Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Instruction Manual

Battery Crimping Tool 902-484

Due to continuing improvements, actual product may differ

slightly from the product described herein.

Read this material before

Failure to do so can result in serious injury.

SAVE THIS MANUAL

using this product.

LIMITED 1 YEAR WARRANTY

We make every effort to assure that its products meet high quality and durability standards,

and warrants to the original purchaser that this product is free from defects in materials and

workmanship for the period of one year from the date of purchase (90 days if used as rental

equipment). This warranty does not apply to damage due directly or indirectly, to misuse,

abuse, negligence or accidents, repairs or alterations outside our facilities, normal wear and

tear, or to lack of maintenance. We shall in no event be liable for death, injuries to persons

or property, or for incidental, contingent, special or consequential damages arising from the

use of our product. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation of exclusion may not apply to you. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS.

To take advantage of this warranty, the product or part must be returned to us with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection verifies the defect, we will either repair

or replace the product at our election or we may elect to refund the purchase price if we

cannot readily and quickly provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning

the product.

The warranty gives you specific legal rights and you may also have other rights which vary

from state to state.

TROUBLESHOOTING

FAUL

T ANALYSIS SOLUTION

1. Dirt, contaminants, etc

in ram area of tool.

Tool

is inoperative

Motor

is inoperative

Motor runs

but tool will not

complete a cycle

Dies stop during

operation

LED glows for 20

seconds

Tool loses oil

(leaks)

2. Tool battery contacts

damaged

3. Tool components worn

or damaged.

1. Low or uncharged

2. Broken

1. Oil level low

2. Air in

3. Cold oil

1. Oil level low

2. Air in

1. Battery charge low 1. Charge or replace battery

1. Damaged

internal seal

battery

switch components

hydraulic system

hydraulic system

1. Clean tool

2. Reform contacts

3. Return tool to manufacturer or

distributor

1. Check charge of battery.

Inoperative battery may be

discharged or may have

reached life expectancy

2. Return tool to manufacturer or

distributor

1. Return tool to manufacturer or

distributor

2. Return tool to manufacturer or

distributor

3. Store tool in warm area.

1. Return tool to manufacturer or

distributor

2. Return tool to manufacturer or

distributor

1. Return tool to manufacturer or

distributor

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating, inspection,

maintenance and cleaning procedures. Write the month and year of purchase. Keep this

manual and the receipt in a safe and dry place for future reference.

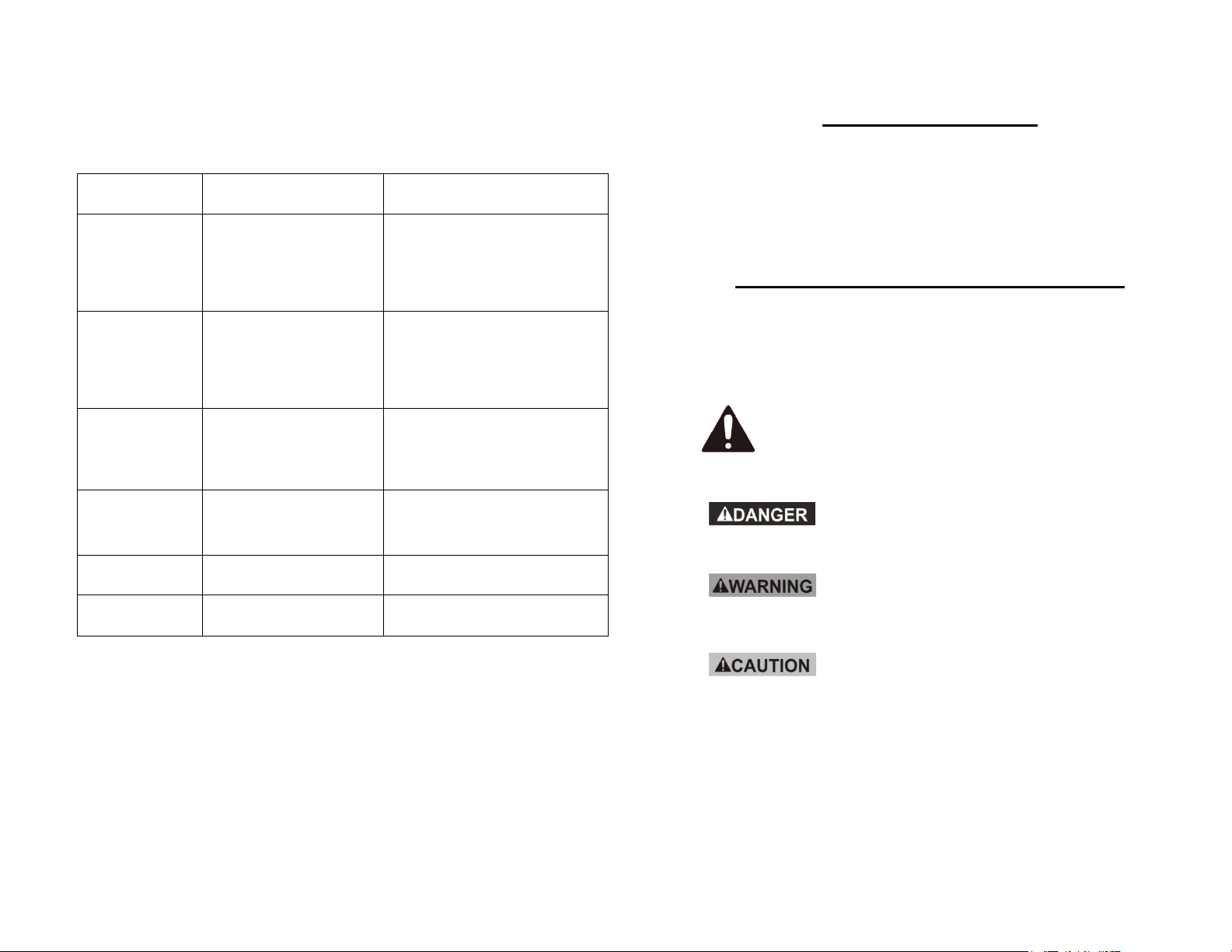

IMPORTANT SAFETY INFORMATION

In this manual, on the labeling, and all other information

provided with this product:

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol,

indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

GENERAL SAFETY RULES

TO WORK IN SAFE CONDITIONS WITH THIS TOOLING, IT IS IMPERATIVE TO

READ CAREFULLY THE DIRECTIONS FOR USE AND TO FOLLOW THE

INSTRUCTIONS IT CONTAINS. IF YOU DO NOT RESPECT THE INFORMATION

WRITTEN IN THAT INSTRUCTION MANUAL THE WARRANTY WILL BE

CANCELED.

1. Work area safety

a. Keep work area clean and clear. Cluttered or dark areas invite accidents.

b. This tool is not insulated; please do not use it on live conductors.

c. Please do not use or store the tool under high temperature, or one filled with

corrosive fluid. Pay attention to the sealing kits becoming aged and worn out.

d. Keep children and bystander away while operating the battery powered crimping

tool. Distractions will cause you to lose control.

e. Do not use or charge the tool around flammable, explosive environment

2. Electrical safety

f. Make sure the plug matches with the plug socket. Never make any changes on

the plug.

g. Do not put tool, battery and charger in rainy or humid surroundings, it is easy to

trigger an electric shock accident if any water gets into the electric system of the

tool.

h. Do not use electric cord to carry, pull, or to pull out the plug and do not connect

the “-” to “+”, damaged or twisted wire may cause an electric shock accident.

i. If the charger was dropped or crashed to the floor, please do not try to repair it by

yourself, send it back to the authorized service center as soon as possible. The

damaged charger may cause an electric shock accident.

j. If the tool not used for a long time, please make sure the piston stays on its starting

position, clean up the tool and rub rustproof oil both to the tool and accessories. Take

out the battery and put it into the box and store the tool in a dry surrounding.

MAINTENANCE AND SERVICING

Damaged equipment may cause serious personal injury. Do not use damaged

equipment. If abnormal noise or vibration occurs, have the problem corrected before

further using.

1. Before each use, inspect the general condition of the tool. Check for loose screws,

misalignment or binding of moving parts, cracked or broken parts, or any other

condition that may affect its safe operation.

2. After using, clean external surfaces of the tool with clean, moist, rub rust preventing

oil on the metal surface of the tool and the dies to avoid rusty. Store the tool in the dry

environment.

3. Service to the tool should only be done by a qualified Service Technician.

4. In order to prolong the life of the tool please change the oil per year. Make sure the oil

filtered by 120 mesh net or over 30µm strainer. Meantime avoid the dusty into the oil

cup.

5. After a long time using, the sealing kits will be damaged, if there is leakage please

contact with the manufacturer and/or the distributor to change the sealing kits.

j. The best temperature for charging is between 10℃-40℃. Make sure the air hole

of the battery and charger are uncovered during charging.

k. Please cut off the power of the charger each time to reduce the hazard from child

or the person who not expert on the tool.

l. Do not wait until the battery runs over for recharging, the recharging will caused

the battery does not working anymore. Please keep the battery out of the tool to

avoid the power discharge.

m. Please do not burn the battery or make it being short-circuited, it may cause

explosion.

n. Do not use the waste battery otherwise it will caused the electric shock.

o. Do not disassemble the battery and charger. If any problem please contact with

manufacture or agent.

3. Personal safety

p. Stay alert, watch what you are doing and use common sense when operating the

tool. Do not use the tool while you are tired or still under the influence of drugs,

alcohol or medication. A moment of inattention may result in series personal

injury.

q. Use safety equipment. Always use safety equipment such as mask, helmet, safety

cap, insulating shoes and etc to reduce the risk of personal injury.

r. Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts. Loose clothes jewelry or long hair can be

caught in moving parts.

s. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the tool operation. If

damaged, have the tool repaired before use. Many accidents are caused by poorly

maintained power tools.

t. Please use the tool properly, the tool with correct power will do the job better and

safer at the rate for which it was designed.

u. Do not put your fingers into the head of the tool during operating. Your fingers

could be pinched very severely.

4. Service

Have your Battery Crimping Tool serviced by a qualified service technician using

only identical replacement parts. This will ensure that the safety of the Battery

Crimping Tool Kit is maintained.

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates on the tool which carry important safety information.

If unreadable or missing, contact the agent to replace.

2. This product is not a toy, keep it out of reach of children.

3. Do not put your fingers into the head of the tool during operating. Your fingers could

be pinched very severely.

4. Make sure the head was locked firmly during operation.

5. Do not use the tool without dies

6. Do not crimp on live cables or conductors

7. Do only crimp copper or aluminum conducting material

8. Do not knock any parts of the tool, otherwise it will cause injury.

9. Do not operate at will, it will damage the MCU and electric system

10. The design of the limit screw on the head is for preventing the head from dropping or

popping.

11. Make sure the head was locked firmly during operation.

12. Do not use this tool for continuous use. After 30 to 40 cycles, allow the tool to cool for

15 minutes.

13. Do not secure this tool in a vise. This tool is designed for hand-held operation.

14. The built-in safety valve goes through strict pressure test before marketing; please do

not adjust the pressure by unprofessional person. If the pressure is not enough please

return the tools back to the service center. The tool only can be reused after checking

and testing by trained person.

15. The warnings, precautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be

Make sure that all the parts are clean without any oil, dust, especially on the

handle and control parts, to avoid the tool drop easily during the operation.

1) 1) First press the for 3 s to turn on the power, the tool will self-test for 1 s,

the data showing the last record, the tool is ready to work.

Inspect the battery to see if it is charged or run out.

2) Select the right dies for the intended application,

Don’t operate the tool without dies.

the crimping head has to be opened by pushing the Latch, insert two dies top and

bottom, the steel ball located center of the die will match the hole of the latch and die

holder when both die halves are in place. Then the connecting material shall be

positioned in the crimping head correctly, in order to start the crimping procedure,

3) A crimping process is initiated by switching the trigger. It is defined by the closing

motion of the dies. The connection material is positioned in the stationary half of the

crimping dies and the moving part is approaching the compression point.

4) A crimping cycle is terminated when the dies contacted each other and when the

maximum crimping force is reached. After the crimping cycle is completed, the piston

retracts automatically. Afterwards a new crimping cycle can be initiated or the

crimping process can be terminated by opening the latch and removing the connector

material out of the head.

understood by the operator that common sense and cau

be built into this product, but must be supplied by the operator

are factors which cannot

tion

.

UNDERST AND YOUR TOOL

902-484 is a tool for crimping Cu lugs with cables from 16-400 mm2. It is powered by

Li-ion, actuated by motor and controlled by MCU. With a high pressure hydraulic system,

LED light, LCD , error warning alarm, pressure showing..etc function, it is a perfect tool to

be used in electrical construction site.

1. Specification

Max. crimping force: 6 Ton

Crimping range: CU AWG 6 to 600MCM

Stroke: .67 inch

Crimp/Charge 320 times(Cu 300MCM)

Time/crimp: 3-6s( depend on the size of cable)

Hydraulic oil: Shell Tellus T15#

Capacity: 115ml

Ambient temperature

Voltage: DC 18V,3Ah

Charging voltage:

Charging time: Approx.2 hours

-10-40℃

AC 100V~240V ;50~60Hz

The crimping process can be interrupted at

button.

Do not put your fingers into the head of the tool during operating. Your fingers could

be pinched very severely.

any moment b

y releasing the trigger

Accessories:

Crimping die: 6,4,.2,.1/0.2/0.3/0.4/0. 300,350,500,600MCM

Battery: 2 pcs

Charger: 1 pc

Sealing ring of cylinder: 1 set

Sealing ring of safety valve. 1 set

2. Description of components:

Set the output

force

Press for 3 s enter into setting status, the data display

will flash. Press the per time, output data increase by

10 KN (1Ton) (or 5 KN (1.2 Ton), according to requirement),

this action is circulated from Min KN to Max KN. Press

for 3 s or leave it 15 s, it returns to initial state.

Parts No. Description Function

1 Die holder For fixing die

2 Die For crimping, interchangeable die

3 Latch For locking /unlocking the crimping head

4 Die holder For fixing die

5 LCD

6 Keyboard For power switch, function switch, LED light switch

7 Limited screw For prevent head from dropping or popping

8 LED indicator For lighting

9 Trigger

10 Lock Locking the battery

11 Battery

Showing the data (crimping times, electricity

capacity, error information)

For operating or retracting the piston in case of

incorrect operation.

For supplying power, rechargeable Li-ion(18V).

LED

Battery power

Convenient in dark environment, with a light symbol showing

on the LCD, through to get into start status.

display, and lighting. LCD background lighting, meanwhile

press the power button, the front LED lighting, after 20 s, the

light turn off automatically. During LED lighting, keep for

pressing to turn off the LED even for the LCD

background light.

full power.

, meanwhile flash and buzzing according to the flash

frequency . Charge the battery.

Error showing Error occured, such as motor damaged, drive system error and

hydraulic system problem… the tool stop working. LCD

showing “error data” as following: it stands for “over power

capacity”

Power off

USB port with

computer

Press for 3 s or leave the tool 30 s to off the power

Take the battery away from the tool, connect the USB with a

computer to exchange the data. LCD showing symbol

The battery can be charge cycled hundreds of times, when the charge time is reduced

considerably, change to a new battery.

Please charge the battery in time to avoid it to be used up completely; otherwise it will

become useless forever. If the battery not be used for a long time, it will discharge

automatically, so take it out of the tool and make sure to charge it one time per/each

quarter.

2. Usage of the tool

3. Function description

MCU –automatically detect the pressure during operation and provide

Security protect, shut off the motor and reset automatically after

operation.

Auto reset- Release the pressure automatically, retract the piston to the

starting position when reached the max output.

1. LCD board instruction:

2. LCD board showing and setting:

Please note: tool in power off , there is no any data showing.

Power on

Press for 3 s, the tool into starting status, the

keyboard showing all the data for 1 s, then the tool is self

inspecting for 1 s. the data will be changed and increased in

order

Exchange

showing

In the power on status, press , the data exchange

One key control- press the trigger to start working, half pressing the trigger

means stop forcing pressure, letting go fully means piston returns to the

original position.

The unit is equipped with a double piston pump which is characterized

by a rapid approach of the die towards the connector and a slow crimping

motion.

The head can be smoothly turned by 350° around the longitudinal axis

in order to gain better access to tight corners and other difficult working

areas.

Suspend—finish working or withdraw the hand from the trigger or any

accident happened, the device inside of the tool can stop power supply.

One significant sound will be heard and a red display flashes if any error

occurs or lower power being.( Ref. table 1)

Per time pressing on the trigger, the LED will lighting for 20 seconds.

High-performances Li-ion battery in strong power supply, No discharge

memory effect., Ultra lower power consumption standby design keep the

tool 6 months storage, meanwhile over discharge device prolong the life

span of the battery.

A temperature sensor makes the tool stop working automatically when

the temperature over 60˜ under long time working, the fault signal

Table 1.

Series

No

1

sounds, it means the tool can’t continue working until the temperature

reduced to normal.

Micro computer control system with the feature of self-pressure detecting,

double protection during operation, counting and realize the exchange

between computer with data by the converter.

Error code

On ---

Instruction What it means

Self-checking

Self-checking to assure

everything is ok

OPERATING INSTRUCTION

Read the entire SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before using this product.

Use this tool for the manufacture’s intended purpose only. Use other than that which is

described in this manual can result injury or property damage.

1. Charging

Push battery into charger and connect the plug with the plug seat. Make sure the room

temperature is between 10˜ -40˜ 。The charging time is around 2 hours. Please see the

Hydraulic system may

2

E01

3

4

5

E02

6

E03

7

E04

●●●

●—5sec

●●●●

●●●●●

Overload

Charging

signal

Po

wer lacking

warning

Sensor error

Temperature

warning

No pressure

be damaged and need

checking immediately

Lack

ing power and

needs charging.

No power and needs

charging immediately

Temperature sensor and

power inspecting error

Temperature too high,

tool need to be cooled

Motor working but

without pressure

illustration below.

The detail of the charging information, please refer the manual (MANUAL

CHARGER)

FOR

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Loading...

Loading...