Eddyfi technologies Lyft User Manual

Corrosion Assessment Redened

User’s

Manual

ii | www.eddy.com

Contents

General Precautions and Conventions

General Precautions x

Safety Precautions x

Conventions xi

Acronyms xii

EMC Directive Compliance xii

Calibration and Warranty Seals xii

Limited Warranty xiii

Copyrights xiii

Lyft System Overview

Introducing the Lyft System 2

Positioning Lyft 8

Removing the PECA Probe Encoder 9

Calibrating PECA Probes 9

Starting Lyft 9

Shutting Down Lyft 10

Connecting Probes 10

Batteries 10

Software Overview

Introducing the Lyft Software 14

Workow Overview

Typical Inspection Workow 28

Creating/Selecting a Project 29

Creating/Opening a Component 29

Adding/Editing a Scan Zone 30

Creating a Setup 31

Applying SmartPULSE 33

Acquiring Data 35

Recalibrating the Wall Thickness 36

Adding Indications to a Report 37

Generating a Report 38

Managing Data 38

Enabling and Disabling the Multi-Touch Display 40

Remote Control Reference 41

Lyft Pro Software

Lyft Pro 46

| iii

Preferences

Managing Preferences 50

Keypad and Keyboard Functions

Keyboard Shortcut Keys 54

Maintenance and Troubleshooting

Maintaining Lyft 56

Updating and Upgrading Software 58

Troubleshooting 60

Specications

General 62

Environmental 62

Probes 62

Performance 63

Connector Reference

PEC Connector 66

I/O Connector 66

Ethernet Connector 66

HDMI Connector 67

USB Connectors 67

Audio Jack 68

Using the Optional Harness

Adjusting the Harness 70

Setting Up the Extension Pole

Setting Up the Extension Pole 78

Using the Array Probe Straps

Adjusting the Probe Curvature 82

Lyft Software & Service Plans/Lyft Software Licensing Terms

Lyft Software and Service Plans/Lyft Software Licensing Terms 88

iv | www.eddy.com

Figures

Figure 1 PECA probe 7

Figure 2 Lyft in horizontal position 8

Figure 3 Lyft in tilted position 8

Figure 4 PECA probe encoder removal 9

Figure 5 Shutting down Lyft 10

Figure 6 Optional battery charger 11

Figure 7 Backstage view: General 14

Figure 8 Backstage view: Scan Area 15

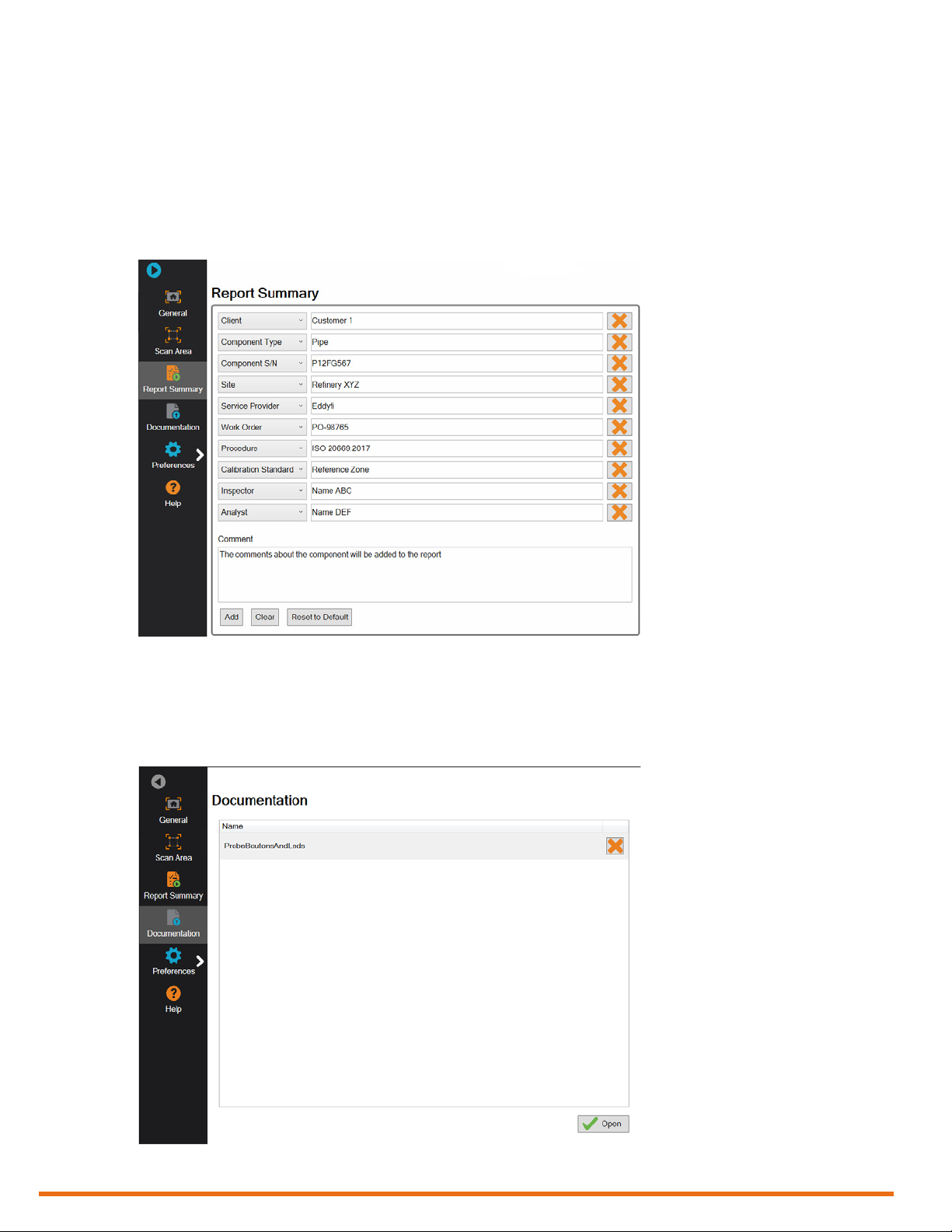

Figure 9 Backstage view: Report Summary 16

Figure 10 Backstage view: Documentation 16

Figure 11 Backstage view: Help 17

Figure 12 Front-stage view 18

Figure 13 Pulsed eddy current array A-scan view 19

Figure 14 Information view 20

Figure 15 Home ribbon 22

Figure 16 Setup ribbon 23

Figure 17 Layout ribbon 23

Figure 18 Current A-scan view ribbon 24

Figure 19 Current information view ribbon 24

Figure 20 Current C-scan view ribbon 25

Figure 21 Analysis Ribbon 25

Figure 22 Edge Smoothing dialog box 26

Figure 23 Typical inspection workow 28

Figure 24 Open dialog box 29

Figure 25 Create Component dialog box 29

Figure 26 Open dialog box 30

Figure 27 Add Scan Zone dialog box 30

Figure 28 Probe selection 31

Figure 29 Scan denition 31

Figure 30 SmartPULSE dialog box 33

Figure 31 PEC Autoset dialog box 33

Figure 32 Wall Thickness Calibration dialog box 34

Figure 33 Repeatability Optimization dialog box 34

Figure 34 Wall Thickness Calibration dialog box 36

Figure 35 Placing cursor over target defect 37

Figure 36 Add indication dialog box 37

| v

Figure 37 Indication added 37

Figure 38 Generate Report dialog box 38

Figure 39 Component Transfer dialog box 39

Figure 40 Project Transfer dialog box 39

Figure 41 Help section 40

Figure 42 Setup tab 41

Figure 43 External Path Selection dialog box 46

Figure 44 Scan Area section 47

Figure 45 Calibration Propagation dialog box 47

Figure 46 Selecting an output in a C-scan 48

Figure 47 CWT% C-scan 48

Figure 48 System preferences 50

Figure 49 Selecting a logo 50

Figure 50 System preferences 51

Figure 51 Wi-Fi Networks dialog box 51

Figure 52 Display preferences 52

Figure 53 Keyboard Shortcuts dialog box 54

Figure 54 Encoder and replacement clamp ring 56

Figure 55 Pliers in expanding conguration 57

Figure 56 Clamp ring sitting on plier 57

Figure 57 Clamp ring installation 57

Figure 58 Clip-on encoder protective cap 58

Figure 59 Update dialog box 58

Figure 60 Options menu 59

Figure 61 System recovery interface 59

Figure 62 Slipping the harness on 70

Figure 63 Adjusting the shoulder straps 71

Figure 64 Adjusting the belt’s height 71

Figure 65 Securing the chest straps 71

Figure 66 Securing the belt 72

vi | www.eddy.com

Figure 67 Shoulder anchor straps 72

Figure 68 Unfastening the straps 73

Figure 69 Sliding strap loop through bumper hook 73

Figure 70 Securing anchor strap 73

Figure 71 Alternative method of securing anchor strap to bumper 74

Figure 72 Anchor strap on harness belt 74

Figure 73 Slipping male buckle through bumper 74

Figure 74 Mating battery compartment side anchor strap 75

Figure 75 Closing battery compartment door. 75

Figure 76 Mating shoulder anchor strap 75

Figure 77 Tightening shoulder anchor straps 76

Figure 78 Belt-slinging probe cable 76

Figure 79 PEC probe supports and screws 78

Figure 80 Securing supports to PEC probe 78

Figure 81 Sliding PEC probe on extension pole head 79

Figure 82 Securing PEC probe to extension pole head 79

Figure 83 Running PEC probe cable through pole hoops 79

Figure 84 Connecting PEC probe connector to extension pole remote control 80

Figure 85 Locked latches 82

Figure 86 Unlocked latches 82

Figure 87 Probe on a pipe with curvature locked 83

Figure 88 Carriage installed on straps 83

Figure 89 Handle installed on element 6 84

Figure 90 Installed erasable marker 84

Figure 91 Grid-As-U-Go the PECA probe 85

Figure 92 Installed Grid-A-U-Go 85

| vii

Tables

Table 1 Lyft single-element probe status LEDs 6

Table 2 PECA probe status LEDs 7

Table 3 Multi-touch behavior in C-scan view 21

Table 4 Analysis mode remote control reference 41

Table 5 Grid mapping data acquisition remote control reference 41

Table 6 Dynamic mode data acquisition remote control reference 42

Table 7 SmartPULSE remote control reference 42

Table 8 Survey mode remote control reference 42

Table 9 PEC Autoset remote control reference 42

Table 10 Wall thickness calibration remote control reference 43

Table 11 Repeatability optimization remote control reference 43

Table 12 Keyboard shortcut 54

Table 13 General specications 62

Table 14 Environmental specications 62

Table 15 Single-element probe specications 62

Table 16 Array probe specications 63

Table 17 Performance 63

Table 18 I/O connector data 66

Table 19 I/O connector pinout 66

Table 20 Ethernet connector data 66

Table 21 Ethernet connector pinout 66

Table 22 HDMI connector data 67

Table 23 HDMI connector pinout 67

Table 24 USB connector data 67

Table 25 USB connector pinout 67

Table 26 Audio jack data 68

Table 27 Audio jack pinout 68

viii | www.eddy.com

General Precautions and Conventions

General Precautions and

Conventions

| ix

General Precautions and Conventions

General Precautions

The following safety precautions are to be observed at all times when using Lyft®. Make sure that you

review them before turning on the system.

• Keep this document in a safe place for future reference.

• Carefully follow the installation and operation procedures detailed herein.

• Respect the safety warnings on the instrument and in this document.

• Lyft should only be used by qualied personnel.

• When transporting Lyft, it is your responsibility to make sure that you apply the safety precautions

dictated by the relevant local governing bodies.

• Always connect the power supply to a properly grounded receptacle, extension cord, or power

bar. Grounding a single conductor of a two-conductor outlet is not sufcient protection for Lyft.

• Only connect the system to a power source corresponding to the type indicated on the rating plate.

• If you use the system in a manner that deviates from that specied by Eddy, the protection

provided on the equipment may be rendered null and void.

• Do not use substitute parts or perform unauthorized modications to the system.

• Service instructions, when applicable, are intended for trained service personnel only.

• Always make sure that the system is unplugged from any power supply before servicing.

• To avoid dangerous electric shock, do not perform any service on the system unless qualied to do

so. If you encounter any problems or have questions regarding this system, contact Eddy or an

authorized Eddy representative.

Safety Precautions

Observe the following safety precautions scrupulously when using Lyft.

Rear Stand

Because Lyft is a portable system, it is designed to be used under tough conditions. It is, however, not

indestructible. To avoid damaging Lyft, use its rear stand when operating Lyft in a tilted position. Do not

use Lyft in the upright position, as it may topple over or fall off the work surface.

x | www.eddy.com

General Precautions and Conventions

Conventions

Typographical

The following typographical conventions are used throughout this document:

Italic

Used for le names and paths.

Bold

Used to indicate menu items, named user interfaces, and place emphasis on specic words or phrases.

Items in bold type are capitalized to reect the actual interface.

SMALL CAPITALS

Used to indicate instrument interface indications.

Marking and Symbols

The following symbols ap p e ar on t he instr u m e nt a nd p e rt a i n to safet y re g u l ations that shou l d be care fully

observed:

This label is used as a general warning sign. It indicates that you should refer to this user’s

guide to obtain the necessary information for proper protection of the instrument and its

users.

This label is used to indicate high voltage. It draws your attention to the presence of

hazardous voltages (within the product enclosure or accessible externally) that may

constitute a risk of electric shock to persons. Always refer to the user’s guide to ensure

proper protection and safety.

The RoHS compliance logo signies that this product complies with the Restriction of

Hazardous Substances directive 2002/95/EC. This directive restricts the use of lead,

mercury, cadmium, hexavalent chromium, polybrominated biphenyl, and polybrominated

diphenyl ether in certain classes of electrical and electronic units as of July 1, 2006.

This label acts as a reminder that you should dispose of this system in accordance with your

local Waste Electrical and Electronic Equipment (WEEE) regulations. This system was

manufactured to the high quality standards of Eddy to ensure safe and reliable operation

when it is used as stated in this document. Due to its nature, this instrument may contain

small quantities of substances known to be hazardous to the environment and to human

health if released in the environment. As such, systems falling under WEEE regulations

should not be disposed of in the public waste stream.

| xi

General Precautions and Conventions

Safety Indications in This Document

The safety indications in this document are intended to ensure your safety and the integrity of the

system.

Warning

The warning indication calls your attention to a procedure or a practice (or the like) that, if performed

incorrectly, can result in injury. Do not ignore warning indications — make sure that you understand the

condition before proceeding.

Caution

The caution indication calls your attention to a procedure or practice (or the like) that, if performed

incorrectly, can result in material damage, loss of data, or both. Do not ignore caution indications —

make sure that you understand the condition before proceeding.

Important

Calls attention to information important to completing tasks.

Note

Calls attention to an operating procedure, a practice, or the like that requires special attention. Notes

also indicate useful related, but parenthetical information that is unessential.

Acronyms

PEC: Pulsed eddy current

PECA: Pulsed eddy current array

CWT: Compensated wall thickness

EMC Directive Compliance

FCC Compliance (USA)

This equipment was tested and found to comply with the limits for a Class A digital device, pursuant

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the user’s

guide, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case you will be required to correct the

interference at your own expense.

ICES Compliance (Canada)

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

AS/NZS Compliance (Australia/New Zealand)

This device complies with Australia and New Zealand AS/NZS 4252.2 (IEC 61000-6-4) and AS/NZS

61000-6-2 (IEC 61000-6-2).

Calibration and Warranty Seals

The calibration seal is at the back of the instrument. Lyft is also equipped with a warranty seal.

Important

Broken seals void the calibration certication and product warranty.

xii | www.eddy.com

General Precautions and Conventions

Limited Warranty

Eddy NDT, Inc. warrants the hardware to be free of any defects in materials or workmanship for a

period of twelve (12) months from the date of delivery, under normal use and service. These warranties

are limited to the original purchase of the product and are not transferable.

Eddy NDT, Inc. will repair or replace any product component or documentation, at its option and at

no additional charge, if found defective within the warranty period. The purchaser is responsible for

returning the product to Eddy NDT, Inc.

Eddy NDT, Inc., will not be held responsible in any way whatsoever for damage resulting from improper

installation, accident, misuse, or from service or modication of the product by anyone other than Eddy

NDT, Inc., or an authorized Eddy NDT, Inc. service center.

Eddy NDT, In c . wil l no t b e h eld res p onsi b l e i n a ny w ay what soever for di r e ct , indire c t , s peci a l, inc i d ent al,

or consequential damages resulting from possession, use, improper installation, accident, service,

modication, or malfunction of the product (including, without limitation, damages for loss of business

prots, business interruption, loss of business information, or other pecuniary loss). Eddy’s total shall

in no event exceed the purchase price of the applicable item(s).

This warranty is in lieu of all other warranties, whether oral, written, expressed, or implied, including

any warranty of merchantability or tness for a particular purpose, and no other representation or

claims of any nature shall be binding on or obligate Eddy NDT, Inc.

This agreement is governed by the laws of the province of Québec, Canada. Each of the parties hereto

irrevocably attorns to the jurisdiction of the courts of the province of Québec and further agrees to

commence any litigation which may arise hereunder in the courts located in the judicial district of

Québec.

Copyrights

This document and the product and programs it describes are protected by the Copyright Act of Canada,

by laws of other countries, and by international treaties, therefore may not be reproduced, in whole or

in part, whether for sale or not, without prior written consent from Eddy NDT, Inc. Under copyright

law, copying includes translation in other languages and formats.

© Eddy NDT, Inc., 2018

This document was prepared with particular attention to usage to ensure the accuracy of the information

it contains. It corresponds to the version of the product manufactured prior to the date appearing on

the back cover. There may, however, be some differences between this document and the product, if

the product was modied after publication.

The information contained in this document is subject to change without notice.

| xiii

General Precautions and Conventions

xiv | www.eddy.com

Chapter 1

Lyft System Overview

Lyft System Overview

| 1

Lyft System Overview

Introducing the Lyft System

Thank you for purchasing the Eddy® Lyft® system. This chapter offers an overview of the system, its

components, and probes.

What is in the Box

Lyft comes with the following standard accessories:

• Two, high-capacity batteries

• One power adapter (100–240 V)

• Power cords (one for North America, one for Europe)

• User documentation

• Stylus

• Transport case

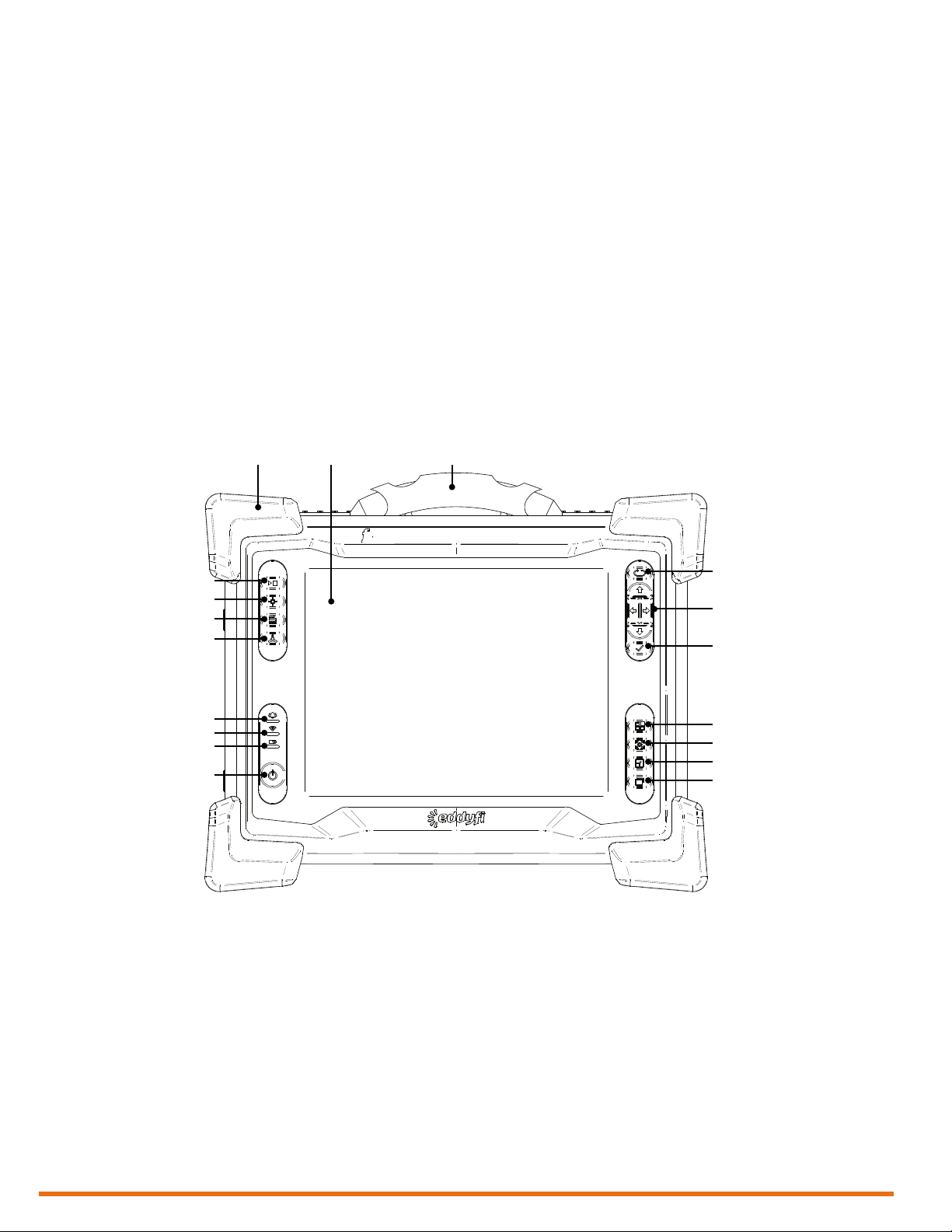

Instrument Overview

Front

10 119

8

7

6

5

4

3

2

1

12

13

14

15

16

17

18

1. Power button

2. Battery indicator

2 | www.eddy.com

Use to turn the instrument on and off. The

power indicator at the center of the button

behaves as follows:

• Green: Lyft is on

• Blin k ing yell o w /or a nge: Ly f t is on st andby

• Unlit: Lyft is off

Displays the state of the batteries when the

instrument is on. Depending on the power

mod e ( DC or bat t er y), th e ind i ca t or be hav e s

differently:

DC power

• Green: batteries fully charged

• Blinking green: batteries charging

• Red: battery or charger error

• Unlit: no batteries

Battery power

• Unlit: remaining charge over 40 %

• Orange: remaining charge 20–40 %

• Blinking yellow: remaining charge less

than 20 %

• Red: battery error

Lyft System Overview

3. Wi-Fi indicator

Displays the Wi-Fi status. When the

indicator is lit, the Wi-Fi is enabled. When

it is off, the Wi-Fi is disabled.

4. Alarm indicator

Used to display user- programmed errors.

The indicator remains unlit until it detects a

predened error condition, at which time it

lights red.

5. Wall thickness calibration button

Use to perform a wall thickness calibration

on the nominal thickness. A short press

calibrates on a new point, while a long press

calibrates on the data at the cursor’s

location.

6. Index button

Use to increment the index line during data

acquisition.

7. Get point button

Only use during data acquisition in gridmapping mode. It allows performing a

measurement at the cursor coordinates.

8. Start/Stop acquisition button

Use to start or stop data acquisition.

11. Handle

Use this handle to carry Lyft.

12. Keypad arrow mode selection/Disable

touchscreen button

Press to select the operation mode of the

keypad arrows (see 13). Long press this

button to enable or disable the touchscreen

(depending on its state). Follow the

instructions on the screen to complete the

operation.

13. Keypad arrows

Use these arrows to navigate the Lyft

software interface according to the selected

mode.

14. Enter button

Unused at this time.

15. Change active view button

Press to activate a different view than the

one currently active.

16. Data display button

When PECA probes are connected to the

instrument: used to activate probe guides in

C-scans. Unused with single-element

probes.

9. Heavy-duty bumpers

The four corner bumpers provide shock

absorption and support Lyft at an angle

when it is set on a at surface. The bumpers

are also hooked for harnessing. For details

about harnessing, see page 70.

10. Multi-touch display

10.4”, non-reective, backlit, high-resolution

display.

17. Maximize/Minimize view button

Use to maximize or minimize the active

view.

18. Change layout button

Use to change the Lyft software layout to

another predened one.

| 3

Lyft System Overview

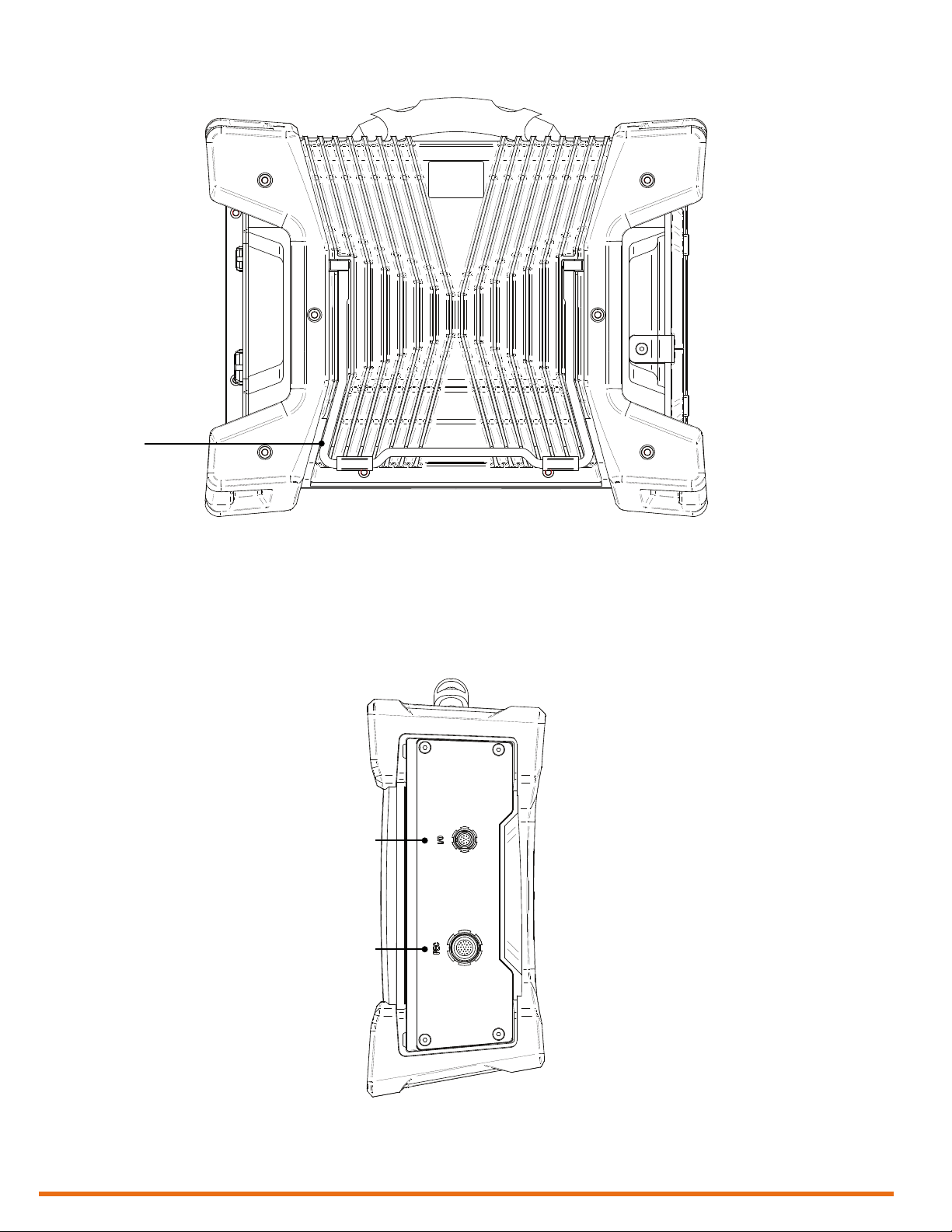

Rear

1

1. Instrument stand

The stand retracts outward to hold Lyft at

an angle, preventing the instrument from

tilting over horizontally.

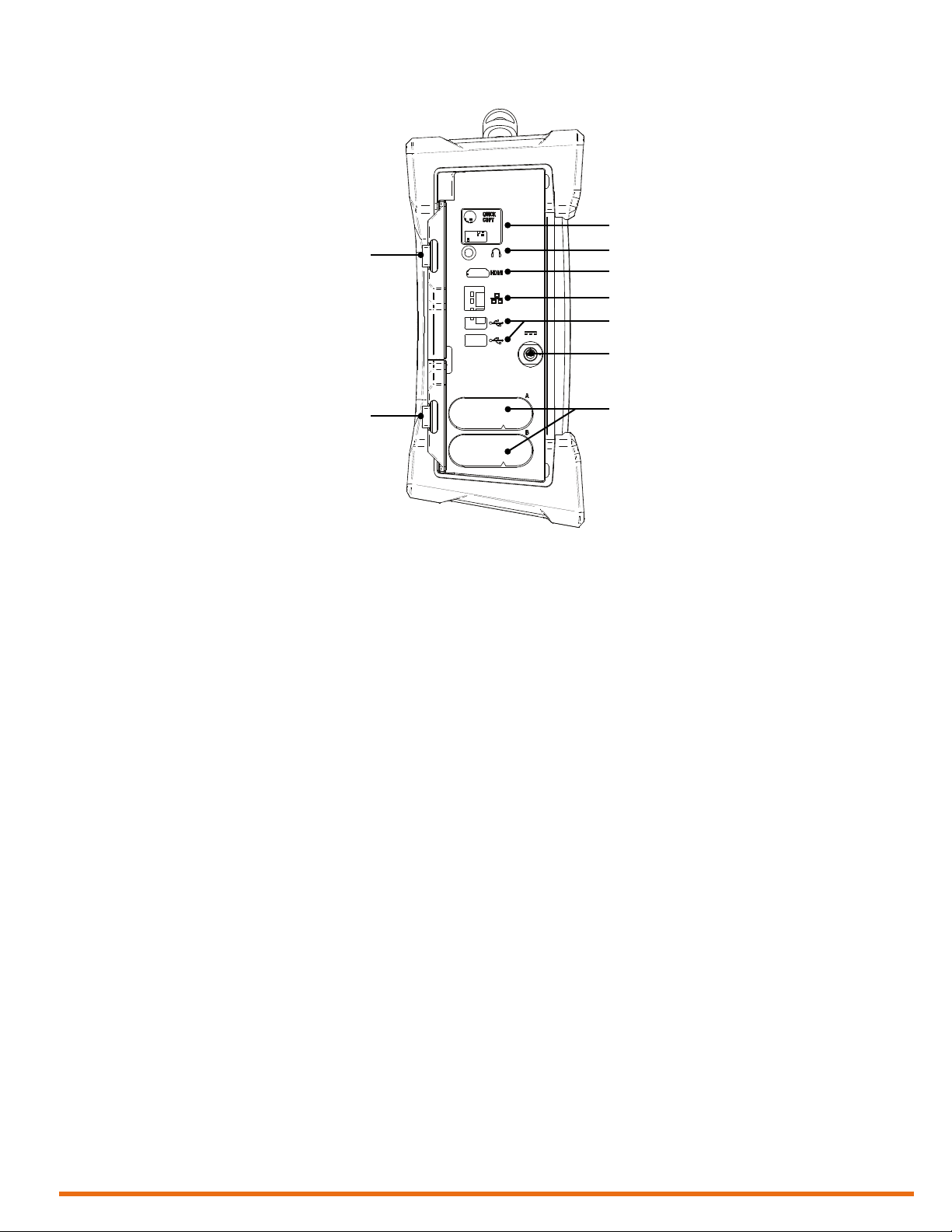

Right

1

2

1. I/O connector

4 | www.eddy.com

Used to communicate with the probe’s

encoder, for example.

2. PEC connector

Con n e ct yo u r P EC pro b es to this co n nec tor.

Left

Lyft System Overview

2

1

3

4

5

6

7

9

1. Protective connector door

Protects the Lyft connectors from the

elements when they are unused.

2. Quick Copy

Use to transfer all your inspection data to a

USB mass storage device.

3. Audio connector

Use to plug a headset to Lyft.

4. HDMI® connector

Use to connect an external monit or to Ly f t.

5. Network connector

Use to connect Lyft to a local area network

(LAN). The connector is equipped with two

indicators with the following behaviors:

Connection indicator (upper)

8

Connection speed indicator (lower)

• Amber : op e r ating as a gig a b i t co n n e ction

(1 G b p s)

• Green: operating as a 100 Mbps

connection

• Off: operating as a 10 Mbps connection

6. USB 2.0 connectors

Use to connect USB devices to Lyft such as

a mouse or an external disk drive.

7. Power connector

Use the supplied power cord to operate

Lyft and recharge its batteries.

8. Battery compartments

Insert the supplied batteries into the

compartments. For details about batteries,

see Batteries on page 10.

• Green: communication established with

the network

• Blinking green: activity between Lyft and

the network

• Unlit: no link to the network

9. Protective battery compartment

door

Protects the battery compartments from

the elements.

| 5

Lyft System Overview

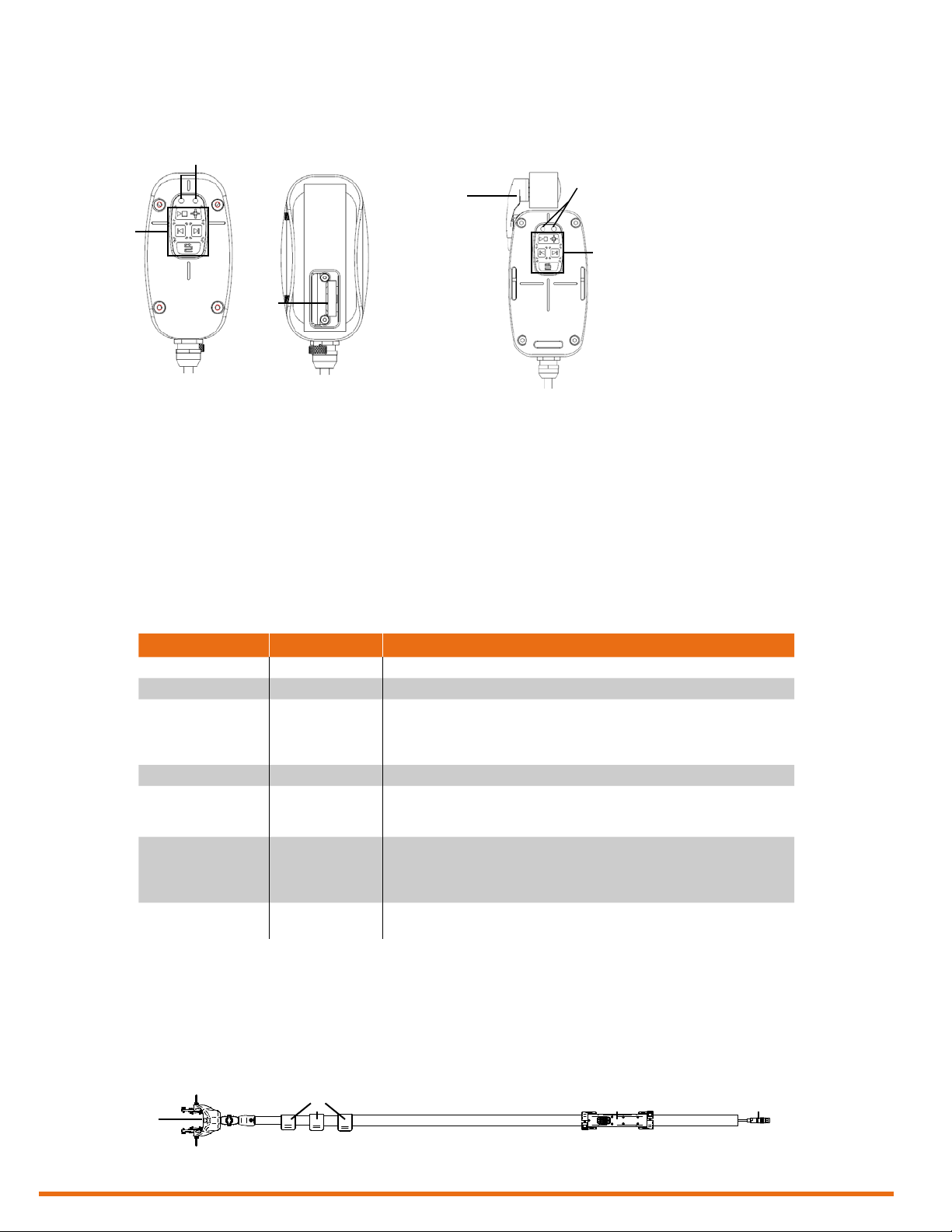

Single-Element Probe Overview

Lyft single-element probes come in three sizes: small, medium, and large. They feature the following

components.

2

First-generation probes Second-generation probes

1. Status LEDs

2. Remote controls

Table 1 Lyft single-element probe status LEDs

1

3

The green LED on the left and the red LED

on the right convey information to users, as

outlined below.

Used to perform a variety of operations

without handling the instrument. See page

41.

4

3. Built-in encoder

First-generation probes are equipped with a

high- precision, 20.53 counts/mm encoder.

4. Clip-on encoder

Second-generation probes are equipped

with high-precision, 16.04 counts/mm

encoder.

1

2

Green Red Status

Off Off Probe unconnected or unable to receive data.

1 Hz blinking (slow) Off Analysis mode: Probe detected and waiting for action.

10 Hz blinking (normal) Off Acquisition mode: Data is being acquired.

20 Hz blinking (fast) Off Dynamic acquisition mode: The probe’s position is outside the scan zone.

20 Hz blinking (fast) 20 Hz blinking (fast) PEC Autoset: Routine failed or was canceled.

On Off Grid mapping acquisition mode: Probe ready to perform acquisition.

Off On Dynamic acquisition mode: Probe moving too quickly on sample.

PEC Autoset: Routine is running.

Wall thickness calibration: Routine is running.

Repeatability optimization: Routine is running.

Wall thickness calibration: Routine failed or was canceled.

Repeatability optimization: Routine failed or was canceled.

PEC Autoset: Probe ready to perform routine.

Wall thickness calibration: Probe ready to perform routine.

Repeatability optimization: Probe ready to perform routine.

Other circumstances: Error occurred during requested operation.

Single-Element Probe Accessories

For details about these accessories, refer to the PEC probe catalog.

Single-Element Extension Pole Overview

For details about how to install a single-element or splash zone probe on the extension pole, see Setting

Up the Extension Pole on page 78.

1

2 3 4

1. Probe holder

2. Extension rings

6 | www.eddy.com

3. Remote control (see above)

4. PEC connector

Lyft System Overview

Encoder Element 1 Element 2 Element 3 Element 4 Element 5 Element 6

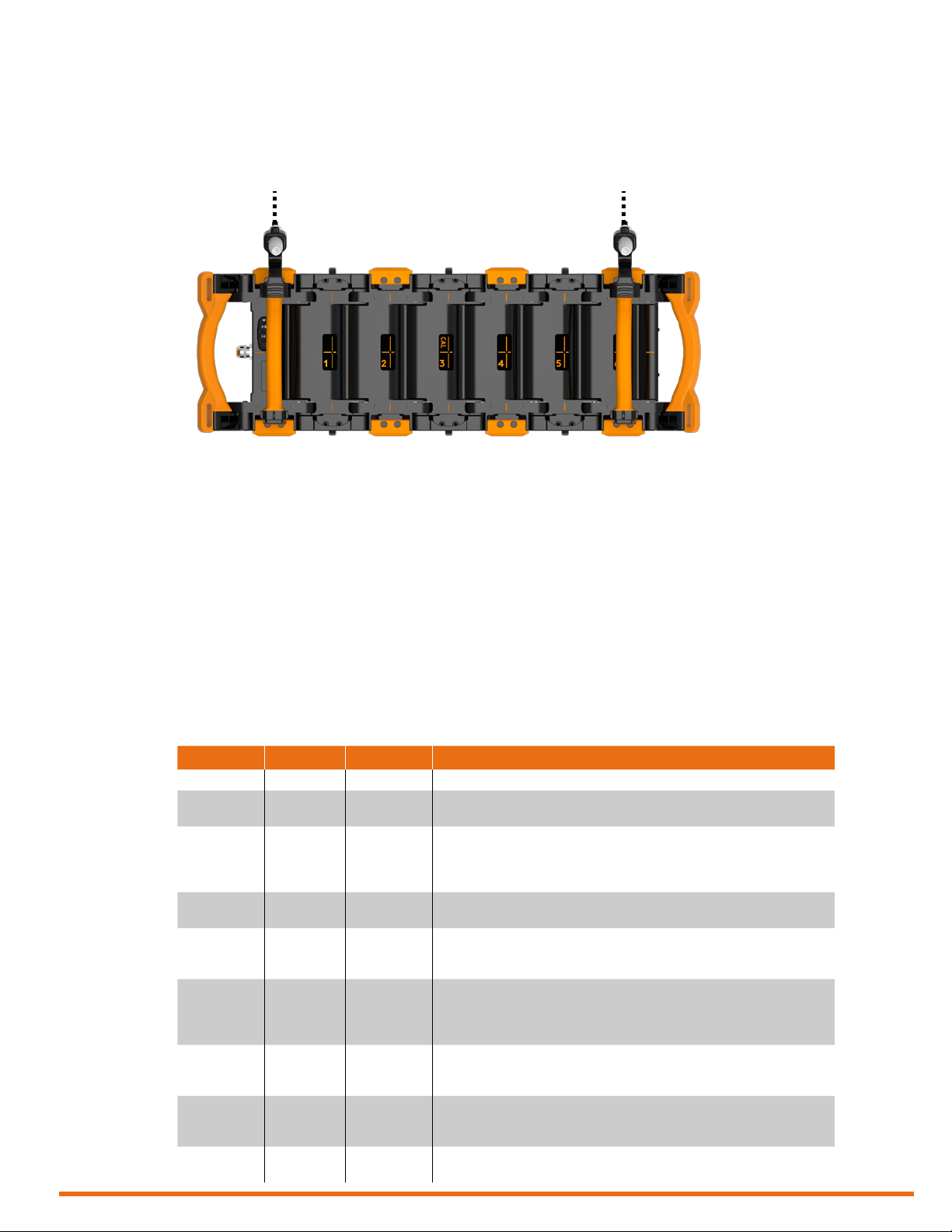

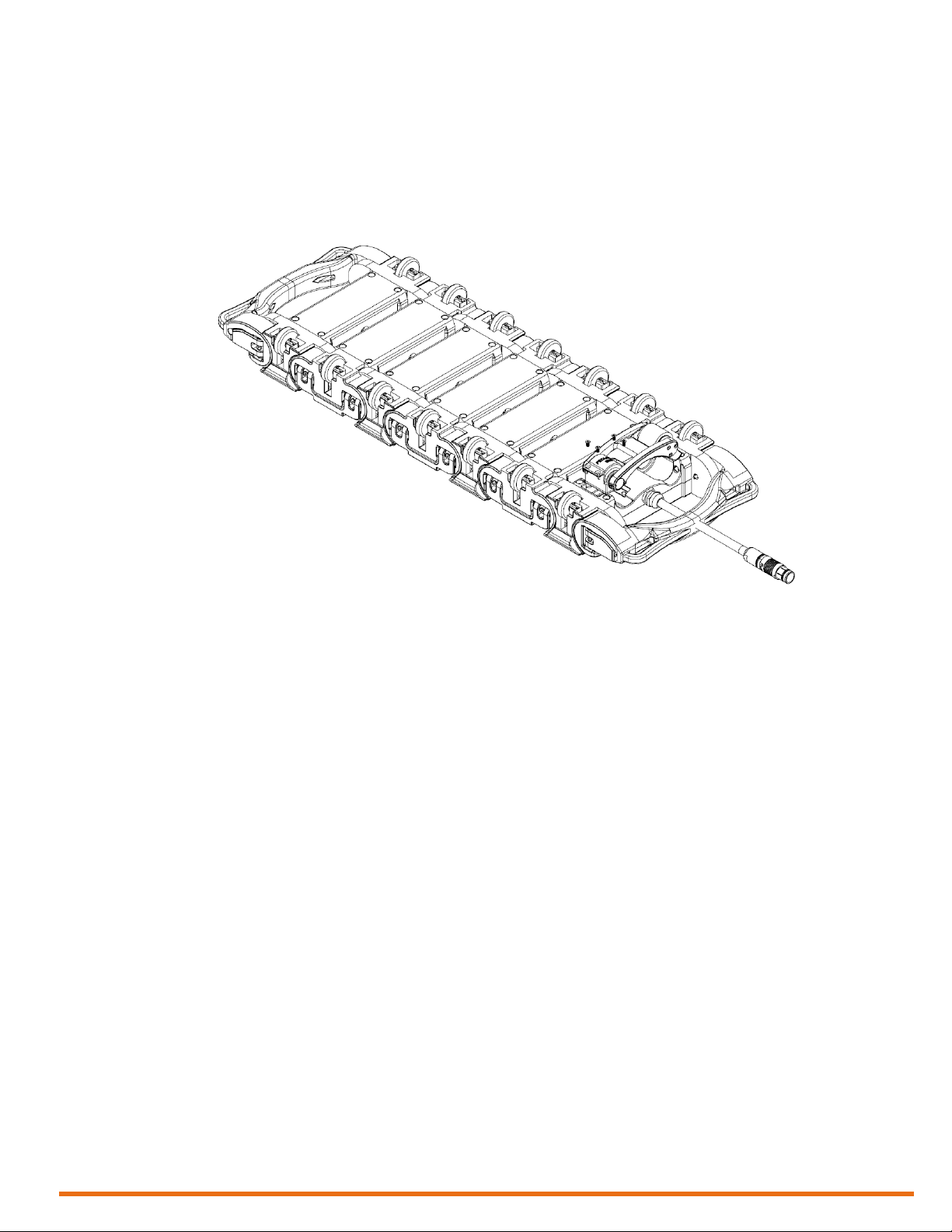

PECA Probe Overview

The PECA-6CH-MED-XXX-GA and PECA-6CH-MED-XXX-GDA 6-element PECA probes are capable

of a single-pass coverage of 457 mm (18 in) in grid or high-resolution, dynamic mode.

Figure 1 PECA probe

PECA probes roll on wheels that lift them off 12.7 mm (0.5 in) to ease inspection on insulated pipes with

straps and buckles securing the insulation. Do not add this additional liftoff to the insulation thickness

when calculating your probe’s footprint or smallest detectable defect. You can remove the wheels to

use the probe in restricted-access situations.

PECA probes are also designed to wrap around curved surfaces like pipes. Once curved, lock the shape

by pressing the locking handles toward the probe’s body. You will get the best sizing results when all the

probe elements are curved by the same amount, forming a circular arc. Positioning marks are visible on

the probe to validate the relative curvature of all array elements. To see how to lock and unlock the

probe body, see appendix D.

The probes are equipped with the same buttons as single-element probes. The red, green, and blue LEDs

indicate the operational status of the probes.

Table 2 PECA probe status LEDs

Green Red Blue Status

Off Off – Probe unconnected or unable to receive data.

1 Hz blinking

(slow)

10 Hz blinking

(normal)

20 Hz blinking

(fast)

20 Hz blinking

(fast)

On Off – Grid mapping acquisition mode: Probe ready to acquire.

Off On – Dynamic acquisition mode: Encoder is moving. Blue LED is off if red LED

– – On Dynamic acquisition mode: Typically used to conrm that the encoder is

– – Off Dynamic acquisition mode: Encoder is stopped.

Off – Analysis mode: Probe detected and waiting.

Off – Acquisition mode: Data being acquired.

Off – Dynamic acquisition mode: The probe’s position is outside the scan zone.

20 Hz blinking

(fast)

20 Hz blinking

(fast)

PEC Autoset: Routine running.

Wall thickness calibration: Routine running.

Repeatability optimization: Routine running.

PEC Autoset: Routine failed or canceled.

Wall thickness calibration: Routine failed or canceled.

Repeatability optimization: Routine failed or canceled.

PEC Autoset: Probe ready to perform routine.

Wall thickness calibration: Probe ready to perform routine.

Repeatability optimization: Probe ready to perform routine.

is active.

Other circumstances: Error occurred during requested operation.

in contact with the component.

Other circumstances: Unused.

Other circumstances: Unused.

| 7

Lyft System Overview

PECA Probe Accessories

For details about PECA probes accessories, refer to the PEC probe catalog. To learn how to install the

probe on a pipe using accessory straps and carriages, see Appendix D on page 81.

Application-Specific Probes and Accessories

For details about the splash zone, underwater, galvanized-steel, and tank oor probes, as well as cables

and other PEC accessories, refer to the PEC probe catalog.

Positioning Lyft

Lyft must be properly positioned prior to use so that you do not run the risk of dropping the instrument

or the instrument falling over. Lyft has two safe operating positions: horizontal and tilted. To use there

a tilted position, simply pull out the stand located at the rear of the instrument until Lyft is at the desired

angle. If you are using Lyft with the optional harness, see Adjusting the Harness on page 70 for details.

Figure 2 Lyft in horizontal position

Figure 3 Lyft in tilted position

Caution

It is possible to use Lyft while it rests on its lower bumpers, but this is not a safe operational position

as the instrument may fall over. If you want to use Lyft at an angle, use the stand located at the rear of

the instrument.

Important

Regardless of how you position the instrument, you must always have a minimum clearance of 10 cm

(4 in) on all sides of the instrument. Always position the instrument away from heat sources. This ensures

proper heat dissipation while the instrument is in use.

8 | www.eddy.com

Lyft System Overview

Removing the PECA Probe Encoder

The GDA probe is equipped with a detachable encoder. The encoder can be retracted when it is not

used. To remove the encoder, place the probe on a secure surface and unscrew the four screws visible

at the base of the encoder arm when the probe is upside down.

Figure 4 PECA probe encoder removal

Calibrating PECA Probes

The probe is calibrated using the element 3 (marked CAL) as a reference. Refer to the PECA training

material for details.

Starting Lyft

Proceed as follows to turn on your instrument or exit the standby mode:

1. Make sure that at least one of the two batteries is inserted into battery compartment A of the

instrument or that the instrument is plugged to an external power source using the supplied power

cord.

2. Press the power button.

The power indicator at the center of the power button lights green.

| 9

Lyft System Overview

Shutting Down Lyft

Proceed as follows to shut down your instrument:

1. Save all your data.

2. Press the power button.

Figure 5 Shutting down Lyft

3. Tap the button of your choice.

Connecting Probes

Four options are available.

The instrument shuts down.

Connecting a PEC Probe

Eddy PEC probes come in three models: small, medium, and large. These probes hook up to Lyft’s PEC

connector. Proceed as follows to do so:

1. If you have not already done so, remove Lyft from its carrying case and place it on your working

surface as outlined in Table 2 on page 7.

2. If you have not already done so, remove the protective caps from the PEC and I/O connectors.

3. Align the probe’s 27-pin male connector with the PEC connector on the instrument.

Hint

The alignment mark on the connector should be facing you when you face the instrument.

4. Push the connector until you hear it click.

5. Align the probe’s 12-pin male encoder connector with the I/O connector on the instrument.

Hint

The alignment mark on the connector should be facing you when you face the instrument.

6. Push the connector until you hear it click.

Batteries

Lyft can be used under battery power. The instrument is designed with two battery cradles under the

protective battery compartment door, but can be powered by a single battery. Lyft uses Li204SX-7800

lithium-ion rechargeable batteries from Emerging Power, which do not suffer from the memory effect

affecting previous generations of batteries.

Warning

Whenever carrying Lyft in its transport case, remove the batteries from the instrument and make sure

that they cannot come in contact during transport, as this poses a signicant re and explosion hazard.

When carrying Lyft, it is the user’s responsibility to make sure that the safety precautions used are in

accordance with the local department of transportation (or equivalent governing body) rules and

regulations.

Lyft’s transport case comes with two slots, tted to receive the batteries when removed from the

instrument.

10 | www.eddy.com

Lyft System Overview

Note

Make sure that you do not replace the batteries by batteries other than Li204X-7800 lithium-ion

rechargeable batteries from Emerging Power. Contact your Eddy representative for more information

about pricing and availability or replacement batteries.

Inserting/Removing Batteries

Inserting Batteries

1. On Lyft’s left side, unlatch the battery compartment’s door, and then open it.

2. Align your battery with one of the battery cradles.

Note

Battery cradles are marked A and B. If you are inserting only one battery, it does not matter which

of the two cradles you use.

3. Make sure that the battery contacts are facing inward and upward.

4. Slide the battery into the battery cradle until it is fully inserted. You should feel the battery contacts

snap into place.

Removing Batteries

1. On the left side of Lyft, unlatch the battery compartment’s door, and then open it.

2. Grab the battery tab between thumb and forenger.

3. Pull on the tab.

You will feel the battery contacts being released.

4. Slide the battery out of its cradle.

Hot Swapping Batteries

You can remove one of the Lyft batteries when the instrument is turned on as Lyft can operate with a

single battery. Should the power in the remaining battery be insufcient to keep Lyft operating, the

instrument shuts down without damaging electronic components, but all your work in progress in the

Lyft software (acquisition, etc.) is lost.

Charging Batteries

Note

Batteries do not recharge when their internal temperature exceeds 45 °C (113 °F). Batteries also do not

power Lyft when the instrument’s internal temperature exceeds 55 °C (131 °F).

Using the Optional Battery Charger

An optional battery charger is available from Eddy. Contact your Eddy representative for more

information about pricing and availability. This charger conditions and calibrates the instrument’s

batteries, which is important to maximize their lives. We recommend calibrating the batteries every six

months.

Figure 6 Optional battery charger

Status window

Calibration buttons

Battery slots

| 11

Lyft System Overview

To charge the batteries with the optional charger:

1. Place the charger on a at and level surface, away from heat and moisture sources.

2. Insert the power supply’s DC connector into the back of the external charger.

3. Connect the power supply to an AC supply using the supplied cable. All the LEDs ash momentarily

4. Insert the batteries into the battery slots while making sure that the contacts are fully seated.

Calibrating Batteries

To ensure that your batteries perform at their full capacity for the longest possible time, it is important

to calibrate them on a regular basis. Calibration involves a standard battery charge followed by a deep

discharge, and then a complete charge. This procedure usually takes 10 to 13 hours, whereas a standard

charge only takes approximately 3.5 hours.

Calibrate batteries by placing them in the optional charger and then pressing the calibration button. We

recommend calibrating your batteries at least every six months.

to let you know that power is present.

The charger automatically begins charging the batteries and the LEDs in the status window display

the following information:

• Blinking green: battery charging

• Green: battery fully charged

• Blinking blue: battery calibrating

• Blue: battery charge gauge calibrated

• Blinking red: battery charge gauge in need of calibration

• Red: error

Storing Batteries

Whenever transporting Lyft in its case, remove the batteries from the instrument, place them in plastic

bags, and then make sure that they cannot come in contact during transport, as this is a signicant re

and explosion hazard. Lyft’s transport case is outtted with two slots intended for the batteries. We

recommend that you take advantage of them.

12 | www.eddy.com

Chapter 2

Software Overview

Software Overview

| 13

Software Overview

Introducing the Lyft Software

The software running on Lyft is a powerful and easy-to-use acquisition and analysis software. It is

specically designed for pulsed eddy current inspections and relies on intuitive wizards to congure

setups.

The software benets from a graphical user interface (GUI) designed to simplify the inspection process

and enhance your experience. The multi-touch display is the best way of interacting with Lyft, but you

can also use a USB mouse and keyboard, if necessary.

Through the GUI, all the functions associated to inspection project management, the global settings, and

the preferences are in what is referred to as the backstage view. All inspection work, calibration,

acquisition, and analysis is in what is referred to as the front-stage view. This is how the software offers

a streamlined and coherent interface that makes the learning process easy.

Backstage Overview

The backstage view is composed of ve sections.

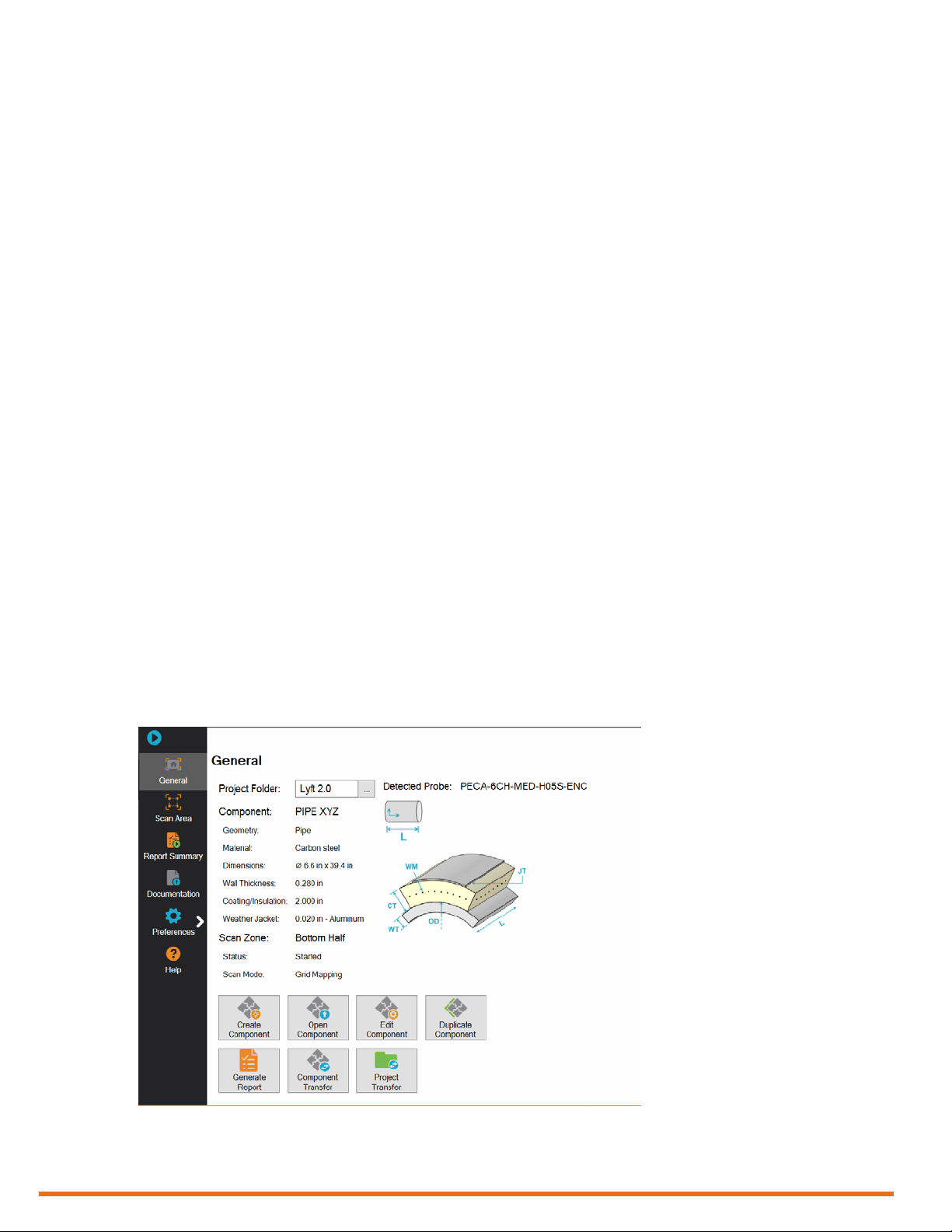

General Section

The default section and rst section of the backstage view is the General section, which contains

information about:

• Probe currently connected to Lyft

• Component description (pipe, insulation, jacket)

• Current scan zone

This is where you:

• Select project folders

• Create, open, edit, or duplicate components

• Transfer components and projects

• Generate reports

Figure 7 Backstage view: General

14 | www.eddy.com

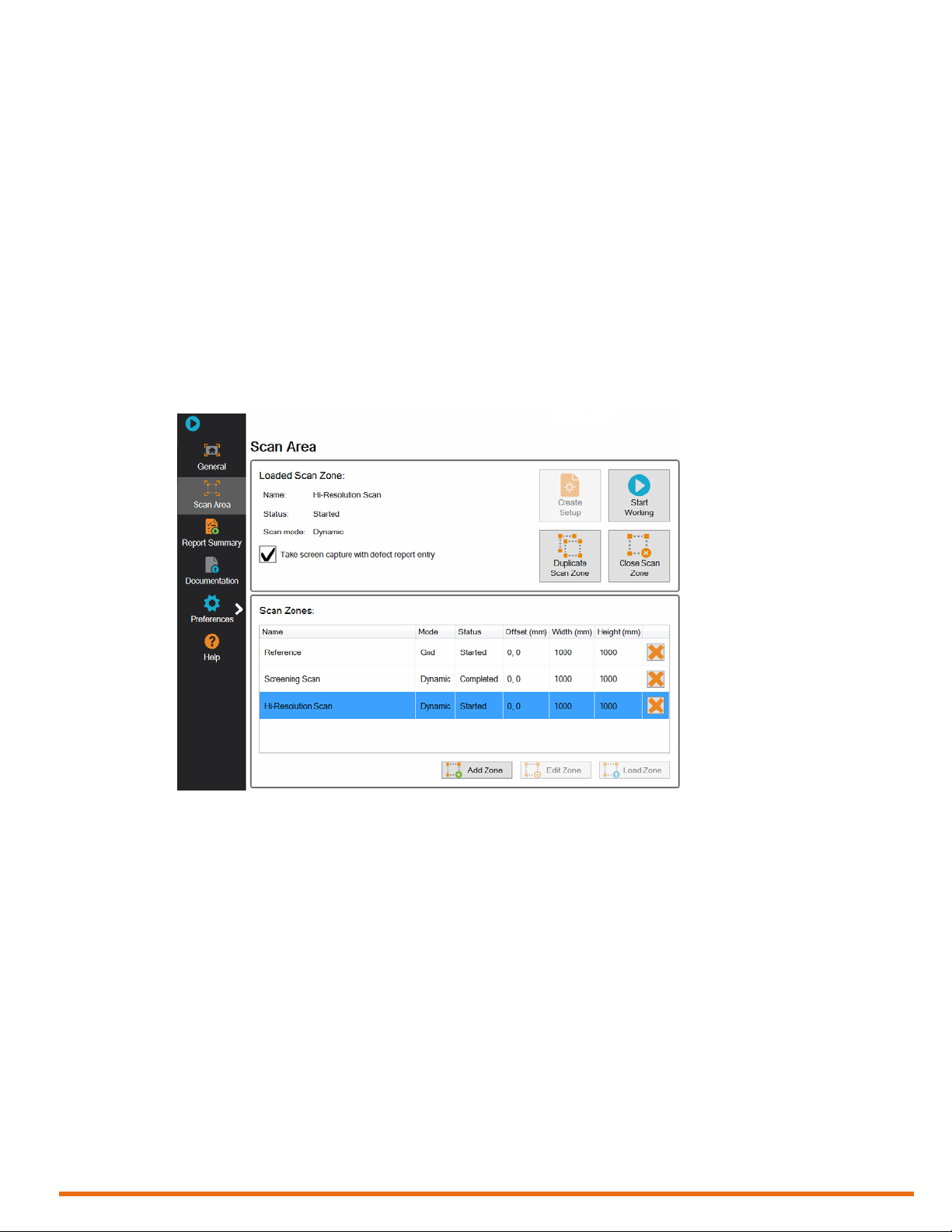

Scan Area Section

This section of the backstage contains information about the loaded scan zone and all the scan zones of

the component. This is where you (upper portion of the view):

• Create setups

• Start inspections

• Duplicate the loaded scan zone

• Close scan zones for modication

Also (bottom portion of the view):

• Add new scan zones

• Delete scan zones

• Edit scan zones

• Load scan zones

Figure 8 Backstage view: Scan Area

Software Overview

| 15

Software Overview

Report Summary Section

This section of the backstage serves to congure the summary included with your reports. This is where

you can:

• Add information about the component type, serial number, operator, service company, etc.

• Create new information elds to be included in reports

• Add comments about the component inspection

Figure 9 Backstage view: Report Summary

Documentation Section

This section of the backstage allows you to open PDFs located in the UserData folder of the in s t rument .

Opening a PDF here can display the document full page for easier reading.

Figure 10 Backstage view: Documentation

16 | www.eddy.com

Loading...

Loading...