wires, tubes and hoses from carburetor and note their location. NOTE: There should be a maximum of one wire to the electric choke and one to the idle compensator solenoid. Any other electrical wiring attached to your carburetor indicates a computer controlled engine, and Edelbrock Q-Jet carburetors for Thermo-Quad applications will not function correctly on computer controlled applications.

6. Carefully remove fuel line from carburetor or fuel filter. Take extreme care not to spill any excess fuel. Place a rag underneath the fuel line to absorb any spillage that may occur. Certain models require two wrenches to remove the fuel line; one to hold the fitting on the carburetor and the second to turn the fitting on the fuel line. Use a tubing wrench to avoid rounding the tube fitting nut.

© 2001 Edelbrock Corporation |

Page 1 of 6 |

Rev. 10/01 |

Brochure No. 63-0018 |

|

|

CARBURETOR REMOVAL (Continuation)

7.Remove mounting nuts or bolts and or washers. Be sure to put them where they won't fall into the intake manifold upon carburetor removal.

8.Remove carburetor, being careful not to spill any dirt into the intake manifold. Immediately place a clean rag into the manifold to keep foreign objects out.

9.Thoroughly remove old mounting gasket and clean mounting surface.

CARBURETOR PREPARATION

1.Install throttle adapter bracket on throttle arm (see Figure 2).

2.Place old and new carburetors side by side and transfer any accessories that are needed onto the new carburetor.

CARBURETOR INSTALLATION

1.Remove rag from intake manifold and install new mounting studs supplied in kit. The two longer studs will go towards the front. Install new gasket spacer and carburetor base. NOTE: Do not use any cement, glue or liquid gaskets.

2.Carefully place new carburetor over studs and onto base gasket.

3.Install all mounting nuts and washers. Hand-tighten with a short box end wrench, using even increments alternating between diagonally opposed bolts. CAUTION: Over tightening may break carburetor base.

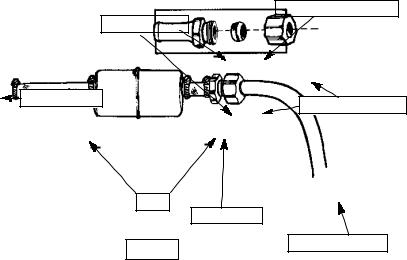

FUEL LINE CONNECTION

1.Cut OEM fuel line in the selected location using either a hacksaw or tubing cutter. It is easier to make the cut if you first remove the fuel line from the vehicle (after marking the place to be cut).

2.Make sure that you file and remove the burrs from the rough cut end of the steel line. Also be sure to thoroughly clean out all filings and metal particles from the line.

3.Install the Edelbrock special brass hose fitting completely over the OEM steel fuel line (see Figure 1) and securely tighten the compression unit. Use tubing wrenches if possible to avoid rounding the hex nut.

4.Install brass adapter fitting in carburetor.

5.Cut the proper length of the fuel hose supplied in this kit to connect the compression fitting to the brass adapter fitting in the carburetor.

6.Install one clamp on each end of this hose and securely push the fuel hose onto the compression fitting and brass adapter fitting in the carburetor. Make certain that the hose is completely installed on each fitting before tightening the screw-type worm clamp.

CAUTION: Do not over-tighten the clamps or you may cut into the fuel line and cause a leak.

Models with externally mounted fuel filters, install new fuel filter, starting threads by hand to avoid crossing or stripping threads. Replace any old or cracked hoses with new hoses designed for use with fuel. Note: If externally mounted fuel filter has 3/8" barbed outlet, that may be used in place of the fuel line compression fitting as an attachment point for the fuel hose to the carburetor.

Compression Sleeve

Adapter Fitting

To Carburator |

Compression Nut |

|

|

|

Fuel Filter |

Hose |

|

|

Hose Clamp |

Fig. # 1 |

Original Fuel line |

|

CHOKE WIRE INSTALLATION

Electric choke carburetor #1905 requires a 12-volt lead that is hot only when the ignition is “On”. Use volt meter to locate suitable source of electric power. Splice the wire with plastic connector (supplied) into this connection, then plug connector into carburetor electric choke. Do not use 12-volt coil wire.

© 2001 Edelbrock Corporation |

Page 2 of 6 |

Rev. 10/01 |

Brochure No. 63-0018 |

|

|

Loading...

Loading...