Inuktun Services Ltd.

2569 Kenworth Road, Suite C

Nanaimo, BC, V9T 3M4

CANADA

+1.250.729.8080

info@eddyfitechnologies.com

www.eddyfitechnologies.com

2569 Kenworth Road, Suite C

Nanaimo, BC, V9T 3M4

CANADA

+1.250.729.8080

info@eddyfitechnologies.com

www.eddyfitechnologies.com

INUKTUN MICROTRAC™

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 2 of 26

User Manual

Table of Contents

About This Manual ........................................................................................................................................ 3

Description .................................................................................................................................................... 3

Specifications ............................................................................................................................................ 4

Precautions ............................................................................................................................................... 5

Certification ............................................................................................................................................... 5

Connector Pin-Out .................................................................................................................................... 6

Load and Speed Specifications ................................................................................................................ 7

Basic Loading Specifications ................................................................................................................. 7

Influences on Loading ............................................................................................................................ 8

Safety ...................................................................................................................................................... 11

System Setup .............................................................................................................................................. 13

Mounting the Track ................................................................................................................................. 13

Flange Adapter ....................................................................................................................................... 15

Connector Handling ................................................................................................................................ 16

Impulse Connector: Lubrication and Cleaning ..................................................................................... 16

Belt Installation........................................................................................................................................ 17

Maintenance ................................................................................................................................................ 22

Rinsing and Cleaning .............................................................................................................................. 22

Scheduled Maintenance and Servicing .................................................................................................. 22

Overhaul ................................................................................................................................................. 23

Parts and Repairs ....................................................................................................................................... 24

Ordering Parts/Customer Service ........................................................................................................... 24

Warranty Repairs .................................................................................................................................... 24

Factory Returns to Canada ..................................................................................................................... 25

Product/System Drawing Package Availability ....................................................................................... 25

Limited Warranty Policy .............................................................................................................................. 26

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 3 of 26

User Manual

About This Manual

This manual has been prepared to assist you in the operation and maintenance of your Eddyfi

Technologies’ Inuktun equipment. Correct and prudent operation rests with the operator who must

thoroughly understand the operation, maintenance, service and job requirements. The specifications and

information in this manual are current at the time of printing.

This product is continually being updated and improved. Therefore, this manual is meant to explain and

define the functionality of the product. Furthermore, schematics or pictorials and detailed functionality

may differ slightly from what is described in this manual.

Eddyfi Technologies reserves the right to change and/or amend these specifications at any time without

notice. Customers will be notified of any changes to their equipment.

Information in this manual does not necessarily replace specific regulations, codes, standards, or

requirements of others such as government regulations.

This manual copyright © 2019 by Inuktun Robotics Inc. All rights reserved.

Description

Inuktun Microtrac™ 4000 is a small, self-contained tractor module complete with its own electric motor

and drive train. They are designed for harsh environments including confined spaces, underwater,

radioactive areas, and in some harsh chemical solutions. Microtrac modules may be operated in pairs to

make a steerable platform or used in-line to fit in small spaces. Applications include storm and sewer

pipe inspection, use with bomb disposal robots, industrial inspection, and custom vehicles for nuclear

facility inspection and waste cleanup. Microtracs are made in three varieties: aluminum, brass or

stainless steel. The choice of track material will depend on its end use. In all versions, the final drive

power is delivered through a deep lug rubber track belt in either standard or extended length. As well, the

track can be configured for both left-hand or right-hand operation.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 4 of 26

User Manual

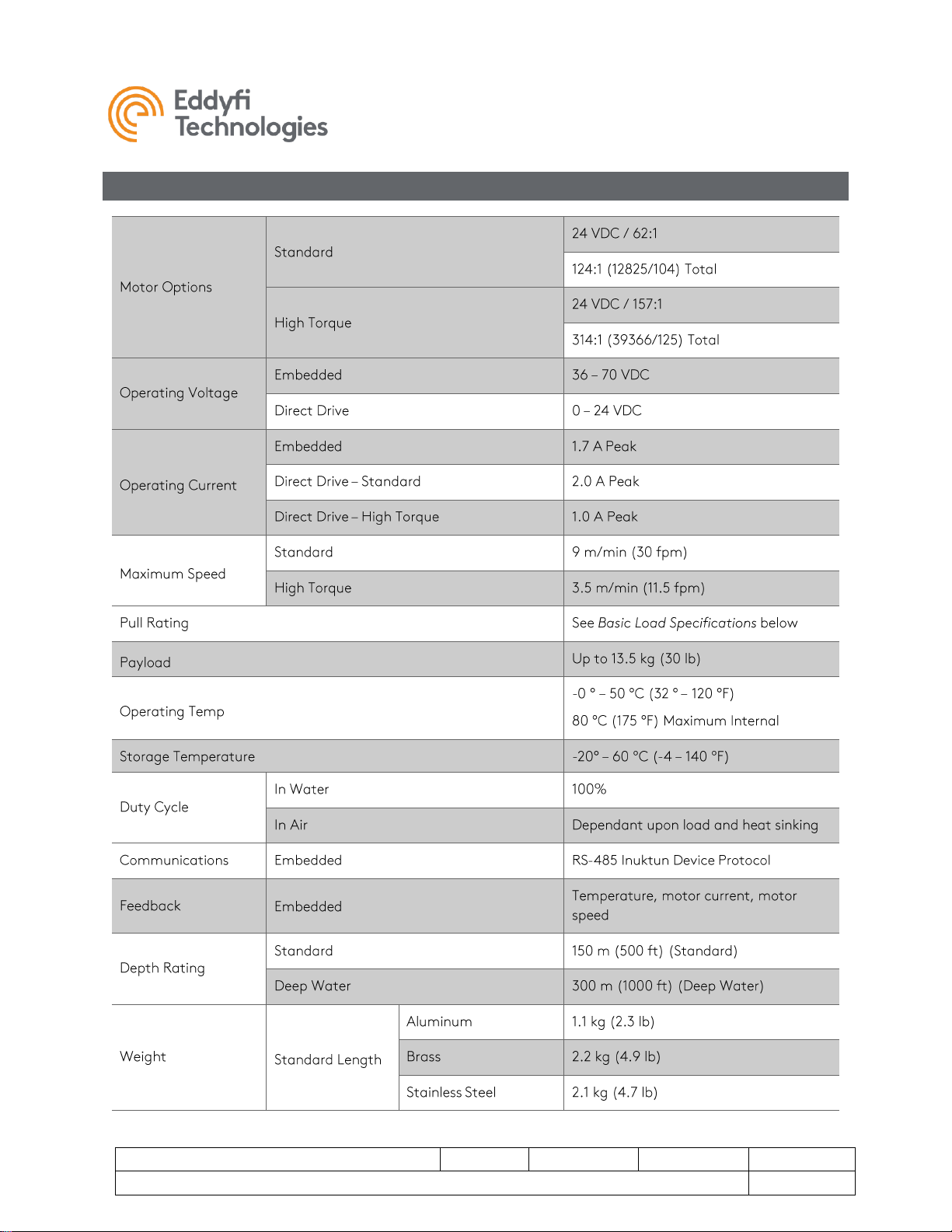

Specifications

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 5 of 26

User Manual

Precautions

IMPORTANT: When configuring a 70V system, check to see if the tracks are

compatible. Older versions of 4000 series Microtracs™ are not 70V

compatible. Look for the Wide Input Voltage symbol \V/ located on the side

plate of the track indicating 70V compatibility.

Certification

The product is built in accordance with:

Machinery Directive 2006/42/EC, and

Electromagnetic Compatibility Directive 2004/108/EC and Directive 2014/30/EU

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 6 of 26

User Manual

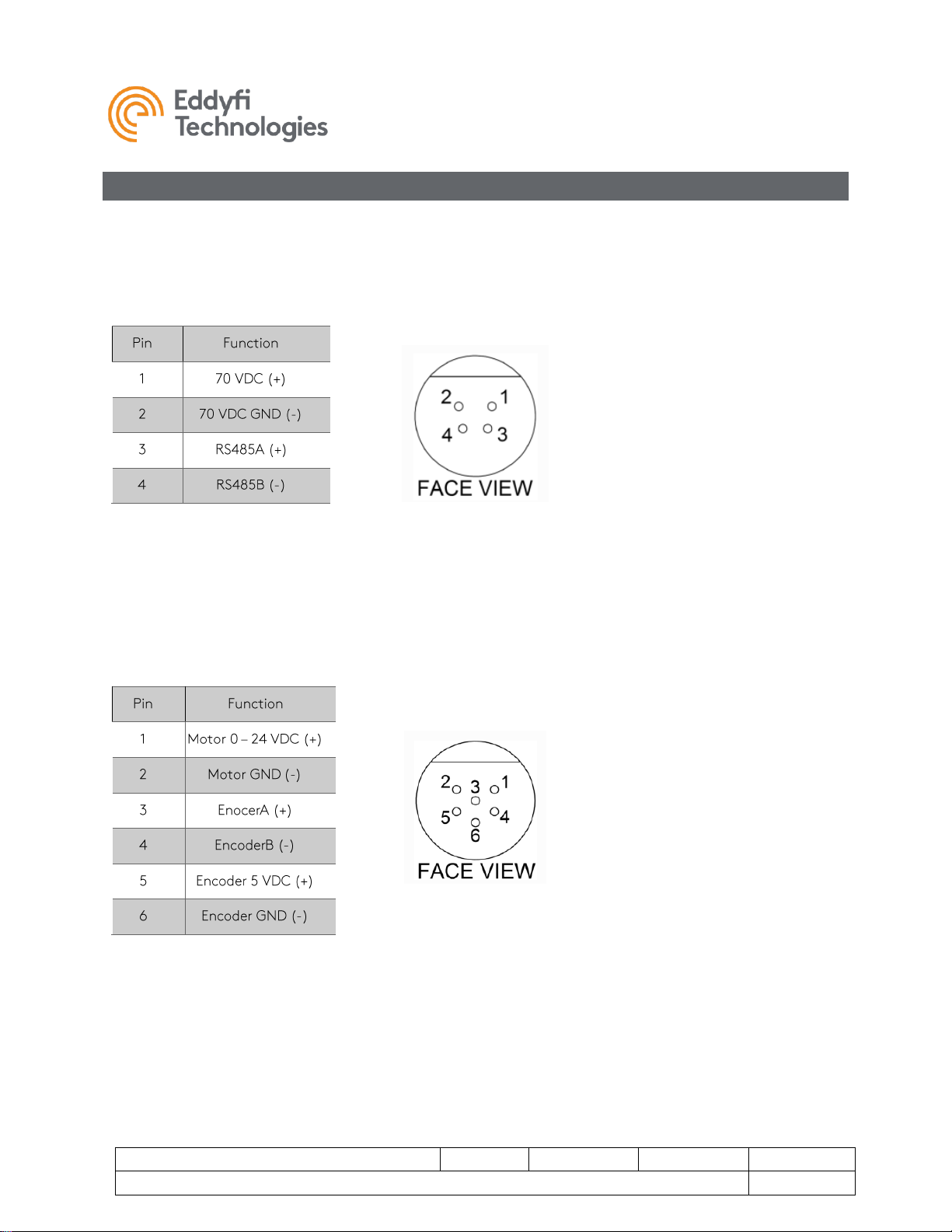

Connector Pin-Out

Standard Tracks

The embedded Microtrac 4000™ uses a 4-pin Impulse IE-55 connector on the side of the track to connect

power and communications. Contact Eddyfi Technologies for details of the RS-485 control protocol.

Note: Pin-out is shown for the Bulkhead Connector on the track.

Direct Drive Tracks

The embedded Microtrac 4000 uses a 6-pin Impulse IE-55 connector on the side of the track to connect

motor power, encoder power and encoder signals. Contact Eddyfi Technologies for details of the

encoder feedback.

Note: Pin-out is shown for the Bulkhead Connector on the track.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 7 of 26

User Manual

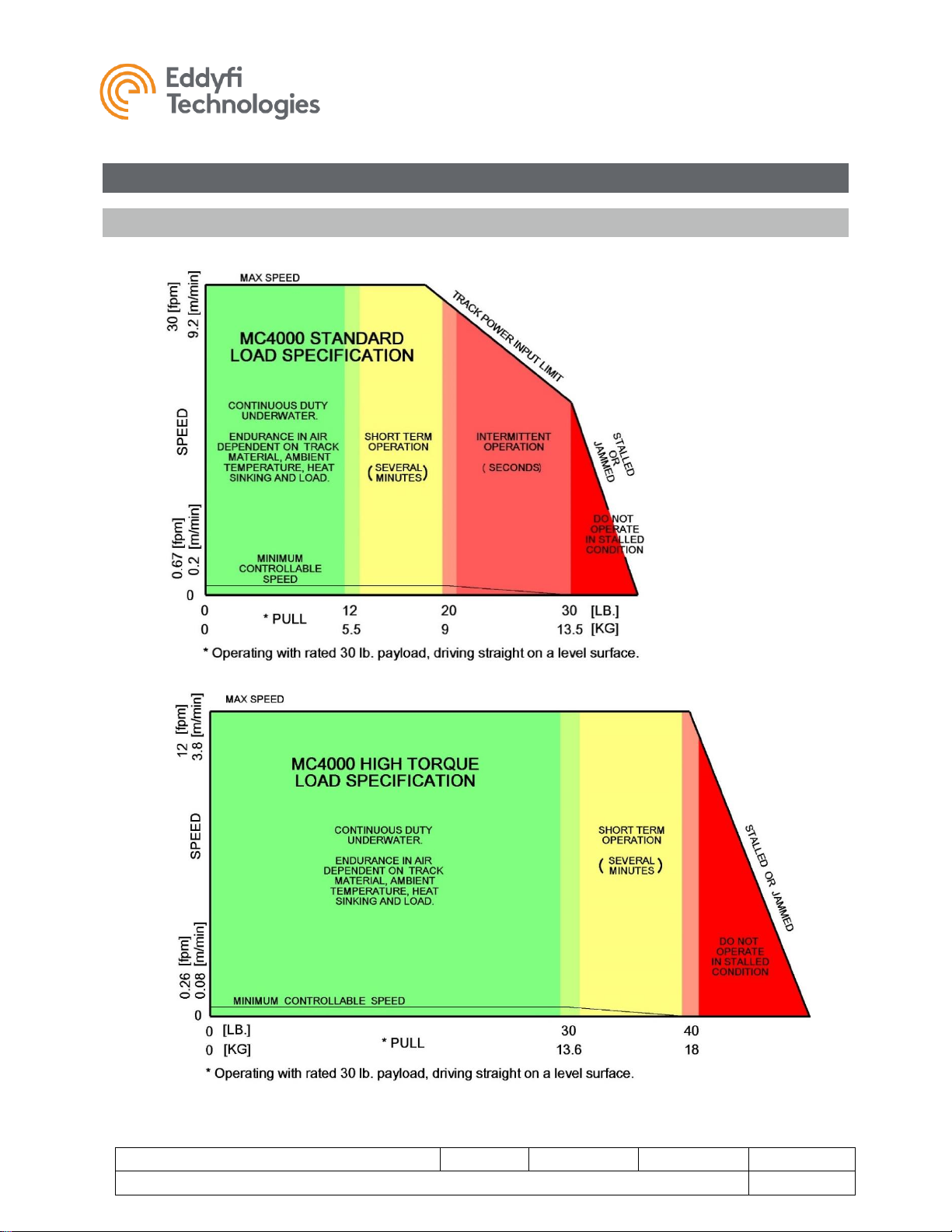

Load and Speed Specifications

Basic Loading Specifications

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 8 of 26

User Manual

The above diagram details the speed and loading specifications of the standard and high-torque

Microtracs™. There are four regions defining performance:

• Continuous Duty: Preferred operating region.

• Short Term Operation: Operation permitted for several minutes.

• Intermittent: Surge loading allowable for a few seconds at a time.

• Stalled / Jammed Condition: Automatic limiting is engaged to protect the motor and gearing.

Do not operate the track in the stalled or jammed condition.

Influences on Loading

For a typical tracked vehicle there are multiple factors that can increase load and diminish track

performance. These include the following and are detailed below:

• Additional Payload

• Inclines

• Effects of Differential Steering (skid steering with parallel tracks)

• Curved Geometry of a pipe

• Elevated Temperature / Poor Heat Sinking / Thermal Shut-Down

Additional Payload

Additional Payload may be added to the track, but the expected pull performance must be de-rated as

per the calculation below. Additional payload also affects differential steering, inclines and curved pipe

geometry (see below).

Pull Reduction = 0.25 x Extra Weight

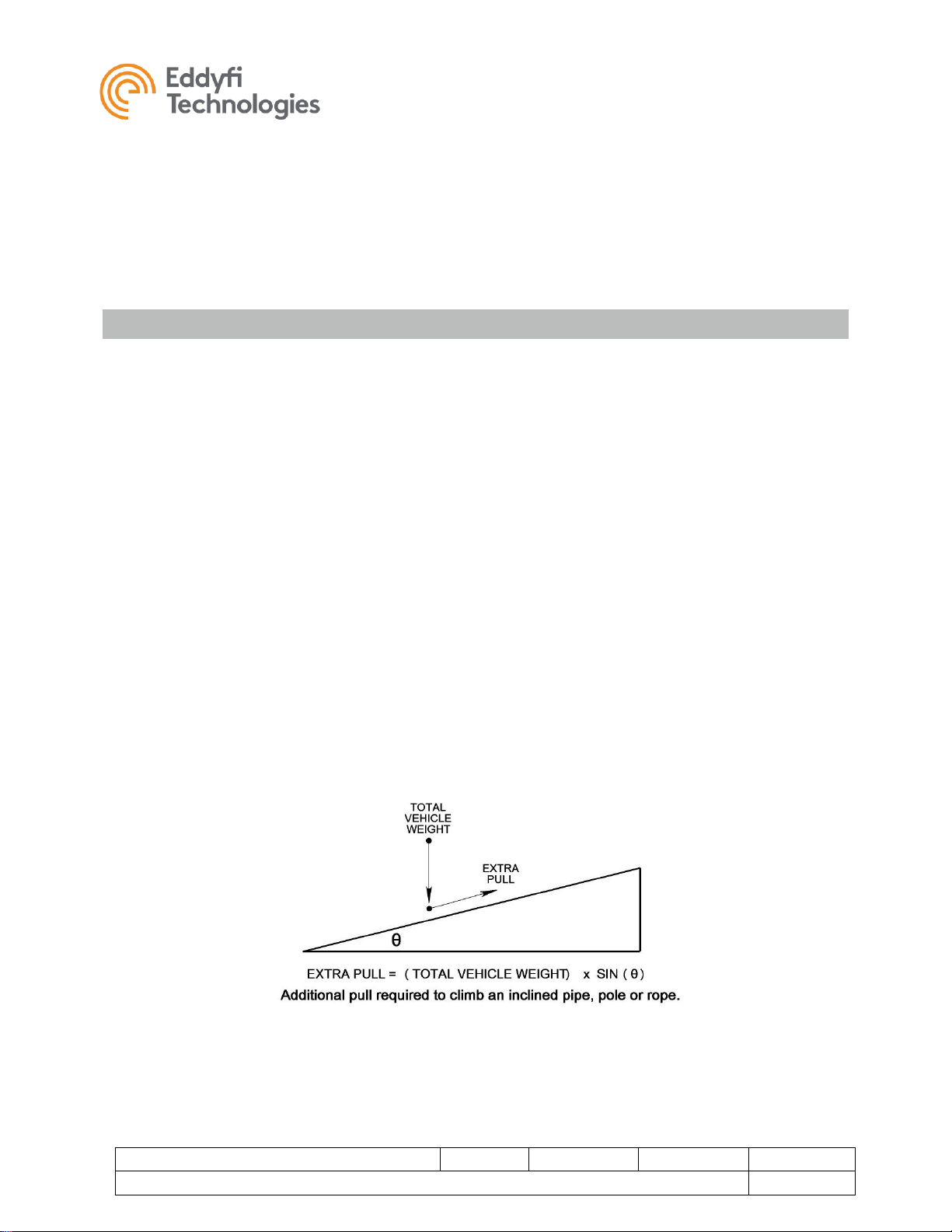

Inclines

Inclines cause the track to lift the vehicle weight against gravity and increase the track pulling load.

Calculate the incline load using the equation below. Magnetic downforce does not affect loading from

inclines — only forces from gravity. Note that the constant load from gravity becomes a significant factor

on vertical surfaces because the motor is working to resist the load even when the track is stopped.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 9 of 26

User Manual

Differential Steering

Differential Steering means steering by varying the speed of two tracks such as with a tank or bulldozer.

During the steering process the tracks are dragged sideways in addition to forward / backward

movement. The sideways movement adds to the total track load and requires extra torque from the

motor. The greatest increase in loading occurs during a spot turn; the load being calculated as per the

equation below. A typical 13.5 kg (30 lb) magnetic VT100 with 13.5 kg (30 lb) of down-force on a surface

with friction coefficient µ = 0.5 will experience an additional 8kg (18 lb) load per track to execute the spot

turn. When steering on a vertical surface include only the magnetic down-force for the differential

steering load calculation.

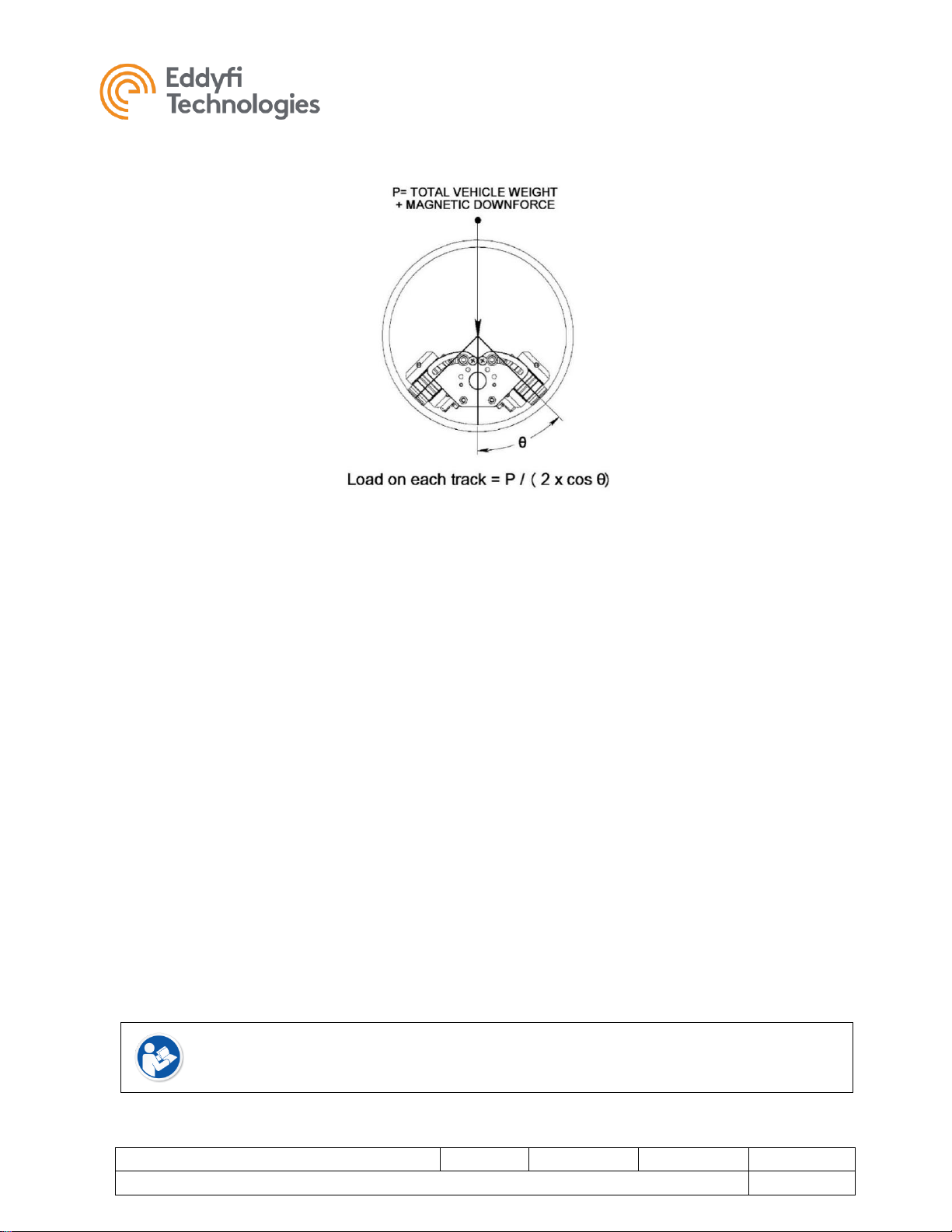

Curved Geometry

Curved Geometry inside a pipe will increase the payload on a track depending on the angle of contact

with the pipe. For nearly flat tracks the increase is small. For a contact angle of 60°, the load is doubled.

The same calculation is used for a track contacting the outside of a pipe. Include both vehicle weight and

magnetic downforce for this calculation.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 10 of 26

User Manual

Elevated Temperature & Thermal Shutdown

‘Duty Cycle’ refers to the length of time a track can run before overheating, and the following time

required to cool down. The duty cycle of the Microtracs 4000™ depends on:

• Track Material Thermal Conductivity (Aluminum, Brass = Good; Stainless = Poor)

• Ambient Temperature

• Track Load & Speed

• Wet / Dry Operation

• Heat Sinking

A track typically converts about 25% of the electrical input into motive mechanical power with the

remainder being converted into waste heat transferred to the environment outside the track. When run

continually at maximum power in a warm environment - up to 50 °C (120 °F), the tracks can heat up to

the maximum temperature within ½-hour. However, this does not represent normal operation. Typical

usage will include much starting and stopping for visual/NDT inspections and moderate loading for most

of a pipe run for pulling tether – so reaching the thermal limit of the track is not expected to be a common

operational concern. When tracks are bolted to a chassis, it further acts as a heat sink to help cool the

tracks.

When a tracks internal temperature reaches 80 °C (175 °F) it will automatically shut down and wait until

its internal temperature drops below 70 °C (160 °F) before restarting. If the tracks are operating

underwater, such as in a flooded pipe, heat transfer is excellent, and the duty cycle may be considered

continuous.

Note: Stainless steel tracks will require special consideration for cooling, as they

reach thermal shutdown sooner due to the extremely poor thermal conductivity of

the stainless steel itself.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 11 of 26

User Manual

Safety

In order to be able to use this product properly and safely, every user must first read these operating

instructions and observe the safety instructions contained therein. Take care of these operating

instructions and keep them in a place where they can be accessed by everyone.

CAUTION: Failure to follow these safety instructions may result in injury or

equipment damage.

WARNING: High Voltage 36-70 VDC. If the equipment is powered from a source

other than an Eddyfi Technologies provided controller, the power supplied to the

product must have reinforced isolation from the mains with no reference to earth

ground.

CAUTION: Disconnecting the track while the power is on can cause damage to the

camera. Disconnect the power source before servicing the product.

CAUTION: High Temperature. Under rated operating conditions this track can

become very hot, up to 80 °C (175 °F).

WARNING: Spark Hazard - Under no circumstances should this equipment be

used in a potentially explosive atmosphere.

• The Microtrac 4000™ is an industrial product. All personnel operating or maintaining this

equipment must be competently trained.

• There are no user serviceable parts inside. This product may be serviced only by qualified

technicians or trained personnel.

• Eddyfi equipment is used in many varied environments from hot/dry to confined spaces to deep

underwater. Such diverse environment risks must be addressed by the operators who are trained

to work in such surroundings. As such, the operator is responsible to determine safe site setup

and appropriate procedures for operation and maintenance of the equipment.

• Appropriate personal protective equipment (PPE) must be worn while operating and maintaining

the equipment.

• Do not use the product or any component exposed to pressures higher than the rated working

pressure.

In addition, observe the following precautions when cleaning or servicing the Microtrac 4000™

• Do not operate the track with a damaged connector or cable. Inspect connectors and cables

regularly for damage.

• Avoid creating a pinching hazard when designing a vehicle based on these tracks.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 12 of 26

User Manual

• Lay the track on its side if you are powering it up on the workbench.

• DC-Controlled tracks (without internal driver) must be protected by current limiting either by fuse

or electronically by the power supply. Current limiting and fuses are included standard with

Inuktun system controllers.

Call the Eddyfi Technologies Service department for assistance or service if needed.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 13 of 26

User Manual

System Setup

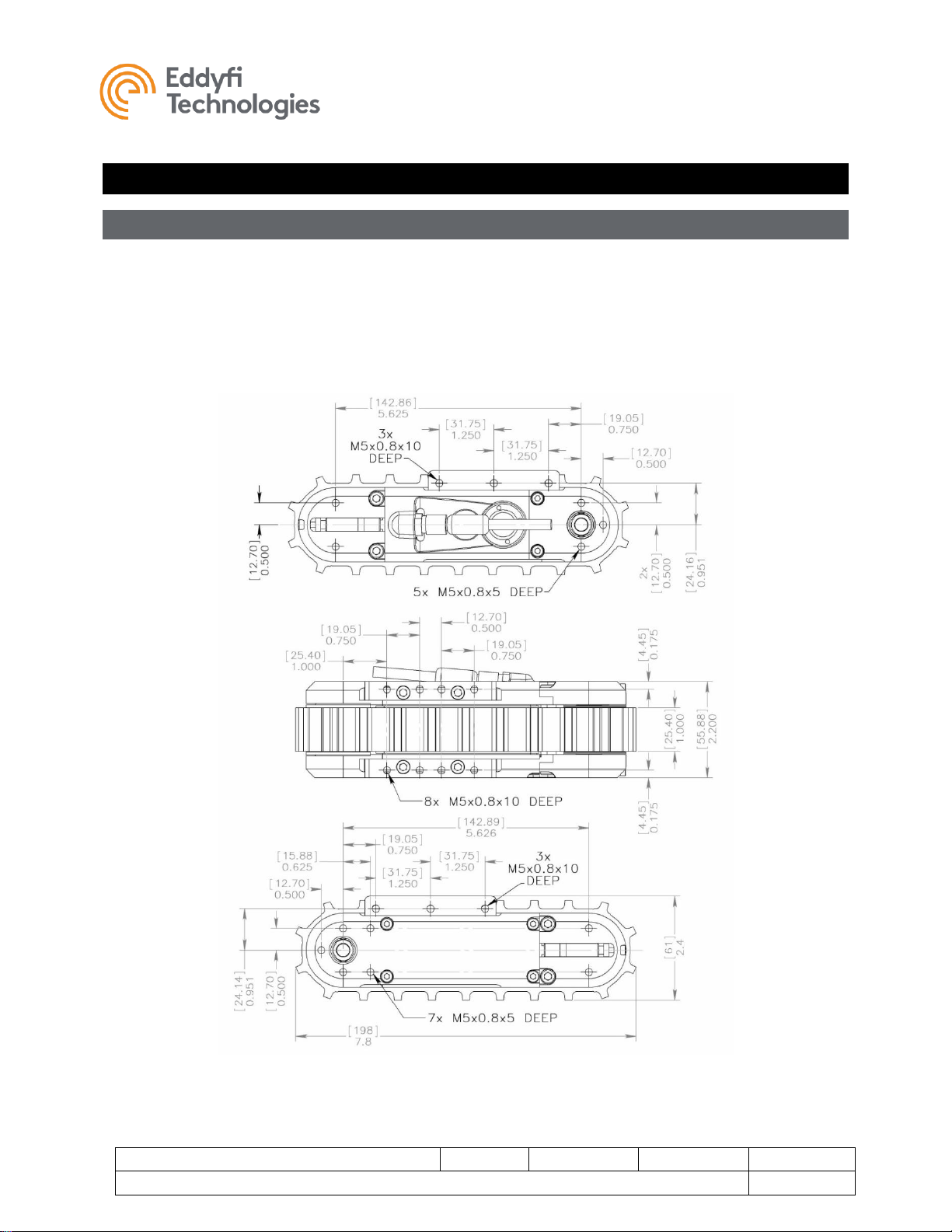

Mounting the Track

Microtracs™ are provided with a variety of mounting locations on the sides, top and bottom. Use of any

three mounting holes is enough to support the rated load. When using the side flange holes, make sure

the screws do not protrude beyond the flange and into the track belt. Mounting holes are also provided

on the sides of the Microtracs for in-line or chassis side-wall mounting. Note that hole depths can be

different depending on the position. All holes are tapped M5. Mounting hole locations are shown below

for standard and extended tracks.

MICROTRAC 4000 STANDARD

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 14 of 26

User Manual

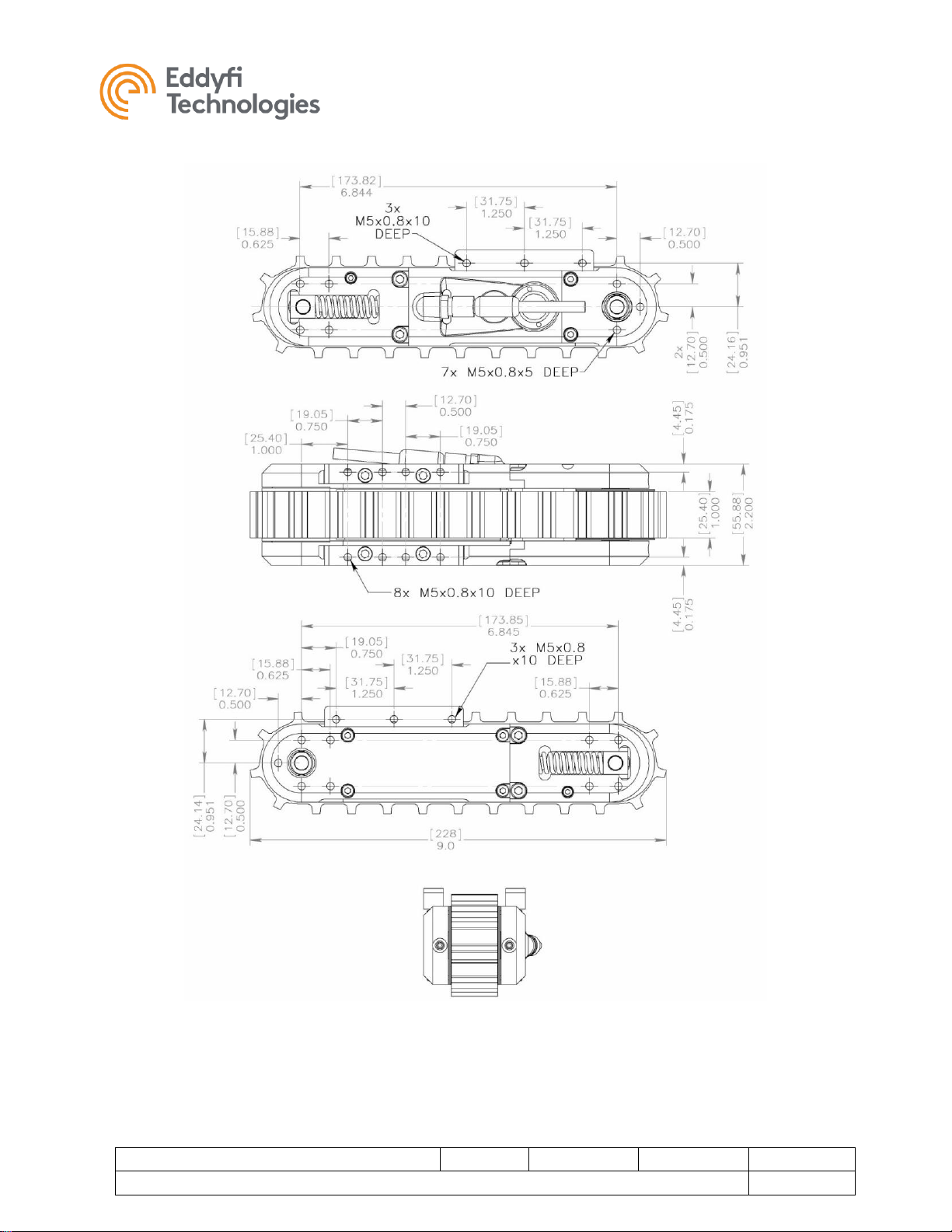

MICROTRAC 4000 EXTENDED LENGTH

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 15 of 26

User Manual

MICROTRAC™ 4000 DEEP WATER

Flange Adapter

Flange adapters come standard with the Microtrac 4000 for mounting to chassis plates or legacy

systems. Tracks can be configured for left or right-hand operation depending on which side the flanges

are mounted – top or bottom. Flanges may also be ordered with Imperial threads for non-metric

installations.

MICROTRAC FLANGE ADAPTER

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 16 of 26

User Manual

Connector Handling

Connectors are an essential part of system reliability. They should be properly maintained and cared for

to ensure long life and reliability. It is recommended to follow these steps to help prevent damage and

increase the life of connectors.

• Always put the cap back on the tether bulkhead when the tether is disconnected

• Always inspect the end of the connector prior to engaging

• Never plug in a dirty or damaged connector

• Visually align key-ways or locating pins prior to engaging the connector

• Always fully engage or tighten the connector

• Secure locking collars finger tight

• Install dummy plugs on unused connectors

• Disconnect by pulling straight, not on an angle

• Do not pull on the cable to disengage the connector

IMPORTANT: Never “Hot Plug” any connector, this will result in internal damage to the

electronics. Power down the system prior to connecting the inspection system tether.

Note:

Never use WD-40 or similar solvent-based fluids on connectors or crawlers. These will cause

the rubber parts of the connector or crawler to soften and swell rendering them inoperable.

Impulse Connector: Lubrication and Cleaning

• Lubricate mating surfaces regularly with 3M Silicone spray or equivalent, DO NOT GREASE

• Lubricate O-rings with Molykote 111 or equivalent

• Use dust caps to protect connectors wherever possible

• Clean connectors with soap and fresh water, rinse out with alcohol and allow connector to air

dry before using.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 17 of 26

User Manual

Belt Installation

Microtrac 4000™ belt replacement has been made easy by a spring tensioning system (except for

manual option) that automatically aligns and tensions the track belt. Procedures vary between the

standard-length and extended-length track as detailed below.

Standard Length Track

1. Remove the mounting flange from the label side of the track.

2. Release the belt tension. Notice the tensioning spring is compressed by a captured nut. Turn the

tensioning screws (counter clock-wise) until all the spring tension is released and both nuts are

resting against the housing shoulder. The tensioning screws do not need to be fully removed leave them in place. Procedure is the same for the manual tensioning option.

3. Remove the front side plate as shown, exposing the three screws on the front idler wheel.

Remove the three screws and the idler wheel flange.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 18 of 26

User Manual

4. The belt can now be lifted from the track. The track is now ready for cleaning or installation of a

new belt.

5. When replacing the belt ensure the drive wheel lugs are engaged with the belt before slipping the

belt back over the idler wheel.

6. Replace the idler wheel flange and side plate.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 19 of 26

User Manual

7. Tension the belt by turning the tensioning screws clockwise until the captured nuts bottom out in

their groove. They will be in position as shown below. Again – the tensioning screws stay in

place.

Manual tensionioning option is identical except that belt tension is set by screw depth – adjust the

tensioning screws until the belt is tensioned. Belt should be taut but still allow some deflection.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 20 of 26

User Manual

Extended Length Track

1. Remove the drive wheel cover and mounting flange on the side shown. The opposite mounting flange

can remain in place.

2. Compress the tensioning springs using M6 x 16 or longer jack screws.

The jack screws are fully removed from the track when the belt is replaced.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 21 of 26

User Manual

3. Manual Tension: Thread the tensioning screws on both sides of the track into the main housing

(CW) to release the belt tension.

4. Pull the belt off the track from the rear wheel first. The track is now ready for cleaning or installation

of a new belt.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 22 of 26

User Manual

Maintenance

Rinsing and Cleaning

After every mission check to see if the tracks need cleaning. To maintain top performance of the

Microtrac™ units, it is important to prevent excessive buildup of dirt under the track belt. A buildup will

increase the belt tension, causing the track to lose speed and pulling ability. Ultimately excessive tension

may stretch and ruin the track belt.

1. If the tracks have been used in salt water, thoroughly rinse the tracks with fresh water prior to being

stored away. Accelerated corrosion will result if the inspection system is not rinsed properly. Pay

close attention to rinsing and cleaning the spring and underneath the track belt.

2. Use an open hose or tap at regular water line pressure for rinsing – use a mild detergent and soft

brush. Do not pressure wash the equipment – water will be forced into the track at these high

pressures.

If it is necessary to apply aggressive cleaning fluids, consult the factory before use. Clean away

any dirt, grit or build-up near joints or moving parts. Also clean the drive wheel teeth, wear strip

and idler wheels.

CAUTION: Do not use a pressure washer to clean the camera. Very highpressure water can push past seals and flood the components resulting in

electrical damage or personal injuries.

Scheduled Maintenance and Servicing

Microtrac crawlers are designed to provide reliable service accompanied by a minimum downtime for

maintenance. The frequency of maintenance and/or repairs will be largely dictated by the type of use and

the environments the units are subjected to. Eddyfi recommends the following maintenance procedures

in addition to normal equipment operational inspections.

Daily

Daily or before each use of the Microtrac units:

1. Tracks with Spring Tensioners - Check that the belt tensioning springs are freely moving. This

can be done by pulling up on the edge of the track belt with your thumb – the belt should have a

small amount of give. If the springs are bottomed out, the material under the belt must be

removed before deployment to avoid damage and to attain best performance.

Tracks with Manual Belt Tensioners – Check that the tensioning screws have not slackened. Belt

should be taut but manual deflection with normal hand force should be possible. If the belts feel

too tight, check for debris or build-up underneath the belts and remove if present. Do not

overtighten belts or performance could be degraded, and damage could occur.

2. Visually inspect the Microtrac and track belt for damage; if the track belt is torn or stretched it

should be replaced.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 23 of 26

User Manual

3. Ensure that all fasteners are in place and secure.

Weekly

1. Tracks with Spring Tensioners - In addition to the daily check, examine the condition of the

tension springs at least once per week. Worn or corroded springs may weaken and cause low

belt tension and idler wheel misalignment.

2. Verify by visual inspection that there are no traces of grease near or on the sides of the drive

wheel and the track belt. This would indicate that the grease seals may have been damaged by

debris or have become worn by abrasion.

3. If necessary, remove the belt and thoroughly clean the track.

Overhaul

Eddyfi recommends that the Microtracs™ be thoroughly serviced once a year or after 600 hours of

operation. This includes complete disassembly, cleaning and inspection of the Microtrac components

with focus on the drivetrain, bearings, output shaft and seals. At this time the track is re-lubricated.

For extended service and maximum reliability of your Microtracs, Eddyfi offers a factory overhaul. The

factory overhaul constitutes an investment by the equipment owner in preventative maintenance. As

such, the overhaul should be considered discretionary. In the overhaul, the track unit is completely

disassembled. All internal components including the motor, driver, bevel gears, bearings, and seals are

inspected and replaced where necessary.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 24 of 26

User Manual

Parts and Repairs

Ordering Parts/Customer Service

Spare and/or replacement parts are available for your product and can be ordered directly from your local

office.

When ordering parts always make sure to quote the sales order acknowledgement (SOA) number and/or

the serial number of the system component in question.

Eddyfi Robotics Inc. (Canadian Headquarters and Manufacturing Location)

2569 Kenworth Road, Suite C

Nanaimo, BC, V9T 3M4

CANADA

TF 1.877.468.5886

T +1.250.729.8080

info@eddyfi.com

www.eddyfitechnologies.com

Eddyfi Technologies – US (American Authorized Distributor and Service Centre)

812 W 13th Street

Deer Park, TX, 77536

USA

T +1.281.542.3292

info@eddyfi.com

www.eddyfitechnologies.com

Warranty Repairs

Warranty conditions are specified in the Warranty section. Should any conditions of the manufacturer’s

warranty be breached, the warranty may be considered void. All returned items must be sent prepaid to

Eddyfi Technologies at the above address.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 25 of 26

User Manual

Factory Returns to Canada

Some sub-assemblies of your Eddyfi Technologies product are not field-serviceable and may need to

return to the factory for repair. Warranty claims must return to the factory for evaluation.

To return an item for evaluation or repair, first contact Eddyfi Technologies at our toll-free number or email address. Eddyfi Technologies will supply a Return Merchandise Authorization (RMA) number with

detailed shipping and customs instructions. Items shipped without an RMA number will be held at Eddyfi

Technologies until the correct paperwork is completed. If cross-border shipments are not labelled as per

the instructions, the items may be held by customs and issued additional fees.

All returned items must be sent prepaid unless other specific arrangements have been made.

When the product or system is being shipped anywhere by courier or shipping company, it must be

packaged in the original packaging it was received in. This measure greatly reduces the consequences of

rough handling and subsequent shipping damage.

Eddyfi Technologies cannot be held responsible for damages due to improper packaging. Shipping

damage may have significant impact on repair turnaround times.

Product/System Drawing Package Availability

Mechanical assembly and electrical wiring diagram drawing packages for your equipment are available in

PDF format upon request. Printed copies may also be purchased from Eddyfi Technologies. Contact your

local sales contact for more information.

Microtrac™

Document: UMDB007595.docm

Revision: B13

Created by: KB

Date: 17 Nov 2019

IPN: 3042830-B13

Source Location: C:\ePDM\ISLEng\products\db-microtracs4000\manuals\UMDB007595.docm

Page 26 of 26

User Manual

Limited Warranty Policy

Eddyfi Technologies will repair or replace, at its expense and at its option, any system or component,

subject to the limitations and / or exclusions specified herein, which in normal use has proven to be

defective in workmanship or material provided that, within one (1) year of the purchase date, the original

purchaser returns the product prepaid, accompanied by proof of purchase, from a sales agent authorized

by Eddyfi Technologies, and provides Eddyfi Technologies with reasonable opportunity to verify the

alleged defect by inspection.

Warranty Limitations and/or Exclusions:

1. This warranty does not apply to light bulbs.

2. Batteries, fuses, transistors, integrated circuit modules (IC’s), voltage regulating devices and electrical

plugs and / or connectors are warranted to be free from defects in material and workmanship for a

period of ninety (90) days from the date of shipment to the original purchaser.

3. Any article purchased from, but not manufactured by, Eddyfi Technologies is sold with only such

warranties as are made by the manufacturer therein. Eddyfi Technologies only warrants that it has

title thereto, free of all liens or encumbrances.

4. This warranty does not apply to units which are damaged by connection to improperly wired AC

receptacles.

5. Track belts, tethers, view ports and other components subject to wear through abrasion are

warranted to be free from defects in material and workmanship for a period of ninety (90) days from

the date of shipment to the original purchaser.

6. Any damage caused by failure to observe proper packing or to observe instructions for operation and

maintenance as contained in the Instruction Manual furnished with the equipment, by accident in

transit or elsewhere, will not be covered by the warranty.

7. Repairs are warranted for 90 days.

Eddyfi Technologies may require that certain components may be returned, prepaid, to a manufacturer’s

authorized station for inspection and repair or replacement.

Eddyfi Technologies will not be responsible for any asserted defect which has resulted from Acts of God,

normal wear, misuse, abuse, improper configuration, repair, or alteration made, or specifically authorized

by, anyone other than a representative of Eddyfi Technologies authorized to do so. The giving of, or

failure to give, any advice or recommendation by Eddyfi Technologies shall not constitute any warranty

by, or impose any liability on, Eddyfi Technologies.

The foregoing constitutes the sole and exclusive remedy of the purchaser and the exclusive liability of

Eddyfi Technologies and is in lieu of any and all other warranties, express, implied or statutory as to

merchantability, fitness for purpose sold, description, quality productiveness, or any other matter. Under

no circumstances shall Eddyfi Technologies be liable for special, incidental or consequential damages, or

for delay in performance of this warranty.

Loading...

Loading...