Page 1

Rev. A-2/12 - CP/mc

©2012 Edelbrock LLC

Brochure #63-0351

Page 1

FORD FLATHEAD CYLINDER HEADS

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common tools and

procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable performing this installation,

it is recommended to have the installation completed by a qualified mechanic. If you have any questions, please call our Technical Hotline at:

1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through Friday.

IMPORTANT NOTE: Proper installation is the responsibility of the installer. Improper installation

will void your warranty and may result in poor performance and engine or vehicle damage.

CATALOG #’S

1115: 8.0:1 compression ratio with a 3/16” base relief and stock bore & stroke. Compression ratio increase is approximately 3/10 of a

point with each 1/8” increase in stroke.

1116: Features a “raised roof” combustion chamber design that is intended to support high lift cams, or for use in applications requiring

decreased compression; such as supercharged engines or to run on low octane fuel.

1125: 8.0:1 compression ratio with a 3/16” base relief and stock bore & stroke. Compression ratio increase is approximately 3/10 of a

point with each 1/8” increase in stroke.

1126: Identical to 1125, except features Edelbrock’s original Block Letter Logo for a vintage look.

1127: Features a “raised roof” combustion chamber design that is intended to support high lift cams, or for use in applications requiring

decreased compression; such as supercharged engines or to run on low octane fuel.

1128: Identical to 1127, except features Edelbrock’s original Block Letter Logo for a vintage look.

Edelbrock Aluminum Flathead Cylinder heads are designed for Ford & Mercury 24-stud V8 engines. These cylinder heads feature a rugged, ribbed

design featuring a large water capacity and excellent breathing characteristics. Individual features are listed above.

DESCRIPTION

HEAD GASKETS:

For 1938-1948: Use Cometic #C5908-051 or C5108-51 (dependent on bore size)

For 1949-1953: Use Fel-Pro #1055 (right) and #1056 (left) copper/ fiber gaskets.

NOTE: Those who require a water bypass must drill the cylinder head deck using their gasket as a template. A 1/4” diameter hole

should be adequate.

HEAD STUDS:

For 1938-48(P/N’s 1125 & 1126): use Edelbrock P/N 8505

- With offset generator bracket (P/N 1144or 1155) use Edlebrock P/N 8506 to supplement P/N 8505

For 1949-53 (P/N’s 1115 & 1116): use Edelbrock P/N 8502

COMPRESSION RATIO: These heads will yield an 8:1 compression ratio with a 3/16" base relief and the stock bore and stroke. There is a 3/10

ratio increase for every 1/8" increase in stroke.

SPARK PLUGS: A 14mm, 3/4” reach, gasket seat, 5/8” hex sparkplug is recommended, such as Champion RC12YC, RC14YC, or equivalent. Heat

range will vary with different combinations and conditions. Use anti-seize on spark plug threads to prevent thread galling!

ADDITIONAL PARTS & INFO

1949 -19531938 -1948

Page 2

Rev. A-2/12 - CP/mc

©2012 Edelbrock LLC

Brochure #63-0351

Page 2

Edelbrock LLC • 2700 California St. • Torrance, CA 90503

Tech Line: 1-800-416-8628

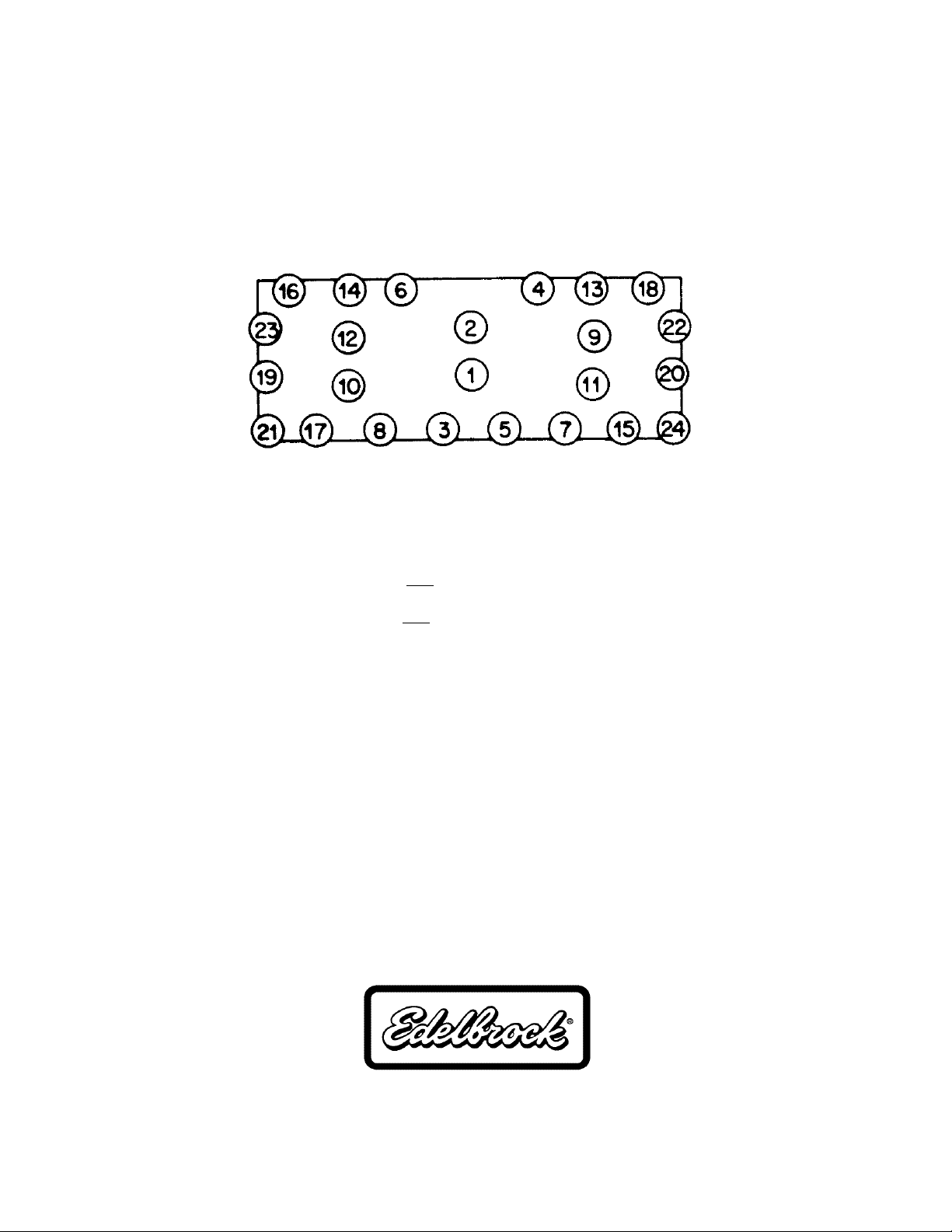

FIGURE 1 - CYLINDER HEAD FASTENER TORQUE SEQUENCE

• Torque to 55 ft./lbs.

Torque in 3 steps: 20, 40, 55 ft./lbs

• Re-torque required after initial warm-up and cool-down

- Re-torque after each

of three (3) hot-cold cycles for

normally aspirated engines

- Re-torque after each

of five (5) hot-cold cycles for

forced induction (blown) engines

Installation is the same as for stock, except for torque values and sealants. Please note specifications below:

NOTE: It is the customer’s responsibility to check valve to cylinder head clearance prior to final assembly.

Failure to do so could result in serious engine damage.

INSTALLATION

Loading...

Loading...