Page 1

Page 1 of 4

© 2002 Edelbrock Corporation

Brochure No. 63-0073

Rev 02/02

PERFORMER REPLACEMENT SERIES

CARBURETORS FOR Q-JET APPLICATIONS

for non-computer controlled Chevrolet/GMC V8s; 1966-89

CATALOG #1901, #1902, #1903, #1904 & #1906

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before installing your new Carburetor. If you have any questions or problems, do not hesitate to contact

our Technical Hotline at: 1-800-416-8628, 7 am - 5 pm, Monday-Friday, Pacific Standard Time or e-mail us at edelbrock.edelbrock.com.

IMPORTANT INFORMATION ABOUT YOUR WARRANTY

If you have any problems with installation or performance, do not return to the retailer. The retailer is not authorized to perform

Warranty Service. Instead, call the Edelbrock Carb Tech Hotline at 800-416-8628 from 7am - 5pm PST on weekdays. All returns must

be accompanied by the original purchase receipt. The warranty period is 90 days for new carburetors and 30 days for "as-new" (remanufactured)

carburetors.

DESCRIPTION

The Edelbrock Performer Replacement Series Carburetor for

Q-Jet applications is a high quality, all new carburetor designed to

replace the original equipment Q-Jet spread-bore carburetors found

on most 1966 -1989 non-computer controlled Chevrolet/GMC V8s.

These carburetors are street legal/stock replacement parts when used

on the applications for which they are listed. Edelbrock replacement

carbs for Q-Jet applications are compatible with all OEM linkage and

components for the years listed, and will fit stock intake manifolds.

For best performance, they may be used with the matching Performer

or Performer EGR intake manifold for those who wish to use a new

stock replacement carburetor.

Five models are available for the following applications:

1. #1901 (750 cfm) - Recommended for most small-block and bigblock Chevrolet/GMC V8s, 327 through 454 c.i.d., in both truck and

passenger car applications using a remote style choke; 1966 to

1973.

2. #1902 (750 cfm) - Recommended for most small-block and big-

block Chevrolet/GMC V8s, 350 through 454 c.i.d., in both truck and

passenger car applications using a remote style choke; 1974 to

1978.

3.

#1903 (795 cfm) - Recommended for most small-block

Chevrolet/GMC V8s, 305 through 454 c.i.d., in both truck and

passenger car applications using a hot air style choke; 1975 to

1985. (Electric choke conversion, see choke linkage section.)

4. #1904 (795 cfm) - Recommended for most small-block

Chevrolet/GMC V8s, 305 through 350 c.i.d., in truck applications only

using a full electric choke; 1980 to 1989.

5. #1906 (795 cfm) - Recommended for big-block Chevrolet/GMC

V8s-454 engines in truck applications only using a full electric

choke; 1980 to 1989.

BEFORE YOU BEGIN, ALWAYS REMEMBER TO:

❑ Replace fuel filter. Dirt found in carburetor voids warranty.

❑ Check and replace the air filter if necessary.

❑ Check PCV valve and replace if clogged.

❑ Check all hoses for leaks or cracks and replace if necessary.

❑ Check fuel pump for proper operation and replace if necessary.

❑ Check the intake manifold and cylinder head gaskets for leaks and

replace if necessary.

❑ Check the ignition system: clean and gap or replace spark plugs, plug

wires, and adjust ignition timing.

CARBURETOR REMOVAL

1. Prior to removal make sure that the engine is cool.

2. Disconnect negative battery cable from battery.

3. Remove air cleaner. Be sure to carefully disconnect any hoses from

the air cleaner and note their location for re-installation. You may want

to mark them with masking tape for easy reference.

4. Disconnect throttle linkage, kickdown linkage (certain automatic

transmission applications only), cruise control (if equipped) and any

return springs if present. NOTE: Check carefully for the precise

location of all these linkages and return springs. You may want to

mark them with masking tape for easy reference. Compare throttle

arm of your new carburetor with the old one to be sure that all

required linkages will hook up. Ball stud is usually removable and

must be installed in the proper location (see Figures 1 & 2).

5. Disconnect all wires, tubes and hoses from carburetor and note their

location. NOTE: There should be a maximum of one wire to the

electric choke and one to the idle compensator solenoid. Any other

electrical wiring attached to your carburetor indicates a computer

controlled engine, and Edelbrock Q-Jet carburetors will not function

correctly on computer controlled applications. Disconnect the heater

tube from the choke housing

(#1903 only). If the tube is

burned out, replace it. Failure

to do so will cause deposits to

form inside the carburetor,

improper choke operation, and

void the warranty.

6. Carefully remove fuel line

from carburetor or fuel filter.

TAKE EXTREME CARE NOT

TO SPILL ANY EXCESS

FUEL. Place a rag

underneath the fuel line to

absorb any spillage that

may occur . Certain

models require two

wrenches to remove the

fuel line; one to hold the

fitting on the carburetor

and the second to turn the

fitting on the fuel line. Use

a tubing wrench to avoid

rounding the tube fitting

nut.

Figure 1

Throttle arm of #1901

Figure 2

Throttle arm of #1902,#1903,#1904 ݲ

Page 2

Page 2 of 4

© 2002 Edelbrock Corporation

Brochure No. 63-0073

Rev 02/02

7. Remove mounting nuts or bolts and or washers. Be sure to put them

where they won't fall into the intake manifold upon carburetor removal.

8. Remove carburetor, being careful not to spill any dirt into the intake

manifold. Immediately place a clean rag into the manifold to keep

foreign objects out.

9. Thoroughly remove old mounting gasket and clean mounting surface.

Inspect gasket and match to gasket included with new carburetor.

CARBURETOR PREPARATION

1. Place old and new carburetors side by side and transfer any accessories

that are needed onto the new carburetor.

CARBURETOR INSTALLATION

1. Remove rag from intake manifold and install new mounting gasket.

NOTE: Do not use any cement, glue or liquid gasket.

2. Carefully place new carburetor on gasket.

3. Replace all mounting bolts, nuts and washers. Hand tighten with a short

box end wrench, using even increments alternating between diagonally

opposed bolts. Use stock mounting bolts or Edelbrock Q-Jet Bolt Kit

#1925. CAUTION: Overtightening may break carb base.

4. For models with externally mounted fuel filters, install new fuel filter,

starting threads by hand to avoid crossing or stripping threads. Replace

any old or cracked hoses with new hoses designed for use with fuel.

5. Hook up fuel line to fuel filter. Start threads by hand. NOTE: Be sure

threads are properly aligned before tightening to avoid crossing or

stripping threads. When tightening fuel line use two wrenches; one to

hold the fitting on the carburetor and the second to turn the fuel line

fitting. Use a tubing wrench to avoid rounding the tube fitting nut.

6. Re-connect throttle linkage, wires, hoses, etc.Your Edelbrock carburetor

may have more vacuum outlets than the original. Leave the caps on

those outlets which won't be used.

NOTE: #1901 and #1902 will accept the stock idle speed

compensator bracket, GM #7042682.

7. Re-connect the air cleaner being careful not to over-tighten the

mounting nut which could damage the carburetor. Install a new air filter

(if needed) and re-connect all hoses.

IMPORTANT NOTE: With engine off, make sure that there is no

interference when opening and closing the throttle. Be sure that there

is no binding or hanging up between idle and wide open throttle as this

could cause the throttle to stick, resulting in loss of engine speed

control.

8. Re-connect the negative battery cable to the battery.

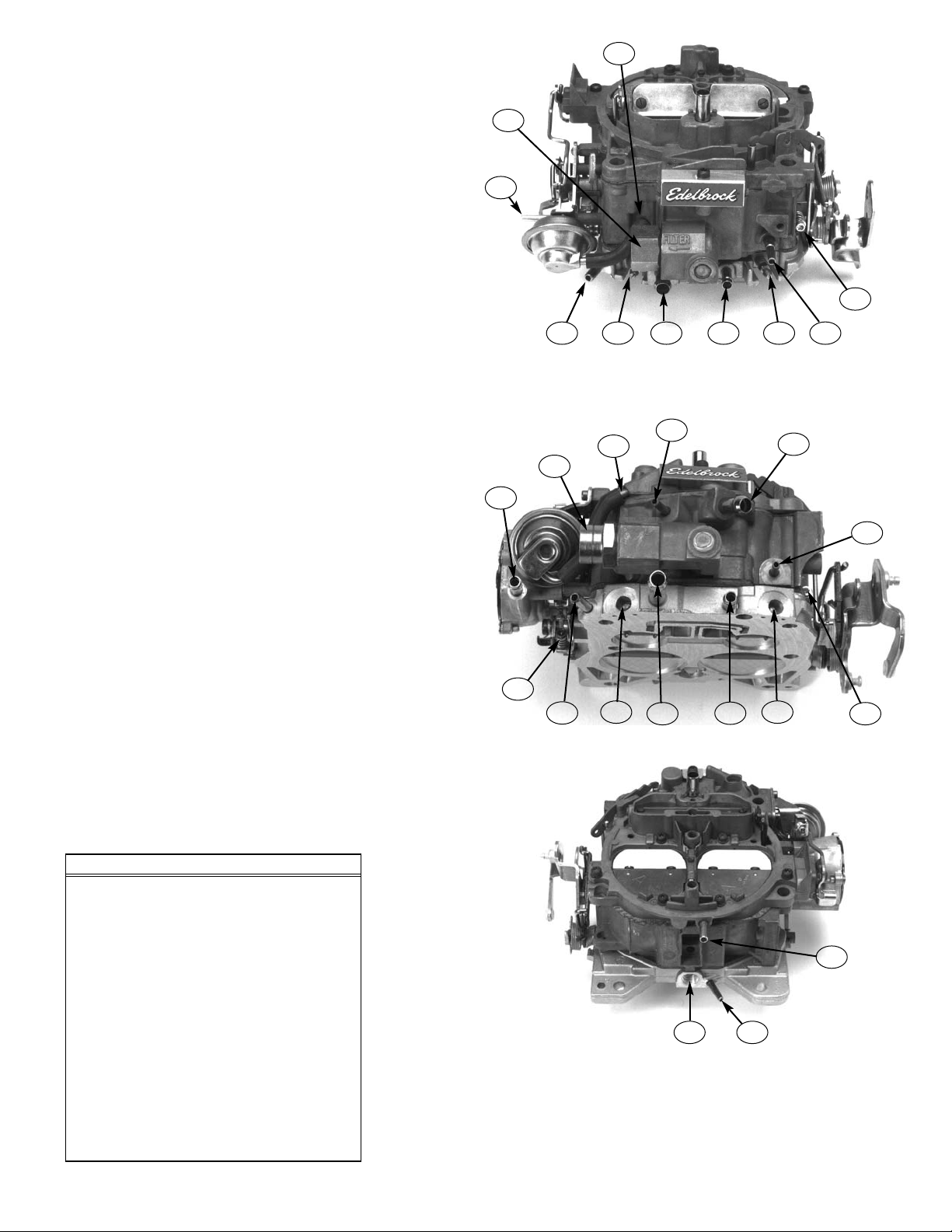

LEGEND

A - Diverter Port

B - Choke Pull-down

C - Fuel Inlet

D - Exhaust Gas Recirculation (EGR) Port

E - Idle Mixture Screws

F - Positive Crankcase Ventilation (PCV) Port

G - Canister Purge

H - Distributor Port

I - Idle Speed Screw

J - Accessory Port

K - Bowl Vent

L - Hot Air (#1903 only)

M - Fast Idle Screw

N - Clean Air (#1903 only)

O - 1/4" N.P.T. (Power Brake Port)

A

D

K

M

O A

N

E

F

G

D

E

I

L

C

H

B

J

E F G E

I

C

B

H

Front View of #1901 and #1902

Front View of #1903, #1904 and #1906

Typical Rear View

Page 3

Page 3 of 4

© 2002 Edelbrock Corporation

Brochure No. 63-0073

Rev 02/02

CARBURETOR TESTING

1. Be wary of fuel leaks! If a fuel leak occurs, stop immediately and repair the

leak. Failure to do so could result in engine fire and serious injury.

NOTE: The following adjustments can affect vehicle emissions. Laws in

your area may govern these emissions.

2. Set idle adjustments per factory recommendations for your vehicle.

3. The choke system is pre-set at the factory. However, minor adjustments

may be required. Adjust using factory specifications for your vehicle.

IDLE MIXTURE ADJUSTMENT

The Edelbrock Performer Replacement Series Carburetor for Q-Jet

applications has conventional Idle Mixture Screws (IMS) that provide a

leaner Air/Fuel (A/F) ratio when turned clockwise and richer A/F ratio when

turned counterclockwise. The idle air flow is controlled by a conventional

screw that opens the primary throttles. The following procedure should be

used to set the idle mixture and speed.

1. Fully warm engine and ensure choke is fully open.

2. Install air cleaner.

3. Set desired speed with the air screw.

4. Adjust the IMS on one side to get the maximum possible rpm or highest

vacuum if you are using a manifold vacuum gauge. Do not go rich beyond

the maximum speed point.

5. If the procedure above changed the idle speed more than 40 rpm, then readjust the idle speed.

6. Adjust the opposite side of that in Step 4 to get maximum rpm or vacuum.

7. Reset the speed.

8. Carefully trim each IMS to again get the maximum idle rpm or manifold

vacuum.

9. Go leaner just enough to get a 20 rpm drop in speed.

10. Reset the speed to the desired rpm.

11. This is a Lean-Best Idle Set. Setting richer than this will not improve idle

quality or performance, but could cause higher hydrocarbon emissions and

tend to foul spark plugs.

12. Emission legal carburetors #1903, #1904 and #1906 are supplied with

tamper resistant protective metal caps for idle mixture screw wells. These

covers should be installed following completion of final idle mixture

adjustments. NOTE: Use idle mixture adjustment tool K&D #2776 or

equivalent.

WINTER FUEL IDLE SETS

During the winter months (in most parts of the country) the local fuel will be

a "winter" blend that is very volatile, as an assist to cold-engine starting

and driveability during warm-up. However, the high volatility has the

disadvantage of allowing excessive vaporization of the fuel if the vehicle is

operated in a heated area such as a garage. This can result in problems in

the idle-set procedures since the carburetor's internal vents will allow this

excess vapor to be drawn into the throats and enrichen the mixture. The idle

will be erratic and not seem to be able to hold a set. To resolve this

problem, it is advisable to perform the final settings outdoors after the

vehicle has been stabilized with a drive of several miles.

FAST IDLE SOLENOID BRACKETS:

Your original Fast Idle Solenoid Bracket should mount to the Edelbrock QJet Series carburetor. If a replacement bracket is desired, use GM

#7042682 for #1901 and #1902. Edelbrock #1997 is an adapter to connect

a factory vacuum operated throttle kicker to carburetor #1903, #1904 and

#1906.

CHOKE LINKAGE INSTALLATION

The Edelbrock Performer Replacement Series Carburetors for

Q-Jet applications have three different types of chokes; divorced (remote),

hot air, and electric. Figure 3 shows typical divorced choke linkage used

on #1901 and #1902. The metal housing which snaps in place over the

choke coil on manifold has been left off to show choke rod/coil relationship.

The metal housing should be installed on your engine, as it retains the

choke rod in the coil. Stock manifolds can use original equipment choke

Q-JET CARBS WITH EGR VACUUM PORTS

The original carb on some Chevy/GMC trucks and Suburbans has the EGR

vacuum port machined higher in the carb venturi than the Edelbrock QJet. This may have an effect on off-idle performance resulting in a flat

spot. If you get a flat spot off-idle after installing the Edelbrock Q-Jet

carb, you may need to install a vacuum delay valve. A simple test will let

you know if the delay valve is needed: a) Temporarily remove and plug the

vacuum line to the EGR valve. If the flat spot disappears, you will need to

purchase a vacuum delay valve (GM #14020691) and install it in the

vacuum line between the carb and the EGR valve. This valve will delay the

opening of the EGR valve long enough for the carburetor to transition

through the off-idle phase without a stumble, then the EGR circuit will

operate normally.

Note: The vacuum line to the EGR valve should only be removed

temporarily as a test to determine whether the delay valve is

needed. You must re-install the vacuum line to the EGR valve in

compliance with local and/or federal law!

Edelbrock Q-Jet Rebuild Kits

The Edelbrock Performer Replacement Series Carburetors for Q-Jet

applications can be rebuilt with the following rebuild kits:

Carb #s

Rebuild Kit #

1901 & #1902 #1920

1903, #1904 & #1906 #1921

Replacement Fuel Filters

The Edelbrock Performer Replacement Series Carburetors for Q-Jet

applications has a replaceable fuel filter element behind the Fuel Inlet Nut.

Replacement filters are available as follows:

Carb

#s Fuel Filter #

1901 & #1902 #1970

1903, #1904 & #1906 #1971

parts, and Edelbrock makes choke linkage kits for use with Performer

manifolds. Use Choke Kit #1931 for small-block Chevy Performers with

divorced choke carbs #1901 & #1902; use Choke Kit #1935 for big-block

Chevy Performers with divorced choke carbs #1901 & #1902. Figure 4

shows typical hot air choke connections as used on carburetor #1903.

Stock manifolds can use original equipment choke parts, and Edelbrock

makes choke linkage kits for use with Performer manifolds. Use Choke

Kit #1930 for small-block Chevy Performers with hot air choke carb

#1903; use Choke Kit #1934 for big-block Chevy Performers with hot air

choke carb #1903. Some OE Q-Jet carbs with hot air chokes use a screw

on nut located at the rear of the choke housing. For these applications,

we recommend the use of the Edelbrock #1932. Some models use

auxiliary vacuum diaphragm on the passenger side rear of carb, remove

the diaphragm and install on the Edelbrock carb. Electric choke

carburetor #1904 and #1906 require a 12-volt lead that is hot only when

the ignition is on

.

Figure 3 - Divorced choke

(#1901 and #1902)

Figure 4

- Hot air choke

(#1903)

Page 4

Page 4 of 4

© 2002 Edelbrock Corporation

Brochure No. 63-0073

Rev 02/02

TROUBLESHOOTING INSTRUCTIONS

HARD STARTING: When starting the engine for the first time, it maybe difficult to start until fuel reaches the carburetor.

FLOODING: Carburetor flooding immediately after installation is usually due to dirt or foreign matter lodged under the float needle. Gently tap on the air horn over the fuel inlet area with the

head of a screwdriver. If flooding does not stop, pinch the fuel line (if possible), start engine and run until it stalls. Then release the pinched line. If flooding still persists, drain the fuel and re-

start.

HESITATION: It is not unusual for hesitation upon acceleration to be caused by the carburetor's storage time. Allow a few hours of operation for the internal gaskets to become wet, and the

problem will usually cure itself.

ROUGH IDLE: Rough idle is often caused by an air leak in the vacuum lines, or by dirt in the air bleeds. Disconnect the vacuum lines one at a time and plug the hose end and the fitting at the

carburetor. If the idle roughness disappears, it indicates a leak.

IMPROPER VACUUM: If rough idle cannot be cured by any of the vacuum leak checks, connect a vacuum gauge to a suitable source of full manifold vacuum. If the gauge needle fluctuates, it

indicated internal engine problems.

THE FOLLOWING TROUBLESHOOTING CHART COVERS ONLY THE MOST COMMON PROBLEMS

Edelbrock Corporation

2700 California St.

Torrance, CA 90503

Tech Line: 1-800-416-8628

E-Mail: edelbrock@edelbrock.com

Loading...

Loading...