®

Guided Wave Radar

Level Transmitter

Installation and Operating Manual

™

705

software V3.x

2

UNPACKING

Unpack the instrument carefully. Make sure all components

h

ave been removed from the foam protection. Inspect all

components for damage. Report any concealed damage to

the carrier within 24 hours. Check the contents of the carton/crates against the packing slip and report any discrepancies to Magnetrol. Check the nameplate model number

to be sure it agrees with the packing slip and purchase

order. Check and record the serial number for future reference when ordering parts. To avoid moisture ingress in the

housing, covers should be fully tightened at all times. For

t

he same reason, plugs should remain properly installed in

the cable entries until replaced with a cable gland.

SPECIAL CONDITIONS FOR ATEX INTRINSICALLY SAFE USE

These units are in conformity with the

provisions of:

1. The EMC Directive: 2014/30/EU.

T

he units have been tested to EN

61326: 1997 + A1 + A2.

2. Directive 2014/34/EU for Equipment or protective system for use in potentially explosive atmospheres. ECt

ype examination certificate number KEMA99ATEX0518X

(intrinsic safe units) or BKI 12 ATEX 0017 (Ex d units) or

KEMA99ATEX5014 (Non sparking units).

3. The PED directive 2014/68/EU (pressure equipment

directive). Safety accessories per category IV module

H1.

Amplifier nameplate:

-

partnumber

- amplifier

- serial n°

-

temperature/pressure

- approval data

Probe nameplate

- partnumber

-

serial number

0

038

0

344

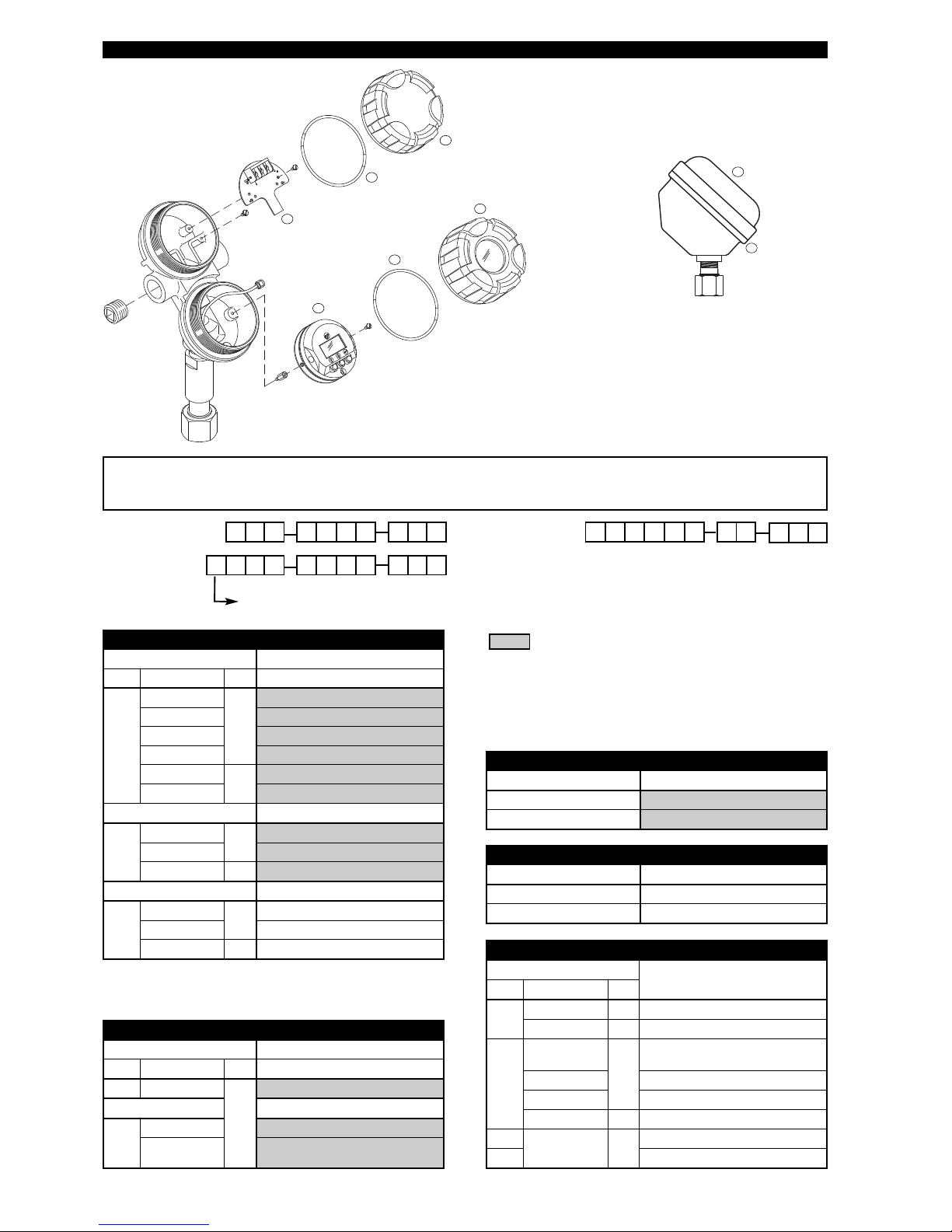

Because the enclosure of the Guided Wave Radar Level Transmitter Eclipse Model 705-5xxx-x1x and 705-5xxx-x7x and/or

Probe Eclipse Model 7xx-xxx-xxx is made of aluminium, if it is mounted in an area where the use of category 1G apparatus is

required, it must be installed such, that, even in the event of rare incidents, ignition sources due to impact and friction sparks

are excluded.

For applications in explosive atmospheres caused by combustible dust, gases, vapours or mists and where category 1G or 1D

apparatus is required, electrostatic charges on the non-metallic parts of the Probe Eclipse Model 7M5-xxx-xxx, Model 7M7-xxxxxx and Model 7xF-xxx-xxx shall be avoided.

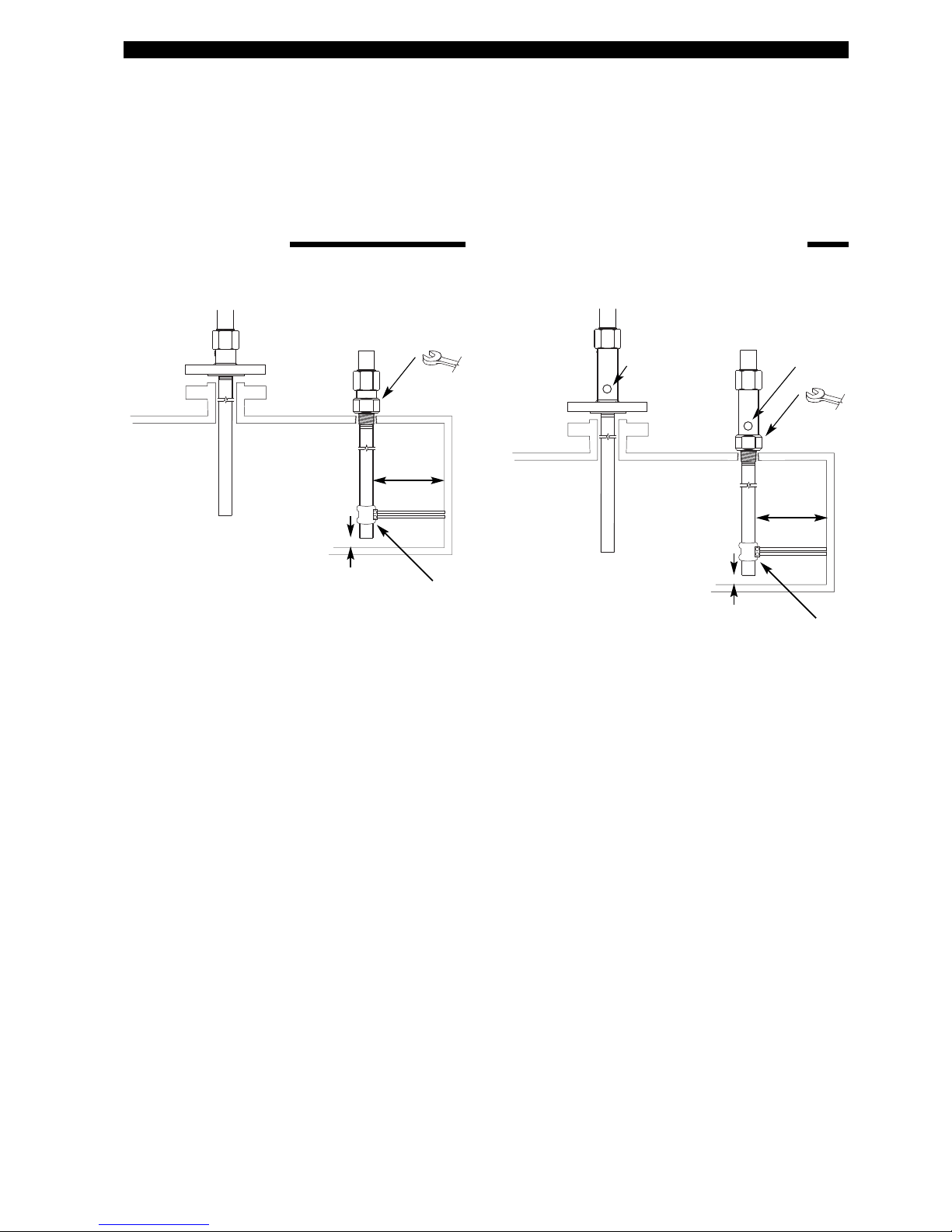

S

ize: 38 mm

(

1 1/2") or

a

djustable

w

rench

Customer supplied brackets are recommended

per each 3 m length. (Required for WGH § 19

i

nstallations.)

Not important

min 25 mm (1")

from tank bottom

3

Overfill safe and Overfill proof

Eclipse 7MD/7ML, 7MR/7MM and 7MT/7MN coaxial GWR

probes are “Overfill safe” in use and “Overfill proof” certified.

Overfill safe means that the unit is capable to measure up

to the process connection.

Overfill proof protection (such as WHG or VLAREM) certifies reliable operation when the transmitter is used as

overfill alarm but assumes that the installation is designed

in such way that the vessel/ cage cannot overfill.

Eclipse 7MQ/7MS has a transitioning zone (zone in which

the unit does not measure accurately) at the top. Maximum

level should not be higher than 25 mm (1") up to 200 mm

(8") (depending dielectrics - see probe specifications) below

the process connection. This may include utilizing a nozzle

or spool piece.

Note: When using the 7MQ or 7MS probe, keep transmitter

and probe matched as a set.

Metallic (or any conductive) obstructions in the tanks

Metallic obstructions have no influence on the measuring

performance of coaxial GWR probes.

Turbulence

Customer supplied mounting brackets are recommended

per each 3 m (10’) length and have no influence on the measuring performance of coaxial GWR probes.

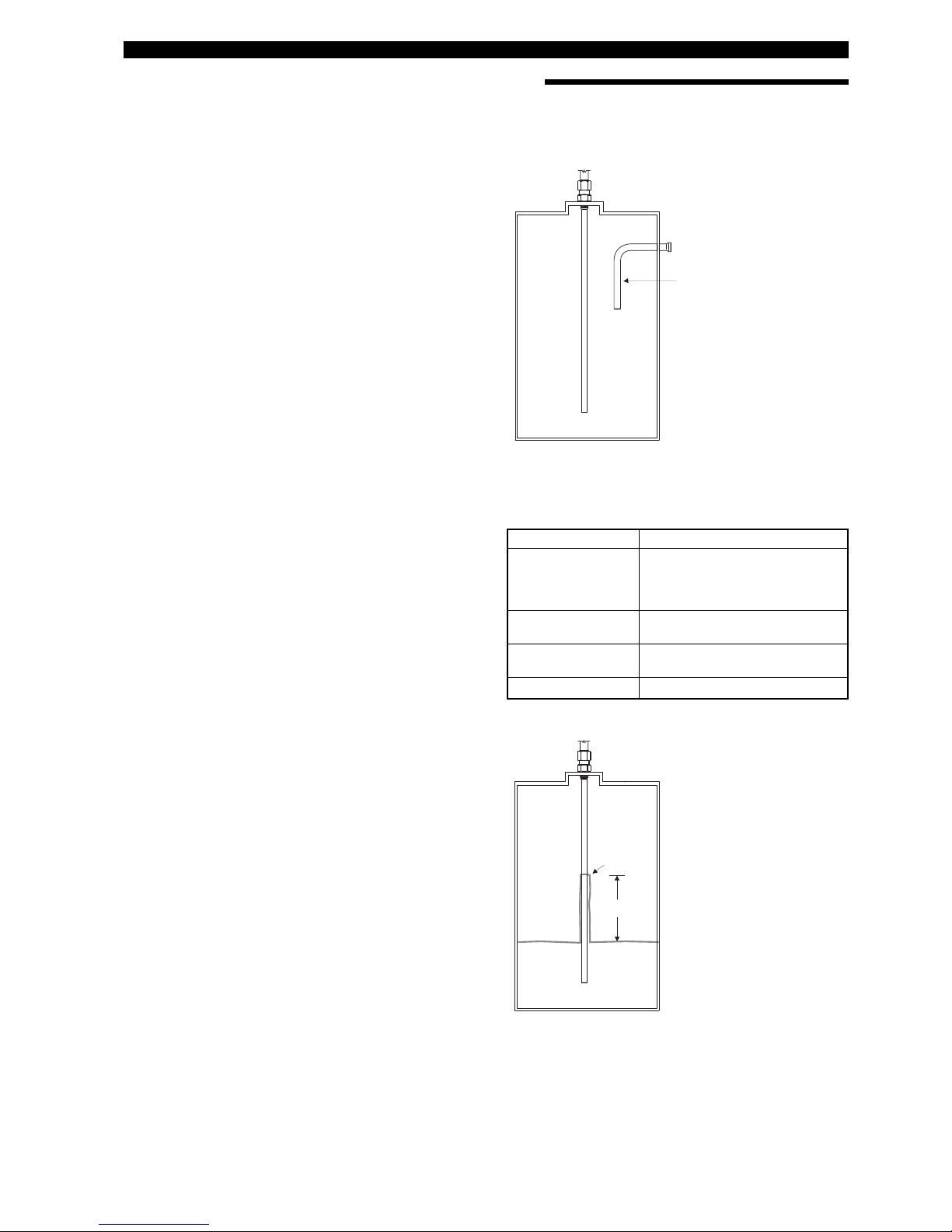

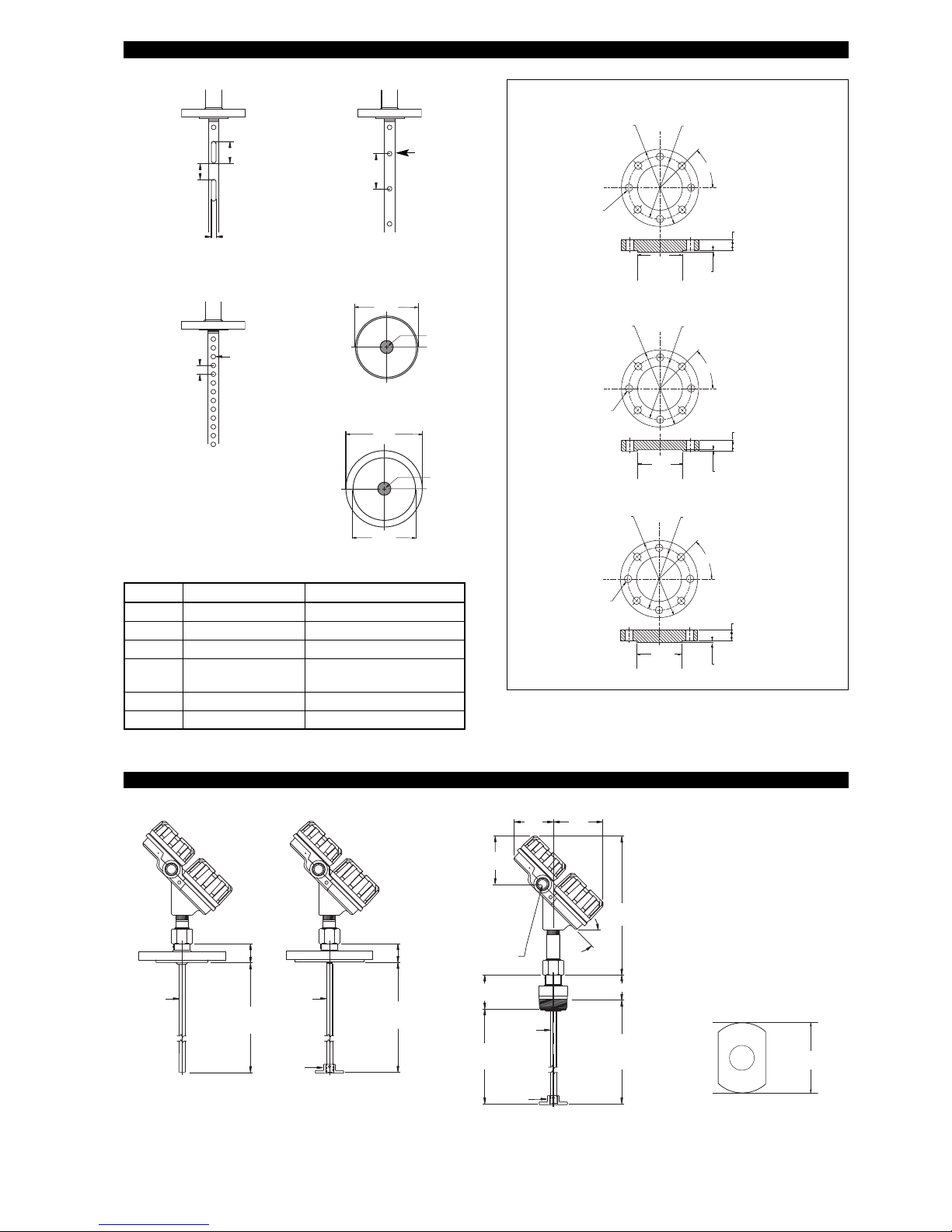

Stillwell /cages

Coaxial GWR probes are ideally suited for use in stillwells

or cages. There is no min. clearance allowance to be taken

into consideration.

Shortening of probe length

Coaxial GWR probes can be easily shortened on site when

a procedure for this is strictly followed. This procedure can

be separately obtained from factory.

Size: 38 mm

(1 1/2") or

adjustable

wrench

1/4" NPT

plugged

flushing

connection

1

/4" NPT

p

lugged

fl

ushing

c

onnection

Customer supplied brackets are recommended

p

er each 3 m length. (Required for WGH § 19

installations.)

Not important

min 25 mm (1")

f

rom tank bottom

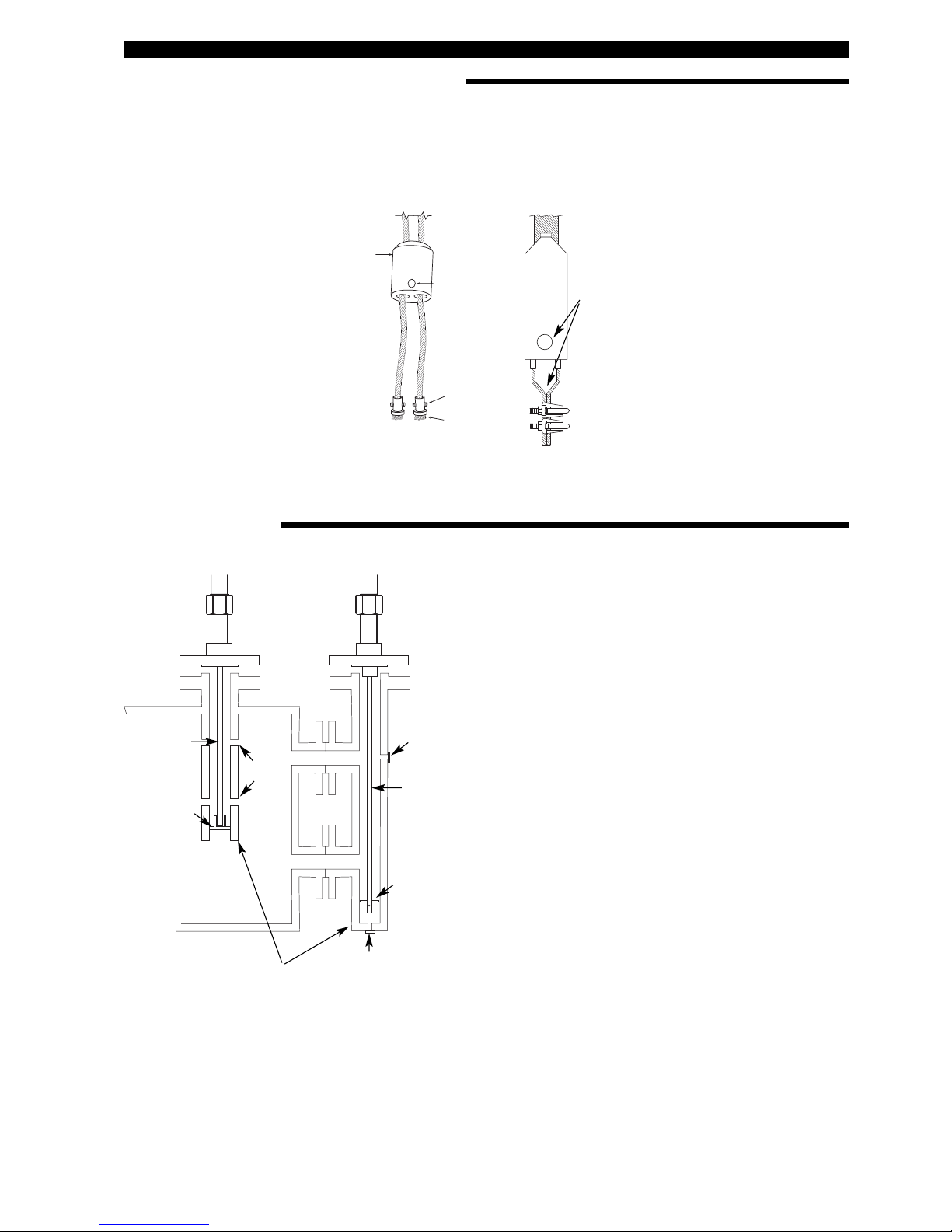

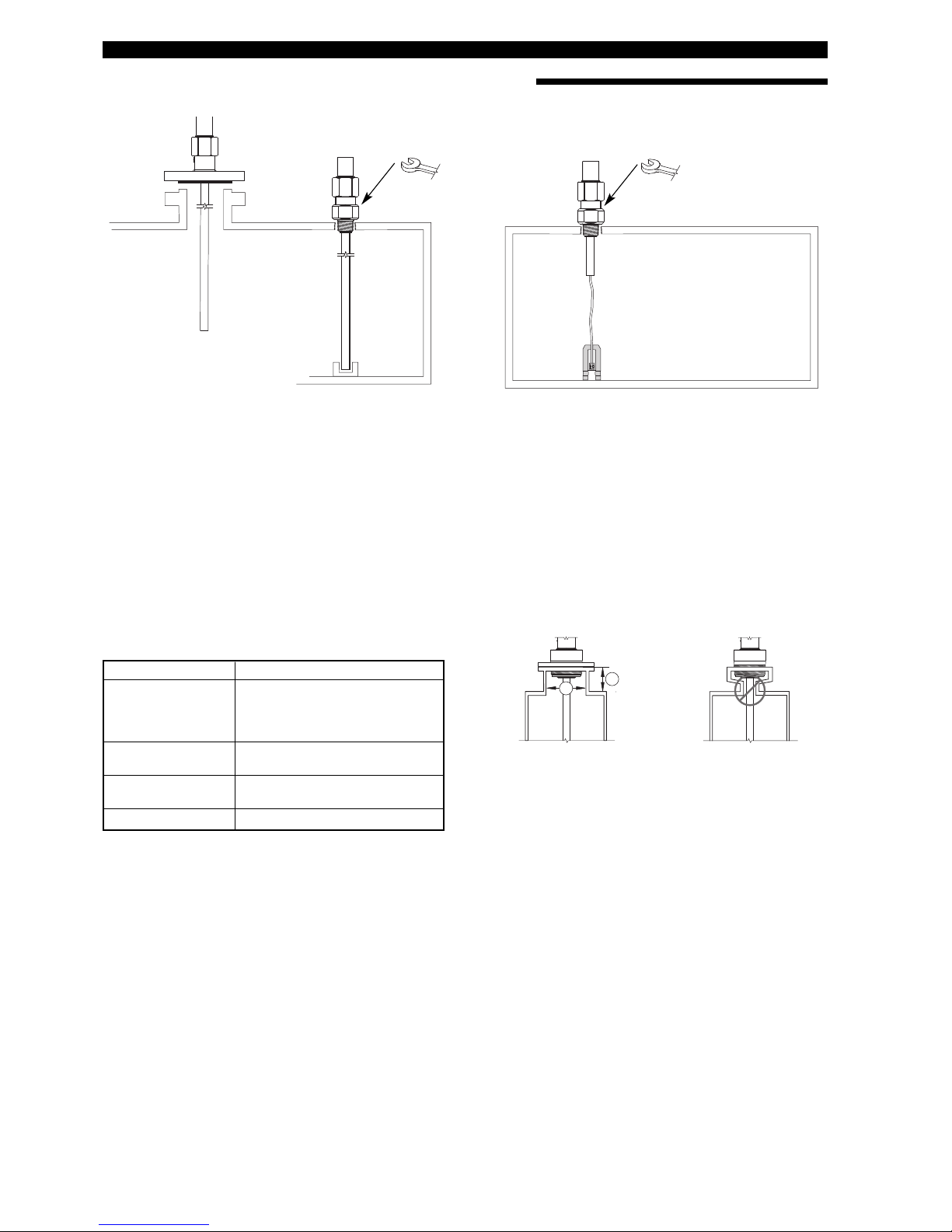

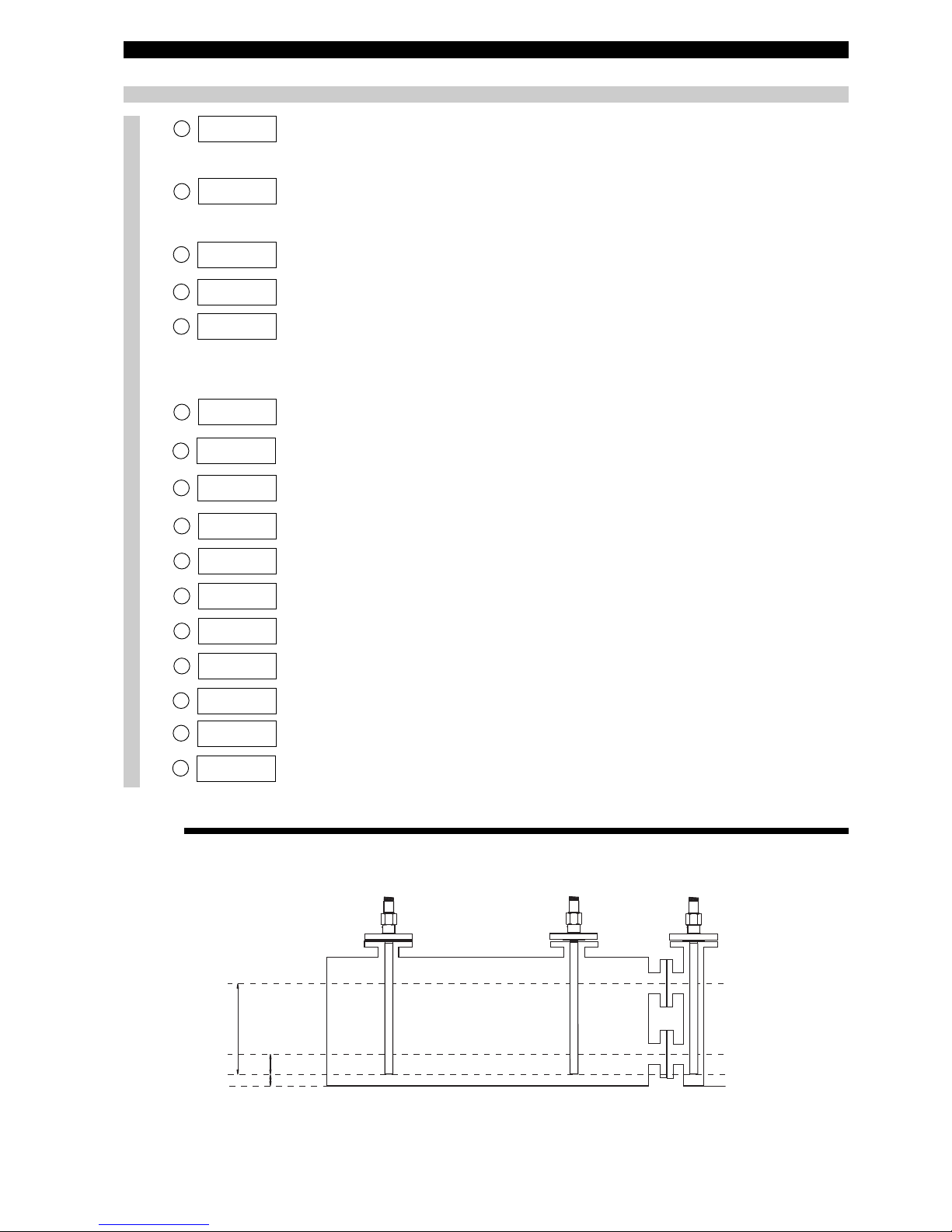

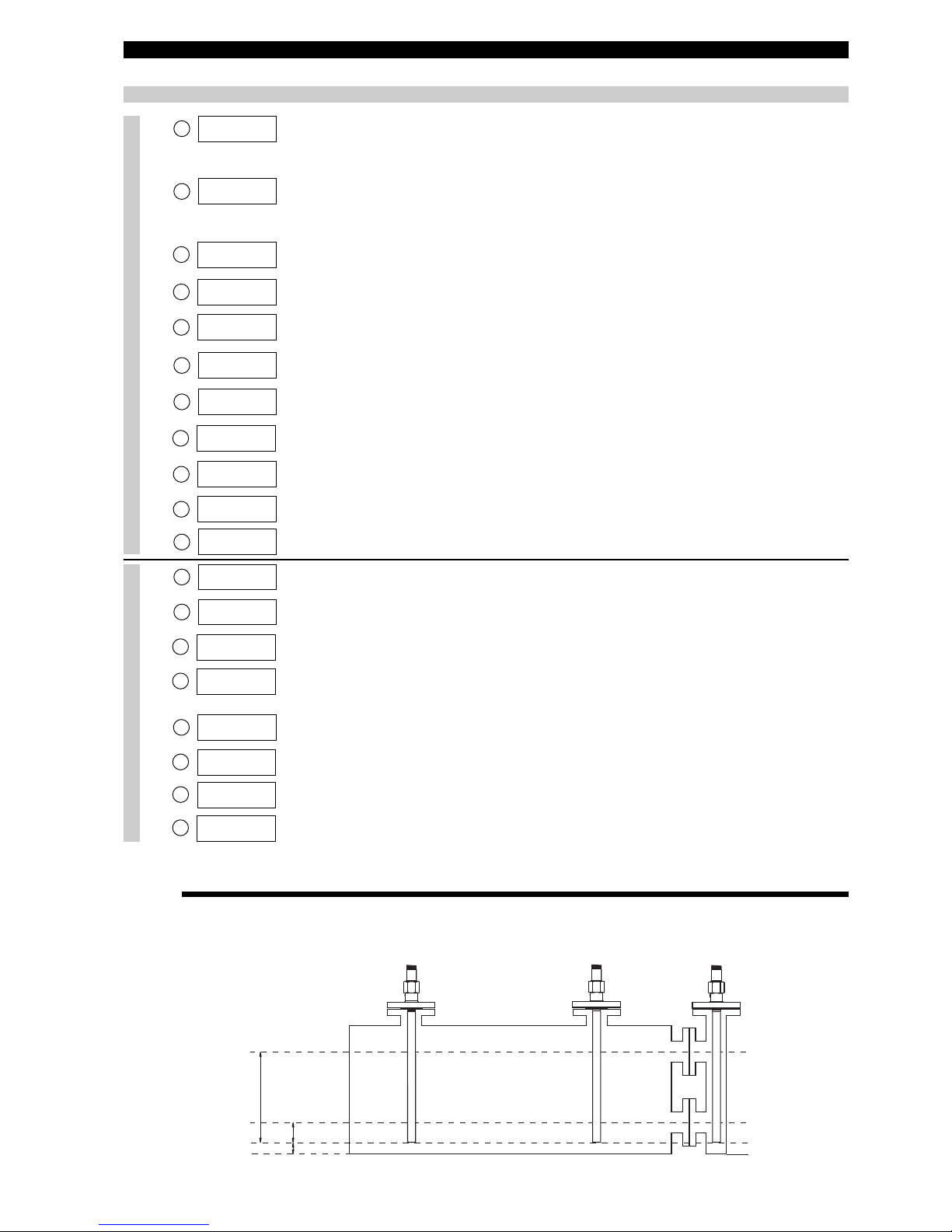

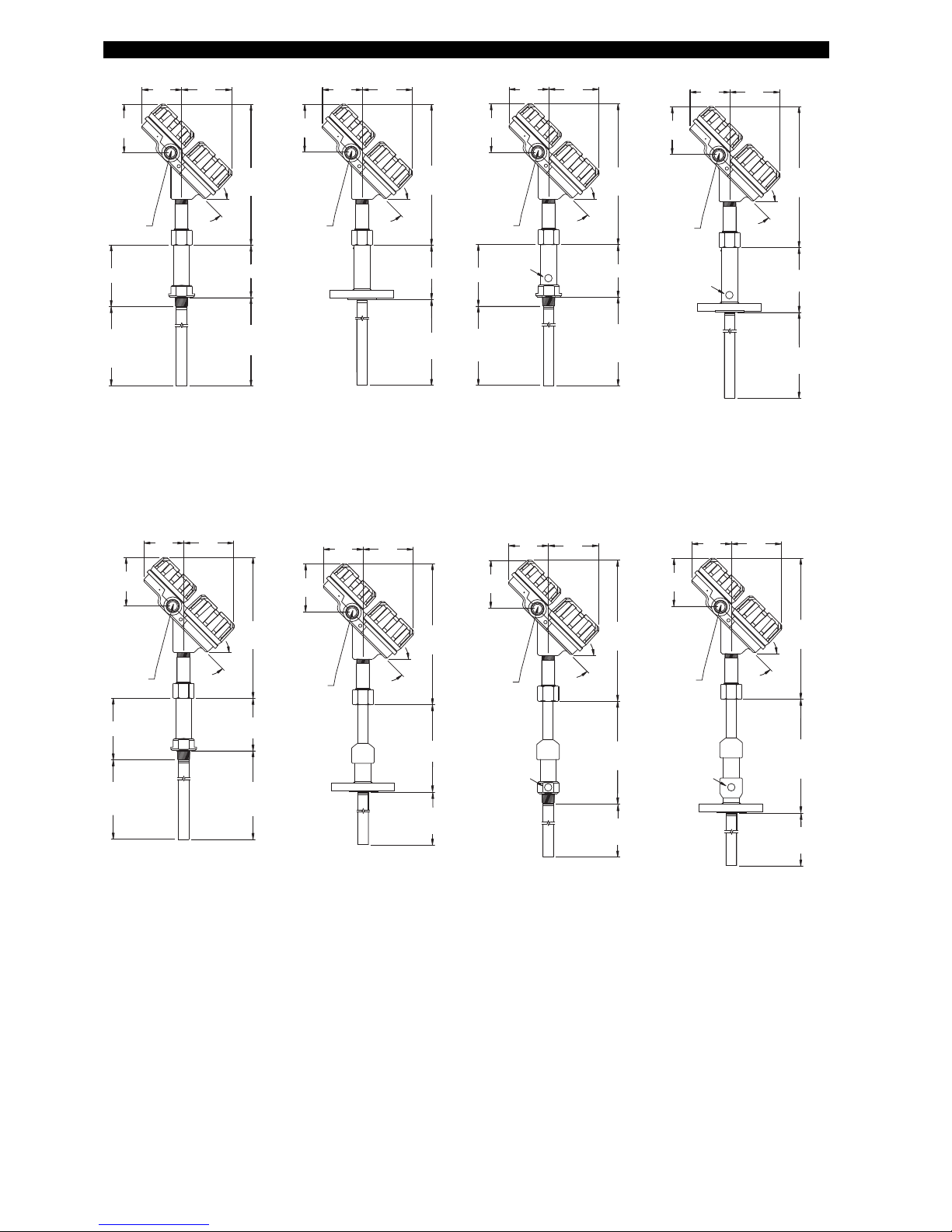

MOUNTING

C

oaxial type GWR probes

(7MD - 7MQ - 7MR - 7MS - 7MT)

Note: The flushing connection allows to purge the inside of

the coaxial probe without dismantling. Re-assure the use of

compatible purging liquid/gas to avoid unwanted chemical

reaction.

C

oaxial type GWR probes: Flushing connection

(7ML - 7MM - 7MN)

IMPORTANT:

To avoid damaging during transportation, Eclipse

®

7MD/7ML large coax probes are shipped with 3 transport screws, securing

the inner antenna. The 3 screws have to be removed prior to installation. They are located nearby the process connection. A

separate label is attached to draw the attention to remove the screws.

To avoid moisture ingress in the housing, covers should be fully tightened at all times. For the same reason, cable gland and

plugs should be properly installed in the cable entries.

The unit is preconfigured from factory, based on given application details (when available). Therefore transmitter and GWR

probe have the same serial n°.

Please make sure that corresponding serial numbers are mounted together.

4

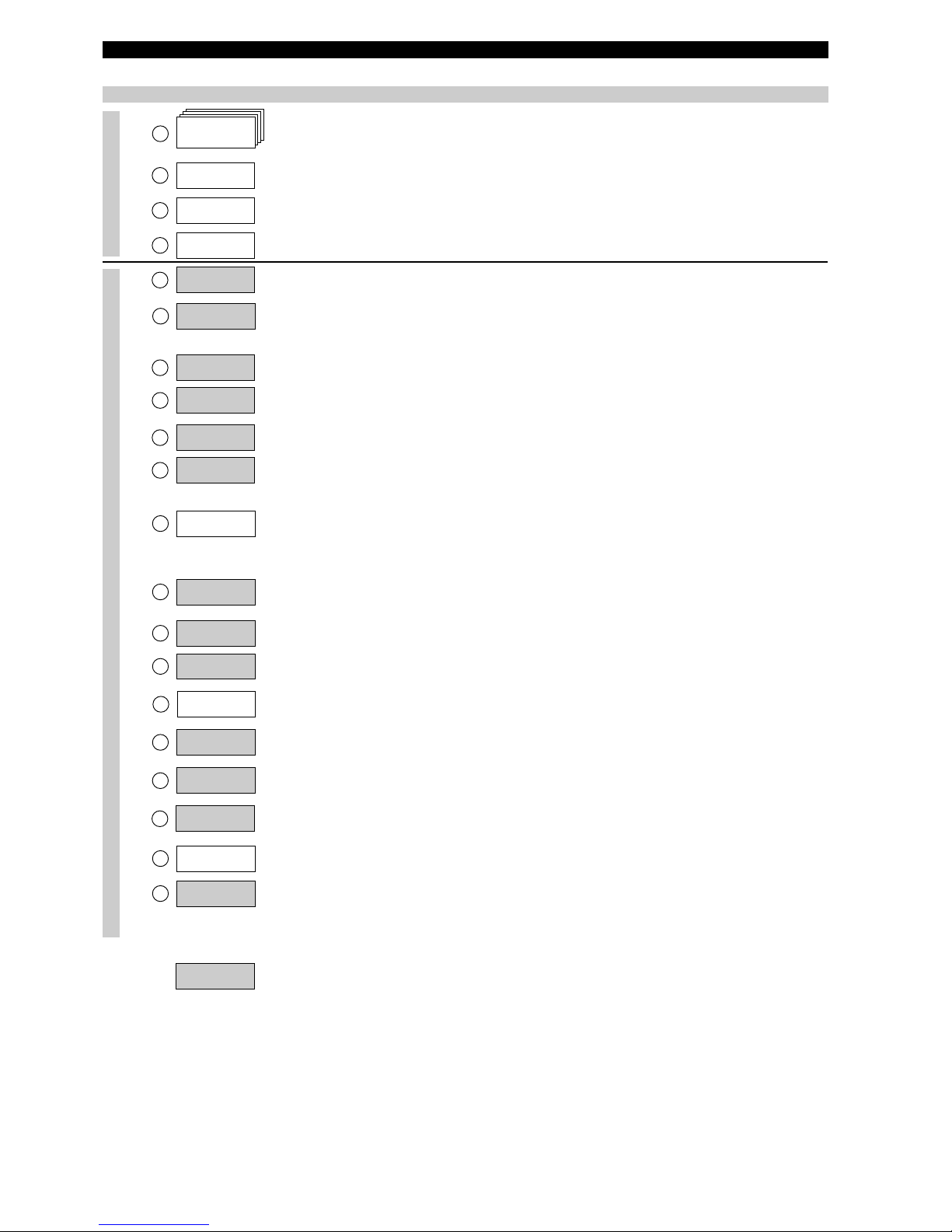

MOUNTING

Overfill safe and Overfill proof

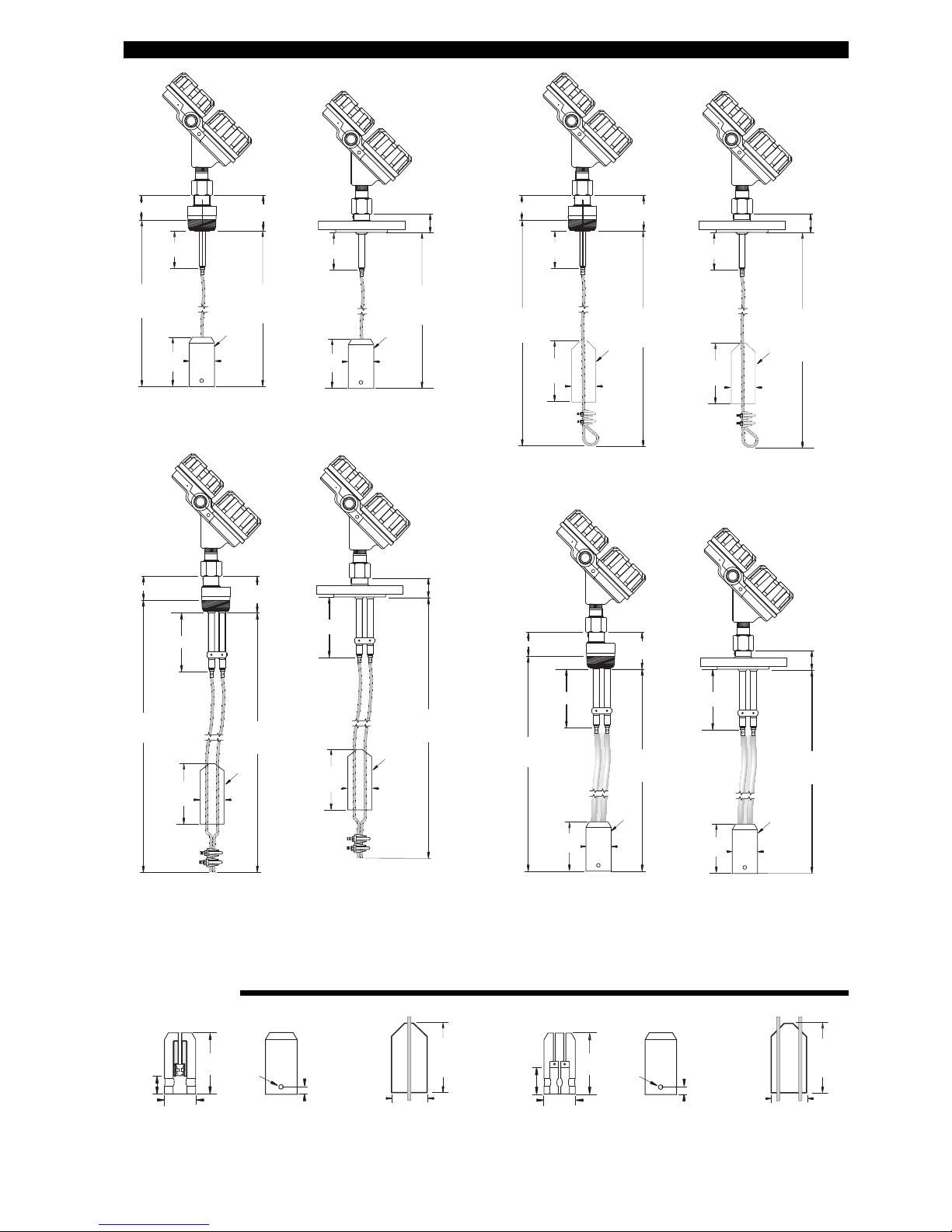

Eclipse twin rod GWR probes use software to ignore level

readings in the transitioning zone at the top of the GWR

probe. The maximum level is a minimum of 150 mm (6")

below the process connection. This may include utilizing a

nozzle or spool piece to raise the probe. Twin rod probes

are overfill proof certified but not overfill safe in use.

Eclipse twin cable GWR probes, used in media with low

dielectrics (hydrocarbons, powders) may require the setting

of a blocking distance (zone in which the unit will not measure) of 300 mm up to 500 mm (12" to 20") depending probe

length. The longer the probe, the longer the blocking distance will be. Eclipse twin cable GWR probes are not overfill proof certified and not overfill safe in use.

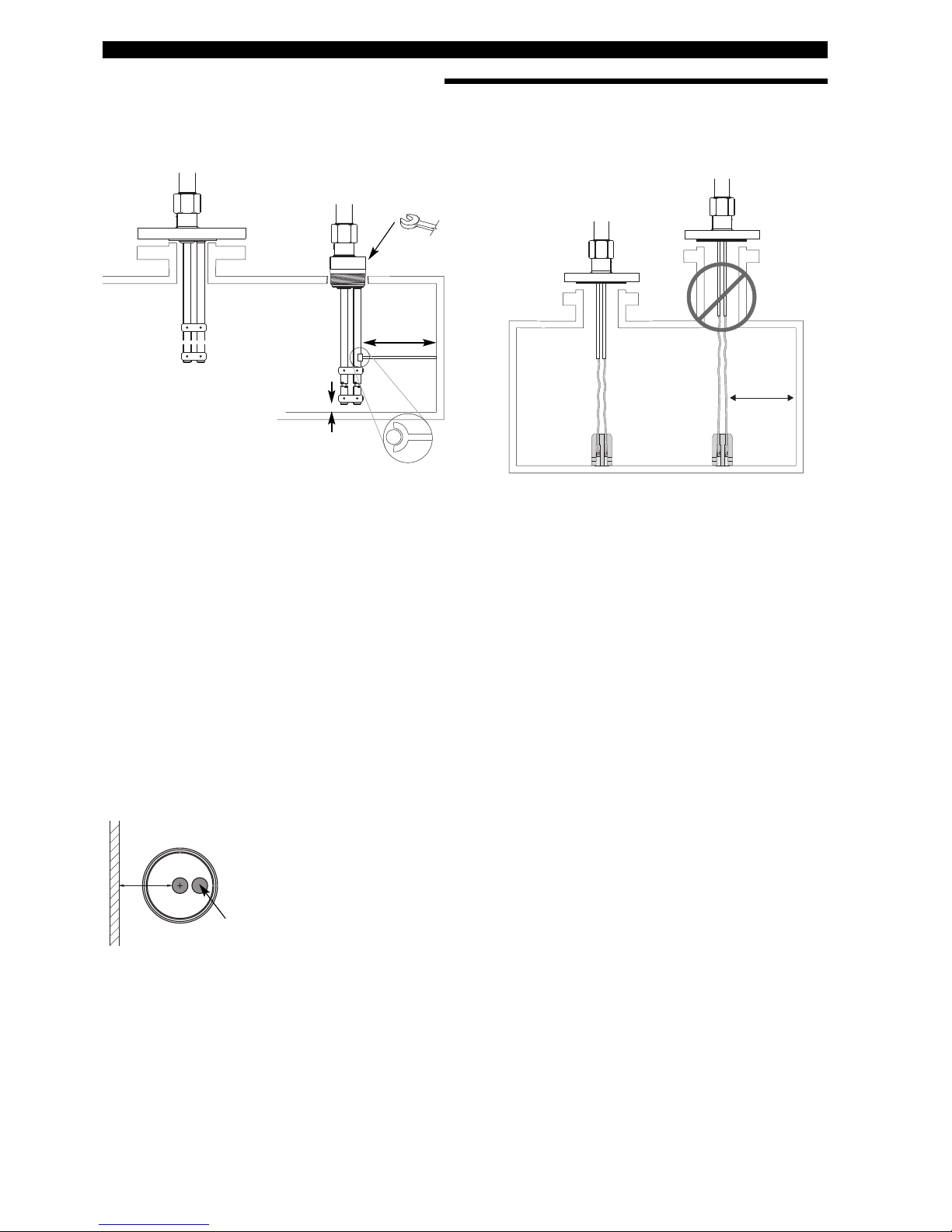

Metallic (or any conductive) obstructions in the tanks

Objects in the proximity within 25 mm (1") or closer such as

pipes, support beams, metal ladders etc… may cause erroneous readings.

Turbulence

7MB: Customer supplied brackets are recommended per

each 3 m (10') length and have no influence on the measuring performance of 7MB GWR probes. Use the “off center” rod to fasten the brackets (see above drawings).

7M5/7M7: It is recommended to secure the probe if significant turbulence exists. Optional weights are available to

keep the probe taught. The probe should not make any contact with the metal tank wall. The 7M7 (liquids) probe can be

attached to the bottom of the tank – it is not recommended

to attach the 7M5 (solids) probe at the bottom of the tank.

Stillwell/cages

Min. 3" / DN 80 size nozzles, stillwells or by-pass cages are

required for a good operation. Twin rod/cable probes should

be min 25 mm (1") away from any metal tank wall. 7M5/7M7

have a 76 mm (3") inactive section. For nozzles < 3"/

DN 80, this section should be flush with the bottom of the

nozzle or extend into the vessel.

IMPORTANT:

Twin rod/cable probes should be installed into a metal tank,

stillwell or by-pass cage to meet CE requirements

(EN 61326: 1997 + A1 + A2) electromagnetic compatibility.

Tank or cage wall

Off center rod

min 25

(1)

Size: 47 mm

(1 7/8") or

adjustable

wrench

min. 25 mm (1")

from any metal

object

m

in 25 mm (1")

from tank bottom

Use half open brackets

f

or twin rod probes.

Twin rod (7MB) / Twin cable (7M5 - 7M7) GWR probes

For twin cable:

min 25 mm

(1") from any

metal object

M

ounting considerations for 7MB

Nozzle should be DN80 (3") diameter or larger.

Mounting considerations for 7M5/7M7

For nozzles < DN80 (3") diameter, the bottom of the inactive section of the probe should be flush with the bottom of

the nozzle or extend into the vessel.

5

MOUNTING

1

3 mm Ø

(

0.50")

1

3

2

4

7M7/7M5 probe can be shortened

in field.

a.raise the weight (1) to expose the two

securing devices (2)

b.loosen the two #10-32 set screws (3)

on both securing devices using a

2.5 mm (3/32") hex wrench and slide

the securing devices off of the probe

c. slide the TFE weight off of the probe.

d.cut and remove the required cable (4)

l

ength

e.remove 90 mm (3 1/2") of the rib

between the two cables

f. strip 16 mm (5/8") of coating from the

two cables.

g.slide the TFE weight back on to the

probe.

h.enter new probe length (cm or inches)

in software (See page 12, Item 9)

Note: Probe can be attached to the tank

b

ottom using the noose or the 13 mm Ø

(0.50") hole provided in the TFE weight.

7M7 GWR probes: cable tension should

not exceed 89 N

7M5 GWR probes: pull down force should

not exceed 1360 kg (3000 lbs)

Twin rod (7MB) / Twin cable (7M5 - 7M7) GWR probes

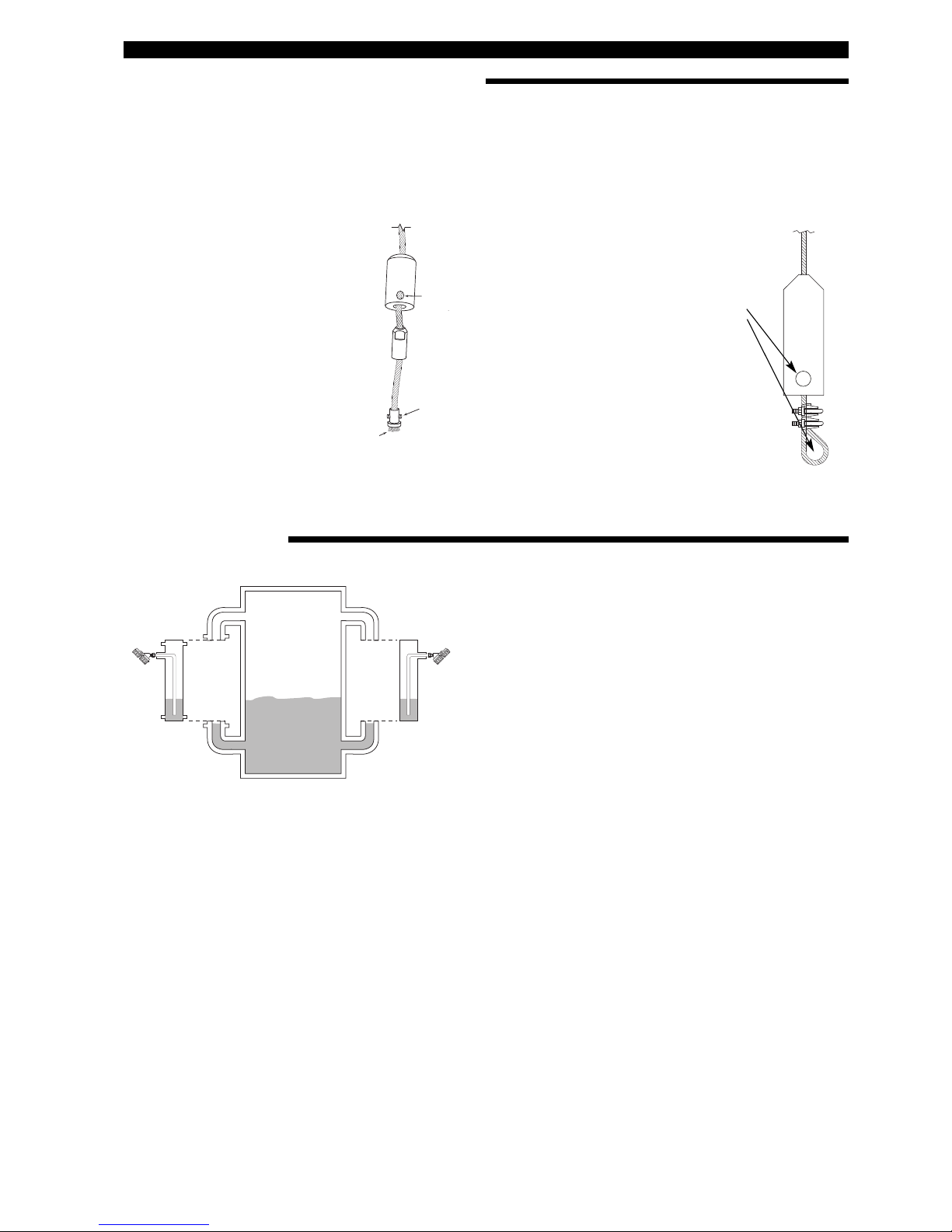

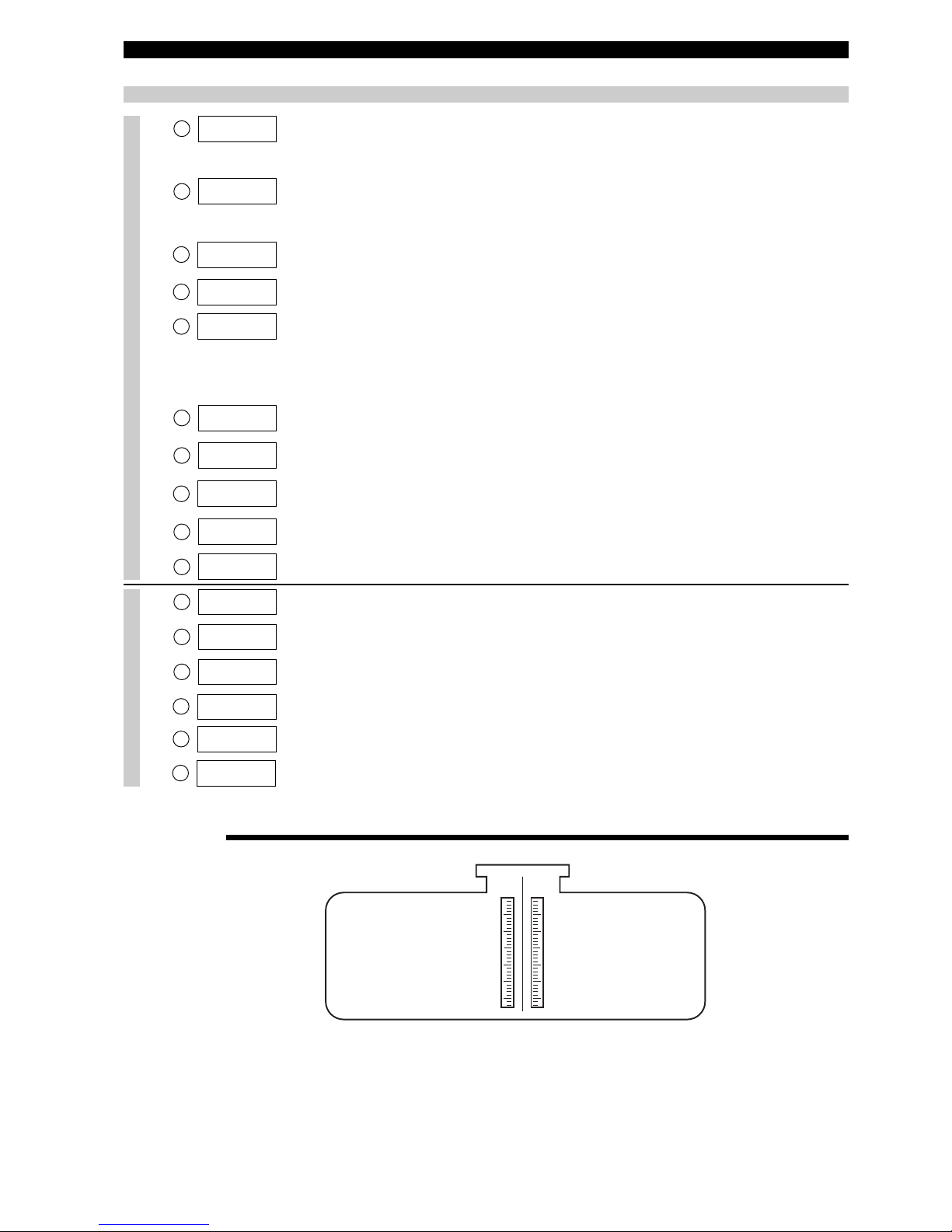

Cage GWR probe (7MG)

Shortening of probe length

7MB probes can be shortened safely in the field. Make sure to re-install the bottom spacer for proper alignment and to adapt

t

he probe length/ 4-20 mA settings in the menu.

Twin cable probes can be safely shortened in the field using below procedure. Make sure to adapt the probe length / 4-20 mA

settings in the menu.

Vent

Drain

Customer or magnetrol

supplied cage/bridle or still well.

Venting

holes

Bottom spacer

Bottom spacer

For cage/still well:

2": Ø 13 mm

(0.50") rod

For cage/still wells:

3": Ø 19 mm (0.75") tubing

4": Ø 25 mm (1.00") tubing

Overfill safe

All 7MG GWR probes are overfill safe. Overfill safe means

that the impedance match of the waveguide (probe) is

aligned from electronics down to the bottom of the GWR

probe. This allows the Eclipse 705 to measure up to the process flange without any dead zone at the top of the GWR

probe.

Metallic (or any conductive) obstructions in the tanks

Metallic obstructions have no influence on the measuring

performance of cage GWR probes.

Stillwell/cages

The cage GWR probe is a single rod GWR probe which

uses an existing or new cage, bridle or schedule pipe stillwell to re-create the same propagation of signal of a coaxial GWR probe. Cage GWR probes are suited for 2", 3" or 4"

size diam. and use an impedance matching part that aligns

in the same way with the characteristic impedance of a

standard coaxial style GWR probe.

Shortening of probe length

Cage GWR probes can be easily shortened on site. Always

re-install the bottom spacer and adapt the new probe length

in the menu of the amplifier.

6

MOUNTING

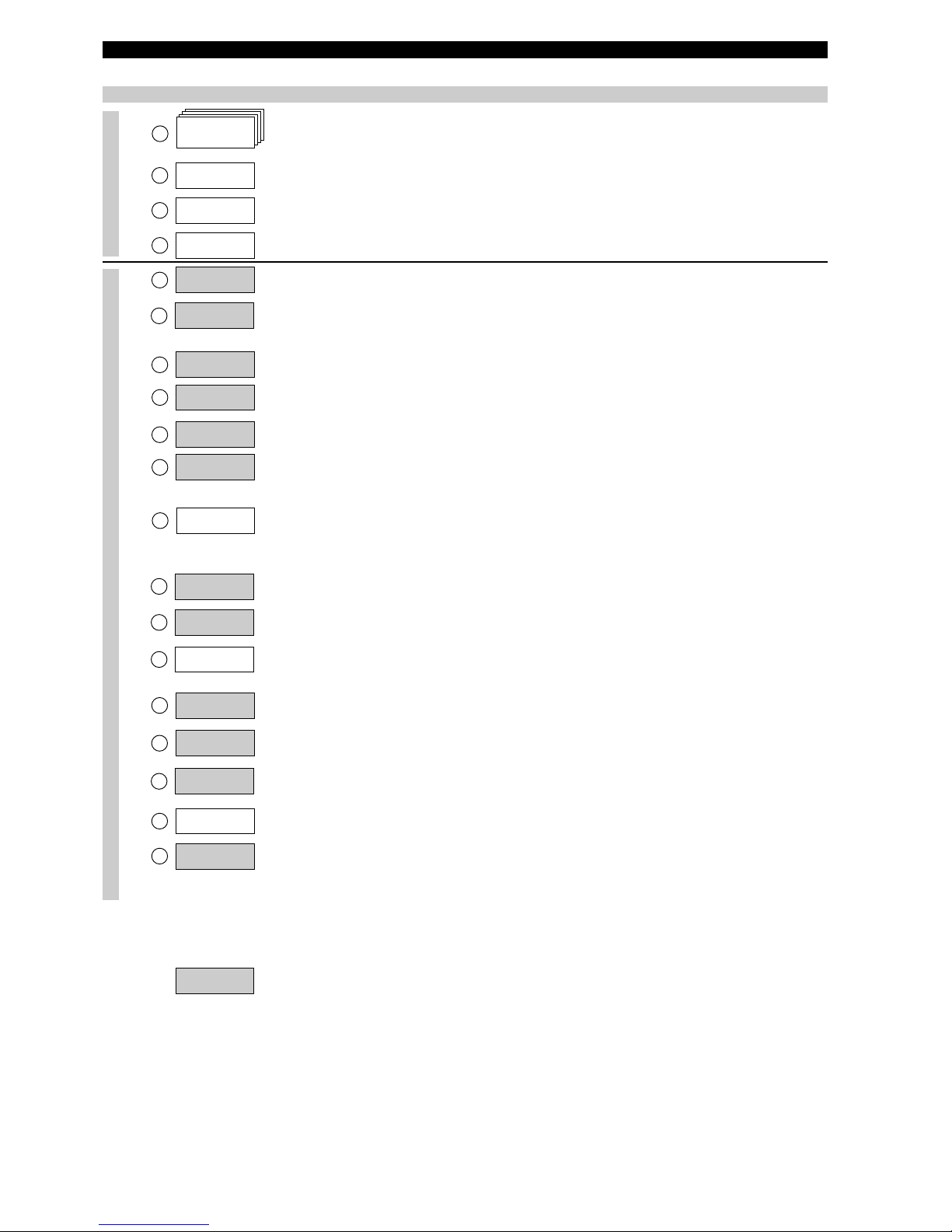

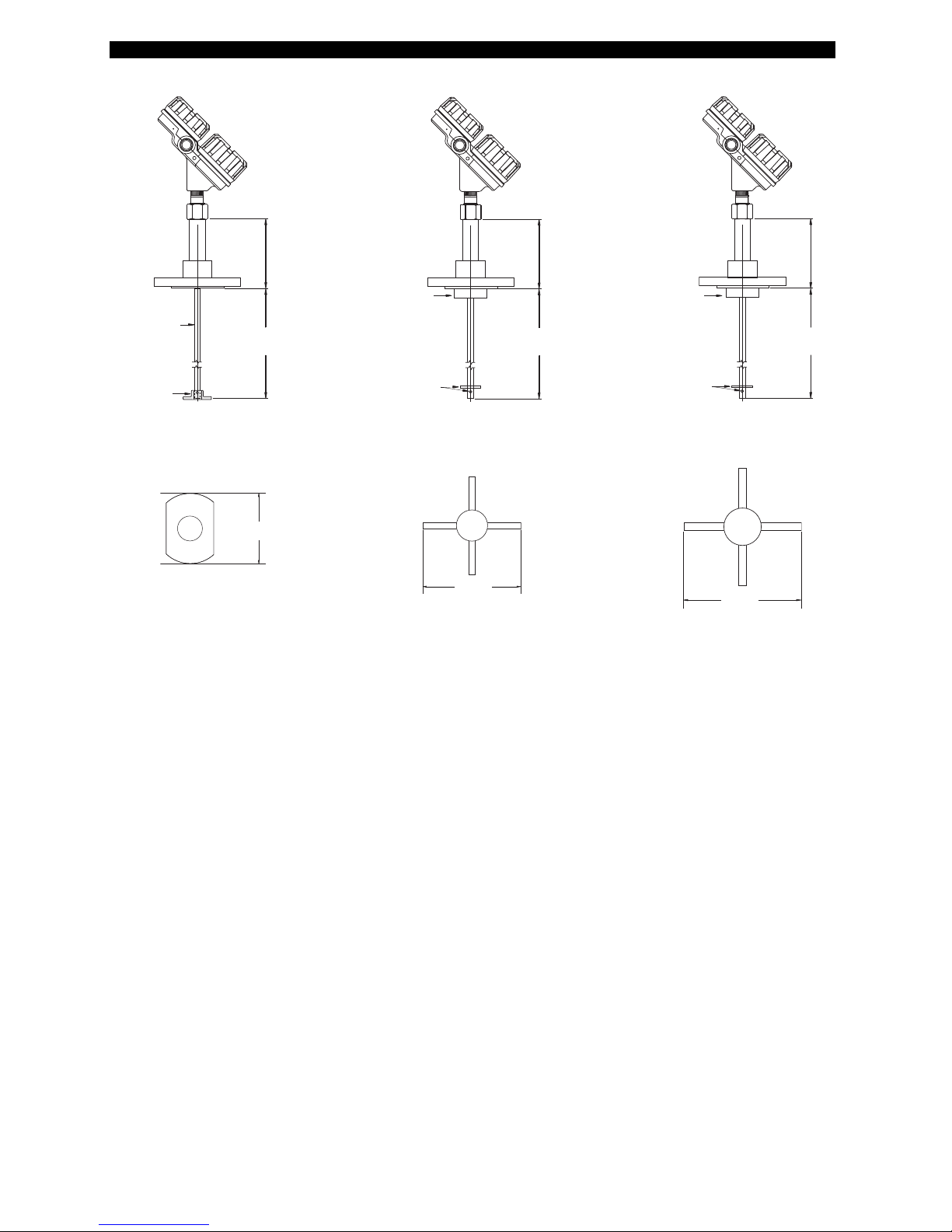

Single rod (7MF - 7MH - 7MJ) / Single cable (7M1 - 7M2) GWR probes

Size: 38 mm

(1 1/2") or

adjustable

wrench

Size: 38 mm

(1 1/2") or

adjustable

wrench

High Level shutdown and Overfill protection

Special consideration is necessary in any high level shutdown / overfill protection application where single rod GWR

probes are used. To ensure proper measurement, the guided wave radar probe should be installed so the maximum

overfill level is at a minimum of 120 mm (4.8") up to

910 mm (36") – blocking distance depending application

below the process connection. Consult factory for further

information.

Metallic (or any conductive) obstructions in the tanks

Objects in the proximity of the probe may cause erroneous

readings.

Turbulence

The bottom of the probe should be stabilized if turbulence

will cause a deflection of more than 75 mm at 3 m (3" at 10')

of length. Optional bottom spacers in TFE (for 7MF) or

PEEK (for 7MJ) should be used to stabilize the probe, in

case turbulence exists. It is recommended to secure the

probe (7M1/7M2) if significant turbulence exists (see above

drawing at right side). Optional weights are available to

keep the probe taught. The 7M1 (liquids) probe can be

attached to the bottom of the tank – it is not recommended

to attach the 7M2 (solids) probe at the bottom of the tank.

The probe should not make any contact with the metal tank

wall.

Stillwell/cages

Max. 6” / DN 150 size stillwells or by-pass cages or a metal

tank wall within 150 mm (6”) of the probe, will allow the unit

to measure accurately in media with dielectrics down to

ε

r

1,9.

Nozzles do not restrict the performance by ensuring the following:

1. Nozzle must be 50 mm (2") or larger diameter.

2. Nozzle inside diameter (A) should be ≥ to nozzle height

(B). If this is not the case, it is recommended to adjust

BLOCKING DISTANCE and/or SENSITIVITY settings.

IMPORTANT:

Single rod/cable probes should be installed into a metal

tank, stillwell or by-pass cage to meet CE requirements

(EN 61326: 1997 + A1 + A2) electromagnetic compatibility.

When used in a non-metallic vessel flange (metal) mounting

is recommended for optimal performance.

Distance to probe

Acceptable objects

< 150 mm (6") Continuous, smooth, parallel,

conductive surface (e.g. metal

tank wall);

probe should not touch

tank wall

> 150 mm (6") < 1"/DN25 diameter pipe and

beams, ladder rungs

> 300 mm (12") < 3"/DN80 diameter pipe and

beams, concrete walls

> 450 mm (18") All remaining objects

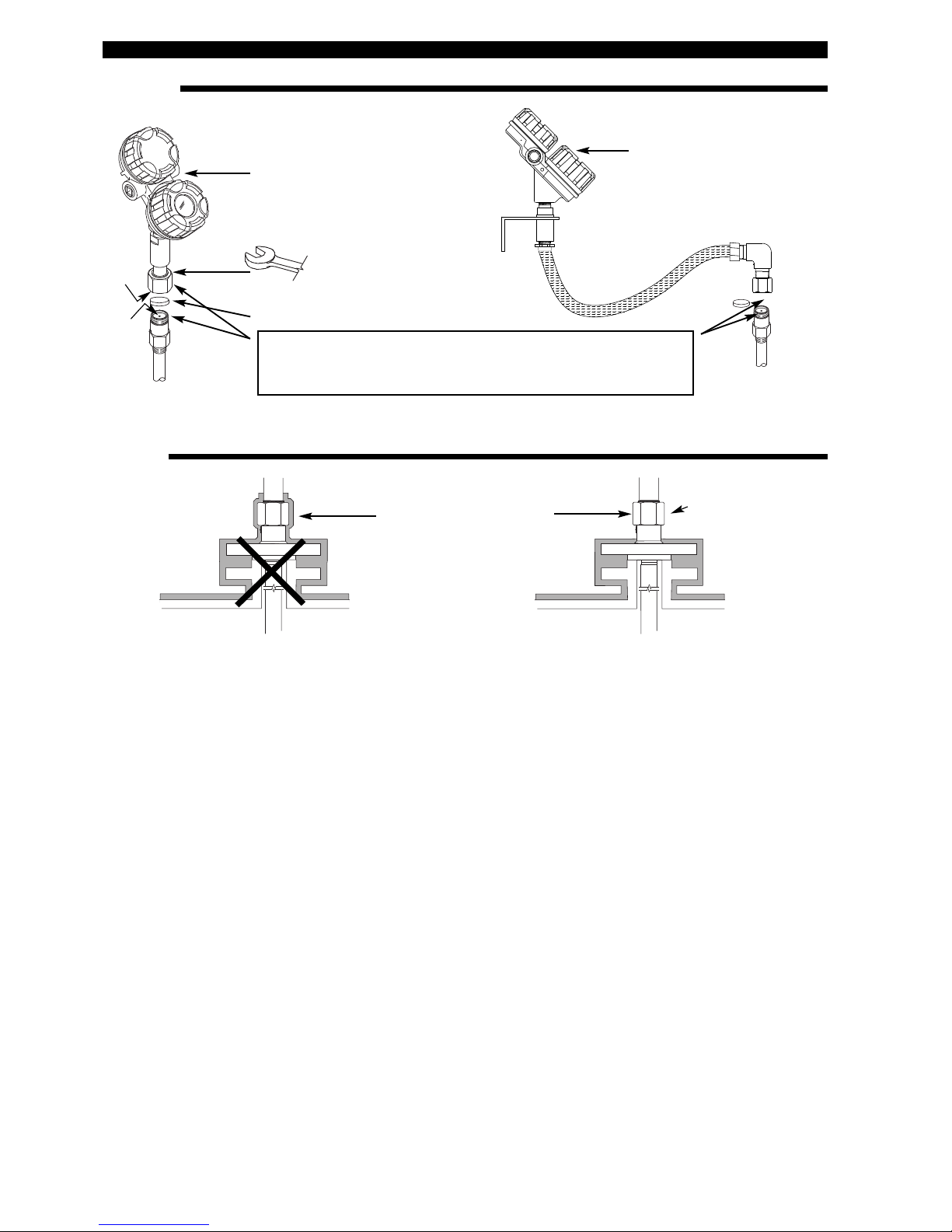

Pipe reducers

should not be used

Correct installation

A

B

7

MOUNTING

Shortening of probe length

Single rod/cable probes can be shortened safely in the field. Make sure to adapt the probe length/ 4-20 mA settings in the menu

and the re-install of a bottom spacer when applicable.

Single cable probes can be safely shortened in the field using below procedure. Make sure to adapt the probe length/ 4-20 mA

settings in the menu.

13 mm fl

(0.50")

1

2

3

4

7M1/7M2 probe can be shortened in

field.

a.raise TFE weight (1) exposing secur-

ing device (2)

b.loosen both #10-32 set screws (3)

using 2.5 mm (3/32") hex wrench

and remove securing device

c. cut and remove needed cable length

(4)

d

.re-attach securing device (2) and

tighten screws

e.enter new probe length (cm or inch-

es) in software (See page 12, Item 9)

13 mm Ø

(0.50")

Note: Probe can be attached to the tank

bottom using the noose or the 13 mm Ø

(0.50") hole provided in the TFE weight.

7M1 GWR probes: cable tension should

n

ot exceed 89 N (20 lbs).

7M2 GWR probes: pull down force

should not exceed 1360 kg (3000 lbs)

Single rod (7MF - 7MH - 7MJ) / Single cable GWR probes

Overfill safe and Overfill proof

Eclipse 7EK GWR probes are “Overfill safe” in use and

“Overfill proof” certified.

Overfill safe means that the unit is capable to measure up

to the process connection. Units with “non overfill safe”

probes use software to ignore level readings in the blocking distance or transitioning zone. When level rises too high

in this zone, the unit may consider the end of probe reflection as the real level and may report an empty vessel

instead of an overfilling vessel.

Overfill proof protection (such as WHG or VLAREM) certifies reliable operation when the transmitter is used as

overfill alarm but assumes that the installation is designed

in such way that the vessel/cage cannot overfill.

The 7EK probe is designed to replace without modification

top/bottom mounted displacer transmitters. The unit will

measure over the entire probe length and indicate for

20.5 mA above the highest measurable point and 3.8 below

the lowest measurable point.

Top/Bottom GWR probes

(7EK)

1 1/2" or 2"

socket weld or

NPT

1

1/2" or 2"

F

langed

8

MOUNTING

Do not insulate the

high frequency connector

in case of high temperature

applications

Insulation

WRONG GOOD

M

ax +150 °C (+300 °F)

Max +100 °C (+212 °F) for Ex d unit

360° rotatable: Position for

optimum wiring/viewing

Max. rotation 270°

Size: 38 mm (1 1/2") or

adjustable wrench

Recommended torque 60 Nm

(45 ft-lbs)

Remove protection

Remove

protection

C

AUTION: be careful not to bend or dirty the gold, high frequency

male connector (a) and its female connector (b). Clean with isopropyl alcohol and cotton swabs, if necessary

(a)

(b)

Transmitter

Integral

Remote

9

WIRING

CAUTION: power must be switched OFF before wiring the unit.

–+

I

S

®

–

L

OOP

C

URRENT

IS

0 %

100 %

Positive supply to (+) terminal

N

egative supply to (-) terminal

Shield wire to green grounding screw (resistance to

ground must be < 1 Ω).

Standard shielded twisted

pair cable recommended.

Non shielded cable can be

used per NAMUR NE 21

for field strenghts up to

10 V/m).

Use certified flameproof cable

gland(s) and cable for Explosion

proof area.

Current loop test

point (HART

®

only)

ANALOG I/O

or

DIGITAL I/O

(only for units with HART)

Customer supplied

local current meter

Do not connect shield

Ex

Non Ex

Ex

Non Ex

Ex

Non Ex

IMPORTANT:

The shield wire should only be grounded at ONE side only. It is recommended to connect the shield to ground in the field (at

the transmitter side - as shown above) but connecting in the control room is also allowed.

LOOP RESISTANCE

1200

1000

800

600

400

200

0

0 10 20 30 40 Vdc

20,5 mA

24 Vdc

630

11

Ω

Galvanic Barrier (only needed for intrinsically safe units):

HART

®

: max. 28,4 V DC @ 124 mA

Foundation Fieldbus™ / Profibus PA™: max. 17,5 V DC

@ 380 mA

10

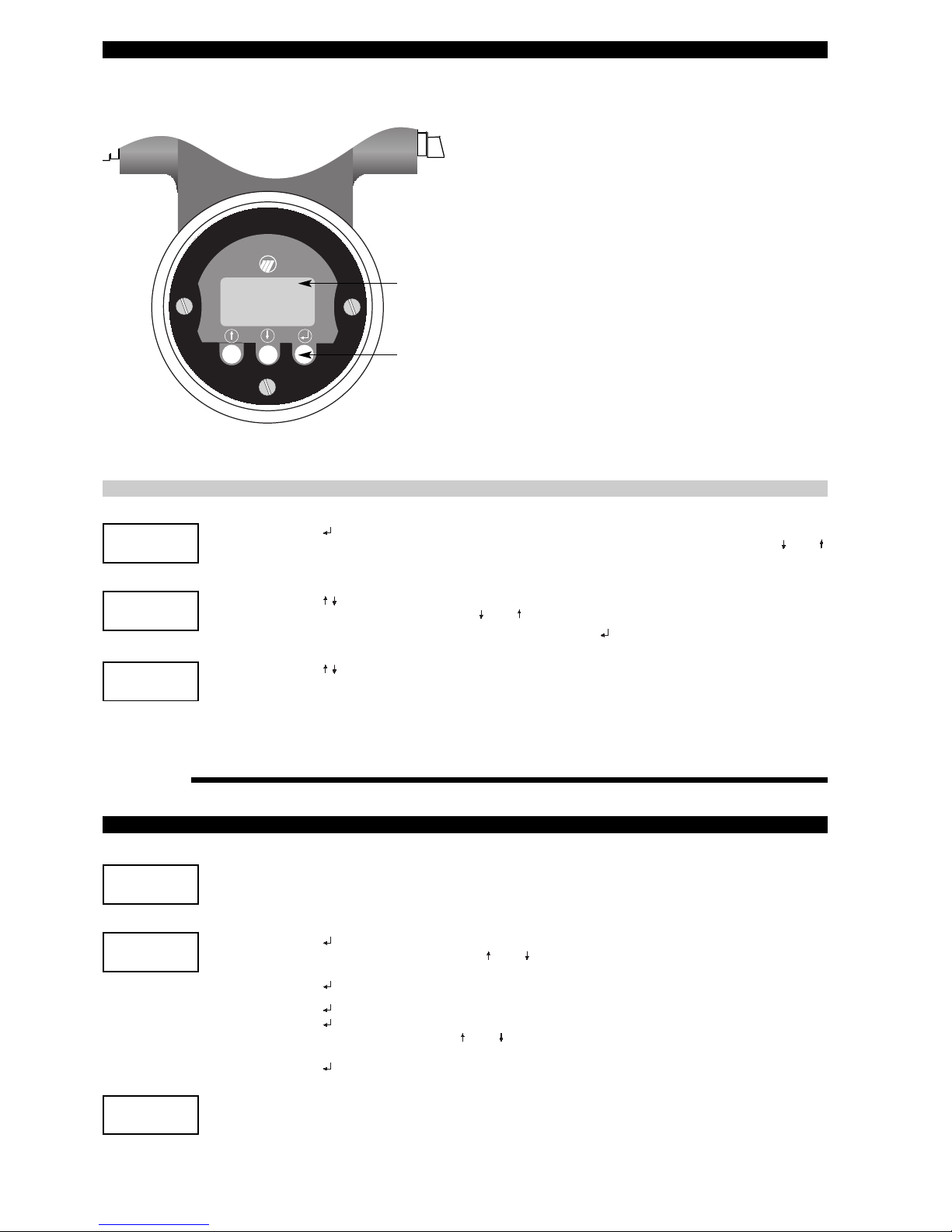

Display Action Comment

Units!

cm

Units

cm

Units!

cm

CONFIGURATION

NOTE: When connected to an approved barrier, the intrinsically safe electronics of the Eclipse allow to remove the

covers with power switched on – even if the area is known to be hazardous

2 line – 8 characters LCD

Default display cycles every 5 s through Status «STATUS» / Level

«

LEVEL» / % output «% OUTPUT» / Loop «LOOP».

Up/Down and Enter pushbuttons

IMPORTANT: The Eclipse amplifier can be bench configured without GWR

probe connected. Ignore the start up message «No Level Signal» / «STA-

TUS» / «WeakSgnl» in this case.

Press :

The last character on the first line of the display changes to «!». This sign confirms that the values/choices of the second line can be modified via the and

push buttons.

Press

*

Scroll through the choices or increase/decrease the values on the second line

of the display by and pushbuttons.

*

Accept values/choices as selected by pushbutton.

Press

Scroll through the menu.

PASSWORD

DISPLAY ACTION COMMENT

Ent Pass

0

New Pass

4096

Ent Pass!

1

NOTE: Password protection is activated when after 5 minutes no keystrokes are sensed.

Display shows «0»

Factory default setting

Data is not protected

Press and last character changes into «!»

Enter your personal password with and

(any value between 1 and 255)

Press to confirm

Setting password

Press and enter old password

Press and last character changes into «!»

Enter your new password with and

(any value between 1 and 255)

Press to confirm

Changing password

Display shows an encrypted value, enter your password

or call Magnetrol for assistance to recoop your password

if necessary

Data is protected by a valid

Password

11

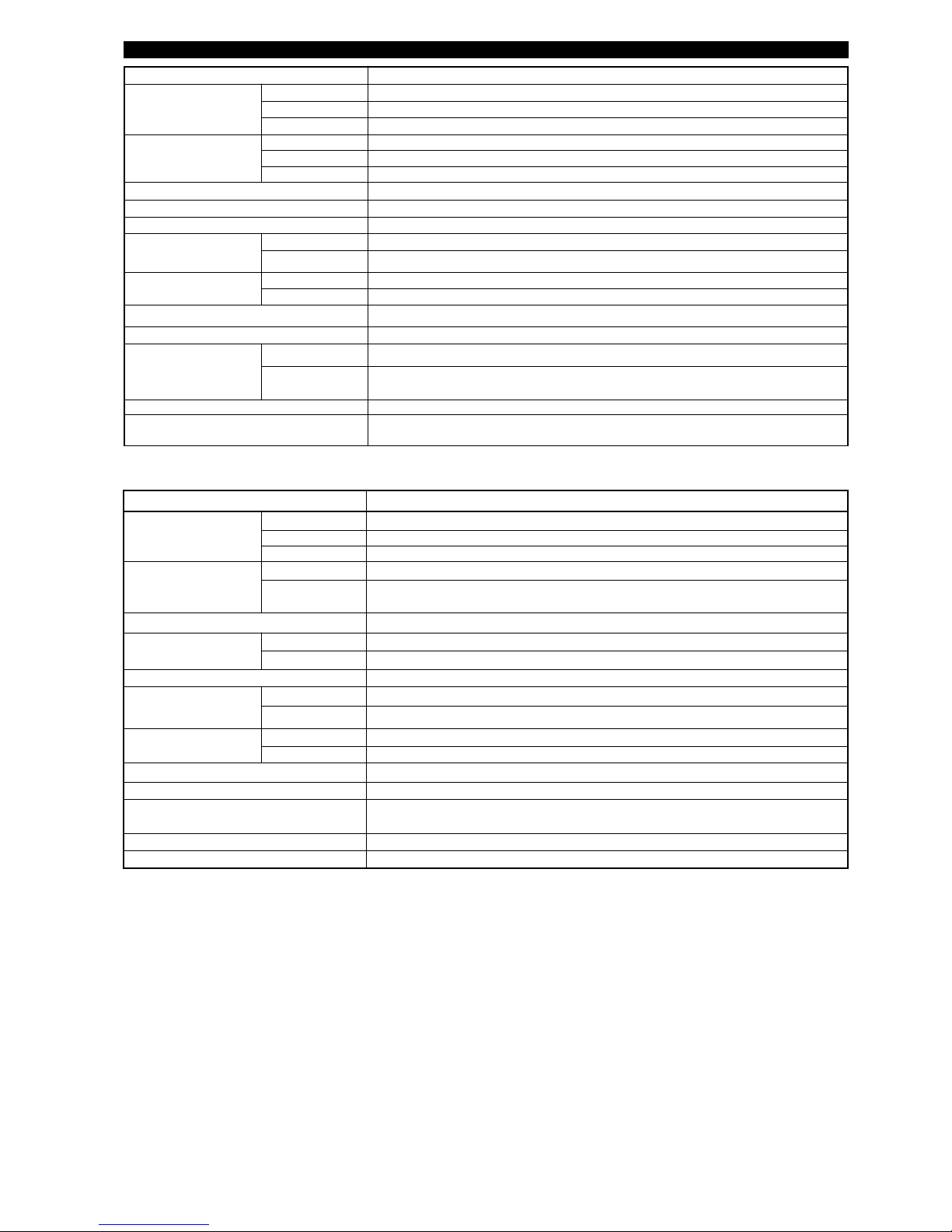

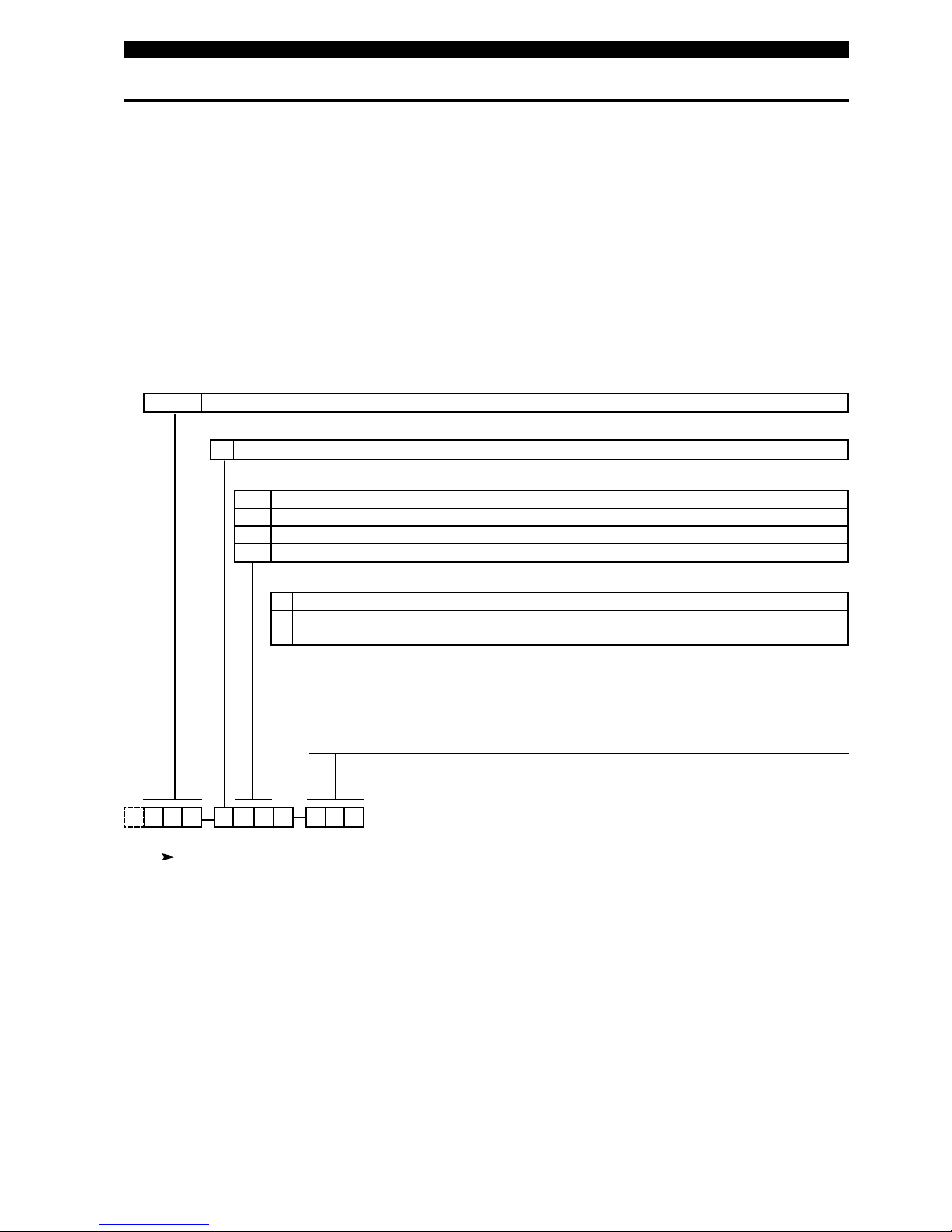

20 mA Level

(100%-point)

Reference

point

Probe Type

Probe

L

ength

Offset

Safety

Zone

Inch or cm

Dielectric

o

f medium

Blocking

distance

4 mA Level

(

0%-point)

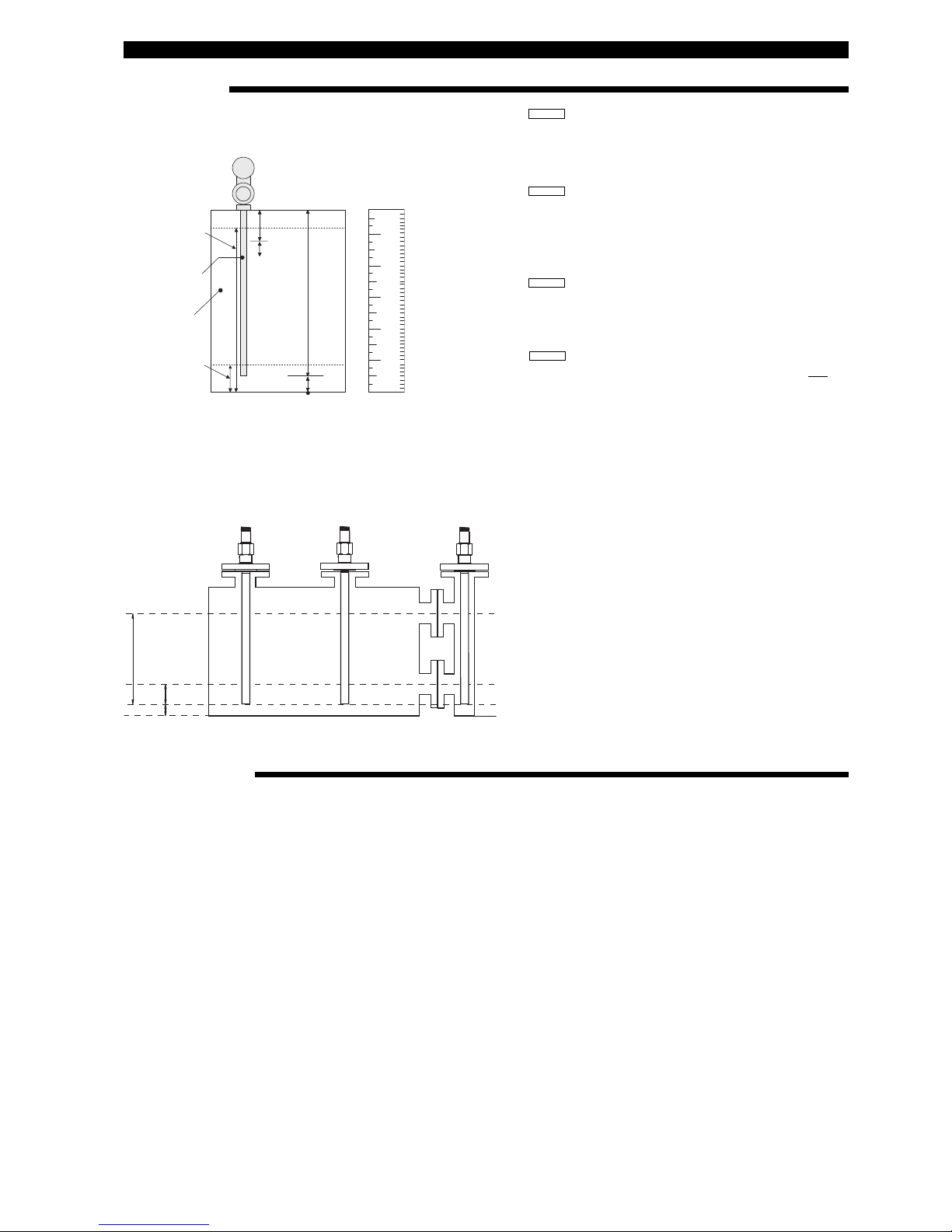

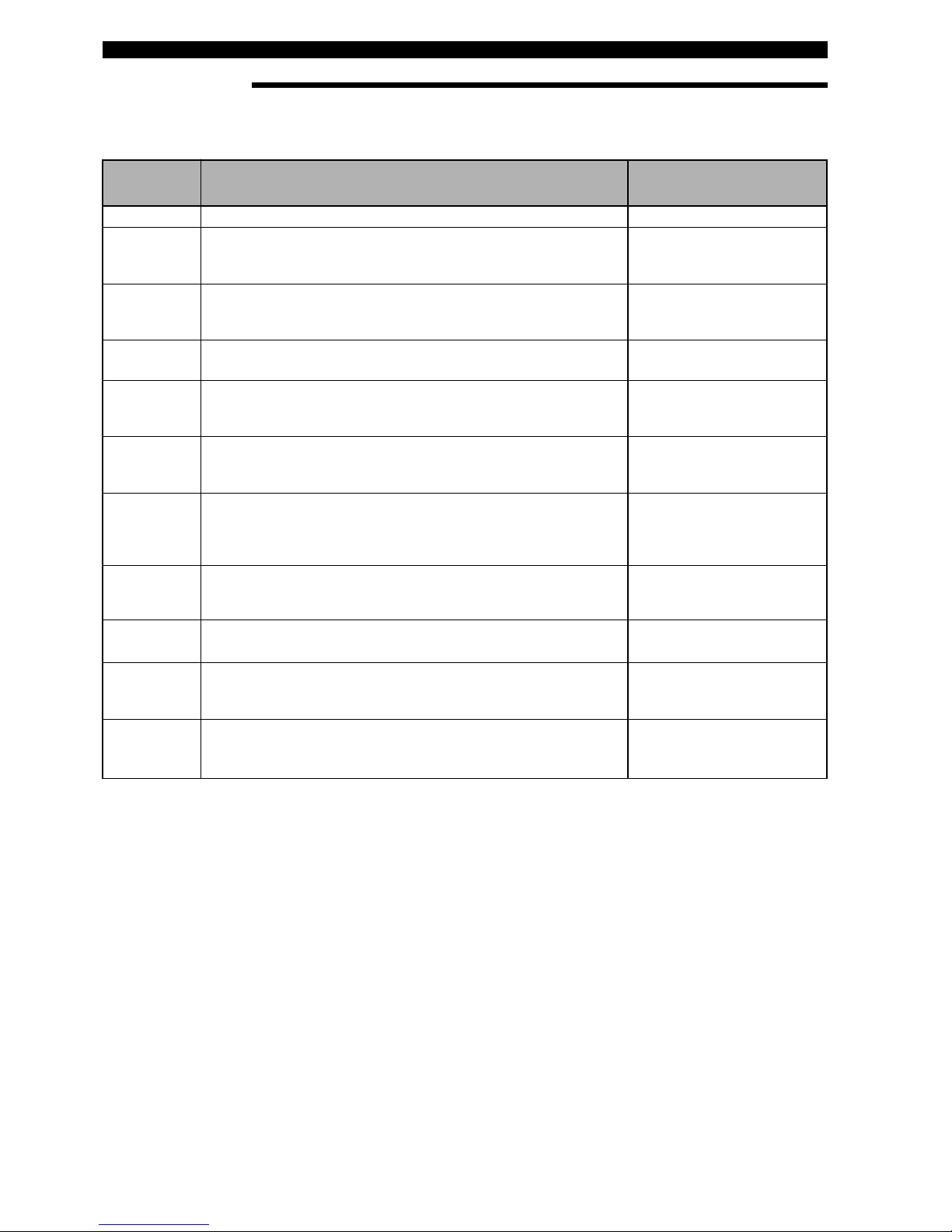

TERMINOLOGY

BEFORE STARTING

Offset = cm or inches

The offset is the distance between reference point (e.g.

bottom of tank) and end of probe. From the reference point

both 4 mA and 20 mA levels are calibrated. When offset is

set at zero, the end of the probe is the reference point.

4 mA Level = cm or inches

or zero level point, is measured from the reference point.

The unit has a transition zone at the bottom of the probe.

Min. level to enter for media with:

ε

r = 2.0: 150 mm (6") + Offset

ε

r = 80: 25 mm (1") + Offset

20 mA Level = cm or inches

or 100 % level point, is measured from the reference point.

The unit has a transition zone at the top of the probe.

Transition zone varies depending on probe type and

media: see probe specifications page 34 and continuing.

P

robe length = cm or inches, record the exact probe length as

printed on the nameplate: 705-xxxx-xxx / 7Mx-xxx-xxx

Dielectric Select the dielectric scale of the media to measure: 1.4–

1.7 or 1.7–3 or 3–10 or 10–100. When the dielectric is

known, it will enhance the overall accuracy of the unit but

select the dielectric scale ALWAYS to the lowest expected

dielectricum.

CONFIGURATION

Start from run mode:

1. Select the desired language for configuration: English, French, German or Spanish in the language screen (32)

«language». Scroll up for quickly reaching the language selection screen.

2. Define type of measurement:

a. Level only (pages 12 & 13)

b. Level and Volume (pages 14 & 15)

c. Interface only (pages 16 & 17)

d. Interface and Volume (pages 18 & 19)

Scroll down until the screen reads «MeasType». The unit will now show only the applicable screens for the selected type

of measurement.

3. Scroll one screen down and select the applicable engineering unit in «LvlUnits», all configuration values will be entered

in that engineering unit.

4. Move to the loop control screen «LoopCtrl», select the loop control in function of the type of measurement «MeasType»

selected.

5. Refer to the configuration procedure of the selected type of measurement.

6. Refer to page 20 for all hidden diagnostic screens and advanced configuration parameters. These screens allow the

advanced user to configure the unit for special applications or to troubleshoot the unit in the field. It is NOT recommended

to access this toolset without proper guidance or having followed proper training.

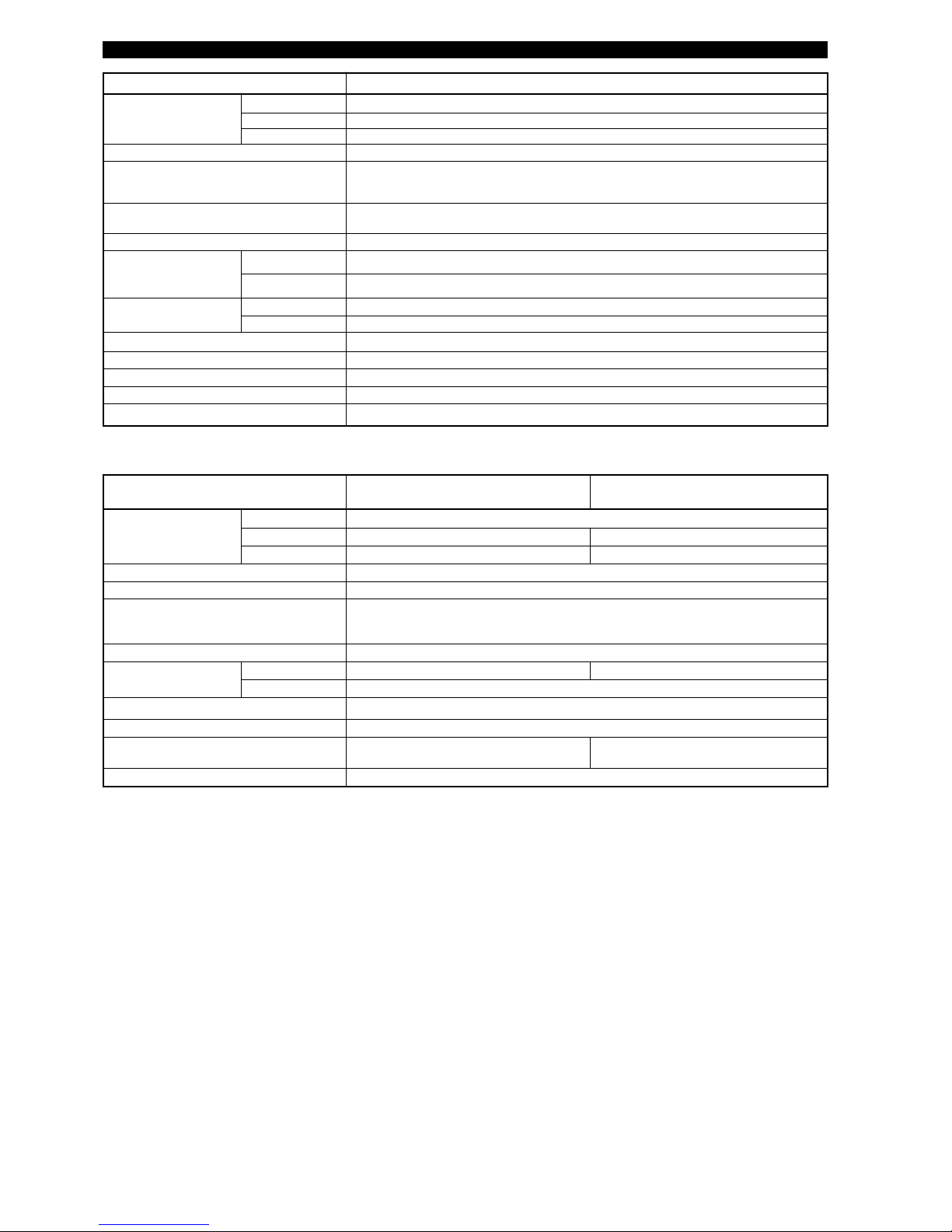

No offset

(Offset at 0 cm)

Positive offset

(Offset at 10 cm)

Negative offset

(Offset at -15 cm)

75 cm

100 %

0 %

15 cm

10 cm

20 mA = 75 cm

4 mA = 15 cm

20 mA = 85 cm

4 mA = 25 cm

20 mA = 60 cm

4 mA = 0 cm

Safety zone: In addition to the blocking distance,

the user can introduce a safety zone

to warn for liquid level entering this

zone beneath the blocking distance.

The loop signal will shift in this zone

to a selectable fault signal. The unit

will go to normal read out, when level

drops lower than the safety zone,

unless a latched fault signal is used.

The safety zone is disabled from factory. Safety zone related settings

include:

«SZ Fault»: to select the preferred

error signal

«SZ Height»: to define the safety

zone area

«SZ Alarm Reset»: to manually

reset a latched «SZ Fault»

12

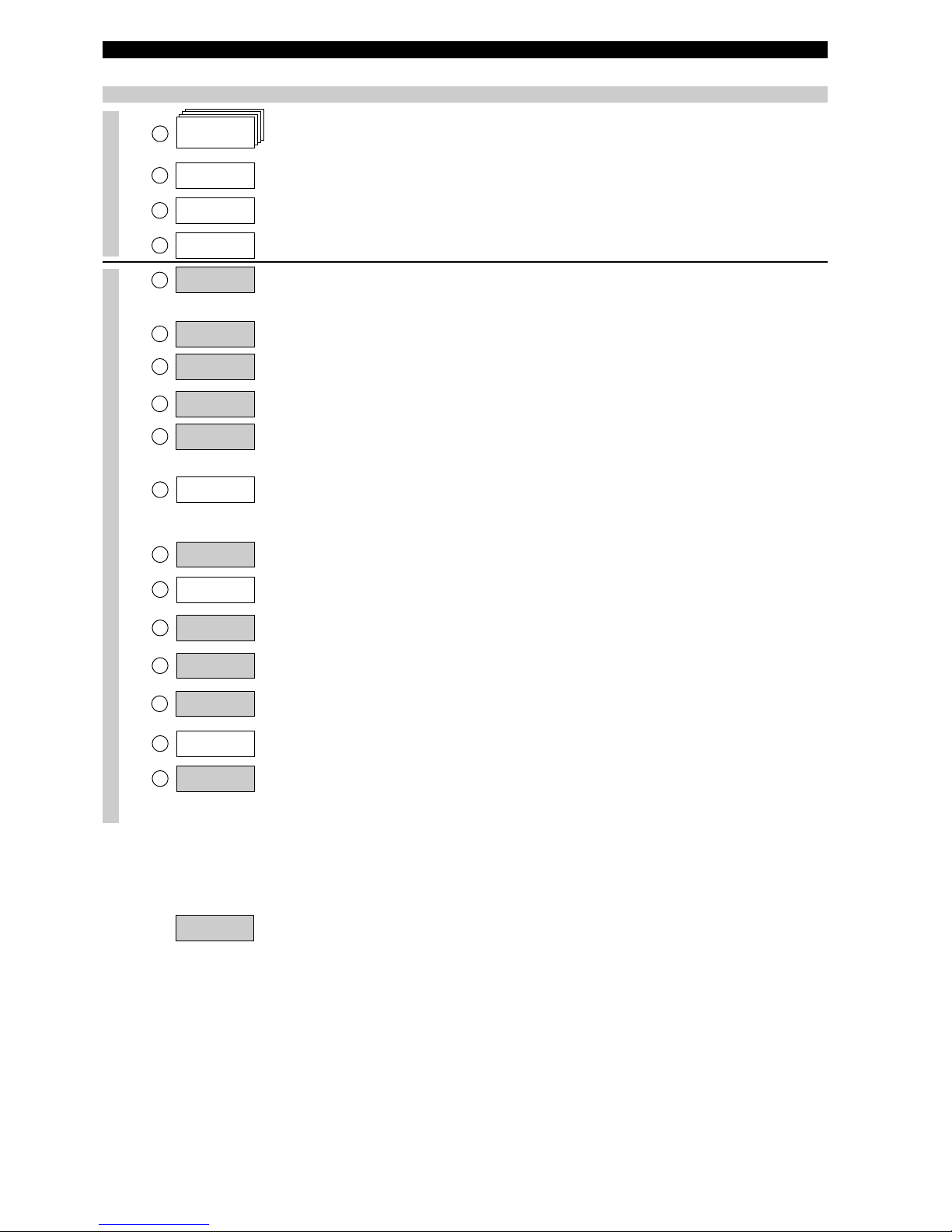

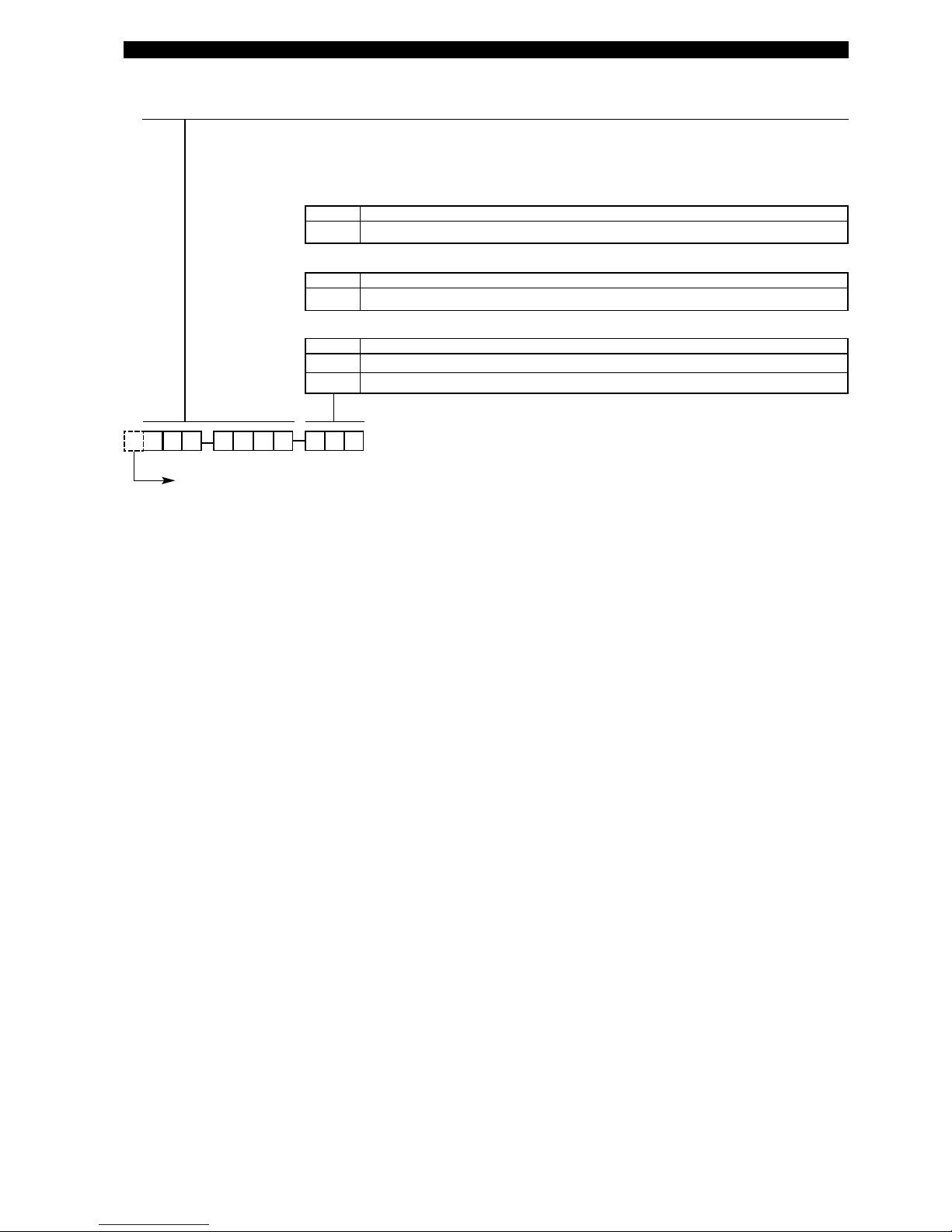

= Quick Start up

MENU: STEP BY STEP PROCEDURE – Eclipse 705: Level only

Screen Action Comment

Run modeConfiguration

1

2

3

4

7

10

12

13

16

17

*Status*

*

Level*

*%Output*

*Loop*

Level

xx.x

%Output

xx.x%

Loop

xx.xx mA

5

PrbModel

(select)

MeasType

(select)

6

PrbMount

(select)

9

Probe Ln

xxx.x

8

LvlUnits

(select)

Lvl Ofst

xxx.x

1

1

Dielctrc

(Select)

Senstvty

xxx

Loop Ctrl

(Select)

14

Set 4mA

xxx.x

Damping

xx sec

15

Set 20mA

xxx.x

Fault

(Select)

T

ransmitter Display

T

ransmitter default values cycle every 5 seconds. Status «Status»,

L

evel «Level», % Output «% Output», and Loop «Loop».

T

ransmitter Display

T

ransmitter displays level value in selected engineering units.

Transmitter Display Transmitter displays % Output measurement derived from 20 mA

span.

T

ransmitter Display

T

ransmitter displays Loop measurement (mA).

Select the type of probe Select as per the 3 first digits of the probe partnumber. The partnumber

i

s shown on the nameplate: e.g. 705-510A-A11/7MT-A230-218, select

7

xT-x from the list.

S

elect the type of probe

m

ounting.

Select NPT «NPT», BSP «BSP» or Flange «Flange». (consult facto-

ry when a «7xK» GWR probe is used)

Select the type of measurement

Select level «Levl Only».

S

elect units for level

c

m «cm», m «m», inches «inches» or feet «feet».

E

nter the exact length of

p

robe.

E

nter as per the 3 last digits of the probe partnumber on the nameplate:

- rigid probes, enter value cm or inches,

-

flexible probes, enter value in meters or feet

e

.g. 705-510A-A11/7MR-A230-218, enter «218» cm probe length.

Enter the offset value. When entering configuration values from the end of the probe is

cumbersome, an offset can be introduced to determine a new

reference point. This reference point can be either below the probe

(positive offset) or at the probe (negative offset). See page 11

“Terminology”.

Enter the dielectric range

value of the media

Select: «

1.4–1.7»; «1.7–3»; «3–10» or «10–100»

«1.7–3» is recommended for dielectrics ≥ 1,7

Enter sensitivity value Allows fine adjustment of internal gain.

Select primary variable (PV)

Primary variable is the loop controlling parameter. Select level

«Lvl only»

Enter the level value

for the 4 mA point.

A transition zone may exist at the bottom of the probe. See Functional

Specifications Probe, see page 34 and continuing.

Enter the level value

for the 20 mA point.

A transition zone / blocking distance may exist at the top of the probe.

See Functional Specifications Probe, see page 34 and continuing.

Enter the damping factor. A Damping factor (1-10 seconds) may be added to smooth a noisy

display and/or output due to turbulence.

Enter the value for error.

Select «3.6 mA», «22 mA» or hold last value «HOLD». In case of

loop failure, error signal will follow the failing trend; meaning the unit

will show 3.6 mA when the reviewed loop current by the device is

found too low. The unit will show 22 mA in case the reviewed loop

current is found too high.

13

MENU: STEP BY STEP PROCEDURE – Eclipse 705: Level only

Screen Action Comment

Diagnostics

23

2

6

27

28

29

30

Poll Adr

xx

Trim 4

xxxx

2

5

Trim Lvl

xx.x

2

4

Loop Mode

Trim 20

xxxx

Loop Tst

xx.x mA

LvlTicks

xxxxx

New Pass

xxx

31

32

Language

Mdl705HT

Ver xx.xx

33

DispFact

(select)

18

19

20

2

1

22

BlockDis

xx.x

SZ Fault

(select)

SZHeight

xx.x

SZ Alarm

Reset

Threshld

(select)

E

nter distance in

selected level units

A

llows to ignore level measurements near the top of the probe,

caused by e.g. condensation, crystalization. Make sure that the liquid

level does NOT enter this zone. Consult factory or the

‘Troubleshooting’ section before entering any value. Normaly to be

u

sed with single rod probe.

Select the safety zone fault.

Select «None» (None), «3.6mA», «22mA», «Latch 3.6mA» or

«

Latch 22mA». When either «Latch 3.6 / 22mA» signals is

s

elected, the loop current remains in alarm until it is manually cleared

w

ith the «SZAlarm» screen ( for safety zone explanation see

T

erminology - page 11).

S

elect the safety zone value

E

nter safety zone in cm or inches (see Terminology - page 11).

Reset safety zone latch fault

Clear a latched safety zone alarm «SZFault».

S

elect the type of threshold

«

Fixed» = the first reflection from the top will be considered as level

(

default setting)

«

CFD» = the strongest reflection from the top will be considered as

l

evel.

O

nly change to «CFD», in case the unit is reading incorrect level.

A

djustment of trim level «Trim Lvl» may be necessary when

t

hreshold is changed.

Enter HART ID number. Select a HART poll address (0-15). Enter 0 for a single transmitter

installation.

E

nable/Disable

D

etermines whether the loop is fixed at 4.0 mA or controlled by the

PV.

E

nter value

t

o adjust level reading.

A

llows to compensate for a fixed level deviation.

Fine tune the 4 mA point. Attach a mA meter to the output. If the output does not equal 4.0 mA,

adjust the value on the display to equal 4.00 mA.

Fine tune the 20 mA point. Attach a mA meter to the output. If the output does not equal

20.0 mA, adjust the value on the display to equal 20.00 mA.

Enter a mA output value. Set mA Output to any given value to perform loop test .

Diagnostic display. Shows time of flight from fiducial pulse to reflected signal from level.

Enter new password. Use arrows to select desired value. Values between 0 and 255.

Select language

Select «English», «Français», «Deutsch» or «Espagnol».

None, do not adjust.

Factory setting. «Ver» refers to software version.

Advanced diagnostics. See page 20.

No offset

(Offset at 0 cm)

Positive offset

(Offset at 10 cm)

Negative offset

(Offset at -15 cm)

75 cm

100 %

0 %

15 cm

10 cm

20 mA = 75 cm

4 mA = 15 cm

20 mA = 85 cm

4 mA = 25 cm

20 mA = 60 cm

4 mA = 0 cm

OFFSET

14

= Quick Start up

MENU: STEP BY STEP PROCEDURE – Eclipse 705: Level & Volume

Screen Action Comment

Run mode

Configuration

1

2

3

4

8

11

12

13

19

20

*Status*

*

Volume*

*%Output*

*Loop*

Volume

xxx

%Output

xx.x%

Loop

xx.xx mA

5

Level

xxx

MeasType

(select)

7

PrbMount

(select)

6

PrbModel

(select)

1

0

Probe Ln

xxx.x

9

LvlUnits

(select)

Lvl Ofst

xxx.x

14

Dielctrc

(Select)

VolUnits

(select)

StrapTbl

xx pnts

17

Set 4mA

xxx.x

Damping

xx sec

18

Set 20mA

xxx.x

15

Senstvty

xxx

16

Loop Ctrl

(Select)

Fault

(Select)

T

ransmitter Display

T

ransmitter default values cycle every 5 seconds. Status «Status»,

V

olume «Volume», % Output «% Output», and Loop «Loop».

T

ransmitter Display

T

ransmitter displays Volume Value in selected engineering units.

Transmitter Display Transmitter displays % Output measurement derived from 20 mA

span.

T

ransmitter Display

T

ransmitter displays Loop measurement (mA).

Transmitter Display

Transmitter displays level in selected volume units «LvlUnits».

S

elect the type of probe

S

elect as per the 3 first digits of the probe partnumber. The partnumber

i

s shown on the nameplate: e.g. 705-510A-A11/7MT-A230-218, select

7xT-x from the list.

Select the type of probe

mounting.

S

elect NPT «NPT», BSP «BSP» or Flange «Flange».

(consult facto-

ry when a «

7xK» GWR probe is used)

Select the type of measurement

Select level and volume «Lvl&Vol».

S

elect units for level

c

m «cm», m «m», inches «inches» or feet «feet».

Enter the exact length of

probe.

Enter as per the 3 last digits of the probe partnumber on the nameplate:

- rigid probes, enter value cm or inches,

- flexible probes, enter value in meters or feet

e

.g. 705-510A-A11/7MR-A230-218, enter «218» cm probe length.

Enter the offset value. When entering configuration values from the end of the probe is

cumbersome, an offset can be introduced to determine a new

reference point. This reference point can be either below the probe

(positive offset) or at the probe (negative offset). See page 11

“Terminology”.

Select units for volume

Liters «l» or gallons «g».

Enter level/volume

pairs in max 20 steps

Liters «l» or gallons «g».

Enter the dielectric range

value of the media

Select: «

1.4–1.7»; «1.7–3»; «3–10» or «10–100»

«1.7–3» is recommended for dielectrics ≥ 1,7

Enter sensitivity value Allows fine adjustment of internal gain.

Select primary variable (PV)

Primary variable is the loop controlling parameter. Select level

«Lvl only» or volume «volume»

Enter the level value

for the 4 mA point.

A transition zone may exist at the bottom of the probe. See Functional

Specifications Probe, see page 34 and continuing.

Enter the level value

for the 20 mA point.

A transition zone / blocking distance may exist at the top of the probe.

See Functional Specifications Probe, see page 34 and continuing.

Enter the damping factor. A damping factor (1-10 seconds) may be added to smooth a noisy

display and/or output due to turbulence.

Enter the value for error.

Select «3.6 mA», «22 mA» or hold last value «HOLD». In case of

loop failure, error signal will follow the failing trend; meaning the unit

will show 3.6 mA when the reviewed loop current by the device is

found too low. The unit will show 22 mA in case the reviewed loop

current is found too high.

15

MENU: STEP BY STEP PROCEDURE – Eclipse 705: Level & Volume

Screen Action Comment

Advanced configurationDiagnostics

26

29

30

31

32

33

Poll Adr

xx

Trim 4

xxxx

28

Trim Lvl

xx.x

27

Loop Mode

Trim 20

xxxx

Loop Tst

xx.x mA

LvlTicks

xxxxx

New Pass

xxx

34

35

Language

Mdl705HT

Ver xx.xx

21

22

23

2

4

25

BlockDis

x.x

SZ Fault

(select)

SZHeight

xx.x

SZ Alarm

Reset

Threshld

(select)

E

nter distance in

selected level units

A

llows to ignore level measurements near the top of the probe,

caused by e.g. condensation, crystalization. Make sure that the liquid

level does NOT enter this zone. Consult factory or the

‘Troubleshooting’ section before entering any value. Normaly to be

u

sed with single rod probe.

Select the safety zone fault.

Select «None» (None), «3.6mA», «22mA», «Latch 3.6mA» or

«

Latch 22mA». When either «Latch 3.6 / 22mA» signals is

s

elected, the loop current remains in alarm until it is manually reset

w

ith the «SZAlarm» reset screen ( for safety zone explanation see

T

erminology - page 11).

S

elect the safety zone value

E

nter safety zone in cm or inches (see Terminology - page 11).

Reset safety zone latch fault

Select «Reset» «No» or «Yes» to reset alam when either «Latch

3.6mA» or «Latch 22mA» was selected in «SZFault».

S

elect the type of threshold

«

Fixed» = the first reflection from the top will be considered as level

(

default setting)

«

CFD» = the strongest reflection from the top will be considered as

l

evel.

O

nly change to «CFD», in case the unit is reading incorrect level.

A

djustment of trim level «Trim Lvl» may be necessary when

t

hreshold is changed.

Enter HART ID number. Select a HART poll address (0-15). Enter 0 for a single transmitter

i

nstallation.

E

nable/Disable

D

etermines whether the loop is fixed at 4.0 mA or controlled by the

PV.

E

nter value

t

o adjust level reading.

A

llows to compensate for a fixed level deviation.

Fine tune the 4 mA point. Attach a mA meter to the output. If the output does not equal 4.0 mA,

adjust the value on the display to equal 4.00 mA.

Fine tune the 20 mA point. Attach a mA meter to the output. If the output does not equal

20.0 mA, adjust the value on the display to equal 20.00 mA.

Enter a mA output value. Set mA Output to any given value to perform loop test.

Diagnostic display. Shows time of flight from fiducial pulse to reflected signal from level.

Enter new password. Use arrows to select desired value. Values between 0 and 255.

Select language

Select «English», «Français», «Deutsch» or «Espagnol».

None, do not adjust.

Factory setting. «Ver» refers to software version.

Advanced diagnostics. See page 20.

Strapping table

max. Pt 20 Lvl = ...... cm

Pt 4 Lvl = 200 cm

Pt 3 Lvl = 120 cm

Pt 2 Lvl = 50 cm

Pt 1 Lvl = 0 cm

max. Pt 20 Vol = ...... l

Pt 4 Vol = 3000 l

Pt 3 Vol = 2000 l

Pt 2 Vol = 1000 l

Pt 1 Vol = 0 l

36

DispFact

(select)

NOTE: Consult page 13 for level offset «Lvl Ofst» details.

16

= Quick Start up

MENU: STEP BY STEP PROCEDURE – Eclipse 705: Interface

Screen Action Comment

Run mode

Configuration

1

2

3

4

8

1

1

12

15

18

19

*Status*

*

IfcLevel*

*%Output*

*Loop*

IfcLevel

xx.x

%Output

xx.x%

Loop

xx.xx mA

5

Level

xxx

MeasType

(select)

7

PrbMount

(select)

6

PrbModel

(select)

1

0

Probe Ln

xxx.x

9

LvlUnits

(select)

Lvl Ofst

xxx.x

13

Dielctrc

(Select)

14

Senstvty

xxx

Upr Diel

(Select)

Loop Ctrl

(Select)

16

Set 4mA

xxx.x

Damping

xx sec

17

Set 20mA

xxx.x

Fault

(Select)

T

ransmitter Display

T

ransmitter default values cycle every 5 seconds. Status «Status»,

I

nterface level «Ifclevel», % Output «% Output», and Loop

«

Loop».

T

ransmitter Display

T

ransmitter displays interface level in selected engineering units.

Transmitter Display Transmitter displays % Output measurement derived from 20 mA

span.

T

ransmitter Display

T

ransmitter displays Loop measurement (mA).

Transmitter Display

Transmitter displays interface level in selected level units «LvlUnits».

S

elect the type of probe

S

elect as per the 3 first digits of the probe partnumber. The partnumber

is shown on the nameplate: e.g. 705-510A-A11/7MT-A230-218, select

7xT-x from the list.

S

elect the type of probe

m

ounting.

Select NPT «NPT», BSP «BSP» or Flange «Flange». (consult facto-

ry when a «

7xK» GWR probe is used)

Select the type of measurement

Select interface «Interface».

Select units for level

cm «cm», m «m», inches «inches» or feet «feet».

E

nter the exact length of

probe.

E

nter as per the 3 last digits of the probe partnumber on the nameplate:

-

rigid probes, enter value cm or inches,

-

flexible probes, enter value in meters or feet

e.g. 705-510A-A11/7MR-A230-218, enter «218» cm probe length.

Enter the offset value. When entering configuration values from the end of the probe is

cumbersome, an offset can be introduced to determine a new

reference point. This reference point can be either below the probe

(positive offset) or at the probe (negative offset). See page 11

“Terminology”.

Enter the dielectric range

value of the upper media.

Enter the dielectrics of the upper layer liquid (between 1,4 and 5,0) –

only upper layer dielectrics need to be entered.

Select the dielectric range

value of the lower media

Select: «

10–100»

Enter sensitivity value

Allows fine adjustment of internal gain.

Select primary variable (PV)

Primary variable is the loop controlling parameter. Select interface level «Ifc Level» or top level «Lvl Only»

Enter the level value

for the 4 mA point.

A transition zone may exist at the bottom of the probe. See Functional

Specifications Probe, see page 34 and continuing.

Enter the level value

for the 20 mA point.

A transition zone / blocking distance may exist at the top of the probe.

See Functional Specifications Probe, see page 34 and continuing.

Enter the damping factor. A damping factor (1-10 seconds) may be added to smooth a noisy

display and/or output due to turbulence.

Enter the value for error.

Select «3.6 mA», «22 mA» or hold last value «HOLD». In case of

loop failure, error signal will follow the failing trend; meaning the unit

will show 3.6 mA when the reviewed loop current by the device is

found too low. The unit will show 22 mA in case the reviewed loop

current is found too high.

17

MENU: STEP BY STEP PROCEDURE – Eclipse 705: Interface

Screen Action Comment

26

25

3

0

31

32

35

Poll Adr

xx

IfcThrs

(select)

2

4

Threshld

Trim 20

xxxx

Loop Tst

xx.x mA

28

29

Trim Lvl

xx.x

2

7

Loop Mode

Trim 4

xxxx

LvlTicks

xxxxx

New Pass

xxx

36

37

Language

Mdl705HT

Ver xx.xx

33

34

IfcTicks

xxxx

Medium

20

21

22

2

3

BlockDis

x.x

SZ Fault

(select)

SZHeight

xx.x

SZ Alarm

Reset

E

nter distance in

selected level units

A

llows to ignore level measurements near the top of the probe,

caused by e.g. condensation, crystalization. Make sure that the liquid

level does NOT enter this zone. Consult factory or the

‘Troubleshooting’ section before entering any value. Normaly to be

u

sed with single rod probe.

Select the safety zone fault.

Select «None» (None), «3.6mA», «22mA», «Latch 3.6mA» or

«

Latch 22mA». When either «Latch 3.6 / 22mA» signals is

s

elected, the loop current remains in alarm until it is manually reset

w

ith the «SZAlarm» reset screen ( for safety zone explanation see

T

erminology - page 11).

S

elect the safety zone value

E

nter safety zone in cm or inches (see Terminology - page 11).

Reset safety zone latch fault

Clear a latched safety zone alarm «SZFault».

S

elect top level threshold.

D

efault selection for most common applications is «Fixed».

S

elect interface threshold.

D

efault selection for all applications is «CFD». In case the unit does

not track the correct interface layer, select «Fixed».

Enter HART ID number. Select a HART poll address (0-15). Enter 0 for a single transmitter

installation.

E

nable/Disable

D

etermines whether the loop is fixed at 4.0 mA or controlled by the

P

V.

Enter value

to adjust level reading.

Allows to compensate for a fixed level deviation.

Fine tune the 4 mA point. Attach a mA meter to the output. If the output does not equal 4.0 mA,

adjust the value on the display to equal 4.00 mA.

Fine tune the 20 mA point. Attach a mA meter to the output. If the output does not equal

20.0 mA, adjust the value on the display to equal 20.00 mA.

Enter a mA output value. Set mA Output to any given value to perform loop test .

Diagnostic display. Shows time of flight from fiducial pulse to reflected signal from level.

Diagnostic display. Shows time of flight through the upper liquid layer.

Diagnostic display.

Shows type of detected upper liquid; unknown «Unknown» oil only

«Oil Only», thin oil layer «Thin Oil», thick oil layer «Thick

Oil», or no level «Dry Probe».

Enter new password. Use arrows to select desired value. Values between 0 and 255.

Select language

Select «English», «Français», «Deutsch» or «Espagnol».

None, do not adjust.

Factory setting. «Ver» refers to software version.

Advanced diagnostics. See page 20.

38

DispFact

(select)

No offset

(Offset at 0 cm)

Positive offset

(Offset at 10 cm)

Negative offset

(Offset at -15 cm)

75 cm

100 %

0 %

15 cm

10 cm

20 mA = 75 cm

4 mA = 15 cm

20 mA = 85 cm

4 mA = 25 cm

20 mA = 60 cm

4 mA = 0 cm

OFFSET

Advanced configuration

Diagnostics

18

= Quick Start up

MENU: STEP BY STEP PROCEDURE – Eclipse 705: Interface & Volume

Screen Action Comment

Run modeConfiguration

1

2

3

4

7

13

16

19

22

23

*Status*

*

IfcVol*

*%Output*

*Loop*

IfcLevel

or Ifc Vol

%Output

xx.x%

Loop

xx.xx mA

6

Volume

xx.x

Level

xxxx

5

IfcLvl

xxxx

12

Probe Ln

xxx.x

11

LvlUnits

(select)

Lvl Ofst

xxx.x

17

Dielctrc

(Select)

Upr Diel

(Select)

Loop Ctrl

(Select)

14

VolUnits

Damping

xx s

15

StrapTbl

xx pnts

Fault

(Select)

T

ransmitter Display

T

ransmitter default values cycle every 5 seconds. Status «Status»,

I

nterface volume «IfcVolume», % Output «% Output», and Loop

«

Loop».

T

ransmitter Display

T

ransmitter displays Interface volume or Interface level in selected

engineering units (depending selection in Loop control «Loop Ctrl»

Transmitter Display Transmitter displays % Output measurement derived from 20 mA

span.

T

ransmitter Display

T

ransmitter displays Loop measurement (mA).

Transmitter Display Transmitter displays interface level in selected level units

«LvlUnits».

T

ransmitter Display

T

ransmitter displays volume in selected volume units «VollUnits».

Transmitter Display

Transmitter displays level in selected level units «LvlUnits».

S

elect the type of probe

S

elect as per the 3 first digits of the probe partnumber. The partnumber

i

s shown on the nameplate: e.g. 705-510A-A11/7MT-A230-218, select

7xT-x from the list.

Select the type of probe

mounting.

S

elect NPT «NPT», BSP «BSP» or Flange «Flange».

(consult facto-

ry when a «

7xK» GWR probe is used)

S

elect the type of measurement

S

elect interface - volume «IfcVol».

S

elect units for level

c

m «cm», m «m», inches «inches» or feet «feet».

Enter the exact length of

probe.

Enter as per the 3 last digits of the probe partnumber on the nameplate:

- rigid probes, enter value cm or inches,

- flexible probes, enter value in meters or feet

e.g. 705-510A-A11/7MR-A230-218, enter «218» cm probe length.

Enter the offset value. When entering configuration values from the end of the probe is

cumbersome, an offset can be introduced to determine a new

reference point. This reference point can be either below the probe

(positive offset) or at the probe (negative offset). See page 11

“Terminology”.

Select units for volume.

Liters «l» or gallons «g».

Enter level/volume

pairs in max 20 steps

Liters «l» or gallons «g».

Enter the dielectric range

value of the upper media.

Enter the dielectrics of the upper layer liquid (between 1,4 and 5,0) –

only upper layer dielectrics need to be entered.

Select the dielectric range

value of the lower media

Select:

«10–100»

Enter sensitivity value Allows fine adjustment of internal gain.

Select primary variable (PV)

Primary variable is the loop controlling parameter. Select interface level «IfcLevel» or interface volume «Ifc Vol»

Enter the level value

for the 4 mA point.

A transition zone may exist at the bottom of the probe. See Functional

Specifications Probe, see page 34 and continuing.

Enter the level value

for the 20 mA point.

A transition zone / blocking distance may exist at the top of the probe.

See Functional Specifications Probe, page 34 and continuing.

Enter the damping factor. A damping factor (1-10 seconds) may be added to smooth a noisy

display and/or output due to turbulence.

Enter the value for error.

Select «3.6 mA», «22 mA» or hold last value «HOLD». In case of

loop failure, error signal will follow the failing trend; meaning the unit

will show 3.6 mA when the reviewed loop current by the device is

found too low. The unit will show 22 mA in case the reviewed loop

current is found too high.

10

8

PrbModel

(select)

MeasType

(select)

9

PrbMount

(select)

18

Senstvty

xxx

20

Set 4mA

xxx.x

21

Set 20mA

xxx.x

19

MENU: STEP BY STEP PROCEDURE – Eclipse 705: Interface & Volume

Screen Action Comment

3

1

29

34

35

36

39

Loop Mode

30

Poll Adr

xx

IfcThrsh

(select)

2

8

Threshld

Trim 20

xxxx

Loop Tst

xx.x mA

LvlTicks

xxxxx

New Pass

xxx

40

41

Language

Mdl705HT

Ver xx.xx

37

38

IfcTicks

xxxx

Medium

24

25

26

2

7

BlockDis

x.x

SZ Fault

(select)

SZHeight

xx.x

SZ Alarm

Reset

E

nter distance in

selected level units

A

llows to ignore level measurements near the top of the probe,

caused by e.g. condensation, crystalization. Make sure that the liquid

level does NOT enter this zone. Consult factory or the

‘Troubleshooting’ section before entering any value. Normaly to be

u

sed with single rod probe.

Select the safety zone fault.

Select «None» (None), «3.6mA», «22mA», «Latch 3.6mA» or

«

Latch 22mA». When either «Latch 3.6 / 22mA» signals is

s

elected, the loop current remains in alarm until it is manually reset

w

ith the «SZAlarm» reset screen ( for safety zone explanation see

T

erminology - page 11).

S

elect the safety zone value

E

nter safety zone in cm or inches (see Terminology - page 11).

Reset safety zone latch fault

Clear a latched safety zone alarm «SZFault».

S

elect top level threshold.

D

efault selection for most common applications is «Fixed».

Select interface threshold.

Default selection for all applications is «CFD». In case the unit does

not track the correct interface layer, select «Fixed».

Enter HART ID number. Select a HART poll address (0-15). Enter 0 for a single transmitter

installation.

E

nable/Disable

D

etermines whether the loop is fixed at 4.0 mA or controlled by the

P

V.

Enter value

to adjust level reading.

Allows to compensate for a fixed level deviation.

Fine tune the 4 mA point. Attach a mA meter to the output. If the output does not equal 4.0 mA,

a

djust the value on the display to equal 4.00 mA.

Fine tune the 20 mA point. Attach a mA meter to the output. If the output does not equal

20.0 mA, adjust the value on the display to equal 20.00 mA.

Enter a mA output value. Set mA Output to any given value to perform loop test .

Diagnostic display. Shows time of flight from fiducial pulse to reflected signal from level.

Diagnostic display. Shows time of flight through the upper liquid layer.

Diagnostic display.

Shows type of detected upper liquid; unknown «Unknown» oil only

«Oil Only», thin oil layer «Thin Oil», thick oil layer «Thick

Oil» or no level «Dry Probe».

Enter new password. Use arrows to select desired value. Values between 0 and 255.

Select language

Select «English», «Français», «Deutsch» or «Espagnol».

None, do not adjust.

Factory setting. «Ver» refers to software version.

Advanced diagnostics. See page 20.

Strapping table

max. Pt 20 Lvl = ...... cm

Pt 4 Lvl = 200 cm

Pt 3 Lvl = 120 cm

Pt 2 Lvl = 50 cm

Pt 1 Lvl = 0 cm

max. Pt 20 Vol = ...... l

Pt 4 Vol = 3000 l

Pt 3 Vol = 2000 l

Pt 2 Vol = 1000 l

Pt 1 Vol = 0 l

32

3

3

Trim Lvl

xx.x

Trim 4

xxxx

42

DispFact

(select)

NOTE: Consult page 17 for level offset «Lvl Ofst» details.

Advanced configurationDiagnostics

20

MENU: STEP BY STEP PROCEDURE: ADVANCED CONFIGURATION

Screen Action Comment

Diagnostics

1

3

4

6

7

8

DispFact

Select

Run time

xx h

2

History

(current status)

History

Reset

FidTicks

xxxx

5

HF cable

(select)

14

Ifc Ampl

xxx

FidSprd

X

Fid Type

(select)

9

10

20

Fid Gain

xxx

Window

xxx

11

Conv Fct

xxxx

1

2

Scl Ofst

xxx

13

Neg Ampl

xxx

15

Pos Ampl

xxx

16

Signal

xxx

17

Compensate

(select)

18

DrateFct

Xxxx

19

Targ Ampl

Xxxx

Targ Tks

Xxxx

21

Targ Cal

Xxxx

22

OperMode

(select)

25

23

7xKCorr

xxx

24

ElecTemp

xxx C

Max Temp

xxx C

26

Min Temp

xxx C

27

SZ Hyst

xx.x

R

eview factory parameters

S

elect «YES» to reveal Factory parameters; «NO» to hide.

R

eview Diagnostic messages.

A

cumulative review of all diagnostic messages. Press the enter but-

t

on twice to clear.

Display mode. Shows time in hours that unit is in operation since last power on.

D

iagnostic display.

S

elect «YES» to clear «History».

S

uperuser parameter

S

elect from 1 m (3') or 3,6 m (12') remote.

D

iagnostic display.

S

hows time of flight from electronics to fiducial pulse. Value should

r

emain stable within ± 10 ticks.

D

iagnostic display.

V

alue represents the variation of fiducial ticks – a value indicates that

u

nit is OK, a problematic spread results into an error message.

Select fiducial pulse type.

Requires superuser password.

«positive» or «negative» (selection only allowed for some

probes). Consult factory before changing status.

C

hange gain.

V

alue represents the # of gain applied to the fiducial signal.

None, do not adjust. Factory setting.

None, do not adjust. Factory setting.

None, do not adjust. Factory setting.

Enter new value.

Requires superuser password.

Negative amplitude threshold.

Enter new value.

Requires superuser password.

Interface amplitude threshold.

Enter new value.

Requires superuser password.

Positive amplitude threshold.

Diagnostic display. Indication of signal strength.

Access compensation screens.

Requires superuser password.

«None» default.

The selection of «Manual» or «Auto» activates the screens 16

through 20 for 7MS/7MQ probes.

None, do not adjust.

Diagnostic display if «Compsate» is on «Auto».

Shows velocity derating factor.

None, do not adjust.

Diagnostic display if «Compsate» is on «Auto».

Shows amplitude of steam reference target.

Diagnostic display if «Compsate» is on «Auto».

Shows # of ticks from fiducial to steam reference target.

None, do not adjust.

Diagnostic display if «Compsate» is on «Auto».

Shows the calibrated # of ticks at ambient temperature.

Select operating mode.

Selection screen if «Compsate» is on «Auto».

Select run automatically «Run», calibrate «Cal», deactivate «Off».

Enter a value.

Requires additional password.

Distance in mm (regardless .«LvlUnits») from fiducial to user reference point. Only for 7EK (top/bottom) probe.

None, do not adjust. Shows internal housing temperature.

None, do not adjust. Diagnostic display, shows maximum internal housing temperature

recorded.

None, do not adjust. Diagnostic display, shows minimum internal housing temperature

recorded.

None, do not adjust. Safety zone Hysterisis, diagnostic factory setting

Hidden diagnostic screens. Do not acces without assistance or having followed advanced training.

21

For more details about the use of PACTware™ and FDT technology, refer to instruction manual 59-601

PACTware™ – Configuration and Troubleshooting

WHAT IS FDT, PACTware AND DTM

Power

Transmitter

HART connections

24 V DC

PC with

HART Serial

Interface

• FDT (Field Device Tool) is a new interface code that

describes the standardization between frame programs

(e.g, PACTware) and DTMs (Device Type Manager).

• PACTwa re (Process Automation Configuration Tool)

is a frame program. It is a device-independent software

program that communicates with all approved DTMs.

• DTM (Device Type Manager) is a device-specific software driver designed to operate within a FDT compatible

frame program such as PACTware. It includes all special

information needed to communicate with a specific

device (e.g, Pulsar RX5). There are two basic categories

of DTM’s—Communication (HART, Fieldbus

®

, Profibus®,

etc.) and Field Device (e.g. Pulsar RX5 Radar transmitter).

QUICK START

CONNECTIONS

1. Start a project

Open Pactware and add the Hart modem key and then

the Magnetrol instrument to your project.

Select: «Device» – «add device» – select device

(repeat for each device in your project)

Important: Make sure that the COM port settings for

y

our Hart modem key are correct;

2. Connect the devices

Select in the left window the Magnetrol instrument.

Select: «Device» – «connect» (both modem and

M

agnetrol instrument are getting connected)

3. Configure the instrument

Select: «Device» – «parameter» – «Online

parameterization»

O

pen «+ Main Menu» and select «+ Device set

up» – «Calibration»

Parameters can be changed in the window at right, via

the drop down boxes. ENTER confirms the change

online.

4. Troubleshoot / Monitior the instrument

Process trend:

Select: «Device» – «Additional functions» –

«Process Trend»

Process trend: all key data (level % Output, Loop, Signal

strength) can be trended and saved, time scales can be

adapted.

Echo Curve:

Select: «Device» – «Additional functions» –

«Echo Curve»

Echo Curve: shows the actual waveform. The echo

curve is an efficient tool for advanced calibration and

troubleshooting.

Present Status:

Open Main Menu and select «+ Device set up» –

«Diagnostics» – «Present status»

Present status: shows the entire overview of all

detectable faults and warnings. Blank boxes indicate the

healthy condition of the instrument. Ticked off boxes

indicate for a possible fault or warning.

The following diagram shows a typical hardware configuration. Observe all safety codes when attaching to instrument

loops in hazardous areas or when measuring flammable

media. Computers are not intrinsically safe devices.

Magnetrol recom-

mends the VIATOR

®

USB HART®Interface

from MACTek

®

Corporation.

22

PACTware™ – Configuration and Troubleshooting

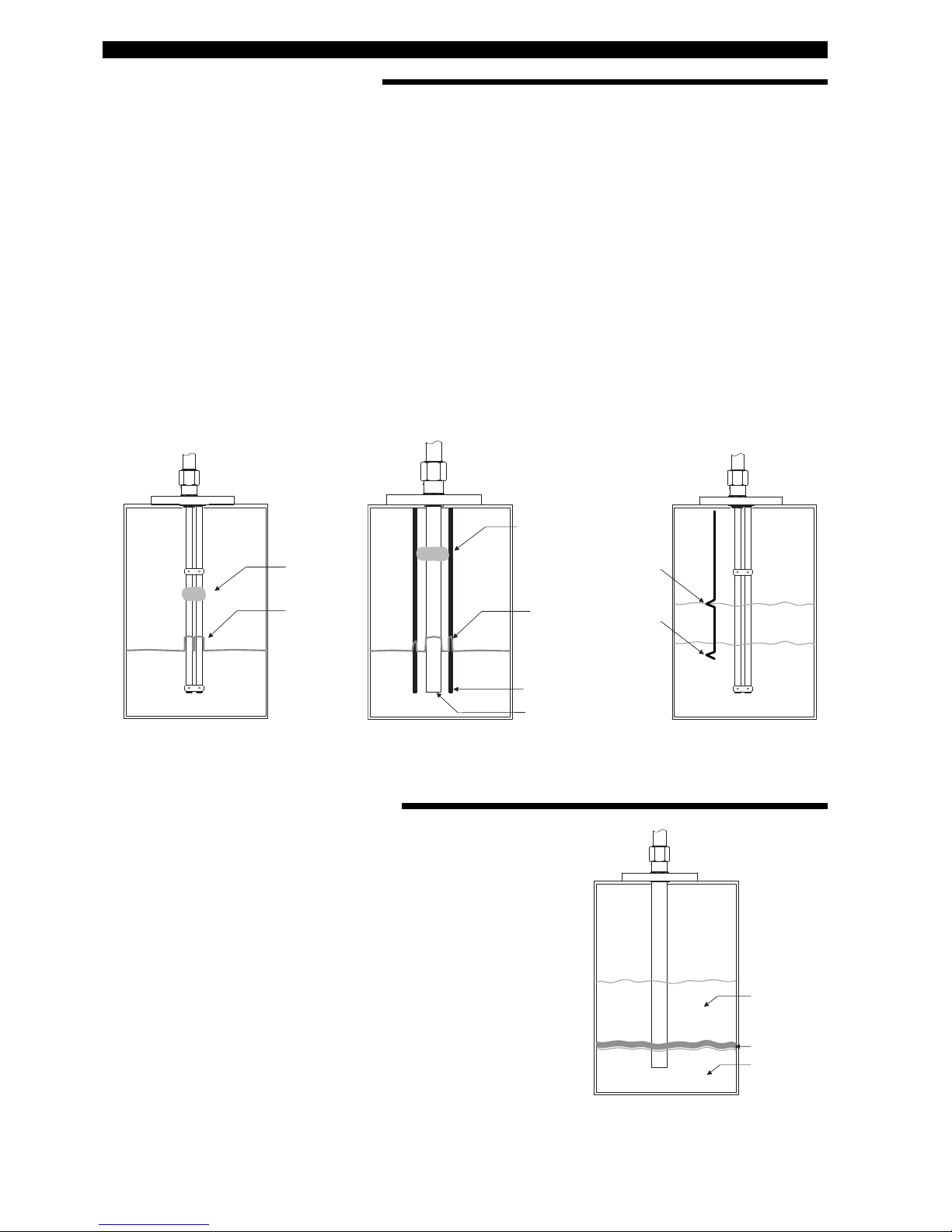

Echo Curve patterns

N

ormal oil/water interface

Below screens are examples of the most typical echo curves that occur in normal operation / error condition.

Normal signal pulses from oil over water

L

evel with Blocking Distance correction

Signal pulse from level. Unit suffered from build up on top

of the probe. The introduced blocking distance (see area in

frame) solves the problem.

Dry Probe

Signal pulse from an empty vessel/ cage – displayed message on the unit is «DryProbe» Dry Probe

EOP High or Low

Signal pulse from an empty vessel or cage but with wrongly entered probe length – displayed message is «EOP

High» or «EOP Low» (as shown in graph). Correct the

probe length in either case.

Weak Signal

Signal pulse of a weak signal. Displayed message is

«WeakSgnl». Solve this by either to:

- change dielectric setting to a lower range or

- increase the sensitivity

Threshold Fixed or CFD

Signal pulse of oil over water level. Always select

«Threshld Fixed» (as shown in the graph). «Threshld

CFD» will track the stronger reflection pulse. In case of level

measurement, the unit will not compensate for the signal

velocity in the upper oil layer and show an erroneous level

reading.

23

CONFIGURATION USING HART

®

I

MPORTANT: The digital HART

®

c

ommunication is superimposed on the

4-20 mA loop and requires a min. load resistance of 250 Ω and a max load

resistance of 450 Ω.

+

+

-

-

Junction

C

ontrol

Room

Display

Power

Supply

Current

Meter

2

50 Ω < R

L

<

450 Ω

CONNECTIONS

CHECK HART

®

Connection of your Hart communicator:

• at power terminals (+) and (-) in wiring compartment

• at first junction box between unit and control room.

Before starting the HART

®

configuration procedure – check if your HART®commu-

n

icator is equipped with the proper Eclipse Device Descriptors (DD’s).

I/O start up the communicator

Select NO: go offline

Select 4: utility

Select 5: simulation

Check manufacturer: Magnetrol

HART MENU

I/O Start up the device

1 Enter Device Set Up «

DEVICE SET UP»

Press one of the following alphanumeric keys (if no key is sensed after 5 s, the

unit will automatically jump to RUN mode and alternatively show Level/% Output

and Loop signal

1 for entering Calibration «CALIBRATION» (see page 24 for additional informa-

tion)

2 for entering Basic Set Up «

BASIC SET UP» – general HART

3 for Advanced Set Up «

ADVANCED SET UP» (see page 24 for additional infor-

mation)

4 for entering Diagnostics «DIAGNOSTICS» (see page 24 for additional infor-

mation)

5 for entering Review «

REVIEW» to review all settings.

When the proper software version is not found, consult your local HART

®

Service

Center to load the correct Eclipse DD’s.

HCF Release Date

HART Version

Model

Compatible with software

September 2008 Dev V1 DD V2

705 3.x

Version 3.0A and later

February 2013 Dev V2 DD V2 Version 3.2A and later

24

CONFIGURATION USING HART

®

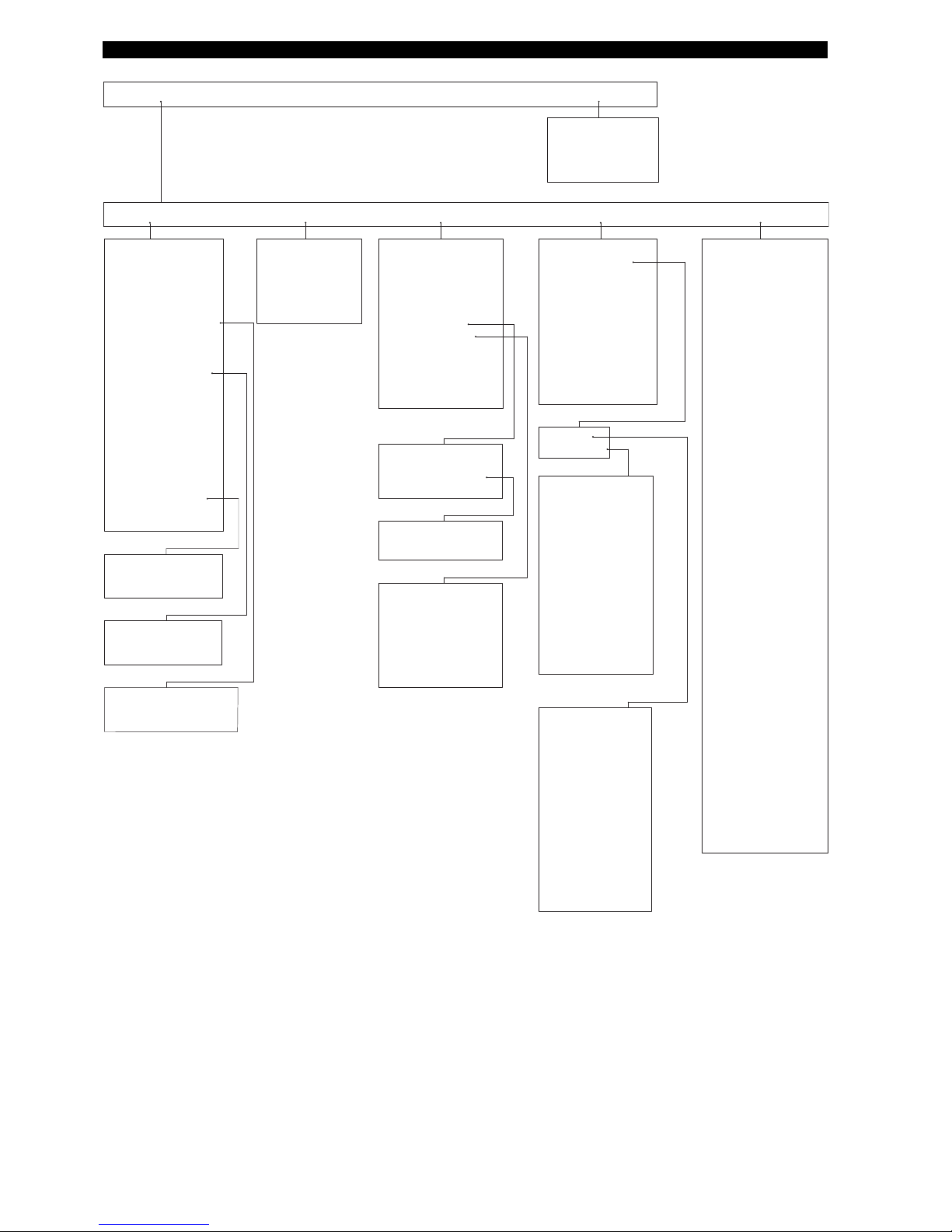

1 Calibration 2 Basic Setup 3 Advanced Setup 4 Diagnostics

5

Review

1

Device Setup 2 Level 3 % Range 4 Loop 5 Device Variables

1 Tag

2

Descriptor

3 Date

4 Message

5 Poll Address

6 Final Asmbly Num

1

Model

2 Manufacturer

3 Magnetrol S/N

4 Firmware Version

5 Tag

6 Descriptor

7 Date

8

Message

9 Poll Address

10 Final asmbly num

11 Device ID

12 Probe Model

13 Probe Mount

1

4 Measurement Type

16 Probe Length

1

5 Level Units

17 Level Offset

18 Volume Units

19 Dielectric Range

20 Sensitivity

21 PV is

22 SV is

23 TV is

24 QV is

25 4mA Set Point

26 20mA Set Point

27 Damping

28 System Fault State

29 Blocking Distance

30 SZ Fault State

31 SZ Height

32 Trim Level

33 4 mA Trim Value

34 20 mA Trim Value

35 Threshold

36 Interface Threshold

37 Fiducial Type

38 Fiducial Gain

39 Neg Threshold Ampl

40 Pos Threshold Ampl

41 Ifc Threshold Ampl

42 Compensation Mode

43 Upper Dielectric

44 7xK Correction

45 SZ Hysteresis

46 Universal rev

47 Field dev rev

48 Software rev

49 Num req preams

3

Measurement Type

4 Level Units

6 Level Offset

7 Volume Parameters

9

Sensitivity

8

Dielectric Range

10 PV is

11 Variable Selection

12 4 mA Set Point

13 20 mA Set Point

14 Damping

15 System Fault State

16 Blocking Distance

17 SZ Fault State

18 SZ Height

19 SZ Alarm Reset

20 Threshold

21 Interace Params

22 Trim Level

23 Date/Time/Initials

5 Probe Length

1

Probe Model

2 Probe Mount

1 Faults

2 Warnings

1 Loop Test

2 Present Status

3 Status History

4 Level Ticks

5 Fiducial Ticks

6 Fiducial Spread

7 Signal Strength

8 Elec Temperature

9 Interface Ticks

10 Interface Medium

11 Derating Factor

12 Target Amplitude

13 Target Ticks

1 Software Failure

2 CPU Failure

3 EEPROM Failure

4 Default Params

5 No End of Ramp

6 Loop Failure

7 Fiducial Shift

8 Slope Error

9 No Probe

10 No Fiducial

11 Safety Zone Alrm

12 No Signal

13 EOP High

14 Hi Volume Alrm

15 Lvl < Probe Length

16 EOP < Probe Length

1 Trim Loop Current

2 Enter Password

3 Fiducial Type

4 Fiducial Gain

5 Neg Threshold Ampl

6 Pos Threshold Ampl

7 Compensation

8 Factory Settings

9 SZ Hystersis

1

0 Max Temperature

11 Min Temperature

12 Reset Temperatures

13 New User Password

1 Level

2 Volume

3 IfcLvl

4 IfcVol

3 Table Length

2 Strapping Table

1 Volume Units

3 QV IS

2 TV IS

1 SV IS

3 Ifc Threshold Ampl

2 Interface Threshold

1 Upper Dielectric

1 Magnetrol S/N

2 Device ID

3 HF Cable

4 Window

5 Conversion Factor

6 Scale Offset

7 Waveform Selection

8 Factory Param 2

1 Compensation Mode

2 Upper Dielectric

3 Target Calibration

4 7xK Correction

1 Target Oper Mode

2

Target Calib Value

3

Auto Target Calib

1 Seal Leak

2 Fiducial Spread

3 Hi Temperature

4 Lo Temperature

5 Calib Required

6 EOP Too Low

7 Trim Required

8 Initializing

9 May Be Flooded

10 Dry Probe

11 Weak Signal

12 System Warning

13 Warning 1

14 Warning 2

15 No Steam Target

16 Warning 4

25

MAINTENANCE

TROUBLESHOOTING

Symptom Problem Solution

LEVEL, % OUTPUT and LOOP values

are all inaccurate.

Basic configuration data is

questionable.

Reconfigure the Probe Length «Prb Ln»

and Offset «Offset». Check also the

Probe Model «Prb Model» / Probe

Mount «Prb Mount»

1) Ensure the Level is accurate.

2) Reconfigure Loop values.

Interface level has significant emulsion. Examine process to reduce/eliminate

emulsion layer.

LEVEL readings are repeatable but

consistently high or low from actual

by a fixed amount.

Configuration data does not

accurately match probe length or tank

height.

Ensure proper probe length

«Prb Ln»

&

probe Model

«Prb Model»

.

Adjust trim level value by the amount of

noted inaccuracy.

LEVEL, % OUTPUT and LOOP

values fluctuate.

Turbulence.

I

ncrease the Damping «Damping» fac-

t

or until the readings stabilize.

High frequency connection.

Check Fiducial Spread «FidSprd»

(should be stable within ± 10 counts.)

LEVEL, % OUTPUT and LOOP

values all reading low vs. actual

(level or volume applications).

Lower dielectric material over higher

dielectric material, e.g. oil over water.

Select Fixed Threshold option «Fixed»

and/or select dielectric range from top layer.

Coating, clumping or buildup on probe. Expected inaccuracies due to affect on

pulse propagation.

Dense, water based foam. Expected inaccuracies due to affect on

pulse propagation.

LEVEL reading on Display is correct

but LOOP is stuck on 4 mA

Basic configuration data

is questionable.

Set Hart poll address «POLL ADR» to

«0». If not using HART®multi drop

HART device only: handheld will only

read Universal Commands.

Most current Device Descriptors

(DDs) are not installed in handheld.

(see page 20)

Contact local HART service center for

the latest DD’s.

LEVEL reading on display is stuck

at full scale, LOOP is stuck at 20,5 mA.

Software believes probe is flooded

(level near very top of probe).

Check actual level. If probe is not flooded, check for build up or obstructions

near top of probe. Select higher dielectric range.

Check for condensation in probe connection. Add Blocking Distance.

LEVEL, % OUTPUT and LOOP

values all at maximum level.

Possible configuration issue with single

rod probe

1) Increase Blocking Distance

2) Increase Dielectric Range

LEVEL, % OUTPUT and LOOP

values all reading high vs. actual.

Possible obstruction in tank affecting

single rod probe.

1) Increase Dielectric Range until

obstruction is ignored.

2) Relocate probe away from obstruction.

LEVEL value reading high when

should be zero.

Transmitter loose or disconnected

from probe.

Ensure transmitter connected securely

to probe.

HART ERROR MESSAGES

Error Screen Displayed status

Faults Enlists possible error messages. OFF: safe status

ON: highlighted error is occurring – see

page 27

Warnings Enlists warning messages. OFF: safe status

ON: highlighted warning is occurring –

see page 26

History Built in log of the last 26 error messages. See page 20.

PACTware™PC Program

The Eclipse Model 705 offers the ability to do Trending and Echo Curve analysis using a PACTware DTM. This is a powerful troubleshooting tool that can aid in the resolution of some of the Error Messages shown above.

Refer to Bulletins 59-101 and 59-601 for more information.

26

MAINTENANCE

Display

Message

Action Comment

OK None Normal operating mode

Initial None Program is Initializing, level

reading held at 4 mA set point.

T

his is a transient condition.

DryProbe None Normal message for a dry

probe. End of probe signal is

being detected.

WeakSgnl 1) Set transmitter to lower dielectric range

2) Increase sensitivity

Signal amplitude is lower than

desired.

Flooded? 1) Decrease level in vessel

2) Set transmitter to lower dielectric range

3) Replace with Model 7MR Overfill probe

Loss of level signal possibly

due to flooding, twin rod

probes only

Fid Sprd* 1) Check connection between probe and transmitter

2) Check for moisture on top of probe

3) Consult factory

Fiducial Ticks variation is

excessive.

Hi Temp 1) Transmitter may need to be moved to ensure ambient temperature

is within specification

2) Change to remote mount transmitter

3) Use sunshade

Present temperature in

electronics compartment is

above +80° C

Lo Temp 1) Transmitter may need to be moved to ensure ambient temperature

is within specification

2) Change to remote mount transmitter

Present temperature in

electronics compartment is

below -40° C.

Sys Warn Consult factory Unexpected but non-fatal

software event

TrimReqd Consult factory Factory set Loop values are

defaults, loop output may be

inaccurate

Cal Reqd Consult factory Factory set default calibration

parameters are in use, level

reading may be inaccurate

WARNING MESSAGES

A warning message identifies the status of the instrument. A warning message does not necessarily require immediate action but may

require close attention and/or follow up. The warning message will be displayed on the unit and/or selected on the Pactware screen while

the output signal will remain normal.

27

MAINTENANCE

D

isplay

Message

Action Comment

H

iVolAlm

V

erify strapping table is entered correctly.

L

evel more than 5% above

highest point in strapping table.

SlopeErr Consult factory Ramp circuit generating

improper voltage

LoopFail Consult factory

Note: In case of loop failure, error signal will follow the failing trend;