Page 1

Test Equipment Depot - 800.517.8431

- 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Instruction Manual

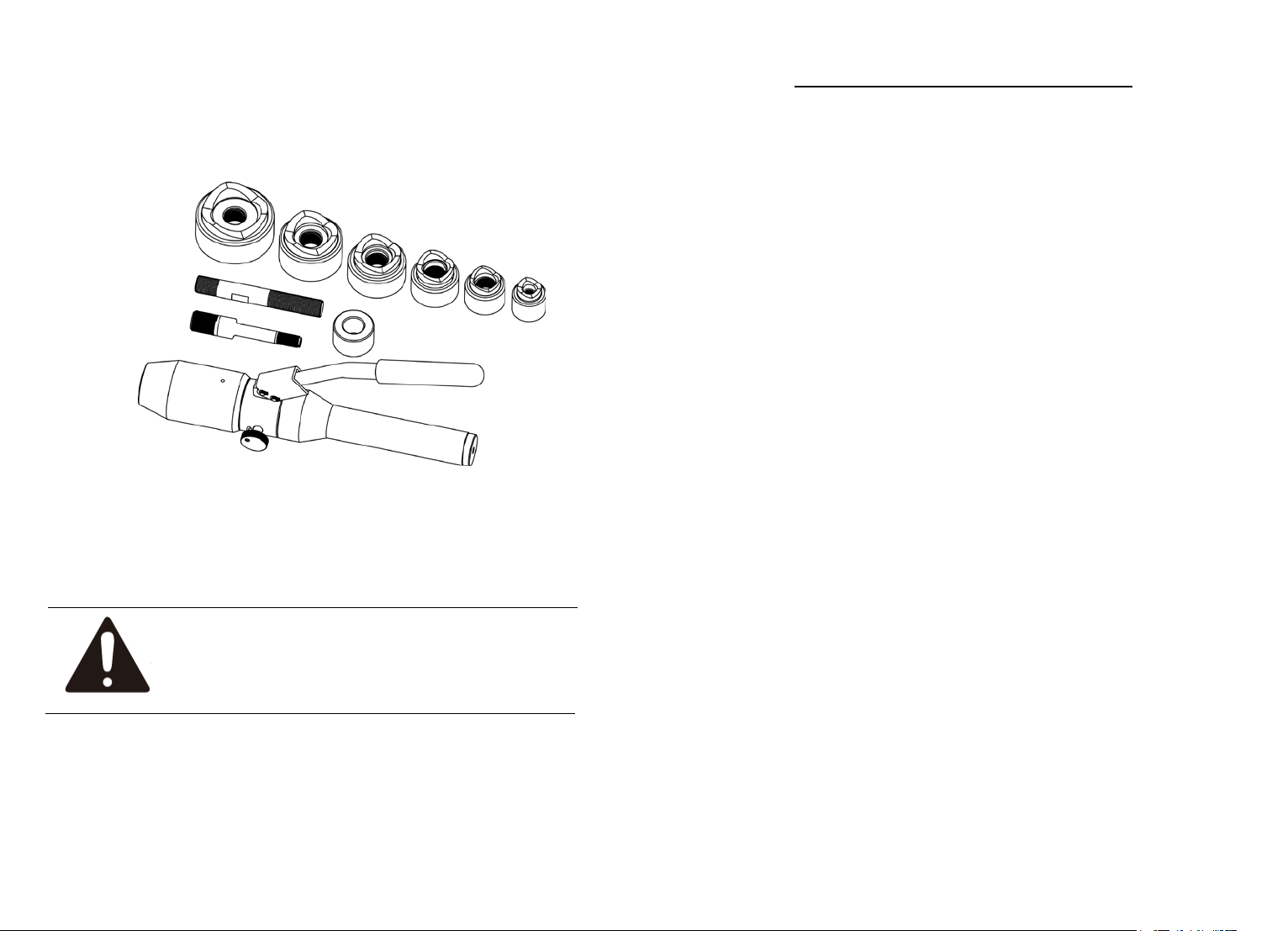

Hydraulic Punch Driver 902-482

Due to continuing improvements, actual product may differ

slightly from the product described herein.

R

ead this material before using this product.

Failure to do so can result in serious injury.

LIMITED 1 YEAR WARRANTY

We make every effort to assure that its products meet high quality and durability standards,

and warrants to the origin al purchaser that this product is free from defects in materi als

and workmanship for the period of one year from the date of purchase (90 days if used

as rental equipment). This warranty does not apply to damage due directly or indirectly, to

misuse, abuse, negligence o r accidents, r epairs or alterations ou tside our facilities, no rmal

wear and tear, or to lack of maintenance. We shall in no event be liable for death, injuries

to persons or property, or for incidental, contingent, special or consequential damages

arising from the use of our product. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation of exclusion may not apply to

you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL O THER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF M E RCHANTABILITY

AND FITNESS.

To take advantage of this warranty, the product or part must be returned to Eclipse with

transportation charges prepaid. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection verifies the defect, we will either

repair or replace th e produ ct at our el ectio n or we may ele ct to ref un d th e purch ase p rice i f

we cannot readily and quickly provide you with a replacement. We will return repaired

products at our expense, but if we determine there is no defect, or that the defect resulted

from causes not within the scope of our warranty, then you must bear the cost of returning

the product.

SAVE THIS MANUAL

The warranty gives you specific legal rights and you may also have other rights which

vary fr om place to place.

Page 2

GENERAL SAFETY RULE

SAVE THIS MANUAL

Keep this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures. Write the month and year of

purchase. Keep this manu al and the receipt in a safe and dry place for

future reference.

IMPORTANT SAFETY INFORMATION

In this manual, on the labeling, and all other information provided wi th this

product:

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obe y all safety messages that follow

this symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which,

if not avoi ded, will result in death or serious injury.

WARNING indicates a hazardous situ ati on which,

if not avoi ded, could result in death or serious injury.

CAUTION, used with the safety al ert symbol,

indicates a hazardous situat ion which, if not avoided,

could result in minor or moderate injury.

TO WORK IN SAFE CONDITIONS WITH THIS TOOLING, IT IS IMPERATIVE TO

READ THE DIRECTIONS CAREFULLY FOR USE AND TO FOLLOW THE

INSTRUCTIONS IT CONTAINS. IF YOU DO NOT RESPECT THE INFORMATION

WRITTEN IN THE INSTRUCTION MANUAL THE WARRANTY WILL BE VOIDED.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark areas invit e accid ents.

b. This tool is not insulated; please do not use it on live conductor.

c. Keep children and bystander away while operating the hydraulic punch driver.

Distractions will cause you to lose control.

d. Please do not use or store this tool under high temperature, or one surrounding

filling with corrosive fluid. Pay attention to the sealing kits becoming aging.

2. Personal safety

a. Stay alert, watch what you are doing and use common sense when operating

the tool. Do not use the tool while you are tired or under the influence of drugs,

alcohol or medication.. A moment of inattention while operating hydraulic tools

may result in serious personal injury.

b. Use safety equipment. Always wear eye pro tection . Safety equip ment such as

dust mask, non-skid shoes, hard hat, or hearing protection used for appropriate

conditions wi ll reduc e d pe r s ona l injuries.

c. Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes jewelry or long hair

can be caught in moving parts.

d. Do not force the tool. Use the correct power tool for your application .The

correct power tool will do the job better and safer at the rate for which it was

Page 3

designed.

Does not

1. Refer to “Operation” and Capaci ty

the “Maintenance” section

1. Improper assembly or use

of punch, die, or

is too thick or too hard.

Pump does

not build

1. Prefer to “Adding Hydraulic Oil”

and replace it by trained person

e. Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the hydraulic punch driver. This tool is dangerous in the hands

of untrained users.

f. Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the Hydraulic Punch

Driver operation. If damaged, have the Hydraul ic Punch Driver repair ed before

use. Many accidents are caused by poorly maintained power tools.

g. Use the Hydraulic P unch Dri ver, accessories and tool bits etc., in accordance

with these instructions and in the manner intended for the particular type of tool,

taking into account the working conditions and the work to be performed. Use of

the Hydraulic Punch Dr iver for operations different from those intended could

result in a hazardous si tuation..

TROUBLESHOOTING

FAULT ANALYSIS SOLUTION

A.

punch hole

B. Requires

excessive

lever force.

C.

pressure.

1. Improper assembly or use

of punch, die, or accessori es

2. Low oil level

accessories.

2. Material being punched

1. Air in system

2. Oil leakage on the ram

and Draw Stud selection Guide.”

2. Refer to “Adding Hydraulic Oil: in

1. Refer to “Operation”

2. Refer to “Cap acity and Draw Stud

Selection Guide”

in the Maintenance Section.

2.Contact manufacturer or distributor

3. Service

Have your Hydraulic Punch Driver serviced by a qualified s ervice technician using

only identical replacement parts. This will ensure that the safety of the Hydraulic

Punch Driver Kit is maintained. For service contact Eclips e Tools at 804-561-2610

for instructions.

Dust or air inside the to ol will damage the sealing kit caused the tool lose

function. Make sure the oil is clear and no dust enters into oil when

changing oil. Wait for a while and exhaust the oil completely out of the oil

tubes before inserting the oil plug.

SPECIFIC SAFETY RULES

1. Maintain labels and n ameplates on the tool which carry important safety information.

If unreadable or missing, contact the agent to replace.

2. This product is not a toy, keep it out of reach of children.

3. Do not slide your fingers in the punch & dies profile.

4. Do not put your fingers in the head of the tool when you slide the dies inside it. Your

fingers could be pinched very severely.

5. Do not use the tool without punch & die.

6. Hand-tighten all couplers completely before operating the pump.

7. Do not use hands to check for leakage.

8. Do not hold hose or coupler while the hydraulic system is pressurized.

9. Do not use this tool near live circuits.

10. The warnings, precautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be

understood by the operator that common sense and caution are factors which cannot

be built into this product, but must be supplied by the operator

.

Page 4

SAVE THESE INSTRUCTIONS

UNDERST AND YOUR TOOL

The 902-482 punch is for punching mild metal plate. It carries many advantages of good

design, easy operation, high pressure, high efficiency etc. They are the perfect tool to be

used in construction site.

Item 902-482

Punching range: 7/8” to 2.5” below 10 gauge mild steel plate

Punching force: 6.6 Tons

Stroke: 0.875 inches

Length: Approx.. 12.6 inches

Weight: Approx 6.0 pounds

Package: plastic box

Weight of box: Approx. 2.6 pounds

Oil capacity: Approx. 2.02 ounc e s l

hydraulic oil: 15#

Ambient temperature: -4ºF - 104ºF

ADDING HYDRAULIC OIL:

a. Place the driver in a vise in a vertical position with the handles up. Unscrew the

reservoir handle and remove th e bladder plug. Open the turn screw to assu re the ram

is fully extended.

b. Fill the rubber bladder to the point of overflow with hydraulic oil.

c. Purge air from the system: Pump the lever h andle several times to remove air fro m

the pumping chamber. Close the turn screw until the ram completes its full travel.

Repeat as necessary.

Open the turn screw slowly so the ram extends slowly.

Rapid return of oil and air may cause the oil to overflow

the rubber bladder.

If this procedure fails to remove air, remove the bladder plug and open the turn screw.

Place thumb over the plug hole in the bladder and squeeze the bladder while pumping

the lever handle several times. Close the turn screw and pump the pump handle until

the ram completes its full t r avel . Repeat as necessary.

d. Fill the rubber bladder to the point of overflow and replace the bladder plug. Wipe the

bladder clean of excess oil and reassemble the reservoir handle.

OIL LEAKS

Accesso ries:

Round Knockout Pu nc he s Type D: .89, 1.11, 1.36, 1.71, 1.96 and 2.43 inches

Draw St ud: 7/16 x 3/4”: 1pc

Draw St ud: 3/4”x 3/4”: 1pc

Spacer: 1pc

Sealing kit: 1set

Plastic box: 1pc

The size of punch & die is marked on the surface of the lower punch half (die).

a. Check for external oil leaks

b. Check that the turn s cr ew and stem are closed tightly and seating properly.

c. Remove the reservoir handle and check for oil leaks around the rubber bladder and

bladder plug.

Please w e a r t he rubber gloves to avoid skin touching the oi l directly, if touches it,

please wash the skin by soap and water quickly. In order to protect the

environment please drain the waste oil to the treatment center where was

approved by local or federal governments.

Page 5

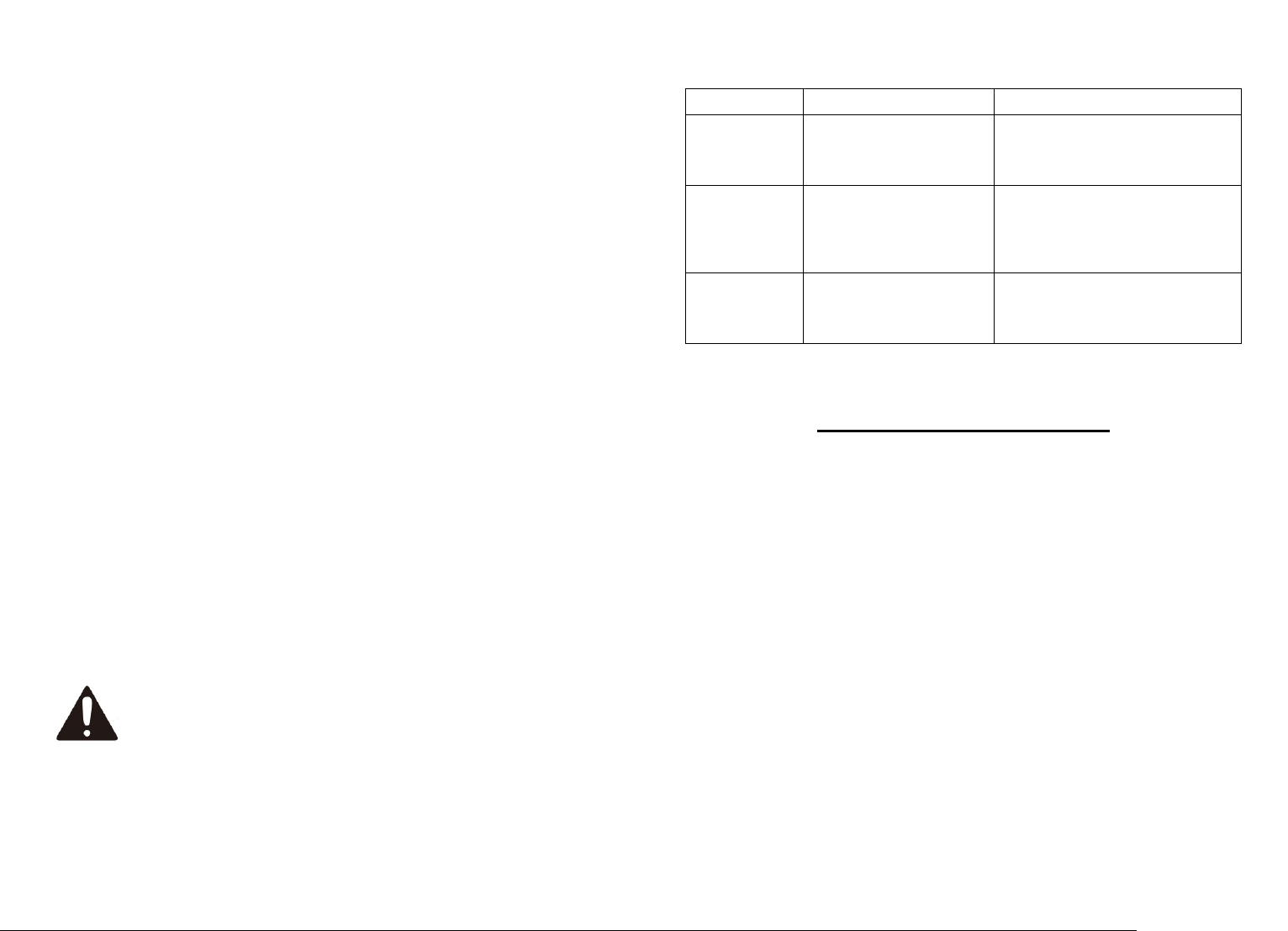

MAINTENANCE AND SERVICING

7/16”Draw Stud

+Spacer

3/4”Draw Stud

Damaged equipment may cause serious personal injury. Do not use damaged

equipment. If ab nor mal nois e or vi brati on o ccurs , have t he probl em c orrect ed be fore

further using.

1. Before each use, inspect the general condition of the tool. Check for loose screws,

misalignment or binding of moving parts, cracked or broken parts, or any other

condition that may affect its safe operation.

2. After using, clean external surfaces of the tool with clean, moist, smear the rust

preventing oil on the metal surface of the tool and the dies to avoid rusty. Store the

tool in the dry env ir onment.

3. Service to the tool should only be done by a qualified Service Technician.

4. After a long time, the sealing kits will be damaged, if there i s leakage please con tact

the manufacturer and/or the distributor to have the sealing kits changed.

1. Description of the components.

Code Name Function

1 Ram Output high pressure to active the piston

2 Turn screw To release the pressure

3 Active handle For operating

4 Fixed handle For storing oil and protect rubber bladder

5 Punch &die For punching

6 Spacer To protect the ram and assist tool for punching

7 Draw St ud For connecting cylinder with punch & die

Capacity and Draw Stud Selection Guide

Draw Studs and

Accessories

+Spacer

3/4”Draw Stud

Standard Round Knockout Pu nches (Type D)

.89” 1.11” 1.36” 1.71” 1.96” 2.43”

▲

▲ ▲ ▲

▲ ▲

Page 6

OPERATING INSTRUCTIONS.

remaining the lower half of the punch.

7. Turn the screw counterclockwise to release the pressure at th e pump.

Read the entire SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before using thi s product.

Use this tool for the manufacture’s intended purpose only. Use other than that which is

described in this manual can result injury or property damage.

1. Select the appropriate punch die set. Ask an authorized facility or distributor to

choose proper punch die set for hole punching.

Do not exceed the rated capacity of this tool, otherwise it will

caused a component failure, which could throw broken parts

with great force. Failure to observe this warning can

result injury or de ath.

2. Drill a pilot hole 1/2” diameter with an electric or co r dl es s drill on the metal sheet.

3. Turn the turn screw counterclockwise to fully extend the ram

4. Thread the draw stud completely into the ram.

5. Slide the spacer in necessary onto the draw stud, and the die after, then let the metal

sheet go through the draw stud by the hole. Finally, thread the punch facin g the steel

plate. Make sure the spacer, punch, die and material are tightly aligned.

An improper setu p could cause the components damag e .

Step-up Punching

The 1/2” conduit-size punch is often used to increase the size of the pilot hole, this is

called “step-up punching.” After enlarging the pilot hole, the 3/4” draw stud is used to

punch the final hole.

Do not allow anyone to stand in front of the punch or behind the hydraulic ram.

Ignoring this warning can result in injury or damage.

PLEASE SEE THE ILLUSTRATION BELOW:

Do not operate the pump after ram motion stops. Continuing

to operate the pump l ever after the ram stops will damage t he

ram. If the ram stops before the hole is complete, stop

pumping, check that the setup is correct and that you have

not exceeded the tool ’s capacity. See the setup instruction. If

necessary, disassemble the setup and add or remove the

spacer.

6. Pump the handle lever until completely punched through.

Make sure the punching operation is completed to avoid th e scrap

Page 7

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

Loading...

Loading...