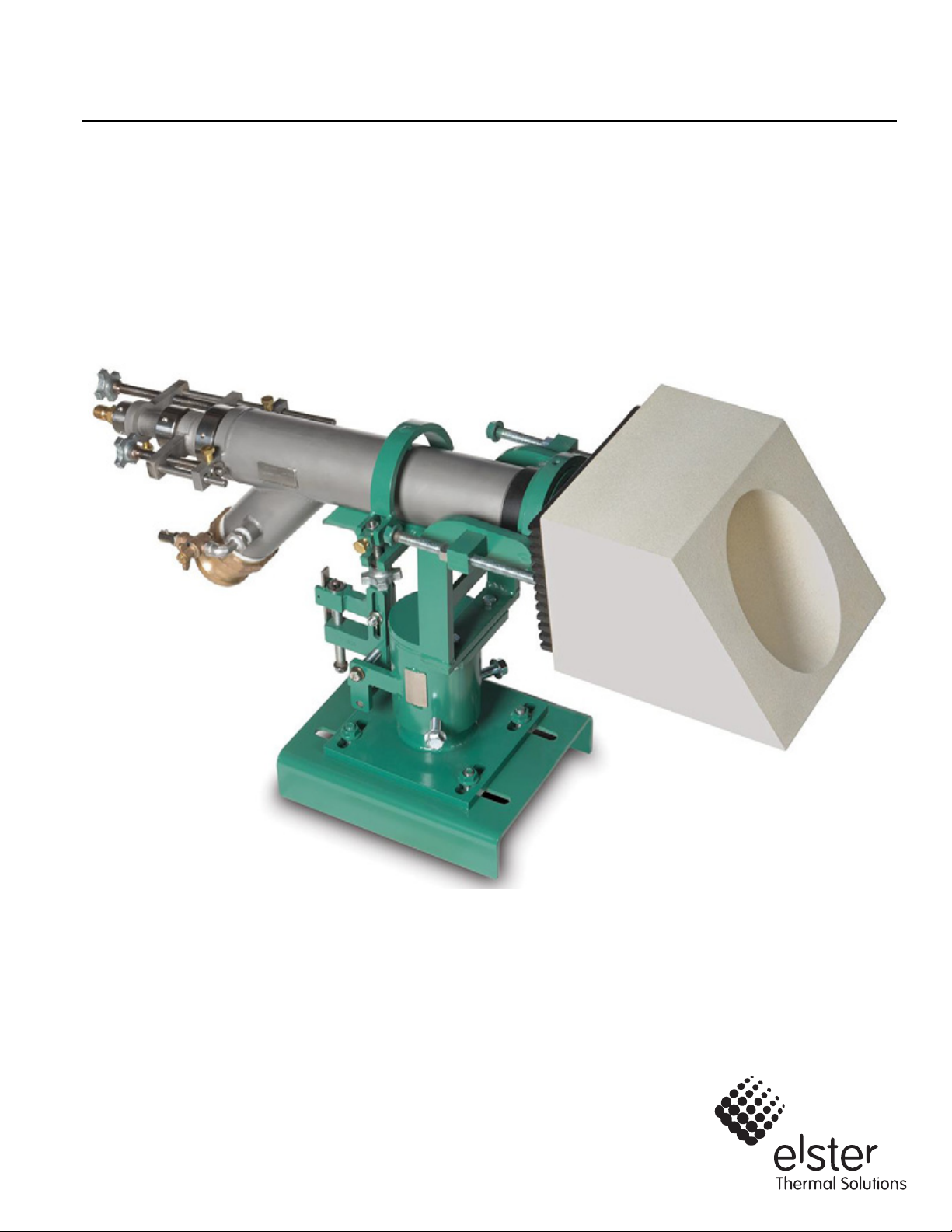

Eclipse BrightFire 200 Burners

BRT Size G, M, and B

Operating Instructions Edition 09.15

Version 1

Copyright

Copyright 2013 by Eclipse, inc. All rights reserved

worldwide. This publication is protected by federal

regulation and shall not be copied, distributed,

transmitted, transcribed or translated into any human or

computer language, in any form or by any means, to any

third parties, without the express written consent of

Eclipse, inc.

Disclaimer Notice

In accordance with the manufacturer’s policy of continual

product improvement, the product presented in this

brochure is subject to change without notice or obligation.

The material in this manual is believed adequate for the

intended use of the product. If the product is used for

purposes other than those specified herein, confirmation

of validity and suitability must be obtained. Eclipse

warrants that the product itself does not infringe upon any

United States patents. No further warranty is expressed or

implied.

Liability & Warranty

We have made every effort to make this manual as

accurate and complete as possible. Should you find errors

or omissions, please bring them to our attention so that we

may correct them. In this way we hope to improve our

product documentation for the benefit of our customers.

Please send your corrections and comments to our

Technical Documentation Specialist.

It must be understood that Eclipse’s liability for its product,

whether due to breach of warranty, negligence, strict

liability, or otherwise is limited to the furnishing of

replacement parts and Eclipse will not be liable for any

other injury, loss, damage or expenses, whether direct or

consequential, including but not limited to loss of use,

income, or damage to material arising in connection with

the sale, installation, use of, inability to use, or the repair

or replacement of Eclipse’s products.

Any operation expressly prohibited in this manual, any

adjustment, or assembly procedures not recommended or

authorized in these instructions shall void the warranty.

Document Conventions

There are several special symbols in this document. You

must know their meaning and importance.

The explanation of these symbols follows below. Please

read it thoroughly.

How To Get Help

If you need help, contact your local Eclipse

representative. You can also contact Eclipse at:

1665 Elmwood Rd.

Rockford, Illinois 61103 U.S.A.

Phone: 815-877-3031

Fax: 815-877-3336

http://www.eclipsenet.com

Please have the information on the product label available

when contacting the factory so we may better serve you.

www.eclipsenet.com

Product Name

Item #

S/N

DD MMM YYYY

WARNING

CAUTION

NOTICE

NOTE

This is the safety alert symbol. It is used to alert you to potential personal

injurt hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Is used to address practices not related to personal injury.

Indicates an important part of text. Read thoroughly.

2

Table of Contents

Introduction ..................................................................................................................................... 4

Product Description .............................................................................................................. 4

Benefits ................................................................................................................................ 4

Audience .............................................................................................................................. 4

BrightFire Documents........................................................................................................... 4

Purpose ................................................................................................................................ 4

Safety................................................................................................................................................ 5

Capabilities........................................................................................................................... 5

Operator Training ................................................................................................................. 5

Replacement Parts...............................................................................................................5

Installation .......................................................................................................................................6

Handling & Storage ..............................................................................................................6

Approval of Components...................................................................................................... 6

BrightFire 200 Adjustable Burners ....................................................................................... 7

Gimbal Mounting Bracket Installation................................................................................... 7

Pre-Start Considerations ...................................................................................................... 7

BrightFire 200 Installation and Start-Up During Initial Heat-Up Furnace.............................. 8

BrightFire 200 Installation to Convert Existing Burners........................................................ 9

Adjustment....................................................................................................................................... 11

BrightFire 200 Flame Adjustments ....................................................................................... 11

Converting BrightFire 200 from Gas to Oil Firing ................................................................. 12

Maintenance..................................................................................................................................... 13

Periodic Checklist................................................................................................................. 13

Monthly Checklist ................................................................................................................. 13

Yearly Checklist.................................................................................................................... 13

Instructions for Cleaning.......................................................................................................13

Appendix .......................................................................................................................................... i

3BrightFire 200, V1, Operating Instructions, Edition 09.15

Introduction

1

Product Description

The BrightFire® 200 burner is an adjustable, low NOX, airfuel burner for installation in regenerative type glass

furnaces. It can be installed in either end-fired or crossfired furnaces, as well as in under port or side-of-port

configurations. It is designed to work with the Eclipse

Gimbal Mounting Bracket to provide excellent adjustability of the flame position within the furnace. Additionally

the socket plate provides for a positive seal against the

burner block ensuring air is not infiltrated into the furnace.

Cooling air is provided through the inner gas tube during

off-firing cycles to prevent nozzle burnout.

These burners are of a welded, stainless steel body

construction, produce a highly adjustable flame, and

provide superior heat transfer to the glass melt. Multiple

burners may be used in each port. Port design must be

compatible with the burner.

Benefits

• Additional adjustments for increased flame control

and burner flexibility.

• Lower NOX emissions.

• Compatible with current mounting bracket for easy

installation.

• Compatible with current BrightFire™ gas and cooling air connections for easy conversion.

• Nozzle combinations allow firing to be tailored to furnace requirements.

• Durable construction.

• Low Maintenance.

• Improved glass quality.

• Reduced fuel usage due to improved heat transfer

into the glass.

Audience

This manual has been written for people who are already

familiar with all aspects of a glass burner and its add-on

components, also referred to as “the burner system”.

These aspects are:

• Installation

• Use

• Maintenance

The audience is expected to have previous experience

with this type of equipment.

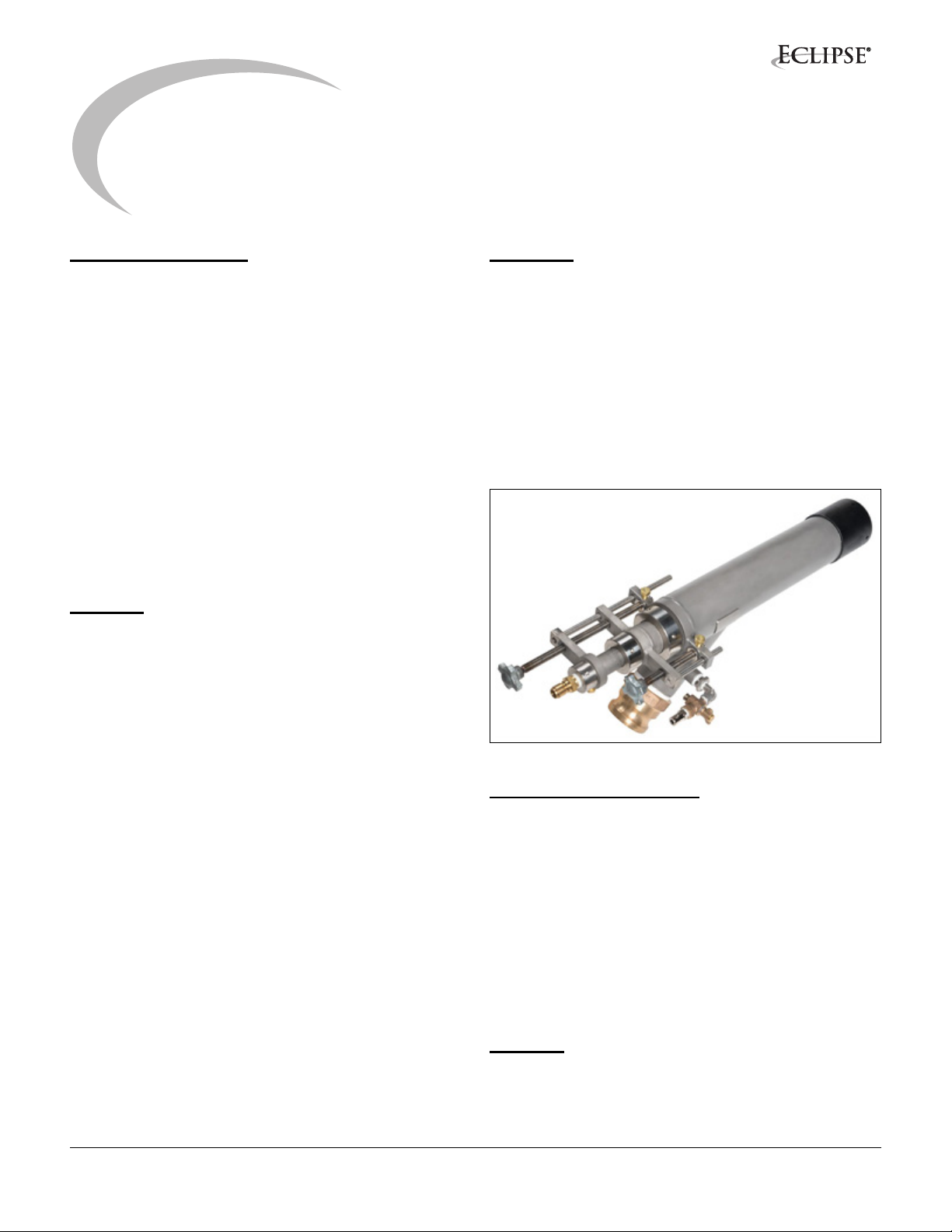

Figure 1.1. BrightFire

®

200 Burner

BrightFire® Documents

Information Guide

• This document

Datasheet, Series 1112-1 through 1112-3

• Available for individual BrightFire 200 models.

Spare Parts List

• Recommended replacement part information

Related Documents

• EFE 825 (Combustion Engineering Guide)

• Gimbal Mounting Bracket Information Guide 1113

Purpose

The purpose of this manual is to ensure the installation

and adjustment of a safe, effective and trouble-free

combustion system.

4BrightFire 200, V1, Operating Instructions, Edition 09.15

Safety

2

Important notices, which help provide safe burner

operation, will be found in this section. To avoid personal

injury and damage to the property or facility, the following

warnings must be observed. All involved personnel

should read this entire manual carefully before attempting

to start or operate this system. If any part of the

information in this manual is not understood, contact

Eclipse before continuing.

WARNING

■ DO NOT disassemble any component WITHOUT

first reading the manufacturer’s instructions.

Several components contain parts under

compression or pressure and could injure

personnel if not disassembled properly.

■ Control panels contain voltages which can

severely injure personnel. These panels are

normally double fed from the emergency supply.

NO engineer/maintenance technician who is not

fully conversant with the equipment should be

allowed access to the panel internals.

■ The burners, described herein, are designed to

mix fuel with air and burn the resulting mixture. All

fuel burning devices are capable of producing fires

and explosions if improperly applied, installed,

adjusted, controlled or maintained.

■ Do not bypass any safety feature; fire or explosion

could result.

■ Never try to light a burner if it shows signs of

damage or malfunction.

■ The burner and duct sections are likely to have

HOT surfaces. Always wear the appropriate

protective equipment when approaching the

burner.

NOTICE

■ This manual provides information regarding the

use of these burners for their specific design

purpose. Do not deviate from any instructions or

application limits described herein without written

approval from Eclipse.

■ Control circuits MUST not be altered at any time

unless Eclipse has been consulted and has

approved the modifications.

■ No naked lights are to be used in the area of gas

pipeline components.

■ Any gas leaks should always be isolated and

rectified immediately. Any piece of pipeline

equipment and its surrounding area should be

properly vented and/or purged as appropriate after

isolation and before the start of any maintenance.

■ Extreme care should be taken when working on

burner equipment installed under the furnace port.

■ Eclipse recommends installing a safety guard

around moving parts.

■ Eclipse recommends considering any area with

moving mechanical parts a restricted area.

Capabilities

Only qualified personnel, with sufficient mechanical

aptitude and experience with combustion equipment,

should adjust, maintain or troubleshoot any mechanical or

electrical part of this system.

Operator Training

The best safety precaution is an alert and trained

operator. Train new operators thoroughly and have them

demonstrate an adequate understanding of the

equipment and its operation. A regular retraining schedule

should be administered to ensure operators maintain a

high degree of proficiency.

Replacement Parts

Order replacement parts from Eclipse only. All Eclipse

approved valves or switches should carry UL, FM, CSA,

CGA and/or CE approval where applicable.

5BrightFire 200, V1, Operating Instructions, Edition 09.15

Installation

3

In this section you will find information and instructions

needed to install the burner and the system components.

Handling & Storage

Handling

• Make sure the area is clean.

• Protect all components from weather, damage, dirt

and moisture.

• Protect the components from excessive

temperatures and humidity.

• Take care not to drop or damage components.

Storage

• Make sure the components are clean and free of

damage.

• Store the components in a cool, clean, dry room.

• After you have made sure everything is present and

in good condition, keep the components in their

original packaging as long as possible

Approval of Components

Limit Controls & Safety Equipment

All limit controls and safety equipment must comply with

all applicable local codes and/or standards and must be

listed for combustion safety by an independent testing

agency. Typical application examples include:

• American: NFPA 86 with listing marks from UL, FM,

CSA

• European: EN 746-2 with CE mark from TuV,

Gastec, Advantica

Electrical Wiring

All the electrical wiring must comply with all applicable

local codes and/or standards such as:

• NFPA Standard 70

• IEC60364

• CSA C22

• BS7671

Gas Piping

All the gas piping must comply with all applicable local

codes and/or standards such as:

• NFPA Standard 54

• ANSI Z223

• EN 746-2

Where to Get the Standards:

The NFPA Standards are available from:

National Fire Protection Agency

Batterymarch Park

Quincy, MA 02269

www.nfpa.org

The ANSI Standards are available from:

American National Standard Institute

1430 Broadway

New York, NY 10018

www.ansi.org

The UL Standards are available from:

333 Pfingsten Road

Northbrook, IL 60062

www.ul.com

The FM Standards are available from:

1151 Boston-Providence Turnpike

PO Box 9102

Norwood, MA 02062

www.fmglobal.com/approvals

Information on the EN standards and where to get them is

available from:

Comité Européen de Normalisation

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196811

Fax: +32-25196819

www.cen.eu

Comité Européen de Normalisation Electronique

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196871

Fax: +32-25196919

www.cenelec.org

6BrightFire 200, V1, Operating Instructions, Edition 09.15

BrightFire® 200 Adjustable Burners

The BrightFire® 200 is available in three body sizes, G, M

and B, with diameters of 73.0 mm (2.88”), 88.9 mm (3.50”)

and 101.6 mm (4.00”), respectively. All three sizes consist

of an outer tube with a separate inner tube to provide two

separate gas jets.

Each burner includes two adjustments (see Figure 2.1).

The first adjustment (the longer adjusting screw) changes

the annulus area between the inner and outer nozzle tips,

providing changes to the annular gas jet velocity at the

burner tip to control flame length. The second adjustment

(the shorter adjusting screw) is incorporated into the

middle tube and is used to open and close an orifice within

the annular gas jet which changes the gas flow

distribution between the inner and outer gas jets. This

unique inner flow adjustment allows the heat release from

the flame to be adjusted independent of the flame length.

See BrightFire®200 Flame Adjustment section for more

information.

4. Install the alignment tube in the bracket, ensuring that

the alignment tube pin is in contact with the gimbal ring

of the bracket to simulate burner position and allow for

proper working distance from the socket plate to the

face of the burner nozzle.

5. With the alignment tube in place, push the bracket

assembly forward to hold the socket plate in place.

6. Sight down the alignment tube and adjust the bracket

to match the centerline of the tube to the centerline of

the burner block opening.

7. Tighten the mounting bolts of the bracket and secure

the socket plate to the block using the jack bolts on the

bracket. Slight adjustments may be required after heatup due to thermal expansion.

8. Tighten the bracket mounting bolts after final

adjustment and remove the alignment tube.

9. Seal the block opening with refractory fiber blanket for

heat up.

Nozzles can be supplied with the burners for a variety of

inputs (2 to 10 MM Btu/h gross (528 to 2638 kW net) for

G-size; 5 to 17 MM Btu/h gross (1319 to 4484 kW net) for

M-size; and 10 to 31 MM Btu/h gross (2638 to 8177 kW

net) for B-size). Two types of nozzles are available to

provide flame length, heat release, and emissions tailored

to specific furnace requirements.

The two available nozzle types are a straight body nozzle

and a profiled nozzle. The profiled nozzle provides greater

heat and flame control when compared to the similarly

sized straight body nozzle. However, the same size

straight body nozzle will provide a reduction in NO

emissions compared to the profiled nozzle.

Oil lances are also available in a variety of inputs from 2

to 28 MM Btu/h (528 to 7388 kW). Oil lances are easy to

install in place of the inner gas tube for a flexible back-up

option in the event of natural gas interruptions.

The burner length and diameter must be determined from

the furnace and port information.

Gimbal Mounting Bracket Installation

NOTE: For additional info on the Gimbal Mounting

Bracket, refer to Info Guide 1113.

1. Set all bracket adjustments to zero using the scales and

pointers.

2. Place the socket plate in the recess of the burner block

3. Loosely attach bracket to furnace steel and roughly

align with the centerline of the burner block opening.

Pre-Start Considerations

• Ensure all components are on site: burners,

brackets, socket plates, etc.

• All threaded components should have anti-seize

applied.

• Ensure burner tool kit matches burner size. Kits

include: ratchet, spanner wrenches, burner

alignment tube, and anti-seize.

• Confirm cooling air has local flow control and

X

pressure gauge (0-15 PSI (0 – 1 bar)) for each

burner.

• Confirm gas has local flow control and measurement

provisions.

• Test the fit of the gas and cooling air flex hoses.

• Mount the burner and ensure supply lines can easily

be attached.

• Confirm cooling air and natural gas check valves are

fitted and within 2.5 m (8 ft) of the burner.

• Confirm that the check valves have been properly

installed in the gas and cooling air lines.

• Preset the manual gas flow control valve for each

burner to 50% open to allow for adjustment in both

directions and to establish a rough gas flow balance

across the burners.

7BrightFire 200, V1, Operating Instructions, Edition 09.15

• Ensure local gas and cooling air valves are closed.

The main gas and cooling air supplies should

remain closed until the main burners are to be

brought on line.

• Confirm that the burner blocks are plugged prior to,

and during, heat-up.

• Confirm that the external cooling wind ducts are in

place and directed at the socket plates.

BrightFire® 200 Installation and Start-Up

During Initial Heat-up of Furnace

NOTE: Once the furnace temperature is above the auto-

ignition temperature of the gas, the main burners can be

gradually brought on line.

CAUTION

■ To ensure ignition of gas, allow the furnace to

reach a minimum of 1400º F (760º C) before

starting gas flow to the burners.

NOTE: as the gas flow to the main burners is increased,

the heat-up burner input is decreased to maintain the

heat-up schedule until the heat-up burner can be

removed.

Figure 3.2. Typical Installation (Side of Port)

1. Ensure everyone involved is aware of, and ready for,

the main burner lite-off.

Support Channel

Supplied by Customer

Figure 3.1. Typical Installation (Under port)

2. Ensure there is sufficient air flow for combustion.

3. Set the main gas flow control to manual and open to 1015%.

4. Establish gas and cooling air supply up to the local shut

off valves.

5. Prior to installing the burner in the bracket, set the area

adjustment (refer to figure 2.1 for burner adjustment

identification) so that the tip of the inner nozzle is about

even with the beginning of the taper of the outer nozzle

(see figure 1.3).

6. Set the flow adjustment to position 6 (refer to figure

2.3).

7. Attach the cooling air and gas hoses to the burner prior

to placing the burner in the bracket.

8BrightFire 200, V1, Operating Instructions, Edition 09.15

Start of Outer Nozzle Taper

Figure 3.3. Inner nozzle initial position for installation

8. Place one burner onto bracket on “off side” and push

forward until burner is tight against the socket plate.

9. Secure the burner in place by tightening the t-bolt or

split ring clamp, depending on which bracket style has

been supplied.

10. Ensure sufficient combustion air flow is present in all

ports.

11. Open the local cooling air valve and set the pressure

to 3 – 4 psi (207 – 276 mbar).

NOTE: To prevent damage to the burners in the event the

cooling air is lost for more than 20 minutes, the burner

should be removed and the block openings plugged with

refractory fiber.

12. After reversal, open the local gas valve at the installed

burner.

13. Visually confirm ignition and adjust the main gas flow

control to achieve the desired gas flow, ensuring the

flow is above the minimum input rating of the burner.

19. With all of the main burners in operation, a preliminary

gas flow balance may now be achieved and will vary

based on furnace design and/or the desired input or

temperature profile of the furnace. This should be done

with the gas control in manual.

The side of port firing arrangement incorporates two

burners per port. Both burners of any given port should

have equal gas flow and be adjusted in pairs when

balancing gas flow.

On a typical under port fired furnace, either side port or

end port, balancing the burners is usually a visual task

and can be checked with either gas inlet pressure or

differential pressure at an orifice plate.

In most conditions final burner balancing will not take

place until after the furnace is full and the regenerators

have heated to normal operating temperatures, thus

combustion air velocity at the port is at normal levels.

Air/fuel ratio to this point has been primarily controlled

visually with aid from instrumentation. Once the thermal

expansion of the furnace is complete, any cracks or gaps

will be sealed. Port flue gas readings should then be taken

and the air/fuel ratio should be adjusted and balanced to

achieve 0.5 - 2.0% excess oxygen in the exhaust stream.

NOTE: For lower NOX applications, the air fuel ratio

should be adjusted to be between 0.5 – 1.0% excess

oxygen in the exhaust stream.

BrightFire® 200 Installation to Convert

Existing Burners

NOTE: Prior to conversion, it should be verified that the

burner block is compatible with BrightFire200.

14. Repeat steps 1 through 13 on the opposite side of the

furnace (Ex: Complete port 1 left side and then

complete port 1 right side.)

15. Working closely with the heat-up crew, gradually

increase the main burner input.

16. Check for flame impingement and stability.

17. When enough gas flow is achieved, with the first

installed burner in each side, to support the minimum

input of two burners, a second burner per side may be

installed, following steps 1 through 16.

18. Repeat steps 1 through 17 until all burners are

installed and operational.

NOTE: As burners are added, cooling air pressures

should be monitored and adjusted as necessary.

To install the BrightFire® 200 in an existing furnace midcampaign with the furnace at operational temperatures,

use the following procedures for either conversion from

existing gas burners or existing oil burners:

Conversion from Existing Gas Burner to

BrightFire® 200 Gas Burner

1. To minimize furnace disruptions and maintain glass

quality, start with one burner during the off-firing cycle

2. Prior to installing the burner in the bracket, set the area

adjustment (refer to figure 2.1 for burner adjustment

identification) so that the tip of the inner nozzle is about

even with the beginning of the taper of the outer nozzle

(see figure 1.3).

3. Set the flow adjustment to position 6.

4. Close the local gas and cooling air supply shut off

valves.

5. Disconnect gas and cooling air hoses.

9BrightFire 200, V1, Operating Instructions, Edition 09.15

6. Remove the existing burner from the burner bracket.

7. Follow the Gimbal Mounting Bracket installation steps if

necessary.

8. Install the BrightFire

®

200 burner into the burner

bracket, ensuring a tight seal against the socket plate.

9. Connect gas and cooling air hoses to the burner.

10. Ensure sufficient combustion air flow is present in all

ports.

11. Open the local gas and cooling air shut-off valves for

the burner and set the pressure to 3 -4 psi (207-276

mbar).

NOTE: To prevent damage to the burners in the event the

cooling air is lost for more than 20 minutes, the burner

should be removed and the block openings plugged with

refractory fiber.

12. Once firing cycle reverses and gas is flowing to the

installed BrightFire® 200, visually inspect flame and

make changes to the burner adjustments per the

“BrightFire® 200 Flame Adjustments” section below.

13. Repeat steps 1 through 12 until all burners are

converted to BrightFire® 200’s.

9. Secure the burner in place by tightening the t-bolt or

split ring clamp, depending on which bracket style has

been supplied.

10. Connect the cooling air and gas hoses to the burner.

11. Ensure sufficient combustion air flow is present in all

ports.

12. Open the local cooling air valve and set the pressure

to 3 – 4 psi (207 – 276 mbar).

NOTE: To prevent damage to the burners in the event the

cooling air is lost for more than 20 minutes, burner should

be removed and the block openings plugged with

refractory fiber.

13. After reversal, open the local gas valve at the installed

burner.

14. Visually confirm ignition and adjust the main gas flow

control to achieve the minimum input rating of the

burner.

15. Repeat steps 1 through 14 on the opposite side of the

furnace (Ex: Complete port 1 on the left side and then

complete port 1 on the right side.)

16. Gradually increase the main burner input.

17. Check for flame impingement and stability.

Conversion from Existing Oil Burner to BrightFire

200 Gas Burner

1. Ensure all gas and cooling air systems are in place prior

to BrightFire® 200 install.

2. Ensure all local gas and cooling air valves at the

burners are shut off prior to installation.

3. Prior to installing the burner in the bracket, set the area

adjustment (refer to figure 2.1 for burner adjustment

identification) so that the tip of the inner nozzle is about

even with the beginning of the taper of the outer nozzle

(see figure 1.3).

4. Set the flow adjustment to position 6 (refer to figure

2.3).

5. Follow Gimbal Mounting Bracket Installation guide.

6. Set the main gas flow control to manual and open to 1015%.

7. Establish gas and cooling air supply up to the local shut

off valves.

8. Beginning with one burner on the off-firing side of the

furnace, disconnect oil and atomizing air hoses and

remove oil burner.

18. When enough gas flow is achieved, with the first

®

installed burner in each side, to support the minimum

input of two burners, a second burner per side may be

installed, following steps 1 through 17.

19. Repeat steps 1 through 18 until all burners are

installed and operational.

NOTE: As burners are added, cooling air pressures

should be monitored and adjusted as necessary.

20. With all of the main burners in operation, a preliminary

gas flow balance may now be achieved and will vary

based on furnace design and/or the desired input or

temperature profile of the furnace. This should be done

with the gas control in manual.

10BrightFire 200, V1, Operating Instructions, Edition 09.15

Adjustment, Start

A

and Stop

4

BrightFire 200 Flame Adjustments

Area

djustment

Flow

Adjustment

Figure 2.1. BrightFire 200 Adjustments

The BrightFire® 200 has two adjustment valves, an area

adjustment (see Figure 2.1) and a flow adjustment. The

area adjustment (see Figure 2.2) changes the annulus

area between the inner and outer nozzles and is used to

control flame length. The flow adjustment (see Figure 2.3)

opens and closes an internal valve that changes the

distribution of gas flow between the outer and inner gas

tubes and is used to control where the heat from the flame

is released in the furnace. This can be changed

independently of the flame length. In addition, the firing

angle of the burner can be adjusted using the gimbal

mounting bracket adjustments to optimize gas flow into

the air stream. (Refer to Gimbal Bracket Info Guide 1113.)

To read the indicator rod positions for the area and flow

adjustments, the first ring starting from the back of the

burner indicates position ‘1’. The position is indicated by

the ring that is flush with the back face of the adjusting lug.

Position 1 on the area adjustment rod indicates the inner

nozzle is all the way forward within the outer gas annulus,

flush with the face of the outer nozzle. Position 1 on the

flow adjustment rod indicates the inner flow valve is

closed with the maximum amount of gas flow through the

center jet. Refer to figures 2.2 and 2.3 which show an area

adjustment at position 1 and a flow adjustment at position

10.

Position 1

Adjusting

Lead Screw

Figure 2.2. Area Adjustment Mechanism

Adjusting

Lead Screw

Position Indicator:

Read Markings Here

Position Indicator:

Read Markings Here

Position

Indicator

Position

Indicator

NOTE: Mounting bracket adjustments should only be

done on the off-firing side to prevent natural gas from

deflecting back into the port area if the seal between the

socket plate and burner nozzle is lost.

To adjust the burners once the furnace is at, or near,

normal operating conditions, begin by adjusting the area

adjustment to set the flame to the desired length.

Increasing the annulus area by moving the adjustment

back (counter-clockwise rotation of the adjustment knob)

will lengthen the flame while moving the adjustment

forward (clockwise rotation of the adjustment knob) will

shorten the flame.

The flame is typically set about 2/3 of the width of the

furnace (length for end fired furnaces). The flame should

not impinge on the far wall or fire into the opposite side

port. Excessive lofting of the flame should also be avoided

to prevent damage to the furnace crown. Flames should

be above the glass or batch pile surface, and should not

be too low to prevent dust kick-up and batch carry-over

into the opposite port.

Figure 2.3. Flow Adjustment Mechanism

Position 1

11BrightFire 200, V1, Operating Instructions, Edition 09.15

Once acceptable flame length has been achieved, the

heat release into the furnace should be adjusted to

provide the desired heat profile using the flow adjustment.

In general, opening the inner valve (counter-clockwise

rotation of adjustment knob) will move the heat release

closer to the burner block opening while closing the valve

(clockwise rotation of the adjustment knob) will move the

heat further away from the burner block opening. Furnace

temperatures should be monitored during flow adjustment

to determine the correct flow adjustment setting. The

optimal flow adjustment setting will vary depending on

furnace type and design.

NOTE: The flame length will be affected when reaching

the extreme positions on the flow adjustment. A setting of

1 will shorten the flame due to increased velocity through

the center jet while a setting of 10 will lengthen the flame.

To achieve low NOX, the flow adjustment should be set to

the higher (6 and higher) settings. This will reduce the

velocity in the center gas jet, moving the heat distribution

closer to the port and lowering NOX emissions.

NOTE: After adjusting the area or flow valves, check the

packing nuts to verify they are tight to prevent gas leaks.

The BrightFire®200 may be installed with a mechanical

gas swirler. To install, remove the outer nozzle (and the

inner nozzle if the profiled nozzle is installed) and slide the

swirler over the inner gas tube. The inner gas tube

alignment pins inside the burner will sit inside the notches

in the swirler to prevent spinning. The swirler should be

flush with the end of the burner body if seated correctly.

Once it is installed, the inner and outer nozzles can be

installed.

Installing the swirler into the gas tube of the burners will

allow the center jet velocity to be increased without

increasing NOX. The heat distribution from the flame can

then be moved further from the port opening while

maintaining lower NOX emissions.

Converting BrightFire® 200 from Gas to Oil

Firing

NOTE: If firing heavy fuel oil, the oil must be conditioned

to maintain a viscosity of 100 SSU or less at the burner.

NOTE: The following procedure assumes the capability of

firing gas and oil at the same time, allowing for individual

burners to be converted to oil firing. Fuel and atomizing

services should be readily available prior to conversion.

Internal off-side cooling air provisions via the atomizing air

piping must be provided with a required pressure of 4 to 7

PSIG (0.28 to 0.48 BARG) at the burner for internal tip

cooling, depending on conditions.

1. Shut off gas and internal cooling air to one off-side

burner.

2. Remove internal cooling air and gas flexible hoses and

cap the burner’s gas inlet.

3. Loosen the inner gas tube locking nut and packing

gland nut and remove the inner gas tube.(Refer to

Figure 4.1 in the Maintenance Section.)

4. Install the oil/atomizing assembly and secure the

packing gland and inner gas tube locking nut. (Refer to

Figure 4.2 in the Maintenance Section.)

5. Set the area adjustment to 1 to align the oil nozzle flush

with the outer nozzle face.

6. Connect atomizing and oil flex lines.

7. Introduce internal cooling air through the atomizing air

line at around 4 to 7 PSIG (0.28 to 0.48 BARG) at the

burner.

8. After reversal, adjust the atomizing air to around 30 - 40

PSIG (2.07 – 2.76 BARG) at the burner.

9. Introduce fuel at a flow rate equal to the burner’s

minimum capacity.

10. Visually confirm ignition and adjust atomizing

pressure as required.

11. Repeat steps 1 through 9 for all burners to be

converted from gas to oil firing.

NOTE: Steps 3 and 4 may be done on a spare burner not

installed in the furnace. Install the oil-ready burner in place

of a gas burner in the furnace and follow steps 5 through

9. The gas burner can then be moved to a workstation to

install the oil lance. Repeat until all burners have been

converted from gas to oil firing. This will be necessary with

the profiled nozzle installed as it cannot be removed

through the back of the burner.

12BrightFire 200, V1, Operating Instructions, Edition 09.15

Maintenance and

Troubleshooting

5

Preventative maintenance is the key to a reliable, safe

and efficient system. The following are suggested

guidelines for periodic maintenance. Burners in severe

environments or operational conditions should be

checked more frequently.

NOTE: The periodic, monthly, and yearly lists are an

average interval. If your environment is dirty, the intervals

may be shorter. Check with local authorities having

jurisdiction regarding their recommended maintenance

schedules.

Periodic Checklist

Remove and inspect the burners at least once per month,

paying close attention to any build-up/degradation of the

burner nozzles.

1. Frequently monitor flame patterns for flames that

appear to be deflected, abnormal, or impinging on

refractory surfaces. These are signs of dirty nozzles or

blocks.

2. Cooling air pressure should be monitored daily to

ensure proper tip cooling is maintained.

NOTE: Excessive cooling air pressure may create

recirculation in the burner block and cause fouling. If

frequent burner block fouling is an issue, reduce the

cooling air pressure, making sure to not allow cooling air

pressure to go below 2 psi (138 mbar) or damage to the

burner nozzles may occur.

3. Burner gas flow and pressure should be monitored

daily. Irregularities in flow or pressure may indicate a

dirty burner or block.

Monthly Checklist

1. Clean all burner nozzles on a routine bases once per

month and when required by flame appearance,

making sure the burner nozzles are not damaged or

distorted.

2. Test all the system alarms for proper response signals.

3. Check for the proper operation of ventilating

equipment.

4. Test the manual gas shut-off valves for proper

operation.

Yearly Checklist

1. Test (leak test) safety shut-off valves for tightness of

closure.

2. Test pressure switch settings by checking switch

movements against pressure settings and comparing

these with the actual impulse pressure..

3. Clean and inspect all burners.

Instructions for Cleaning

NOTE: A matching spare burner can be used to replace a

burner in need of cleaning to minimize furnace disruption

and eliminate the need to plug the burner block during

cleaning.

NOTE: Only remove a burner during the off-firing cycle.

1. Shut off local gas and cooling air valve supplying the

burner to be cleaned.

2. Disconnect gas and cooling air hoses at the burner.

4. Regular port flue gas readings should be taken to

ensure proper air/gas ratios are being maintained. Flue

gas irregularities may indicate plugging of the

regenerator ports, instrumentation issues, or furnace

wear allowing infiltration of ambient air. A side to side

bias in the ratios may be required.

5. Check the rear packing nuts to verify tightness to

prevent gas leaks. If the packing nuts bottom out,

contact the burner body, and cannot be tightened any

further, the packing needs to be replaced due to wear

from adjusting the area and flow valves or removing the

gas tube insert.

3. Loosen t-bolt or split ring clamp and remove burner

from the bracket.

4. Inspect the socket plate and carefully clean out any

debris using a steel rod.

CAUTION

■ Molten glass is electrically conductive. DO NOT

make contact with glass surface when cleaning

burner blocks.

13BrightFire 200, V1, Operating Instructions, Edition 09.15

5. Install spare burner or plug the block opening with fiber

blanket.

6. Remove the outer nozzle using the 2” x 4-3/4” spanner

wrench (or equivalent).

7. Remove the gasket from the outer nozzle.

8. Inspect the outer nozzle for damage and clean with a

metal brush of medium stiffness.

9. Remove the inner nozzle using the 1-1/4” x 3” spanner

wrench (or equivalent).

10. Inspect the inner nozzle for damage and clean with a

metal brush of medium stiffness.

11. Remove swirler if installed.

12. Inspect swirler for damage.

13. Remove the cooling air boss from the rear of the inner

gas tube and inspect for any blockage. Clean if

necessary.

14. Remove the inner gas tube locking nut and packing

gland nut and pull the tube straight out from the rear of

the burner.

15. Inspect the tube for damage and clean with a metal

wire brush, if needed.

16. Inspect the packing in the packing gland nut and

replace if necessary.

17. Loosen and remove the packing gland nut for the flow

adjustment valve. Inspect the packing and remove if

necessary.

18. Reassemble the burner by replacing the packing

gland nut on the flow adjustment valve. Inspect the

packing and remove if necessary.

19. Install the inner gas tube packing gland nut but do not

tighten.

25. If new packing was installed, there may be additional

resistance when adjusting the flow and area

adjustments initially.

26. Apply anti-seize to the inner nozzle threads and the

threads on the burner body for the outer nozzle.

NOTE: Replace the outer nozzle gasket whenever the

outer nozzle is removed from the burner.

27. Install inner nozzle and tighten with spanner wrench,

then install outer nozzle and tighten with spanner

wrench.

28. Re-install the burner into the gimbal bracket and

attach gas and cooling air hoses.

29. Open cooling air and gas valves at the burner.

30. Make flow and area adjustments as needed.

Outer

Nozzle

Inner Gas Tube

Locking Nut

Flow Valve

Packing

Gland Nut

Inner

Nozzle

Outer

Nozzle

Gasket

Cooling

Air Boss

Inner Gas

Tube

Packing

Gland Nut

Figure 4.1.

20. Insert the inner gas tube through the rear of the burner

until the end is flush with the area adjustment lug.

21. Tighten the inner gas tube locking nut and the packing

gland nut.

22. Once the inner gas tube is installed, tighten the flow

adjustment valve packing gland nut.

23. If necessary, install the swirler on the inner gas tube

so that the inner gas tube alignment pins inside the

burner sit in the notches in the swirler.

24. Install and tighten the cooling air boss on the rear of

the inner gas tube.

Flow Valve

Packing Nut

Inner Gas Tube

Packing Nut

Figure 4.2.

Inner Gas Tube

Locking Nut

Oil Lance

Atomizing

Air Inlet

Oil Inlet

14BrightFire 200, V1, Operating Instructions, Edition 09.15

Appendix

Conversion Factors

Metric to English

From To Multiply By

actual cubic meter/h (am³/h) actual cubic foot/h (acfh) 35.31

normal cubic meter/h (Nm³/h) standard cubic foot /h (scfh) 38.04

degrees Celsius (°C) degrees Fahrenheit (°F) (°C x 9/5) + 32

kilogram (kg) pound (lb) 2.205

kilowatt (kW) Btu/h 3415

meter (m) foot (ft) 3.281

millibar (mbar) inches water column ("w.c.) 0.402

millibar (mbar) pounds/sq in (psi)

millimeter (mm) inch (in) 3.94 x 10

MJ/Nm³ Btu/ft³ (standard) 26.86

Metric to Metric

14.5 x 10

-3

-2

English to Metric

actual cubic foot/h (acfh) actual cubic meter/h (am³/h) 2.832 x 10

standard cubic foot /h (scfh) normal cubic meter/h (Nm³/h) 2.629 x 10

degrees Fahrenheit (°F) degrees Celsius (°C) (°F - 32) x 5/9

inches water column ("w.c.) millibar (mbar) 2.489

From To Multiply By

kiloPascals (kPa) millibar (mbar) 10

meter (m) millimeter (mm) 1000

millibar (mbar) kiloPascals (kPa) 0.1

millimeter (mm) meter (m) 0.001

From To Multiply By

pound (lb) kilogram (kg) 0.454

Btu/h kilowatt (kW) 0.293 x 10

foot (ft) meter (m) 0.3048

pounds/sq in (psi) millibar (mbar) 68.95

inch (in) millimeter (mm) 25.4

Btu/ft³ (standard) MJ/Nm³ 37.2 x 10-3

-2

-2

-3

i

© Eclipse, Inc. All Rights Reserved

Loading...

Loading...