Page 1

630-2 Installation Guide

6/22/2010

Eclipse BoostPak

Packaged Gas Booster System

Model MS, MR and MH

Version 2

Page 2

Copyright

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

minor or m

oderate injury.

Is used to address practices not related to personal injury.

Indicates an important part of text. Read thoroughly.

NOTE

NOTICE

CAUTION

WARNING

Copyright 2007 by Eclipse, Inc. All rights reserved

worldwide. This publication is protected by federal

regulation and shall not be copied, distributed,

transmitted, transcribed or translated into any human or

computer language, in any form or by any means, to any

third parties, without the express written consent of

Eclipse, Inc.

other injury, loss, damage or expenses, whether direct or

consequential, including but not limited to loss of use,

income, or damage to material arising in connection with

the sale, installation, use of, inability to use, or the repair

or replacement of Eclipse’s products.

Any operation expressly prohibited in this manual, any

adjustment, or assembly procedures not recommended or

authorized in these instructions shall void the warranty.

Disclaimer Notice

In accordance with the manufacture’s policy of continual

product improvement, the product presented in this

brochure is subject to change without notice or obligation.

The material in this manual is believed adequate for the

intended use of the product. If the product is used for

purposes other than those specified herein, confirmation

of validity and suitability must be obtained. Eclipse

warrants that the product itself does not infringe upon any

United States patents. No further warranty is expressed or

implied.

Liability & Warranty

We have made every effort to make this manual as

accurate and complete as possible. Should you find errors

or omissions, please bring them to our attention so that we

may correct them. In this way we hope to improve our

product documentation for the benefit of our customers.

Please send your corrections and comments to our

Marketing Communications Manager.

It must be understood that Eclipse’s liability for its product,

whether due to breach of warranty, negligence, strict

liability, or otherwise is limited to the furnishing of

replacement parts and Eclipse will not be liable for any

Document Conventions

There are several special symbols in this document. You

must know their meaning and importance.

The explanation of these symbols follows below. Please

read it thoroughly.

How To Get Help

If you need help, contact your local Eclipse representative.

Your Eclipse representative can be reached at:

2011 Williamsburg Road

Richmond, Virginia 23231 U.S.A.

Phone: 804-236-3800 Fax: 804-236-3882

http://www.peconet.com

Please have the information on the product label available

when contacting the factory so we may better serve you.

www.peconet.com

Product Name

Item #

S/N

DD MMM YYYY

2

Page 3

Table of Contents

1 Introduction............................................................................................................................ 4

Product Description .............................................................................................................. 4

Audience .............................................................................................................................. 4

Purpose................................................................................................................................ 4

Related Documents.............................................................................................................. 4

2 Safety...................................................................................................................................... 5

Safety Warnings ................................................................................................................... 5

Capabilities........................................................................................................................... 5

Operator Training ................................................................................................................. 5

Replacement Parts...............................................................................................................5

3 Installation.............................................................................................................................. 6

Introduction .......................................................................................................................... 6

Handling & Storage ..............................................................................................................6

Checklist Before Installation ................................................................................................. 6

Mechanical Installation .........................................................................................................6

Piping Installation ................................................................................................................. 6

Electrical Installation............................................................................................................. 7

Checklist After Installation ....................................................................................................8

4 Commissioning...................................................................................................................... 9

Introduction .......................................................................................................................... 9

Applying Power .................................................................................................................... 9

Motor Rotation Check........................................................................................................... 9

Applying Gas Supply ............................................................................................................ 9

Operational Tests ................................................................................................................. 9

Verifying Settings ................................................................................................................. 9

Commissioning Record for Models MS/MR/MH................................................................... 10

MH Models Temperature Control Settings ........................................................................... 11

MH Models Rotary Actuator Settings ................................................................................... 11

5 Operation................................................................................................................................ 12

Introduction .......................................................................................................................... 12

Heat Exchanger Loop Operation.......................................................................................... 12

Alarm Silence ....................................................................................................................... 12

Shutdown ............................................................................................................................. 12

6 Maintenance & Troubleshooting.......................................................................................... 13

Monthly Checklist ................................................................................................................. 13

Yearly Checklist.................................................................................................................... 13

Alarm Conditions.................................................................................................................. 13

BoostPak Models MS/MR/MH Wiring Diagram .................................................................... 15

Boost Motor Voltage.............................................................................................................17

Heat Exchanger Motor Voltage ............................................................................................ 17

Panel Layout and Enclosure ................................................................................................ 18

BoostPak Model MS/MR/MH Piping Schematics ................................................................. 19

Appendix ................................................................................................................................... i

Conversion Factors ..............................................................................................................i

Key to System Drawings ...................................................................................................... ii

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

3

Page 4

Introduction

1

Product Description

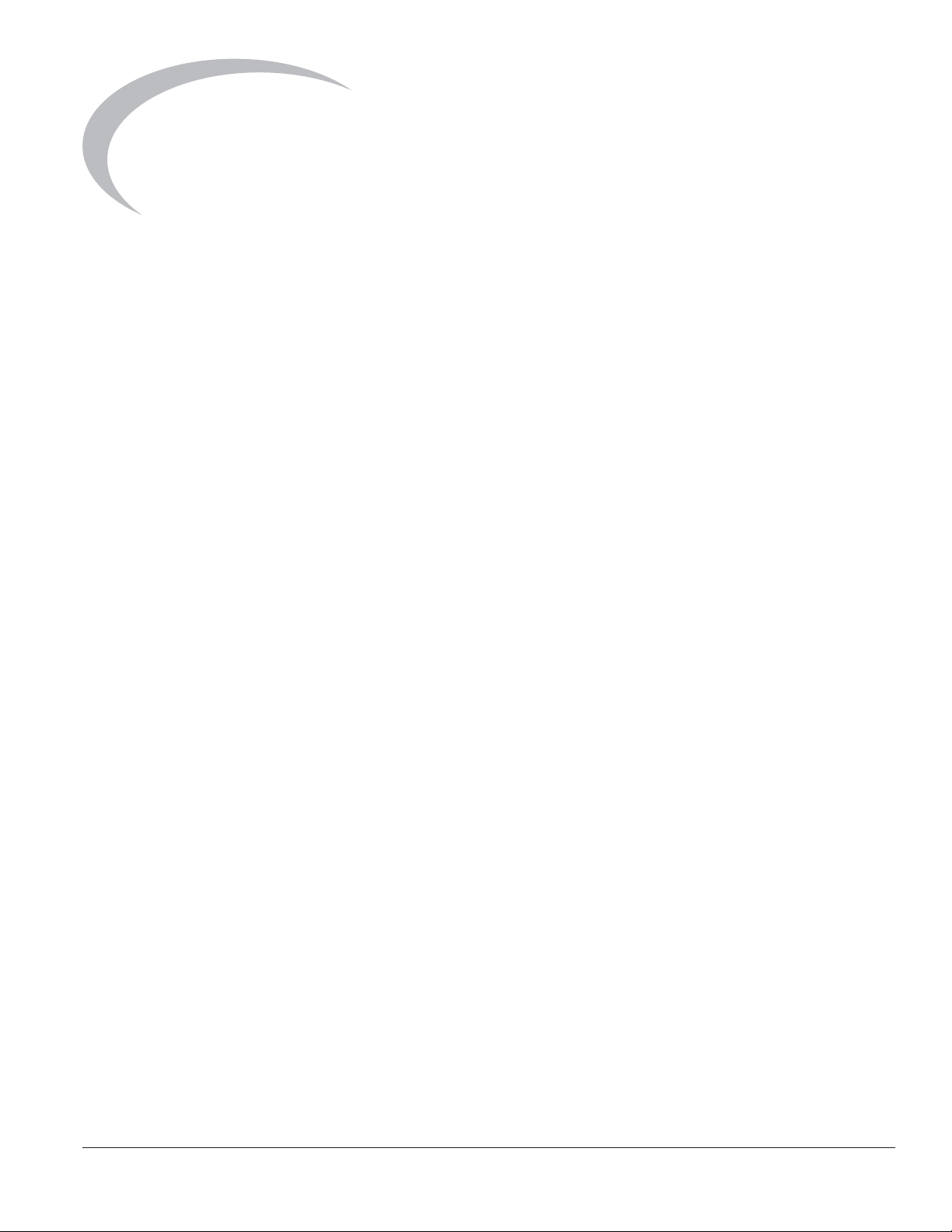

The Eclipse BoostPak is designed for installations when

the gas pressure to a building is inadequate to operate the

appliances. It provides a reliable cost-effective packaged

solution for pumping low natural gas supply pressures up

to meet the requirements of high performance combustion

equipment. The discharge pressure is the total of the

booster added pressure plus the incoming gas pressure.

The BoostPak is a completely integrated skid mounted

package. It is factory assembled, wired, tested, and ready

for field power and gas connections. The system includes

but is not limited to a hermetically sealed centrifugal type

gas booster blower, check valve, gas pressure switch,

isolating valves, inlet and outlet piping and flange

connectors, pressure gauges, and control system all

mounted, assembled, wired, and tested. All essential

components for automatic operation are enclosed in an

industrial control panel designed to meet local and

national electrical codes.

Various standard options may be selected to configure a

complete model number. The options determine the

control modes, pressure boost, flow, and environmental

conditions.

Figure 1.1. Eclipse BoostPak

Audience

This manual has been written for personnel already

familiar with all aspects of a gas booster system and it’s

add-on components.

These aspects are:

• Installation

• Use

• Maintenance

• Safety

The audience is expected to be qualified and have

experience with this type of equipment and its working

environment.

Purpose

The purpose of this manual is to make sure that you carry

out the installation of a safe, effective and trouble-free

system.

BoostPak Documents

Installation Guide No. 630-2

• This document

Datasheet No. 630-2

• Available for BoostPak model MS

• Provides assembly drawing numbers

• Required to complete installation

Datasheet No. 630-3

• Available for BoostPak model MR

• Provides assembly drawing numbers

• Required to complete installation

Datasheet No. 630-4

• Available for BoostPak model MH

• Provides assembly drawing numbers

• Required to complete installation

Related Documents

• EFE 825 (Combustion Engineering Guide)

• Eclipse Bulletins and Information Guides: 620, 710,

780, 904 (MH only), 925 (MH only), 940

4

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

Page 5

Safety

2

Important notices for safe operation of the BoostPak

system will be found in this section. To avoid personal

injury, damage to property or the facility, the following

warnings must be observed. Read this entire manual

before attempting to start the system. If any part of the

information in this manual is not understood, contact

Eclipse before continuing.

Safety Warnings

DANGER

Ŷ The BoostPak packaged gas booster systems,

covered by this guide are designed to increase gas

pressure to a gas utilization appliance. All fuel

handling devices are capable of producing fires

and explosions if improperly applied, installed,

adjusted, controlled or maintained.

Ŷ Do not bypass any safety feature; fire or explosion

could result.

Ŷ Never try to operate a BoostPak if it shows signs

of damage or malfunction.

Capabilities

Only qualified personnel, with good mechanical aptitude

and experience with combustion equipment, should

adjust, maintain or troubleshoot any mechanical or

electrical part of this system.

Operator Training

The best safety precaution is an alert and trained

operator. Train new operators thoroughly and have them

demonstrate an adequate understanding of the

equipment and its operation. A regular retraining schedule

should be administered to ensure operators maintain a

high degree of proficiency.

Replacement Parts

Order replacement parts from Eclipse only. Any customer

supplied valves or switches should carry UL, FM, CSA,

CGA and/or CE approvals where applicable.

NOTICE

Ŷ This manual provides information in the use of the

BoostPak for its specific design purpose. Do not

deviate from any instructions or application limits

described herein without written advice from

Eclipse.

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

5

Page 6

Installation

3

Introduction

In this chapter you will find information and instructions

needed to install the BoostPak and system components.

The system drawings are shipped with the BoostPak.

Refer to the data sheet for the drawing number and

contact Eclipse for a replacement.

WARNING

Ŷ All installation work must be carried out in

compliance with current legislated standards.

Handling & Storage

Handling

• Make sure the area is clean.

• Inspect the system, ensure that all components are

clean and free from damage.

• Use appropriate support and handling equipment

when lifting the BoostPak.

• Protect the components from weather, damage, dirt

and moisture.

• Protect the system and components from excessive

temperatures and humidity.

around the BoostPak in order to facilitate servicing and

field replacement of components. Avoid obstructing the

open access to the control panel.

NOTE:

from the front of the control panel door and the swing of

the door should not be obstructed from opening 120°. If

local codes are different than these requirements, those

codes should be adhered to during installation.

There should be no less than 36" of clearance

Environment

Be sure the operating environment matches the original

operating specifications. Check the following items:

• Voltage, frequency, and stability of electrical power

• Ambient temperature and humidity

• Area classification (non-hazardous or hazardous)

• Exposure to sunlight, water, ice, wind, and vibration

Mechanical Installation

Lift Points

Use lifting lugs on mounting base for all lifting. Do not use

piping or supports as lift points unless designated by

manufacturer labeling.

Mounting

Storage

• Make sure the components are clean and free of

damage.

• Store the components in a cool, clean, dry room.

• After making sure everything is present and in good

condition, keep the components in original

packages as long as possible.

Checklist Before Installation

Placement

The Eclipse BoostPak is completely factory piped, wired

with controls, tested and ready for field connections. The

system should be installed in an accessible ventilated

location on a level concrete floor or substantial mounting

pad. Place the BoostPak to avoid excessive numbers of

bends and fittings in the interconnecting piping.

Access

The BoostPak location must allow easy accessibility for

inspection and maintenance. Provide adequate space all

6

Bolt the unit base securely using the mounting holes

provided in the BoostPak base.

Piping Installation

Gas Piping

All gas piping must be done in accordance with the

national fuel gas code, local utility company and municipal

agency requirements. Protect and prevent contamination

of the piping during installation.

NOTE:

devices are properly oriented with respect to flow direction

and vertical (gravity) orientations.

NOTE:

unnecessary fittings, and excessive bends that may

cause additional flow restriction and pressure loss.

Elbows within 5 pipe diameters may reduce pressure and

capacity below operating requirements.

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

If it is necessary to redirect piping, make sure all

Avoid severe size reductions in pipe connections,

Page 7

Piping Support

WARNING

Leak Testing

Use brackets or hangers to support the gas piping. If you

have questions, consult your local gas company.

Initial Fitting

• Remove any shipping materials and inspect for

foreign objects in the piping.

• Connect inlet gas piping from the utility supply to the

inlet flange as indicated by directional arrows and

system drawings.

• Connect the gas pipe requiring the boosted gas

pressure feeding your appliance to the discharge

gas pipe outlet flange, also indicated by label and

system drawing.

Vent Piping

The model MS, MR and MH BoostPaks do not require

vent piping. Vent piping may be required for components

added to the system. Check the individual product data

sheets for specific manufacturer’s recommendations.

Inlet Low Gas Manual Reset Pressure Switch

This switch may come already mounted and wired on the

BoostPak, or it may be supplied as a kit to be remotely

mounted. Install loose inlet gas low pressure switch kit in

location determined by the utility company. Normally it is

located downstream of the main regulator just inside the

building where the supply pipe enters.

Inlet High Gas Pressure Switch

If used, this optional switch may come already mounted

and wired on the BoostPak, or it may be supplied as a kit

to be remotely mounted. Install loose inlet gas high

pressure switch kit in location determined by the

specifying engineer. Normally it is located downstream of

the main regulator just inside the building where the

supply pipe enters.

Pressure Switch Settings

• Check and adjust the pressure switches as

required.

• The utility company dictates the setting of the low

inlet gas pressure switch typically at 3-4" w.c. to

prevent operation when there is insufficient gas

volume.

• The discharge gas pressure switch should be set 24" w.c. below the rated discharge pressure at the

maximum flow conditions for the site application.

• If installed, the optional inlet high gas pressure

switch should be set to 90% of the pressure where

the sum of the inlet plus the rated boost equals the

maximum rating of downstream equipment.

(Alternately it can be set to 20% above the minimum

requirement of the downstream equipment.)

The BoostPak is tested and leak tight at the factory,

however, shipping and installation may cause joints to

loosen. Check and test all piping for leaks.

Ŷ Test pressure must not exceed 5 PSIG and the

pressure gauges or any components with ratings

less than the test pressure should first be isolated.

Check the individual product datasheets for

specific ratings.

Electrical Installation

General

All electrical wiring must be done in accordance with the

national electrical code, local utility company and

municipal agency requirements. The schematics are

shipped with the BoostPak. Contact Eclipse for

replacement, drawing 10025020.

The BoostPak is pre-wired and therefore only the

electrical power supply and any externally supplied

control devices must be terminated. Depending on the

specific model configuration, the external devices can

include the appliance run interlock contact and the low

inlet gas pressure switch.

Review Name Plate

Before making any electrical connections, compare the

electrical supply circuit ratings at the installation site to

those on the nameplates of the BoostPak, control panel,

booster and (MH only) heat exchanger motor(s). The

supply for the BoostPak model MS/MR/MH varies based

on booster and motor option, and may be 120VAC,

208VAC, 230VAC or 460VAC nominal and must be

capable of supplying the booster and (MH only) heat

exchanger motor full load current and starting current.

Terminal Check

During shipment, the control panel terminals may have

loosened. Check the tightness of all connections in the

panel and at the pressure switches.

Supply Power Wiring

The incoming power to the control panel must be wired

into the terminals as designated in the schematic diagram.

Earth ground must be connected to terminal G.

Wiring for Continuous Operation

This control mode allows an operator to turn a local

control panel switch on when pressure boost is needed

and turn the switch off when the boost is not needed. For

this mode, a jumper is installed between terminals 1321

and 2161.

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

7

Page 8

Wiring for Appliance On Demand Operation,

Start Circuit Interlock

This control mode requires a customer supplied run

interlock. It must be a dry (voltage free) contact that

makes continuity when the booster is required and opens

when the booster should shut down. Commonly used

devices include: automatic time clock, flow switch, relay

contact, or switch contact. For this mode, wire the contact

between terminals 1321 and 2161. Be sure to remove any

jumper connection between terminals if present.

Wiring for Flow Sensor Demand Control

Operation

This control mode is an option that is typically ordered and

installed at the factory. If it has been supplied as a kit, refer

to Data 630-FC and Installation Guide 630-FC.

Wiring for Inlet Low Gas Manual Reset

Pressure Switch

This switch may come already mounted and wired on the

BoostPak, or it may be supplied as a kit to be remotely

mounted. This switch is required by local utility company

as a safety device. The kit version must be wired into the

BoostPak control panel. Wire the low inlet gas pressure

switch terminal 3 (COM) to panel terminal 1321, and

switch terminal 2 (NO) to panel terminal 2121. Be sure to

remove any jumper connection between these terminals if

present.

Checklist After Installation

Ensure the system was properly installed and verify:

• The skid is securely bolted to the floor or mounting

pad and is rigid and level.

• There are no loosely mounted components.

• There are no leaks in the gas lines.

• The external gas piping has appropriate brackets

and is not supported by the BoostPak.

• Verify correct orientation of gas piping – from utility

point of entry to BoostPak inlet, from BoostPak

outlet to the appliance.

• Verify sufficient unobstructed access to the control

panel and booster and (MH only) heat exchanger

motor(s).

• Verify electrical power supply and all external

devices are wired correctly.

• Verify tightness of all terminal connections on all

devices.

• Verify the gas pressure switch(es) are installed in

the correct location and confirm the proper settings.

• Verify all device orientations are correct with respect

to flow direction.

Wiring for Inlet High Gas Pressure Switch

If installed, this optional switch may come already

mounted and wired on the BoostPak, or it may be supplied

as a kit to be remotely mounted. The kit version must be

wired into the BoostPak control panel. Wire the high inlet

gas pressure switch terminal 3 (COM) to panel terminal

2161, and switch terminal 1 (NC) to panel terminal 2162.

Be sure to remove the jumper wire between these

terminals if present.

Alarm Output Wiring

A terminal is provided to connect an external alarm. If

used, wire the external alarm to panel terminal 2331 (hot)

and 1323 (neutral). The external alarm should be rated for

120VAC and not exceed 2 amps.

8

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

Page 9

Commissioning

4

Introduction

In this chapter you will find information and procedures for

the first operation and adjustment of the BoostPak.

WARNING

Ŷ Only qualified personnel, with good mechanical

and electrical aptitude should adjust, maintain, or

troubleshoot any mechanical or electrical part of

this system. They should have knowledge and

experience with combustion equipment including

piping, valves, motors, blowers, boosters,

switches, control panels and wiring.

These instructions rely on the expertise of the person

performing the start up. If you do not understand any

portion of this procedure or do not feel qualified, stop and

call Eclipse.

Applying Power

Before applying the site electrical power supply to the

BoostPak control panel:

• Turn off the main disconnect switch.

• Turn the HAND/OFF/AUTO control switch to OFF.

Motor Rotation Check

Ensure that the booster gas supply is off and the booster

has no gas under pressure in it. Remove the pipe plug in

the observation port on the booster body. Turn the control

panel main disconnect switch on and verify that the panel

instrumentation has power. Momentarily turn the MAN/

OFF/AUTO switch to MAN position to “bump” the motor

starter such that the motor just starts to turn and rotates

slowly. Observe the direction of rotation of the fan blades

through the observation port. They should be turning in

the direction indicated by the rotation arrow on the

booster. If rotation direction is incorrect, have a qualified

electrician rewire the incoming power for the proper

direction.

Turn on the gas supply to the BoostPak and press the

reset on the Inlet Low Gas Manual Reset Pressure

Switch.

Operational Tests

Test the operation of the BoostPak and verify:

• DISCHARGE PRESSURE SWITCH: The low gas

light and alarm comes on with the outlet valve

closed. The booster should remain running.

• LOW INLET GAS PRESSURE SWITCH: The

booster stops, the low gas light and alarm comes on

when the Inlet Low Gas Manual Reset Pressure

Switch is adjusted above the inlet gas supply. Adjust

this switch back to the original specified set point

and observe that the system will not restart unless

the pressure switch is first manually reset.

• APPLIANCE RUN INTERLOCK: For appliance on

demand operation mode, turn the control switch to

AUTO and test that the system runs when the

appliance interlock makes contact.

Verify Settings

1. Run system at nominal flow rating.

2. Verify pressure increase from booster is correct. Read

the inlet and outlet pressure gauges on the BoostPak.

Subtract the inlet from outlet pressure to verify added

pressure agrees with the datasheet.

3. Verify that outlet pressure is sufficient for appliance

operation.

4. Verify flow is sufficient for appliance via gas metering

located at the appliance (not included with BoostPak).

5. Run system to minimum flow condition; verify flows

and pressures within acceptable range. For model

MR or MH BoostPak, verify that recirculation flow is

sufficient to keep outlet pipe surface temperature

below 160°F.

6. Record all setup data as an aid for future

troubleshooting and setup operations.

Applying Gas Supply

Before applying the site gas supply, reinstall the pipe plug

and initially set the manual butterfly valves:

• Open the booster inlet valve

• Close the booster outlet valve

• Close the heat exchanger isolation valves (MH only)

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

9

Page 10

Commissioning Record

Models MS/MR/MH

Nameplate Information

Mechanical Installation

Low Inlet Gas Pressure Switch Setting ______________

High Inlet Gas Pressure Switch Setting ______________

Performance

BoostPak Outlet Pressure, Low Flow ______________

BoostPak Model ______________

Serial Number ______________

Control Panel Serial Number ______________

Ambient Temperature ______________

Mounting Secure, Rigid, Level ______________

Supply and Feed Piping Supported ______________

Leak Test ______________

Outlet Gas Pressure Switch Setting ______________

Gas Inlet Pressure ______________

BoostPak Outlet Pressure, High Flow ______________

Power Supply Voltage ______________

Booster Motor Current ______________

MR only: Position of Manual BV ______________

MH only: Heat Exchanger Motor Current ______________

Temperature Control Settings (Next Page)

Rotary Actuator Settings (Next Page)

10

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

Page 11

MH Models Temperature

Control Settings

SETUP FUNCTION FACTORY

ALGOR CTRALG PDMR _______________

TUNING PB 6 _______________

OUTALG OUTALG RLY _______________

INPUT1 IN1TYP JL _______________

CONTRL ACTION DIR _______________

OPTION AUXOUT OUT _______________

ALARMS A1S1TY DE _______________

Controller Set Point: 120 _______________

MR 45 _______________

RATE 0 _______________

BRNOUT UP _______________

A1S1VA 5.0 _______________

A1S1HL HIGH _______________

ALHTST 0.3 _______________

Parameters not listed here are set at default values found in Installation Guide 925.

MH Models Rotary

Actuator Settings

PARAMETER CODE FACTORY

LF 15T 0 _______________

HF 15S 90 _______________

LO 12T 0 _______________

(C6) 6 6 _______________

(C0) 10 10 _______________

Parameters not listed here are set at default values found in Installation Guide 904.

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

11

Page 12

Operation

5

Introduction

In this chapter, you will find instructions on how to start

and stop the booster system. Become familiar with

booster control methods before operating the equipment.

DANGER

Ŷ The BoostPak system, described herein, is

designed to increase gas pressure to an appliance.

All fuel handling devices are capable of producing

fires and explosions if improperly applied,

installed, adjusted, controlled, or maintained.

Ŷ Do not bypass any safety feature; fire or explosion

could result. Never try to operate a BoostPak if it

shows signs of damage or malfunction.

1. Be sure the inlet and outlet valves are open. On model

MH, make sure both heat exchanger isolation valves

are open.

2. Turn the main disconnect switch on.

The green POWER ON light comes on.

3. Check for ALARM conditions and correct before

proceeding.

heat exchanger loop to keep the outlet gas temperature

below this maximum value.

Alarm Silence

To silence the alarm, press the ALARM SILENCE button.

Shutdown

The booster can be stopped by:

• Opening the run interlock contact (appliance

dedicated control mode)

• Turning the control switch to off

• Turning the main disconnect switch off

When shutting the system down to prevent operation, turn

the main disconnect switch off and turn off the main power

supply to the control panel.

4. Turn the control switch to AUTO.

The BoostPak is in operation.

• For Continuous Operation mode, the booster will

run within 15 seconds of the switch operation.

• For Appliance On Demand mode, the booster will

run within 15 seconds of the closure of the

appliance run interlock contact.

The booster motor starter contact closes, the motor starts

running, and the yellow BOOSTER ON light comes on.

The LOW GAS light will flash on and off until the outlet gas

pressure switch makes contact. If it does not make contact

within 15 seconds, the red LOW GAS light comes on

steady and the alarm sounds.

Heat Exchanger Loop Operation

For model MH, the heat exchanger will operate when the

temperature sensed in the outlet pipe exceeds the set

point and deviation alarm value, which is 125°F with

factory default settings. The temperature controller

adjusts the position of the automatic butterfly valve in the

12

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

Page 13

Maintenance &

Troubleshooting

6

Monthly Checklist

• Inspect and tighten loose mechanical components

• Look for signs of damage and repair

• Test operation if the unit has not run and check for

excessive vibration

• Clean the booster motor housing

• Clean the heat exchanger, its motor, and cooling fan

(MH only)

• Wipe clean the control panel surfaces

Yearly Checklist

• Check inlet and outlet pressure switch settings

• Check and compare inlet and outlet pressures to the

initial commissioning record sheet

• Measure and compare the power supply and motor

current to the record sheet

• Perform operational test in the commissioning

section of this guide

Problem Possible Cause Solution

No POWER ON light Main supply power is off Be sure main power to the system is

Main disconnect switch is off Turn the control panel main disconnect

Loose connection Check for voltage on panel terminals,

Blown fuse Verify that all fuses are good and

Cannot initiate start sequence Inlet low gas manual reset pressure

switch has activated

Alarm Conditions

Certain conditions will cause the ALARM to come on. To

silence the alarm, press the ALARM SILENCE push

button.

• INLET LOW GAS MANUAL RESET PRESSURE

SWITCH opens due to low utility line pressure. The

LOW GAS light comes on and the booster motor will

stop running. When the pressure is restored, this

switch must be manually pushed to reset its contact.

• DISCHARGE GAS PRESSURE SWITCH fails to

make contact within 15 seconds. The LOW GAS

light comes on; the booster will not shut down.

• If the motor wiring or internal temperature switch

opens, then the motor will stop causing the

discharge gas pressure switch to open. Then the

ALARM and LOW GAS light come on.

• A booster motor overload condition will shut down

the booster and the MOTOR FAULT light and

ALARM will come on.

• A heat exchanger motor overload condition will shut

down the heat exchanger fan and the MOTOR

FAULT light and ALARM will come on (MH only).

switched “on”.

switch on.

turn off main power and inspect,

tighten wire connection.

properly installed. If blown, have a

qualified electrician determine the

cause and fix before replacing fuse.

Check incoming gas pressure: adjust if

necessary.

Check pressure switch setting and

operation.

If used, check that the pressure switch

isolating valve is not closed.

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

13

Page 14

Problem Possible Cause Solution

Cannot initiate start sequence If used, Inlet High Gas Pressure Switch

has activated

Normal operation, when the inlet

pressure drops below the switch

setting, then the system will start.

Motor starter overload tripped Check for defective motor, reset

overload unit.

Startup sequence runs, but booster

shuts down after several minutes

Appliance interlock not made or jumper

(continuous operation) is loose

Booster motor overload, thermal cutout switch open

Have qualified electrician verify and

rewire.

Verify voltage supply, booster motor

rotation direction, sufficient inlet

pressure, and that inlet/outlet valves

are open. Let motor cool and reset

overload.

Cannot achieve full capacity Inlet/outlet piping too restricted Rerun larger/straighter pipe runs.

Inlet pressure too low Consult with utility company.

Booster motor rotation incorrect Verify and have qualified electrician

rewire.

Manual inlet or outlet valve is partially

Open inlet/outlet valves fully.

closed

Cooling loop control valve too wide

open (MR/MH only)

See OPERATIONAL TESTS in the

COMMISSIONING section. Check

ACT parameters (MH only). Check for

missing or loose coupling, damaged

butterfly valve.

Recirculation loop or heat exchanger

loop is providing insufficient cooling

Actuator settings incorrect,

temperature controller settings

Verify Parameters

incorrect

Butterfly/actuator coupling loose; not

Check and Reinstall.

tracking

Isolation valves not fully open (MH

Open inlet/outlet isolation valves fully.

only)

14

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

Page 15

BoostPak Model MS, MR, and MH Wiring Diagram

Phantom componnents marked 1

are installed on BoostPak models

with the heat exchanger option.

Phantom Components Marked 2

are installed on BoostPak models

with the flow control option. The flow

control contact is set to close when

gas fired equipment causes flow.

Notes:

Phantom components marked 3

are installed on BoostPak models

with the high inlet gas pressure

switch option. Set@value above

which the downstream appliance

can operate. Auto reset.

Phantom components marked 4

are installed on BoostPak models

using 3 phase power.

Phantom components marked 6

are used when the motor thermal

overloads are required. Reference

the MTR. section charts on page 24.

Phantom component marked 7 is

installed on BoostPak models using

the customer supplied appliance

run interlock dry contact.

Phantom component marked 8 is

the optional customer alarm.

Maximum current is 2 amps.

1

2

3

4

6

7

8

SIMPLEX BOOSTPAK

317FCM

FLOW

CONTROL

MODULE

G

MTR

THERMAL OL

REFERENCE THE

HEAT EXCH. MTR

SELECTION CHART

FOR MOTOR WIRING

AND FLA

THERMOCOUPLE

ACTUATOR

TYPE “J”

311 ACT

ROTARY

P1

P2

P1

7

8

3

2

P2

RED

SEPARATE

CONDUIT

2

1

G

2

1

G

119T1

119T2

119T3

CONTROL PANEL

SHIELD

G

MAIN

1321

1323

1321

2161

G

*

2041

TB1

TERM

2042

STRIP

2 T1

4 T2

6 T3

26

TEMPERATURE

CONTROLLER

27

1321

1323

GND

*

TB1

3071

TERM

STRIP

3081

SHD

SINGLE

PHASE

DETAIL “A”

*

TB1

TERM

STRIP

304 MS

HEAT

EXCHANGER

MOTOR

STARTER

303 TC

SINGLE

PHASE

W/UPS

DETAIL “B” DETAIL “C”

1L1 3L2 5L3

4T26T3

2T1

TERM

STRIP

237MS

BOOSTER

MOTOR

STARTER

TB1

*

THREE

PHASE

7L4

8T4

2331

1323

1321

2

161

1321

GND

2081

1321

GND

2121

2161

GND

2162

2102

2101

2 T1

4 T2

6 T3

OPTIONAL

CUSTOMER

ALARM

OPTIONAL

CUSTOMER

SUPPLIED

APPLIANCE RUN

INTERLOCK

208 PS

2

3

1

G

212 PS

2

3

1

G

218 PS

2

3

1

G

P1

110T1

110T2

110T3

G

LOW

DISCHARGE GAS

AUTO RESET

PRESSURE SWITCH

(SEE NOTE 12)

LOW INLET GAS

MANUAL RESET

PRESSURE SWITCH

(SEE NOTE 11)

HIGH INLET GAS

AUTO RESET

PRESSURE SWITCH

P2

MTR

THERMAL OL

REFERENCE THE

BOOSTER MTR

SELECTION CHART

FOR MOTOR WIRING

AND FLA

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

15

Page 16

BoostPak Model MS, MR, and MH Wiring Diagram, Continued

SINGLE PHASE INCOMING POWER WITHOUT THE UPS OPTION

DETAIL “A”

SINGLE PHASE CUSTOMER SUPPLY

104 DISC

MAIN PWR

DISC S

WITCH

DETAIL “B”

SINGLE PHASE INCOMING POWER WITH THE UPS OPTION

SINGLE PHASE CUSTOMER SUPPLY

MAIN POWER

DISCONNECT

TB1

TERMINAL STRIP

THREE PHASE INCOMING POWER

104DISC

MAIN POWER

DISCONNECT

SWITCH

TB1

TERM STRIP

104 DISC

SWITCH

DETAIL “C”

THREE PHASE CUSTOMER SUPPLY

MAIN

CONTROL PANEL

104 UPS

REFERENCE

DETAILS “D”

AND “G”

FOR PROPER

UPS WIRING

USED WHEN THE BOOSTPAK UNIT

DETAIL “F”

IS MOUNTED INSIDE AND THE

BOOSTER MOTOR IS 1/2 OR 3/4 HP

7000VA/208/230V

MGE #HV EX 7RT

JUMPER

DETAIL “G”

USED WHEN THE BOOSTPAK UNIT

IS MOUNTED INSIDE AND THE

BOOSTER MOTOR IS 1 HP

11000VA/208/230V

MGE #HV EX 11RT

JUMPER

104 UPS

NORMAL AC

SOURCE

BYPASS AC

SOURCE

OUTPUT

104 UPS

NORMAL AC

SOURCE

BYPASS AC

SOURCE

OUTPUT

JUMPER

104 DISC

MAIN PWR

DISC SWITCH

NOTES:

Phantom components marked 5

5

are installed on BoostPak models

with the UPS option.

Eclipse External Wiring

Customer Field Wiring

Te rminal Block

Te rminal on Device

Panel Ground Lug

Used to define the different options available.

16

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

Page 17

Booster Motor Voltage

115 VAC/1 PHASE/60HZ 208 VAC/1 PHASE/60 HZ

1/4

HP

1/2

HP

3/4

HP

1

HP

2

HP

230 VAC/1 PHASE/60 HZ 208 VAC/3 PHASE/60 HZ

230 VAC/3 PHASE/60 HZ

460 VAC/3 PHASE/60 HZ

5

HP

Heat Exchanger Motor Voltage

115 VAC/1 PHASE/60HZ

1/2

HP

208 VAC/1 PHASE/60 HZ

230 VAC/1 PHASE/60 HZ 208 VAC/3 PHASE/60 HZ

230 VAC/3 PHASE/60 HZ

460 VAC/3 PHASE/60 HZ

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

17

Page 18

Panel Layout and Enclosure

G

Y

Y

R

B

Innovative Thermal Solutions

Eclipse Combustion

Rockford, Illinois, U.S.A.

www.eclipsenet.com

Enclosure 16”H x 20”W x 8”D

100

70

18

80

90

Internal View, Panel 13”H x 17”W

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

Page 19

BoostPak Model MS Piping Schematic

Outlet

Inlet

BoostPak Model MR Piping Schematic

Outlet

Inlet

BoostPak Model MH Piping Schematic

Outlet

Inlet

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

19

Page 20

Appendix

Conversion Factors

Metric to English

From To Multiply By

cubic meter (m³) cubic foot (ft³) 35.31

cubic meter/hr (m³/h) cubic foot/hr (cfh) 35.31

degrees Celsius (°C) degrees Fahrenheit (°F) (°C x 9/5) + 32

kilogram (kg) pound (lb) 2.205

kilowatt (kW) BTU/hr 3415

meter (m) foot (ft) 3.281

millibar (mbar) inches water column ("w.c.) 0.402

millibar (mbar) pounds/sq in (psi)

millimeter (mm) inch (in) 3.94 x 10

MJ/Nm³ BTU/ft³ (standard) 26.86

Metric to Metric

14.5 x 10

-3

-2

English to Metric

cubic foot/hour (cfh) cubic meter/hour (m³/h) 2.832 x 10

degrees Fahrenheit (°F) degrees Celsius (°C) (°F - 32) x 5/9

inches water column ("w.c.) millibar (mbar) 2.489

From To Multiply By

kiloPascals (kPa) millibar (mbar) 10

meter (m) millimeter (mm) 1000

millibar (mbar) kiloPascals (kPa) 0.1

millimeter (mm) meter (m) 0.001

From To Multiply By

cubic foot (ft³) cubic meter (m³) 2.832 x 10

pound (lb) kilogram (kg) 0.454

BTU/hr kilowatt (kW) 0.293 x 10

foot (ft) meter (m) 0.3048

pounds/sq in (psi) millibar (mbar) 68.95

inch (in) millimeter (mm) 25.4

BTU/ft³ (standard) MJ/Nm³ 37.2 x 10

-2

-2

-3

-3

i

Page 21

System Schematics

Key to System Schematics

Symbol Appearance Name Remarks

Hermetic Booster Booster is used to increase gas

pressure.

Bulletin/

Info Guide

630-1

Control Panel The control panel encloses the

booster motor starter, smart replay/

PLC, disconnect and indicator lights

for BoostPak operation.

Check Valve A check valve permits flow only in

one direction and is used to prevent

back flow of gas.

Pressure Switch A switch activated by rise or fall in

pressure. A manual reset version

requires pushing a button to transfer

the contacts when the pressure

setpoint is satisfied.

Pressure Gauge A device to indicate pressure. 940

Gas Cock Gas cocks are used to manually shut

off the gas supply.

Butterfly Valve Butterfly valves are used to either

manually or automatically control the

flow of gas.

Heat Exchanger Forced air to gas cooler removes

excess heat that is generated in the

booster.

630-1

780

Dungs

80110

710

Thermocouple A sensor for measuring gas

Flexible Connector Isolates booster from vibration,

Eclipse Packaged Gas BoostPak, V2, Installation Guide 630-2, 6/22/2010

temperature.

mechanical, and thermal stresses.

ii

Page 22

Offered By:

Power Equipment Company

2011 Williamsburg Road

Richmond, Virginia 23231

Phone (804) 236-3800

Fax (804) 236-3882

www.peconet.com

Loading...

Loading...