Page 1

©2004 Edelbrock Corporation

Rev. 1/04 - RS/mc

Catalog #15008

Brochure #63-0248

Page 1 of 2

BLOW OFF VALVE

Catalog # 15008

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before installing your new Edelbrock Blow Off Valve. If you have any questions or

problems, do not hesitate to contact our Technical Hotline at: 1-800-416-8628, from 7am-5pm, Monday-Friday, Pacific

Standard Time or via e-mail at: Edelbrock@Edelbrock.com

. Please fill out and mail your warranty card.

Installation Procedure

KIT CONTENTS

Qty

. Description

❑ 1 Blow-Off Valve

❑ 1 O-Ring

❑ 1 V-Band Mounting Clamp

❑ 1 Steel Mounting Flange

❑ 1 Aluminum Mounting Flange

❑ 1 10mm Hose Banjo Fitting

❑ 1 Hose Fitting Banjo Bolt

❑ 2 Hose Fitting Sealing Washers

• Description: This blow off valve is designed to allow boost pressure to be bled from the intake piping on throttle off, while

in boost. Bleeding off boost pressure keeps turbocharger speed up during shifts which reduces turbo boost lag. This also

protects the turbo from surging when the throttle is closed suddenly.

•

NOTE: This kit requires cutting and welding. If you are not experienced with fabrication and welding, you should have

this installation performed by a professional.

1. The blow-off valve should be located between the turbo

compressor outlet, and the throttle body.

2. Select either the steel or aluminum mounting flange,

depending on whether your intake plumbing is steel or

aluminum. Mark the area where the flange will be

attached, cut the piping to accept the flange, and weld

the flange to the piping. After welding the mounting

flange to your compressor plumbing, and allowing the

materials to cool sufficiently, you may attach the blowoff valve to the mounting flange using the supplied vband clamp and o-ring.

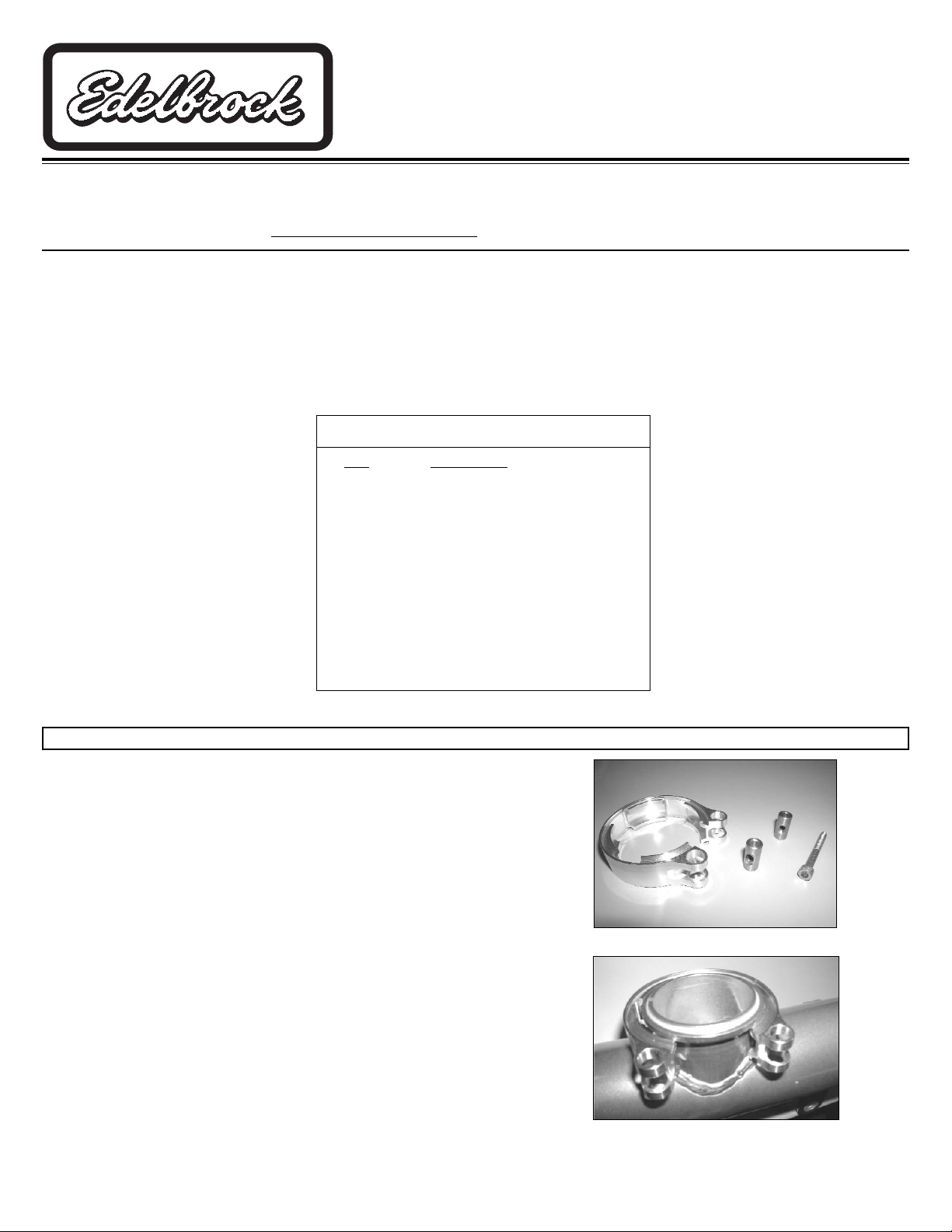

3. The easiest way to attach the blow off valve is to

remove the allen bolt and threaded sleeves from the vband clamp

(See Fig. 1)

. You will then be able to

stretch the v-band clamp over the flange. Allow the

clamp to slip completely over the flange

(See Fig. 2)

.

Fig. 1

Fig. 2

®

Page 2

©2004 Edelbrock Corporation

Rev. 1/04 - RS/mc

Catalog #15008

Brochure #63-0248

Page 2 of 2

Edelbrock Corporation

2700 California St.

Torrance, CA 90503

Tech Line: 1-800-416-8628

Office: (310) 781-2222

E-Mail: Edelbrock@Edelbrock.com

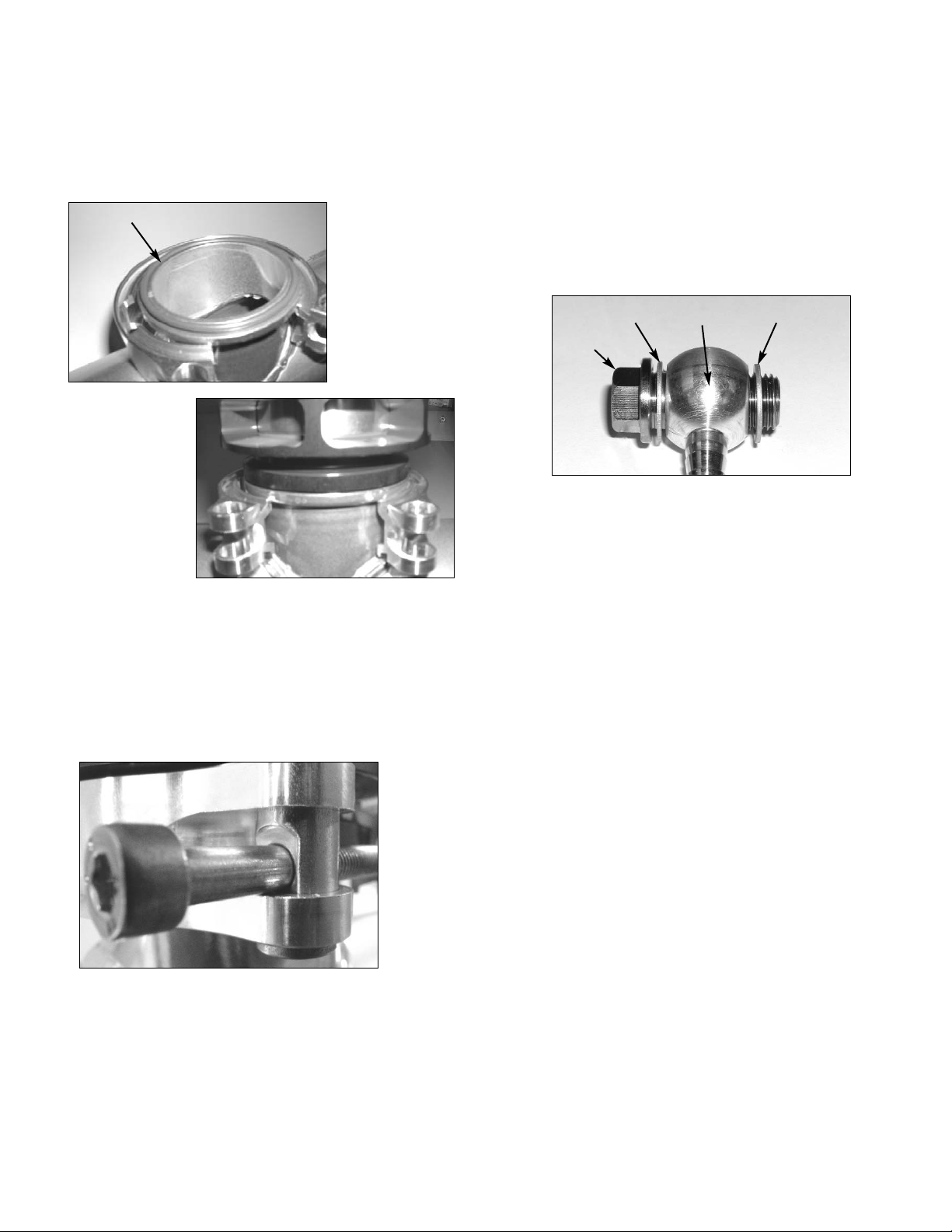

5. Now you may install the allen bolt and threaded sleeves

into the clamp. You may need to squeeze the clamp

together by hand to get the bolt to reach all the way

across. When installing the threaded sleeves, make

sure the sleeve with the machined area faces towards

the head of the allen bolt

(See Fig. 5)

. Tighten the

clamp using an allen wrench.

6. Attach the supplied banjo fitting using the supplied

banjo bolt, and using one sealing washer on each side

of the fitting

(See Fig. 6)

. Adjust the banjo to the

desired direction and tighten the banjo bolt. Use a 1/4”

hose (not supplied) and connect the banjo fitting to a

vacuum source. A 1/4” x 1/8” NPT (minimum) fitting on

the intake manifold is the preferred source. If this is not

available, tee into a vacuum hose that is larger than

1/4”, such as the power brake booster line.

Fig. 6

Fig. 5

Bolt

WasherBanjo FittingWasher

Fig. 4

Fig. 3

O-Ring

4. Now place the o-ring into position around the receiver

groove of the mounting flange

(See Fig. 3)

. Place the

blow off valve over the o-ring and press until flush with

the flange

(See Fig. 4)

. Position the clamp over the

blow off valve and flange. If your blow off valve is not

mounted vertically, you may need assistance to hold it

in place while positioning the clamp.

Loading...

Loading...