Page 1

Installation Guide 818

1/15/2015

Eclipse Veri-Flame Single

Burner Monitoring System

Model 5600

Modulation Model

Purge ModelNo Purge Model

Page 2

Copyright

Copyright 2008 by Eclipse, inc. All rights reserved

worldwide. This publication is protected by federal

regulation and shall not be copied, distributed,

transmitted, transcribed or translated into any human or

computer language, in any form or by any means, to any

third parties, without the express written consent of

Eclipse, inc.

Disclaimer Notice

In accordance with the manufacturer’s policy of continual

product improvement, the product presented in this

brochure is subject to change without notice or obligation.

The material in this manual is believed adequate for the

intended use of the product. If the product is used for

purposes other than those specified herein, confirmation

of validity and suitability must be obtained. Eclipse

warrants that the product itself does not infringe upon any

United States patents. No further warranty is expressed or

implied.

Liability & Warranty

We have made every effort to make this manual as

accurate and complete as possible. Should you find errors

or omissions, please bring them to our attention so that we

may correct them. In this way we hope to improve our

product documentation for the benefit of our customers.

Please send your corrections and comments to our

Technical Documentation Specialist.

It must be understood that Eclipse’s liability for its product,

whether due to breach of warranty, negligence, strict

liability, or otherwise is limited to the furnishing of

replacement parts and Eclipse will not be liable for any

other injury, loss, damage or expenses, whether direct or

consequential, including but not limited to loss of use,

income, or damage to material arising in connection with

the sale, installation, use of, inability to use, or the repair

or replacement of Eclipse’s products.

Any operation expressly prohibited in this manual, any

adjustment, or assembly procedures not recommended or

authorized in these instructions shall void the warranty.

Document Conventions

There are several special symbols in this document. You

must know their meaning and importance.

The explanation of these symbols follows below. Please

read it thoroughly.

How To Get Help

If you need help, contact your local Eclipse

representative. You can also contact Eclipse at:

1665 Elmwood Rd.

Rockford, Illinois 61103 U.S.A.

Phone: 815-877-3031

Fax: 815-877-3336

http://www.eclipsenet.com

Please have the information on the product label available

when contacting the factory so we may better serve you.

www.eclipsenet.com

Product Name

Item #

S/N

DD MMM YYYY

This is the safety alert symbol. It is used to alert you to potential personal

injurt hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

CAUTION

NOTICE

NOTE

2

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

Is used to address practices not related to personal injury.

Indicates an important part of text. Read thoroughly.

Page 3

Table of Contents

Introduction...................................................................................................5

Product Description ..................................................................................5

Audience ..................................................................................................5

Veri-Flame Documents.............................................................................4

Safety .............................................................................................................5

Safety Warnings .......................................................................................5

Capabilities...............................................................................................5

Operator Training .....................................................................................5

Replacement Parts...................................................................................5

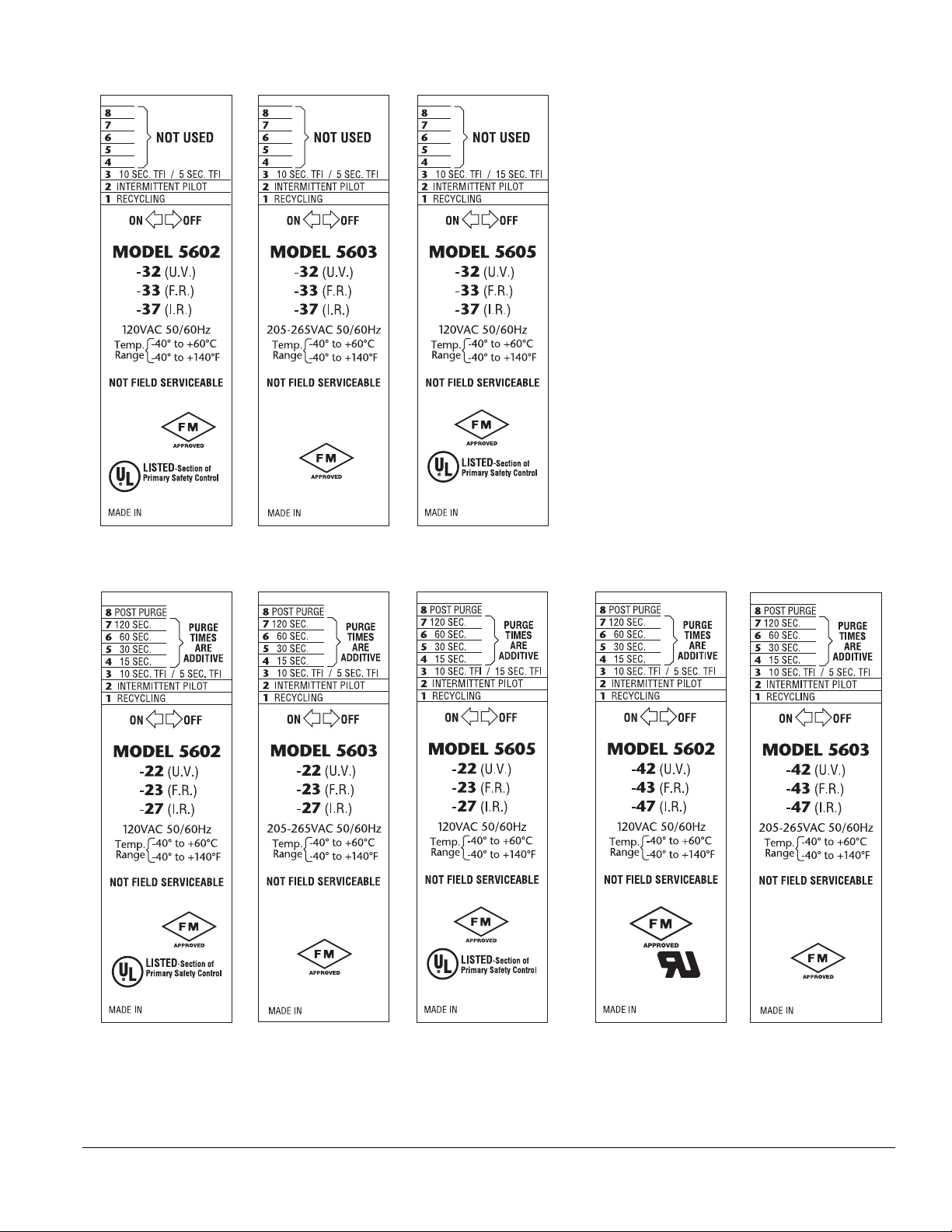

DIP Switch Selection ....................................................................................6

Introduction...............................................................................................6

Handling & Storage ..................................................................................6

Approvals of Components ........................................................................6

DIP Switch Location .................................................................................7

DIP Switch Access ...................................................................................7

No Purge DIP Switch Settings..................................................................7

Modulation and Purge DIP Switch Settings..............................................7

Function Summary .......................................................................................9

Introduction...............................................................................................9

Standard Features....................................................................................9

Optional Features.....................................................................................11

System Installation .......................................................................................12

Introduction...............................................................................................12

Interlocks and Limit Switch Input..............................................................12

Combustion Air Switch Input ....................................................................12

Ignition Wiring...........................................................................................12

Low Fire Input...........................................................................................12

Main Valve Closed Switch........................................................................12

High Purge Input ......................................................................................13

Remote Reset ..........................................................................................13

Remote Display and Power Supply..........................................................13

Sensor Installation........................................................................................18

Introduction...............................................................................................18

Sensor Wiring...........................................................................................18

Flame Rods ..............................................................................................18

Scanners ..................................................................................................19

Scanner Sighting Considerations .............................................................19

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015 3

Page 4

Test Procedures............................................................................................20

Introduction...............................................................................................20

Flame Signal Strength..............................................................................20

Minimum Pilot Test...................................................................................20

Pilot Flame Failure Test ...........................................................................20

Main Flame Failure Test (For Interrupted Pilot Systems).........................20

Spark Sighting Test ..................................................................................20

Limits and Interlocks Test.........................................................................21

Maintenance and Troubleshooting .............................................................22

Introduction...............................................................................................22

Monthly Checklist .....................................................................................22

Yearly Checklist........................................................................................22

Troubleshooting........................................................................................23

LED Status ...............................................................................................24

Remote Display Messages...........................................................................27

Introduction...............................................................................................27

Veri-Flame Operating Sequence..............................................................27

Remote Display Diagnostic Messages.....................................................31

Appendix .......................................................................................................i

4

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 5

Introduction

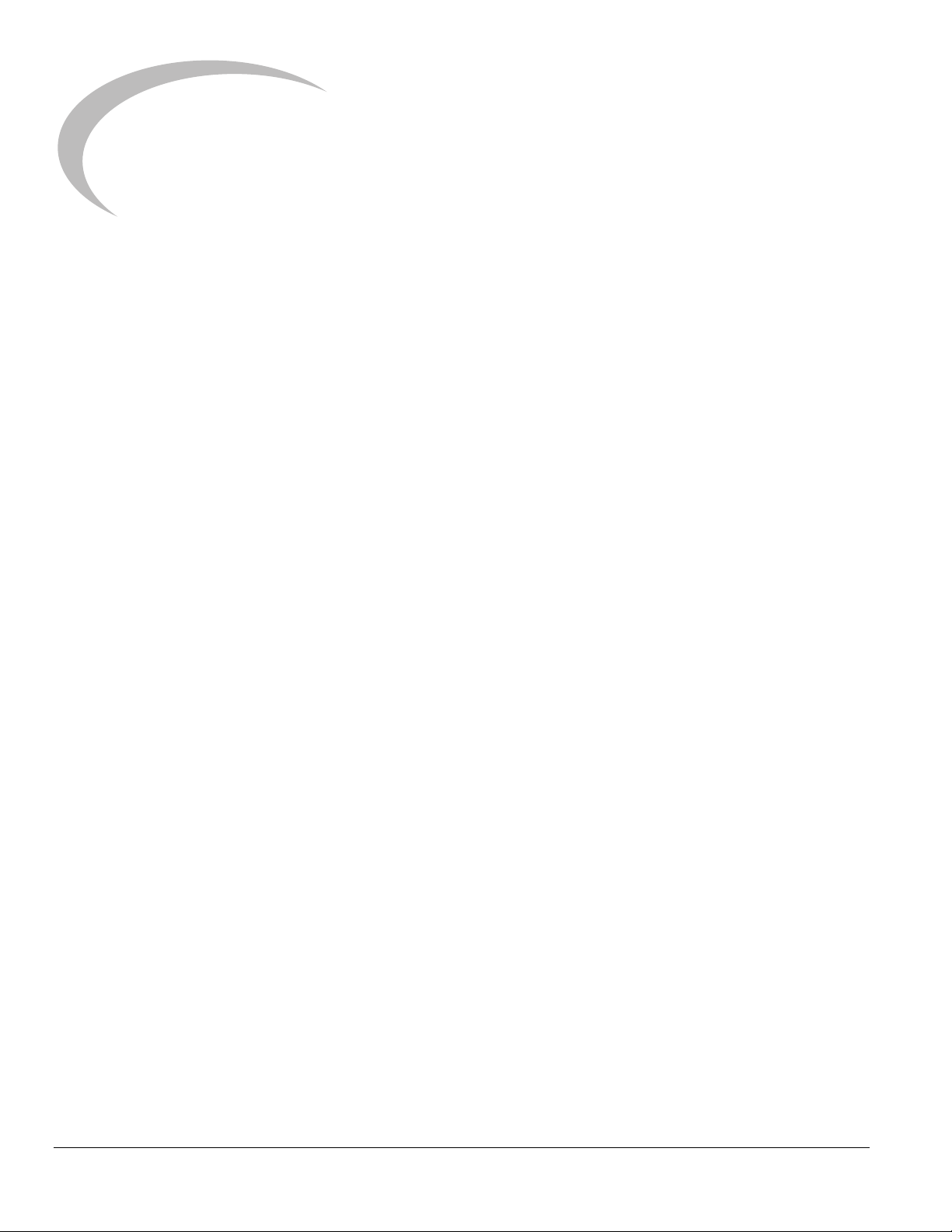

Product Description

The Eclipse Veri-Flame Single Burner Monitoring System

controls the start-up sequence and monitors the flame of

single gas, oil, or combination gas/oil burners. There are

three different models of the Veri-Flame line: no purge,

purge and modulation models. Each model features field

selectable trial for ignition (TFI). Each model is also

available for use with three types of flame sensor:

ultraviolet (UV), self-check UV and flame rod

Required components are the Veri-Flame, matching

wiring base and a flame sensor. Optional components

include a remote display and cable, tester, and various

scanner accessories.

The Veri-Flame No Purge and Purge models are available

in three different series - 5602, 5603 and 5605. The 5602

Series is UL listed for the USA and Canada and FM

approved; the 5605 Series is UL listed and FM approved.

The 5603 Series is for 240 VAC applications and is FM

approved.

1

Figure 1.1 Veri-Flame Single Burner Monitoring

System (Purge Unit Shown)

The Veri-Flame Modulation model is available in two

different series: 5602 and 5603. Both series are capable

of modulation (high purging and low fire start). The 5602

Series is UL recognized for the USA and Canada and FM

approved. The 5603 Series is for 240 VAC and is FM

approved.

Audience

This manual has been written for people who are already

familiar with all aspects of a nozzle-mix burner and its addon components, also referred to as “the burner system”.

These aspects are:

• Design / Selection

• Use

• Maintenance

The audience is expected to have previous experience

with this type of equipment.

Veri-Flame Documents

Installation Guide 818

• This document

Datasheet 818

• Required to complete design and selection

Spare Parts List Series 818

• Recommended replacement part information

Related Documents

• EFE 825 (Combustion Engineering Guide)

• Eclipse Bulletins and Info Guides: 684, 710, 732,

756, 760, 902, 930

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015 5

Page 6

Safety

Important notices which help provide safe burner

operation will be found in this section. To avoid personal

injury and damage to the property or facility, the following

warnings must be observed. All involved personnel should

read this entire manual carefully before attempting to start

or operate this system. If any part of the information in this

manual is not understood, contact Eclipse before

continuing.

Safety Warnings

DANGER

■ The burners, described herein, are designed to mix

fuel with air and burn the resulting mixture. All fuel

burning devices are capable of producing fires and

explosions if improperly applied, installed,

adjusted, controlled or maintained.

■ Do not bypass any safety feature; fire or explosion

could result.

■ Never try to light a burner if it shows signs of

damage or malfunction.

WARNING

■ The burner and duct sections are likely to have

HOT surfaces. Always wear the appropriate

protective equipment when approaching the

burner.

2

NOTICE

■ This manual provides information regarding the

use of these burners for their specific design

purpose. Do not deviate from any instructions or

application limits described herein without written

approval from Eclipse.

Capabilities

Only qualified personnel, with sufficient mechanical

aptitude and experience with combustion equipment,

should adjust, maintain or troubleshoot any mechanical or

electrical part of this system. Contact Eclipse for any

needed commissioning assistance.

Operator Training

The best safety precaution is an alert and trained

operator. Train new operators thoroughly and have them

demonstrate an adequate understanding of the

equipment and its operation. A regular retraining schedule

should be administered to ensure operators maintain a

high degree of proficiency. Contact Eclipse for any needed

site-specific training.

Replacement Parts

Order replacement parts from Eclipse only. All Eclipse

approved valves or switches should carry UL, FM, CSA,

CGA and/or CE approval where applicable.

■ Eclipse products are designed to minimize the use

of materials that contain crystalline silica.

Examples of these chemicals are: respirable

crystalline silica from bricks, cement or other

masonry products and respirable refractory

ceramic fibers from insulating blankets, boards, or

gaskets. Despite these efforts, dust created by

sanding, sawing, grinding, cutting and other

construction activities could release crystalline

silica. Crystalline silica is known to cause cancer,

and health risks from the exposure to these

chemicals vary depending on the frequency and

length of exposure to these chemicals. To reduce

the risk, limit exposure to these chemicals, work in

a well-ventilated area and wear approved personal

protective safety equipment for these chemicals.

6

Page 7

DIP Switch Selection

3

Introduction

This section describes the location, selection and

description of the Veri-Flame DIP switches, which allow

for sequence and timing functions as well as system

configuration.

Handling & Storage

Handling

• Make sure that the area is clean.

• Protect the components from the weather, damage,

dirt and moisture.

• Protect the components from excessive

temperatures and humidity.

• Take care not to drop or damage components.

Storage

• Make sure that the components are clean and free

of damage.

• Store the components in a cool, clean, dry room.

• After you have made sure that everything is present

and in good condition, keep the components in the

original package as long as possible.

Approval of Components

Gas Piping

All the gas piping must comply with all applicable local

codes and/or standards such as:

• NFPA Standard 54

• ANSI Z223

• EN 746-2

Where to Get the Standards:

The NFPA Standards are available from:

National Fire Protection Agency

Batterymarch Park

Quincy, MA 02269

www.nfpa.org

The ANSI Standards are available from:

American National Standard Institute

1430 Broadway

New York, NY 10018

www.ansi.org

The UL Standards are available from:

333 Pfingsten Road

Northbrook, IL 60062

www.ul.com

Limit Controls & Safety Equipment

All limit controls and safety equipment must comply with

all applicable local codes and/or standards and must be

listed for combustion safety by an independent testing

agency. Typical application examples include:

• American: NFPA 86 with listing marks from UL, FM,

CSA

• European: EN 746-2 with CE mark from TuV,

Gastec, Advantica

Electrical Wiring

All the electrical wiring must comply with all applicable

local codes and/or standards such as:

• NFPA Standard 70

• IEC60364

• CSA C22

• BS7671

The FM Standards are available from:

1151 Boston-Providence Turnpike

PO Box 9102

Norwood, MA 02062

www.fmglobal.com/approvals

Information on the EN standards and where to get

them is available from:

Comité Européen de Normalisation

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196811

Fax: +32-25196819

www.cen.eu

Comité Européen de Normalisation Electronique

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196871

Fax: +32-25196919

www.cenelec.org

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015 7

Page 8

CAUTION

SW2: Pilot selection (On = Intermittent, where pilot

remains on during burner cycle; Off = Interrupted, where

pilot valve closes after main burner is established).

■ To avoid electric shock, shut off the power supply

when installing or removing any control device.

Flame monitoring systems must be installed by a

qualified, licensed technician.

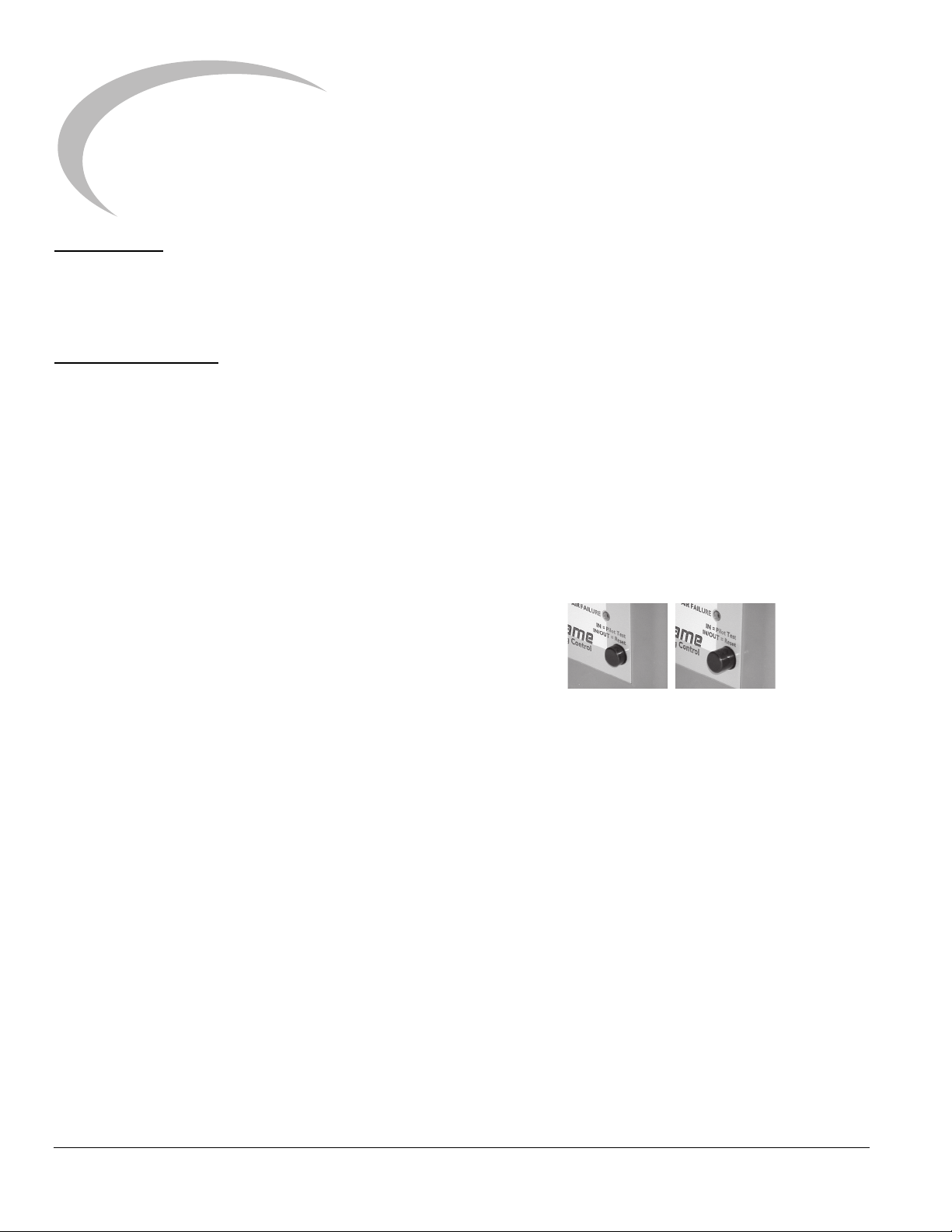

DIP Switch Location

All of the DIP switches are located in the back of each

Veri-Flame unit (see Figure 3.1 on page 11, or the

photograph on page 7).

DIP Switch Access

To gain access to the DIP switches, the Veri-Flame must

be separated from the back box (for visual reference,

please refer to “Dimensions” on page 9). This separation

will expose the DIP switches on the back of the VeriFlame unit.

No Purge DIP Switch Settings

No Purge models of the Veri-Flame only use three of the

eight DIP switches, as shown in the labels in Figure 3.2 on

page 11. They are as follows:

SW1: Recycling mode selection (On = Recycling; Off =

Non-recycling)

SW3: Trial-for-ignition (TFI) range selection (For 5602/

5603 units: On = 10 seconds; Off = 5 seconds. For 5605

units: On = 10 seconds; Off = 15 seconds).

Modulation and Purge DIP Switch Settings

Modulation and purge models of the Veri-Flame use all of

the eight DIP switches, as illustrated in Figure 3.2 on page

11. They are as follows:

SW1: Recycling mode selection (On = Recycling; Off =

Non-recycling)

SW2: Pilot selection (On = Intermittent, where pilot

remains on during burner cycle; Off = Interrupted, where

pilot valve closes after main burner is established).

SW3: Trial-for-ignition (TFI) range selection (For 5602/

5603 units: On = 10 seconds; Off = 5 seconds. For 5605

units: On = 10 seconds; Off = 15 seconds).

SW4 through 7: Purge time selection. Total purge time is

the sum of each switch selected. If all are set off, the trial

for ignition starts when the air switch input comes on.

SW8: Post purge selection. (On = 15 second post purge).

Close-up of DIP switches on

back side of all Veri-Flame models.

Figure 3.1. DIP Switch Location

8

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 9

No Purge Models

c us

Purge Models Modulation Models

c us

c us

Figure 3.2. DIP Switch Labels with Selections

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

9

Page 10

Function Summary

4

Introduction

This section describes the features of the Veri-Flame. It is

divided into three categories: standard features, optional

features and the LED indicator lights on the front cover.

Refer to Figure 5.5 for sequence diagrams.

Standard Features

The following function features are standard on the VeriFlame models as noted:

Interlocks and Limit Switch Input (Terminal 7)

This input is considered the normal operation control or

run input to the Veri-Flame system. Interlocks are

generally pressure or temperature switches which, when

activated, start the burner. Limit switches are generally

pressure, temperature and other switches which, when

activated, stop the burner. The interlocks and limit

switches are wired in series. A break in this circuit will shut

the burner down, but will not produce an alarm.

Combustion Air Switch Input (Terminal 6)

For purge and modulation models: This input is for

monitoring the combustion air switch separately from

other interlocks and limits. The Veri-Flame checks the air

flow switch input is open before start-up, closed during

operation, and open again at burner shutdown, thus

preventing operation with an air switch that is defective,

maladjusted or jumped. This input has about a 2 second

delay to filter out and ignore a momentary interruption.

The input will be proven open before start-up and after

shutdown.

If the input is improperly powered before the fan output is

energized, the system error light will blink. The input must

de-energize within 30 seconds or the Veri-Flame will

lockout.

After the fan output has energized, the air switch input

must be made within 10 seconds. If not proven, then the

system will lockout, the alarm output and the air failure

light will come on. However, if the unit has the optional air

switch input hold feature, the sequence is held indefinitely

without causing a lockout. When the air switch input is

made, then the sequence continues.

Main Fuel Valve Closed Switch (Terminal V)

For purge and no-purge models: The Veri-Flame can be

interlocked with the main valve closed switch. This feature

checks the switch position before start-up and after

shutdown to insure proper valve operation when the

jumper on the base is cut.

Low Fire Start

For modulation models: When wired, the system checks

for the low fire start position prior to light-off.

Main Fuel Valve Closed / High Fire Purge Check

(Terminal D)

For modulation models: This feature is enabled when the

jumper on the base is cut. The system checks that the

high fire position switch and the main valve closed switch

are both made at the end of the high fire purge.

Recycle Mode

Test Mode

(Button In)

For all models: When selected, the Veri-Flame will restart

the sequence after flame or air failure. The recycle mode

allows the system to re-initiate the start-up sequence

automatically provided the main burner has been

operating for at least 35 seconds. If the pilot flame fails to

light during recycling, the system will lock out and

annunciate a pilot flame fail. If the recycle is successful

and the main burner is operational for at least 35 seconds,

the system is ready for another recycle. At no time will the

system recycle in the event of pilot flame fail.

Run Mode

(Button Out)

If the air switch opens during the main firing cycle, the

system will either lockout or recycle, depending on the

DIP switch recycle selection.

10

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 11

Pilot Test Mode

For all models: This mode is entered by depressing the

TEST/RESET button on the front cover. In the pilot test

mode, the Veri-Flame will hold the sequence once the

pilot flame is established (i.e., the main valve is not

energized). When in the pilot test mode, the green

“Interlocks Closed” light blinks.

To exit the pilot test mode, push the TEST/RESET button

three times (the green “Interlocks Closed” light stops

blinking but remains lit) and the Veri-Flame will restart the

sequence.

Interrupted or Intermittent Pilot

For all models: Pilot mode is selected using the DIP switch

SW2. An interrupted pilot shuts off 10 seconds after the

main valve opens. An intermittent pilot continues during

the entire main flame firing cycle.

Post Purge

For purge and modulation models: Post purge is enabled

by DIP switch SW8. A post purge maintains the

combustion air fan output for 15 seconds after the

interlocks and limit switch input have opened.

Spark, Pilot, Flame and Main Flame Separation

For all models: During the trial for ignition period (TFI), the

pilot valve and ignition coil remains energized. If a flame

signal is present at the end of the TFI, the pilot output

remains on and the ignition coil is de-energized. After a

five second delay to prove the pilot flame, the main gas

valve is energized.

System Errors and Lockout Conditions

A system error (illuminated by the red “System Error” LED

on the front cover) prevents gas ignition. The unit will

continue its sequence after the error is cleared. A lockout

condition energizes the alarm output and de-energizes

the gas valve and ignition outputs. The unit must be reset

to clear the alarm and start the sequence. To reset, the

button must be pressed twice so that the button is in the

out position.

The following system errors result in immediate lockout

conditions:

5. High fire fail (for modulating model)–high fire switch

is not closed at the end of high fire purge.

6. Air failure (for purge and modulation models) – loss

of combustion air anytime during the operational

cycle. The Air Failure LED will be on for this

condition. (See “Recycle Mode” on page 13.)

7. Pilot flame fail (for all models) loss of flame during

the trial for pilot ignition period. The Flame Failure

LED will be on for this condition.

8. Main flame fail (for all models) loss of flame during

the main burner trial for ignition or run period

(recycling not selected). The Flame Failure LED will

be on for this condition.

The following result in lockout conditions after 30

seconds, the system error light blinks about 14 times and

then remains on:

9. If a flame is detected out of sequence, which may

be caused by:

a. A faulty scanner (for all models)

b. Electrical interference on the sensor wiring (for

all models)

c. A flame exists in the burner or in the line of sight

of a scanner, due to a gas leak, product fire or

other conditions (for all models)

10. Air flow switch closed before start-up (for purge

and modulation models).

High to Low Fire Purge Modulation Capability

with High to Low Fire Position Switch Interlocks

For modulation models: The modulation feature

incorporates a high fire purge time and a low fire purge

time into the purge sequence. This feature allows the VeriFlame to sequence internal dry contacts which can be

used by the customer requiring a high fire purge of the

combustion chamber before ignition.

The high fire and low fire purge times are selectable by

means of DIP switches (see Section 3, “DIP Switch

Settings” on page 10):

SW4 15 seconds SW6 60 seconds

SW5 30 seconds SW7 120 seconds

1. Wiring error which puts external voltage on the

output terminals (for all models).

2. Welded internal contacts or other malfunctions in

the Veri-Flame (for all models).

3. Main fuel valve (for all models)–open after cycle

shut down or before start-up. The system error light

blinks twice and then remains on. The fan output

terminal 8 will energize.

4. Low fire fail (for modulating model)–low fire switch

open prior to trial for ignition.

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

The selected times are additive and apply to both the high

fire and low fire purge times (that is, high and low fire times

are always identical).

11

Page 12

The modulation terminals will sequence as follows:

Sequence Step Internal Contact Connections

Power Off Terminal 10 (Common) Terminal 12 (Low Fire)

Power On, Limits Open Terminal 10 (Common) Terminal 12 (Low Fire)

Purge to High Fire Terminal 10 (Common) Terminal 13 (High Fire)

Purge to Low Fire Terminal 10 (Common) Terminal 12 (Low Fire)

Automatic Modulation Terminal 10 (Common) Terminal 11 (Auto)

Alarm & Lockout Terminal 10 (Common) Terminal 12 (Low Fire)

The purge to high fire sequence does not start until the air

switch input is on. The Automatic step occurs when the

burners are operating and allows the burner firing rate to

be controlled by an automatic temperature controller.

Optional Features

The following features are available on select models, or

when optional equipment is purchased.

Air Switch Input Hold

For purge models: Holds the sequence indefinitely until air

switch input is confirmed without affecting the air failure

function and causing a lockout.

Remote Display and Power Supply

The model 5602DBP operates on 120 VAC and has a

keypad for reset function. The display is door panel

mounted and features a liquid crystal display in a 1/4 DIN

housing. The unit connects to the Veri-Flame by a cable to

the flame signal test jack, and receives a serial

communication on each sequence state change. The

display incorporates the following functions:

1. Provides status messages for the Veri-Flame

sequence (see section 9).

2. Indicates lockout conditions when they occur, as

well as the amount of time into the sequence when

the lockout occurred (see section 9).

3. Provides continuous monitoring of the burner’s

flame signal strength and run time during main

burner operation.

Status Lights and Pushbutton

All of the status lights and the TEST/RESET push-button

are located on the front cover of the Veri-Flame. This

section describes their respective functions.

• Air Failure

For purge and modulation models: This red LED

illuminates whenever combustion air is lost during

the operational cycle of the Veri-Flame.

• System Error

For all models: This red LED illuminates when a

system error is detected (see “System Errors &

Lockout Conditions” on pages 13).

• Flame Failure

For all models: This red LED illuminates when a pilot

or main flame fails.

• Low Fire

For modulation models: This yellow LED illuminates

during the low fire period of the purge cycle.

• High Fire

For modulation models: This red LED illuminates

during the high fire period of the purge cycle.

• Auto

For modulation models: This green LED illuminates

during the automatic period which occurs 20

seconds after the main valve is energized.

• Test/Reset

For all models: This push-button is used to activate

the pilot test mode or to reset the Veri-Flame unit.

• Flame Signal

For all models: This red LED is located behind the

signal test port and illuminates when a flame signal

is present.

• Interlocks Closed

For all models: This green LED illuminates when the

operation limits are made. These limits are wired in

series to terminal 7. This input becomes energized

to begin the burner sequence. When in the test

mode, this LED blinks (see “Pilot Test Mode” on

page 13).

12

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 13

r

r

System Installation

5

Introduction

This section describes the necessary procedures to

integrate a Veri-Flame into a burner system. Figures 5.1

and 5.2 illustrate the various terminal strips mentioned.

NOTE: Shut off the power supply before the Veri-Flame is

removed or replaced from the base.

CAUTION

■ Installation and maintenance must conform with

the National Electrical Code and all other national

and local codes and authorities having

jurisdiction. Flame monitoring systems must be

installed by a qualified licensed technician.

Interlocks and Limit Switch Input

Wire external interlock, control, and limit switches in

series to this input. Guard against induced voltage levels

to wiring connected to this input. In some extreme wiring

runs, reduction of induced voltages may require a load

(relay or light) connected to terminal 7 to avoid system

error lockouts. This input is the power source for the valve

and ignition output terminals. Be sure all switches wired to

this input can handle the current required by the total of all

loads connected to terminals 3, 4, and 5.

Combustion Air Switch Input

To Fan Ouput

Terminal

For purge and modulation models: Wire any switches and

contacts in series to this terminal for proving air flow

function and relating to the air failure light. Power must not

be immediately present at terminal 6 when power is first

applied to terminals 1 or 7.

If this terminal is not used, place a jumper between the

combustion blower output (terminal 8) and the air switch

input (terminal 6).

If the combustion air blower is controlled outside of the

Veri-Flame system, then a three way solenoid valve must

be connected between the air switch port and the blower

sensing port. The valve de-energized state should vent

the switch to ambient pressure. The energized state then

connects the air switch to the blower sensing port. Power

the valve from the blower output terminal 8. If accepted by

local codes, the air switch could be wired between the

combustion blower output and the air switch input.

Connecting the air switch in this manner will satisfy the

open contact (air short) check on the switch.

Ignition Wiring

Route ignition wiring a sufficient distance from all sensors

and other low voltage wiring to avoid electrical

interference, which may cause erratic operation of the

Veri-Flame system. Keep the high voltage wire run from

the ignition transformer as short as possible. The best

condition is to mount the ignition transformer close to the

burner and keep a low impedance path from the burner

ground to the case of the transformer. Make sure the high

voltage lead and ground return paths do not create a loop

antenna around the Veri-Flame and sensor wiring.

Low Fire Input

FAN

To Burne

3-Way Solenoid Valve

De-energized

To Fan Ouput

Terminal

FAN

3-Way Solenoid Valve

Energized

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015 13

Air

Switch

Closed

To Burne

For modulation models: It is possible to wire the system

for checking low fire start position prior to pilot ignition. To

use this feature, the low fire start switch must be

connected between terminal 3 and the pilot valve (see

Figure 5.2). On direct spark burners, a by-pass contact

must be wired around the low fire switch, see relay and

contact CR in Figure 5.3.

Main Valve Closed Switch

The system can be wired to check for the main valve

closed switch on the main gas valve prior to start-up and

after the end of the burner cycle.

Page 14

For purge and no purge models: The main valve closed

switch must be connected to Terminal V and the jumper in

the base must be cut (see Figure 5.4).

For modulation models: The main valve closed switch

must be wired in series between the air flow switch and

the high purge damper switch (see Figure 5.1). To use this

feature, the jumper in the base must be cut.

High Purge Input

For modulation models: The system can be wired to check

for high purge position during the high fire purge portion of

the sequence. To use this feature, the red jumper in the

base must be cut and the high purge position switch must

be connected from terminal 6 to D. If this feature is not

used, the jumper in the base remains intact or a jumper

must be installed between terminals 1 and D. Please note

that the yellow jumper on the base has no effect whether

cut or intact.

Remote Reset

This feature permits remote mounting of a switch to reset

the Veri-Flame. To use this feature, a normally closed

remote reset switch must be wired so power is interrupted

to terminal 1. When it is depressed or actuated, the

connection to terminal 1 is momentarily interrupted and

resets the Veri-Flame.

Remote Display and Power Supply

Wire the display according to Figure 5.3. Mount through a

1/4 DIN cutout using the two supplied brackets in either

the top and bottom or the side slots. Locate the display

and wiring to minimize electrical interference. Applying

and disconnecting the display power supply should

coincide with power to terminal 1 of the Veri-Flame. Use

the appropriate cable (Eclipse part number 20318) to

connect to the test jack and to the S2 terminal of the VeriFlame wiring base. Do not attempt to parallel the test jack

signal to other devices when using a remote display. The

LCD display contrast can be adjusted on the back with a

small blade screwdriver.

NOTE: Power for terminal 7 of the Veri-Flame must not

flow through the R1-R2 contact of the remote display

when load currents exceed 5 amps.

Notes for Figures 5.1, 5.2 and 5.3 below:

1. Ground, shielding and conduit must not be

connected to terminal S2.

2. Control circuit wires must meet 90°C (194°F)

specification minimum and must be number 16

AWG or larger and in accordance with all applicable

codes.

3. Flame sensor wires must be individually run in their

own separate conduit; flame sensor wires

CANNOT be run together in a common conduit or

wireway (See Section 6).

4. Flame signal should read between 4 and 10 VDC

with a digital volt meter. Drop off is approximately

4.0 VDC. Positive test jack point is on the cover

marked “Flame Signal” with negative point being

the S2 or ground.

5. Purge time, TFI, intermittent/interrupted pilot, and

recycle/non-recycle selections are made with a DIP

switch located on the rear plate of the control unit.

6. Neutral must be grounded.

14

15 A

Fuse

On/Off

Interlocks & Limits

No Purge Models Purge Models

5602/5605:

120 VAC

50/60 HZ

Proof of

Closure

240 VAC

50/60 HZ

1

Piloted Burner

2

3

4

5

7

A

V

S1

S2

5603:

Pilot

Ignition

Main

Alarm

15 A

Fuse

5602/5605:

120 VAC

50/60 HZ

On/Off

Air Flow Switch

Interlocks

& Limits

Proof of Closure

S1

S2

Figure 5.1. No Purge and Purge Wiring Diagram

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

5603:

240 VAC

50/60 HZ

1

2

3

4

5

6

7

8

A

V

Piloted Burner

Pilot

Ignition

Main

Fan

Alarm

Page 15

5602/5605:

120 VAC

50/60 HZ

5603:

240 VAC

50/60 HZ

15 A. Fuse

Air Flow

To Activate

Terminal D.

Interlocks

& Limits

Proof of

Closure

On/Off

Cut Red

Jumper

High Purge

Damper

Switch

1

2

3

4

5

6

7

8

A

D

S2

S1

10

11

12

13

G

Flame

Sensor

Terminals

Common

Automatic

Low Fire

High Fire

Low Fire Proving

Pilot

Ignition

Main

Fan

Alarm

See the

chart below

for contact

connections.

Figure 5.2. Modulation Wiring Diagram

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

15

Page 16

Self Check UV 5602-91

(Requires 5602-91-7 cable)

Model 5602 DBP

120 VAC Remote Display

2

1

S1

S2

A

B

C

D

Self-Check UV 5602-91

(Requires 5602-91-7 cable)

for 240 VAC Veri-Flame

2

1

S1

S2

T1

Third party transformer required. Must be at least 25 VA.

T1

240V

120V

A

B

C

D

No Purge & Purge

Direct Spark

3

4

IGNITION

S1

Blue (Signal)

S2

Yellow (Neutral)

UV

UV

Scanner

5

NOTE:

Intermittent pilot must be

selected, DIP-SW2 = ON

12V

MAIN

12V

Tx Rx

-

+

Cable

#20318

NOTE:

Power for terminal 7 must not flow

through the R1-R2 contact when load

currents exceed 5 amps.

120V

120V

N

to 120 VAC

L

R1 R2

G

PLUG

To 1

Flame Signal

Test Jack

To S2

Veri-Flame

Flame Rod

S1

Blue

Flame Rod

S2

Modulation

Direct Spark with

Low Fire Start

Neutral

Low Fire Proving

3

CR

4

5

NOTE:

Intermittent pilot must be selected, DIP-SW2 = ON

CR is a control relay used to bypass the low fire

switch after the burner is lit.

CR

MAIN

IGNITION

Neutral

16

Figure 5.3. Typical Connections for All Models

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 17

Model Number 5602-10P Model Number 5602-10-1P

P3

3

6

2

1

1

3

2

1

4

6

4

P3

P2

P1

Jumper

P2

5

6

S2

S1

7

8

P1

3

4

Jumper

V

2

1

A

Internal Diagram

Purge & No-purge

P1 P1

5

P1

P3

P3

P2

6

3

J1

Fan

Alarm

Fault

P1

Pilot

P3

Ign

P3

Main

P3

Supervisor

1

7

V

6

2

1

8

2

A

4

6

3

4

5

3

5

Model Number 5602-40

3

2

1

1

3

2

1

Gnd

12345678AD 11121310S2 S1

6

P3

4

P2

6

P1

4

Jumper

5

6S2S17 8 A 1 2 V 4 3

Modulating Base

1

1

J2J1

S2

P2

1

S1

NOTE: No-purge models do not use 6 & 8.

Flame

Signal

Amplifier

Jack

Internal Diagram

Modulation Model

P1 P1

5

1

6

Alarm

Fault

P1

3

7

22K

22K

D

P3

6

2

P2

2

2

S2

P2

1

S1

J2

10

4

Fan

P3

4

Flame Signal

1

2

Red

P1

4

Pilot

P3

6

Ign

P3

5

Main

P3

3

Supervisor

Amplifier

J2

2

J2

1

J2

3

Auto

Low

High

8

A

3

4

5

Jack

11

12

13

Figure 5.4. Purge and No Purge Base

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

17

Page 18

Outputs

Inputs

Terminal

1

3

4

5

7

V

Function

Control Power

Pilot Valve

Ignition

Main Valve

Interlocks

POVC

Start

TFI

Pilot

Trial

Flame

Check

Pilot Off

(Interrupted)

35 Seconds

Main

Trial

10 Sec

Recycle

Permitted

Firing

Cycle

Pilot Off

(Intermittent)

End

Outputs

Inputs

Outputs

Inputs

Continuity

Between

Modulation

Terminals

Terminal

1

3

4

5

8

6

7

V

Terminal

1

3

4

5

8

6

7

D

3

10 to 12

10 to 13

10 to 11

Function

Control Power

Pilot Valve

Ignition

Main Valve

Fan

Air Switch

Interlocks

POVC

Function

Control Power

Pilot Valve

Ignition

Main Valve

Fan

Air Switch

Interlocks

High Fire & POVC

Low Fire Switch

Low Fire Purge

High Fire Purge

Automatic

Start

10

Sec

Start

10

Sec

Air Proven

Purge

Air Proven

High Fire

Purge

TFI

Pilot

Trial

Flame

Check

5 Sec

Low Fire

Purge

35 Seconds

Main

Trial

10 Sec

Pilot Off

(Interrupted)

Recycle

Permitted

Firing

Cycle

Flame

Check

TFI

5 Sec

Pilot

Trial

Pilot Off

(Intermittent)

Post

Purge

15 Sec

Main

Trial

10 Sec

20 Seconds

35 Seconds

End

Pilot Off

(Interrupted)

Firing Cycle

Recycle

Permitted

Pilot Off

End

(Intermittent)

Post

Purge

15 Sec

18

Figure 5.5. Sequence Diagrams

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 19

Sensor Installation

6

Introduction

This section describes the proper wiring, installation and

sighting considerations for all sensors that can be used

with a Veri-Flame.

WARNING

■ Incorrect sensor installation may cause the sensor

to generate a false flame signal, possibly resulting

in the collection of unburned fuel in the

combustion chamber. This unburned fuel creates

the potential for explosions which can result in

injuries, death and property damage. Be certain

that the flame sensor detects acceptable pilot and

main flames only.

Sensor Wiring

Route sensor wiring a sufficient distance from ignition and

other high voltage or high current wiring to avoid electrical

interference. Interference from ground currents, nearby

conductors, radio-frequency emitters (wireless devices),

and inverter drives can induce false flame signals.

Shielded cables can help reduce interference with the

shield connected to ground at the control end only. The

wire type and its capacitance (picofarads or microfarads)

to ground may cause low signal problems, so a grounded

shield may decrease the signal due to the cable’s internal

capacitance. Multiple UV tube-type sensor leads run

together without shielding may interfere or “cross talk”, so

the shield or flexible armor must be grounded to prevent

this situation. For flame rod sensor running approximately

30 meters (100 feet) or greater, use Eclipse part number

21741 coax cable. To achieve the maximum wiring

distance, the shield should not be grounded (keep in mind

that an ungrounded shield provides less protection

against electrical interference).

NOTE: Unshielded sensor wiring must not be run in

common with other wires; it must be run in separate

conduit. Multiple unshielded flame sensor wiring must not

be run together for long lengths in a common conduit or

wireway. Use number 14 to number 18 AWG wire suitable

for 90°C (194°F) and 600 volt insulation, or a better grade

if required by the application. Multiple shielded flame

sensor cables can be run in a common conduit.

Flame Rods

WRONG

Rod Detects

Weak Pilot

PILOT

Figure 6.1. Flamerod Position

Flame rods should be used only on gas burners. They

accumulate soot from oil burners, causing nuisance

shutdowns and unsafe operating conditions.

See the burner manufacturer’s literature for flamerod

mounting location. When installing flame rods, please

consider the following:

1. Keep the flamerod as short as possible and at least

13 mm (1/2 inch) away from any refractory.

2. Position the rod into the side of both the pilot and

main flames, preferably at a descending angle to

minimize drooping of the flamerod against burner

parts, see Figure 6.1. Flamerod position must

adequately detect the pilot flame at all burner draft

conditions. Extend the rod 13 mm (1/2 inch) into

non-luminous flames, such as blue flames from

burning an air/gas mixture. For partially luminous

flames, such as atmospheric air/gas mixtures,

place the rod at the edge of the flame.

3. Provide a burner/flame grounding area that is at

least four times greater than the flamerod area

contacting the flame. The flamerod/burner ground

ratio and position of the rod in the flame may need

adjustment to yield maximum flame signal strength.

4. Ignition interference from the spark plug may

increase or decrease the flame signal strength.

Reversing the ignition transformer primary leads

may reduce this effect. Changing the spark gap or

adding grounding area between the flamerod and

spark plug may eliminate the interference.

CORRECT

Rod Detects

Only Strong

Pilot Flame

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015 19

Page 20

WARNING

■ Use only Eclipse scanner models as listed in the

Illustrated Parts List at the end of this document.

Scanners

When installing scanners, please consider the following:

1. Position the scanner within 457 mm (18 inches) of

the flame. Consult factory for longer distances.

2. Bushing threads are 1/2" FNPT for all scanner

models except 5602-91 which has 1" FNPT

bushing threads.

3. The ambient temperature limits of each scanner

varies; check the literature for the specific scanner

model. For higher temperatures, use Eclipse heat

block seal 23 HBS for 1/2" NPT. scanners and if

necessary, add cooling purge air.

4. An optional magnifying lens may also be used to

increase the flame signal strength in difficult

sighting situations.

Scanner Sighting Considerations

MAIN

BURNER

Scanner

Sight

Line

SCANNER

1/3 of

Flame Length

Figure 6.2.

Aim scanners at the third of the flame closest to the burner

nozzle, see Figure 6.2 (oil flames typically have less UV

radiation in the outer flame). The scanner should view the

intersection of the pilot and main flames. When sighting

scanners, please consider the following:

1. If possible, sight the scanner away from the ignition

spark. Sighting the spark or its reflections from

burner internals may lead to a misdiagnosis of

shutdowns during burner ignition. If necessary, use

a scanner orifice to reduce spark pickup.

2. Do not allow the scanner to detect a pilot flame that

is too small to ignite the main burner.

3. Perform a minimum pilot test when installing or

adjusting any pilot or main burner system; see

“Minimum Pilot Test”.

20

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 21

Test Procedures

7

Introduction

This section describes the test procedures that must be

performed after installation to insure that the Veri-Flame is

operating properly; these procedures are mandatory.

Flame Signal Strength

Insert the positive probe of a 0-15 VDC, digital volt meter

into the test point on the front cover of the Veri-Flame;

connect the negative probe to S2 or ground. A good flame

signal strength will read between 6 and 11 VDC; anything

below 4 VDC is inadequate. Also, the red LED inside the

test point illuminates when a flame signal is indicated.

Minimum Pilot Test

Run the following test procedures to ensure that the

sensor will not detect a pilot flame too small to reliably light

the main flame:

1. Manually shut off the fuel supply to the burner, but

not to the pilot.

2. Start the system normally.

3. To enter the pilot test mode, depress the test/reset

button located in the lower right corner on the front

cover.

4. The control will hold the operating sequence at the

pilot flame step. Measure signal strength as

described above.

5. Reduce pilot fuel until the flame relay drops out.

Increase pilot fuel until the flame signal is greater

than 4 VDC, and flame relay just manages to pull in.

This is the minimum pilot. If you don’t think this

flame will be able to safely light the main burner,

realign the sensor so that it requires a larger pilot

flame and repeat steps 2 through 5.

6. Push the test/reset button located in the lower right

corner on the front cover to exit the test mode

(reset) and begin the normal start-up sequence

again.

7. When the sequence reaches the main flame trial for

ignition, smoothly restore the fuel supply to the

burner. If the main burner does not light within five

seconds, immediately shut off the burner supply to

shut down the system. Realign the sensor so that it

requires a larger pilot flame. Repeat steps 1

through 6 until the main burner lights off smoothly

and reliably.

Pilot Flame Failure Test

1. Manually shut off the fuel supply to the pilot and the

main burner.

2. Place system in pilot test mode (please refer to

page 13).

3. Start the system normally. The controller should

lock out*; if it doesn’t, then the controller is

detecting a false flame signal (see Section 6). Find

the problem and correct it before resuming normal

operation.

Main Flame Failure Test (For Interrupted

Pilot Systems)

1. Manually shut off the fuel supply to the main burner

but not to the pilot.

2. Start the system normally. This should ignite the

pilot and lock out* after pilot interruption. If the

system does not lock out, the controller is detecting

a false flame signal (see Section 6). Find the

problem and correct it before resuming normal

operation.

Spark Sighting Test

1. Manually shut off the fuel supply to the pilot and the

main burner.

2. Start the system normally.

3. Measure the flame signal as described in “Flame

Signal Strength” in this section.

4. If a flame signal greater than 4 VDC is measured for

more than three seconds during the trial for ignition,

then the sensor is picking up a signal from the spark

plug; see “Sensor Wiring”. It is not necessary to

correct a spark sighting condition for a Veri-Flame

when the ignition transformer is connected to

terminal 4.

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015 21

Page 22

Limits and Interlocks Test

Periodically check all interlock and limit switches by

manually tripping them during burner operation to make

sure they cause the system to shut down.

WARNING

■ Never operate a system that is improperly adjusted

or has faulty interlocks or limit switches. Always

replace faulty equipment with new equipment

before resuming operation. Operating a system

with defective safety equipment can cause

explosions, injuries, and property damage.

*Indicated by the illuminated red “Flame Failure” LED on

the Veri-Flame front cover.

22

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 23

Maintenance and

Troubleshooting

8

Introduction

This section is divided into two parts. The first part

describes the maintenance procedures, and the second

part helps you to identify problems that may occur and

gives recommendations on how to solve these problems.

Preventative maintenance is the key to a reliable, safe

and efficient system. The following are suggested

guidelines for periodic maintenance. Burners in severe

environments or operational conditions should be

checked more frequently.

NOTE: The monthly and yearly lists are an average

interval. If your environment is dirty, then the intervals may

be shorter. Check with local authorities having jurisdiction

on their recommended maintenance schedules.

CAUTION

■ Turn off the power to the burner and controls

before proceeding with burner inspection.

Monthly Checklist

1. Inspect flame-sensing devices for good condition

and cleanliness. Keep scanner lenses clean with a

soft, damp cloth, since small amounts of dust will

measurably reduce the flame signal strength. Wash

the flamerod electrode and insulator with soap and

water, then rinse and dry thoroughly.

2. Test all the alarm systems for proper signals.

3. Check ignition spark electrodes and check proper

gap.

4. Test interlock sequence of all safety equipment as

described on page 25: manually make each

interlock fail, noting what related equipment closes

or stops as specified by the manufacturer.

5. Test flame safeguard by manually shutting off gas

to the burner.

Yearly Checklist

1. Test (leak test) safety shut-off valves for tightness

of closure.

2. Test pressure switch settings by checking switch

movements against pressure setting and

comparing with actual impulse pressure.

3. Visually check ignition cable and connectors.

4. Make sure that the following components are not

damaged or distorted:

• the burner nozzle

• the spark plugs

• the flame sensors

• the flame tube or combustion block of the burner

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015 23

Page 24

Troubleshooting

Problem Possible Cause Solution

Cannot initiate a start

sequence

Scrambled messages on the

remote display

"Unsafe Air Short" message

appears on the display

Burner flame fails but no

flame failure indication

occurs

Voltage reading is greater

than 15 VDC at "Test Point"

on Veri-Flame faceplate

Main valve is not closed

Check the main valve closed switch.

No voltage on V (or D)

Check the air pressure switch adjustment

Check the air filter

Air pressure switch has not made contact

Check the blower rotation

Check the outlet pressure from the blower.

No voltage on 6 after 8 is on

Check the incoming gas pressure; adjust

the gas pressure if necessary

High pressure gas switch has tripped

Check the pressure switch setting and

operation

No voltage to 7

Check the incoming gas pressure; adjust

the gas pressure if necessary

Low gas pressure switch has tripped

Check the pressure switch setting and

operation

No voltage to 7

Malfunction of the flame safeguard system

such as a short-out flame sensor or

Have a qualified electrician troubleshoot

and correct the problem

electrical noise in the sensor line

Purge cycle not completed

Main power is off

No power to the control unit

Check the switch setting

Check the air switch

Make sure the power to the control system

is on

Have a qualified electrician troubleshoot

and correct the problem

Check the grounding in the system.

Electrical interference

Separate the communication cable.

Move the ignition circuit.

Improperly adjusted air switch Check the air switch settings

Air switch either shorted or it is wired

Check the wiring to the air switch

incorrectly

A faulty scanner

Improperly connected sensor wires

Electrical interference from other current

carrying wires

Check the scanner as explained in the

"Maintenance" section above

Check the wiring diagram in the "System

Installation" chapter of this manual

See Figures 5.1, 5.2, 5.3 and their

associated notes in the "System

Installation" chapter of this manual

Check grounding of neutral at the control

Improper grounding

power transformer

24

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 25

LED Status

This section describes the status of operating conditions based on the LED or combination of LEDs which are lit on the

front cover of each Veri-Flame model.

LED Status and Conditions for Veri-Flame No Purge Models

LED(s) Lit Possible Cause

Interlocks Closed The interlocks are closed (normal operation), power on terminal 7.

System Error 1. The flame detected is out of sequence, flame signal light is on.

2. The sensor is “runaway,” flame signal light is on.

3. Inductance is detected on sensor wires, flame signal light is on.

4. Voltage wired into terminals 3, 4, or 5.

5. Internal relay contacts welded.

6. Internal controller failure.

7. Main valve closed switch defective, no power to V.

Flame Failure 1. Pilot flame is not established in selected TFI.

2. Main flame is not established in selected TFI.

3. Main flame fails within 35 seconds of TFI.

4. Flame failed during operation in non-recycle mode.

5. Flame failed 35 seconds after TFI and was not established after try in recycle mode.

No Purge Model

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

25

Page 26

LED Status and Conditions for Veri-Flame Purge Models

LED(s) Lit Possible Cause

Interlocks Closed The interlocks are closed (normal operation), power on terminal 7.

System Error 1. The flame detected is out of sequence, flame signal light is on.

2. The sensor is “runaway”, flame signal light is on.

3. Inductance is detected on sensor wires, flame signal light is on.

4. Voltage wired into terminals 3, 4 or 5.

5. Internal relay contacts welded.

6. Internal controller failure.

7. Air flow switch closed before start-up.

8. Main fuel valve switch opens after shutdown or before start-up, no power to V.

Flame Failure 1. Pilot flame is not established in selected TFI.

2. Main flame is not established in selected TFI.

3. Main flame fails within 35 seconds of TFI.

4. Flame failed during operation in non-recycle mode.

5. Flame failed 35 seconds after TFI and was not established after one try in recycle mode.

Air Failure 1. Air flow switch not closed within ten seconds of start-up.

2. Air flow switch is open during timing cycle.

3. Air flow switch is open during firing cycle.

26

Purge Model

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 27

LED Status and Conditions for Veri-Flame Modulation Models

LED(s) Lit Possible Cause

Interlocks Closed The interlocks are closed (normal operation), power on terminal 7.

System Error 1. The flame detected is out of sequence, flame signal light is on.

2. The sensor is “runaway”, flame signal light is on.

3. Inductance is detected on sensor wires, flame signal light is on.

4. Voltage wired into terminals 3, 4 or 5.

5. Internal relay contacts welded.

6. Internal controller failure.

7. Air flow switch closed before start-up.

8. Main fuel valve switch opens after shutdown or before start-up, no power to V.

Flame Failure 1. Pilot flame is not established in selected TFI.

2. Main flame is not established in selected TFI.

3. Main flame fails within 35 seconds of TFI.

4. Flame failed during operation in non-recycle mode.

5. Flame failed 35 seconds after TFI and was not established after one try in recycle mode.

Air Failure 1. Air flow switch not closed within ten seconds of start-up.

2. Air flow switch is open during timing cycle.

3. Air flow switch is open during firing cycle.

Interlocks Closed and

Auto

Interlocks Closed and

High Fire

Interlocks Closed and

Low Fire

Burner in run mode, firing rate determined by automatic controller (normal operation).

Purge high sequence (normal operation).

Purge low sequence (normal operation).

Modulation Model

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

27

Page 28

Remote Display

9

Messages

Introduction

This section describes how the optional remote display is used with the Veri-Flame. The remote display provides LCD

messages which monitor the status of the Veri-Flame’s functions as well as any lockout conditions. This section is

divided into two parts or tables:

Veri-Flame Operating Sequence

This section describes the start-up and shutdown monitoring sequences of the Veri-Flame and how the progress (or halt)

of the sequence can be monitored by the messages on the remote display.

POWER ON

REMOTE DISPLAY

NORMAL MESSAGE

REVISION X.X

ERROR MESSAGE #1

UNSAFE FLAME ON

Fan is energized. If signal is eliminated

within 30 seconds, sequence

continues. If not, then . . .

ERROR MESSAGE #2 – 30 SECONDS AFTER #1

UNSAFE FLAME ON

XX:XX:XX LOCKOUT

Alarm energized.

FOR PURGE & MODULATING

UNSAFE AIR SHORT

If switch is opened within 30 seconds,

sequence continues. If not, then . . .

ERROR MESSAGE #2 – 30 SECONDS AFTER #1

UNSAFE AIR SHORT

XX:XX:XX LOCKOUT

SAFE START OK

Check_Sum = XX

FAN ENERGIZED

Was internal safe start check successful?

YES NO

EXTERNAL INTERLOCK CHECKS

Is ame signal present?

YES NO

Is voltage present at air ow switch?

ERROR MESSAGE #1

Alarm energized.

NORMAL MESSAGE

NORMAL MESSAGE

YES NO

Is voltage present at interlock switch?

YES NO

LIMITS OPEN

TIME = XXXX:XX:XX

Holds until answer is yes.

Various lockout messages

Is main valve closed switch made?*

YES NO

ERROR MESSAGE

MAIN VALVE FAIL

XX:XX:XX LOCKOUT

ERROR MESSAGE

28

Fan output is energized; modulator is

sent to low re.

BURNER START-UP

(see next page)

* Applies to purge and no purge models only.

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 29

BURNER START-UP

Is voltage present at air flow switch

within ten seconds?

NO PURGE MODELS

PURGE MODELS

NORMAL MESSAGE

AIR PROVEN

Purge based on selected time.

NORMAL MESSAGE

PILOT TRIAL FOR

IGNITION

Spark and pilot valve energized

for selected trial for ignition.

Is voltage present at air switch . . .

YES NO

ERROR MESSAGE

AIR NOT PROVEN

XX:XX:XX LOCKOUT

MODULATION MODELS

NORMAL MESSAGE

AIR PROVEN

NORMAL MESSAGE

PURGE TO HIGH FIRE

Modulator sent to high fire for

selected purge time.

NORMAL MESSAGE

PURGE TO LOW FIRE

Modulator sent to low fire for

selected purge time.

Is voltage present at air switch . . .

YES NO

ERROR MESSAGE

AIR NOT PROVEN

XX:XX:XX LOCKOUT

Is voltage present

at high purge switch?

YES NO

ERROR MESSAGE

HI DAMPER FAIL

XX:XX:XX LOCKOUT

Is low fire switch closed?

YES NO

ERROR MESSAGE

LOW FIRE FAIL

XX:XX:XX LOCKOUT

NORMAL MESSAGE

PILOT FLAME ON

Flame signal detected

NORMAL MESSAGE

PILOT FLAME XX.XV

TIME = XXXX:XX:XX

Spark turns off at end of TFI;

sequence delayed 5 seconds.

Is flame signal present?

YES NO

Is flame signal present?

PILOT FLAME FAIL

ERROR MESSAGE

XX:XX:XX LOCKOUT

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

29

Page 30

BURNER START-UP (continued)

Is ame signal present?

YES

NORMAL MESSAGE

MAIN FLAME ON

NO

MAIN FLAME FAIL

ERROR MESSAGE

XX:XX:XX LOCKOUT

NORMAL MESSAGE

MAIN FLAME ON

PILOT OFF

Pilot will shut o 10 seconds after

main ame is energized.

MODULATION MODELS

PURGE & NO PURGE MODELS

IF Interrupted Pilot is selected IF Intermittent Pilot Is Selected

NORMAL MESSAGE

AUTOMATIC

MODULATION

Modulator sent to automatic 20

seconds after main valve is

energized.

NORMAL MESSAGE

MODULATION MODELS

BURNER ON XX.XV

TIME = XXXX:XX:XX

PURGE & NO PURGE MODELS

Main ame of burner is proven.

Flame signal = XX.XVolts DC;

elapsed time is shown in hours:

minutes:seconds.

Is ame signal present?

YES

NO

NORMAL MESSAGE

MAIN FLAME ON

Was the main ame on more

than 35 seconds?

YES

NO

ERROR MESSAGE

AIR FAILURE

RECYCLING

Unit returns to beginning

sequence.

Is air switch signal on?

YES

NO

Is recycle selected?

YES

NO

AIR FAILURE

XX:XX:XX LOCKOUT

ERROR MESSAGE

Was the main ame on more

than 35 seconds?

YES

NO

ERROR MESSAGE

MAIN FLAME FAIL

RECYCLING

Unit returns to beginning

sequence.

Is recycle selected?

YES

NO

MAIN FLAME FAIL

XX:XX:XX LOCKOUT

ERROR MESSAGE

30

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

Page 31

BURNER SHUTDOWN

Shutdown is started by opening

the operating interlock circuit.

Is voltage present at interlocks?

Continued operation.

POST PURGE

XX

Fuel valves de-energized; fan

energized for 15 seconds.

FOR PURGE & MODULATING

ERROR MESSAGE #1

UNSAFE AIR SHORT

If switch is opened within 30

seconds, sequence

continues. If not, then ...

ERROR MESSAGE #2 – 30 SECONDS AFTER #1

UNSAFE AIR SHORT

XX:XX:XX LOCKOUT

Alarm energized.

NORMAL MESSAGE

YES NO

Is post purge selected?

YES NO

Is main valve closed switch made?*

YES NO

YES NO

ERROR MESSAGE #1

UNSAFE FLAME ON

Fan is energized. If signal is

elimi-nated within 30 seconds,

sequence continues. If not, then. . .

ERROR MESSAGE #2 – 30 SECONDS AFTER #1

UNSAFE FLAME ON

XX:XX:XX LOCKOUT

Alarm energized.

MAIN VALVE FAIL

ERROR MESSAGE

XX:XX:XX LOCKOUT

Fan energized; alarm sounds.

YES NO

NORMAL MESSAGE

LIMITS OPEN

TIME = XXXX:XX:XX

* Applies to purge and no purge models only.

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

31

Page 32

Remote Display Diagnostic Messages

This section alphabetically lists and explains the diagnostic messages which can appear on the remote display.

Message Type Explanation

Air Failure

XX:XX:XX Lockout

Lockout

Air Failure Recycling

Status

Air Not Proven

XX:XX:XX Lockout

Air Proven

Automatic Modulation

Lockout

Status

Status

Burner on XX.XV

Time = XXXX:XX:XX Status

D-Internal Fail

XX:XX:XX:XX Lockout

Fan Energized

Flame Failure

XX:XX:XX Lockout

HI Damper/POVC

XX:XX:XX Lockout

K-Internal Fail

XX:XX:XX Lockout

L-Internal Fail

XX:XX:XX Lockout

Limits Open

Time = XXXX:XX:XX

Low Fire Fail

XX:XX:XX Lockout

Main Flame Fail

XX:XX:XX Lockout

Main Flame Fail

Recycling

Main Flame ON

Main Flame ON

Pilot OFF

Lockout

Status

Lockout

Lockout

Lockout

Lockout

Status

Lockout

Lockout

Status

Lockout

Status

For purge & modulation models: Combustion air flow limit switch opened

for more than two seconds once initially proven.

For purge & modulation models: Combustion air flow limit switch opened;

if “recycle” has been selected, the Veri-Flame will restart the sequence

after air failure (see “Recycle Mode” on page 13).

For purge & modulation models: Combustion air flow limit switch did not

make within ten seconds of fan being energized.

For purge & modulation models: Combustion air flow limit switch closed

within ten seconds of fan being energized.

For modulation models only: Modulating motor is sent to automatic

operation.

Main flame of burner is proven in the automatic modulation mode; flame

strength is XX.XV (volts DC). Elapsed time is shown in

hours:minutes:seconds.

For modulation models only: Internal control failure; replace controller.

For purge & modulation models: Blower motor is energized at the start of

pre-purge.

Main flame lost during operation in the automatic modulation mode.

For modulation models only: High damper or high purge rate switch did not

make at the end of pre-purge to high fire.

Internal control failure; replace controller.

Internal control failure; replace controller.

The controller has completed its internal checks and is standing by for the

interlocks to close.

For modulation models only: Low fire switch is open just prior to pilot trial

for ignition.

Main flame was not established during the main burner trial for ignition.

Main flame lost during automatic modulation; control will recycle once if

“recycle” has been selected.

Main valve has been energized and main flame proven during trial for

ignition.

Pilot valve is de-energized and main flame is on.

Main Valve Fail

XX:XX:XX Lockout

Pilot Flame Fail

XX:XX:XX Lockout

Pilot ON

Pilot Trial for Ignition

32

Lockout

Lockout

Status

Status

Eclipse Veri-Flame Single Burner Monitoring System, Model 5600, V1, Installation Guide 818, 1/15/2015

For purge and no purge models: Main valve closed switch is open before

start-up or after burner shutdown.

Pilot flame was not established during the pilot trial for ignition.

Pilot flame is proven; transformer is de-energized; remaining countdown

for pilot trial for ignition is.

Pilot valve and ignition transformer are energized; countdown for pilot trial

for ignition begins.

Page 33

Message Type Explanation

Post Purge