856 Instruction Manual

10/18/2010

Eclipse Self-Check

UV Scanner

Model 5602-91

Version 1

Introduction

The self-check UV Scanner is used for continuous gas or

oil flames. A mechanical shutter in the scanner closes

briefly every ten seconds, at which time the scanner’s

internal circuit checks for a flame signal. If a signal is

present, indicating a failed sensor, the output signal to the

flame safeguard is stopped and the system shuts down.

The scanner features a high quality fused silica quartz

lens, machined alloy housing with seals and a long life

push-pull electromagnetically driven photo shutter. This

scanner operates with the series 5600 and VF56 series

Veri-Flames, the series 6000 Multi-Flame, Series 6500 BiFlame controllers, and series 7000 Peek-A-Flame.

Factory Mutual (FM) recommends these scanners be

used when any fired equipment is operated continuously

(more than 24 hours without shutdown).

Mechanical Specifications

Parameter Specification

Overall Length 7-3/4" (197mm)

Diameter 3-1/4" (83mm)

Housing Material Aluminum

Finish Clear anodized

Sight Tube Entrance 1" NPT

Purge Air Entrance 1/4" NPT

Purge Air Flow 5 cfm, 10 psi maximum (140

lpm, 0.7mbar)

Electrical Specifications

CAUTION

CAUTION

Parameter Specification

Supply Voltage 120V +10/-15%, 50/60 Hz

Supply Current 0.04A

Output Pulse frequency modulated tran-

sistor

Required Accessory Cable with connector, 10 feet

(3m), model 5602-91-7, Part

49602-91-7

Wiring Extension Instrumentation cable with two

pairs of individually shielded #18

AWG conductors, 300V

minimum, BELDEN #9368 or

equivalent.

Temperature Range 0°F to 140°F (-20° to +60°C)

case temperature

Shipping Weight 4.5 lbs (2 kg)

Optical Angle of view @ 2.5° depending

on sight pipe size and length

Spectral Sensitivity: 185 to 260

nanometers; scanner is solar

blind

Option Non-Magnifying lens part 18165

property damage. Be certain that the flame sensor

detects only the pilot and/or main flame of the

intended burner by testing the control system

under varying operating conditions and firing

rates. Follow the test procedures given in this

manual and the equipment provider’s instructions

after installation and at regularly scheduled

maintenance intervals.

Sensor Wiring

Route sensor wiring a sufficient distance from ignition and

other high voltage wiring to avoid electrical interference.

To reduce interference, ground both shields.

If sensor wiring is to extend beyond the supplied 10 ft

(305cm) lengths, use wiring extension as shown in

specifications.

Tables 1 - 4 illustrate how the sensor should be wired to

appropriate controls. Near the end of each of the four

cable leads is a letter tag for identifications. The scanner

is only available for 120V supply. Refer to Figure 1 to use

with a 230 VAC supply.

NOTE:

provide a convenient attachment point. A panel ground

wire must also be run to these points.

The shield wire terminals shown in the tables

Sensor Installation

■ Incorrect sensor installation may cause the sensor

to generate a false flame signal. This can cause

unburned fuel to collect in the combustion

chamber, resulting in explosions, injuries, and

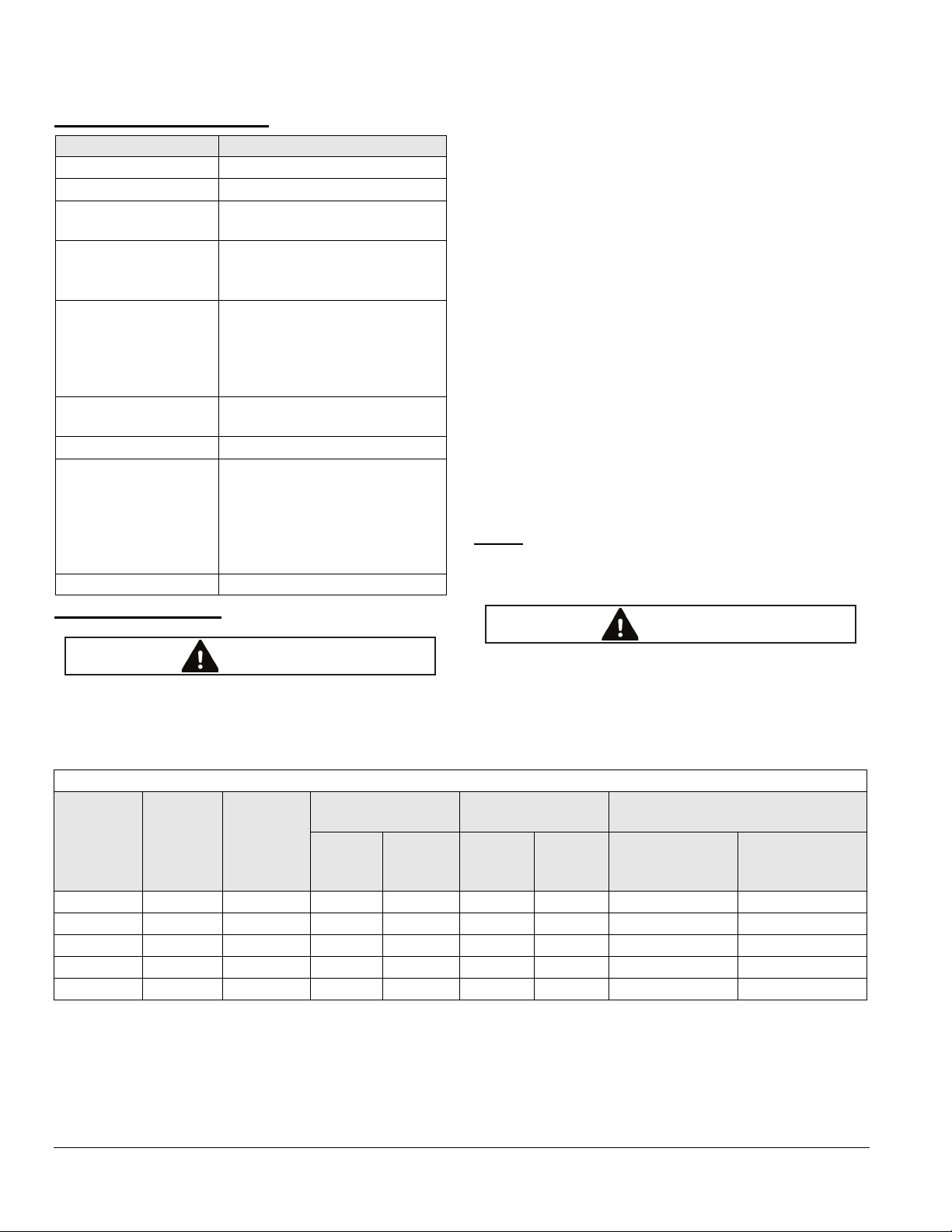

Table 1 - Wiring to Multi-Flame

Multi-Flame

5602-91

Scanner

Connector

Pin

A red Neutral Neutral Neutral Neutral Neutral Neutral Neutral

B white 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC 120 VAC

CblackUV 3 9 3 9 3 9

D green Gnd Return 2 8 2 8 2 8

- shields Ground 4 10 4 10 4 10

5602-91-7

Cable

Wire

Function

J4 Terminal

Scanner#1Scanner#3Scanner#2Scanner

■ Cable lead "B" should only be connected to power

(120 VAC); connecting it to any other terminal will

bypass the safe-start check of the scanner.

Multi-Flame

J5 Terminal

Scanner #5, 6, 9,

10 (also #13, 14,

#4

Expansion Board

J3, J4, J5, J6 Terminals

Scanner #7, 8,

11, 12 (also #15,

17, 18)

16, 19 20)

2

Eclipse Self-Check UV Scanner, V1, Instruction Manual 856, 10/18/2010

Loading...

Loading...