Page 1

Page 1 of 4

©2002 Edelbrock Corporation

Brochure No. 63-0149

Rev. 10/02

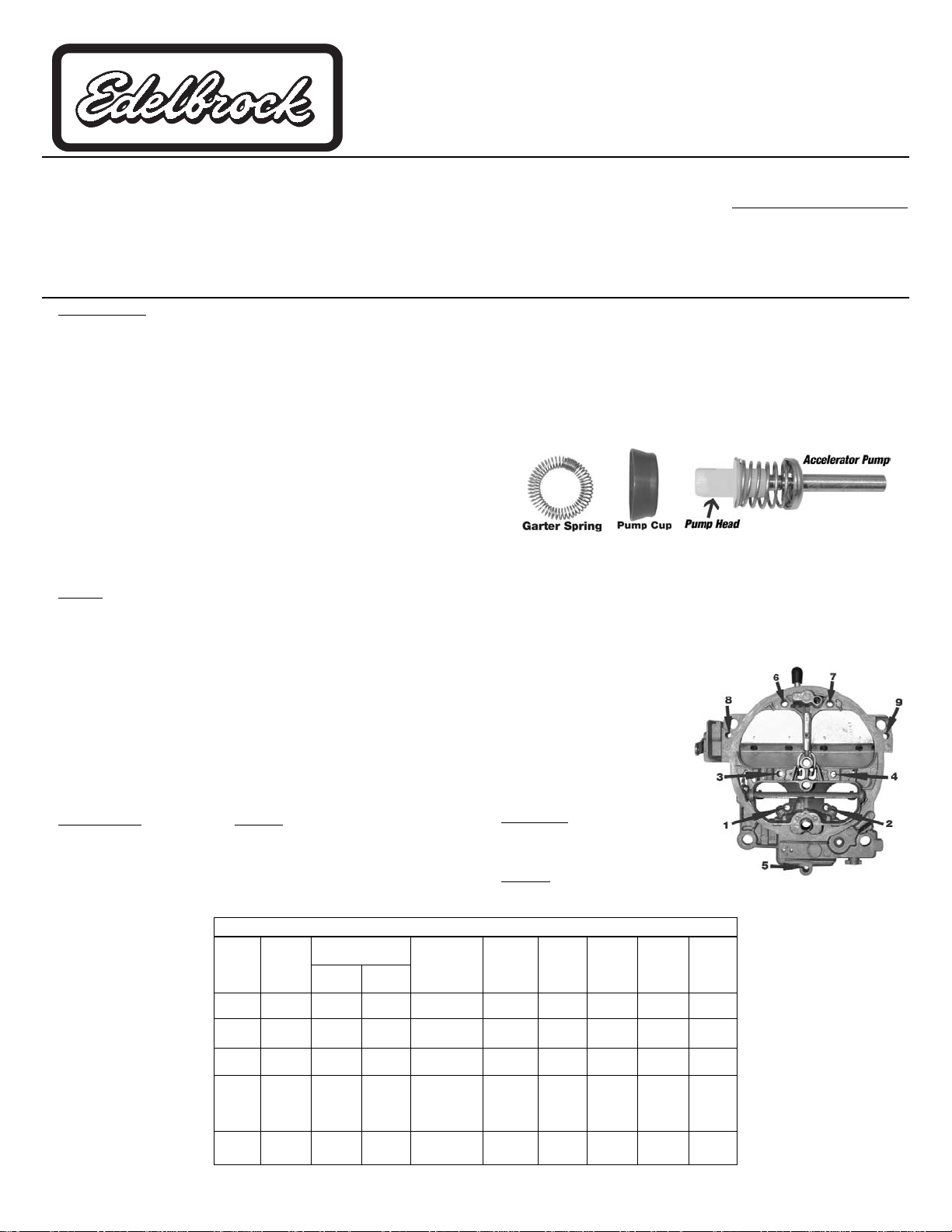

FIG. 1

FLOAT

SETTINGS

15/32”

15/32”

25/64”

25/64”

19/64”

REPLACEMENT Q-JET CARBURETOR

KIT INSTRUCTIONS

KITS #1920, 1921 & 1990

Performer Models 1901, 1902, 1903,

1904,1905,1906,1910

Please read these instructions carefully before attempting to rebuild your carburetor. Make sure to refer to your carburetor Installation

Instructions for further information if need be. If you have any questions or problems, do not hesitate to contact our Technical Hotline at: (800) 416-

8628 from 7:00 am to 5:00 pm, Monday through Friday, Pacific Standard Time or e-mail us at: edelbrock@edelbrock.com.

To check kit contents see exploded view of carburetor and parts description on last page. Verify that all parts underlined on

list are in your kit.

Carb Kit contains all necessary parts and instructions to rebuild your Edelbrock Carburetor properly. When similar parts are contained in the Carb Kit,

choose the ones that most closely match the existing parts. Some parts in the kit may not be needed.

1. DISASSEMBLE carburetor use accompanying exploded view as a

guide..

➾Remove pump lever by driving roll pin through far enough to permit

release of lever.

➾Remove air horn screws.

➾Remove power piston by pressing down and releasing with a snap.

➾Remove power piston spring(s).

➾Do Not turn nor remove factory-adjusted stop screw next to power

piston. (APT) Adjustable part throttle.

➾Do Not turn nor remove factory-adjusted screw in aneroid cover.

➾Turn idle mixture needles clockwise and record number of turns

needed to lightly bottom them, for use during reassembly. Remove

needles.

➾Disassemble choke cap from housing per Figure 13 (not applicable

to remote choke models).

2. CLEAN

carburetor.

➾Soak the carb parts (except as noted below) in a cold immersion

type carb cleaner.

➾Use mineral spirits or kerosene to clean solenoids, choke cover,

aneroid, float, float bowl inserts, vacuum breaks, seals or other

parts containing rubber. Do not immerse these parts in carb

cleaner.

➾Blowout all passages with compressed air .

➾After a thorough cleaning of all castings and parts, pay particular

attention to the cleanliness of the power piston and the body

casting bore where it is housed. Any sticking of the power valve

will prevent proper fuel control and affect driveability.

3. REASSEMBLE

carburetor and ADJUST following sequence illustrated.

➾Refer to model number for specifications. Use figure 1 to find

position of model number

➾Install new intermediate choke shaft seal in float bowl. Lip faces

outward. On Hot Air Choke models, install additional shaft seal in

choke housing. Lip faces float bowl. Disregard for remote choke

models.

➾Do not install float needle pull clip into holes in float arm.

➾Install power piston. Press plastic retainer into bore until flush with

top of float bowl casting.

➾Carefully remove pump cup (with garter spring, if used) from pump

head. Install new cup (with new garter spring, if used) on pump

head.

➾If used, install new pump stem seal and retainer in air horn. Lip

faces toward outside of carburetor. Lightly stake casting around

retainer.

➾Select correct air horn gasket by matching replacement to old

gasket.

➾Tighten air horn screws in numerical sequence per illustration.

Torque screws 32-60 in-lbs.

➾Install the choke cover and

coil assembly per Figure15.

Use the cover gasket on hot

air model only (1903). Do

not use the cover gasket on

electric choke model

1904,05,06,10.

4. REINST

ALL

carburetor to intake

manifold, torque mounting bolts

to 110 in-Ibs.

5. ADJUST idle mixture and speed

according to vehicle manufacturer's specifications.

FIG. 13

CHOKE

SETTINGS

PER

NOTCH

PER

NOTCH

PER

NOTCH

PER

NOTCH

PER

NOTCH

CARB #

1901

(8904S)

1902

(8905S)

1903

(8906S)

1904

1905

1906

(8907S)

1910

(8908S)

FIG. 4

AIR

VALVE

SPRING

7/8 TURN

7/8 TURN

7/8 TURN

7/8 TURN

1 TURN

FIG. 5

CHOKE

COIL

LEVER

1/8”

1/8”

1/8”

1/8”

1/8”

FIG. 6

FAST

IDLER

48°

48°

48°

48°

48°

FIG. 7

VACUUM

BREAK

22°

22°

27°

27°

27°

FIG. 9

UN-

LOADER

40°

40°

40°

40°

40°

FIG. 2

PUMP SETTINGS

LEVER DIM.

HOLE

INNER

INNER

INNER

INNER

INNER

13/32”

13/32”

13/32”

13/32”

5/8”

ADJUSTMENT SPECIFICATIONS

®

Page 2

Page 2 of 4

©2002 Edelbrock Corporation

Brochure No. 63-0149

Rev. 10/02

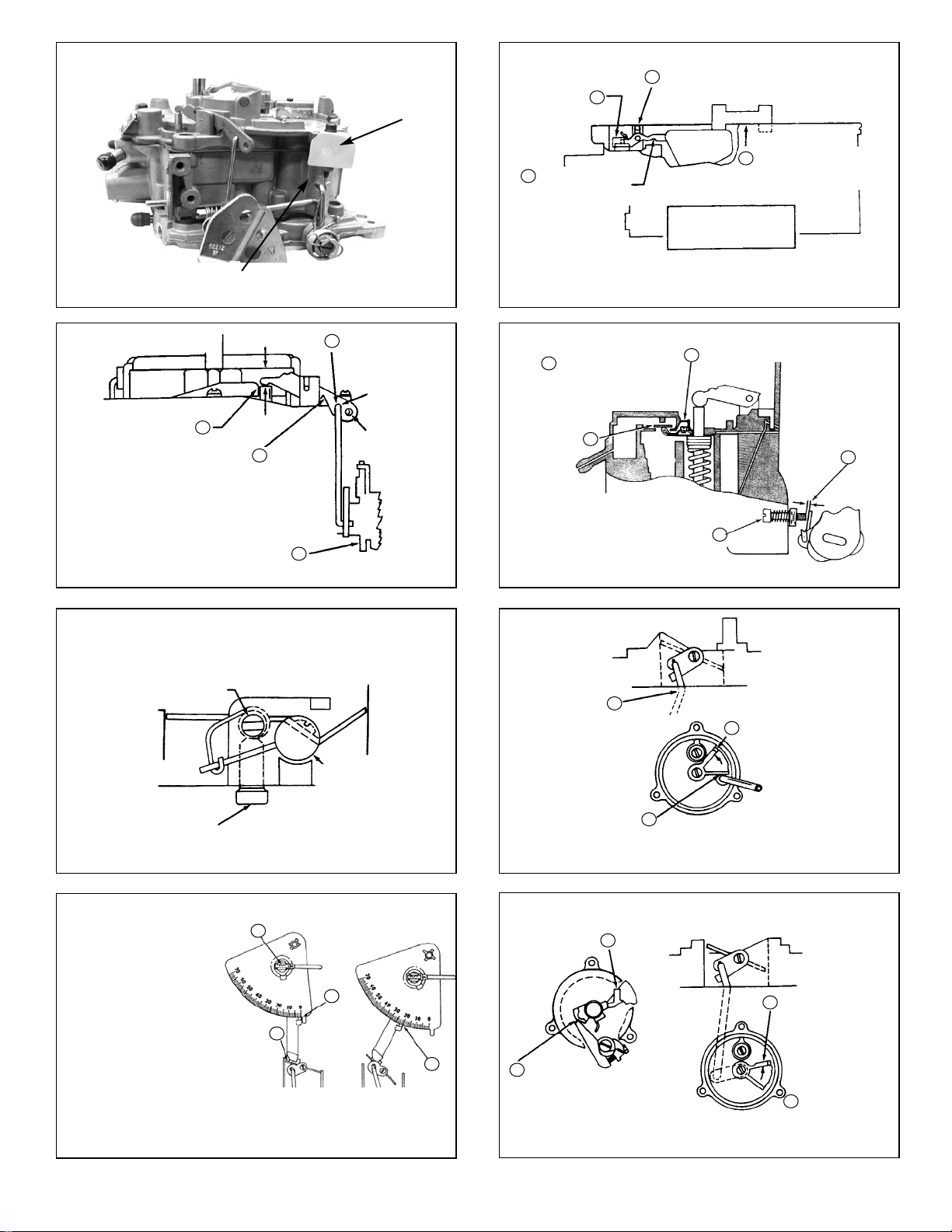

ALUMINUM TAG

WITH EDELBROCK’S

MODEL NUMBER.

MANUFACTURER’S NUMBER.

PRESS DOWN GENTLY

ON FLOAT TANG UNTIL

SEATED ON NEEDLE.

HOLD FLOAT HINGE

PIN FIRMLY IN PLACE.

TO ADJUST, BEND

FLOAT UP OR DOWN.

INSTALL PUMP ROD

IN PROPER HOLE.

VENT VALVE COVER AND SPRING

REMOVED, CHOKE OPEN POSITION,

FAST IDLE CAM FREE.

TO ADJUST, REMOVE PLUG AND

TURN HEX SCREW. REPLACE PLUG

AFTER ADJUSTMENT.

PLACE .075” GAUGE

BETWEEN IDLE STOP

SCREW AND THROTTLE

LEVER TANG.

GAUGE IN PLACE,

VENT VALVE SHOULD

BE CLOSED, GAUGE

REMOVED, VENT

VALVE SHOULD BE

OPEN.

BACK OUT THROTTLE STOP SCREW.

THROTTLE VALVES COMPLETELY

CLOSED. TURN THROTTLE STOP SCREW

IN UNTIL IT CONTACTS TANG ON

THROTTLE LEVER. THEN TURN SCREW

IN 1 1/2 TURNS.

TO ADJUST

BEND ROD.

PUSH UP ON CHOKE COIL LEVER

UNTIL CHOKE VALVE IS CLOSED.

INSERT .120” GAUGE IN HOLE.

LOWER EDGE OF LEVER SHOULD

JUST TOUCH GAUGE.

TO ADJUST SUPPORT

PUMP LEVER ON PUMP

END AND BEND LEVER ON

PUMP ROD SIDE.

BACK OUT THROTTLE STOP

SCREW THROTTLE VALVES

HELD CLOSED.

TO ADJUST LOOSEN ALLEN LOCK SCREW. AIR VALVE HELD CLOSED. TURN ADJUSTING SCREW

CLOCKWISE UNTIL TORSION SPRING CONTACTS PIN ON AIR VALVE SHAFT. THEN TURN

ADDITIONAL SPECIFIED TURNS AND TIGHTEN ALLEN LOCK SCREW.

(ADJUSTMENT SPECIFICATIONS TABLE)

CAUTION: PLACE CARBURETOR ON

HOLDING FIXTURE SO THAT IT WILL

REMAIN IN SAME POSITION WHEN GAUGE

IS USED.

1. ROTATE DEGREE SCALE UNTIL ( 0 ) IS

OPPOSITE POINTER

2. CHOKE VALVE HELD COMPLETELY

CLOSED. PLACE MAGNET SQUARELY

ON TOP OF CHOKE VALVE.

3. ROTATE BUBBLE UNTIL IT IS

CENTERED.

4. ROTATE SCALE SO THAT DEGREE

SPECIFIED FOR ADJUSTMENT IS

OPPOSITE POINTER.

5. FOLLOW NUMERICAL OUTLINE IN

MAKING ADJUSTMENT, INSTEAD OF

MEASURING GAP AT EDGE OF CHOKE

VALVE. MAKE ADJUSTMENT TO BRING

BUBBLE BACK TO CENTER POSITION.

GAUGE: J-26701 KENT MOORE TOOL

BT-7704 BORROUGHS TOOL

PLACE CAM FOLLOWER

ON SECOND STEP OF

FAST IDLE CAM NEXT

TO HIGH STEP.

TO ADJUST,

BEND TANG ON

FAST IDLE CAM

FOLLOW GAUGE SET

PROCEDURE FIG.7

PUSH UPWARD ON

CHOKE COIL LEVER,

MOVING CHOKE TOWARD

CLOSED POSITION UNTIL

STOP IS MADE.

( BUBBLE ON ANGLE

GAUGE SHOULD BE

CENTERED.)

SPRING ADJUSTING

SCREW.

AIR VALVE SHAFT.

ALLEN LOCK SCREW.

MEASURE FROM TOP OF

CHOKE VALVE WALL TO

TOP OF PUMP STEM.

INNER.

OUTER.

BOWL COVER GASKET REMOVED

MEASURE FROM TOP OF CASTING

TO TOP OF FLOAT 3/16” IN

FROM TOE OF FLOAT.

CAUTION : DO NOT EXERT

PRESSURE ON RESILIENT

NEEDLE VALVE.

DRY FLOAT LEVEL ADJUSTMENT

CARBERUTOR IDENTIFICATION

ACCEL. PUMP ROD ADJUSTMENT

AIR VALVE SPRING ADJUSTMENT

ANGLE GAUGE METHOD

FAST IDLE CAM (CHOKE ROD) ADJUSTMENT

BOWL VENT VALVE ADJUSTMENT

CHOKE COIL LEVER ADJUSTMENT

2

1

4

1

3

4

2

2

3

1

4

4

1

2

3

1

2

1

2

3

3

4

5

3

Fig. 2

Fig. 1

Fig. 3

Fig. 5

Fig. 7

Fig. 8

Fig. 4

Fig. 6

Page 3

Page 3 of 4

©2002 Edelbrock Corporation

Brochure No. 63-0149

Rev. 10/02

FRONT VACUUM BREAK ADJUSTMENT

AIR VALVE ROD ADJUSTMENT

UNLOADER ADJUSTMENT

SECONDARY OPENING ADJUSTMENT

SECONDARY CLOSING ADJUSTMENT

REMOVE & REPLACING TAMPER RESISTANT CHOKE COVER

SECONDARY THROTTLE LOCK-OUT ADJUSTMENT

MEASURE DISTANCE

BETWEEN UPPER EDGE

OF CHOKE VALVE AND

AIR HORN WALL.

BUBBLE ON ANGLE GAUGE

SHOULD BE CENTERED.

SEE FIG. 7

TO ADJUST TURN

SCREW

PLACE CAM FOLLOWER ON

HIGH STEP OF FAST IDLE

CAM.

TAPE PURGE BLEED HOLE IN

COVER. (WHEN USED). APPLY

OUTSIDE VACUUM SOURCE

TO FULLY SEAT DIAPHRAGM.

TO ADJUST

BEND ROD

MEASURE BETWEEN UPPER EDGE OF

CHOKE VALVE AND AIR HORN WALL.

STEP A

CHOKE VALVE AND THROTTLE VALVES

CLOSED.

STEP B

CHOKE VALVE HELD WIDE OPEN BY

PUSHING DOWN ON TAIL OF FAST

IDLE CAM.

TO ADJUST BEND

LOCKOUT PIN.

MEASURE DISTANCE

BETWEEN LOCK-OUT PIN AND

LOCK-OUT LEVER.

MEASURE DISTANCE BETWEEN

END OF LOCK-OUT PIN &

LOCK-OUT LEVER.

TO ADJUST FILE

END OF PIN.

(.015” CLEARANCE)

(.015” CLEARANCE)

CLOSE CHOKE VALVE BY

PUSHING UP ON TANG ON

VACUUM BREAK LEVER.

(BUBBLE ON ANGLE GAUGE

SHOULD BE CENTERED).

TO ADJUST

BEND TANG.

THROTTLE VALVES HELD IN

WIDE OPEN POSITION.

OPEN PRIMARY THROTTLE SLOWLY

UNTIL ACTUATING LINK CONTACTS

TANG.

TO ADJUST

BEND TANG.

TO ADJUST

BEND TANG.

LINK SHOULD BE IN

CENTER OF SLOT.

2 0’CLOCK

POSITION

3/16”

1/8”

3/4”

ADAPTER MADE

FROM STEEL TUBING

DISASSEMBLY: CAREFULLY ALIGN A #21 DRILL (.159”) ON PO RIVET HEADS AND

DRILL ONLY ENOUGH TO REMOVE RIVET HEAD, DRILL ALL RIVET HEADS (3) AND

USE A DRIFT PUNCH AND HAMMER TO DRIVE THE REMAINDER OR THE RIVETS OUT

OF THE CHOKE HOUSING. REMOVE CHOKE COMPONENTS.

REASSEMBL

Y: PLACE CHOKE CAP IN PLACE AND ROTATE CLOCKWISE UNTIL COIL

TANG ENGAGES LEVER TANG AND CLOSES CHOKE VALVE. IT IS IMPORTANT THAT

THIS ENGAGEMENT IS ACHIEVED FOR PROPER OPERATION.

MODEL 1903

: ROTATE AND ALIGN THE NOTCH IN THE COVER WITH THE PROTRUSION

ON THE RETAINER INSTALLED AT THE 2 O’CLOCK POSITION.

MODEL 1904

: ROTATE AND ALIGN THE NOTCH IN THE COVER WITH THE RAISED

CASTING BOSS AT THE 2 O’CLOCK POSITION. RETINING THE COVER WITH THE POP

RIVETS PROVIDED IN THE KIT. IT MAY BE NECESSARY TO USE AN ADAPTER (TUBE)

IF INSTALLATION TOOL INTERFERES WITH THE ELECTRICAL CONNECTION TOWER IN

THE CHOKE COVER.

TURN CLOCKWISE

FOR RICHER SETTING

CHOKE VALVE WIDE OPEN FAST

IDLE CAM FREE OF CAM

FOLLOWER.

CURB IDLE SET TO

PROPER RPM

LEVER AGAINST TANG.

MEASURE DISTANCE BETWEEN

ROD AND SLOT IN LEVER.

(.020” CLEARANCE)

AIR VALVE COMPLETELY

CLOSED. MEASURE DISTANCE

BETWEEN ROD AND END OF

SLOT IN LEVER

TAPE PURGE BLEED HOLE IN

COVER (WHEN USED). APPLY

OUTSIDE VACUUM SOURCE TO

FULLY SEAT DIAPHRAGM

PUSH UP ON INSIDE CHOKE COIL

LEVER UNTIL TANG ON

INTERMEDIATE CHOKE SHAFT

CONTRACTS TANG ON VACUUM

BREAK PLUNGER STEM

Fig. 9

Fig. 10

Fig. 11

Fig. 13

Fig. 14

Fig. 15

Fig. 12

3

4

2

3

2

3

4

1

3

2

1

2

3

1

1

3

2

2

1

5

3

4

2

1

5

1

(ON CAR)

(ON CAR)

Page 4

Page 4 of 4

©2002 Edelbrock Corporation

Brochure No. 63-0149

Rev. 10/02

PART DESCRIPTION

1. SCREW (2) - THROTTLE LEVER ACTUATOR

2. THROTTLE LEVER ACTUATOR ASSY.

3. SCREW (2) REAR VAC. BREAK

4. REAR VAC BREAK ASSY.

5. LINK -REAR VAC. BREAK

6. SCREW (2) - FRONT VAC. BREAK

7. FRONT VAC. BREAK & HOSE ASSY .

8. LINK - FRONT VAC. BREAK

9. LEVER - PUMP

10. ROD - PUMP

11. SCREW - CHOKE LEVER

12. LEVER - CHOKE SHAFT

13. ROD - CHOKE

14. SCREW - SEC. METERING ROD HOLDER

15. HOLDER -SEC. METERING RODS

16. METERING ROD (2) - SECONDARY

17. SCREW & LOCKWASHER - BOWL COVER

18. SCREW {2) -BOWL COVER (TAPERED HEAD)

19. BOWL COVER ASSY.

20. RETAINER - PUMP STEM SEAL

21. SEAL - PUMP STEM (1980 UP')

22. GASKET - BOWL COVER

23. PUMP PLUNGER ASSY.

24. SPRING - PUMP RETURN

25. BAFFLE PUMP WELL

26. INSERT - ANERIOD CAVITY ( SOME MODELS )

27. POWER PISTON ASSY.

28. SPRING - METTERING ROD

29. METERING ROD (2) - PRIMARY

30. SPRING - POWER PISTON

31. lNSEAT - FLOAT BOWL

32. FLOAT & LEVER ASSY.

33. HINGE PIN - FLOAT

34. NEEDLE, SEAT & GASKET ASSY.

35. PLUG - PUMP DISC. BALL

36. BALL - PUMP DISC.

37 JET (2) - MAIN METERING

38. SCREW / RIVET (3) - RETAINER

39. RETAINER (3) -CHOKE COVER

40. CHOKE COVER ASSY.

41. GASKET -CHOKE COVER ( HOT AIR ONLY)

42. SCREW & LOCKWASHER - CHOKE HOUSING

43. CHOKE HOUSING ASSY.

44. SCREW - STAT COIL LEVER

45. LEVER - STAT COIL

46. SHAFT ASSY. - INTERMEDIATE CHOKE

47. CAM. - FAST IDLE

48. SEAL - CHOKE HOUSING

49. LEVER - INTERMEDIATE CHOKE

50. CAM - SECONDARY LOCKOUT

51. TUBE - VAC. PASSAGE

52. SEAL - INTERMEDIATE CHOKE SHAFT

53. SCREW & LOCKWASHER (3) - THROTTLE BOOY

54. FLOAT BOWL ASSY.

55. GASKET -THROTTLE BODY

56. FILTER NUT - FUEL INLET

57 . GASKET - FILTER NUT

58. FILTER - FUEL

59. SPRING - FILTER

60. PLUG (2) - IDLE NEEDLE (NOT REPLACED)

61. NEEDLE & SPRING ASSY. (2) - IDLE ADJ.

62. THROTTLE BODY ASSY.

EXPLODED VIEW OF TYPICAL EDELBROCK CARBURETOR

Loading...

Loading...