Page 1

854 Instruction Manual

C

US

10/11/2010

UV Scanner

Model 5600-91

Introduction

This sensor features a high temperature and high

sensitivity ultraviolet (UV) tube for monitoring gas or oil

flames in applications that cycle on and off frequently. The

scanner is UL listed for USA and Canada, and FM

approved when used with Eclipse model 5600 and VF56

series Veri-Flame, model 6000 Multi-Flame, model 6500

Bi-Flame, or series 7000 Peek-A-Flame. This product is

also in conformance with the "CE Mark" Directives when

used with the model VF56 Veri-Flame CE as listed in its

Instruction Manual 818-2. It comes with a 6 ft flexible

metal cable and an insulated coupling.

The UV tube is made of quartz and is filled with a gas that

surrounds two electrodes. These electrodes are

energized continuously by a high voltage. The gas acts as

an insulator in the absence of UV radiation. Combustion

produces UV radiation to ionize the gas and causes

current pulses to flow between the electrodes. These

current pulses result in a flame signal which is transmitted

to the amplifier in the control, where it is processed to

energize and hold in the flame relay.

Specifications

Parameter Specification

Part Number 49600-91

Spectral

Response

Supply

Voltag e

Supply

Current

Wiring 6 foot (183 cm) flexible 3/8" metal conduit

Temperature

Range

Materials Housing: Aluminum

Shipping

Weight

Options Magnifying lens (Part #49600-98)

185 to 260 nm

495 ± 55VDC

0.3 mA

with two #18 AWG conductors

0° to +257°F (-20° to 125°C)

Conduit: Plated Steel

Insulated Coupling: PBT Polyester, Glass

Reinforced

13 oz. (360 grams)

Heat Block Seal 23HBS (Part #400011)

Page 2

Sensor Installation

CAUTION

CAUTION

■ Incorrect sensor installation may cause the sensor

to generate a false flame signal. This can cause

unburned fuel to collect in the combustion

chamber, resulting in explosions, injuries, and

property damage. Be certain that the flame sensor

detects only the pilot and/or main flame of the

intended burner by testing the control system

under varying operating conditions and firing

rates. Follow the test procedures given in this

manual and the equipment provider’s instructions

after installation and at regularly scheduled

maintenance intervals.

Sensor Wiring

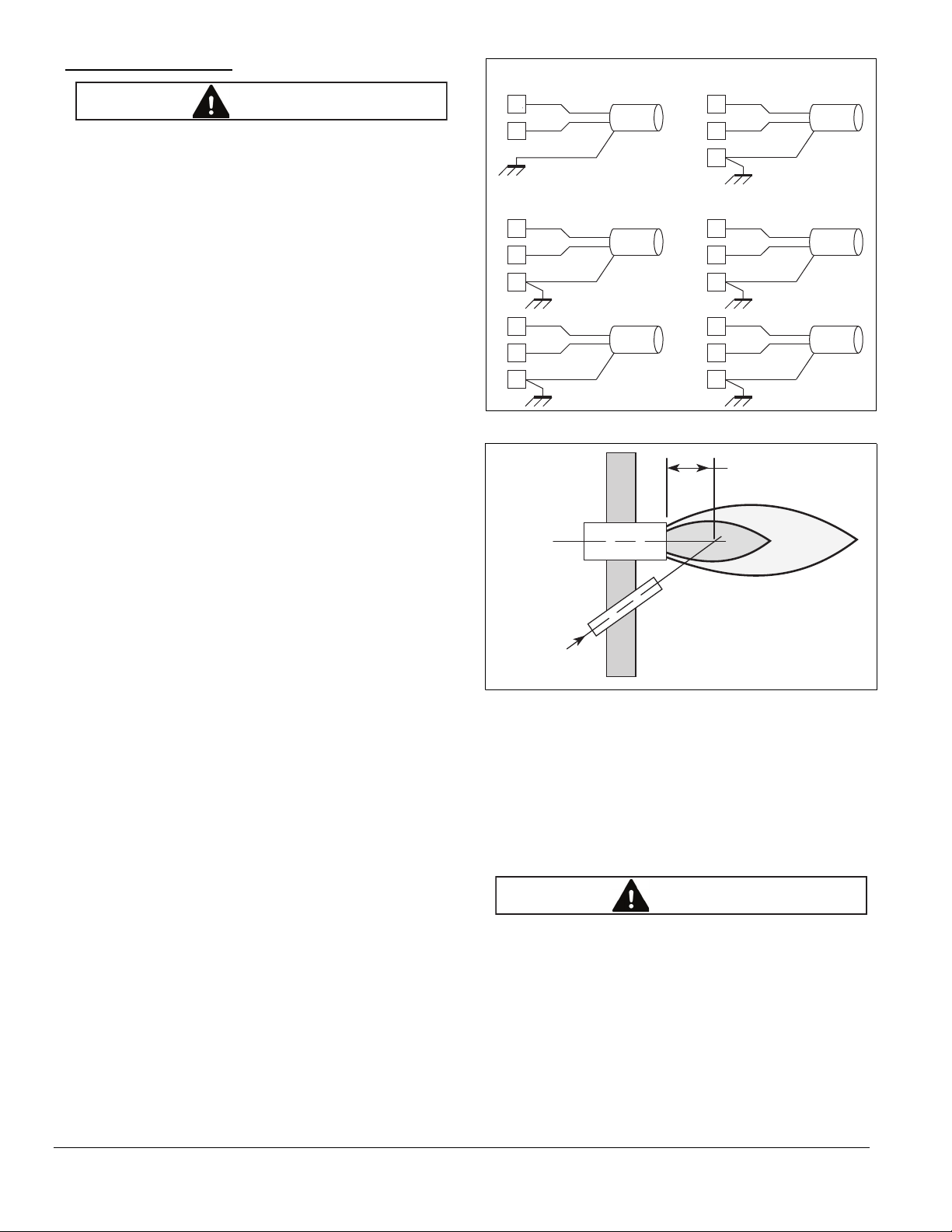

Veri-Flame

Blue

S1

S2

Yellow

Multi-Flame

Blue

3

2

Yellow

4

Blue

9

8

Yellow

10

Scanner

Conduit

Scanner

Conduit

Scanner

Conduit

Peek-A-Flame

Blue

7

8

Yellow

2

Bi-Flame

Blue

J4

3

2

Yellow

4

Blue

J5

1

2

Yellow

4

Scanner

Conduit

Scanner

Conduit

Scanner

Conduit

Route sensor wiring a sufficient distance from ignition and

other high voltage wiring to avoid electrical interference.

Some areas may have high levels of electromagnetic

fields or ground currents that require the use of special

cables, isolation and grounding methods. Figure 1

illustrates the sensor wiring to appropriate Eclipse

controls. The blue wire supplies power and carries the

flame signal, the yellow wire connects to circuit common,

and the flexible metal conduit must be connected to earth

grounding.

If sensor wiring is to extend beyond the supplied 6 foot

(183 cm) length, use #14 to #18 AWG wire suitable for at

least 167°F (75°C) and 600 volt insulation.

If each scanner has its own dedicated conduit, unshielded

wiring may be used for wiring runs less than 20 feet (6 m)

and that have at least one foot of separation from ignition

and other high voltage conductors. For wiring runs greater

than 20 feet (6 m) use two-conductor shielded cable (such

as Belden #8719 or #9342, or for extreme temperatures

#83322E). For multiple burner installations, shielded

cables can be run in a common conduit. Use isolated

shielded pairs to avoid the possibility of interference

(cross-talk) between wiring of multiple scanners. The

success of wiring runs of 150 feet (45 m) or more is

dependent upon site conditions; therefore the equipment

layout should be redesigned to allow the control to be

mounted closer to the burner. For these longer wiring

runs, it may be necessary to use a pair of RG62A/U coax

cables (Eclipse #21741) per scanner, with the shielding

insulated and not grounded.

Figure 1.

One-Third of

Main

Flame Length

Burner

Scanner

Sight Line

Figure 2.

Sensor Installation

In most cases, the location for this scanner will be predetermined by the burner manufacturer. However, proper

application of this scanner requires knowledge of the

burner, the combustion chamber, and the process.

Opposing burners, flame swirl patterns, and substance in

the line-of-sight may require special mounting techniques.

■ The UV tube is fragile. Handle carefully and avoid

dropping or sharp blows.

Consult the burner manufacturer’s instructions for

mounting location. The scanner should view the

intersection of the pilot and main flames. It typically should

be aimed at the first third of the flame closest to the burner

nozzle, see Figure 2. Certain unburned hydrocarbons, oil

mist, recirculated flue gas or other contaminants may

mask and absorb the ultraviolet radiation.

2

Eclipse UV Scanner, V1, Instruction Manual 854, 10/11/2010

Page 3

Position the scanner within 18 inches (457 mm) of the

flame. Longer distances are allowed, but could limit the

field of view and may reduce the turndown or firing range

of the burner.

Mount the scanner to a 1/2" NPT pipe nipple to the burner.

Insure that the scanner body does not exceed 257°F

(125°C) from conducted, radiated, or ambient heat. To

protect from high temperatures, use the insulated

coupling (#49099) with a heat block seal (#400011) and

source of clean purging air (5 CFM typical), or a purge

assembly constructed with a 1/2" WYE fitting.

Keep the scanner lens and line-of-sight free of

contamination. Be aware that scanners looking up are

susceptible to dirt and dust settling. Soot, steam, and

unburned hydrocarbons may reduce or even mask the

radiation from the flame. A purging assembly as described

above may alleviate these problems.

and Enter buttons together then release the Reset and

after a few seconds release the Enter.

3. Start the system normally. The control will hold the

operating sequence at the pilot flame step.

4. Measure the flame signal strength as described above.

5. Slowly reduce the pilot fuel until the signal drops out.

Increase the pilot fuel slightly and restart the system.

Observe the flame signal and adjust the pilot fuel as

required to prevent flame failure. This is the minimum

pilot.

6. Take the control out of the pilot test mode and begin the

start-up sequence again. On the Veri-Flame push the

Test/Reset button again so that it pops out to the Run

position. On the Bi-Flame and Multi-Flame press the

Reset button.

Some burners have an open construction allowing the

scanner to view into a furnace. Avoid sighting background

sources of UV light. If necessary, mask the offending

background source by use of an orifice, the magnifying

lens assembly (#49600-98), or a combination of both to

reduce the field of view.

Two model 5600-91 scanners may be installed on one

burner when necessary to view different areas of the

flame to obtain reliable operation. The wires should be

connected in parallel.

Test Procedures

Perform the following tests for every new installation and

at periodic maintenance intervals. Depending on the

burner equipment (such as pilot versus direct spark),

some of the tests may not be possible.

Measuring Flame Signal Strength

Insert the positive probe of a 0-15 VDC voltmeter (100k

ohm minimum input impedance) into the test point on the

control cover. Connect the negative probe to the GND or

terminal for the yellow wire. Readings greater than 4 VDC

are adequate.

Minimum Pilot Test

Run this test on pilot ignited burners to ensure that the

sensor will not detect a pilot flame too small to reliably light

the main flame.

1. Manually shut off the fuel supply to the burner, but not

to the pilot.

2. Put the control in the pilot test mode. On the Veri-Flame

push the Test/Reset button in the Test position (button

in). On the Bi-Flame and Multi-Flame press the Reset

7. When the sequence reaches the main flame trial for

ignition, smoothly restore the fuel supply to the main

burner. If the main burner does not light within five

seconds, immediately shut off the burner fuel supply,

stop the control and purge the system. Attempt to light

the burner again before proceeding with adjustments in

the next step.

8. For burners with an adjustable scanner sighting

assembly, adjust the sighting assembly further away

from the nozzle of the pilot flame thus requiring a larger

minimum pilot for adequate signal strength. For

burners with fixed sighting, increase the pilot flame.

Repeat steps 1 through 8 until the main burner lights off

smoothly and reliably.

Ignition Interference Test

Test the effect of the ignition system (transformer, spark

plug, wiring and grounding) on the flame signal and

control. Ignition interference can decrease or increase the

flame signal strength or can cause erratic operation of the

control. The scanner placement on some burners allows

direct sighting of the spark, creating a strong but false

flame signal. The Eclipse flame control sequence does

not interrupt the spark upon flame detection until after the

trial for ignition period. Therefore spark detection is not a

problem; however ignition interference should still be

reduced or eliminated where possible.

1. Manually shut off the fuel supply to the burner.

2. Start the system normally. Observe the flame signal

during ignition to see if it responds during the spark.

Readings above 2 VDC indicate spark interference or

spark sighting.

Eclipse UV Scanner, V1, Instruction Manual 854, 10/11/2010

3

Page 4

3. On pilot ignited burners, manually shut off the fuel

WARNING

CAUTION

supply to the main burner. For direct spark burners,

lock the burner firing-rate at the start position.

2. Observe the flame signal as the system operates at

various firing rates under process (at temperature)

conditions.

4. Put the control in the pilot test mode (see step 2 of

Minimum Pilot Test above).

5. Start the system normally. Observe the flame signal

during spark and after the trial for ignition. Spark

interference causes the signal during the spark to differ

more than 2 VDC from the signal after the spark.

6. If spark interference is observed, try to minimize its

affect:

a. Ensure proper grounding for the ignition circuit.

b. Isolate the scanner from ground and/or remove

the shield connection from ground.

c. Check for proper spark gap.

d. Clean, repair, or replace faulty wiring and

connectors.

e. Separate or shield the scanner wiring from the

ignition wiring.

f. Reverse the wires feeding the primary to the

ignition transformer.

g. Move the location of the ignition transformer.

Pilot Flame Failure Test

1. Put the control in the pilot test mode (see step 2 of

Minimum Pilot Test above).

2. Start the system normally.

3. After the pilot has lit, manually turn off the fuel supply.

The controller should lock out of flame failure. If not,

then the controller is detecting a false flame signal.

Find the problem and correct it before resuming normal

operation.

Main Flame Failure Test

1. Put the control in the "Run" position (see step 6 of

Minimum Pilot Test above).

2. Start the system normally.

3. Perform the Main Flame Failure Test under these

conditions and verify that the control shuts down in less

than 4 seconds after visually observing that the flame

extinguished.

Limit & Interlock Tests

Periodically check all interlock and limit switches by

manually tripping them during burner operation to make

sure they cause a system to lock out.

■ Never operate a system that is improperly adjusted

or had faulty interlocks or limit switches. Always

replace faulty equipment before resuming

operation. Operating a system with defective or

bypassed safety equipment can cause explosions,

injuries, and property damage.

Maintenance

■ High voltage, turn off power before disconnecting

or installing sensors or controls.

All burner systems must be maintained to ensure their

safe operation. The operator of this equipment must be

trained in safe operating procedures. The owner and

operator must set a regularly scheduled maintenance

interval based on recommendations from the equipment

manufacturers, environmental conditions, and their own

operational history.

System Checks

Periodically test the sensors as described in "Test

Procedures".

Sensor Lens

3. After the sequence lights the main flame, manually shut

off the fuel supply. If the control does not shut down in

less than 4 seconds after visually observing that the

flame extinguished, it may be detecting a false flame

signal. Find the problem and correct it before resuming

normal operation.

Process Conditions Test

1. Start the system normally.

4

Clean the lens regularly with a soft, damp cloth. The

presence of foreign material will measurably reduce the

flame signal strength.

Rotation

To ensure operability of stored items and to reduce the

possibility of extended down-time, periodically swap spare

sensors and control units with active ones.

Eclipse UV Scanner, V1, Instruction Manual 854, 10/11/2010

Page 5

Dimensions in inches (mm)

84

(2134)

72

(1829)

3.13

(79.4)

Ø 0.63

(16)

1/2" Int.

F.N.P.T.

1/2-14

NPT

Thread

1/2-14

NPSL Thread

0.3 (9.58) MIN

Full Threads

2.5

(63.5)

0.47

(11.9)

Ø 1.13

(28.58)

Eclipse UV Scanner, V1, Instruction Manual 854, 10/11/2010

5

Page 6

854 Instruction Manual, 10/11/2010

Loading...

Loading...