Eddyfi Robotics Inc.

2569 Kenworth Road, Suite C

Nanaimo, BC, V9T 3M4

CANADA

+1.250.729.8080

info@eddyfitechnologies.com

www.eddyfitechnologies.com

INUKTUN VERSATRAX 150™

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 2 of 57

User Manual

Table of Contents

About This Manual ........................................................................................................................................ 5

System Description ....................................................................................................................................... 5

Specifications ............................................................................................................................................ 6

Certification ............................................................................................................................................... 7

Safety ........................................................................................................................................................ 7

System Setup ................................................................................................................................................ 9

Working Environment ............................................................................................................................... 9

System Power ........................................................................................................................................... 9

Power Requirements ............................................................................................................................. 9

Set the Line Voltage............................................................................................................................. 10

Generators / Inverters .......................................................................................................................... 10

Connections ............................................................................................................................................ 11

Pre-Configured Control Rack ............................................................................................................... 11

Control System Connections – SD Video ............................................................................................ 12

Control System Connections – HD Video ............................................................................................ 12

Fiber Optic Tether ................................................................................................................................ 13

Client Configured Rack ........................................................................................................................ 14

Vehicle and Tether ............................................................................................................................... 15

Winch Installation .................................................................................................................................... 16

Portable Reel Setup ................................................................................................................................ 16

Tether Handling ...................................................................................................................................... 17

Connector Handling ................................................................................................................................ 17

SubConn Connector: Lubrication and Cleaning .................................................................................. 18

Impulse Connector: Lubrication and Cleaning ..................................................................................... 18

System Installation .................................................................................................................................. 18

Vehicle Layout ..................................................................................................................................... 18

Vehicle Handling .................................................................................................................................. 19

Communication .................................................................................................................................... 19

Personnel Requirement ....................................................................................................................... 19

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 3 of 57

User Manual

Vehicle Configuration .................................................................................................................................. 20

Parallel Vehicle ....................................................................................................................................... 20

Chassis Pipe Sizing ............................................................................................................................. 20

Powered Camera Raise ....................................................................................................................... 21

Minimum Bend Sizes ........................................................................................................................... 22

Spectrum 90™ Installation ................................................................................................................... 23

Spectrum 120HD™ Installation ........................................................................................................... 25

Spectrum 120™ Bumper Bars ............................................................................................................. 25

Light Installation ................................................................................................................................... 26

Minitrac™ Installation........................................................................................................................... 28

Track Height Extensions ...................................................................................................................... 31

Spectrum™ Camera Extension ........................................................................................................... 32

Rear Camera Installation ..................................................................................................................... 33

Advanced Accessories......................................................................................................................... 34

Minitrac™ Length Extensions .............................................................................................................. 34

Active Track Chassis Articulation ........................................................................................................ 34

Sonde ................................................................................................................................................... 35

Fiber Optic Tether ................................................................................................................................ 36

Laser Scanner Mount........................................................................................................................... 37

Odometry Module ................................................................................................................................ 38

Inline Vehicle........................................................................................................................................... 40

Minitrac™ Installation........................................................................................................................... 40

Spectrum 90™ Installation ................................................................................................................... 41

Guide Wheel Adjustment ..................................................................................................................... 41

Camera Height / Skid Adjustment ........................................................................................................ 43

Rear Camera Installation ..................................................................................................................... 44

Operation..................................................................................................................................................... 45

Pre-Operations Check ............................................................................................................................ 45

Post-Operations Check ........................................................................................................................... 46

ICON™ & ICON™ RPT .......................................................................................................................... 46

Power-Up Sequence ............................................................................................................................... 46

Ground Fault Detection & Alarms ........................................................................................................... 47

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 4 of 57

User Manual

Dealing With Obstacles .......................................................................................................................... 48

Inspection Guidelines ............................................................................................................................. 48

Powered Winch Operation ...................................................................................................................... 48

Vehicle Recovery .................................................................................................................................... 49

Emergency Recovery........................................................................................................................... 50

Troubleshooting .......................................................................................................................................... 50

Camera Control Problems ...................................................................................................................... 50

Video Problems....................................................................................................................................... 51

Vehicle Problems .................................................................................................................................... 51

Winch Problems ...................................................................................................................................... 52

Maintenance ................................................................................................................................................ 53

Rinsing and Cleaning .............................................................................................................................. 53

Fuse Replacement .................................................................................................................................. 53

Minitrac™ Maintenance .......................................................................................................................... 53

Camera Maintenance ............................................................................................................................. 53

Tether Re-termination ............................................................................................................................. 54

Parts and Repairs ....................................................................................................................................... 54

Ordering Parts/Customer Service ........................................................................................................... 54

Warranty Repairs .................................................................................................................................... 55

Factory Returns to Canada ..................................................................................................................... 55

Product/System Drawing Package Availability ....................................................................................... 55

Limited Warranty Policy .............................................................................................................................. 56

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 5 of 57

User Manual

About This Manual

This manual has been prepared to assist you in the operation and maintenance of your Eddyfi

Technologies’ Inuktun equipment. Correct and prudent operation rests with the operator who must

thoroughly understand the operation, maintenance, service and job requirements. The specifications and

information in this manual are current at the time of printing.

This product is continually being updated and improved. Therefore, this manual endeavors to explain and

define the functionality of the product. Furthermore, schematics or pictorials and detailed functionality

may differ slightly from what is described in this manual.

Eddyfi Technologies reserves the right to change and/or amend these specifications at any time without

notice.

Information in this manual does not necessarily replace specific regulations, codes, standards, or

requirements of others such as government regulations.

This manual is copyright © 2019 by Eddyfi Robotics Inc. All rights reserved.

System Description

The Inuktun Versatrax 150™ is a system of pipeline video inspection vehicles based on the Minitrac™ 8000

crawler. Using In-Line and Parallel chassis’, the system navigates pipelines from 150 – 900 mm (6 – 36 in)

internal diameter with the camera centered, with an infinite size range with the camera non-centered. As

such, the parallel chassis is often used for inspections over industrial floor space, pools and other harsh

environments as well.

The inspection system has been manufactured with the hazards and demands of pipe inspection in mind.

The rugged dual tracks permit pipe penetration up to 1,000 m (3,300 ft), with extended range possible using

an optional fiber optic tether.

All Versatrax hardware can be used dry, underwater, or in dirty, muddy conditions. The rugged design

ensures a long service life and helps protect the vehicle from damage during normal use.

Typical applications include inspection of:

• Sewer and storm drains

• Hydroelectric pipe and infrastructure

• Steam headers

• Tanks and pressure vessels

• Oil and gas refineries and pipelines

• Pulp and paper mills

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 6 of 57

User Manual

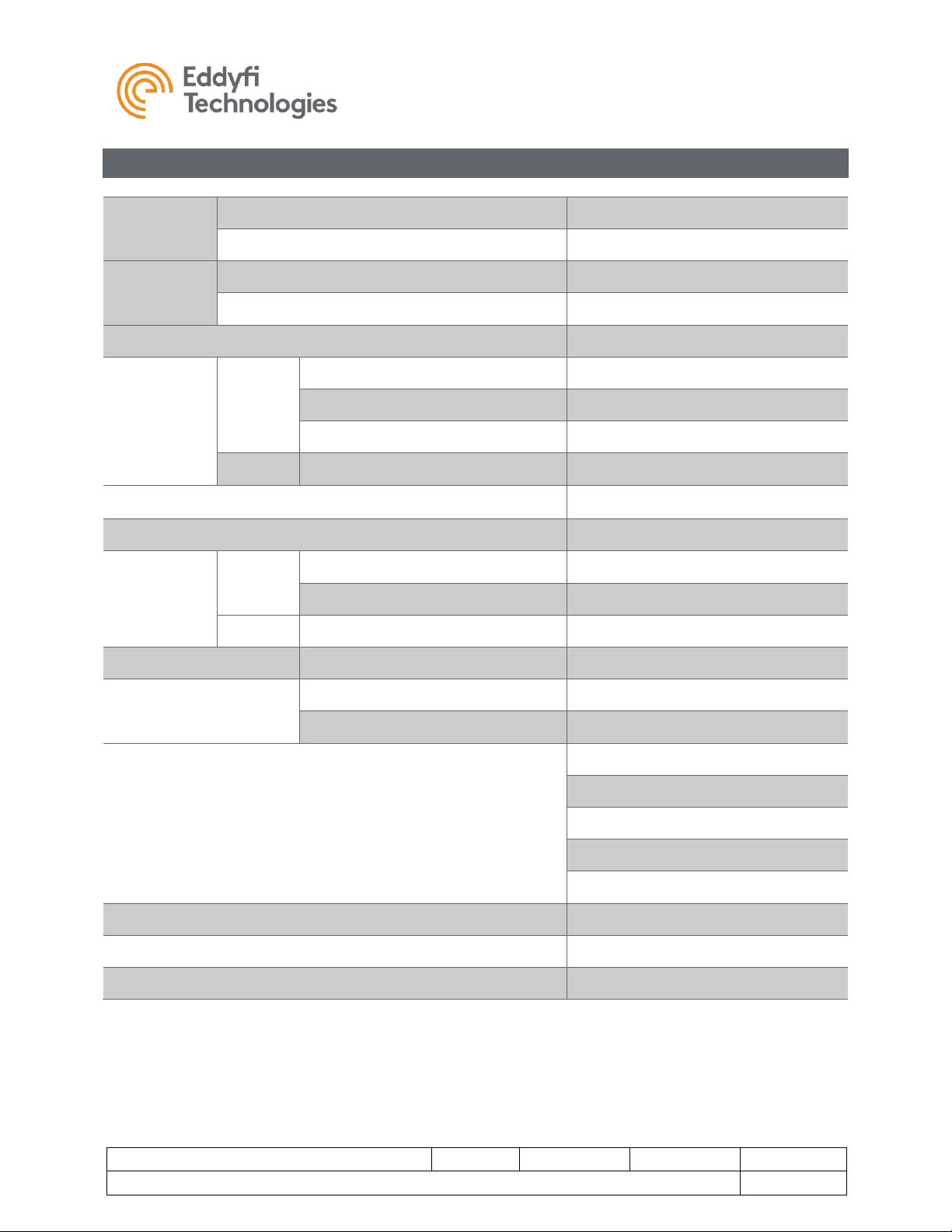

Specifications

Min Vehicle

Dimensions

Parallel

Ø300 x 1050 mm (Ø12 x 41.5 in)

Inline

Ø150 x 2000 mm (Ø6 x 79 in)

Vehicle

Weight1

Parallel

45 kg (100 lb)

Inline

45 kg (100 lb)

Depth Rating

60 m (200 ft)

Pipe Size

Range2

Parallel

Camera Centered

305 – 610 mm (12 – 24 in)

Camera Centered with Track Extension

460 – 700 mm (18 – 28 in)

Camera not Centered

610 mm (24 in) – Flat

Inline

Camera Centered with Skids

150 – 305 mm (6 – 12 in)

Maximum Tether Length3

1,000 m (3,300 ft)

Tracks

2x Minitracs™ 8000

Camera

Front

Standard

Spectrum 90™

Option

Spectrum 120HD™

Rear

Standard

Sapphire™

Lights

(Parallel Only)

2x 901 Lights

Reel

Standard

Portable tether reel with payout encoder

Option

High capacity powered winch

Parallel Chassis Optional Components

Manual Camera Raise

Weight Kit – 25.5 kg (56 lb)

Track Extension Kit

Camera Extension Kit

Powered Active Track Angle Adjustment

Power Requirements

100 – 240 VAC 50/60Hz, 1.9 – 3.1 kW

Operating Temperature

0 – 50 ºC (32 – 122 ºF)

Storage Temperature

-20° – 60 ºC (-4 –140 ºF)

1

Weights may vary depending on optional components

2

Specified pipe sizes are internal diameters

3

Actual travel distance may be decreased depending on inspection geometry (traction and number of bends)

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 7 of 57

User Manual

Certification

The Inuktun Versatrax 150™ system is built in accordance with the Low Voltage Directive 2006/95/EC,

Machinery Directive 2006/42/EC, and Electromagnetic Compatibility Directive 2004/108/EC.

Safety

In order to be able to use this product properly and safely, every user must first read these operating

instructions and observe the safety instructions contained therein. Take care of these operating

instructions and keep them in a place where they can be accessed by everyone. Untrained personnel

should not handle or operate this equipment.

CAUTION: Failure to follow these safety instructions may result in injury or

equipment damage.

This system includes some specific devices that have their own User Manuals. Instructions on those

manuals must be also read before using the system.

WARNING: High Voltage

The tether carries 400 VDC to the rear harness block, and the Minitrac™ whips

carry 400 VDC from the harness block to the tracks. Always Keep the tether

capped when not installed on the vehicle. Follow the guidelines for preventing

tether damage.

400 VDC can cause serious injury or death. Do not operate with a damaged

tether or Minitrac™ whip. Do not operate the system with damaged wires.

Damaged cabling poses a shock hazard. Repair damaged cabling before

operating the vehicle. A short circuit may also damage the controller, cameras, or

any attached equipment.

Disconnect the power source before servicing the product; otherwise, damage or

fatal injury may result.

The power supply is equipped with a ground fault interrupt circuit. Do not cheat or

bypass the ground fault interrupt circuit. Do not power the equipment from a

source other than the Eddyfi Technologies provided power supply.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 8 of 57

User Manual

WARNING: Intense Optical Radiation - The Versatrax 150™ camera lights and

901 auxiliary lights are extremely bright and can cause temporary flash blindness.

Never look directly at the lights, or even from a shallow angle. Use a welding filter

(shade #8 or higher) if inspecting the LEDs.

CAUTION: Class II Laser: The Spectrum 90/120™ camera may

be equipped with laser lines. Do not intentionally stare into the

beam. Typically, Class II relies on the blink reflex to limit exposure

to no more than ¼-second. Intentionally staring into the beam can

cause eye injury.

• When performing maintenance or functional checks of the

lasers and camera lights, take precautions to protect

nearby personnel from unintended exposure which could

be temporarily blinding.

• Observe safe lifting and handling practices. Component parts of the Inuktun Versatrax 150™

system are heavier than the recommended lifting load for a single person. Two people are

recommended for lifting the vehicle.

• Never drop the vehicle. Although built tough, the vehicle is heavy and can suffer structural

damage when dropped.

• Prevent impact to the front of the 901 lights, Spectrum 90/120™ camera and Inuktun Sapphire™

cameras as they can suffer damage.

• Eddyfi equipment is used in many varied environments from hot/dry to confined spaces to deep

underwater. Such diverse environmental risks must be addressed by the operators who are

trained to work in such surroundings. As such, the operators are responsible to determine safe

site setup, work procedures and appropriate personal protective equipment (PPE) for setup and

operation of the equipment.

WARNING: Trip Hazard - Never stand on the tether. The vehicle and winch are

strong enough to pull it out from underneath you and cause you to fall. Standing

on the tether may also cause damage to the internal conductors and decrease the

life of the protective jacket.

WARNING: High Temperature - The camera head, 901 lights and harness block

may become extremely hot during operation. Always wear protective gloves when

handling these parts of the vehicle after they have been in use. Allow a cool-down

period before handling without gloves.

WARNING: Spark Hazard - Under no circumstances should this equipment be

used in a potentially explosive atmosphere

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 9 of 57

User Manual

WARNING: Mechanical Pinch Hazard – Rotating or moving components can

draw fingers into a pinch position. Do not handle the vehicle while mobile parts are

running, turn off power or disconnect the tether while reconfiguring or maintaining

the vehicle.

System Setup

Working Environment

The control system (interface box, power supply, and Control computer) is to be used in a dry, covered

environment only. These components are not waterproof. Keep all cords and cables away from water.

The tether and vehicle are depth rated to 60 m (200 ft) of water. The tether connector is a wet-mate type

which may be wet when plugged in but cannot be plugged in underwater. Keep the tether connector

capped with a dummy plug when not connected to the vehicle to help keep out dirt. The tracks are

tolerant to sandy and muddy conditions, although this decreases seal life. The vehicle may also be

operated in dry or dusty environments.

The portable reel and winch are splash resistant only. Refer to the reel manual.

To maximize component life and minimize deployment time it is recommended that the vehicle and tether

be cleaned after use and the entire system stored in a dry, dust free, location.

System storage temperatures are between -20 ˚C – 60 ˚C (-4 ˚F – 140 ˚F)

System Power

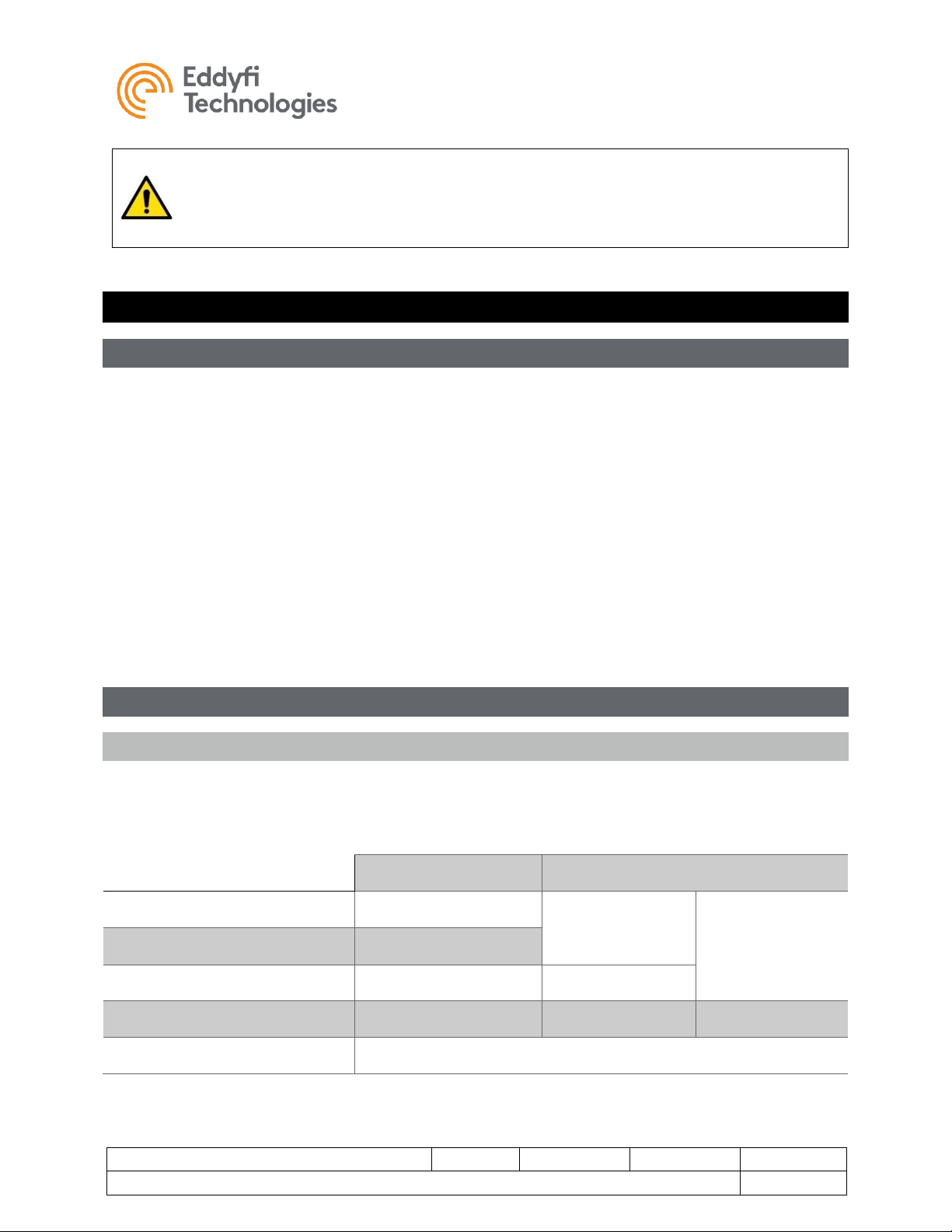

Power Requirements

The power requirements given below are maximums for a fully configured system with cable reel. For

use with 110 VAC source, a fully configured Versatrax150™ system requires three independent standard

15 A circuits for power, or one 20 A and one 15 A circuits as follows.

Power

Circuit

Control Computer

500W

110 VAC @ 15 A

110 VAC @ 20 A

Monitor

80W

Power Supply / Interface Box

1300W

110 VAC @ 15 A

Powered Winch

1200W

110 VAC @ 15 A

110 VAC @ 15 A

System Total

3080 W

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 10 of 57

User Manual

Set the Line Voltage

Before powering on the Versatrax 150™ system, it is important to check that the input voltage settings

are correct - an incorrect voltage setting will damage the system power supply and the winch controller.

When installing the system in a new location always check the line voltage.

• Monitor: Universal - no action required.

• Computer: Universal - no action required.

• Interface Box: Universal - no action required.

• Power Supply: Set the line voltage switch to 115/230VAC and change fuse.

o For 115 VAC use 15 A MDA type fuse.

o For 230 VAC use 10 A MDA type fuse.

• Winch: Jumpers must be set inside the hand-held controller to switch between 115 VAC and

230 VAC. Refer to the winch manual for instructions.

WARNING: Line Voltage Select – Failing to select the proper line voltage on the

power supply and winch will result in equipment damage.

Generators / Inverters

If powering the system from a generator or inverter, refer to that unit’s operating manual for

recommendations on continuous and peak load ratings. These power sources may apply a reduced

output rating based on electrical load and environmental temperature. Remember to include the power

needs of all other connected devices (external monitors, recording devices, lighting, etc.) when selecting

a generator or inverter.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 11 of 57

User Manual

Connections

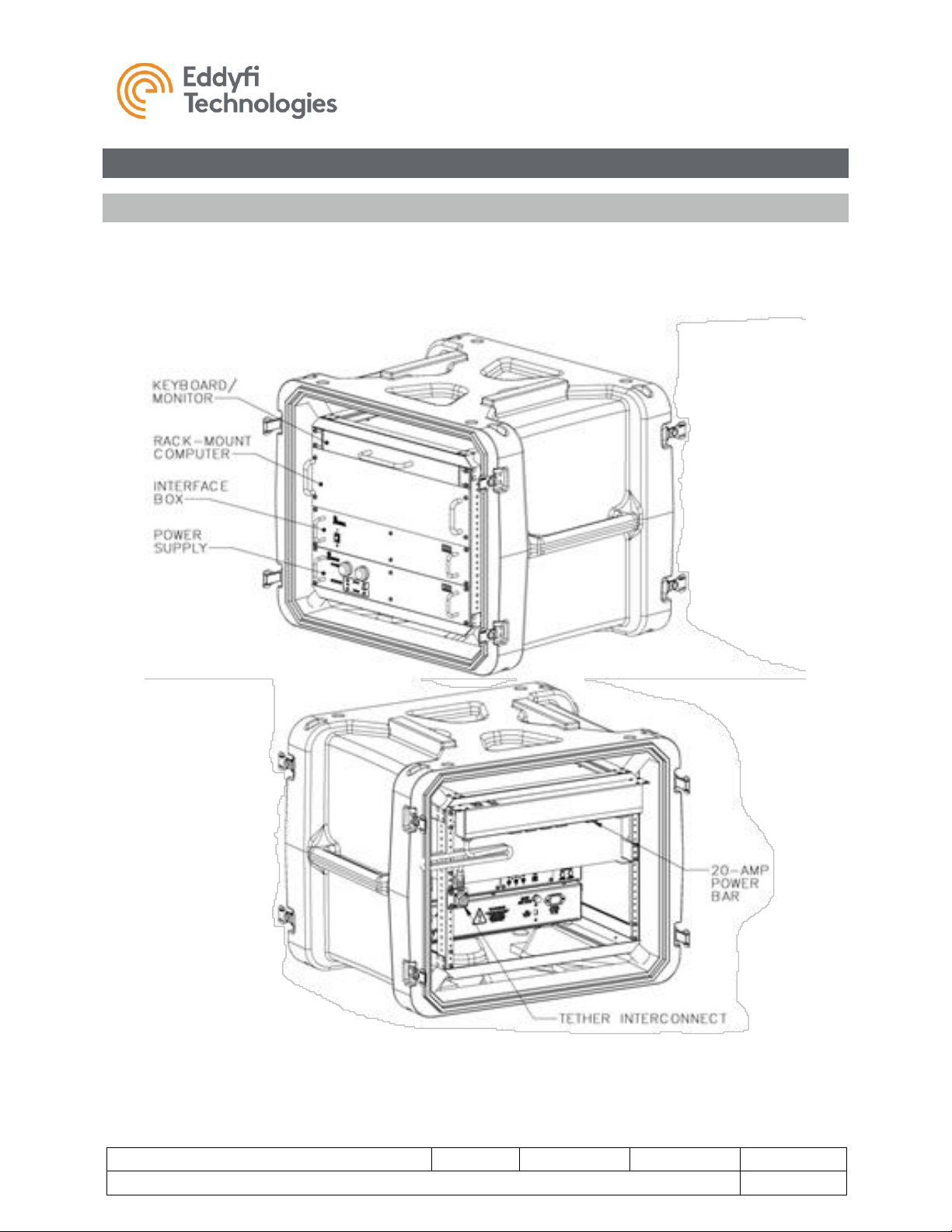

Pre-Configured Control Rack

The monitor, computer, interface box and power supply are typically installed and connected in a shockmount portable 19 in rack case. Systems pre-configured in a control rack will only need the tether, winch

and vehicle connections to be made before operations.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 12 of 57

User Manual

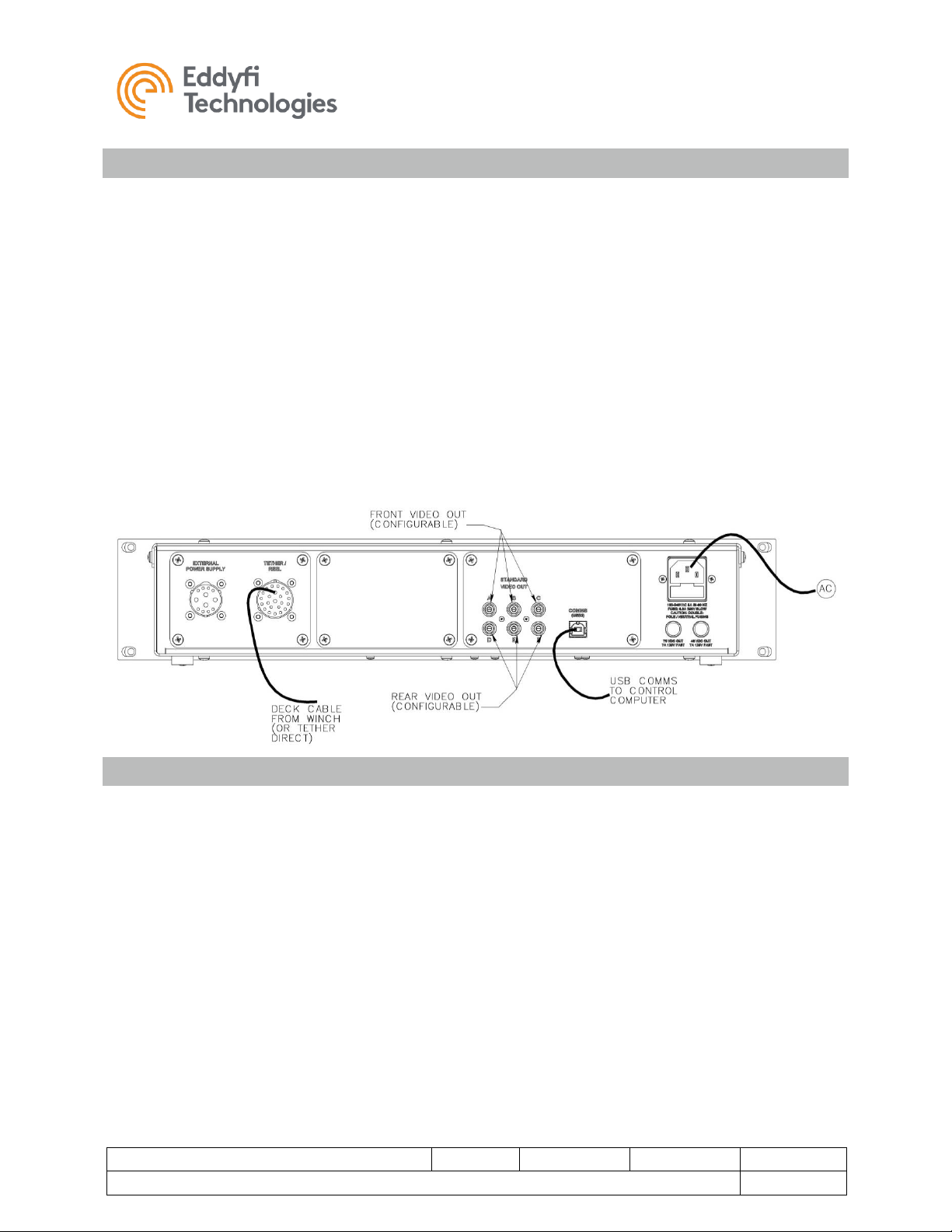

Control System Connections – SD Video

The ability to receive standard definition or high definition video depends on the interface box used with

the system. A standard definition interface box is depicted below which would be connected to the high

voltage power supply.

1. Connect the power supply to the interface box using the supplied interface cable. Ensure the

locking collars are screwed on all the way.

2. Connect the USB comms to the control computer.

3. Using equipment power cords connect the power supply and interface box to the 20-Amp power

bar supplied with the equipment rack. Note that the power bar will only accept equipment power

cords. The input cord on the power bar can be changed depending on the input voltage and

location.

4. Connect the tether (or deck cable from the winch or reel) to the interface box as illustrated below.

5. Connect the front monitor or video capture to channels A, B or C (three-way splitter) and the rear

monitor or video capture to channel D, E or F. These are the default output, but the connector

assignments are also software configurable.

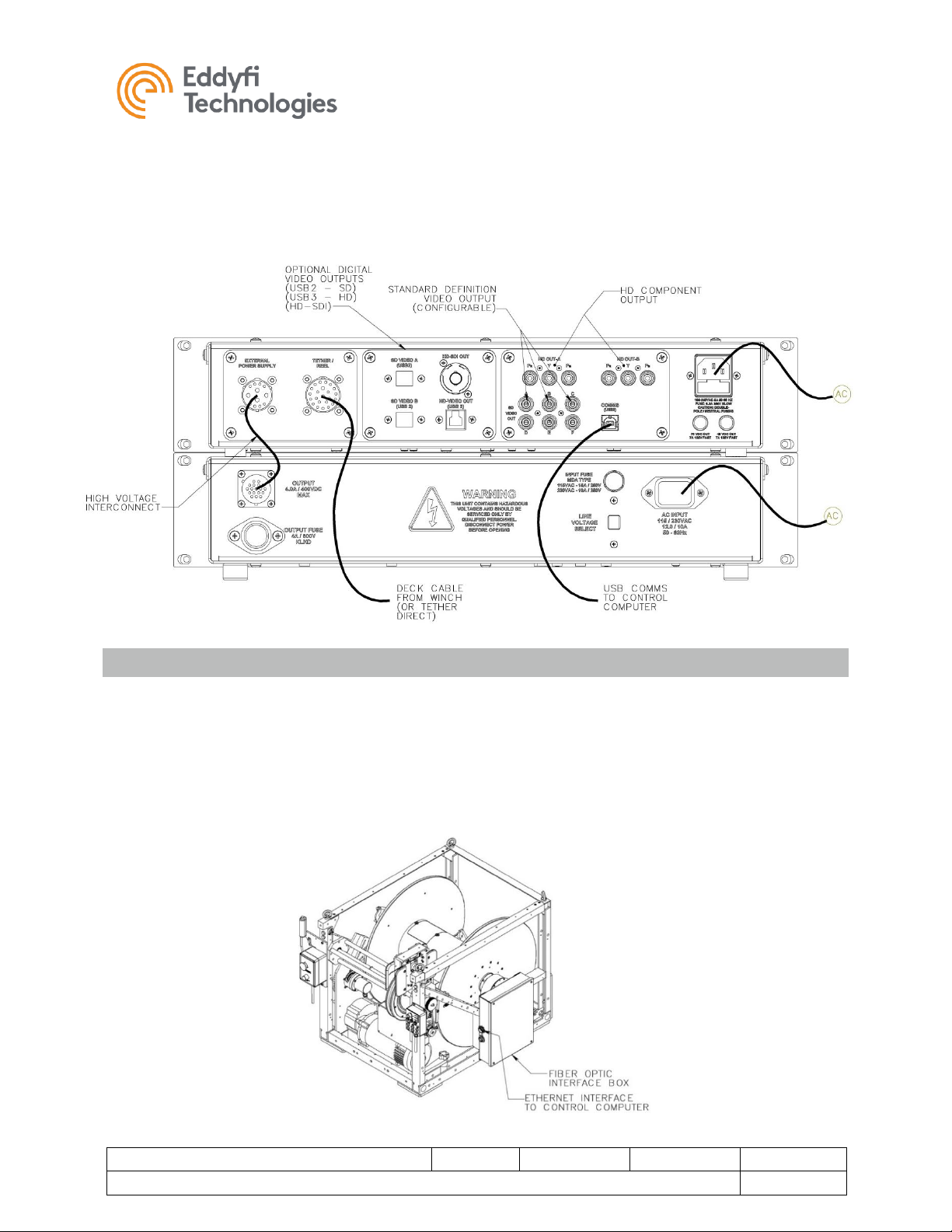

Control System Connections – HD Video

A high definition interface box is depicted below which would be connected to the high voltage power

supply. For an HD system make the following connections:

1. Connect the power supply to the interface box using the supplied interface cable. Ensure the

locking collars are screwed on all the way.

2. Connect the USB2 comms to the control computer.

3. Using equipment power cords connect the power supply and interface box to the 20-Amp power

bar supplied with the equipment rack. Note that the power bar will only accept equipment power

cords. The input cord on the power bar can be changed depending on the input voltage and

location.

4. Connect the tether (or deck cable from the winch or reel) to the interface box as illustrated below.

5. Different options may be present for SD video, depending on interface box model. If the interface

box has an internal video capture card there will be two USB2 ports labelled Video A and Video

B. These will be the front and rear standard definition cameras on the vehicle. Analog SD video

is available as normal through the RCA connectors. Use A,B or C for front video (if this is an SD

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 13 of 57

User Manual

video system) and D, E or F for rear video. There are spare front and rear video outputs which

can be connected to external monitors.

6. Options for HD video out include HD-SDI, USB3 (internal capture device) and component Pr-YPb. These connectors are for the front High Definition Camera. Spare connectors are active and

may be connected to external monitors, capture cards or recording devices.

Fiber Optic Tether

Systems equipped with a fiber optic tether employ a fiber bundle running down the middle of the tether to

transmit communications and video to and from the vehicle. The fiber bundle is terminated through a slip

ring into an interface box mounted to the side of the winch. All the necessary fiber receiver equipment is

in the interface box. From the interface box, video signals are routed through the deck cable as they

would through a copper tether, and control communications connect directly to the control computer

through an Ethernet cable.

See the winch manual for detailed operating instructions.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 14 of 57

User Manual

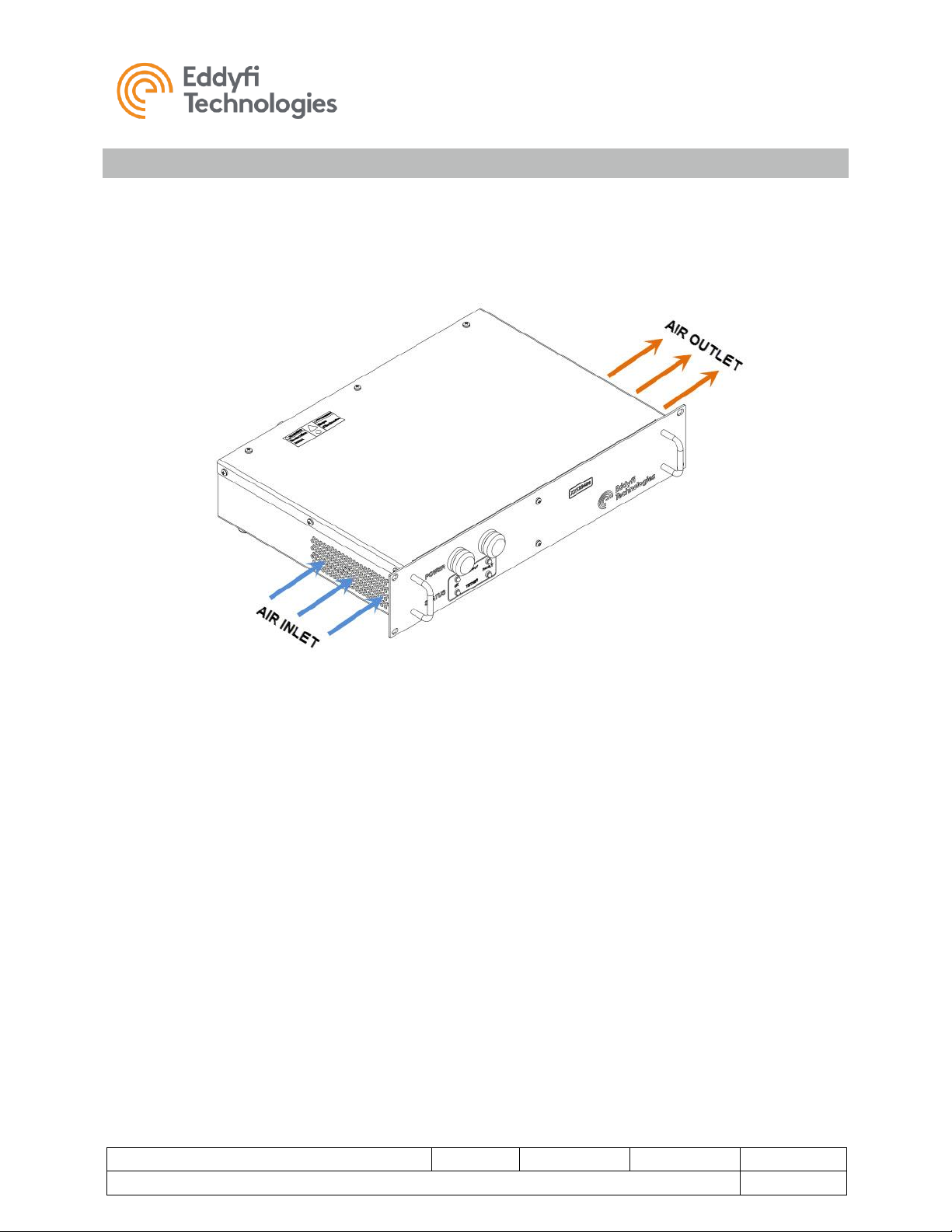

Client Configured Rack

If you are installing the power supply and interface box into your own 19 in rack installation, consideration

must be given to adequate air flow for cooling the power supply. In any installation, ensure that the air

inlet and outlet at the sides of the power supply are free of obstructions. The system could overheat if

airflow is restricted. The front or back of the 19 in rack must also be open for air flow.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 15 of 57

User Manual

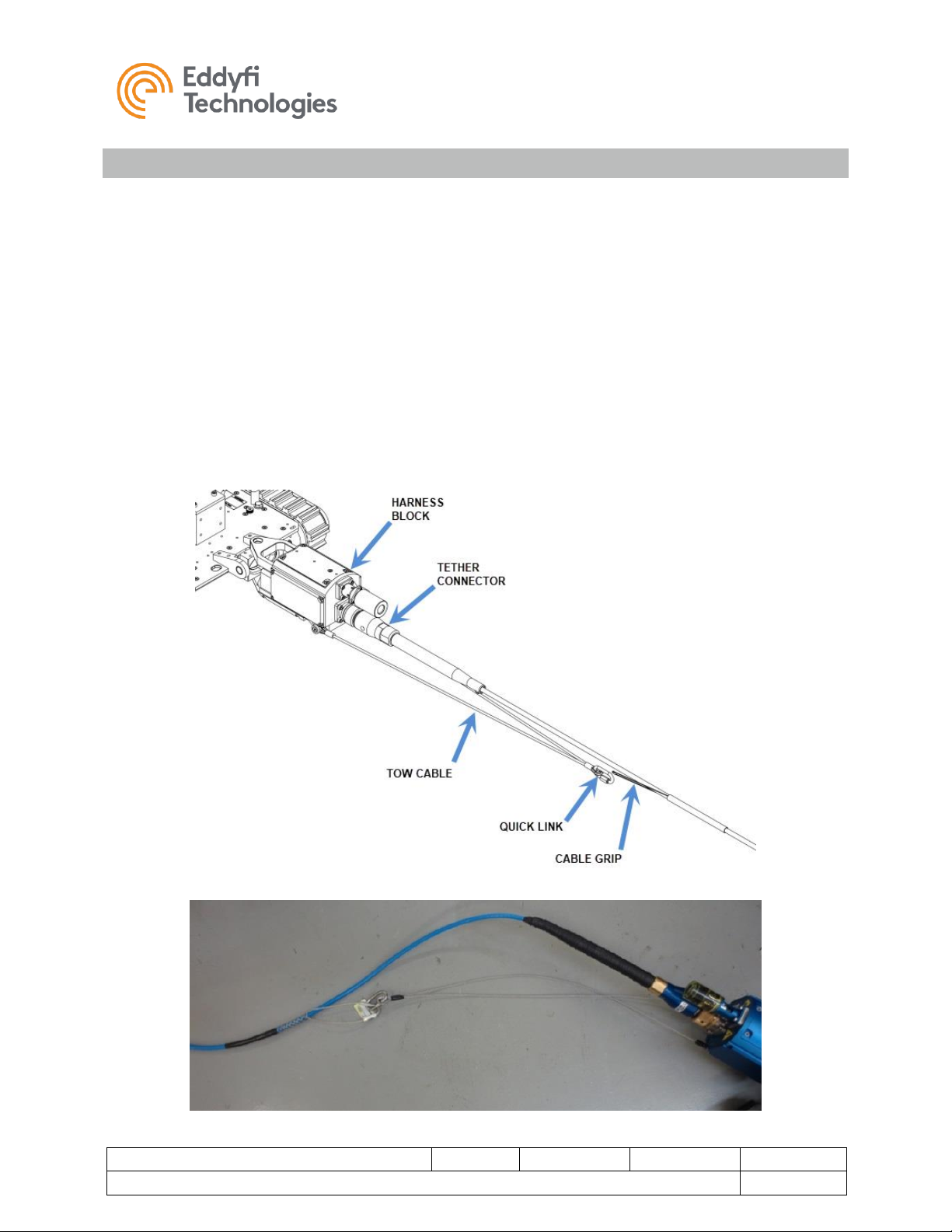

Vehicle and Tether

It is important that the tether be properly connected to the vehicle – otherwise damage to the system may

result.

1. Connect the vehicle end of tether to the back of the integrated harness block. Visually line up the

key in the connector before mating. Fully screw down and hand-tighten the locking collar.

2. Secure the tow cable to the cable grip on the tether using the quick-link. Adjust the cable grip

position to maintain a small amount of slack tether regardless the direction the tether is pulled, as

illustrated below.

3. Verify all device whips from the harness block to their respective components are securely

connected, and the whips are free from damage.

4. Ensure any unused connectors are capped with dummy plugs to insulate and protect their

electrical contacts.

5. Tether connection to the parallel and inline vehicles are identical.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 16 of 57

User Manual

Winch Installation

If your system includes an AC powered winch refer to the winch manual for setup and installation

instructions.

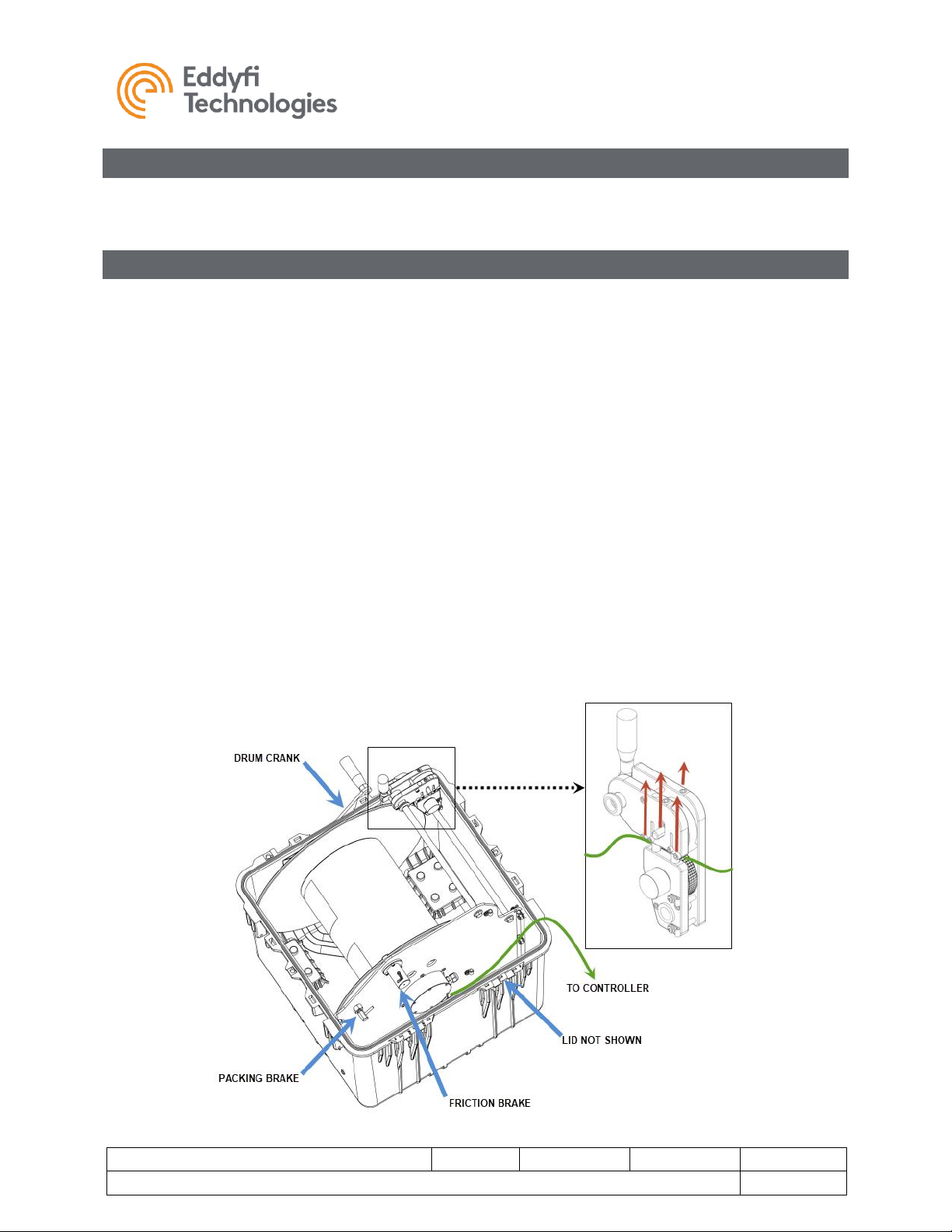

Portable Reel Setup

If your system includes a portable reel, follow these steps to operate:

1. Remove the shipping cap from the front of the case and insert the crank handle.

2. Connect the deck cable from the reel to the controller.

3. Disengage the packing brake (pull back and turn on the locking pin).

4. Make sure the friction brake is engaged; disengaging the friction brake can result in slack tether

potentially jamming the reel.

5. Unwind some tether and connect the tether to the vehicle.

6. Run the tether through the level wind as follows:

a. There is an access slot which must be opened by lifting up the two exposed screw heads

to raise the tether support shafts.

b. Pull up on both sides of the axle on the top wheel and slide the tether beneath it - failing

to lift up on the wheel can scuff and damage the tether.

c. Make sure that the two wheels that sandwich the tether top and bottom in the level wind

are tracking properly as the tether is paid out - this tells the controller how much tether

the reel has unwound and how far your vehicle has travelled.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 17 of 57

User Manual

Tether Handling

The tether is one of the most important parts of the system. It feeds power and control signals to the

system and returns data to the controller. If the tether is damaged from improper use, poor handling or an

accident, the system may become inoperable. This could lead to significant downtime, loss of production,

and avoidable costly repairs. It is encouraged to stress the importance of the tether and its use to anyone

operating or maintaining the system. For maximum tether life and reliability, we recommend the following

tether handling tips.

• Do not step on the tether

• Do not drive over the tether

• Do not bend the tether beyond its minimum bend radius

• Do not kink the tether

• Do not snap load the tether

• Avoid loading the tether whenever possible

• Always use the cable grip strain relief if applicable to your system

• Regularly inspect the tether for damage

• Regularly clean the tether

Note:

Protecting the conductors inside the tether is critical to the life and operation of the tether.

Proper tether handling and care will result in extended tether life and system reliability.

Connector Handling

Connectors are an essential part of system reliability. They should be properly maintained and cared for

to ensure long life and reliability. It is recommended to follow these steps to help prevent damage and

increase the life of connectors.

• Always put the cap back on the tether bulkhead when the tether is disconnected

• Always inspect the end of the connector prior to engaging

• Never plug in a dirty or damaged connector

• Visually align key-ways or locating pins prior to engaging the connector

• Always fully engage or tighten the connector

• Secure locking collars finger tight

• Install dummy plugs on unused connectors

• Disconnect by pulling straight, not on an angle

• Do not pull on the cable to disengage the connector

IMPORTANT: Never “Hot Plug” any connector, this will result in internal damage to the

electronics. Power down the system prior to connecting the inspection system tether.

Note:

Never use WD-40 or similar solvent-based fluids on connectors or crawlers. These will cause

the rubber parts of the connector or crawler to soften and swell rendering them inoperable.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 18 of 57

User Manual

SubConn Connector: Lubrication and Cleaning

• Periodically apply Molykote 111 silicone grease or equivalent before mating connectors

• For dry mate connections, a layer of grease corresponding to 1/10 the socket depth should

be applied to the female connector

• After greasing, fully mate the male and female connector and remove excess grease from the

connector joint

• General cleaning and removal of sand or mud on a connector should be performed using a

spray-based contact cleaner like isopropyl alcohol

Impulse Connector: Lubrication and Cleaning

• Lubricate mating surfaces regularly with 3M Silicone spray or equivalent, DO NOT GREASE

• Lubricate O-rings with Molykote 111 or equivalent

• Use dust caps to protect connectors wherever possible

• Clean connectors with soap and fresh water, rinse out with alcohol and allow connector to air

dry before using.

System Installation

The following describes a typical installation scenario recommended by Eddyfi Technologies.

Vehicle Layout

A typical set up for a pipe inspection system is based on a covered two ton or larger box truck. The truck

carries the power source (generator) and houses the power supply and control system in a dry, covered

environment. The computer / control console and recording equipment are placed in an office-like room

built into the truck. The rear wall of the truck should open completely. The winch, crane and other

equipment can be mounted at the back of the truck box near the door for easy deployment. The truck

should also contain the maintenance space with ample bench room for maintaining, configuring, and

washing down the vehicle and equipment.

The vehicle should be operated by a crew of at least two. Most importantly, a person should always be

available to tend to the tether. This person may also play a role in vehicle inspection and deployment. A

second person drives the vehicle, conducts the inspection and ensures a good recording.

The operations crew should be able to communicate quickly with each other to allow fast response in

case of an emergency like a tether hang up. It is recommended that a signal system be set up so that the

operators may work efficiently and safely as a team. It is always advantageous for both operators to be

aware of full system status.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 19 of 57

User Manual

Vehicle Handling

Because the vehicle is heavy, some handling equipment is recommended with the system installation:

The first of these is a swinging overhead boom for vehicle deployment which must hold the payout

sheave axle at least 2.75 m (9 ft) above ground level. The capacity of the arm needs to be at least 450

kg (½-tonne) at full extension - enough for full vehicle weight plus full winch power. The payout sheave

diameter should be at least 250 mm (10 in) to help prevent tether fatigue.

An electric cable hoisting winch with at least 450 kg (½-tonne) load capacity is necessary to raise and

lower the vehicle. The cable on this hoist needs to be long enough for the deepest expected deployment.

Eddyfi Technologies recommends a dedicated work bench for vehicle configuration and maintenance.

Ideally this is at least 0.75 x 1.5 m (30 x 60 in) and is accessible from both sides. The lower portions of

the bench may be equipped with racks or drawers where tools, spare parts, and fasteners are kept.

Communication

Establish a good channel of communication between the operator and deployment personnel: whether

this is a system of signals, PA system or audio headsets. Good communication can avoid accidents,

damage to the equipment, and promotes efficiency and productivity. The person deploying the vehicle

and watching the tether must be able to quickly tell the operator to stop the vehicle when something goes

wrong. Because he is situated in the office-like van, the operator is often provided with a CCTV system

or view port so he can see directly what is happening with tether payout. It is best practice for the

operator never to turn on power or initiate movement without first communicating with the vehicle handler.

Personnel Requirement

A typical pipe inspection van operation usually requires two people for operations:

• Console Operator: This person is responsible for driving the vehicle, watching the pipe and

making comments about the location and pipe condition. It is also the operator’s responsibility to

assess whether a pipe is in the appropriate condition for safe passage of the vehicle or if there is

a risk of getting stuck. The operator may also assist in general site setup (cones, warning signs,

etc.), vehicle maintenance and configuration.

• Deployment / Tether Handler / Field Maintenance: This person has several tasks including:

o Configuring the vehicle for the current pipe

o Lowering the vehicle in and out of the manhole

o Watching the tether as the vehicle enters and exits the pipe

o Operating the winch and winding the tether during recovery

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 20 of 57

User Manual

Vehicle Configuration

Parallel Vehicle

Chassis Pipe Sizing

To fit inside specific pipe sizes, the chassis hinges must also be adjusted. To adjust the hinges:

1. Loosen the clamping nut; make sure the camera bed is far enough forward to provide access.

2. Adjust the hinges using the indicator plaque at the back of the chassis; the sizes indicated are

internal diameters (there is a line scribed on the main hinge that is used indicate pipe sizes).

WARNING: Pinch Hazard – Exercise extreme caution while adjusting the track

hinges not to catch your fingers in the linkages.

3. Once the hinges are set, re-tighten the clamping nut.

Note that there are two columns of numbers on the indicator plate. STD is for the standard chassis setup,

while XT is for when the track extension plates are installed.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 21 of 57

User Manual

Powered Camera Raise

Note: When the powered camera raise is installed, the minimum pipe size is increased to 350 mm (14 in)

to allow room for the mechanism.

The camera raise needs to be zeroed before each use. Click the calibrate button on the ICON™

interface after system startup. The mechanism will lower itself to its lowest position, detected through a

magnetic switch. Note that the operator can control the motorized camera raise before calibrating after

system startup however the operator will not have any position feedback and it may be possible to

hyperextend the mechanism.

Note: The Powered Camera Raise will not position feedback until it is calibrated

using ICON (Inuktun Controller Software).

Warning: Keep hands clear of the camera raise when in operation as it presents

a potential pinching hazard.

Note: Always make sure there are no obstructions to the camera’s movement

before operating the camera raise.

When packing the Versatrax 150™ into the optional Pelican shipping case with the powered camera raise

installed, make sure to adjust the height of the camera to its shipping height before powering down the

system. For packing, the tracks should be set FLAT, and the height of the camera should be between

115 – 130 mm (4.5 – 5 in) measured from the floor to the support bar underneath the camera.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 22 of 57

User Manual

Manual Camera Height Adjustment

If the Versatrax 150™ has a manually adjustable camera bed the height of the camera may be adjusted

as follows:

1. Remove the push button locking pin.

2. Adjust the height of the camera to the nearest locking hole.

3. Re-insert the locking pin.

Note that there are two columns of numbers on the indicator plate. STD is for the standard

chassis setup, while XT is for when the track extension plates are installed.

Minimum Bend Sizes

As the vehicle fits into smaller pipe sizes, the

minimum bend radius it can navigate becomes

restricted. The following table lists the minimum

bend radius for different sizes of pipe based on

a 90-degree bend, internal pipe diameters, and

the standard parallel chassis configuration.

Pipe ID

Bend Radius to

Centerline

305 mm (12 in)

Straight

355 mm (14 in)

5D – 1,780 mm (70 in)

405 mm (16 in)

3D – 1,220 mm (48 in)

455 mm (18 in)

1.5D – 685 mm (27 in)

510 mm (20 in)

1D – 510 mm (20 in)

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 23 of 57

User Manual

Spectrum 90™ Installation

The Versatrax 150™ can mount any of the Spectrum 90/120/120HD™ cameras. Installation is typical for

all three camera types as follows:

1. Adjust the camera bed to the position shown below. This will allow access to the camera

mounting screws. If a motorized camera raise mechanism is installed the system will need to be

powered up and raised into position. ALWAYS turn off the system before working near the raise

mechanism pinch points, which may cause injury to fingers and hands.

2. The purge valve indicates the top of the camera, as shown in Error! Reference source not

found.. Mount the camera with the valve on top.

3. Slide the camera into position from the front of the camera bed.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 24 of 57

User Manual

4. Install the connector while the camera is part way in. Push the whip connector all the way onto

the camera. Make sure there is no gap between the rubber faces of the connectors. Screw the

locking collar onto the bulkhead connector; finger tight is good. Periodically apply a small amount

of silicone grease to the connector to keep it lubricated; however, avoid too much grease in the

female socket (vehicle side) because this can make the connector difficult to plug in.

5. Move the camera all the way to the rear tight to the camera mounting plate. Slide the connector

into the square opening and install the camera screws. Use M6 x 16 mm SHCS – note that older

cameras may use ¼-20 x 5/8 in SHCS.

M6x16mm SHCS

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 25 of 57

User Manual

Spectrum 120HD™ Installation

Because of the larger connector on the SP120HD™ camera, it is necessary to use spacers behind the

camera to make room for the connector as shown in Error! Reference source not found.. Thread the

spacers into the back of the camera and mount using 3x M6 x 16 mm SHCS as per the previous section.

Spectrum 120™ Bumper Bars

Bumper bars for the Spectrum 120 are installed directly onto the camera’s rotating head. Typically, the

bumper bars are installed at the factory during system assembly but can be retrofitted as follows:

1. Remove the two rear

screws (M6 x 14 mm

SHCS) from the

camera side-plates –

do one side plate at a

time and make sure

to hold the side-plate

secure so it does not

come loose from the

camera.

2. Install the bumper bar

assembly using 2x

M6 x 30 mm SHCS –

use blue Loctite 243.

Removal is the reverse of installation

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 26 of 57

User Manual

Light Installation

Light Mount When Using Standard Length Tracks

The 901 lights are installed onto the camera mount plate via mounting bracket as follows:

1. If the 901 mounting brackets are not installed, attach them to the back of the camera mount plate

using:

a. Older blue anodized chassis’ use ¼-20 x 5/8 in SHCS

b. Hard gray anodized chassis use M6 x 16 mm SHCS

2. Attach the lights to the front of the brackets using 2x M5 x 16 mm SHCS each.

3. Connect the whips to connector on the back of the lights, grease both the male and female

connectors with a dab of silicone grease.

4. Make sure the whips are routed properly through their P-clamps as shown (automatic camera

raise routing shown).

M6x16mm

SHCS

GRAY: M6x16mm SHCS

BLUE: ¼-20 x 5/8” SHCS

GRAY: M5x8mm

SHCS BLUE: #10-24

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 27 of 57

User Manual

Light Mount For Extended Tracks

When the extended tracks are installed, a different light bracket must be used to avoid interference

between the end of the tracks and the lights.

WARNING: Reduced Clearance. With the 901 lights installed with the extended

tracks, the vehicle will no longer fit into a 305 mm (12 in) ID pipe. Minimum pipe

size is increased to 355 mm (14 in)

To install the light mount:

1. Disconnect the lights and remove the regular light mounts from the frame.

2. Remove the camera

3. Remove the bumper bar holder (3/8-16 x 6 in SHCS).

4. Slide the light holder bracket over the bumper bars until it is 19 mm (0.75 in) away from the

back plate.

5. Use 2x M6 x 10 mm nylon tipped SSCREWs to secure holder to the bumper bars.

6. Reinstall the bumper bar holder and camera.

7. Install the lights onto the brackets using 2x M6 x 16 mm SHCS.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 28 of 57

User Manual

FIGURE 1: 901 LIGHT INSTALLATION – EXTENDED TRACKS

Minitrac™ Installation

To install the Minitracs™ onto the parallel chassis, the vehicle must be configured as follows:

a. Lower the camera raise to the lowest position so the vehicle can be turned over.

b. Power the system down and disconnect the tether.

c. Remove any ballast weights.

d. Adjust the track hinges to the smallest pipe setting so that the inside screws are easily

accessible.

WARNING: High Voltage 400 VDC. Always make sure the system is powered

down and disconnected before performing any maintenance. 400VDC can cause

serious injury and death.

Once the vehicle is properly configured, install the Minitracs™ as shown below:

1. Lay the track onto the inner hinge as shown. The beveled ledge on the track should rest on a

step inside the hinge so that the bolt holes are at the correct height.

2. Bolt the inside link in place using 2x M6 x 16 mm SHCS and Loctite 243 (blue). Use the two rear

screw positions as shown.

STEP 1

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 29 of 57

User Manual

STEP 2

3. Tip the vehicle to access the outside hinge.

STEP 3

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 30 of 57

User Manual

STEP 4

4. Secure the outside hinge using 2x M6 x 16 mm SHCS and Loctite 243 (blue).

5. Secure the cabling as shown in the final illustration. The angled clamps are held on using M5 x 12

mm FHMS. The outside screw secures the cable with a P-Clip underneath.

STEP 5

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 31 of 57

User Manual

Track Height Extensions

Track extension plates simply bolt onto the outer hinges using M6 x 16mm socket cap screws. The tracks

then bolt onto the extension plates as they normally would on the chassis as explained in the previous

section. Extension plates increase the ground clearance of the vehicle from 41 – 69 mm (1.6 – 2.7 in),

depending on chassis configuration. With the extensions installed, the pipe sizes on the indicator plaque

are read from the XT column. Also note that the distance from the face of the P-Clips (see preceding

section) to the face of the Minitrac™ connectors must be increased from 310 mm (12 in) to 380 mm (15in)

by extracting cable length from inside the track hinges, and an additional 8 mm (0.31 in) P-Clip must be

installed on the inside extension plate in the hole provided.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 32 of 57

User Manual

Spectrum™ Camera Extension

The optional camera raise extension is a bolt-on bracket which raises the camera by 356 mm (14 in).

1. Remove the camera, handle, bumper bars and mount, and lights and brackets from the vehicle

and install them on the extension bracket. The top of the extension bracket is made with the

same profile as the original camera mount.

2. Bolt the extension bracket onto the original camera mount. The fasteners used depend on the

chassis color. The height of the bracket can be adjusted to six different positions.

a. Blue anodized chassis – 2x ¼-20 x 5/8 in SHCS from the back and 1x 3/8-16 x 1¼ in

SHCS from the front.

b. Hard gray anodized chassis – 2x M6 x 16 mm SHCS from the back and 1x M10 x 20 mm

SHCS from the front.

3. Mount the camera and lights as usual on the extension bracket.

4. Install the supplied wiring harness extension to the camera and lights.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 33 of 57

User Manual

Rear Camera Installation

The Versatrax 150™ system comes standard with a rear facing Inuktun Sapphire™ camera. A bulkhead

connector, mounting collar and dummy plug is included with the harness block at the back of the vehicle.

WARNING: High Voltage. The bulkhead connector is supplied 36-70 VDC. This

connector must be plugged with a protective cap whenever the Sapphire camera

is removed. Fatal shock or system damage may otherwise result. Never operate

the system with this connector open.

Note:

The Sapphire camera uses a higher voltage and different pin-out than the Inuktun Amber™

camera which is used on other Eddyfi Technologies equipment. You cannot use the Amber

with the Versatrax system. Attempts to install the Amber camera will damage the connector

and burn out the camera.

To install the Sapphire camera if not installed, do the following as shown below:

1. Remove the dummy plug from the rear bulk head connector.

2. Attach the mounting flange to the back of the Sapphire camera using 2x M3 x 16 mm FHMS.

3. Plug the camera into the bulkhead connector – make sure to align the mating pins and grease the

male connector.

4. Screw down the mounting plate using M3 x 8 mm SHCS.

Removal is the reverse of installation – make sure to cap bulkhead connector with a dummy plug.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 34 of 57

User Manual

Advanced Accessories

Minitrac™ Length Extensions

Extensions may be added to the Minitracs™ to increase their length by 114 mm (4.5 in) to improve

vehicle stability and increase weight. The tracks mount to the chassis as normal, and configurations will

function as normal – with the exception that the 901 lights must be removed for use in 300 mm (12 in)

pipe. Refer to the section above on Spectrum 120™ Bumper Bars

Bumper bars for the Spectrum 120 are installed directly onto the camera’s rotating head. Typically, the

bumper bars are installed at the factory during system assembly but can be retrofitted as follows:

3. Remove the two rear screws (M6 x 14 mm SHCS) from the camera side-plates – do one side plate

at a time and make sure to hold the side-plate secure so it does not come loose from the camera.

4. Install the bumper bar assembly using 2x M6 x 30 mm SHCS – use blue Loctite 243.

Removal is the reverse of installation

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 35 of 57

User Manual

Light Installation for details.

Active Track Chassis Articulation

Active track gives the operator remote control over the chassis size configuration. Active track is

configured to install either on the left or right-hand side of the vehicle. Partial chassis disassembly is

required in order to install and is provided as a factory option – see the Active Track user manual for more

information.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 36 of 57

User Manual

Sonde

A standard Ø19 mm (Ø0.75 in) battery powered sonde is able to mount on either side of the chassis as

shown below. The sonde depicted below is a Prototek FV-20 512 Hz. If the Active Track motor is

installed, the sonde can still mount behind the Active Track motor.

To mount the sonde onto the chassis do the following as shown below:

1. Clamp the sonde into the mounting bracket using a M5 x 20 mm SHCS

2. Fasten the sonde and bracket to the back of one of the top hinges using 2x M5 x 20 SHCS

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 37 of 57

User Manual

Fiber Optic Tether

If your system comes equipped with a fiber optic tether, do the following to mate the fiber termination

canister to the harness block as shown below:

1. Mate the electrical connectors between the fiber termination canister and harness block –

make sure to align the keyways on the top of the connectors.

2. Install the two connecting brackets with 2x M6 x 16 mm SHCS into each side of the

harness block and 2x M6 x 12 mm FHMS into each side of the termination canister.

3. Connect the rear camera and other auxiliary devices to the tether termination can. A

whip extension will be needed for the rear camera.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 38 of 57

User Manual

Laser Scanner Mount

If your is equipped with an optional ULS-100 laser scanner module, it can be centered in the pipe by

adjusting the quick-release pin at the base of the linkage.

Mount the adjustable arm for the ULS-100 scanner to the underside of the main camera mounting block

using the M6 x 16 mm SHCS. Bolt the laser scanner with its mounting brace to the “L” shaped bracket at

the end of the adjustable arm using M5 x 20 mm SHCS. The scanner must connect to the harness block

through the power conversion can which drops the voltage from 48 VDC to 24 VDC. Run the cable

through the top of the linkage (not between the links) and secure using P-clips.

M6x16mm

SOCKET CAP SCREW

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 39 of 57

User Manual

Odometry Module

The odometry module is an optional factory installed module which provides the pitch, roll, heading,

ambient temperature and the distance travelled. It is secured to the bumper bar holder above the camera

using 4x M4 x 20 mm SHCS. Make sure the cable whips are installed and routed as shown.

The figure below shows how the orientation sensor is mapped relative to the vehicle.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 40 of 57

User Manual

The axes are defined as follows:

• The Y axis is the length of the vehicle

• The X axis is the width of the vehicle

• The Z axis is the height of the vehicle

A clockwise rotation around the Y axis is defined as the positive direction (increases value). A clockwise

rotation around the X axis is defined as the positive direction (increases value). A clockwise rotation

around the Z axis is defined as the positive direction (increases value).

Note that the coordinate system and rotation directions can be redefined using ICON™

The odometer module has an optional T-type thermocouple. The usable temperature range of this

thermocouple is -200 – 350 °C (-330 – 660 °F). The thermocouple is accurate to +/- 1.0 °C (1.8 °F) or

1.5%.

The module connects to the wheel encoder located underneath the vehicle via the 6-position impulse

connector. The wheel encoder diameter is 80 mm (3.15 in) and outputs 256 pulses-per-revolution using

9-bit quadrature encoding.

If your system includes the Encoder, make sure the cable whip is installed and secured as shown below.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 41 of 57

User Manual

Inline Vehicle

Minitrac™ Installation

WARNING: Pinch Hazard. Keep your fingers and hands out of the X-Hinge. Do

not hold or lift the vehicle by the X-Hinge. Severe pinching and hand injury may

result. Always use the handles next to the hinge for lifting.

All fasteners are M6 x 16 mm SHCS as illustrated above.

1. Lay the vehicle on the work bench with the tracks in the orientation shown. The far side plates

may remain attached to the handles and hinges as shown.

2. Plug the mating connectors into the tracks – make sure to align pins and grease the male

connectors

3. Attach the tracks to the far side plates.

4. Attach the free side plates to the tracks, handles and hinges.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 42 of 57

User Manual

Spectrum 90™ Installation

Install the Spectrum™ camera on to the front of the vehicle using 3x M6 x 16 mm SHCS (older cameras

use ¼-20 x 5/8 in SHCS). Use Loctite 243 (blue) with all fasteners. Lubricate the connector with silicone

grease or silicone spray and fully engage the locking collar.

Guide Wheel Adjustment

For proper operation and stability, the chassis must be adjusted for the target pipe size.

Guide Wheel Adjustment: First, ensure the guide wheels are located correctly on the vehicle. As

illustrated below, the front guide wheels must be toed outward from the vehicle (by 2½°). An incorrect

installation (toed in) will result in vehicle instability. The rear guide wheels are straight.

Set the wheel height to suit the target pipe. The wheels should be just lightly touching the pipe. The

chart below outlines approximate wheel heights for standard pipe sizes. A guide wheel height gauge is

also provided with the system for generic pipe sizes.

Pipe ID

Wheel Height

150 mm (6 in)

28 mm (1.13 in)

200 mm (8 in)

16 mm (0.63 in)

255 mm (10 in)

13 mm (0.5 in)

305 mm (12 in)

11 mm (0.44 in)

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 43 of 57

User Manual

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 44 of 57

User Manual

Camera Height / Skid Adjustment

Rear Camera: The rear camera must be removed for 150 mm (6 in) pipe but may remain in place for 200

– 300 mm (8 – 12 in) pipe.

Camera Adjustment: There are four standard sizes of camera height adjustments; 150, 200, 250, and

300 mm (6, 8, 10 and 12 in). The 150mm (6 in) configuration will use a small skid under the camera.

Wheel placement for 200, 250 and 300 mm (8, 10, 12 in) pipe is illustrated below. Always use Loctite 243

with the shoulder screw. Wheel lubrication is not required.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 45 of 57

User Manual

Rear Camera Installation

The Versatrax™ system comes ready to accept a rear facing Sapphire™ camera. The plug-in whip is

included with the harness block at the back of the vehicle. The Sapphire camera will come supplied with

a mounting bracket and installation hardware. Note that for inline configurations below 200 mm (8 in)

diameter may not have enough clearance for the rear camera.

WARNING: High Voltage. The mating whip is supplied 70 VDC. This whip must

be capped with a dummy plug whenever the Sapphire is removed. Shock or

system damage may otherwise result. Never operate the system with this

connector open.

Note:

The Sapphire camera uses a higher voltage and different pin-out than the Amber camera

which is used on other Eddyfi Technologies equipment. You cannot use the Amber with the

Versatrax system. Attempts to install the Amber camera will damage the connector and burn

out the camera.

Installation

1. Remove the cable clamp holding the camera whip.

2. Install the camera bracket as shown using 2x M4 x 8 mm PHMS.

3. Install the camera using 2x M3 x 16 mm PHMS. Note the camera orientation marked “TOP” seen

on the label inside the epoxy.

4. Plug the mating whip into the camera – make sure to align the pins and grease the male

connector.

5. Secure the locking collar after plugging in the camera.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 46 of 57

User Manual

Operation

Pre-Operations Check

Before each deployment of the Versatrax™ system, ensure everything is completed on the following

checklist:

❑ Verify that the work area has been safely set up.

❑ Verify that the line voltage available at the worksite matches the equipment setup.

❑ Verify that power and deck cable connections are correct.

❑ Verify the vehicle for the following:

Check that the vehicle is in the correct configuration for the deployment.

Check the vehicle for mechanical damage to the chassis or cable harnesses which could affect its

operation.

Ensure that all fasteners are in place and secure. In particular, check the fasteners holding on

cameras, lights, tracks and tow cable.

Visually inspect the vehicle and Minitracs™ to ensure that the moving parts are free of debris and

functional. Make sure the track belt is free of debris and turns freely.

Check the tether and vehicle whips for damage.

Ensure camera viewports are clean.

Check the 901 light fins for fouling

Optional Components - Check that the screw on the automatic camera raise has been well

lubricated.

❑ Check the winch/reel for the following:

Check that nothing will block movement of the level wind shuttle.

Check that the tether has no loose, dangling coils. Dangling coils can propagate as the drum

rotates and have the potential to jump the drum. Take care of these before deploying the tether.

WINCH - Check that no objects, tools, etc., have fallen into the winch mechanism around the chain

and drum.

WINCH - Check that the drum lock is disengaged and latched open. (Models with a disk brake do

not have the drum lock pin.)

WINCH - Ensure that the drive clutch moves freely and is operational.

❑ Power up the system and check the following:

Check for sufficient SSD drive space for recording.

Check record directories are set.

Check video quality and camera control functions.

Test video recording.

Test main lights.

Test track control.

Verify automatic camera raise is zeroed.

Optional Components - verify operation of other optional components.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 47 of 57

User Manual

Post-Operations Check

A Post-Ops inspection should be carried out after every deployment using the following checklist:

❑ Inspect the tether for damage as it is reeled in.

❑ Visually inspect vehicle for entrained debris or mechanical damage.

❑ Test each function to ensure proper operation.

❑ Clean the system by hosing it down with water at regular line pressure. Do not pressure wash. The

tracks may be cleaned off by hosing them down while running. If the system has been used in salt

water, thoroughly rinse the vehicle with fresh water right away.

CAUTION: Do not use a pressure washer to clean the camera. Very highpressure water can push past seals and flood the camera resulting in electrical

damage or personal injuries.

❑ Optional Components - Locate the automatic camera raise height at 80mm (3.1 inches) from its home

position for packing into the plastic shipping case.

❑ Take time to pack the system properly for transport away from the worksite.

❑ Store the system in a dry environment.

Note: Ensuring the Versatrax™ system is always stored in good working condition will minimize

deployment time for future inspections.

ICON™ & ICON™ RPT

Vehicle control and video recording are accomplished using ICON™ graphical interface controller

software. Video playback and reporting are conducted through ICON RPT. Manuals for these two

software packages are included separately. Controls for recording and snapshot functions are kept on-

screen with the camera controls.

• ICON Manual – (Control Interface and Recording)

• ICON RPT Manual - (Reporting, Playback and Video Export)

Power-Up Sequence

After all wiring connections have been made, the system may be powered up. The recommended

sequence for power-up is as follows:

1. Power up the control computer and allow time for it to fully boot.

2. Switch on the Interface Box.

3. Turn on the Vehicle Power Supply.

4. Start the ICON (Inuktun Control) control program.

ICON always begins with identification of attached system components (cameras, tracks, etc.). If vehicle

power is turned on after ICON is started, the system will not function until ICON is closed and restarted.

Versatrax 150™

Document: UMDW014058.docm

Revision: A03

Created by: KW

Date: 10 Oct 2019

3075415-A03

Source Location: C:\ePDM\ISLEng\products\dw-versatrax150mkii\manuals\UMDW014058.docm

Page 48 of 57

User Manual

Ground Fault Detection & Alarms

The front of the high voltage power supply includes power on and off buttons as well as status indicators.

The ON button and status indicators will light green during normal operation. The two red fault indicators

may light momentarily during startup and shut down; this is normal.

There are two status indicators:

1. Supply: This is the main power supply providing 400 VDC to the tether. A SUPPLY fault

warning will trigger if the AC power input drops below 85 VAC or if the power supply reaches

over-temperature levels. The power supply will be automatically shut down.

2. Tether: The power supply is also equipped with fault detection which monitors potential current

leakage from the high voltage power feed to the tether and vehicle. A TETHER fault warning may

indicate possible damage to the tether cable or water leakage inside the harness block or

Minitracs™. This fault will also be triggered if the output fuse has blown due to a short circuit.

Tether faults should not be triggered under normal operation and may be an indication of a major device

malfunction or a potential safety hazard. If a tether fault is announced, the power supply should be

disconnected and the reel, deck cable, tether, and vehicle harness whips should be inspected for

damage. If all cabling looks good, the Minitracs™ and integrated harness block should be examined.

If either of the fault indicators trip, the power supply will automatically disable power to the tether and

vehicle. The corresponding status indicator will light red and the ON button will flash to indicate external

power has been disabled. The power supply will not re-enable vehicle power until it has been reset by

pushing the OFF button.

WARNING: A ground fault alarm may be an indication of a safety risk. The system

should be turned off and carefully examined before powering back up.

Note:

The GFI fault detector monitors the high voltage DC power feed only and is not a