Getting Started with

TSC AMIGO2

Evolving ACFM

User’s

Manual

© Eddy NDT, Inc.

3425 Pierre-Ardouin Québec (QC)

G1P 0B3 CANADA

Eddy NDT, Inc. ACFM, Ami go, Sensu, TSC, and their a ssociated lo gos are trademark s or registered trad emarks of Technical S oftware Con sultants Ltd. (wholly

owned sub sidiary of Edd y NDT, Inc.) in the United Kingdom and/or oth er countries. Edd y Technologi es reserves th e right to change product oerin gs and

specications without notice.

2019-01-14

2 | www.eddy.com

Contents

General Precautions and Conventions

General Precautions ii

Safety Precautions ii

Rear Stand ii

Conventions iii

Typographical iii

Marking and Symbols iii

Safety Indications in This Document iv

Acronyms iv

EMC Directive Compliance iv

FCC Compliance (USA) iv

ICES Compliance (Canada) iv

AS/NZS Compliance (Australia/New Zealand) v

CE Compliance (EU) v

Radio Power Rating v

Calibration and Warranty Seals v

Limited Warranty vi

Copyrights vi

System Overview

Introducing the Amigo2 System 2

What is in the Box 2

Instrument Overview 2

Positioning Amigo2 7

Starting Amigo2 8

Probe Connection 8

Batteries 8

Inserting/Removing Batteries 9

Hot Swapping Batteries 9

Charging Batteries 9

Calibrating Batteries 10

Storing Batteries 10

Software Overview

Introduction 13

Backstage 13

General Section 13

Probe Selection 14

File Transfer 15

View Imported 15

Documentation Section 16

Preference Section 16

Help Section 17

| i

Frontstage Layout 18

Pinning Dialogue Boxes 19

Information bar & warnings 20

The Home Ribbon 21

The Scanning Ribbon 22

Conguring Markers 23

Origin Dialogue Box 24

Row Visibility Dialogue Box 24

The Analysis Ribbon 25

Sizing a Defect 26

Defect Dialogue Box 27

Adding a Region 28

Regions Dialogue Box 28

Creating an Automated Report 29

Standard Layout 30

Layout 2 31

Layout 3 31

Layout 4 32

Layout 5 32

Manipulating Data Through Touch 33

Preferences

Managing Preferences 35

Measurement Units 35

Company Logo 35

Adjusting the Date and Time of the Amigo2 Instrument 36

Keypad and Keyboard Functions

Keyboard Shortcut Keys 40

Modifying Keyboard Shortcuts 41

Maintenance and Troubleshooting

Maintaining Amigo2 43

Cleaning Amigo2 43

Updating and Upgrading Software 43

Standard 43

System Recovery 45

Troubleshooting 47

Specications

General 50

Connector Reference

I/O Connector 53

ii | www.eddy.com

Activating Windows 46

Known Issue With System Updates/Upgrades 46

Troubleshooting System Updates/Upgrades 47

Ethernet Connector 53

HDMI Connector 54

Audio Jack 55

Using the optional Harness

Adjusting the Harness 58

Adjusting the Harness to your Body 58

| iii

Figures

Figure 3-1 Front view 2

Figure 3-2 Rear view 4

Figure 3-3 Right side view 5

Figure 3-4 Left side view 6

Figure 3-5 Amigo2 in horizontal position 7

Figure 3-6 Amigo2 in tilted position 7

Figure 3-7 Optional battery charger 9

Figure 4-1 Backstage view: General 13

Figure 4-2 Probe selection 14

Figure 4-3 View imported probes 15

Figure 4-4 Backstage view: Documentation 16

Figure 4-5 Backstage view: Preferences/System 16

Figure 4-6 Backstage view: Preferences/Display 17

Figure 4-7 Backstage view: Help 17

Figure 4-8 Frontstage layout 18

Figure 4-9 Screenshot of Frontstage 18

Figure 4-10 Pin icon 19

Figure 4-11 Information bar & warnings 20

Figure 4-12 The Home Ribbon 21

Figure 4-13 Coating thickness dialogue box 22

Figure 4-14 Scanning ribbon 22

Figure 4-15 Marker setup dialogue box 23

Figure 4-16 Rows dialogue box 24

Figure 4-17 Rows dialogue box 24

Figure 4-18 The Analysis Ribbon 25

Figure 4-19 The Replay Ribbon 25

Figure 4-20 Sizing 26

Figure 4-21 Defects dialogue box 27

Figure 4-22 Adding a region 28

Figure 4-23 Regions dialogue box 28

Figure 4-24 The Analysis Ribbon 29

Figure 4-25 The layout ribbon 29

Figure 4-26 Standard view 30

Figure 4-27 Layout 2 31

Figure 4-28 Layout 3 31

Figure 4-29 Layout 4 32

Figure 4-30 Layout 5 32

Figure 3-1 System preferences 35

Figure 3-2 Selecting a logo 35

Figure 3-3 System preferences 36

Figure 3-4 Wi-Fi Networks dialog box 36

iv | www.eddy.com

Figure 3-5 Display preferences 37

Figure 4-1 Keyboard Shortcuts 41

Figure 5-1 Update dialog box 44

Figure 5-2 Options menu 45

Figure 5-3 System recovery interface 45

Figure 8-1 Slipping the harness on 58

Figure 8-2 Adjusting the shoulder straps 59

Figure 8-3 Adjusting the belt’s height 59

Figure 8-4 Securing the chest straps 60

Figure 8-5 Securing the belt 60

Figure 8-6 Shoulder anchor straps 61

Figure 8-7 Unfastening the straps 61

Figure 8-8 Sliding strap loop through bumper hook 62

Figure 8-9 Securing anchor strap 62

Figure 8-10 Alternative method of securing anchor strap to bumper 62

Figure 8-11 Anchor strap on harness belt 63

Figure 8-12 Slipping male buckle through bumper 63

Figure 8-13 Mating battery compartment side anchor strap 64

Figure 8-14 Closing battery compartment door. 64

Figure 8-15 Mating shoulder anchor strap 65

Figure 8-16 Tightening shoulder anchor straps 65

Figure 8-17 Belt-slinging probe cable 65

Tables

Table 4-1 Keyboard shortcut 40

Table 6-1 General specications Environmental 50

Table 6-2 Environmental specications 50

Table 7-1 I/O connector data 53

Table 7-2 I/O connector pinout 53

Table 7-3 Ethernet connector data 53

Table 7-4 Ethernet connector pinout 54

Table 7-5 HDMI connector data 54

Table 7-6 USB connector data 55

Table 7-7 USB connector pinout 55

Table 7-8 Audio jack data 55

Table 7-9 Audio jack pinout 55

| v

General Precautions and Conventions

General Precautions and Conventions

General Precautions

The following safety precautions are to be observed at all times when using Amigo2®.

Make sure that you review them before turning on the system.

Keep this document in a safe place for future reference.

Carefully follow the installation and operation procedures detailed herein.

Respect the safety warnings on the instrument and in this document.

Amigo2 should only be used by certied personnel.

When transporting Amigo2, it is your responsibility to make sure that you apply the safety

precautions dictated by the relevant local governing bodies.

Always connect the power supply to a properly grounded receptacle, extension cord, or

power bar. Grounding a single conductor of a two-conductor outlet is not sucient

protection for Amigo2.

Only connect the system to a power source corresponding to the type indicated on the

rating plate.

If you use the system in a manner that deviates from the one specied by Eddy, the

protection provided on the equipment may be rendered null and void.

Do not use substitute parts or perform unauthorized modications to the system.

Service instructions, when applicable, are intended for trained service personnel only.

Always make sure that the system is unplugged from any power supply before servicing.

To avoid a dangerous electric shock, do not perform any service on the system unless

trained to do so. If you encounter any problems or have questions regarding this system,

contact Eddy or an authorized Eddy representative.

Safety Precautions

Observe the following safety precautions scrupulously when using Amigo2.

Rear Stand

Because Amigo2 is a portable system, it is designed to be used under tough conditions. It is,

however, not indestructible. To avoid damaging Amigo2, use its rear stand when operating

Amigo2 in a tilted position. Do not use Amigo2 in the upright position, as it may topple over or

fall o the work surface.

ii | www.eddy.com

General Precautions and Conventions

Conventions

Typographical

The following typographical conventions are used throughout this document:

Italic

Used for le names and paths.

Bold

Used to indicate menu items, named user interfaces, and place emphasis on specic words or

phrases. Items in bold type are capitalized to reect the actual interface.

SMALL CAPITALS

Used to indicate instrument interface indications.

Marking and Symbols

The following symbols appear on the instrument and pertain to safety regulations that should

be carefully observed:

This label is used as a general warning sign. It indicates that you should refer to this

user’s guide to obtain the necessary information for proper protection of the

instrument and its users.

This label is used to indicate high voltage. It draws your attention to the presence

of hazardous voltages (within the product enclosure or accessible externally) that

may constitute a risk of electric shock to persons. Always refer to the user’s guide

to ensure proper protection and safety.

The RoHS compliance logo signies that this product complies with the Restriction

of Hazardous Substances directive 2002/95/EC. This directive restricts the use of

lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyl, and

polybrominated diphenyl ether in certain classes of electrical and electronic units

as of July 1, 2006.

This label acts as a reminder that you should dispose of this system in accordance

with your local Waste Electrical and Electronic Equipment (WEEE) regulations. This

system was manufactured to the high-quality standards of Eddy to ensure safe

and reliable operation when it is used as stated in this document. Due to its nature,

this instrument may contain small quantities of substances known to be hazardous

to the environment and to human health if released in the environment. As such,

systems falling under WEEE regulations should not be disposed of in the public waste

stream.

| iii

General Precautions and Conventions

Safety Indications in This Document

The safety indications in this document are intended to ensure your safety and the integrity of

the system.

WARNING!

CAUTION

Important

Calls attention to important information in order to complete the tasks.

Note

Calls attention to an operating procedure, a practice, or the like that requires special attention.

Notes also indicate useful related information, but the parenthetical information is not

mandatory.

Warning

The warning indication calls your attention to a procedure or a practice (or the

like) that, if performed incorrectly, can result in injury. Do not ignore warning

indications make sure that you understand the condition before proceeding.

Caution

The caution indication calls your attention to a procedure or practice (or the

like) that, if performed incorrectly, can result in material damage, loss of data,

or both. Do not ignore caution indications make sure that you understand the

condition before proceeding.

Acronyms

ACFM: Alternating current eld measurement

HAZ: Heat aected zone

UI: User interface

A/C: Anticlockwise/Clockwise

T: Transverse

Fe: Ferrous

EMC Directive Compliance

FCC Compliance (USA)

This equipment was tested and found to comply with the limits for a Class A digital device,

pursuant Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the user’s guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case you will be required to correct the interference at your own expense.

ICES Compliance (Canada)

This ISM device complies with Canadian ICES-001.

iv | www.eddy.com

General Precautions and Conventions

AS/NZS Compliance (Australia/New Zealand)

This device complies with Australia and New Zealand AS/NZS 4252.2 (IEC 61000-6-4) and

AS/NZS 61000-6-2 (IEC 61000-6-2).

CE Compliance (EU)

The simplied EU declaration of conformity referred to in Article 10(9) shall be provided as

follows:

Hereby, Eddy declares the radio equipment type Amigo2 is in compliance with the Directive

2014/53/EU. The full text of the EU declaration of conformity is available at: https://www.

tscndt.com/wp-content/uploads/2018/12/AMIGO2-CE-Cercate-2018-12-17.pdf.

Radio Power Rating

2.4000–2.4835 GHz, max. 100 mW

The low band 5.15–5.35 GHz is for indoor use only.

Calibration and Warranty Seals

The calibration seal is at the back of the instrument. Amigo2 is also equipped with a warranty

seal.

Important

Broken seals void the calibration certication and product warranty.

| v

General Precautions and Conventions

Limited Warranty

Eddy NDT, Inc. warrants the hardware to be free of any defects in materials or workmanship

for a period of twelve (12) months from the date of delivery, under normal use and service. These

warranties are limited to the original purchase of the product and are not transferable.

Eddy NDT, Inc. will repair or replace any product component or documentation, at its option

and at no additional charge if found defective within the warranty period. The purchaser is

responsible for returning the product to Eddy NDT, Inc.

Eddy NDT, Inc., will not be held responsible in any way whatsoever for damage resulting from

improper installation, accident, misuse, or from service or modication of the product by anyone

other than Eddy NDT, Inc., or an authorized Eddy NDT, Inc. service center.

Eddy NDT, Inc. will not be held responsible in any way whatsoever for direct, indirect, special,

incidental, or consequential damages resulting from possession, use, improper installation,

accident, service, modication, or malfunction of the product (including, without limitation,

damages for loss of business prots, business interruption, loss of business information, or other

pecuniary loss). Eddy’s total shall in no event exceed the purchase price of the applicable

item(s).

This warranty is in lieu of all other warranties, whether oral, written, expressed, or implied,

including any warranty of merchantability or tness for a particular purpose, and no other

representation or claims of any nature shall be binding on or obligate Eddy NDT, Inc.

This agreement is governed by the laws of the province of Québec, Canada. Each of the parties

hereto irrevocably attorns to the jurisdiction of the courts of the province of Québec and further

agrees to commence any litigation which may arise hereunder in the courts located in the

judicial district of Québec.

Copyrights

This document and the product and programs it describes are protected by the Copyright Act

of Canada, by laws of other countries, and by international treaties, and therefore may not be

reproduced, in whole or in part, whether for sale or not, without prior written consent from

Eddy NDT, Inc. Under copyright law, copying includes translation in other languages and

formats.

© Eddy NDT Inc., 2019

This document was prepared with particular attention to usage to ensure the accuracy of the

information it contains. It corresponds to the version of the product manufactured prior to the

date appearing on the back cover. There may, however, be some dierences between this

document and the product if the product was modied after publication.

The information contained in this document is subject to change without notice.

vi | www.eddy.com

General Precautions and Conventions

| vii

Chapter 1

System Overview

System Overview

Introducing the Amigo2 System

Thank you for purchasing the Eddy® Amigo2® system. This chapter oers an overview of the

system, its components, and probes.

What is in the Box

Amigo2 comes with the following standard accessories:

Two high-capacity batteries

One power adapter (100–240 V)

Power cords

User documentation

Stylus

Transport case

Function check plate

Instrument Overview

Front

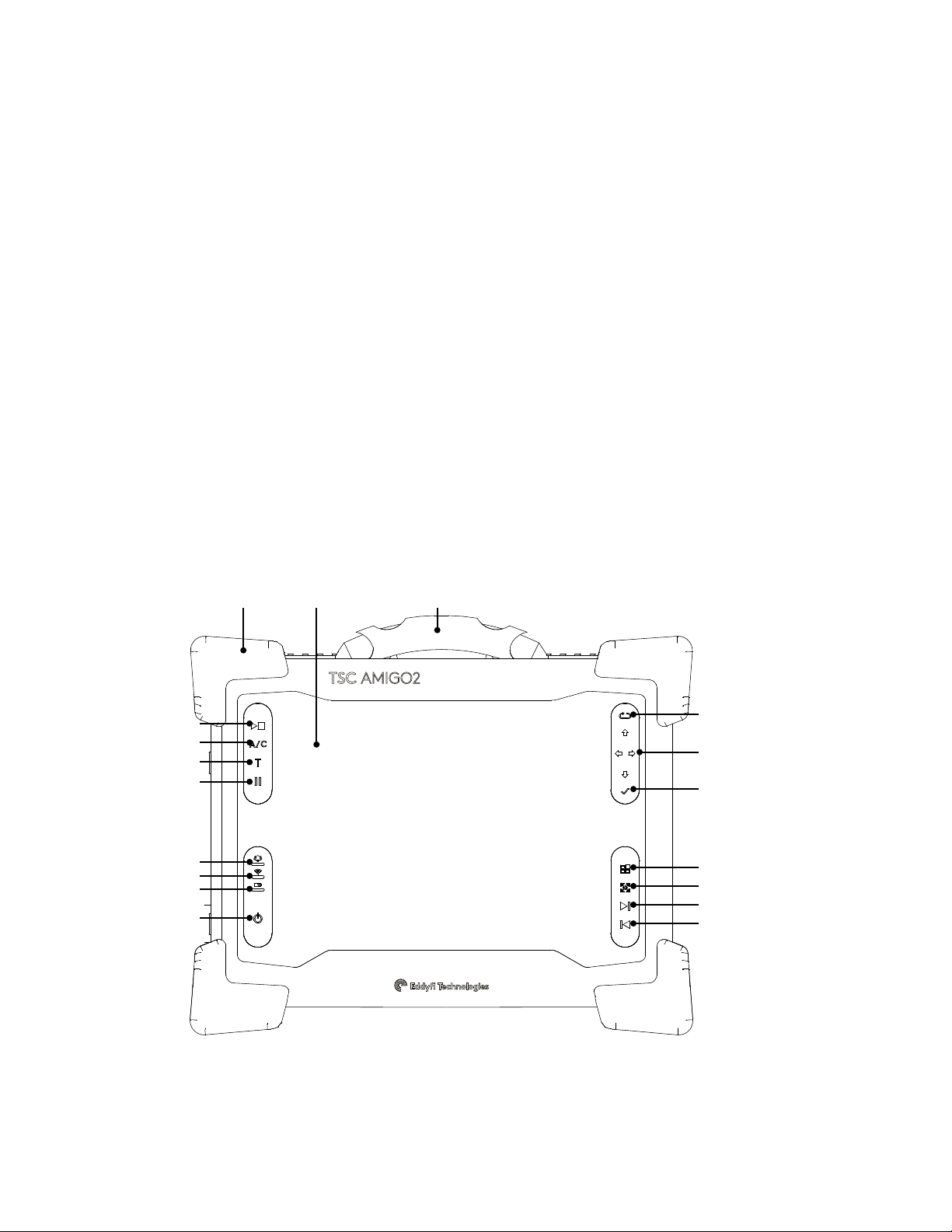

Figure 3-1 Front view

9 10 11

8

7

6

5

4

3

2

1

12

13

14

15

16

17

18

2 | www.eddy.com

System Overview

1. Power button

Short press (approximately 0.5 to 4

seconds):

Use to turn the instrument on and o.

The power indicator at the center of the

button behaves as follows:

Green: Amigo2 is on

Blinking yellow/orange: Amigo2 is on

standby

Unlit: Amigo2 is o

Long press (approximately greater than

4 seconds)

If the instrument is on, a long press will

initiate a forced shutdown.

If the instrument is o, a long press will

activate RDAU mode, which allows the

user to operate the instrument remotely

from a laptop. Press and hold the power

button until the alarm indicator light

ashes, then release the power button.

The power button light will continue to

ash while in RDAU mode.

2. Battery indicator

Displays the state of the batteries when

the instrument is on. Depending on the

power mode (DC or battery), the

indicator behaves dierently:

DC power

Green: batteries fully charged

Blinking green: batteries charging

Red: battery or charger error

Unlit: no batteries

Battery power

Unlit: remaining charge over 40%

Orange: remaining charge 20–40%

Blinking yellow: remaining charge

less than 20%

Red: battery error

5. Pause

Pause data collection.

6. Transverse scan direction

Change the scan direction to transverse.

Pressing this key while data collection is

in progress adds general marks.

7. A/C Scan direction

Toggle scan direction between clockwise

and anticlockwise. Pressing this key

while data collection is in progress adds

clock marks.

8. Start/Stop acquisition button

Use to start or stop data acquisition.

9. Heavy-duty bumpers

The four corner bumpers provide shock

absorption and support Amigo2 at an

angle when it is set on a at surface. The

bumpers are also hooked for harnessing.

10. Multi-touch display

10.4”, non-reective, backlit,

high-resolution display.

11. Handle

Use this handle to carry Amigo2.

12. Keypad arrow mode

selection/Disable

touchscreen button

A long press disables the touchscreen.

Short presses toggle through the keypad

modes depending on the active view.

13. Keypad arrows

Use these arrows to navigate the Amigo2

software interface according to the

selected mode.

14. Enter button

Enter key. Closes text boxes.

15. Change active view button

Selects Bx, buttery plot, Bz or

information pane.

3. Wi-Fi indicator

Displays the Wi-Fi status. When the

indicator is lit, the Wi-Fi is enabled.

When it is o, the Wi-Fi is disabled.

4. Alarm indicator

Used to display user-programmed errors.

The indicator remains unlit until it

detects a predened error condition, at

which time it lights red.

16. Cycle through scale modes

Short press cycles through scale modes:

centered, auto-fit and default. Long

press will switch to manual scale mode.

17. Next page

18. Previous page

| 3

System Overview

Rear

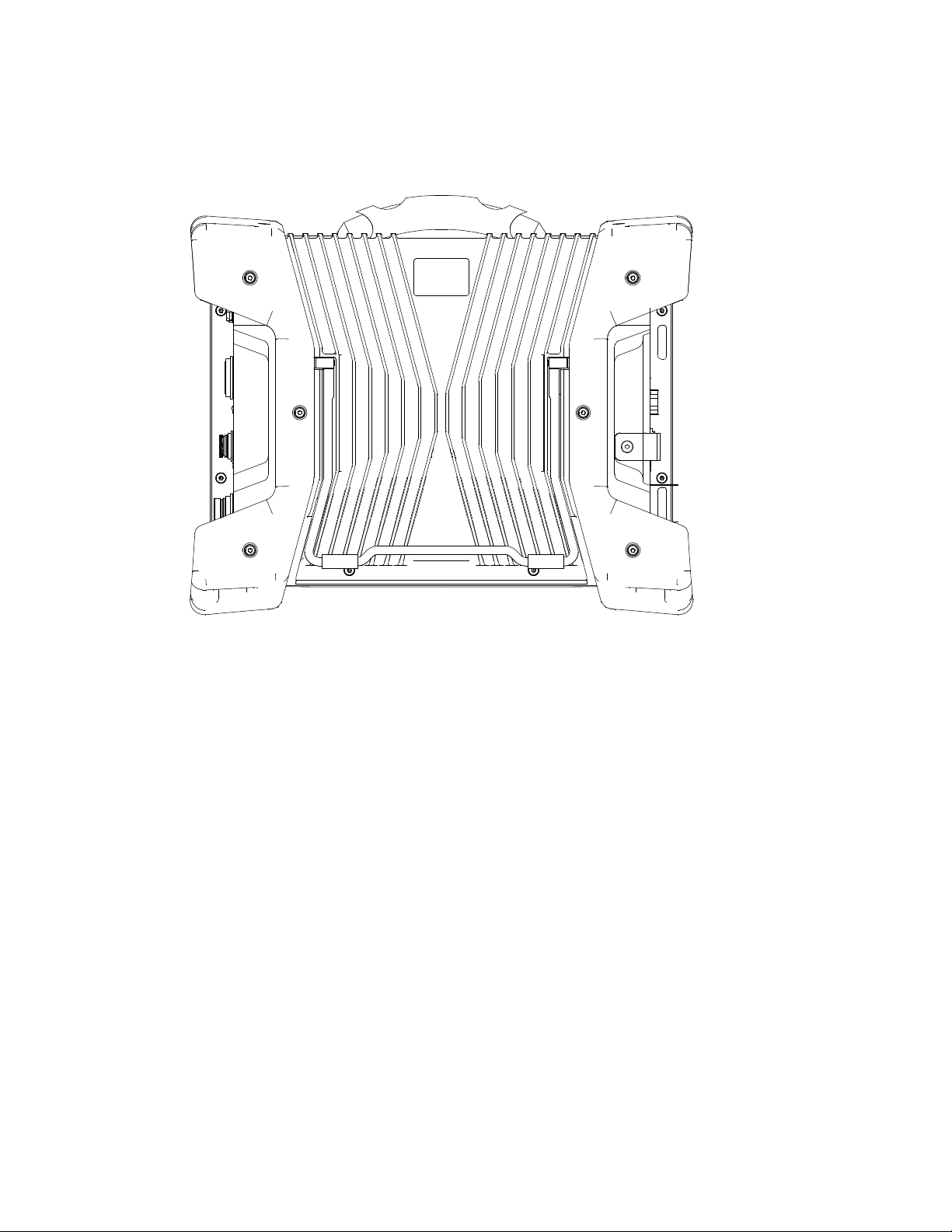

Figure 3-2 Rear view

1. Instrument stand

The stand retracts outward to hold Amigo2 at an angle, preventing the instrument from

tilting over horizontally.

4 | www.eddy.com

Right

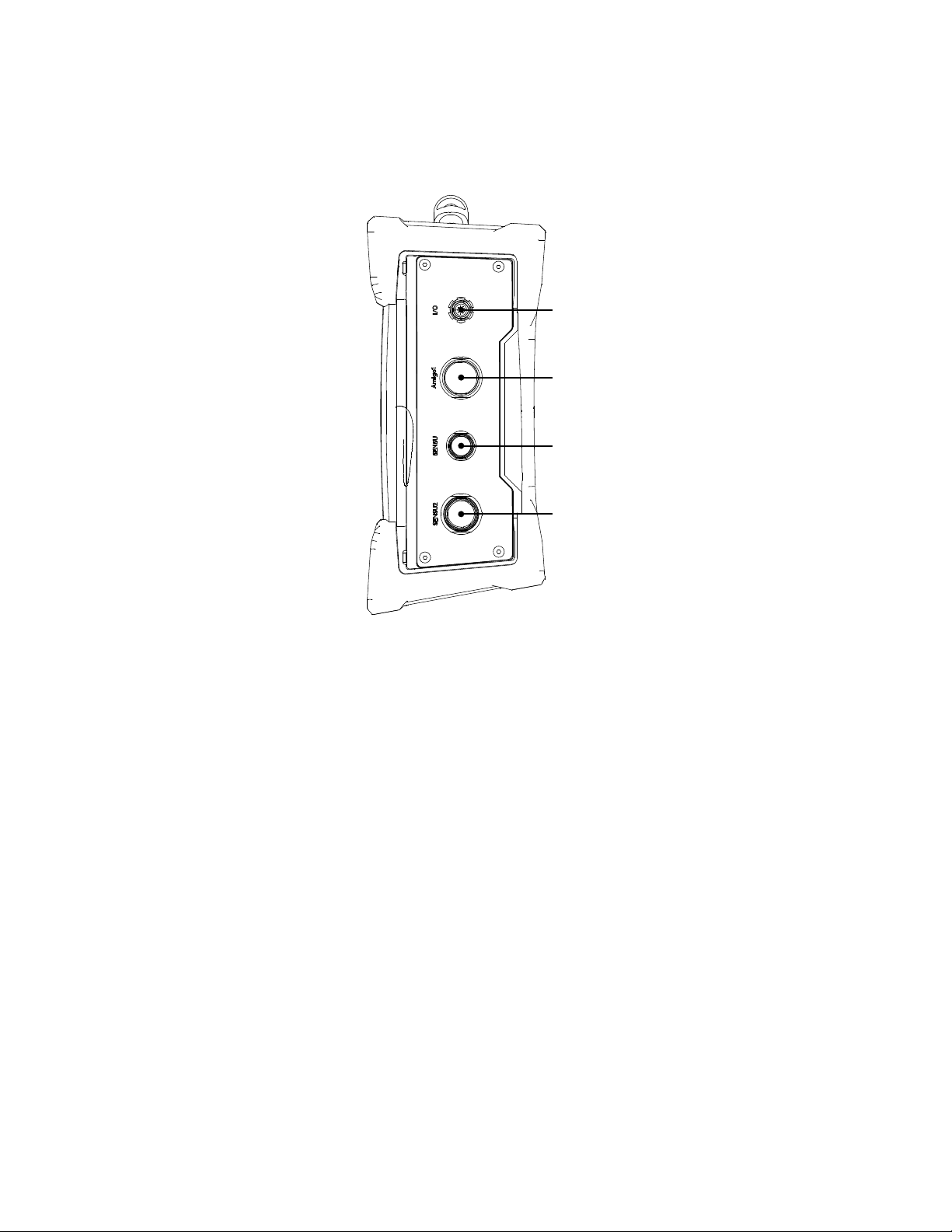

Figure 3-3 Right side view

System Overview

1

2

3

4

1. I/O connector

Used to communicate with external encoders, for example.

2. Amigo1 connector

Used to connect with Amigo1 legacy probes, including arrays.

3. Sensu probe connector (PACE probes)

Used to connect with Sensu probes, typically supplied with the PACE instrument.

4. Second generation Sensu2 connector

Used to connect with second generation Sensu2 probes.

| 5

System Overview

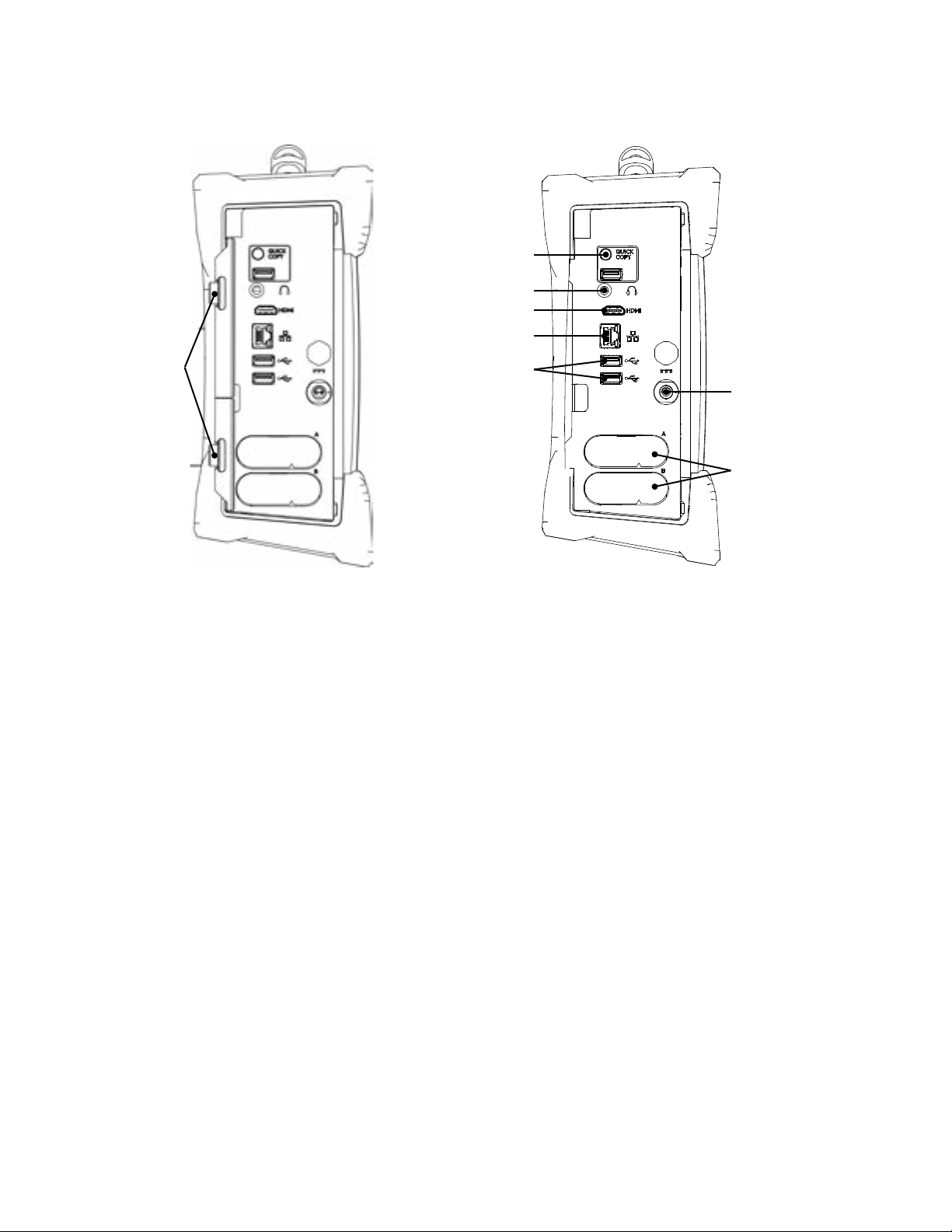

Figure 3-4 Left side view

2

3

4

5

1

1. Protective connector door

Protects the Amigo2 connectors from

the elements when they are unused.

2. Quick Copy

Use to transfer all your inspection data

to a USB mass storage device and import

data from the USB mass storage device's

UserData folder.

3. Audio connector

Use to plug a headset to Amigo2.

®

4. HDMI

connector

Use to connect an external monitor to

Amigo2.

5. Network connector

Use to connect Amigo2 to a local area

network (LAN), also allowing remote

RDAU operation. The connector is

equipped with two indicators with the

following behaviors:

Connection indicator (upper)

Green: communication established

with the network

Blinking green: activity between

Amigo2 and the network

Unlit: no link to the network

6

7

8 9

Connection speed indicator (lower)

Amber: operating as a gigabit

connection (1 Gbps)

Green: operating as a 100 Mbps

connection

O: operating as a 10 Mbps

connection

6. USB 2.0 connectors

Use to connect USB devices to Amigo2

such as a mouse or an external disk

drive.

7. Power connector

Use the supplied power cord to operate

Amigo2 and recharge its batteries.

8. Battery compartments

Insert the supplied batteries into the

compartments. For details about

batteries, see page 6

9. Protective battery compartment

door

Protects the battery compartments

from the elements.

6 | www.eddy.com

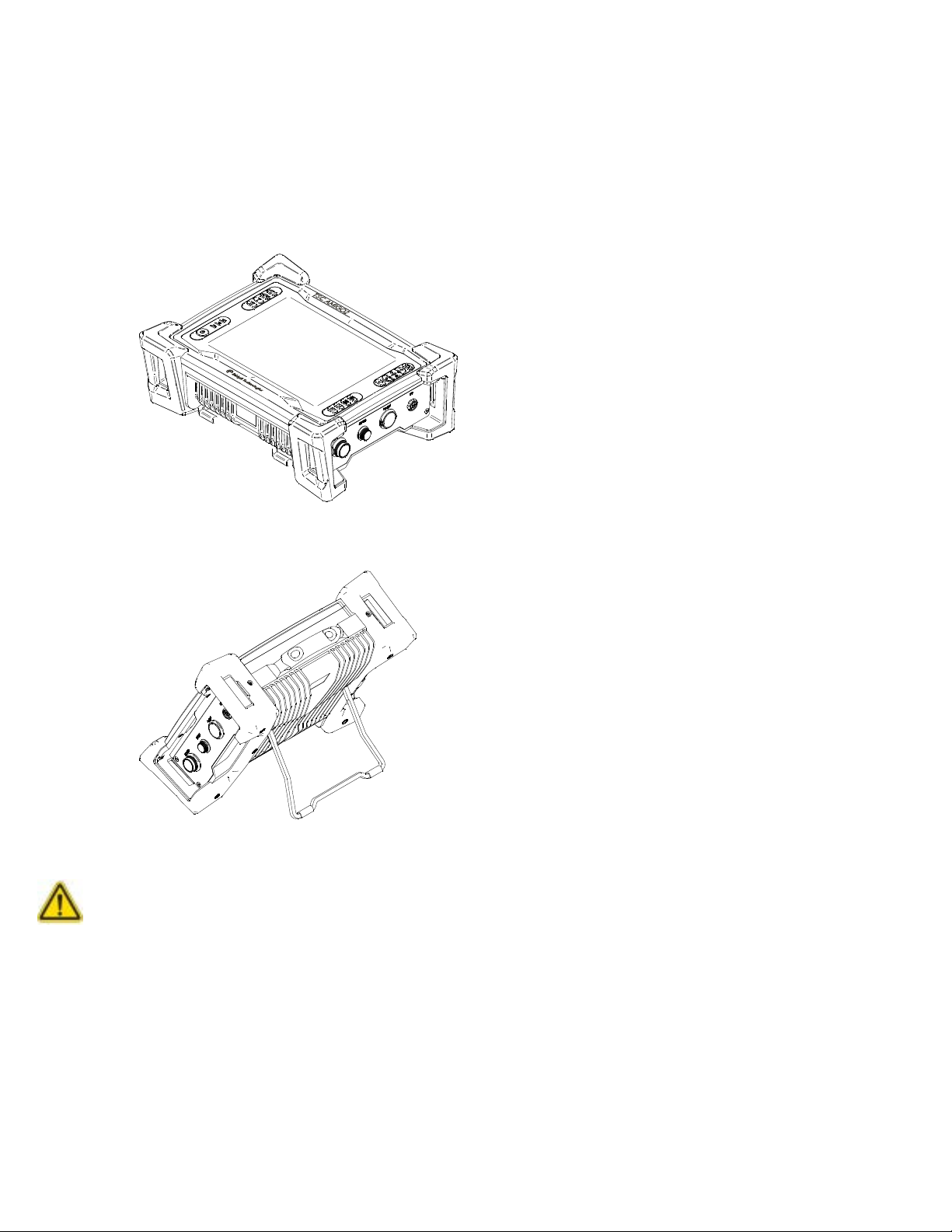

Positioning Amigo2

Amigo2 must be properly positioned prior to use so that you do not run the risk of dropping the

instrument or the instrument falling over. Amigo2 has two safe operating positions: horizontal

and tilted. To use it in a tilted position, simply pull out the stand located at the rear of the

instrument until Amigo2 is at the desired angle. If you are using Amigo2 with the optional

harness, see Adjusting the Harness on page 7 for details.

Figure 3-5 Amigo2 in horizontal position

System Overview

CAUTION

Figure 3-6 Amigo2 in tilted position

Caution

It is possible to use Amigo2 while it rests on its lower bumpers, but this is not a safe operational

position as the instrument may fall over. If you want to use Amigo2 at an angle, use the stand

located at the rear of the instrument.

Important

Regardless of how you position the instrument, you must always have a minimum clearance of

10 cm (4 in) on all sides of the instrument. Always position the instrument away from heat

sources. This ensures proper heat dissipation while the instrument is in use.

| 7

System Overview

Starting Amigo2

Proceed as follows to turn on your instrument or exit the standby mode:

1. Make sure that at least one of the two batteries is inserted into the battery

2. Press the power button.

Probe Connection

The Amigo2 has four connectors running down the righthand side of the instrument. The top

connector is the I/O port, while the lower three connectors are for attaching probes. Three

probes can be connected to the instrument, but only one of them can be used at any one time.

The top two connectors are push t Limo connectors. To make a connection, align the two red

dots and push the plug in until it clicks. To remove the connector, grasp the metal collar and

pull. This releases a catch that would otherwise hold the connector in place. Pulling on the cable,

rather than the metal collar, will severely damage the probe.

The lower two connectors are ratchet connectors. To attach these connectors, align the mating

lugs and screw the outer collar clockwise until the red ring, around the base of the connector,

is no longer visible and the mate is secure.

compartment A of the instrument or that the instrument is plugged in to an external

power source using the supplied power cord.

The power indicator at the center of the power button lights green.

WARNING!

Batteries

Amigo2 can be used under battery power. The instrument is designed with two battery cradles

under the protective battery compartment door but can be powered by a single battery. Amigo2

uses Li204SX-7800 lithium-ion rechargeable batteries from Emerging Power, which do not suer

from the memory eect aecting previous generations of batteries.

Warning

Whenever carrying Amigo2 in its transport case, remove the batteries from the instrument and

make sure that they cannot come in contact during transport, as this poses a signicant re

and explosion hazard.

When carrying Amigo2, it is the user’s responsibility to make sure that the safety precautions

used are in accordance with the local department of transportation (or equivalent governing

body) rules and regulations.

Amigo2’s transport case comes with two slots, tted to receive the batteries when removed

from the instrument.

Note

Make sure that you do not replace the batteries by batteries other than Li204X-7800 lithium-ion

rechargeable batteries from Emerging Power. Contact your Eddy representative for more

information about pricing and availability or replacement batteries.

8 | www.eddy.com

Inserting/Removing Batteries

Inserting Batteries

1. On Amigo2’s left side, unlatch the battery compartment’s door, and then open it.

2. Align your battery with one of the battery cradles.

Note

Battery cradles are marked A and B. If you are inserting only one battery, it does not matter

which of the two cradles you use.

3. Make sure that the battery contacts are facing inward and upward.

4. Slide the battery into the battery cradle until it is fully inserted. You should feel the

battery contacts snap into place.

Removing Batteries

1. On the left side of Amigo2, unlatch the battery compartment’s door, and then open it.

2. Grab the battery tab between thumb and forenger.

3. Pull on the tab.

You will feel the battery contacts being released.

4. Slide the battery out of its cradle.

System Overview

Hot Swapping Batteries

You can remove one of the Amigo2 batteries when the instrument is turned on as Amigo2 can

operate with a single battery. Should the power in the remaining battery be insucient to keep

Amigo2 operating, the instrument shuts down without damaging electronic components, but

all your work in progress in the Amigo2 software (acquisition, etc.) is lost.

Charging Batteries

Note

Batteries do not recharge when their internal temperature exceeds 45 °C (113 °F). Batteries also

do not power Amigo2 when the instrument’s internal temperature exceeds 55 °C (131 °F).

Using the Optional Battery Charger

An optional battery charger is available from Eddy. Contact your Eddy representative for

more information about pricing and availability. This charger conditions and calibrates the

instrument’s batteries, which is important to maximize their lives. We recommend calibrating

the batteries every six months.

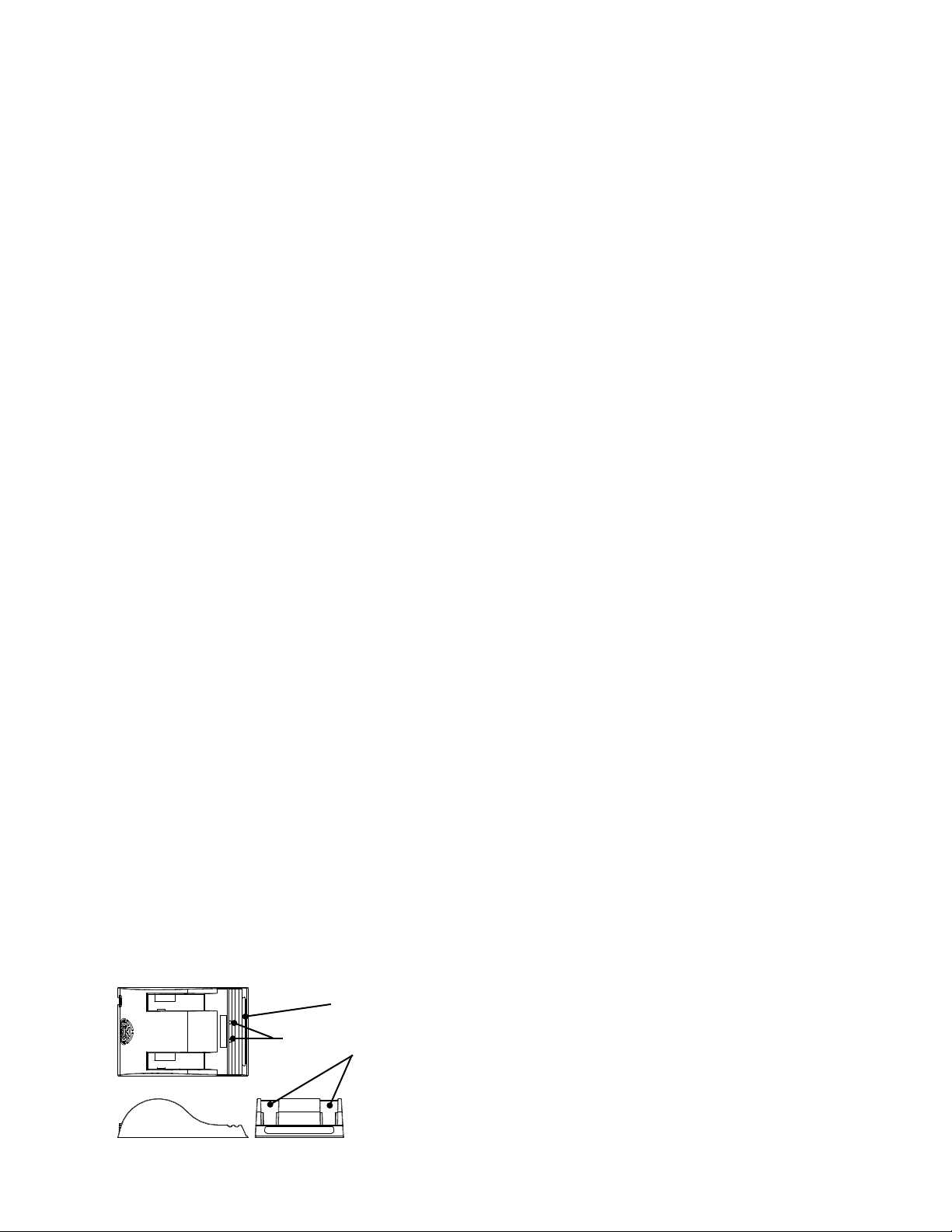

Figure 3-7 Optional battery charger

Status window

Calibration buttons

Battery slots

| 9

System Overview

To charge the batteries with the optional charger:

1. Place the charger on a at and level surface, away from heat and moisture sources.

2. Insert the power supply’s DC connector into the back of the external charger.

3. Connect the power supply to an AC supply using the supplied cable. All the LEDs ash

4. Insert the batteries into the battery slots while making sure that the contacts are fully

Calibrating Batteries

To ensure that your batteries perform at their full capacity for the longest possible time, it is

important to calibrate them on a regular basis. Calibration involves a standard battery charge

followed by a deep discharge, and then a complete charge. This procedure usually takes 10 to

13 hours, whereas a standard charge only takes approximately 3.5 hours.

Calibrate batteries by placing them in the optional charger and then pressing the calibration

button. We recommend calibrating your batteries at least every six months.

momentarily to let you know that power is present.

seated.

The charger automatically begins charging the batteries and the LEDs in the status window

display the following information:

Blinking green: battery charging

Green: battery fully charged

Blinking blue: battery calibrating

Blue: battery charge gauge calibrated

Blinking red: battery charge gauge in need of calibration

Red: error

Storing Batteries

Whenever transporting Amigo2 in its case, remove the batteries from the instrument, place

them in plastic bags, and then make sure that they cannot come in contact during transport,

as this is a signicant re and explosion hazard. Amigo2’s transport case is outtted with two

slots intended for the batteries. We recommend that you take advantage of them.

10 | www.eddy.com

Chapter 2

Software Overview

Introduction

The Amigo2 runs the latest version of TSC’s ACFM data collection and analysis software, known

as Assist 3. Assist 3 is split into the frontstage and backstage. The frontstage is used to collect

and analyse ACFM data. The backstage is primarily used to enter job details, manage probe

congurations, settings and les. The software opens on the backstage.

Pressing either the blue or red arrow button at the top left of the screen toggles between the

two. Pressing the Start/Resume button at the bottom of the backstage screen also takes the

user from the backstage to the frontstage.

Backstage

The backstage consists of four tabs running down the left-hand side.

General. Enter job details, import and export data, manage probe conguration les, etc.

Documentation. View PDF documents relating to the software.

Preferences. Change system settings, units, time and date, connect to wireless networks,

etc.

Help. Software, rmware versions and license information, etc.

The four sections are described in more detail, below.

Software Overview

General Section

Figure 4-1 Backstage view: General

1. Job Details. Enter a Site, Component and Operator name. Component may refer to a

larger structure or assembly that has multiple inspection areas, such as a vessel, line,

tank or vehicle. These names will be used in following inspections. The Part ID could be a

subcomponent name or weld ID which would identify the specic location of a series of

inspection scans. Your work is automatically saved so there is no need to create les and

folders. Instead, the system will use these labels to automatically create les and folder

names for you. For this reason, it is worth entering these labels in a full and formal

manner. The operator’s name will be appended to any reports which are automatically

generated by the system, so it’s best to use your full name. Instrument/Probe. Up to

three probes can be attached to the instrument at any one time. Input connections are

available for Amigo1 probes, the Sensu probes used with PACE and the second generation

Sensu2 probes for Amigo2.

| 13

Software Overview

2. Probe Select allows you to choose which probe and conguration to use. This is described

3. Import Probe copies Amigo1 conguration les found on the root of a USB mass storage

4. View Imported displays all the conguration les imported to the Amigo2’s memory and

5. File Transfer. Transfer les between the Amigo2 and a USB mass storage device.

6. Start/Resume takes the user to the frontstage.

Probe Selection

Up to three probes can be attached to the instrument at any one time. Input connections are

available for Amigo1 probes, the Sensu probes used with PACE and the second generation Sensu2

probes for Amigo2. The Probe Selection dialogue box allows you to choose which probe and

conguration to use. This function can also be accessed from the Backstage/General tab or

the Home Ribbon, as described on "The Home Ribbon", page 21.

Figure 4-2 Probe selection

in more detail on "Probe Selection", page 14.

device to the Amigo2’s memory. This only needs to be done the rst time an Amigo1

probe is used on the instrument, or if a conguration le is changed. In this case the

current conguration le will be overwritten.

allows you to delete any that are no longer required. For example, if you were installing a

new version of the le. For more detail see "View Imported", page 15.

See "File Transfer", page 15 for details.

Many ACFM probes are calibrated for more than one material. If this is the case, the material

Conguration can be selected from the list. The Scan Mode can be set to clock or encoder (if

you have an encoder tted). In clock mode it takes several readings a second, regardless of

whether the probe is moving. In encoder mode it only gathers data when the probe is moving,

then displays the data against distance travelled. Before scanning can start, a connector and

probe must be selected as Active.

14 | www.eddy.com

Software Overview

File Transfer

Transfer les between the Amigo2 and a USB mass storage device. Files can also be deleted

using this function. A new le or “page” of data is created every time Run is pressed. Files are

collected in subfolders labelled by Component name, which are collected within top level

folders labelled by Site name. The lename for each page is based on the Part ID, the type of

Scan (function check [F] or general [G]), the Line (toe 1, weld cap, HAZ, etc) and page number.

For example:

PartID F TO1 001 A Function Check on toe 1, page 1.

PartID G CAP 002 A General inspection scan on the cap, page 2.

PartID G HAZ 003 A General inspection scan on the HAZ, page 3.

Files can be transferred at the component level or the site level, in which case multiple

components, contained within the “Site” folder can be transferred simultaneously.

View Imported

View Imported displays all the conguration les imported to the Amigo2’s memory and allows

you to delete any that are no longer required. For example, if you were installing a new version

of the le. Probe les can be deleted by selecting the relevant item in the list and pressing the

red cross on the touchscreen.

Figure 4-3 View imported probes

| 15

Software Overview

Documentation Section

This section of the backstage allows you to open and read PDFs located in the UserData folder

of the instrument.

Figure 4-4 Backstage view: Documentation

Preference Section

The preference section consists of two tabs, System and Display. System: used to change

units, company logo, date and time, wireless interfaces, etc. Keyboard shortcuts allows the

instrument to be controlled by a USB connected keyboard. A mouse can also be connected if

required.

Figure 4-5 Backstage view: Preferences/System

16 | www.eddy.com

Software Overview

Display: A dark color scheme uses a black background, while a light color scheme is white (note

that the white scheme is best for viewing in bright sunlight while the dark mode may be useful

when viewing in dim conditions). Screen brightness and auto power down can also be adjusted

from this menu.

Figure 4-6 Backstage view: Preferences/Display

Help Section

Software, rmware version and license information are available here as well as the company

contact details, license agreements and Privacy Options. In the event of a malfunction, the

log can be transferred to a USB mass storage device for diagnosis.

Figure 4-7 Backstage view: Help

| 17

Software Overview

Frontstage Layout

The frontstage consists of the ribbon zone, side tabs, main data zones, bottom tabs and

information bar.

Figure 4-8 Frontstage layout

Ribbon zone

Side tabs

Data views

Bottom tabs

Information bar

The Data views can be specied in the Layouts Ribbon. A Standard Layout is shown below. The

frontstage can be further broken down into the following elements:

Figure 4-9 Screenshot of Frontstage

5

6

3

7

1

2

4

1. Bx trace. Top left. Use one nger to scroll on the x-axes and pan the Bx data scale on the

y-axis. Pressing two ngers on the Bx trace zooms and pans through the Bx data.

2. Bz trace. Bottom Left. Use one nger to scroll on the x-axes and pan the Bz data scale on

the y-axis. Touchscreen operates in an identical manner.

3. Buttery plot. Top right. Use one nger to pan the Bx & Bz data scales. Use two ngers to

pinch and zoom.

4. Information pane. Bottom right. Contains information relating to the current page of

18 | www.eddy.com

8 9 10

Software Overview

data, including defects recorded, scan information and notes.

5. Rows: changes the row visibility of array probes. See "Row Visibility Dialogue Box", page

24 for more details.

6. Notes: Append a note to the current page of data using the popup soft keyboard or add

a USB keyboard if required.

7. Pages: View pages (les) in the current work folder. Successfully recorded pages begin

with a grey tick mark. Pages containing a sized defect are marked with an orange circle

around a tick mark. The whole row is highlighted for the current page.

8. Defects: information related to defects sized on the current page. To size a defect, see

"Sizing a Defect", page 26

9. Regions: information related to regions added to the current page, and any associated

comments. See"Regions Dialogue Box", page 28 for more details.

10. Notication center displays system errors, etc.

Pinning Dialogue Boxes

The Rows, Notes, Pages, Defects, Regions and Notication tabs can be xed in place by

pressing the pin symbol at the top right corner of the dialogue box.

Figure 4-10 Pin icon

| 19

Software Overview

Information bar & warnings

A number of information elds run along the bottom of the screen. Any that are suboptimal are

highlighted.

Figure 4-11 Information bar & warnings

1. Scalings OK/Scalings Lost. If the scale is not the same as the probe conguration’s

2. Conguration Factory/Custom or non-factory. The selected probe conguration has or

3. Settings OK/Settings modied. The current setting are/are not recommended by the

4. Rows All/3–8. Some of the rows of an array probe may be hidden. In this example, rows

5. Origin 0 (mm)/22 (mm). If an encoder is used, the origin has been set to a non-zero

6. Direction: The scan direction for the current page. Clockwise, Anticlockwise or Transverse.

7. Scale:

1 2 3 4 5 6 7

default, the Scalings Lost warning appears to warn the operator that the screen scaling

has been changed and the current signals may give a false impression of defect size.

has not been approved for use by the manufacturer.

manufacturer.

3–8 are visible.

position. In this example the origin has been set 22 mm from the datum.

Default. The screen scaling is being set to the default specied for the current probe

conguration.

Fit. The data has been scaled to t neatly on the screen.

WARNING! Large defects may look smaller than they actually are, also small defects

may look larger than they are! The Scalings Lost message will be visible.

Center. The data is being centered on the screen.

Manual. The position and scale of the data have been set manually. If the scale has been

changed, the Scalings Lost warning message will be visible.

20 | www.eddy.com

The Home Ribbon

The Home Ribbon contains the commands necessary for acquiring data.

Figure 4-12 The Home Ribbon

Software Overview

1 2 3 4 5 6 7 8 9 10 11

1. Run begins data collection.

2. Scan function. Function check or general scan.

3. Part ID. This would typically be a sub-component.

4. Line position (HAZ, Weld Cap, Toe1, etc).

5. Scan Type:

Function check. Used to check functionality of equipment.

Ops check. To locate gross defects.

Detection. Typically along the toes of welds

Cap. Detection scan along cap.

Mixed. One or more of the current scans combined onto one page.

Depth. Depth scan for sizing.

Parallel scan. Typically through the HAZ.

Zigzag. Zigzag scan to determine position of crack on the weld.

Sizing. Sizing scan to locate the ends of the crack.

Sizing check scan. Used to check the accuracy of the sizing scan.

6. Scan Direction (Clockwise, Anticlockwise or Transverse).

7. Congure Markers. See"", page 22 for more details.

8. Enter the Coating thickness if it’s non-zero. This will be automatically taken into account

if any defects are sized.

9. Enter an Origin distance and select an automatic end-of-scan increment if required. This

is described in more detail on "", page 23.

10. Select a Probe and conguration. This is described in more detail on "Probe Selection",

page 14.

11. The screen data Scales can be adjusted, as described on "WARNING! Large defects may

look smaller than they actually are, also small defects may look larger than they are! The

Scalings Lost message will be visible.", page 20.

12. Once the data has been collected, the X and Y-eld data can be toggled by pressing the

Field button.

12

| 21

Software Overview

Figure 4-13 Coating thickness dialogue box

The Scanning Ribbon

The following commands are available during data collection:

Figure 4-14 Scanning ribbon

1 2 3 4 5 6 7 8 9

1. Press Stop to end data collection.

2. Pause.

3. Clock/Linear. Adds clock or linear marks to the data. A series of sequentially numbered

vertical lines corresponding to the numbered clock positions running around the

circumference of a pipe or tubular, or linear positions on a at surface. These can be

congured in Home>Markers, as described on "", page 22. These must be congured

before pressing “Run”.

4. General. Adds a series of unnumbered purple vertical lines to the data.

5. Screen Scale Auto-Center, as described on "WARNING! Large defects may look smaller

than they actually are, also small defects may look larger than they are! The Scalings Lost

message will be visible.", page 20.

6. Screen Scale Auto-t.

7. Screen Scale Default.

8. Screen Scale Manual.

9. X and Y Field can be switched during data collection.

22 | www.eddy.com

Software Overview

Conguring Markers

Congure Markers. Pressing the physical A/C button on the left-hand side of the case, while

the instrument is collecting data, adds a series of sequentially numbered vertical lines to the Bx

and Bz traces. For example, if the inspector was inspecting a circumferential weld marked up in

clock positions running from 1 to 12 o’clock, 12 being top dead center, the data could be marked

up accordingly. When the probe passes over one of the clock marks, the operator would press

the A/C key to mark the region of data corresponding to the marked position. The exact sequence

of numbers is congured in the Marker Setup dialogue box, found in Home/Markers.

Figure 4-15 Marker setup dialogue box

1

6

3

4

The default settings assume you are starting at 1 o’clock and ending at 12 o’clock. However this

may not be the case. For example, you may be starting at 9 o’clock, scanning through 12 o’clock

and ending at 2 o’clock. In this case you would want the markers to run in the following sequence:

9, 10, 11, 12, 1, 2. For this conguration you would require the following settings:

1. The numbers are increasing clockwise. This should not be confused with a probe moving

in the clockwise direction.

2. The maximum number in the sequence is 12.

3. The sequence starts with 9.

4. The sequence ends with 2.

5. If the operator then wanted to reverse direction and scan from 2 o’clock, through 12 and

end at 9 o’clock, they would simply press the “Swap” button to recongure the markers.

6. If the operator was inspecting a linear weld, rather than a circumferential weld, then the

numbered sequence would not repeat in a rotational manner. In this case the markers

would be congured to either increase 9, 10, 11, 12, 13, 14… Or decrease: 9, 8, 7, 6, 5…

2

5

| 23

Software Overview

Origin Dialogue Box

Congure next scan Origin. To allow correlation of inspection data to real world datum. Enter

the oset from datum in the Origin eld, or press ‘Use Current’ button to copy the origin value

of the current page. Press OK to save changes.

The new origin value will be applied for next and subsequent scans and represents the origin

value for the rst data point of the page. If you have an encoder, the system can update the

origin automatically at the end of the scan by calculating where the last scan stopped and

assumes that scanning starts from the same position.

Figure 4-16 Rows dialogue box

Row Visibility Dialogue Box

Each row of the array probe consists of a color-coded signal. The “Rows” tab, shown below,

allows the user to hide selected rows. Dragging the tabs (A) reduce or increase the number of

rows visible, while the larger tab (B) can be moved up or down to select the desired rows.

Figure 4-17 Rows dialogue box

24 | www.eddy.com

The Analysis Ribbon

Once data has been collected it can be analysed.

Figure 4-18 The Analysis Ribbon

Software Overview

1 2 3 4 5 6 7 8 9

1. Replay displays the collection of the current page of data as if it were a movie playback.

The replay can be stopped, paused and displayed slower or faster.

Figure 4-19 The Replay Ribbon

2. Size is used for measuring the length and depth of an indication (see "Sizing a Defect",

page 26).

3. Add region is used to highlight sections of data (see page"", page 27).

4. Print Page creates an automated one-page report for the current page of data

(see"Creating an Automated Report", page 29).

5. Auto-Center centers the signals in the middle of the screen, without changing the

screen scalings.

6. Auto-Fit centers the data then changes the screen scaling, so the data lls the screen

without exceeding its borders. Warning! Large defects may look smaller than they

actually are, also small defects may look larger than they are. Signals are shrunk or

expanded to t inside the screen boundaries. If this is the case, the Scalings Lost indicator

will be activated.

7. Default uses the screen scalings specied in the probe’s conguration le.

8. Manual scaling allows the user to readjust the position and size of the signals by pinching

and swiping the touchscreen. This mode is automatically activated when any of the

signals are touched. Warning! Large defects may look smaller than they actually are,

also small defects may look larger than they are. If this is the case, the Scalings Lost

indicator will be activated.

9. X and Y Field toggle. Toggle between the X and Y-eld.

| 25

Software Overview

Sizing a Defect

Once a defect indication has been found, it can be sized from the Analysis Ribbon.

Figure 4-20 Sizing

1. The Size button brings up the defect information dialogue box.

2. You may need to move the defect dialogue box to one side so the Bx and Bz signals are

visible.

3. An area of data is selected by dragging a nger across the Bz trace. This is shown in

green. The ideal place to start the selection is at a point just before the Bz signal begins

to deviate from the background value.

4. The ideal place to end the selection is just after the Bz signal rejoins the background.

5. If this is done correctly, the Bx background value (yellow horizontal line labelled “Bkgd”)

will be in approximately the right position. It can be manually adjusted by touching the

screen.

6. The Bx minimum value (yellow horizontal line labelled “Min”) can also be adjusted by rst

pressing the button consisting of a red horizontal line and a red downward-pointing

arrow.

7. The Bz peak and trough can be adjusted by pressing the button consisting of a red

vertical line and arrows pointing to the left and right.

8. Enter the Length Estimate in the defect dialogue box.

9. Check the Coating Thickness is correct.

10. Add the depth information if it is satisfactory, or press Cancel to clear the current sizing

and start again.

11. This defect can be edited by pressing the Defects tab. See "", page 26 for more detail.

12. The length and depth summary is added to the information pane.

26 | www.eddy.com

Software Overview

Defect Dialogue Box

The defect dialogue box includes the Part ID, line type, estimated length (Bz peak/trough

distance), coating thickness, calculated length and depth, location, minimum and background

Bx value, coil factor and eld used for sizing. Items in the list can be deleted by pressing the red

cross symbol or edited by pressing the green pencil symbol. The numbering of the defects is

chronological.

Figure 4-21 Defects dialogue box

| 27

Software Overview

Adding a Region

Creating a region adds a color coded highlight over the Bx and Bz signals. For example, a signal

feature corresponding to a seam weld could be highlighted in purple.

Figure 4-22 Adding a region

To add a region:

1. Zoom in on your data.

2. Press Add Region.

3. Select an area of data by dragging your nger across either the Bx or Bz trace.

4. Add a region type.

5. Add a comment if required.

6. Press Add to keep the region or Cancel to remove it.

7. The region can be edited by pressing the Regions tab along the bottom of the screen.

Regions Dialogue Box

The regions dialogue box contains information relating to regions added to the current page,

and any associated comments. To add a region, see "", page 27. Information includes region

type, position on the plot, color coding and any user comments. Items in the list can be deleted

by pressing the red cross symbol or edited by pressing the green pencil symbol.

Figure 4-23 Regions dialogue box

28 | www.eddy.com

Software Overview

Creating an Automated Report

An automated report can be generated. This one-page report contains the following information

for the current page of data:

Site, component, date, operator name, etc.

A screenshot of the signals as displayed, zoomed and scaled.

Defects found.

Instrument settings and probe details.

Operator name.

A place for the operator to sign.

Figure 4-24 The Analysis Ribbon

To create a report:

1. Zoom in on the part of the signal of interest. Adjust the scale if necessary.

2. Press Print Page on the Analysis Ribbon to preview the report.

3. To save the report, press one of the Save-To buttons in the preview ribbon (Word, Excel or

PDF). A default le name will be provided, you can accept or change this, then press OK

to save.

4. The report is saved in the same folder as its associated page of data. PDF reports can be

reviewed later in the backstage Documents section for the current selected component

Figure 4-25 The layout ribbon

The layout ribbon has ve options:

1. Standard layout

2. Layout 2

3. Layout 3

4. Layout 4

5. Layout 5

These are described in detail below.

| 29

Software Overview

Standard Layout

The Bx, Bz and buttery plots are arranged in the normal manner. The Y-eld is toggled with the

Field button on the Analysis Ribbon.

Figure 4-26 Standard view

30 | www.eddy.com

Software Overview

Layout 2

C-scans (contour plots) are presented for the Bx and Bz signals if array data available. The

buttery plot is presented in the normal manner.

Figure 4-27 Layout 2

Layout 3

The Bx and Bz traces are positioned on the left. The Bx and Bz C-scans are positioned on the

right. The Y-eld is toggled with the Field button on the Analysis Ribbon.

Figure 4-28 Layout 3

| 31

Software Overview

Layout 4

The X-eld Bx and Bz traces are placed on the left. The Y-eld By and Bz traces are placed on

the right.

Figure 4-29 Layout 4

Layout 5

The X-eld Bx and Bz C-scans are placed on the left. The Y-eld By and Bz C-scans are placed

on the right.

Figure 4-30 Layout 5

32 | www.eddy.com

Software Overview

Manipulating Data Through Touch

The C-scans simultaneously map the data from all rows. Background values are green, lower

values are blue and higher values are red. Measured defects are displayed as yellow rectangles.

In the Standard Layout the Bx and Bz signals can be moved up and down the screen by

touching the buttery and dragging it around the buttery plot. A similar behaviour can be

achieved in other layouts, such as layout 2. In this case, moving the buttery up the screen

moves the color spectrum towards the reds, while dragging it down pulls the C-scan towards

the blues. Pinching and zooming the buttery magnies the depth of the defect on the C-scan.

A combination of moving and resizing the buttery can be used to optimise the C-scan images

before creating a report.

| 33

Chapter 3

Preferences

Managing Preferences

Figure 3-1 System preferences

Preferences

Measurement Units

You can use Amigo2 under the US Customary (imperial) or metric system of measurement units.

To change measurement unit system, tap Imperial or Metric. When you do, measurement units

are adjusted across the software and in your reports.

Company Logo

1. If the logo is already imported, go to step 4. To import a logo in the system, copy the logo

le in a folder named ASSIST\UserData on the root of a USB mass storage device.

2. Plug the USB mass storage device in the QUICK COPY USB port of the Amigo2.

3. Press the QUICK COPY button on the side of the Amigo2.

4. Tap Select Company Logo.

5. Select the logo le, and then tap OK.

Figure 3-2 Selecting a logo

| 35

Preferences

Adjusting the Date and Time of the Amigo2 Instrument

1. In the System preference section of the backstage, tap Change. A dialog box appears

where you can adjust the date, time, and time zone to match requirements.

Connecting your Amigo2 Instrument to a Wireless Network

1. In the System preference section of the backstage, tap Networks.

A dialog box showing all available wireless networks appears.

Note

As of writing, Bluetooth is still unavailable, but will be in future versions.

Figure 3-3 System preferences

2. Tap the desired network.

3. Tap Connect.

4. Input the appropriate user name and password, and then tap OK.

Figure 3-4 Wi-Fi Networks dialog box

Note

Tap Disconnect to break the connection to the wireless network. Tap Forget to remove the login

information of the selected wireless network.

36 | www.eddy.com

Display Preferences

In the Display preferences section of the backstage, you can congure a sleep delay of 1 to 30

minutes. By default, the sleep delay is 15 minutes. If active, once this delay expires, the display

turns o and the power LED goes from green to red.

Figure 3-5 Display preferences

Preferences

To exit, short press the power button, touch the display, or press any keypad button.

| 37

Preferences

38 | www.eddy.com

Chapter 4

Keypad and Keyboard Functions

Keypad and Keyboard Functions

Keyboard Shortcut Keys

The following keyboard shortcuts can be used when a physical keyboard has been connected to

the Amigo2 via one of the USB ports.

Table 4-1 Keyboard shortcut

Amigo2 Function Keyboard Shortcut

Right arrow Right arrow

Down arrow Down arrow

Add clock/linear marker Space

Add general marker Return

Next scan direction set to Anticlockwise A

Next scan direction set to Clockwise C

Next scan direction set to Transverse T

Next scan direction Unset U

Pause/resume acquisition H

Previous page P

Replay begin Y

Replay faster >

Replay slower <

Replay stop S

Scale mode to Center V

Scale mode to Fit F

Scale mode to Probe Default D

Select next keyboard mode K

Select next scale mode F12

Select next view Alt+F7

Show defects Ctrl+D

Show marker setup Ctrl+C

Show notes Ctrl+N

Show pages Ctrl+G

Show regions Ctrl+R

Toggle Clockwise/Anticlockwise W

Left arrow Left arrow

Up arrow Up arrow

Next page N

Run R

Show rows Ctrl+W

Stop S

40 | www.eddy.com

Modifying Keyboard Shortcuts

In the System preferences of the backstage, tap the Keyboard button.

Figure 4-1 Keyboard Shortcuts

Keypad and Keyboard Functions

| 41

Chapter 5

Maintenance and Troubleshooting

Maintenance and Troubleshooting

Maintaining Amigo2

Because of its design, Amigo2 only requires minimal maintenance. Since it has no moving parts,

it also does not require any preventive maintenance on your part. We recommend a regular

inspection of the instrument to ensure it is properly grounded. We also strongly recommend an

annual calibration and a factory-performed preventive maintenance by an ocially qualied

Eddy technician.

Cleaning Amigo2

1. Make sure that the instrument is o and that the power cord is disconnected.

2. To bring the instrument back to its original nish, clean it with a soft cloth.

WARNING!

Warning

Do not spray the instrument with chemical cleansers or water. Doing so may lead to short

circuits and damage to the instrument.

Important

To remove stubborn stains, use a cloth moistened with soft, soapy solution. Do not use

abrasives or strong solvents as they could damage the nish. Wait until the instrument is

completely dry before connecting the power cord or cables.

Updating and Upgrading Software

Before you can perform any software maintenance, you must first meet the following

requirements:

USB mass storage device with a minimum of 4 GB free space

Hardwired Internet connection

There are two ways of updating or upgrading the software:

Standard

1. Connect Amigo2 to a power outlet with the power cable.

2. Turn on Amigo2 and wait for the software to start.

3. Download the *.AmigoUpdate le from our website.

Save the le in an easy-to-remember location on your computer.

4. Copy the *.AmigoUpdate to the root of a USB mass storage device.

5. Once copied, connect the mass storage device to one of Amigo2’s two USB ports A dialog

box appears prompting you to proceed.

Important

Do not connect your mass storage device to the QUICK COPY USB port.

6. Tap Yes.

7. In the list that appears, tap the desired update le, and then tap Update.

Important

If you are performing a complete Amigo2 OS upgrade, perform steps 8 to 10. In the case of

a software update, the instrument restarts automatically.

| 43

Maintenance and Troubleshooting

Figure 5-1 Update dialog box

8. For Yes , press the keypad’s up arrow.

For No, press any other button. You are prompted to conrm again.

9. Press the keypad up arrow again.

The update process starts. This normally takes 5 to 10 minutes, depending on the speed of

your mass storage device. When the process is complete, the system restarts.

10. Activate Windows.

See Activating Windows on page 46 for details.

44 | www.eddy.com

Maintenance and Troubleshooting

System Recovery

1. Connect Amigo2 to a power outlet with the power cable.

2. Make sure Amigo2 is o. If it is not, turn it o.

3. Turn on the instrument.

4. Immediately and simultaneously press the A/C button and the “Previous page” button

(see page 2) until the following appears.

Figure 5-2 Options menu

5. With the keypad arrows, select Enter Eddy System Recovery, and then press the

“Enter” button (see page 2 diagram front).

You are prompted to wait until the following appears.

Figure 5-3 System recovery interface

6. Using the keypad arrows, select Install the factory EddyOS update, keep data.

7. When prompted, press the up arrow of the keypad.

The update process starts. This normally takes between 5 and 10 minutes. When the process

is complete, the system restarts.

8. Activate Windows.

See Activating Windows on page 46 for details.

| 45

Maintenance and Troubleshooting

Activating Windows

Microsoft requires you activate Windows to be able to use it. The activation process is automatic

when you connect Amigo2 to the Internet through an Ethernet cable.

1. Make sure Amigo2 is on and that the software is running.

2. Connect an Ethernet cable to Amigo2.

3. Connect the other end of your Ethernet cable to a network (local area network or other

access point).

4. Wait until a dialog box conrming the activation of Windows appears on screen.

If you do not activate Windows every time you start Amigo2, a message reminds you to do

so. You have 30 days to activate Windows before it locks up.

Known Issue With System Updates/Upgrades

On some units, a blue Windows error screen may appear when you attempt to enter the system

recovery, which can cause the unit to start normally. Try performing the update procedure

again.

46 | www.eddy.com

Maintenance and Troubleshooting

Troubleshooting

Troubleshooting System Updates/Upgrades

No update le found

This appears in the update list or in the system recovery. Make sure that you only have one USB

mass storage device connected to Amigo2. Also make sure that the le is in the root folder of

the device.

Cannot display the options screen

There may be several reasons for this to appear:

You did not press and hold the A/C button and the “Previous page” button seepage 2

long enough

You did not press and hold the correct buttons

You did not press and hold the buttons quickly enough after turning on Amigo2

Try holding the power button for two seconds, and then quickly pressing and holding the

‘’A/C’’ button and the ‘’Previous page’’ button.

Using the system recovery method, Amigo2 restarted normally

or a blue error screen appeared on the screen

Perform the procedure again.

Unable to activate Windows

1. Make sure your Ethernet cable is sound.

2. Make sure that you have Internet access.

3. Make sure you are using DHCP.

4. After connecting the Ethernet cable and to the network, turn on Amigo2.

If you do not see a message warning you Windows is not activated. When it starts, Windows

is activated.

| 47

Maintenance and Troubleshooting

48 | www.eddy.com

Chapter 6

Specications

Specications

General

Dimensions (W×H×D) 355 × 288 × 127 mm (14.0 × 11.3 × 5.0 in)

Weight (with batteries) 6.6 kg (14.5 lb)

Volume 13 L (791 in2)

Power requirements

Power supply Direct VAC (100 W) or onboard batteries

Batteries

Display

Video output HDMI

Storage SSD, 100 GB

Cooling Sealed and fanless

Encoders 2 axes, quadrature

Connectivity

Probe recognition and setup Automatic

Table 6-1 General specications Environmental

Specifications Value

100–240 VAC ± 10%

50–60 Hz

Type

Typical life

Rechargeable lithium-ion, DOT compliant

6–8 hours (with both batteries in instrument)

26.4 cm (10.4 in)

Non-reective (AR coating)

Anti-ngerprint (oleophobic coating)

3 mm (1/8 in), chemically strengthened glass cover

Optically bonded LCD and touchscreen

Passive backlight enhancement

Gigabit Ethernet Wi-Fi, Dual Mode Bluetooth® 2.1,

2.1+EDR,

3.0, 3.0+HS, 4.0 (BLE), USB 2.0 (×3)

Table 6-2 Environmental specications

Specifications

IP rating Designed for IP65

Operating temperature 0–40 °C (32–104 °F)

Operating humidity 95%, non-condensing

Storage temperature -20–60 °C (-4–140 °F)

Storage humidity 95%, non-condensing

Compliance

ASME, EN 61010–1,CE, WEEE, FCC Part 15B, ICES–003,

AS/NZS CISPR 22, RoHS

Value

50 | www.eddy.com

Specications

| 51

Appendix A

Connector Reference

I/O Connector

The I/O connector allows the instrument to send and receive various signals such as the

acquisition start and stop commands, the encoder and rotation synchronization signals, the

relay outputs, etc.

Table 7-1 I/O connector data

Number of contacts 12, female

Manufacturer P/N Fischer DBPU 1031 A012–130

Eddy P/N MACN4090

Suggested cable connector

Table 7-2 I/O connector pinout

Pin Signal Description

1 +5VEXT_2 5V supply output

2 ENC1_PHA Encoder phase A axis 1

3 ENC1_PHB Encoder phase B axis 1

4 ENC2_PHA Encoder phase A axis 2

5 ENC2_PHB Encoder phase B axis 2

6 IN Reserved

7 IN Reserved

8 IN Reserved

9 IN Reserved

10 GND Ground

11 OUT Reserved

12 OUT Reserved

Fischer S 1031 A012–142+

Eddy MACN0238

Connector Reference

Amigo1 Connector (TBD)

SENSU Connector (TBD)

SENSU2 Connector (TBD)

Ethernet Connector

The Ethernet connector is used to connect the Amigo2 to a network through an Ethernet link.

Eddy supplies a high-quality, military-grade Ethernet connector and cable. International

Ethernet standards are used. The connector will facilitate RDAU operation.

Table 7-3 Ethernet connector data

Type RJ45, female

Manufacturer P/N PEI Genesis, Amphenol RJF22B00SCC

Eddy P/N MACN4016

Table 7-4 Ethernet connector pinout

| 53

Connector Reference

Pin I/O

1 Bidirectional Bi_DA+ Bidirectional pair A+

2 Bidirectional Bi_DA– Bidirectional pair A–

3 Bidirectional Bi_DB+ Bidirectional pair B+

4 Bidirectional Bi_DC+ Bidirectional pair C+

5 Bidirectional Bi_DC– Bidirectional pair C–

6 Bidirectional Bi_DB– Bidirectional pair B–

7 Bidirectional Bi_DD+ Bidirectional pair D+

8 Bidirectional Bi_DD– Bidirectional pair D–

Signal Description

Important

Amigo2 must be linked to a workstation with a category 5e, shielded, Ethernet cable or better

of a maximum length of 100 m (328 ft).

HDMI Connector

The HDMI connector is used to output video from Amigo2 to an external display. International

HDMI standards are applied.

Table 7-5 HDMI connector data

Type HDMI, female

Manufacturer P/N Tyco Electronics 2007435-1

Eddy P/N MACN4039

HDMI connector pinout

Pin Signal

1 TMDS Data2+

2 TMDS Data2 Shield TMDS data 2 shield

3 TMDS Data2– TMDS negative data 2

4 TMDS Data1+ TMDS positive data 1

5 TMDS Data1 Shield TMDS data 1 shield

6 TMDS Data1– TMDS negative data 1

7 TMDS Data0+ TMDS positive data 0

8 TMDS Data0 Shield TMDS data 0 shield

9 TMDS Data0– TMDS negative data 0

10 TMDS Clock+ TMDS positive clock

11 TMDS Clock Shield TMDS clock shield

12 TMDS Clock– TMDS negative clock

13 NC Not connected

14 NC Not connected

15 SCL I2C serial clock for data display channel (DDC)

16 SDA I2C serial data line for DDC

17 DDC/CEC/ARC/HEC Ground Grounds for DDC, CEC,ARC, and HEC

18 +5V 5V supply (maximum 0.05A)

19 Hot Plug Detect Hot plug detection pin

Transition minimized dierential signaling

(TMDS)

positive data 2

Description

54 | www.eddy.com

USB Connectors

The USB connectors support USB 2.0. You can use the USB connectors to connect USB-compliant

devices to Amigo2, including external memory, mouse, and keyboard. International USB 2.0

standards are applied.

Table 7-6 USB connector data

Type USB, female

Manufacturer P/N FCi 73725-0110BLF

Eddy P/N MACN4038

Table 7-7 USB connector pinout

Pin Signal Description

1 VCC 5V supply

2 D– Data–

3 D+ Data+

4 GND Ground

Connector Reference

Audio Jack

Table 7-8 Audio jack data

Type USB, female

Manufacturer P/N FCi 73725-0110BLF

Eddy P/N MACN4038

Table 7-9 Audio jack pinout

Pin Signal Description

1 GND Ground

2 Left Left channel

3 Right Right channel

| 55

Connector Reference

56 | www.eddy.com

Appendix B

Using the optional Harness

Using the optional Harness

Adjusting the Harness

Harnessing Amigo2 requires a number of specic adjustments so that you feel comfortable

wearing the harness.

Adjusting the Harness to your Body

1. Grab the harness shoulder straps and slip it over your shoulders as you would with a jacket.

Figure 8-1 Slipping the harness on

2. Verify the t of the harness.

Visualize working with Amigo2 before making any adjustments to the shoulder straps and

height of the belt. Slip out of the harness.

58 | www.eddy.com

Using the optional Harness

3. Use the underarm straps and shoulder blade rings to adjust the t of your shoulder

straps. You may need to perform this adjustment several times to get the proper t.

Figure 8-2 Adjusting the shoulder straps

5. Use the back and side belt straps to adjust the height of the harness’ belt to suit your

body type. You may need to perform this adjustment several times to get the proper t.

Note

Your belt’s height determines the lowest position of Amigo2. Adjust this height so that the

display of the instrument is easy to see—for that, the belt could end up higher than your

hips.

Figure 8-3 Adjusting the belt’s height

| 59

Using the optional Harness

6. Once your belt and shoulder straps are adjusted, clip and tighten the chest straps.

Figure 8-4 Securing the chest straps

7. Secure the belt around your waist, according to the height you have adjusted it.

Figure 8-5 Securing the belt

8. Make sure that the harness ts snuggly.

9. Make sure that the harness’ shoulder anchor straps are loose.

60 | www.eddy.com

Figure 8-6 Shoulder anchor straps

Using the optional Harness

10. Unfasten the two straps at each end of the shoulder anchor straps. Place them within

hands reach. You will need them.

Figure 8-7 Unfastening the straps

11. Sit down.

12. Place Amigo2 horizontally in your lap.

13. Slip the looped portion of the strap removed above in the hook of one of the two upper

Amigo2 bumpers, as illustrated.

Note

Illustrated here is the harness with the Reddy. Manipulations on Amigo2 are the same.

| 61

Using the optional Harness

Figure 8-8 Sliding strap loop through bumper hook

14. Slip the clip through the strap hoop, and then pull to tighten into place, as illustrated.

Figure 8-9 Securing anchor strap

15. Repeat the previous two steps for the opposite upper bumper.

Note

You can also secure the straps to the bumpers in a more elegant and less easy-to-remove

fashion, as illustrated here.

Figure 8-10 Alternative method of securing anchor strap to bumper

62 | www.eddy.com

Using the optional Harness

16. Locate the anchor strap on the harness’s belt.

Figure 8-11 Anchor strap on harness belt

17. Open the battery compartment door and slip the male buckle of the anchor strap, as

illustrated.

Figure 8-12 Slipping male buckle through bumper

| 63

Using the optional Harness

18. Mate the male buckle to its female counterpart.

Figure 8-13 Mating battery compartment side anchor strap

19. Close and secure the battery compartment door.

Figure 8-14 Closing battery compartment door.

20. Repeat the procedure for the opposite belt anchor strap (no door to open).

21. Adjust the length of the anchor straps until comfortable.

64 | www.eddy.com

Using the optional Harness

22. Mate the left male buckle of the shoulder anchor strap to its female counterpart.

Figure 8-15 Mating shoulder anchor strap

23. Repeat for the opposite shoulder anchor strap.

24. Tighten each shoulder anchor straps to achieve the desired view angle for Amigo2.

Figure 8-16 Tightening shoulder anchor straps

Note

Use the belt strap to hook your probe’s cable.

Figure 8-17 Belt-slinging probe cable

| 65

The information in this document is accurate as of its publication. Actual products may dier from

those presented herein. © 2019 Eddy UK LTd. Eddy, TSC, Amigo2, PACE, U41 and their associated

logos are trademarks or registered trademarks of Eddy in the United States and/or other countries.

Eddy reserves itself the right to change product oerings and specications without notice.

www.eddytechnologies.com info@eddy.com

2019-06

Loading...

Loading...