Page 1

©2007 Edelbrock Corporation

Brochure #63-0443

Catalog #1400

Rev. 1/07 - RS/mc Page 1 of 5

PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common tools and

procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable performing this installation,

it is recommended to have the installation completed by a qualified mechanic. If you have any questions, please call our Technical Hotline at:

1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through Friday or e-mail us at Edelbrock@Edelbrock.com

.

IMPORTANT NOTE: Proper installation is the responsibility of the installer. Improper installation

will void your warranty and may result in poor performance and engine or vehicle damage.

DESCRIPTION: Edelbrock Performer Series carburetor #1400 is 50-state street legal for all 1980 and earlier General Motors V8 engines. All Performer

Series Carburetors have been calibrated, factory flow-tested, and preset. Edelbrock Performer Series carburetors are designed to give you excellent

performance, fuel economy, and maintenance-free operation. To ensure that you enjoy these benefits, please read all instructions prior to installation.

NOTE: Edelbrock Performer Series carburetors are not for computer-controlled applications. That includes some 1981 & later GM

vehicles with Q-Jet carburetor and some 1981 & later Ford vehicles with automatic overdrive (AOD) transmissions.

Vehicles equipped with C.E.C. solenoids will require the use of Edelbrocks Idle Compensator Solenoid. Use part #8059.

The factory C.E.C. solenoid will not fit our throttle lever. However, the Edelbrock Idle Compensator Solenoid will allow you to retain

the C.E.C. function and to pass visual emissions inspection in California. See “C.E.C. Function” in the “Adjustments and

Troubleshooting” section for installation and adjustment of the Idle Compensator.

KIT CONTENTS:

❑ 2 5/32” Vacuum caps

❑ 1 5/32” Vacuum “T”

❑ 1 1/4" NPT pipe plug

❑ 1 Throttle cable ball end stud

❑ 1 10-32 Hex nut

❑ 1 Installation instruction sheet

❑ 1 Warranty card

❑ 1 Square-bore, heat-insulating gasket

❑ 1 Air horn gasket

❑ 1 Air cleaner stud

❑ Carburetor Adapter and Fuel Line Kit #2697 (Used to mount

Edelbrock carburetors to stock Quadrajet manifolds. Includes

4-hole carb adapter #2696, fuel filter and fuel line kit #8135 for

3/8" and 5/16" OEM steel fuel lines. Both also available separately)

❑ 90-degree banjo fuel inlet fitting kit #8089 (For use with low profile

air cleaner bases), #6 AN fuel inlet fitting #8087, or Inverted Flare

fuel line fitting #8090 (3/8")

❑ In-line fuel filter #8873

❑ Fuel pressure regulator #8190 (If stock fuel pressure is greater than

6.5 psi)

❑ Chevrolet throttle cable stud #8009 (’77 & later)

❑ Transmission kick-down stud #8018 (TH350 type)

❑ GM cruise control adapter #1484

❑ Throttle cable, transmission, and cruise control bracket #8031 or

8036 (‘79 and earlier) for small-block or big-block Chevy (Some

applications may require modification to stock bracket)

❑ EGR adapter #1476 (For Chevy small-block V8’s. Required for all

EGR applications to provide clearance for Performer Series

carburetors)

❑ Universal throttle return spring kit #8005 (If original return spring

cannot be used)

❑ 3/4" Air Cleaner spacer #8092 (For low profile air cleaner bases to

clear electric choke)

❑ Electrical connectors (For electric choke connection)

EDELBROCK PERFORMER SERIES EMISSIONS LEGAL CARBURETOR

600cfm, Electric Choke, EGR, Square-Bore Carburetor

Catalog #1400

INSTALLATION INSTRUCTIONS

❑ Replace fuel filter. Dirt found in carburetor voids warranty.

❑ Check and replace the air filter, if necessary.

❑ Check PCV valve and replace, if clogged.

❑ Check all hoses for leaks or cracks and replace, if necessary.

❑ Check fuel pump for proper operation and replace, if necessary.

❑ Check the intake manifold and cylinder head gaskets for leaks and

replace, if necessary.

❑ Check the ignition system: clean and gap or replace spark plugs,

plug wires, and adjust ignition timing.

CHECK THE FOLLOWING BEFORE BEGINNING INSTALLATION

WARNING: WHEN WORKING AROUND GASOLINE, ALWAYS WORK IN A WELL VENTILATED AREA, AND KEEP ALL OPEN FLAMES, SPARKS AND

OTHER SOURCES OF IGNITION AWAY FROM THE WORK AREA. FAILURE TO DO SO CAN RESULT IN A FIRE

OR EXPLOSION.

ACCESSORIES (REVIEW THE FOLLOWING AND USE PARTS AS NECESSARY FOR YOUR APPLICATION)

❑ 1 3/16” Internal star washer

❑ 1 Red choke positive wire

❑ 1 Black choke ground wire

❑ 1 E.O. Decal

®

Page 2

©2007 Edelbrock Corporation

Brochure #63-0443

Catalog #1400

Rev. 1/07 - RS/mc Page 2 of 5

INSTALLATION PROCEDURE

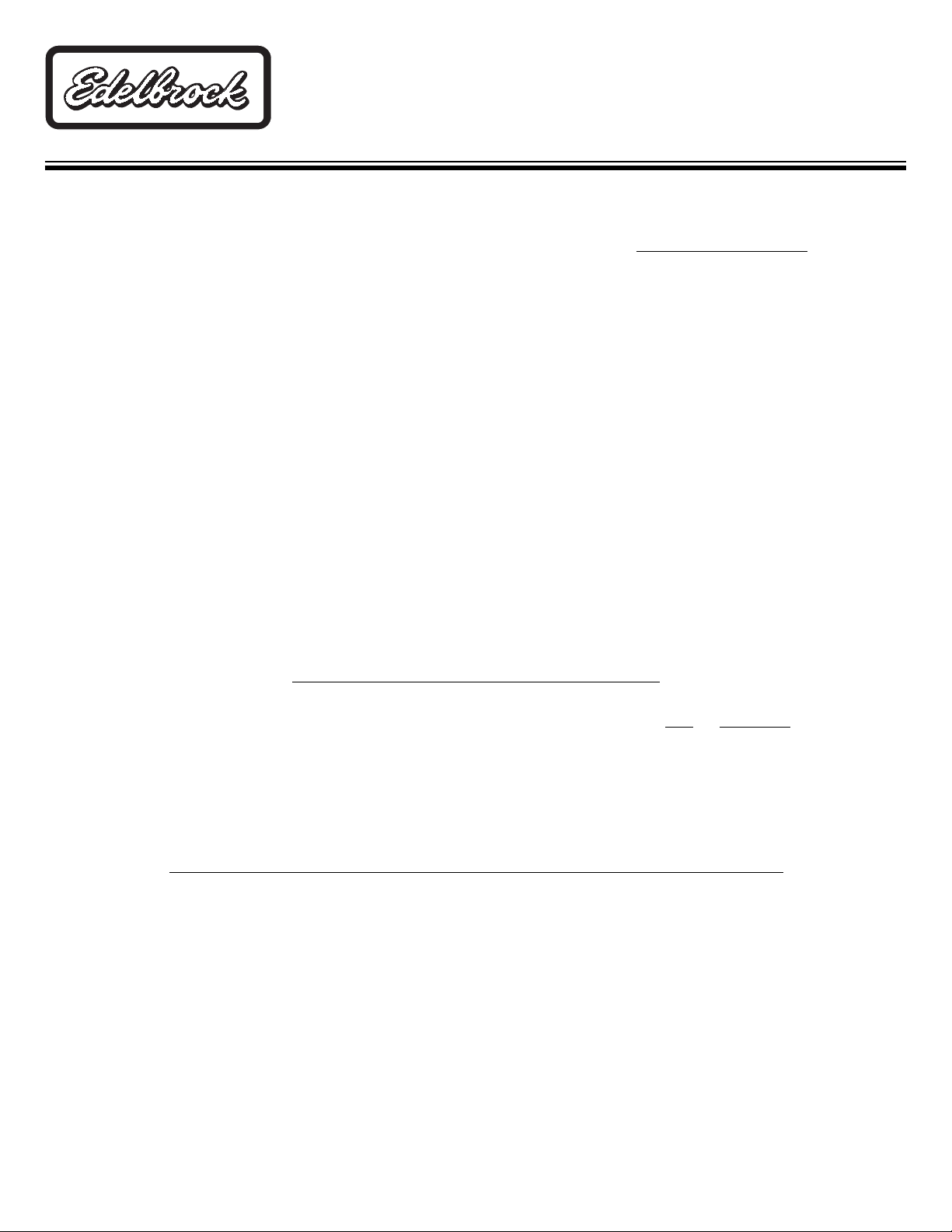

Figure 1 - Fittings and Vacuum Port Locations

CANISTER VAPOR VENT

(#1400 ONLY)

IDLE MIXTURE SCREWS

Left side screw for left side of carb

Right side screw for right side of carb

FUEL INLET for 3/8” hose (Except marine

models #1409 & #1410 which use a 3/8”

inverted flare fitting)

POWER BRAKE PORT

(Except Marine Models)

Rear lower side, 1/4” NPT

MUST BE PLUGGED WITH

1/4” PIPE PLUG (SUPPLIED)

IF NOT USED

IDLE SPEED

SCREW

PCV PORT (For 3/8” hose)

NOT FOR FUEL!

3/16” MANIFOLD VACUUM PORT

(EGR vacuum supply port)

3/16” TIMED VACUUM PORT

(Distributor vacuum advance port for

emissions controlled engines)

PART NUMBER is stamped on

pad at front of carburetor

CARBURETOR PREPARATION

1.

Install proper throttle and transmission linkage for your particular

application. Make sure all linkage is properly secured to carburetor and

works freely.

2.

Check and prepare carburetor for proper vacuum fitting installation

(EGR,

power brakes, PCV, distributor, transmission, etc.) using supplied

vacuum caps, “T”, and hose when applicable. Before removing old

carburetor, determine if distributor vacuum advance port is “timed” (no

vacuum present at idle) or “manifold vacuum” (vacuum present at idle),

and use the matching vacuum port on your Edelbrock carburetor

(See

Figure 1)

. If vacuum port at rear of carb is not used, plug with a 1/4"

pipe plug.

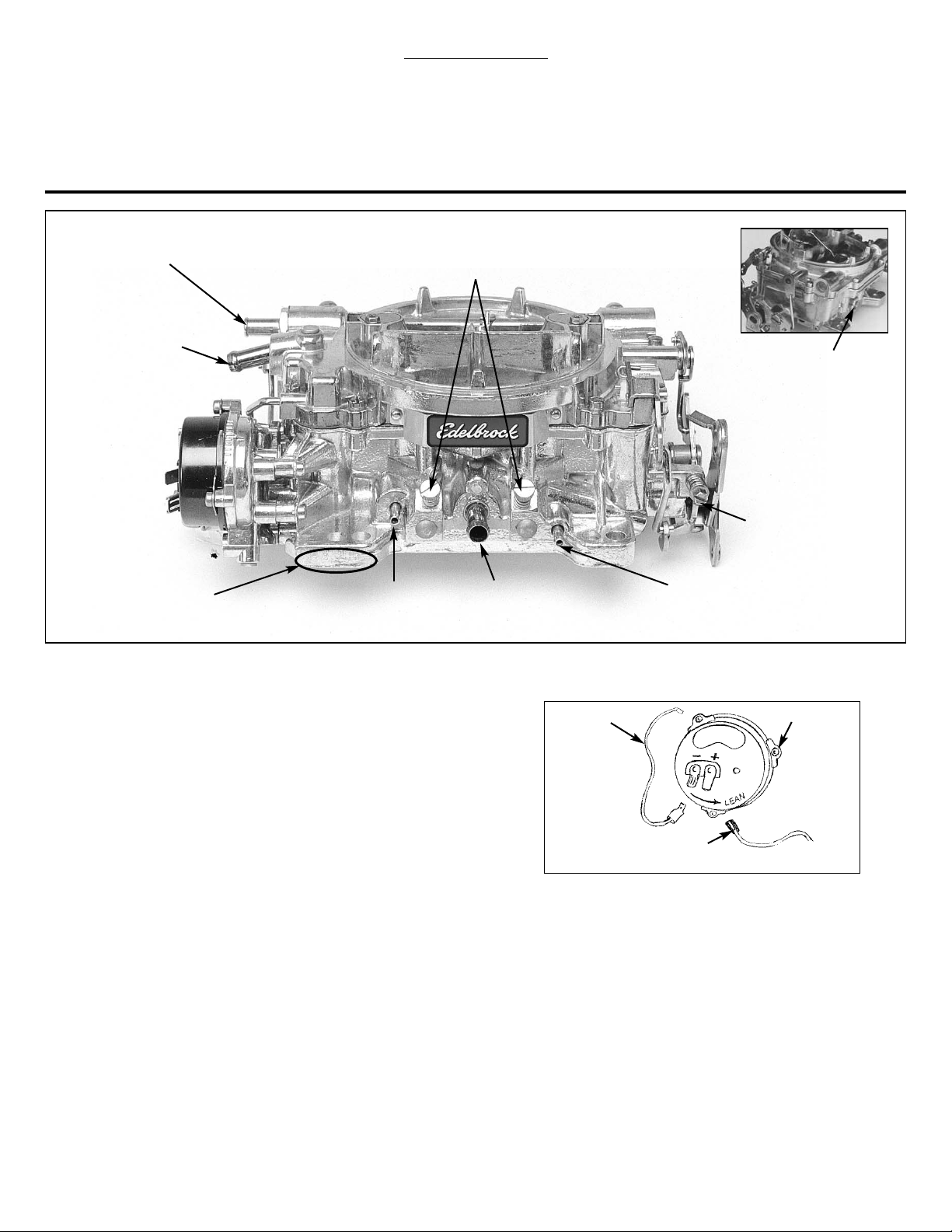

3. For electric choke hook-up

(See Figure 2)

, remove one choke

housing retaining screw and install eyelet end of choke ground wire

(black) to choke housing and reinstall screw. Connect clip end of

choke ground wire to negative (-) spade terminal on choke housing.

Connect red wire spade terminal to positive (+) terminal on choke

housing. Connect other end of red wire to an ignition key activated

12-volt source. DO NOT ATTACH TO COIL OR ALTERNATOR. Ensure

this source maintains 12 volts with engine running.

INSTALLATION OF CARBURETOR

1. Disconnect all linkages and lines from old carburetor, noting their

purpose for reassembly on new carburetor.

CAUTION: When disconnecting fuel line, avoid any exposure to

sparks or open flame. Note position of all throttle and transmission

linkages and/or cables for reassembly. Remove old carburetor and

flange gasket. Do not allow gasket or other material to fall into

manifold.

2. Place new carburetor gasket and adapters (when applicable) on the

manifold. Install carburetor and cross tighten nuts. Be sure not to

overtighten nuts.

Fig. 2

Black Wire (–);

To Ground

(Carb Body)

Red Wire (+); To Key-On 12V

Source

(Not Coil or Alternator!)

Retaining Screws (3)

RECOMMENDED TOOLS

❑ Sockets/wrenches/tubing wrenches

❑ Pliers

❑ Screwdrivers

❑ Hacksaw and/or tubing cutter

❑ #20 Torx Driver (for electric choke models)

❑ Wire crimpers (for electric choke models)

❑ Test Meter or Test Light (for electric choke models)

Page 3

©2007 Edelbrock Corporation

Brochure #63-0443

Catalog #1400

Rev. 1/07 - RS/mc Page 3 of 5

IDLE MIXTURE

The Edelbrock Performer Series carburetor has conventional Idle Mixture

Screws (IMS) that provide a leaner A/F when turned clockwise and richer

A/F when turned counter clockwise. The idle air flow is controlled by a

conventional screw that opens the Primary Throttles. The following

procedure should be used to set the idle mixture and speeds:

1. Fully warm engine and ensure choke is fully open.

2. Air cleaner in place.

3. Set desired speed with the air screw.

4. Adjust the IMS on ONE side to get the maximum possible RPM. Do

not go rich beyond the maximum speed point.

5. If the above changed the idle speed more than 40 RPM, then

re-adjust the speed.

6. Adjust the side OPPOSITE of that in Step 4 to get maximum RPM.

7. Reset the speed.

8. Carefully trim each IMS to again get the maximum idle RPM.

9. Go leaner just enough to get a 20 RPM drop in speed.

10. Reset the speed to the desired RPM.

11. This is a Lean-Best Idle Set. Setting richer than this will not

improve idle quality or performance, but could tend to foul spark

plugs.

WINTER FUEL IDLE SETS

During the winter months (in most parts of the country) the local fuel will

be a “winter” blend that is very volatile, as an assist to cold-engine

starting and driveability during warm-up. However, the high volatility has

the disadvantage of allowing excessive vaporization of the fuel if the

vehicle is operated in a heated area such as a garage. This can result in

problems in the idle-set procedures since the carburetor’s internal vents

will allow this excess vapor to be drawn into the throats and enrichen the

mixture. The idle will be erratic and not seem to be able to hold a set.

To resolve this type of problem, it is advisable to perform the final

settings outdoors after the vehicle has been stabilized with a drive of

several miles.

CALIBRATING THE ACCELERATOR PUMP

If you encounter any hesitations or stumbles that do not seem to be

related to the basic metering or have not responded to changes in the

basic metering, move the pump drive link to one of the holes closer to

the carburetor body. This will increase the stroke length of the plunger

and result in more pump delivery.

FLOAT ADJUSTMENT

To properly adjust the floats in the EPS carburetor, two procedures must

be followed. First, the metering rod/power piston assemblies should be

removed from the top of the carb airhorn. Next, remove the accelerator

pump connecting rod and the choke connec-ting rod. After removing all

the airhorn retaining screws, turn the airhorn upside down with the

gasket in place

(See Figure 3)

. Use a scale, or a 7/16" drill bit (as

shown) to mea-sure the float level. There should be 7/16" between the

air-horn gasket and the top of the outer end of the float. To adjust the

float level, bend the float lever until the recommended level is attained.

DO NOT press the needle into the seat when adjusting the float lever.

Next, you should check the float drop

(See Figure 4).

Hold the airhorn

upright and let the floats hang down. There should be 1-1/4" ± 1/4"

between the airhorn gasket and the top of the outer end of the float. To

adjust the float drop, bend the tab on the back until the recommended

float drop is attained.

3. Connect all throttle and transmission linkages and throttle return

springs.

CAUTION: At this point, make sure all throttle and transmission

linkages operate smoothly from idle to wide open throttle (WOT)

and check return springs for proper pressure.

4. Connect all vacuum hoses to their proper location on carburetor

(See Figure 1)

. Replace hoses that appear brittle or cracked.

5. Connect fuel line to carburetor

(See Figure 1)

. Avoid contact with

any sharp edges or areas of extreme heat. For best results, use

Edelbrock in-line fuel filter #8873 and fuel line kit #8135.

6. Install new air horn gasket and air cleaner stud (supplied). Install

air cleaner making sure it does not contact linkage or fuel line and

has proper hood clearance. Extremely low profile air cleaners will

not fit without #8092 (due to choke interference).

7. Trim air cleaner stud to proper length.

8. Re-check all linkage for smooth throttle operation.

9. Start the engine and check for any possible fuel or vacuum leaks.

CAUTION: Be alert to carburetor flooding. Flooding can be caused

by dirt, small particles of hose cuttings, floats and inlet needles

which have settled during shipping. When the fuel pump is turned

on or when the engine is first started, watch closely for signs of

flooding. If flooding occurs turn engine off immediately and lightly

tap on the side of the carburetor that is flooding, in the rear needle

and seat area with a rawhide mallet or wooden handle of a

hammer. Start engine and see if flooding continues. If flooding

continues, stop the engine. Clean up any raw gasoline and refer to

the “Adjustments and Troubleshooting” section of the

Instruction Sheet.

WARNING: NEVER POUR FUEL DIRECTLY DOWN THE

CARBURETOR WHEN ATTEMPTING TO START THE ENGINE! THIS

MAY CAUSE A BACKFIRE AND POSSIBLE ENGINE

COMPARTMENT FIRE, RESULTING IN ENGINE OR VEHICLE

DAMAGE, PERSONAL INJURY AND/OR DEATH.

10. With engine at normal operating temperature and choke fully open,

set idle speed and mixture screws. This procedure is outlined in the

Instruction Sheet.

ADJUSTMENTS AND TROUBLESHOOTING

Float Level

(7/16")

Bend Here

Fig. 3

Page 4

CHOKE ADJUSTMENT

To adjust the choke piston linkage

(See Figure 5)

, open the choke valve and

insert a .026" wire, with a 90-degree bend 1/8" from the end, between the

top of the slot in the choke piston cylinder and the bottom of the slot in the

piston. Hold the wire in position and close the choke valve by pressing on

piston lever “A” until resistance is felt. The dimension “C” should be .100"

between the top edge of the choke valve and the air horn. To adjust, bend

rod “B”.

©2007 Edelbrock Corporation

Brochure #63-0443

Catalog #1400

Rev. 1/07 - RS/mc Page 4 of 5

To adjust the fast idle linkage

(See Figure 6),

place the fast idle screw A

between the two notches on the cam. Close the choke valve as far as

possible without forcing it. The dimension C should be 3/64" between the

choke valve and the air horn. To adjust, bend rod B.

Fast idle may be

adjusted to manu-facturer’s specifications (usually 1500 rpm) during

normal choke cold operation. The fast idle screw A can be adjusted with

engine off and throttle held open to allow screw head access. Re-check

fast idle speed after each adjustment.

C (3/64")

B

A

Fig. 6

Slot (Piston)

.026" Wire

C (.100")

A

B

Fig. 5

Tab

Float Drop (1-1/4 ± 1/4")

Fig. 4

The length of time during which the choke will stay closed is determined

by the position of the choke cap. As the choke cap is turned clockwise,

the choke will stay closed longer. To properly set the choke, turn the

choke cap to the leanest notch on the choke housing, tighten the choke

housing retaining screws, and run the engine until normal operating

temperature is reached. With the engine running, slowly turn the choke

cap clockwise until the choke valve begins to close. Now turn the choke

housing one notch counterclockwise (LEAN) and tighten the choke

housing retaining screws. Periodic re-adjustment of the choke will be

required as the temperature changes throughout the year. After each

adjustment, verify that the choke valve opens fully after the engine is

warm.

CAUTION!!!

Do not overtighten the small Power Piston Cover screws when

servicing metering rods. They should only be tightened to 12

to 17 inch/pounds. Excessive torque will weaken or snap off

the screw heads. If this happens, they may fall into the

carburetor causing serious engine damage. If an inch/pound

torque wrench is not available, snug the screw until it just

touches the plate, then tighten 1/16th turn more.

C.E.C. FUNCTION

Vehicles equipped with C.E.C. solenoids will require the use of

Edelbrock’s Idle Compensator Solenoid. Use part #8059. The

factory C.E.C. solenoid will not fit our throttle lever. However,

the Edelbrock Idle Compensator Solenoid will allow you to retain

the C.E.C. function and to pass visual emissions inspection in

California.

Remove front driver’s side carb stud and replace with longer stud

supplied in this kit. Place bracket over the stud and install nut and

washer on stud. Position solenoid in bracket and install large washer

(locking tabs face the solenoid) and locknut. Tighten firmly, but be

careful not to over-tighten due to the large size (1-1/4") of the wrench

used. Bend locking tabs on special washer over flats of the nut to

prevent loosening. Attach the wire from the solenoid to the existing

C.E.C. wiring connector.

If the factory connector does not fit, you will need to splice into the wire

from the connector. Use a 1/4" female receptacle and at least 18-20

gauge wire. Some receptacles will require that the locking tab on the

solenoid be flattened before the receptacle will fit.

ADJUSTMENT

With the Idle Compensator Solenoid disconnected, adjust the Idle

Speed Screw until you reach the desired idle RPM.

With the Idle Compensator Solenoid connected and the ignition in

the “On” position, adjust the solenoid until it just contacts the

throttle lever. Next, start the engine and turn the Idle Speed Screw

counter-clockwise to make sure the idle speed is maintained by the

solenoid. If necessary,adjust idle speed by turning solenoid plunger

in or out with a 1/2" wrench. Shut off the engine.

Turn the Idle Speed Screw counter-clockwise until the throttle lever

is completely closed and the Idle Speed Screw is not touching the

throttle lever. Turn the Idle Speed Scruew clockwise until it just

makes contact with the throttle lever. Continue turing 1/4 turn

more. This will make sure the throttle blades will not bind in the

bore when the solenoid is turned off.

Page 5

©2007 Edelbrock Corporation

Brochure #63-0443

Catalog #1400

Rev. 1/07 - RS/mc Page 5 of 5

X X XXXX X X X

XXXXXXXX

XXXXX X X

XX XXX

XX X X X

XXX X

XX

XX

XX X

XXXX

XX XX

XX XX

XXX

XX XX

XX

X

X

Check for air leaks. Make sure carburetor and manifold gaskets

seal properly. All outlets must be plugged or connected.

Check ignition system. Replace parts as necessary. Adjust timing to

proper specifications.

Check choke adjustment.

Change carburetor fuel filter and/or in-line fuel filter.

Check float level and drop.

Check idle mixture screw adjustment.

Increase accelerator pump stroke. Pump squirter size change may

be needed.

Off-road vehicle may need spring-loaded needle and seat kit

Check for dirt or metal in needles and seats. Needles and seats

may need replacement.

Check for dirt blocking the low speed circuit. Clean unit and apply

air pressure. Install in-line fuel filter #8873.

Check floats for leakage. Replace, if necessary.

Check air horn gasket. Replace, if deterioration or breakage is

present.

Fuel is boiling due to excessive under hood temperature.

Fuel pressure too high. Fuel regulator may be needed.

Fuel pressure too low. Check fuel system.

Check secondary latching device and rod for proper movement.

Lower float level from 11/32” to 7/16”.

Carburetor doesn’t

adjust properly

Carburetor floods

Fuel leaks at shaft

Internal fuel leak

Misses or surges

Stumbles or loads up

Engine won’t idle

Rough idle

Backfires

Bogs

Hard starting

Lack of power

Pinging at moderate

cruise just off idle

Engine stalls on hard

braking

Low fuel economy

Possible Solutions

Symptoms

TROUBLESHOOTING CHART

(Refer to the chart below for reference)

Page 6

©2007 Edelbrock Corporation

Brochure #63-0443

Catalog #1400

Rev. 1/07 - RS/mc

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech-Line: 800-416-8628 • E-Mail: Edelbrock@Edelbrock.com

®

Loading...

Loading...