Page 1

SERVICE MANUAL

5

CHANNEL I CHANNEL II

4

6

3

2

1

3

2

1

7

PROTECT

8

CLIP

9

SIGNAL

BRIDGED

100

5

CHANNEL I CHANNEL II

4

6

THERMAL

7 3

PROTECT

8

CLIP

9

SIGNAL

0

BRIDGED

10

5

4

6

THERMALTHERMAL

3

2

1

2

1

7

PROTECT

8

CLIP

9

0

5

4

0

SIGNAL

10

6

THERMAL

7

PROTECT

8

CLIP

9

SIGNAL

10

OFF

ON

OFF

ON

SWITCHING POWER MOSFET AMPLIFIER

SWITCHING POWER MOSFET AMPLIFIER

Page 2

SERVICE MANUAL PAM6100 / 4100

INDEX

PAM6100

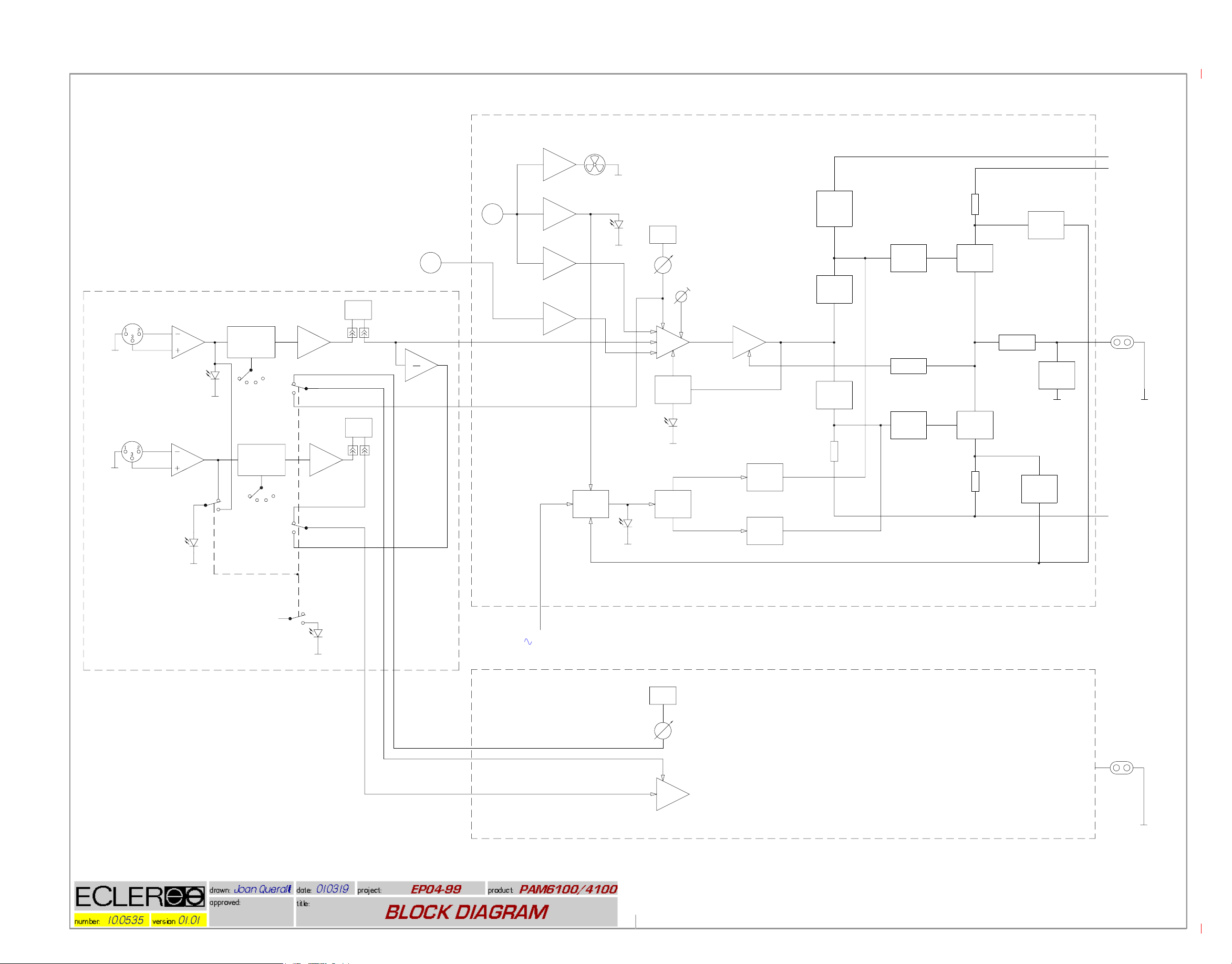

- BLOCK DIAGRAM

- FUNCTIONING DESCRIPTION

SCHEMATICS

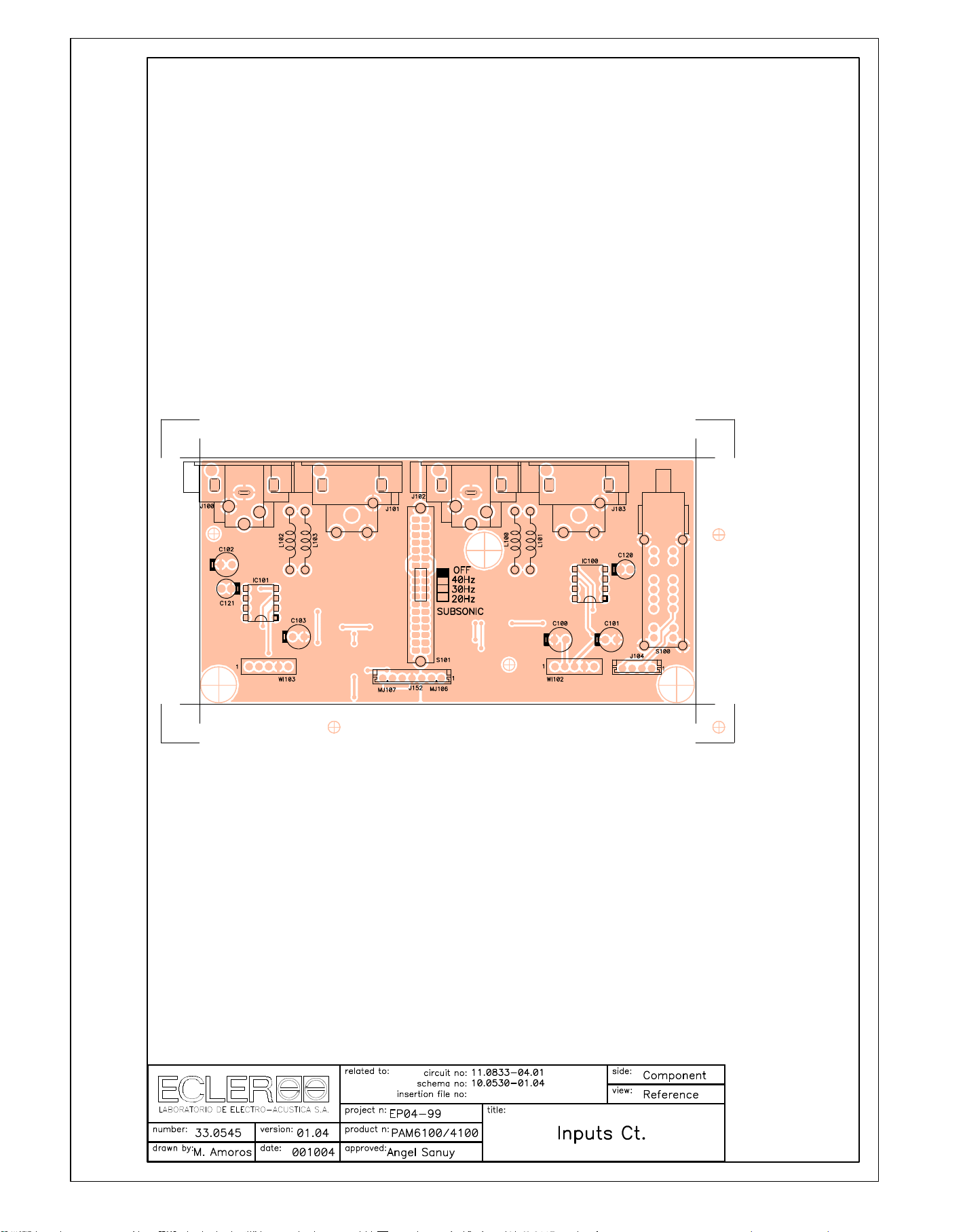

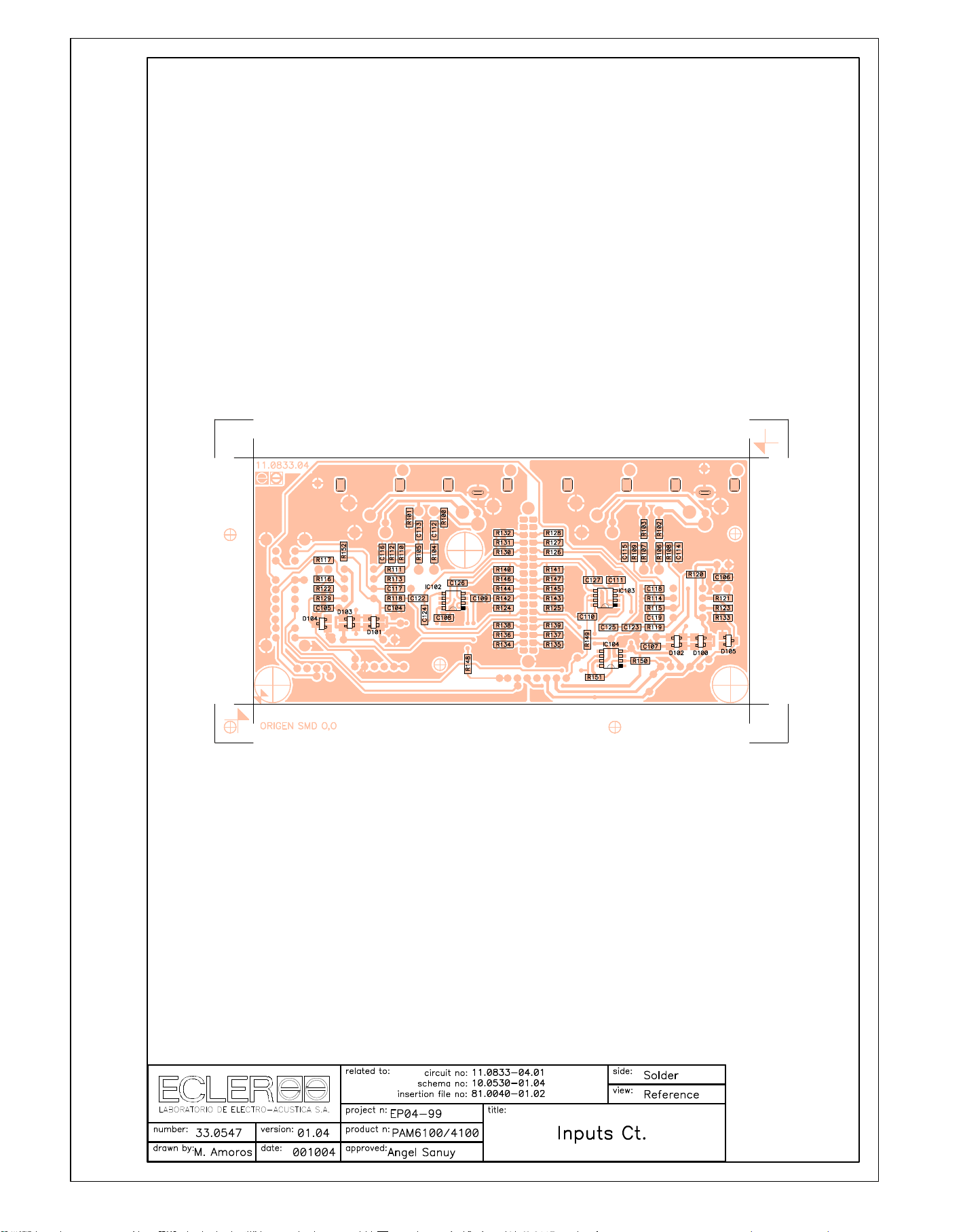

Inputs circuit

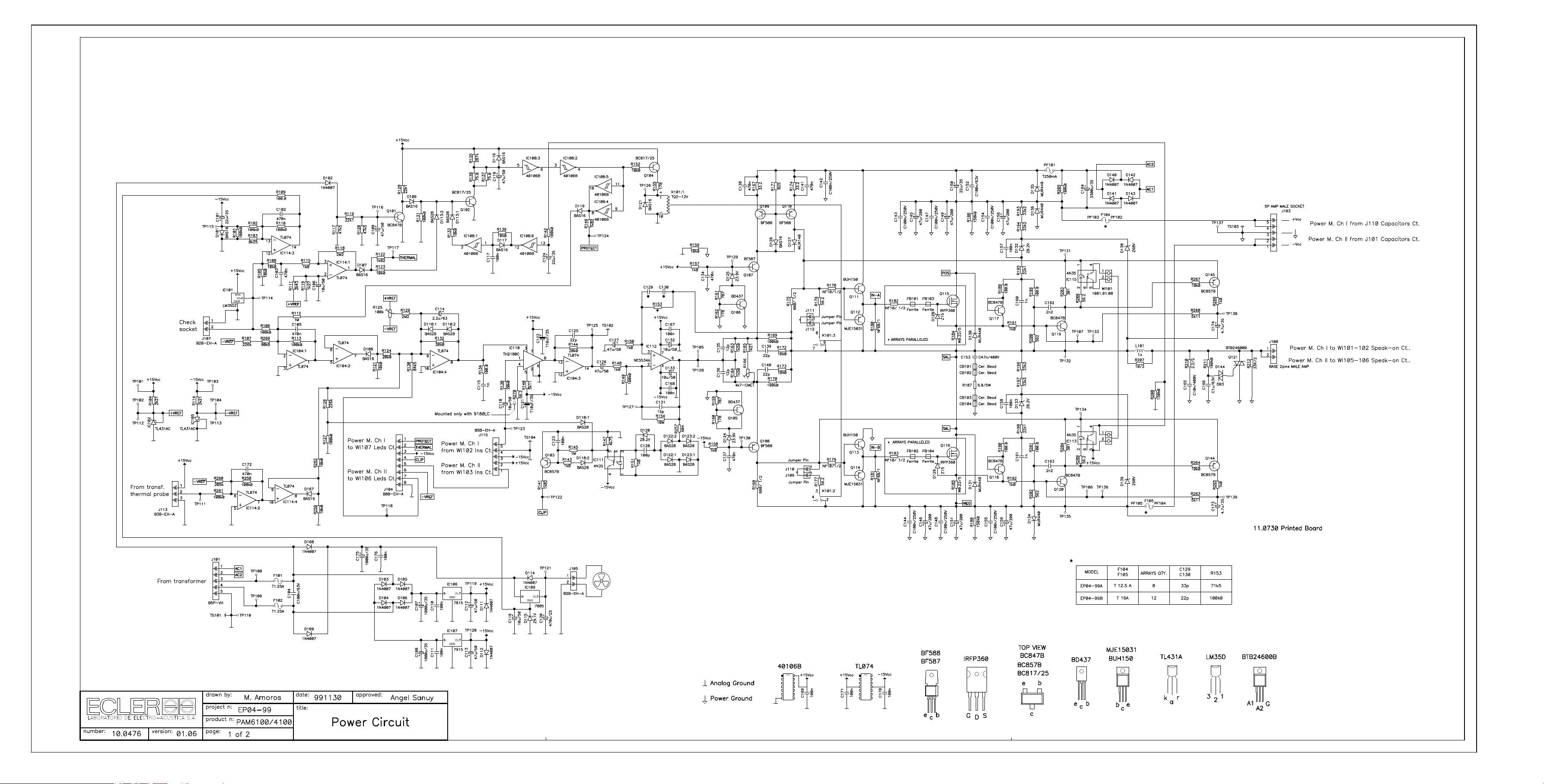

Power Amplifier circuit

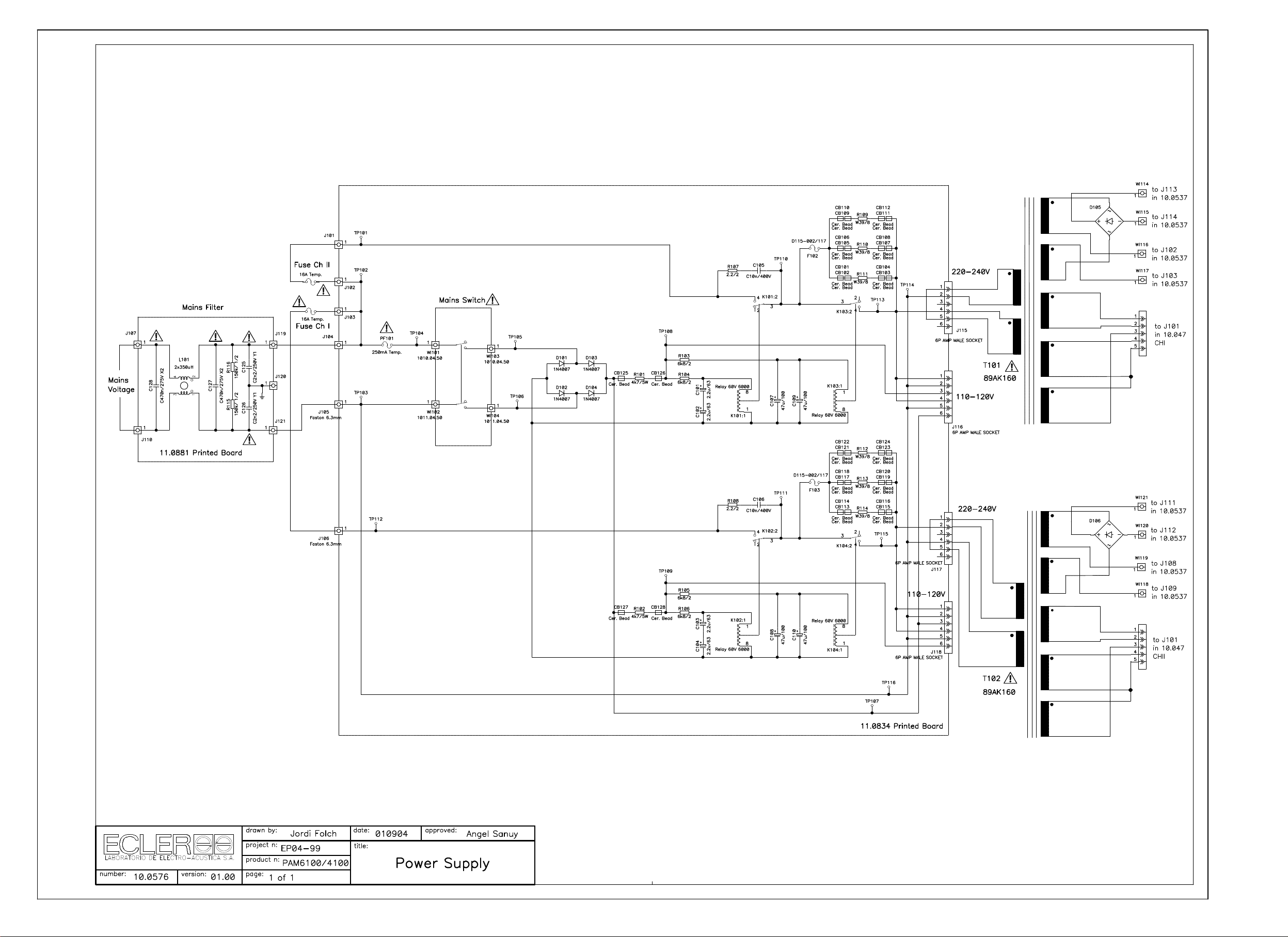

Soft-Start Power Supply circuit

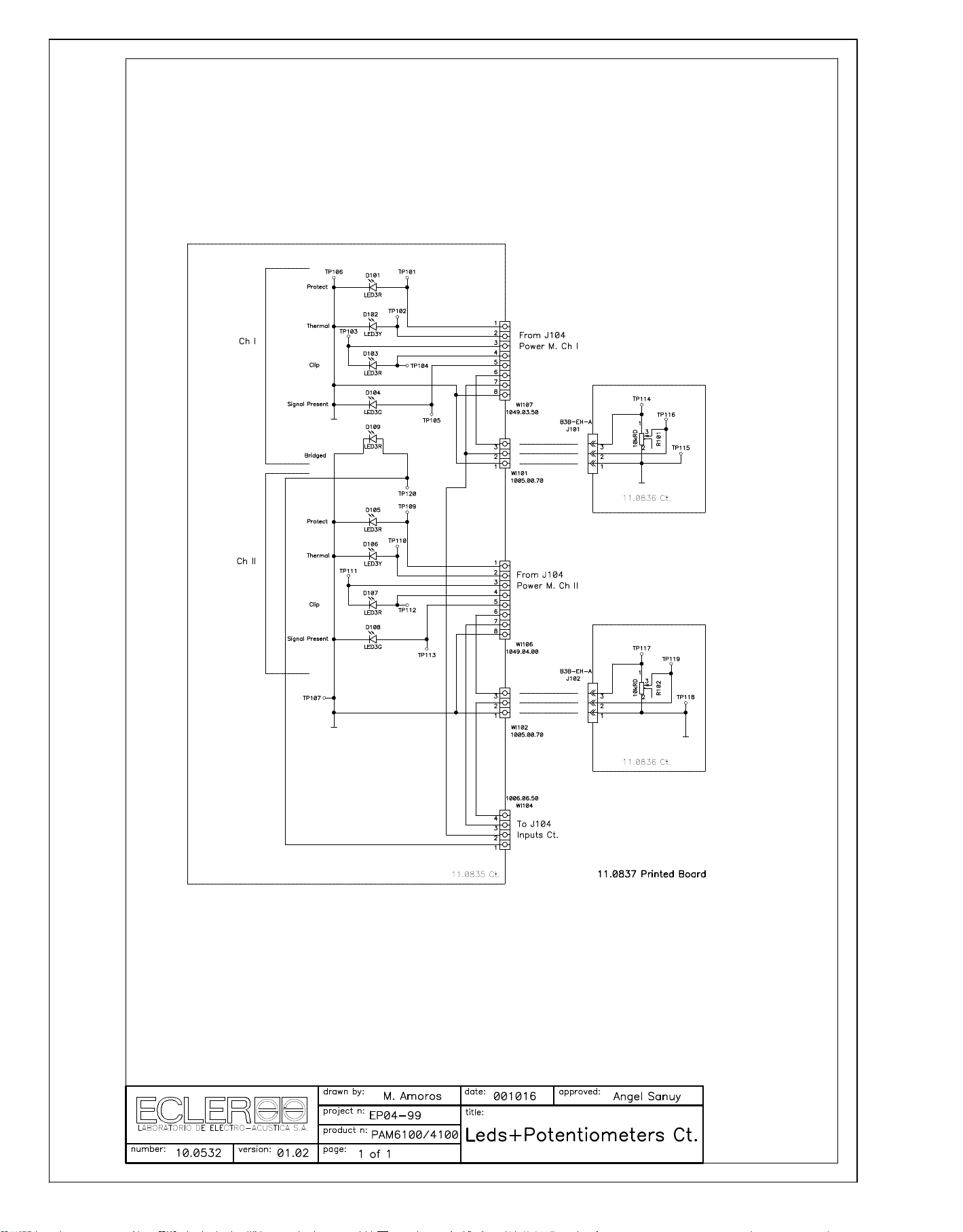

Potentiometers and leds circuit

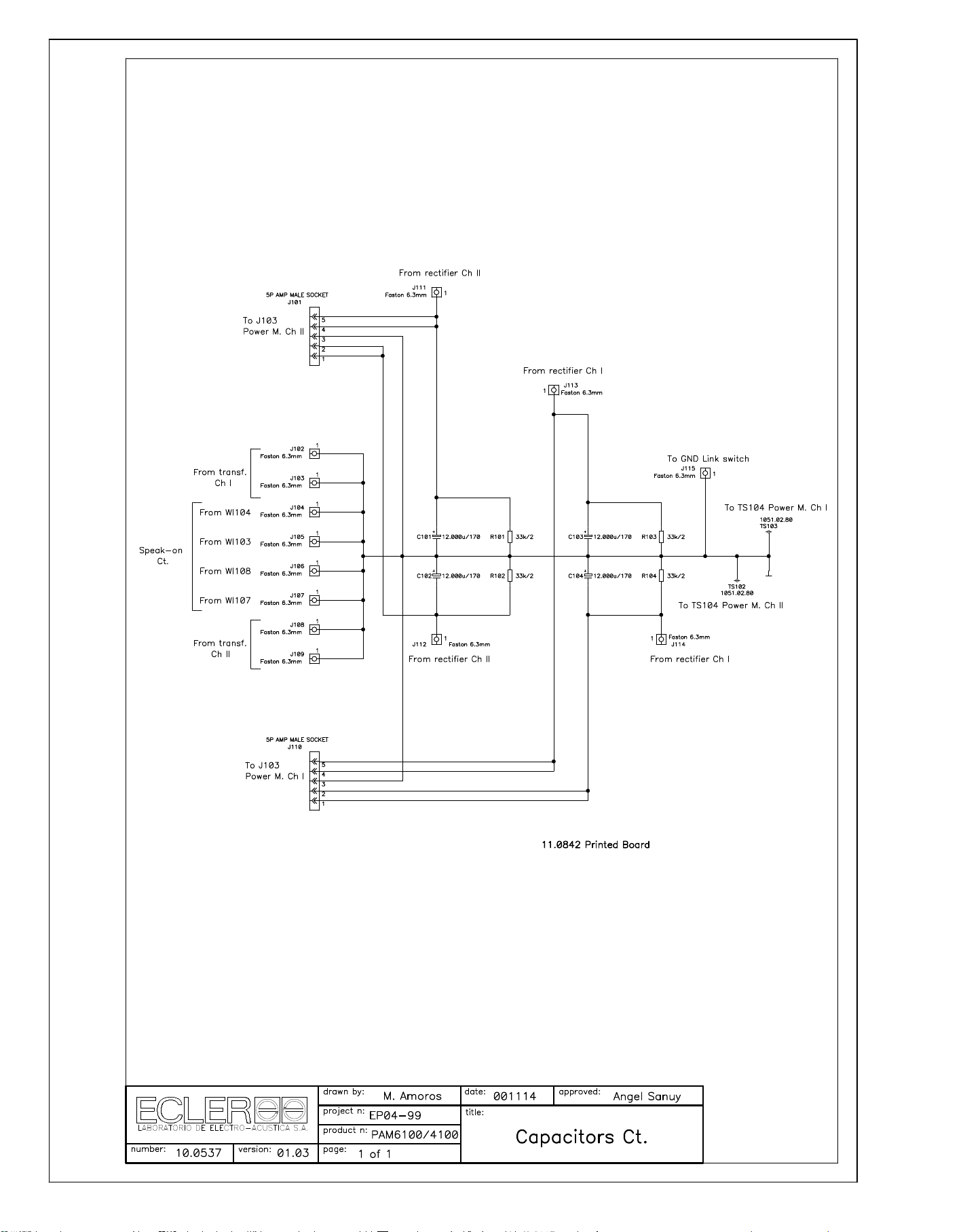

Capacitors circuit

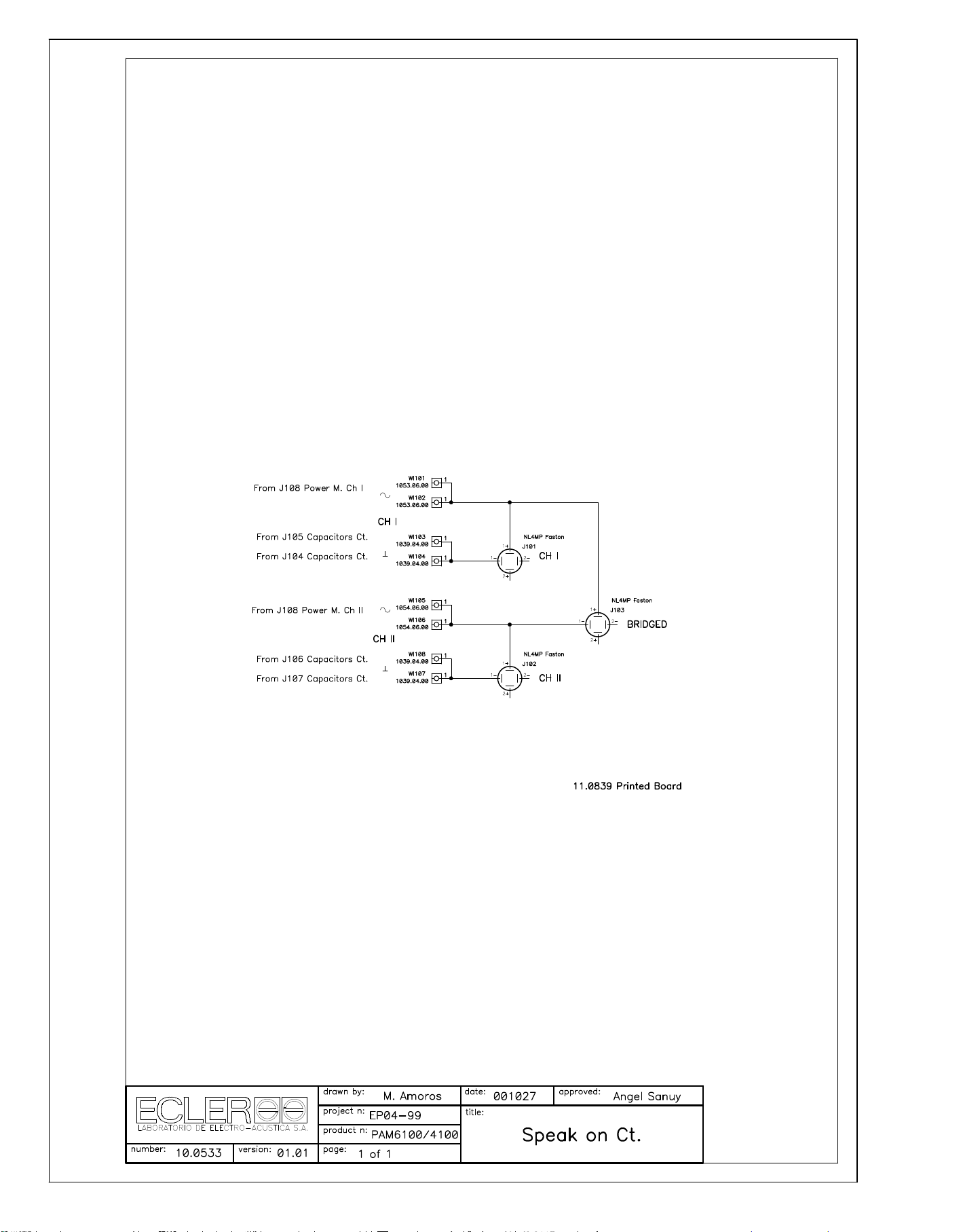

Speak on circuit

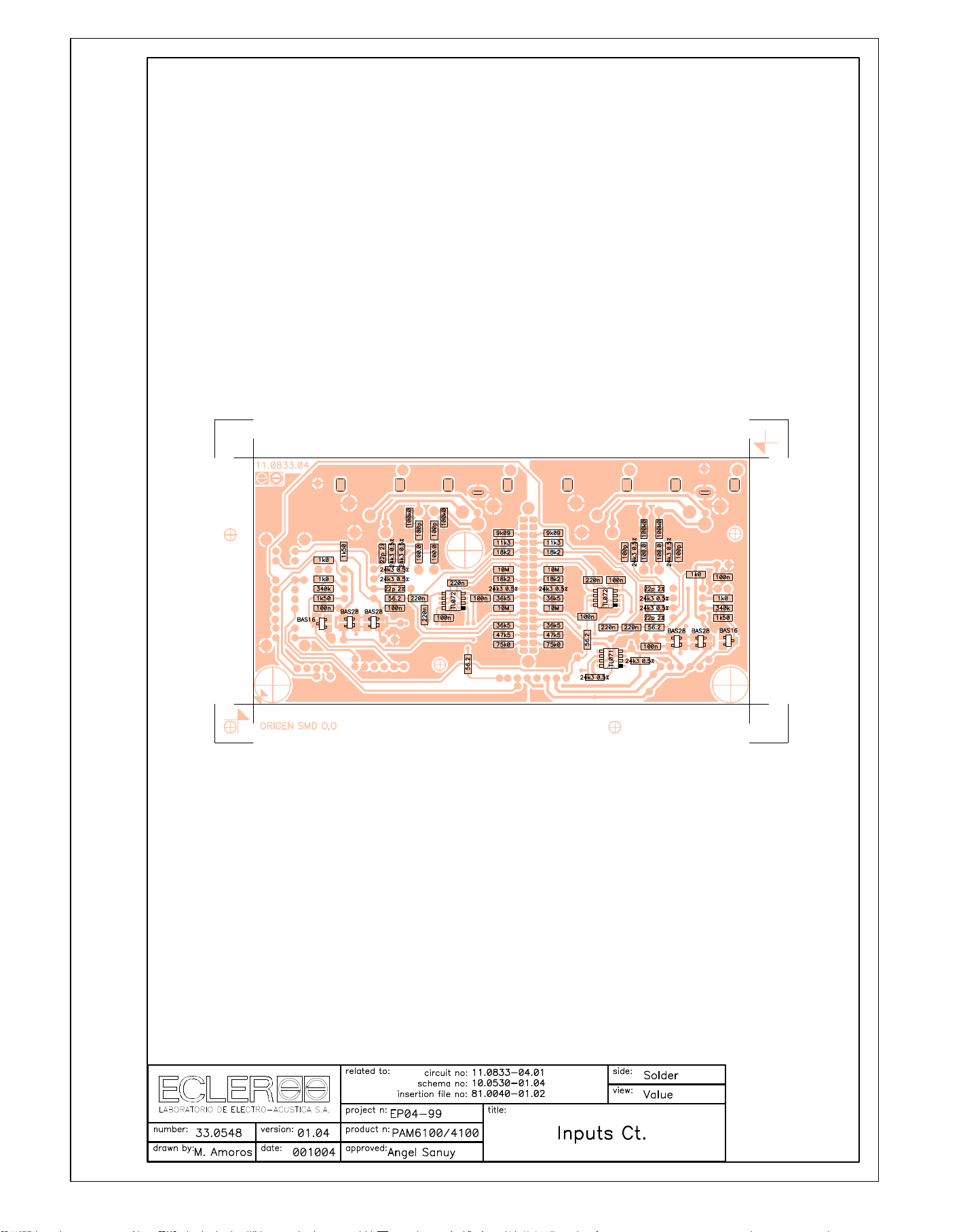

- COMPONENTS LOCATION SCHEMA

AND PARTS LIST

Inputs circuit

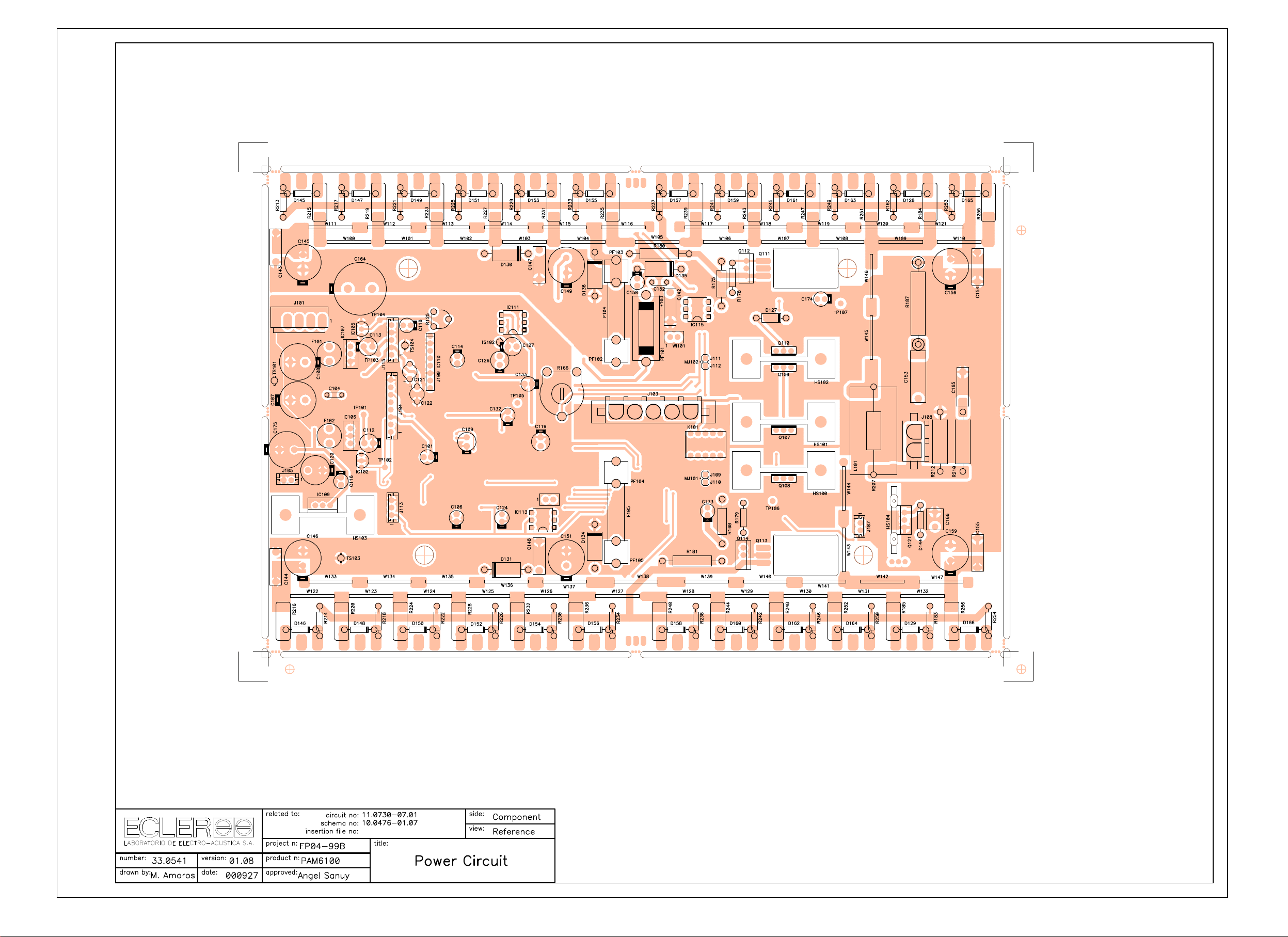

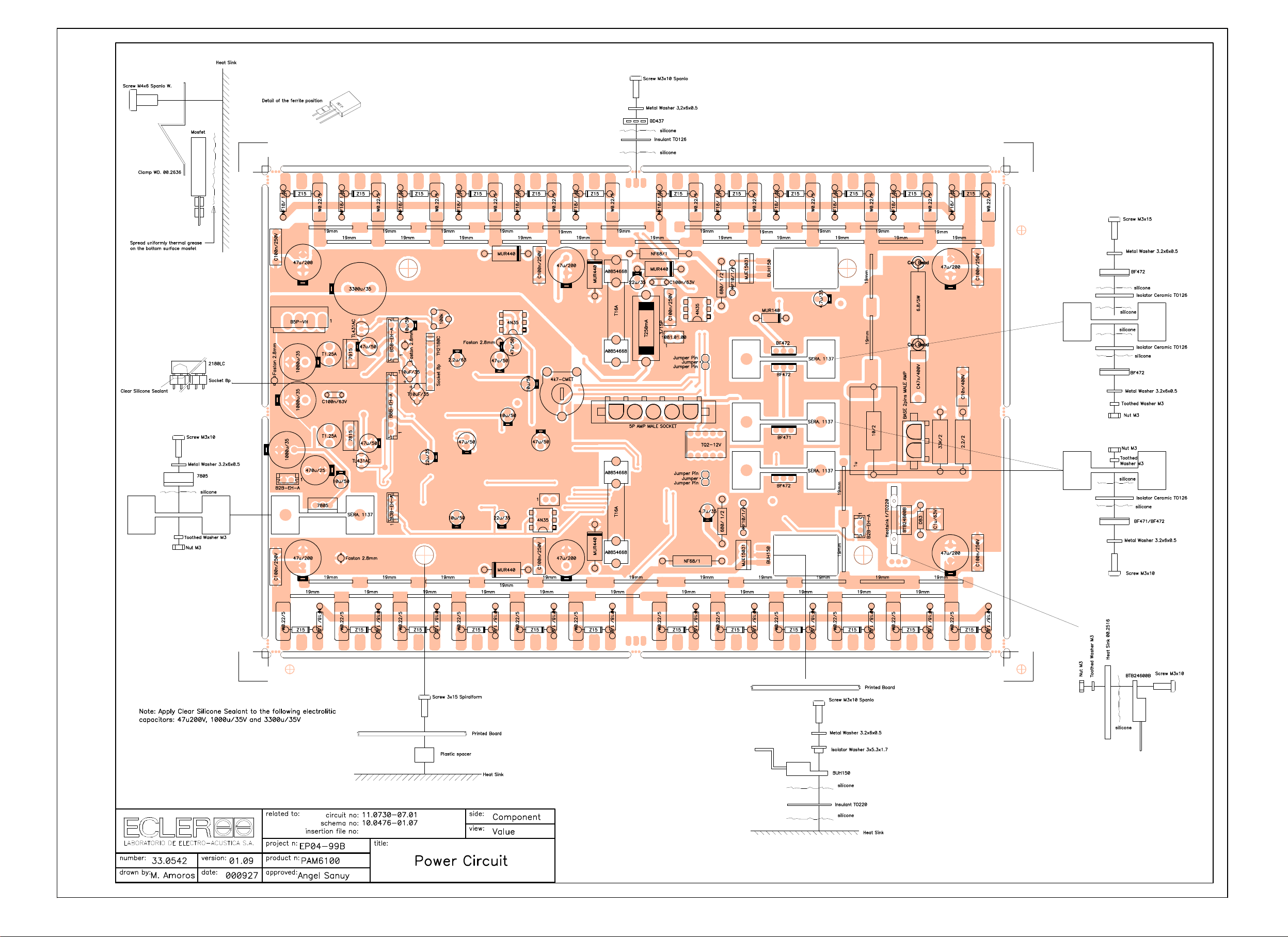

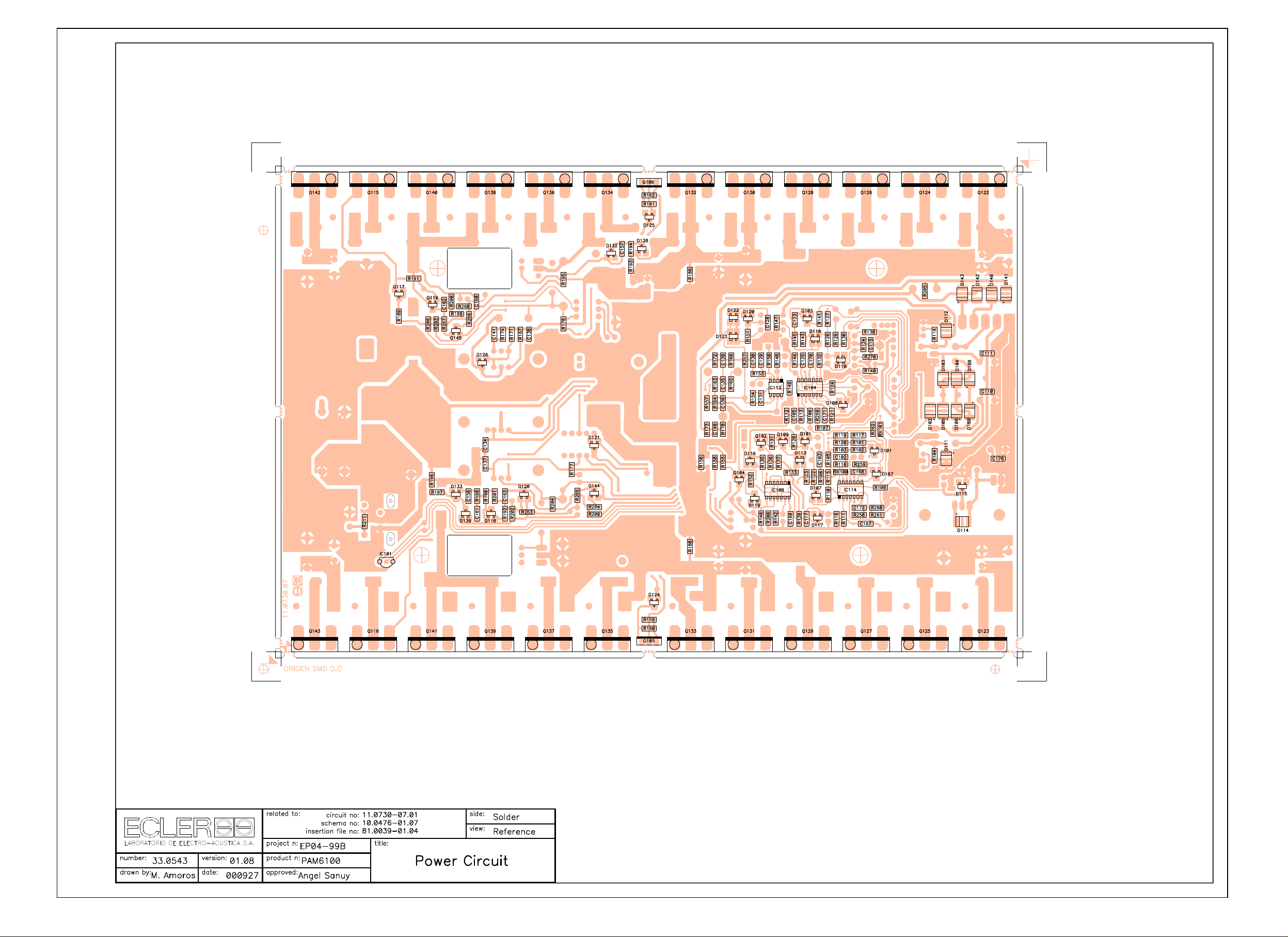

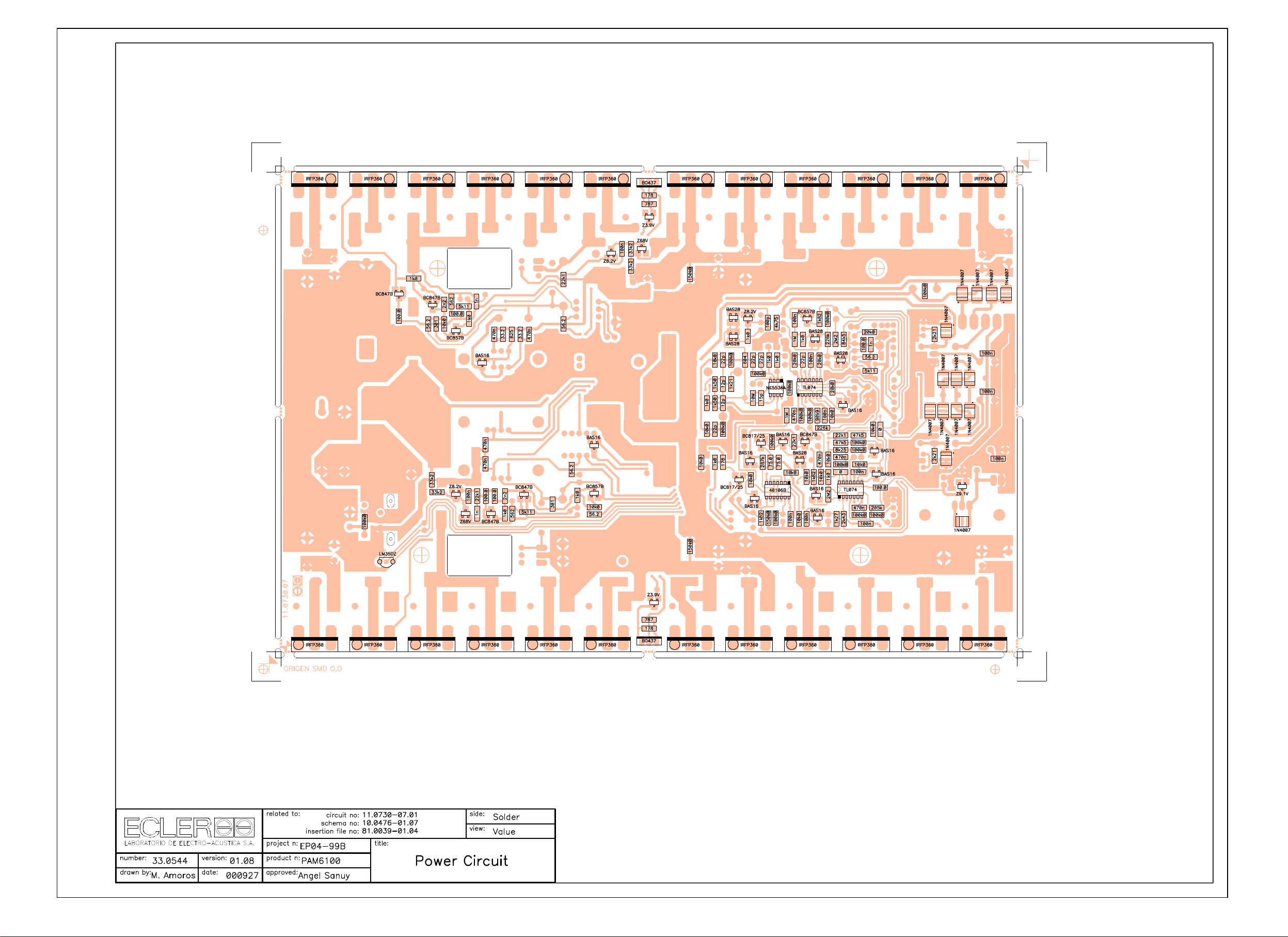

Power Amplifier circuit

Soft-Start Power Supply circuit

Potentiometers and leds circuit

Capacitors circuit

Speak on circuit

- TESTING AND QUALITY CONTROL

- TECHNICAL CHARACTERISTICS

- WIRING DIAGRAM

- MECHANICAL DIAGRAM

- PACKING DIAGRAM

PAM4100

- COMPONENTS LOCATION SCHEMA

AND PARTS LIST

Power Amplifier circuit

- MECHANICAL DIAGRAM

Page 3

CH 1

OPTIONAL

MODULES

TRANSFORMER

THERMAL

PROBE

MODULE

THERMAL

PROBE

FAN CONTROL

THERMAL PROTECT

THERMAL PROCESSOR

THERMAL PROCESSOR

FAN

++Vcc

+Vcc

WILSON

CURRENT

THERMAL

-Vref

VOLUME

MIRROR

DRIVER MOSFET N

LEVEL

CONVERTER

ADJ 0dB

OVERLOAD

HIGH SIDE

CH 2

INPUT CIRCUIT

HIGH PASS FILTER

STEREO

S.P.

OFF

20Hz

30Hz

40Hz

HIGH PASS FILTER

S.P.

BRIG

OPTIONAL

MODULES

PROTECTION

20Hz

OFF

40Hz

30Hz

AND TIMER

PROTECT

VCA

ANTICLIP

CONTROL

RELAY

CONTROL

FEEDBACK

LEVEL

CONVERTER

DRIVER MOSFET N

CLIP

OUTPUT

SHUTDOWN

OUTPUT

SHUTDOWN

ZOBEL

OUT 1

DC PROTECT

CROWBAR

OVERLOAD

LOW SIDE

-Vcc

POWER MODUL CIRCUIT

+15V

BRIG

AC DETECT

-Vref

VOLUME

OUT 2

VCA

POWER MODUL CIRCUIT

Page 4

author: Queralt date: 010418 project:

C

E

num:

EPO4-99 Power Module. Functioning description.

structure differs from the design used untill now. This is due to the breakdown voltage

limit on P-channel MosFET's, wich is 200V. This final stage is formed by several

shunted MosFET's, where those of the positive branch are common-drain configured,

and the negative branch are mounted in common-source configuration.

internally compensated in order to obtain gain levels equal or higher than three. The

amplifier's feedback is given by a resistor and a capacitor associated to the operational

amplifier's non inverting input.

Transistors BF587 and BF588 are common-base configured, forming a current supply

structure. This specific transistor type is used because of the higher Vce voltage level

required by this design. They perform simultaneously two functions: they polarize the

MosFET's gate-source junctions, keeping them on the conducting edge, and they

tranfer the OpAmp's output voltage variations referred to signal ground.

LER

52.0010 version: 01.00

Due to the high power level required on the output load, the amplifier final stage's

The system's controlling device is a NE5534-type operational amplifier, wich is

approved:

title:

FUNCTIONING DESCRIPTION

EP04-99

product:

PAM4/6100

The signal variations normally reflected by Q107 and referred to the positive power

supply, are now needed to be floating variations, and referred to the outputs. This

function is done by Q109-110 (BF588), wich are mounted formig a Wilson-type mirror

current supply. This mirror current supply transfers all of the current variations detected

while descending through Q109's collector, to similar variations on Q110's collector

also downward current. Resistors R167 and R174 are used to balance the current

mirror, in order to avoid the use of transistors with forcibly the same beta value. C138

and C141 suppress their resistance when high frequency signal is processed. Diodes

D126 and D127 avoid the transistors to get saturated, and R171 eliminates the loads

on BF588's bases (Baker Circuit).

The system requires about 12Vdc additional voltage upon the usual Vcc level, this

allows a correct saturation and a symetric clipping at the higher MosFET's.

The correct polarization current value is adjusted by a 4K7 potentiometer connected to

the BF transistor's emitter. This adds an additional current to the current source output

on th BF transistor's loading resistors.

In order to maintain the appropiate stand-by current level against varying temperature

conditions, BD437-type transistors are used. As they have a particular temperaturedepending base-emitter voltage curve, this voltage is used to keep a correct voltage

reference for the current supply. As the temperature rises, the reference voltage level

decreases, the gate-source voltage also decreases and, finally, the bias current also

decreases.

52-0010-0100 EP04-99 Anglès.xls 1 of 3

Page 5

Transistors Q111 and Q112, and their corresponding twins at the lower branch, form

Stand-

a current-buffering circuit wich allows a fast charge and discharge of the power

MosFET's gates.

The Zobel circuit, a resistance-capacitance-inductance formed network associated to

the amplifier's ouput, tries to keep the amplifier's output load impedance constant no

matter wich load value is conected to the output, or wich frequency is processed, in

order to avoid phase shifts on the feedback signal.

To avoid the presence of DC voltage on the output, a diac-triac based system is used,

wich shorts the output to signal ground in case the DC level reaches the diac's

triggering value. To avoid this to happen when processing correct signal (sine

waveform, music...), the diac obtains its reference level from a filtering network formed

by a 100K resistor and a 1mF capacitor.

The protections circuitry overhauls the MosFET's power consumption. Basically, this

circuitry consists of two important sections: MosFET's Id current monitoring, and

MosFET's Vds value detection.

When the MosFET's Id level rises above a certain level, transistor Q119 (controlling

transistor) conducts and decreases the BF transistor's loading resistance, thus reducing

also their gate-source voltage and, finally, lowering the Id current value. This system is

helped by a delayed performance, due to the associated circuitry to Q145 and C174.

This capacitor starts to charge when a current level above the allowed value is

detected, and the protection starts. The greater is the capacitor's charge level, the

higher is also the voltage applied to Q119 controlling transistor's base, increasing its

conduction and, consequently, reducing the gate-source voltage and thus the Id current

value. This system uses a feedback network. The delay used is necessary to avoid

clipping the processed signal's dynamic range, wich should result in the typical clipping

noise. In the negative branch, the protection circuitry is associated to control transistor

Q120.

In case the overcurrent is not ocassional, and persists, after a period of time between

4 and 10 seconds (determined by R142 and C124), the system switches back to

by mode, due to a system-reset. This is done by an optocoupler (IC113) associated to

the negative branch protection circuitry. When protections get activated, IC113

gradually charges C124 untill a 40106-type Schmidt trigger gate switches over . If the

problem persists, this cycle is repeated.

STANDBY CIRCUITRY.

This circuit maintains the Output shutdown relay closed for about 10 seconds, and

thus annulates any current through the MosFET's during this period, just untill the

whole system's power supply voltage reaches its stable level. By this system, we avoid

to hear through the loudspeakers any possible annoying noise proceeding from the

system's start-up.

52-0010-0100 EP04-99 Anglès.xls 2 of 3

Page 6

This delay time is achieved by using a RC cell, where R135=287K and

40106-

C119=47mF/50V. As this cell charges, its voltage increases untill reaching the

type Schmidt trigger (IC108) switching value; at this point, the relay opens and the

amplifier starts to function normally.

The discharge or reset of capacitor C119=47mF can be done by cutting off the power

supply, or by triggering the Thermal or other protections. During a short period of time,

BC817-type transistor Q102 acts like a switch, shunting two 750 ohm resistors to

C119.

Moreover, the amplifier includes some other additional features, like:

· Volume control by a VCA system.

· An ANTICLIP system.

· A Temperature control system.

The ANTICLIP system. When the amplifier reaches clipping levels, the operational

amplifier looses control on the system's performance and at its output some ±Vcc

voltage peaking pulses may appear, proceeding from its power supply. This peaking

pulses are used to be rectified and sent to an optocoupler (IC111), wich varies the

system's VCA control voltage as a function of those pulse's amplitude, creating a

negative feedback wich should pull back the system into stable functioning area.

The Temperature control system has three main functions:

· Controlling the cooling fan speed, as it is a function of the measured temperature. The

fan's operation voltage range is »7 to 4 Volt.

· Suspending the amplifier's functioning when the temperature exceeds »92ºC

· Reducing the amount of power output, depending on the module's temperature (as it

rises above 85ºC) and on the main power supply's transformer (above 120ºC).

The temperature control system consists on two LM35D-type IC's, wich act like a

thermal probe; one is placed on the amplifier's heat sink, and the other is placed into

the main power supply transformer's core. Moreover, three amplifiers, a comparator

for the thermal probe and a 7805-type IC to feed the cooling fan are used.

The first amplifier (1/4 IC114) acts on the cooling fan speed control. The second

amplifier (1/4 IC114) modifies the VCA gain control, in order to reduce the system's

gain if the temperature rises above 85ºC. The third amplifier (1/4 IC114) modifies the

VCA gain control, in order to reduce the system's gain if the temperature rises above

120ºC. The comparator (1/4 IC114) is responsible for the output shutdown relay

performance, in order to close it as the temperature reaches 92ºC, and thus cutting of

the amplifier's MosFETs bias current. As this happens, the signal output of the whole

unit is cutted off.

52-0010-0100 EP04-99 Anglès.xls 3 of 3

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

PARTS LIST: PRINTED CIRCUIT 11.0833.04.00

Q

Code

Description

Reference

1

FCCE250470

47u/50

C100

1

FCCE250470

47u/50

C101

1

FCCE250470

47u/50

C102

1

FCCE250470

47u/50

C103

1

FCXCN41000

100n

C104

1

FCXCN41000

100n

C105

1

FCXCN41000

100n

C106

1

FCXCN41000

100n

C107

1

FCXCN41000

100n

C108

1

FCXCN41000

100n

C109

1

FCXCN41000

100n

C110

1

FCXCN41000

100n

C111

1

FCXCN21000

100p

C112

1

FCXCN21000

100p

C113

1

FCXCN21000

100p

C114

1

FCXCN21000

100p

C115

1

FCXCN12201

22p 2%

C116

1

FCXCN12201

22p 2%

C117

1

FCXCN12201

22p 2%

C118

1

FCXCN12201

22p 2%

C119

1

FCCE250100

10u/50

C120

1

FCCE250100

10u/50

C121

1

FCXCN42200

220n

C122

1

FCXCN42200

220n

C123

1

FCXCN42200

220n

C124

1

FCXCN42200

220n

C125

1

FCXCN42200

220n

C126

1

FCXCN42200

220n

C127

1

FCCIPAM833

11.0833 Printed Board

CI100

1

FCXDDBAS28

BAS28

D100

1

FCXDDBAS28

BAS28

D101

1

FCXDDBAS28

BAS28

D102

1

FCXDDBAS28

BAS28

D103

1

FCXDDBAS16

BAS16

D104

1

FCXDDBAS16

BAS16

D105

1

FCIC553200

NE5532AP

IC100

1

FCIC553200

NE5532AP

IC101

1

FCIC072010

TL072

IC102

1

FCIC072010

TL072

IC103

1

FCIC071010

TL071

IC104

1

FCBASX0900

YKF52-5005

J100

1

FCBASX1000

YKF52-5003

J101

1

FCBASX0900

YKF52-5005

J102

1

FCBASX1000

YKF52-5003

J103

1

FCCTM00040

B4B-EH-A

J104

1

FCCTM00070

B7B-EH-A

J152

1

FCCHK00680

68uH

L100

1

FCCHK00680

68uH

L101

1

FCCHK00680

68uH

L102

1

FCCHK00680

68uH

L103

1

FCMJ000100

Jumper

MJ106

1

FCMJ000100

Jumper

MJ107

1

FCXR151000

100k0

R100

1

FCXR151000

100k0

R101

40-0065-0205 EP04-99B.xls 1 of 3

Page 19

PARTS LIST: PRINTED CIRCUIT 11.0833.04.00

Q

Code

Description

Reference

1

FCXR151000

100k0

R102

1

FCXR151000

100k0

R103

1

FCXR121000

100.0

R104

1

FCXR121000

100.0

R105

1

FCXR121000

100.0

R106

1

FCXR121000

100.0

R107

1

FCXR242430

24k3 0.5%

R108

1

FCXR242430

24k3 0.5%

R109

1

FCXR242430

24k3 0.5%

R110

1

FCXR242430

24k3 0.5%

R111

1

FCXR242430

24k3 0.5%

R112

1

FCXR242430

24k3 0.5%

R113

1

FCXR242430

24k3 0.5%

R114

1

FCXR242430

24k3 0.5%

R115

1

FCXR131000

1k0

R116

1

FCXR131000

1k0

R117

1

FCXR115620

56.2

R118

1

FCXR115620

56.2

R119

1

FCXR131000

1k0

R120

1

FCXR131000

1k0

R121

1

FCXR153400

340k

R122

1

FCXR153400

340k

R123

1

FCXR071000

10M

R124

1

FCXR071000

10M

R125

1

FCXR141820

18k2

R126

1

FCXR141130

11k3

R127

1

FCXR139090

9k09

R128

1

FCXR131500

1k50

R129

1

FCXR141820

18k2

R130

1

FCXR141130

11k3

R131

1

FCXR139090

9k09

R132

1

FCXR131500

1k50

R133

1

FCXR147500

75k0

R134

1

FCXR147500

75k0

R135

1

FCXR144750

47k5

R136

1

FCXR144750

47k5

R137

1

FCXR143650

36k5

R138

1

FCXR143650

36k5

R139

1

FCXR071000

10M

R140

1

FCXR071000

10M

R141

1

FCXR143650

36k5

R142

1

FCXR143650

36k5

R143

1

FCXR242430

24k3 0.5%

R144

1

FCXR242430

24k3 0.5%

R145

1

FCXR141820

18k2

R146

1

FCXR141820

18k2

R147

1

FCXR115620

56.2

R148

1

FCXR115620

56.2

R149

1

FCXR242430

24k3 0.5%

R150

1

FCXR242430

24k3 0.5%

R151

1

FCXR131500

1k50

R152

1

FCINTAP080

NS42J11

S100

1

FCINTD7500

SS050

S101

1

FC6K058460

1058.04.60

WI102

40-0065-0205 EP04-99B.xls 2 of 3

Page 20

PARTS LIST: PRINTED CIRCUIT 11.0833.04.00

Q

Code

Description

Reference

1

FC6K058460

1058.04.60

WI103

40-0065-0205 EP04-99B.xls 3 of 3

Page 21

Page 22

Page 23

Page 24

Page 25

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCCE200220

22u/35

C101

1

FCXCN44700

470n

C102

1

FCXCN44700

470n

C103

1

FCCDK11000

C100n/63V

C104

1

FCXCN44700

470n

C105

1

FCCE250100

10u/50

C106

1

FCCE211000

1000u/35

C107

1

FCCE211000

1000u/35

C108

1

FCCE250470

47u/50

C109

1

FCXCN41000

100n

C110

1

FCXCN41000

100n

C111

1

FCCE250470

47u/50

C112

1

FCCE250470

47u/50

C113

1

FCCE300022

2.2u/63

C114

1

FCXCN40010

1n

C115

1

FCCE250100

10u/50

C116

1

FCXCN41000

100n

C117

1

FCCE250100

10u/50

C118

1

FCCE250470

47u/50

C119

1

FCCE154700

470u/25

C120

1

FCCG001000

T10uF/35

C121

1

FCCG001000

T10uF/35

C122

1

FCXCN41000

100n

C123

1

FCCE200220

22u/35

C124

1

FCXCN12200

22p

C125

1

FCCE250470

47u/50

C126

1

FCCE250470

47u/50

C127

1

FCXCN21000

100p

C128

1

FCXCN12200

22p

C129

1

FCXCN12200

22p

C130

1

FCXCN11500

15p

C131

1

FCCE250100

10u/50

C132

1

FCCE250100

10u/50

C133

1

FCXCN44700

470n

C134

1

FCXCN11200

12p

C135

1

FCXCN11200

12p

C136

1

FCXCN44700

470n

C137

1

FCXCN44700

470n

C138

1

FCXCN12200

22p

C139

1

FCXCN12200

22p

C140

1

FCXCN44700

470n

C141

1

FCCDN11000

C100n/250V

C142

1

FCCDN11000

C100n/250V

C143

1

FCCDN11000

C100n/250V

C144

1

FCCE350047

47u/200

C145

1

FCCE350047

47u/200

C146

1

FCCDN11000

C100n/250V

C147

1

FCCDN11000

C100n/250V

C148

1

FCCE350047

47u/200

C149

1

FCCE200220

22u/35

C150

1

FCCE350047

47u/200

C151

1

FCCDK11000

C100n/63V

C152

1

FCCDH71047

C47n/400V

C153

1

FCCDN11000

C100n/250V

C154

1

FCCDN11000

C100n/250V

C155

1

FCCE350047

47u/200

C156

40-0065-0206 EP04-99B.xls 1 of 11

Page 26

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCXCN41000

100n

C157

1

FCXCN41000

100n

C158

1

FCCE350047

47u/200

C159

1

FCXCN40010

1n

C160

1

FCXCN40010

1n

C161

1

FCXCN40022

2n2

C162

1

FCXCN40022

2n2

C163

1

FCCE213300

3300u/35

C164

1

FCCDH71011

C10n/400V

C165

1

FCCDK20010

C1u/63V

C166

1

FCXCN41000

100n

C167

1

FCXCN41000

100n

C168

1

FCXCN41000

100n

C169

1

FCXCN41000

100n

C170

1

FCXCN41000

100n

C171

1

FCXCN44700

470n

C172

1

FCCE200047

4.7u/35

C173

1

FCCE200047

4.7u/35

C174

1

FCCE211000

1000u/35

C175

1

FCXCN41000

100n

C176

1

FCPERL2550

Cer. Bead

CB101

1

FCPERL2550

Cer. Bead

CB102

1

FCPERL2550

Cer. Bead

CB103

1

FCPERL2550

Cer. Bead

CB104

1

FCCIPAM730

11.0730 Printed Board

CI101

1

FCXDDBAS16

BAS16

D101

1

FCXDD40070

1N4007

D102

1

FCXDD40070

1N4007

D103

1

FCXDD40070

1N4007

D104

1

FCXDD40070

1N4007

D105

1

FCXDD40070

1N4007

D106

1

FCXDDBAS16

BAS16

D107

1

FCXDDBAS16

BAS16

D108

1

FCXDDBAS16

BAS16

D109

1

FCXDDBAS28

BAS28

D110

1

FCXDD40070

1N4007

D111

1

FCXDD40070

1N4007

D112

1

FCXDDBAS28

BAS28

D113

1

FCXDD40070

1N4007

D114

1

FCXZ000091

Z9.1V

D115

1

FCXDDBAS16

BAS16

D116

1

FCXDDBAS16

BAS16

D117

1

FCXDDBAS28

BAS28

D118

1

FCXDDBAS16

BAS16

D119

1

FCXZ000082

Z8.2V

D120

1

FCXDDBAS16

BAS16

D121

1

FCXDDBAS28

BAS28

D122

1

FCXDDBAS28

BAS28

D123

1

FCXZ000039

Z3.9V

D124

1

FCXZ000039

Z3.9V

D125

1

FCXDDBAS16

BAS16

D126

1

FCDDMUR140

MUR140

D127

1

FCDD041500

Z15

D128

1

FCDD041500

Z15

D129

1

FCDDMUR440

MUR440

D130

1

FCDDMUR440

MUR440

D131

40-0065-0206 EP04-99B.xls 2 of 11

Page 27

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCXZ000082

Z8.2V

D132

1

FCXZ000082

Z8.2V

D133

1

FCDDMUR440

MUR440

D134

1

FCDDMUR440

MUR440

D135

1

FCDDMUR440

MUR440

D136

1

FCXZ000680

Z68V

D138

1

FCXZ000680

Z68V

D139

1

FCXDD40070

1N4007

D140

1

FCXDD40070

1N4007

D141

1

FCXDD40070

1N4007

D142

1

FCXDD40070

1N4007

D143

1

FCDIDB3000

DB3

D144

1

FCDD041500

Z15

D145

1

FCDD041500

Z15

D146

1

FCDD041500

Z15

D147

1

FCDD041500

Z15

D148

1

FCDD041500

Z15

D149

1

FCDD041500

Z15

D150

1

FCDD041500

Z15

D151

1

FCDD041500

Z15

D152

1

FCDD041500

Z15

D153

1

FCDD041500

Z15

D154

1

FCDD041500

Z15

D155

1

FCDD041500

Z15

D156

1

FCDD041500

Z15

D157

1

FCDD041500

Z15

D158

1

FCDD041500

Z15

D159

1

FCDD041500

Z15

D160

1

FCDD041500

Z15

D161

1

FCDD041500

Z15

D162

1

FCDD041500

Z15

D163

1

FCDD041500

Z15

D164

1

FCDD041500

Z15

D165

1

FCDD041500

Z15

D166

1

FCXDDBAS16

BAS16

D167

1

FCXDD40070

1N4007

D168

1

FCXDD40070

1N4007

D169

1

FCFUS40125

T1.25A

F101

1

FCFUS40125

T1.25A

F102

1

FCFUS50080

T250mA

F103

1

FCFUS60400

T16A

F104

1

FCFUS60400

T16A

F105

1

FCFER43220

Ferrite

FB101

1

FCFER43220

Ferrite

FB102

1

FCFER43220

Ferrite

FB103

1

FCFER43220

Ferrite

FB104

1

FCFER43220

Ferrite

FB105

1

FCFER43220

Ferrite

FB106

1

FCFER43220

Ferrite

FB107

1

FCFER43220

Ferrite

FB108

1

FCFER43220

Ferrite

FB109

1

FCFER43220

Ferrite

FB110

1

FCFER43220

Ferrite

FB111

1

FCFER43220

Ferrite

FB112

1

FCFER43220

Ferrite

FB113

1

FCFER43220

Ferrite

FB114

40-0065-0206 EP04-99B.xls 3 of 11

Page 28

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCFER43220

Ferrite

FB115

1

FCFER43220

Ferrite

FB116

1

FCFER43220

Ferrite

FB117

1

FCFER43220

Ferrite

FB118

1

FCFER43220

Ferrite

FB119

1

FCFER43220

Ferrite

FB120

1

FCFER43220

Ferrite

FB121

1

FCFER43220

Ferrite

FB122

1

FCFER43220

Ferrite

FB123

1

FCFER43220

Ferrite

FB124

1

FCFER43220

Ferrite

FB125

1

FCFER43220

Ferrite

FB126

1

FCFER43220

Ferrite

FB127

1

FCFER43220

Ferrite

FB128

1

FCFER43220

Ferrite

FB129

1

FCFER43220

Ferrite

FB130

1

FCFER43220

Ferrite

FB131

1

FCFER43220

Ferrite

FB132

1

FCFER43220

Ferrite

FB133

1

FCFER43220

Ferrite

FB134

1

FCFER43220

Ferrite

FB135

1

FCFER43220

Ferrite

FB136

1

FCFER43220

Ferrite

FB137

1

FCFER43220

Ferrite

FB138

1

FCFER43220

Ferrite

FB139

1

FCFER43220

Ferrite

FB140

1

FCFER43220

Ferrite

FB141

1

FCFER43220

Ferrite

FB142

1

FCFER43220

Ferrite

FB143

1

FCFER43220

Ferrite

FB144

1

FCFER43220

Ferrite

FB145

1

FCFER43220

Ferrite

FB146

1

FCFER43220

Ferrite

FB147

1

FCFER43220

Ferrite

FB148

1

FCRAD12636

SERA. 1137

HS100

1

FCRAD12636

SERA. 1137

HS101

1

FCRAD12636

SERA. 1137

HS102

1

FCRAD12636

SERA. 1137

HS103

1

FCMECT0220

Heatsink f/TO220

HS104

1

FCRAD03000

Heatsink f/ Power Module

HS105

1

FCRAD03000

Heatsink f/ Power Module

HS106

1

FCIC350000

LM35DZ

IC101

1

FCIC431000

TL431AC

IC102

1

FCIC074010

TL074

IC104

1

FCIC431000

TL431AC

IC105

1

FCREG78150

7815

IC106

1

FCREG79150

7915

IC107

1

FCIC401060

40106B

IC108

1

FCREG78050

7805

IC109

1

FCIC218000

TH2180C

IC110

1

FCIC435000

4N35

IC111

1

FCIC553410

NE5534A

IC112

1

FCIC435000

4N35

IC113

1

FCIC074010

TL074

IC114

1

FCIC435000

4N35

IC115

1

FCMICTO126

Insulant TO126

IN100

40-0065-0206 EP04-99B.xls 4 of 11

Page 29

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCMICTO126

Insulant TO126

IN101

1

FCMICTO220

Insulant TO220

IN102

1

FCMICTO220

Insulant TO220

IN103

1

FCTERM0080

Socket 8p

J100

1

FCCTJ10050

B5P-VH

J101

1

FCCTAMP050

5P AMP MALE SOCKET

J103

1

FCCTM00080

B8B-EH-A

J104

1

FCCTM00020

B2B-EH-A

J105

1

FCCTM00020

B2B-EH-A

J107

1

FCCTAMP020

BASE 2pins MALE AMP

J108

1

FCTERM0100

Jumper Pin

J109

1

FCTERM0100

Jumper Pin

J110

1

FCTERM0100

Jumper Pin

J111

1

FCTERM0100

Jumper Pin

J112

1

FCCTM00030

B3B-EH-A

J113

1

FCCTM00050

B5B-EH-A

J115

1

FCREL00300

TQ2-12V

K101

1

FCIND00100

1u

L101

1

FCMJ000100

Jumper

MJ101

1

FCMJ000100

Jumper

MJ102

1

FCPINZAM00

Clamp WD. 00.2636

MP100

1

FCPINZAM00

Clamp WD. 00.2636

MP101

1

FCPINZAM00

Clamp WD. 00.2636

MP102

1

FCPINZAM00

Clamp WD. 00.2636

MP103

1

FCTUE00300

Nut M3

NV100

1

FCTUE00300

Nut M3

NV101

1

FCTUE00300

Nut M3

NV102

1

FCTUE00300

Nut M3

NV103

1

FCTUE00300

Nut M3

NV104

1

FCPORF3150

3/15P

PF101

1

FCPORF0100

A0854668

PF102

1

FCPORF0100

A0854668

PF103

1

FCPORF0100

A0854668

PF104

1

FCPORF0100

A0854668

PF105

1

FCXTT08470

BC847B

Q101

1

FCXTT08170

BC817/25

Q102

1

FCXTT08570

BC857B

Q103

1

FCXTT08170

BC817/25

Q104

1

FCTR437000

BD437

Q105

1

FCTR437000

BD437

Q106

1

FCTR471000

BF471

Q107

1

FCTR472000

BF472

Q108

1

FCTR472000

BF472

Q109

1

FCTR472000

BF472

Q110

1

FCTR150000

BUH150

Q111

1

FCTR150310

MJE15031

Q112

1

FCTR150000

BUH150

Q113

1

FCTR150310

MJE15031

Q114

1

FCTR360000

IRFP360

Q115

1

FCTR360000

IRFP360

Q116

1

FCXTT08470

BC847B

Q117

1

FCXTT08470

BC847B

Q118

1

FCXTT08470

BC847B

Q119

1

FCXTT08470

BC847B

Q120

1

FCTI246000

BTB24600B

Q121

1

FCTR360000

IRFP360

Q122

40-0065-0206 EP04-99B.xls 5 of 11

Page 30

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCTR360000

IRFP360

Q123

1

FCTR360000

IRFP360

Q124

1

FCTR360000

IRFP360

Q125

1

FCTR360000

IRFP360

Q126

1

FCTR360000

IRFP360

Q127

1

FCTR360000

IRFP360

Q128

1

FCTR360000

IRFP360

Q129

1

FCTR360000

IRFP360

Q130

1

FCTR360000

IRFP360

Q131

1

FCTR360000

IRFP360

Q132

1

FCTR360000

IRFP360

Q133

1

FCTR360000

IRFP360

Q134

1

FCTR360000

IRFP360

Q135

1

FCTR360000

IRFP360

Q136

1

FCTR360000

IRFP360

Q137

1

FCTR360000

IRFP360

Q138

1

FCTR360000

IRFP360

Q139

1

FCTR360000

IRFP360

Q140

1

FCTR360000

IRFP360

Q141

1

FCTR360000

IRFP360

Q142

1

FCTR360000

IRFP360

Q143

1

FCXTT08570

BC857B

Q144

1

FCXTT08570

BC857B

Q145

1

FCXR151000

100k0

R101

1

FCXR151000

100k0

R102

1

FCXR138250

8k25

R103

1

FCXR132210

2k21

R104

1

FCXR141000

10k0

R105

1

FCXR151000

100k0

R106

1

FCXR152260

226k

R107

1

FCXR141000

10k0

R108

1

FCXR121000

100.0

R109

1

FCXR151000

100k0

R110

1

FCXR132430

2k43

R111

1

FCXR061000

1M

R112

1

FCXR151000

100k0

R113

1

FCXR132210

2k21

R114

1

FCXR131000

1k0

R115

1

FCXR131270

1k27

R116

1

FCXR144750

47k5

R117

1

FCXR062200

2M2

R118

1

FCXR142210

22k1

R119

1

FCXR144750

47k5

R120

1

FCXR141000

10k0

R121

1

FCXR131820

1k82

R122

1

FCXR141000

10k0

R123

1

FCXR142000

20k0

R124

1

FCRJC61000

100k

R125

1

FCXR152260

226k

R126

1

FCXR151000

100k0

R127

1

FCXR142210

22k1

R128

1

FCXR062200

2M2

R129

1

FCXR148450

84k5

R130

1

FCXR151000

100k0

R131

1

FCXR142000

20k0

R132

1

FCXR141000

10k0

R133

40-0065-0206 EP04-99B.xls 6 of 11

Page 31

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCXR121000

100.0

R134

1

FCXR152870

287k

R135

1

FCXR117500

75.0

R136

1

FCXR117500

75.0

R137

1

FCXR142000

20k0

R138

1

FCXR141000

10k0

R139

1

FCXR135110

5k11

R140

1

FCXR131820

1k82

R141

1

FCXR151000

100k0

R142

1

FCXR131000

1k0

R143

1

FCXR142000

20k0

R144

1

FCXR061000

1M

R145

1

FCXR131820

1k82

R146

1

FCXR134750

4k75

R147

1

FCXR131000

1k0

R148

1

FCXR151000

100k0

R149

1

FCXR131000

1k0

R150

1

FCXR131000

1k0

R151

1

FCXR141000

10k0

R152

1

FCXR151000

100k0

R153

1

FCXR071000

10M

R154

1

FCXR121780

178

R155

1

FCXR141000

10k0

R156

1

FCXR131000

1k0

R157

1

FCXR131000

1k0

R158

1

FCXR127870

787

R159

1

FCXR121780

178

R160

1

FCXR127870

787

R161

1

FCXR121780

178

R162

1

FCXR131500

1k50

R163

1

FCXR131500

1k50

R164

1

FCXR131210

1k21

R165

1

FCRJP44700

4k7-CMET

R166

1

FCXR113320

33.2

R167

1

FCRC236800

680/ 1/2

R168

1

FCXR151000

100k0

R169

1

FCXR151000

100k0

R170

1

FCXR128250

825

R171

1

FCXR141000

10k0

R172

1

FCXR141000

10k0

R173

1

FCXR113320

33.2

R174

1

FCRC236800

680/ 1/2

R175

1

FCXR115620

56.2

R176

1

FCXR115620

56.2

R177

1

FCRF221000

NF10/1/2

R178

1

FCRF221000

NF10/1/2

R179

1

FCRF426800

NF68/1

R180

1

FCRF426800

NF68/1

R181

1

FCRF221800

NF18/ 1/2

R182

1

FCRF221800

NF18/ 1/2

R183

1

FCRY000100

W0.22/5

R184

1

FCRY000100

W0.22/5

R185

1

FCXR151500

150k0

R186

1

FCRY000250

6.8/5W

R187

1

FCXR151500

150k0

R188

1

FCXR121000

100.0

R189

40-0065-0206 EP04-99B.xls 7 of 11

Page 32

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCXR121000

100.0

R190

1

FCXR131000

1k0

R191

1

FCXR131000

1k0

R192

1

FCXR143320

33k2

R193

1

FCXR143320

33k2

R194

1

FCXR142210

22k1

R195

1

FCXR143320

33k2

R196

1

FCXR143320

33k2

R197

1

FCXR142210

22k1

R198

1

FCXR121000

100.0

R199

1

FCXR125620

562

R200

1

FCXR121000

100.0

R201

1

FCXR125620

562

R202

1

FCXR123010

301

R203

1

FCXR123010

301

R204

1

FCXR151000

100k0

R205

1

FCXR115620

56.2

R206

1

FCRC521000

10/2

R207

1

FCXR151500

150k0

R208

1

FCXR115620

56.2

R209

1

FCRC512200

2.2/2

R210

1

FCXR151000

100k0

R211

1

FCRC553300

33K/2

R212

1

FCRF221800

NF18/ 1/2

R213

1

FCRF221800

NF18/ 1/2

R214

1

FCRY000100

W0.22/5

R215

1

FCRY000100

W0.22/5

R216

1

FCRF221800

NF18/ 1/2

R217

1

FCRF221800

NF18/ 1/2

R218

1

FCRY000100

W0.22/5

R219

1

FCRY000100

W0.22/5

R220

1

FCRF221800

NF18/ 1/2

R221

1

FCRF221800

NF18/ 1/2

R222

1

FCRY000100

W0.22/5

R223

1

FCRY000100

W0.22/5

R224

1

FCRF221800

NF18/ 1/2

R225

1

FCRF221800

NF18/ 1/2

R226

1

FCRY000100

W0.22/5

R227

1

FCRY000100

W0.22/5

R228

1

FCRF221800

NF18/ 1/2

R229

1

FCRF221800

NF18/ 1/2

R230

1

FCRY000100

W0.22/5

R231

1

FCRY000100

W0.22/5

R232

1

FCRF221800

NF18/ 1/2

R233

1

FCRF221800

NF18/ 1/2

R234

1

FCRY000100

W0.22/5

R235

1

FCRY000100

W0.22/5

R236

1

FCRF221800

NF18/ 1/2

R237

1

FCRF221800

NF18/ 1/2

R238

1

FCRY000100

W0.22/5

R239

1

FCRY000100

W0.22/5

R240

1

FCRF221800

NF18/ 1/2

R241

1

FCRF221800

NF18/ 1/2

R242

1

FCRY000100

W0.22/5

R243

1

FCRY000100

W0.22/5

R244

1

FCRF221800

NF18/ 1/2

R245

40-0065-0206 EP04-99B.xls 8 of 11

Page 33

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCRF221800

NF18/ 1/2

R246

1

FCRY000100

W0.22/5

R247

1

FCRY000100

W0.22/5

R248

1

FCRF221800

NF18/ 1/2

R249

1

FCRF221800

NF18/ 1/2

R250

1

FCRY000100

W0.22/5

R251

1

FCRY000100

W0.22/5

R252

1

FCRF221800

NF18/ 1/2

R253

1

FCRF221800

NF18/ 1/2

R254

1

FCRY000100

W0.22/5

R255

1

FCRY000100

W0.22/5

R256

1

FCXR126040

604

R257

1

FCXR151000

100k0

R258

1

FCXR141000

10k0

R259

1

FCXR152050

205k

R260

1

FCXR151000

100k0

R261

1

FCXR141000

10k0

R262

1

FCXR135110

5k11

R263

1

FCXR141000

10k0

R264

1

FCXR131000

1k0

R265

1

FCXR131000

1k0

R266

1

FCXR141000

10k0

R267

1

FCXR135110

5k11

R268

1

FCXR149090

90k9

R269

1

FCXR115620

56.2

R270

1

FCXR000000

0

RX100

1

FCXR000000

0

RX101

1

FCT8040060

Screw M4x6 SPAN

SC100

1

FCT8040060

Screw M4x6 SPAN

SC101

1

FCT8040060

Screw M4x6 SPAN

SC102

1

FCT8040060

Screw M4x6 SPAN

SC103

1

FCT8040060

Screw M4x6 SPAN

SC104

1

FCT8040060

Screw M4x6 SPAN

SC105

1

FCT8040060

Screw M4x6 SPAN

SC106

1

FCT8040060

Screw M4x6 SPAN

SC107

1

FCT8040060

Screw M4x6 SPAN

SC108

1

FCT8040060

Screw M4x6 SPAN

SC109

1

FCT8040060

Screw M4x6 SPAN

SC110

1

FCT8040060

Screw M4x6 SPAN

SC111

1

FCT8030100

Screw M3x10 SPA

SC112

1

FCT8030100

Screw M3x10 SPA

SC113

1

FCT8030150

Screw 3x15 SPIRALFORM

SC114

1

FCT8030150

Screw 3x15 SPIRALFORM

SC115

1

FCT8030100

Screw M3x10 SPA

SC116

1

FCT8030100

Screw M3x10 SPA

SC117

1

FCT7503010

Screw M3x10

SC118

1

FCT7503010

Screw M3x10

SC119

1

FCT7503010

Screw M3x10

SC120

1

FCT7503010

Screw M3x10

SC121

1

FCT8030150

Screw M3x15

SC122

1

FCSEPPM000

Plastic Spacer f/board ct.

SC123

1

FCT8030150

Screw 3x15 SPIRALFORM

SC124

1

FCT8030150

Screw 3x15 SPIRALFORM

SC125

1

FCSEPPM000

Plastic Spacer f/board ct.

SC126

1

FCSEPPM000

Plastic Spacer f/board ct.

SC127

1

FCSEPPM000

Plastic Spacer f/board ct.

SC128

40-0065-0206 EP04-99B.xls 9 of 11

Page 34

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCTERMF280

Faston 2.8mm

TS101

1

FCTERMF280

Faston 2.8mm

TS102

1

FCTERMF280

Faston 2.8mm

TS103

1

FCTERMF280

Faston 2.8mm

TS104

1

FCMECPON19

19mm

W100

1

FCMECPON19

19mm

W101

1

FCMECPON19

19mm

W102

1

FCMECPON19

19mm

W103

1

FCMECPON19

19mm

W104

1

FCMECPON19

19mm

W105

1

FCMECPON19

19mm

W106

1

FCMECPON19

19mm

W107

1

FCMECPON19

19mm

W108

1

FCMECPON19

19mm

W109

1

FCMECPON19

19mm

W110

1

FCMECPON19

19mm

W111

1

FCMECPON19

19mm

W112

1

FCMECPON19

19mm

W113

1

FCMECPON19

19mm

W114

1

FCMECPON19

19mm

W115

1

FCMECPON19

19mm

W116

1

FCMECPON19

19mm

W117

1

FCMECPON19

19mm

W118

1

FCMECPON19

19mm

W119

1

FCMECPON19

19mm

W120

1

FCMECPON19

19mm

W121

1

FCMECPON19

19mm

W122

1

FCMECPON19

19mm

W123

1

FCMECPON19

19mm

W124

1

FCMECPON19

19mm

W125

1

FCMECPON19

19mm

W126

1

FCMECPON19

19mm

W127

1

FCMECPON19

19mm

W128

1

FCMECPON19

19mm

W129

1

FCMECPON19

19mm

W130

1

FCMECPON19

19mm

W131

1

FCMECPON19

19mm

W132

1

FCMECPON19

19mm

W133

1

FCMECPON19

19mm

W134

1

FCMECPON19

19mm

W135

1

FCMECPON19

19mm

W136

1

FCMECPON19

19mm

W137

1

FCMECPON19

19mm

W138

1

FCMECPON19

19mm

W139

1

FCMECPON19

19mm

W140

1

FCMECPON19

19mm

W141

1

FCMECPON19

19mm

W142

1

FCMECPON19

19mm

W143

1

FCMECPON19

19mm

W144

1

FCMECPON19

19mm

W145

1

FCMECPON19

19mm

W146

1

FCMECPON19

19mm

W147

1

FCARM32000

Metal Washer 3.2x6x0.5

WA100

1

FCARM32000

Metal Washer 3.2x6x0.5

WA101

1

FCARM32000

Metal Washer 3.2x6x0.5

WA102

1

FCARM32000

Metal Washer 3.2x6x0.5

WA103

40-0065-0206 EP04-99B.xls 10 of 11

Page 35

PARTS LIST: PRINTED CIRCUIT 11.0730.07.01

Q

Code

Description

Reference

1

FCARM32000

Metal Washer 3.2x6x0.5

WA104

1

FCARDE0300

Toothed Washer f/M3

WA105

1

FCARM32000

Metal Washer 3.2x6x0.5

WA106

1

FCARDE0300

Toothed Washer f/M3

WA107

1

FCARDE0300

Toothed Washer f/M3

WA108

1

FCARDE0300

Toothed Washer f/M3

WA109

1

FCARDE0300

Toothed Washer f/M3

WA110

1

FCARM32000

Metal Washer 3.2x6x0.5

WA114

1

FCARAT0000

Washer Ins. Tr. 3x5.3x1.7

WA115

1

FCSEPCE126

Ceramic Isolator TO126

WA116

1

FCSEPCE126

Ceramic Isolator TO126

WA117

1

FCSEPCE126

Ceramic Isolator TO126

WA118

1

FCSEPCE126

Ceramic Isolator TO126

WA119

1

FCARM32000

Metal Washer 3.2x6x0.5

WA120

1

FCARAT0000

Washer Ins. Tr. 3x5.3x1.7

WA122

1

FC4G081100

1081.01.00

WI101

40-0065-0206 EP04-99B.xls 11 of 11

Page 36

Page 37

Page 38

Page 39

Page 40

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCCE200220

22u/35

C101

1

FCXCN44700

470n

C102

1

FCXCN44700

470n

C103

1

FCCDK11000

C100n/63V

C104

1

FCXCN44700

470n

C105

1

FCCE250100

10u/50

C106

1

FCCE211000

1000u/35

C107

1

FCCE211000

1000u/35

C108

1

FCCE250470

47u/50

C109

1

FCXCN41000

100n

C110

1

FCXCN41000

100n

C111

1

FCCE250470

47u/50

C112

1

FCCE250470

47u/50

C113

1

FCCE300022

2.2u/63

C114

1

FCXCN40010

1n

C115

1

FCCE250100

10u/50

C116

1

FCXCN41000

100n

C117

1

FCCE250100

10u/50

C118

1

FCCE250470

47u/50

C119

1

FCCE154700

470u/25

C120

1

FCCG001000

T10uF/35

C121

1

FCCG001000

T10uF/35

C122

1

FCXCN41000

100n

C123

1

FCCE200220

22u/35

C124

1

FCXCN12200

22p

C125

1

FCCE250470

47u/50

C126

1

FCCE250470

47u/50

C127

1

FCXCN21000

100p

C128

1

FCXCN12200

22p

C129

1

FCXCN12200

22p

C130

1

FCXCN11500

15p

C131

1

FCCE250100

10u/50

C132

1

FCCE250100

10u/50

C133

1

FCXCN44700

470n

C134

1

FCXCN11200

12p

C135

1

FCXCN11200

12p

C136

1

FCXCN44700

470n

C137

1

FCXCN44700

470n

C138

1

FCXCN12200

22p

C139

1

FCXCN12200

22p

C140

1

FCXCN44700

470n

C141

1

FCCDN11000

C100n/250V

C142

1

FCCDN11000

C100n/250V

C143

1

FCCDN11000

C100n/250V

C144

1

FCCE350047

47u/200

C145

1

FCCE350047

47u/200

C146

1

FCCDN11000

C100n/250V

C147

1

FCCDN11000

C100n/250V

C148

1

FCCE350047

47u/200

C149

1

FCCE200220

22u/35

C150

1

FCCE350047

47u/200

C151

1

FCCDK11000

C100n/63V

C152

1

FCCDH71047

C47n/400V

C153

1

FCCDN11000

C100n/250V

C154

40-0065-0205 EP04-99B.xls 1 of 11

Page 41

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCCDN11000

C100n/250V

C155

1

FCCE350047

47u/200

C156

1

FCXCN41000

100n

C157

1

FCXCN41000

100n

C158

1

FCCE350047

47u/200

C159

1

FCXCN40010

1n

C160

1

FCXCN40010

1n

C161

1

FCXCN40022

2n2

C162

1

FCXCN40022

2n2

C163

1

FCCE213300

3300u/35

C164

1

FCCDH71011

C10n/400V

C165

1

FCCDK20010

C1u/63V

C166

1

FCXCN41000

100n

C167

1

FCXCN41000

100n

C168

1

FCXCN41000

100n

C169

1

FCXCN41000

100n

C170

1

FCXCN41000

100n

C171

1

FCXCN44700

470n

C172

1

FCCE200047

4.7u/35

C173

1

FCCE200047

4.7u/35

C174

1

FCCE211000

1000u/35

C175

1

FCXCN41000

100n

C176

1

FCPERL2550

Cer. Bead

CB101

1

FCPERL2550

Cer. Bead

CB102

1

FCPERL2550

Cer. Bead

CB103

1

FCPERL2550

Cer. Bead

CB104

1

FCCIPAM730

11.0730 Printed Board

CI101

1

FCXDDBAS16

BAS16

D101

1

FCXDD40070

1N4007

D102

1

FCXDD40070

1N4007

D103

1

FCXDD40070

1N4007

D104

1

FCXDD40070

1N4007

D105

1

FCXDD40070

1N4007

D106

1

FCXDDBAS16

BAS16

D107

1

FCXDDBAS16

BAS16

D108

1

FCXDDBAS16

BAS16

D109

1

FCXDDBAS28

BAS28

D110

1

FCXDD40070

1N4007

D111

1

FCXDD40070

1N4007

D112

1

FCXDDBAS28

BAS28

D113

1

FCXDD40070

1N4007

D114

1

FCXZ000091

Z9.1V

D115

1

FCXDDBAS16

BAS16

D116

1

FCXDDBAS16

BAS16

D117

1

FCXDDBAS28

BAS28

D118

1

FCXDDBAS16

BAS16

D119

1

FCXZ000082

Z8.2V

D120

1

FCXDDBAS16

BAS16

D121

1

FCXDDBAS28

BAS28

D122

1

FCXDDBAS28

BAS28

D123

1

FCXZ000039

Z3.9V

D124

1

FCXZ000039

Z3.9V

D125

1

FCXDDBAS16

BAS16

D126

1

FCDDMUR140

MUR140

D127

40-0065-0205 EP04-99B.xls 2 of 11

Page 42

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCDD041500

Z15

D128

1

FCDD041500

Z15

D129

1

FCDDMUR440

MUR440

D130

1

FCDDMUR440

MUR440

D131

1

FCXZ000082

Z8.2V

D132

1

FCXZ000082

Z8.2V

D133

1

FCDDMUR440

MUR440

D134

1

FCDDMUR440

MUR440

D135

1

FCDDMUR440

MUR440

D136

1

FCXZ000680

Z68V

D138

1

FCXZ000680

Z68V

D139

1

FCXDD40070

1N4007

D140

1

FCXDD40070

1N4007

D141

1

FCXDD40070

1N4007

D142

1

FCXDD40070

1N4007

D143

1

FCDIDB3000

DB3

D144

1

FCDD041500

Z15

D145

1

FCDD041500

Z15

D146

1

FCDD041500

Z15

D147

1

FCDD041500

Z15

D148

1

FCDD041500

Z15

D149

1

FCDD041500

Z15

D150

1

FCDD041500

Z15

D151

1

FCDD041500

Z15

D152

1

FCDD041500

Z15

D153

1

FCDD041500

Z15

D154

1

FCDD041500

Z15

D155

1

FCDD041500

Z15

D156

1

FCDD041500

Z15

D157

1

FCDD041500

Z15

D158

1

FCDD041500

Z15

D159

1

FCDD041500

Z15

D160

1

FCDD041500

Z15

D161

1

FCDD041500

Z15

D162

1

FCDD041500

Z15

D163

1

FCDD041500

Z15

D164

1

FCDD041500

Z15

D165

1

FCDD041500

Z15

D166

1

FCXDDBAS16

BAS16

D167

1

FCXDD40070

1N4007

D168

1

FCXDD40070

1N4007

D169

1

FCFUS40125

T1.25A

F101

1

FCFUS40125

T1.25A

F102

1

FCFUS50080

T250mA

F103

1

FCFUS60400

T16A

F104

1

FCFUS60400

T16A

F105

1

FCFER43220

Ferrite

FB101

1

FCFER43220

Ferrite

FB102

1

FCFER43220

Ferrite

FB103

1

FCFER43220

Ferrite

FB104

1

FCFER43220

Ferrite

FB105

1

FCFER43220

Ferrite

FB106

1

FCFER43220

Ferrite

FB107

1

FCFER43220

Ferrite

FB108

40-0065-0205 EP04-99B.xls 3 of 11

Page 43

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCFER43220

Ferrite

FB109

1

FCFER43220

Ferrite

FB110

1

FCFER43220

Ferrite

FB111

1

FCFER43220

Ferrite

FB112

1

FCFER43220

Ferrite

FB113

1

FCFER43220

Ferrite

FB114

1

FCFER43220

Ferrite

FB115

1

FCFER43220

Ferrite

FB116

1

FCFER43220

Ferrite

FB117

1

FCFER43220

Ferrite

FB118

1

FCFER43220

Ferrite

FB119

1

FCFER43220

Ferrite

FB120

1

FCFER43220

Ferrite

FB121

1

FCFER43220

Ferrite

FB122

1

FCFER43220

Ferrite

FB123

1

FCFER43220

Ferrite

FB124

1

FCFER43220

Ferrite

FB125

1

FCFER43220

Ferrite

FB126

1

FCFER43220

Ferrite

FB127

1

FCFER43220

Ferrite

FB128

1

FCFER43220

Ferrite

FB129

1

FCFER43220

Ferrite

FB130

1

FCFER43220

Ferrite

FB131

1

FCFER43220

Ferrite

FB132

1

FCFER43220

Ferrite

FB133

1

FCFER43220

Ferrite

FB134

1

FCFER43220

Ferrite

FB135

1

FCFER43220

Ferrite

FB136

1

FCFER43220

Ferrite

FB137

1

FCFER43220

Ferrite

FB138

1

FCFER43220

Ferrite

FB139

1

FCFER43220

Ferrite

FB140

1

FCFER43220

Ferrite

FB141

1

FCFER43220

Ferrite

FB142

1

FCFER43220

Ferrite

FB143

1

FCFER43220

Ferrite

FB144

1

FCFER43220

Ferrite

FB145

1

FCFER43220

Ferrite

FB146

1

FCFER43220

Ferrite

FB147

1

FCFER43220

Ferrite

FB148

1

FCRAD12636

SERA. 1137

HS100

1

FCRAD12636

SERA. 1137

HS101

1

FCRAD12636

SERA. 1137

HS102

1

FCRAD12636

SERA. 1137

HS103

1

FCMECT0220

Heatsink f/TO220

HS104

1

FCRAD03000

Heatsink f/ Power Module

HS105

1

FCRAD03000

Heatsink f/ Power Module

HS106

1

FCIC350000

LM35DZ

IC101

1

FCIC431000

TL431AC

IC102

1

FCIC074010

TL074

IC104

1

FCIC431000

TL431AC

IC105

1

FCREG78150

7815

IC106

1

FCREG79150

7915

IC107

1

FCIC401060

40106B

IC108

40-0065-0205 EP04-99B.xls 4 of 11

Page 44

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCREG78050

7805

IC109

1

FCIC218000

TH2180C

IC110

1

FCIC435000

4N35

IC111

1

FCIC553410

NE5534A

IC112

1

FCIC435000

4N35

IC113

1

FCIC074010

TL074

IC114

1

FCIC435000

4N35

IC115

1

FCMICTO126

Insulant TO126

IN100

1

FCMICTO126

Insulant TO126

IN101

1

FCMICTO220

Insulant TO220

IN102

1

FCMICTO220

Insulant TO220

IN103

1

FCTERM0080

Socket 8p

J100

1

FCCTJ10050

B5P-VH

J101

1

FCCTAMP050

5P AMP MALE SOCKET

J103

1

FCCTM00080

B8B-EH-A

J104

1

FCCTM00020

B2B-EH-A

J105

1

FCCTM00020

B2B-EH-A

J107

1

FCCTAMP020

BASE 2pins MALE AMP

J108

1

FCTERM0100

Jumper Pin

J109

1

FCTERM0100

Jumper Pin

J110

1

FCTERM0100

Jumper Pin

J111

1

FCTERM0100

Jumper Pin

J112

1

FCCTM00030

B3B-EH-A

J113

1

FCCTM00050

B5B-EH-A

J115

1

FCREL00300

TQ2-12V

K101

1

FCIND00100

1u

L101

1

FCMJ000100

Jumper

MJ101

1

FCMJ000100

Jumper

MJ102

1

FCPINZAM00

Clamp WD. 00.2636

MP100

1

FCPINZAM00

Clamp WD. 00.2636

MP101

1

FCPINZAM00

Clamp WD. 00.2636

MP102

1

FCPINZAM00

Clamp WD. 00.2636

MP103

1

FCTUE00300

Nut M3

NV100

1

FCTUE00300

Nut M3

NV101

1

FCTUE00300

Nut M3

NV102

1

FCTUE00300

Nut M3

NV103

1

FCTUE00300

Nut M3

NV104

1

FCPORF3150

3/15P

PF101

1

FCPORF0100

A0854668

PF102

1

FCPORF0100

A0854668

PF103

1

FCPORF0100

A0854668

PF104

1

FCPORF0100

A0854668

PF105

1

FCXTT08470

BC847B

Q101

1

FCXTT08170

BC817/25

Q102

1

FCXTT08570

BC857B

Q103

1

FCXTT08170

BC817/25

Q104

1

FCTR437000

BD437

Q105

1

FCTR437000

BD437

Q106

1

FCTR587000

BF587

Q107

1

FCTR588000

BF588

Q108

1

FCTR588000

BF588

Q109

1

FCTR588000

BF588

Q110

1

FCTR150000

BUH150

Q111

1

FCTR150310

MJE15031

Q112

40-0065-0205 EP04-99B.xls 5 of 11

Page 45

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCTR150000

BUH150

Q113

1

FCTR150310

MJE15031

Q114

1

FCTR360000

IRFP360

Q115

1

FCTR360000

IRFP360

Q116

1

FCXTT08470

BC847B

Q117

1

FCXTT08470

BC847B

Q118

1

FCXTT08470

BC847B

Q119

1

FCXTT08470

BC847B

Q120

1

FCTI246000

BTB24600B

Q121

1

FCTR360000

IRFP360

Q122

1

FCTR360000

IRFP360

Q123

1

FCTR360000

IRFP360

Q124

1

FCTR360000

IRFP360

Q125

1

FCTR360000

IRFP360

Q126

1

FCTR360000

IRFP360

Q127

1

FCTR360000

IRFP360

Q128

1

FCTR360000

IRFP360

Q129

1

FCTR360000

IRFP360

Q130

1

FCTR360000

IRFP360

Q131

1

FCTR360000

IRFP360

Q132

1

FCTR360000

IRFP360

Q133

1

FCTR360000

IRFP360

Q134

1

FCTR360000

IRFP360

Q135

1

FCTR360000

IRFP360

Q136

1

FCTR360000

IRFP360

Q137

1

FCTR360000

IRFP360

Q138

1

FCTR360000

IRFP360

Q139

1

FCTR360000

IRFP360

Q140

1

FCTR360000

IRFP360

Q141

1

FCTR360000

IRFP360

Q142

1

FCTR360000

IRFP360

Q143

1

FCXTT08570

BC857B

Q144

1

FCXTT08570

BC857B

Q145

1

FCXR151000

100k0

R101

1

FCXR151000

100k0

R102

1

FCXR138250

8k25

R103

1

FCXR132210

2k21

R104

1

FCXR141000

10k0

R105

1

FCXR151000

100k0

R106

1

FCXR152260

226k

R107

1

FCXR141000

10k0

R108

1

FCXR121000

100.0

R109

1

FCXR151000

100k0

R110

1

FCXR132430

2k43

R111

1

FCXR061000

1M

R112

1

FCXR151000

100k0

R113

1

FCXR132210

2k21

R114

1

FCXR131000

1k0

R115

1

FCXR131270

1k27

R116

1

FCXR144750

47k5

R117

1

FCXR062200

2M2

R118

1

FCXR142210

22k1

R119

1

FCXR144750

47k5

R120

1

FCXR141000

10k0

R121

40-0065-0205 EP04-99B.xls 6 of 11

Page 46

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCXR131820

1k82

R122

1

FCXR141000

10k0

R123

1

FCXR142000

20k0

R124

1

FCRJC61000

100k

R125

1

FCXR152260

226k

R126

1

FCXR151000

100k0

R127

1

FCXR142210

22k1

R128

1

FCXR062200

2M2

R129

1

FCXR148450

84k5

R130

1

FCXR151000

100k0

R131

1

FCXR142000

20k0

R132

1

FCXR141000

10k0

R133

1

FCXR121000

100.0

R134

1

FCXR152870

287k

R135

1

FCXR117500

75.0

R136

1

FCXR117500

75.0

R137

1

FCXR142000

20k0

R138

1

FCXR141000

10k0

R139

1

FCXR135110

5k11

R140

1

FCXR131820

1k82

R141

1

FCXR151000

100k0

R142

1

FCXR131000

1k0

R143

1

FCXR142000

20k0

R144

1

FCXR061000

1M

R145

1

FCXR131820

1k82

R146

1

FCXR134750

4k75

R147

1

FCXR131000

1k0

R148

1

FCXR151000

100k0

R149

1

FCXR131000

1k0

R150

1

FCXR131000

1k0

R151

1

FCXR141000

10k0

R152

1

FCXR151000

100k0

R153

1

FCXR071000

10M

R154

1

FCXR121780

178

R155

1

FCXR141000

10k0

R156

1

FCXR131000

1k0

R157

1

FCXR131000

1k0

R158

1

FCXR127870

787

R159

1

FCXR121780

178

R160

1

FCXR127870

787

R161

1

FCXR121780

178

R162

1

FCXR131500

1k50

R163

1

FCXR131500

1k50

R164

1

FCXR131210

1k21

R165

1

FCRJP44700

4k7-CMET

R166

1

FCXR113320

33.2

R167

1

FCRC236800

680/ 1/2

R168

1

FCXR151000

100k0

R169

1

FCXR151000

100k0

R170

1

FCXR128250

825

R171

1

FCXR141000

10k0

R172

1

FCXR141000

10k0

R173

1

FCXR113320

33.2

R174

1

FCRC236800

680/ 1/2

R175

40-0065-0205 EP04-99B.xls 7 of 11

Page 47

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCXR115620

56.2

R176

1

FCXR115620

56.2

R177

1

FCRF221000

NF10/1/2

R178

1

FCRF221000

NF10/1/2

R179

1

FCRF426800

NF68/1

R180

1

FCRF426800

NF68/1

R181

1

FCRF221800

NF18/ 1/2

R182

1

FCRF221800

NF18/ 1/2

R183

1

FCRY000100

W0.22/5

R184

1

FCRY000100

W0.22/5

R185

1

FCXR151500

150k0

R186

1

FCRY000250

6.8/5W

R187

1

FCXR151500

150k0

R188

1

FCXR121000

100.0

R189

1

FCXR121000

100.0

R190

1

FCXR131000

1k0

R191

1

FCXR131000

1k0

R192

1

FCXR143320

33k2

R193

1

FCXR143320

33k2

R194

1

FCXR142210

22k1

R195

1

FCXR143320

33k2

R196

1

FCXR143320

33k2

R197

1

FCXR142210

22k1

R198

1

FCXR121000

100.0

R199

1

FCXR125620

562

R200

1

FCXR121000

100.0

R201

1

FCXR125620

562

R202

1

FCXR123010

301

R203

1

FCXR123010

301

R204

1

FCXR151000

100k0

R205

1

FCXR115620

56.2

R206

1

FCRC521000

10/2

R207

1

FCXR151500

150k0

R208

1

FCXR115620

56.2

R209

1

FCRC512200

2.2/2

R210

1

FCXR151000

100k0

R211

1

FCRC553300

33K/2

R212

1

FCRF221800

NF18/ 1/2

R213

1

FCRF221800

NF18/ 1/2

R214

1

FCRY000100

W0.22/5

R215

1

FCRY000100

W0.22/5

R216

1

FCRF221800

NF18/ 1/2

R217

1

FCRF221800

NF18/ 1/2

R218

1

FCRY000100

W0.22/5

R219

1

FCRY000100

W0.22/5

R220

1

FCRF221800

NF18/ 1/2

R221

1

FCRF221800

NF18/ 1/2

R222

1

FCRY000100

W0.22/5

R223

1

FCRY000100

W0.22/5

R224

1

FCRF221800

NF18/ 1/2

R225

1

FCRF221800

NF18/ 1/2

R226

1

FCRY000100

W0.22/5

R227

1

FCRY000100

W0.22/5

R228

1

FCRF221800

NF18/ 1/2

R229

40-0065-0205 EP04-99B.xls 8 of 11

Page 48

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCRF221800

NF18/ 1/2

R230

1

FCRY000100

W0.22/5

R231

1

FCRY000100

W0.22/5

R232

1

FCRF221800

NF18/ 1/2

R233

1

FCRF221800

NF18/ 1/2

R234

1

FCRY000100

W0.22/5

R235

1

FCRY000100

W0.22/5

R236

1

FCRF221800

NF18/ 1/2

R237

1

FCRF221800

NF18/ 1/2

R238

1

FCRY000100

W0.22/5

R239

1

FCRY000100

W0.22/5

R240

1

FCRF221800

NF18/ 1/2

R241

1

FCRF221800

NF18/ 1/2

R242

1

FCRY000100

W0.22/5

R243

1

FCRY000100

W0.22/5

R244

1

FCRF221800

NF18/ 1/2

R245

1

FCRF221800

NF18/ 1/2

R246

1

FCRY000100

W0.22/5

R247

1

FCRY000100

W0.22/5

R248

1

FCRF221800

NF18/ 1/2

R249

1

FCRF221800

NF18/ 1/2

R250

1

FCRY000100

W0.22/5

R251

1

FCRY000100

W0.22/5

R252

1

FCRF221800

NF18/ 1/2

R253

1

FCRF221800

NF18/ 1/2

R254

1

FCRY000100

W0.22/5

R255

1

FCRY000100

W0.22/5

R256

1

FCXR126040

604

R257

1

FCXR151000

100k0

R258

1

FCXR141000

10k0

R259

1

FCXR152050

205k

R260

1

FCXR151000

100k0

R261

1

FCXR141000

10k0

R262

1

FCXR135110

5k11

R263

1

FCXR141000

10k0

R264

1

FCXR131000

1k0

R265

1

FCXR131000

1k0

R266

1

FCXR141000

10k0

R267

1

FCXR135110

5k11

R268

1

FCXR149090

90k9

R269

1

FCXR115620

56.2

R270

1

FCXR000000

0

RX100

1

FCXR000000

0

RX101

1

FCT8040060

Screw M4x6 SPAN

SC100

1

FCT8040060

Screw M4x6 SPAN

SC101

1

FCT8040060

Screw M4x6 SPAN

SC102

1

FCT8040060

Screw M4x6 SPAN

SC103

1

FCT8040060

Screw M4x6 SPAN

SC104

1

FCT8040060

Screw M4x6 SPAN

SC105

1

FCT8040060

Screw M4x6 SPAN

SC106

1

FCT8040060

Screw M4x6 SPAN

SC107

1

FCT8040060

Screw M4x6 SPAN

SC108

1

FCT8040060

Screw M4x6 SPAN

SC109

1

FCT8040060

Screw M4x6 SPAN

SC110

40-0065-0205 EP04-99B.xls 9 of 11

Page 49

PARTS LIST: PRINTED CIRCUIT 11.0730.07.00

Q

Code

Description

Reference

1

FCT8040060

Screw M4x6 SPAN

SC111

1

FCT8030100

Screw M3x10 SPA

SC112

1

FCT8030100

Screw M3x10 SPA

SC113

1

FCT8030150

Screw 3x15 SPIRALFORM

SC114

1

FCT8030150

Screw 3x15 SPIRALFORM

SC115

1

FCT8030100

Screw M3x10 SPA

SC116

1

FCT8030100

Screw M3x10 SPA

SC117

1

FCT7503010

Screw M3x10

SC118

1

FCT7503010

Screw M3x10

SC119

1

FCT7503010

Screw M3x10

SC120

1

FCT7503010

Screw M3x10

SC121

1

FCT8030150

Screw M3x15

SC122

1

FCSEPPM000

Plastic Spacer f/board ct.

SC123

1

FCT8030150

Screw 3x15 SPIRALFORM

SC124

1

FCT8030150

Screw 3x15 SPIRALFORM

SC125

1

FCSEPPM000

Plastic Spacer f/board ct.

SC126

1

FCSEPPM000

Plastic Spacer f/board ct.

SC127

1

FCSEPPM000

Plastic Spacer f/board ct.

SC128

1

FCTERMF280

Faston 2.8mm

TS101

1

FCTERMF280

Faston 2.8mm

TS102

1

FCTERMF280

Faston 2.8mm

TS103

1

FCTERMF280

Faston 2.8mm

TS104

1

FCMECPON19

19mm

W100

1

FCMECPON19

19mm

W101

1

FCMECPON19

19mm

W102

1

FCMECPON19

19mm

W103

1

FCMECPON19

19mm

W104

1

FCMECPON19

19mm