Page 1

USER MANUAL

MANUAL DE INSTRUCCI O NES

MANUEL UTILISATEUR

BEDIENUNGSANLEITUNG

Page 2

2

Page 3

3

LIST OF CONTENTS

1. IMPORTANT REMARK 04

2. INTRODUCTION 05

3. INSTALLATION 05

4. QUICK START 08

5. OPERATION AND USAGE 10

6. FURTHER CONSIDERATIONS 12

7. FUNCTION LIST 13

8. FUNCTION DIAGRAM 13

9. TECHNICAL CHARACTERISTICS 50

10. CONFIGURATION DIAGRAM 51

11. BLOCK DIAGRAM 52

All numbers subject to variation due to production tolerances. ECLER SA reserves the right to make changes or

improvements in manufacturing or design which may affect specifications.

Page 4

4

1. IMPORTANT REMARK

Safety Instructions

In order to get the optim um operation and efficiency f rom your mixing unit, it is VERY IMPOR TANT - before you

plug anything - to read this m anual v ery car efull y and tak e ser iousl y into acc ount all cons iderat ions sp ecif ied within

it. We strongly recommend that its maintenance be carried out by our Authorised Technical Services.

This apparatus must be earthed through its mains cable.

Do not expose the unit to rain or water splashes, and do not place liquid containers or incandescent

objects like candles on top of the unit.

Any change in the configuration of the unit must be carried out by a qualified technician. Should any

connection / disconnection task be done, always disconnect the unit from the mains supply.

Warranty Descriptions

Your ECLER equipm ent has undergone exhaustive laborat ory and qualit y control tests before leaving the fac tory.

Nevertheless, your may be in need of our Technical Service during the period covered by the Guarantee or

afterwards. In that cas e, caref ully protect your equipm ent in its or iginal pac ket and s end it to our Technical Service

with the transport and insur ance paid. Attac h a photocop y of your Guarantee Certificate an d a detailed desc ription

of the defect you have observed.

ECLER S.A. guarantees th e NUO4.0 mixer against material defec ts and manuf acturing faults for the period of one

year, starting from the original purchase date.

ECLER, S.A., will repair th e defective equipment within the aforem entioned period, with no charge for parts and

labour.

To ensure the validity of the G uarantee, it is essential that the attached Guar antee, Registration Card is f illed out

correctly and remitted to your ECLER distributor, within 10 DAYS after date of purchase.

The Guarantee is non-transferable and protects the original buyer only.

The Guarantee does not cover:

Damages caused by mistreatment or negligent handling, lack of elementary precautions, disregard to the

instructions in the manual, faulty connection or accidents.

ECLER, S.A., will not be held respons ible for any direct or indirect dam age, loss or other damage or iginated b y or

relating to the set.

* sets that have been manipulated, altered or repaired other than at the authorized Technical Service centers.

* the exterior fittings and electro-m ec hanica l parts, nor their wear due to use.

* shipping and insurance expenses, nor for damages the set may incur during its transport.

This Guaranteed is valid only for repairs or services carried out at an authorized Technical Service Center.

Page 5

5

2. INTRODUCTION

Congratulations for acquiring a genuine, profes s ional E CLER device!

The NUO4.0 is a prof essio nal DJ mixer designed and m anufac tured b y ECLER; an ent erprise with headq uarter s in

Barcelona, which works on professional audio equipment since 1965.

The NUO4.0 is a profess ional audio mixer thought f or any kind of DJ, due to its wide range of functions, which

make it a console able to mix any kind of music style: techno, house, minimal, electro, hip hop, …

The NUO4.0 is a mixer though t for scratching techniques, due to the vers atility of the adjustments of faders and

crossfaders. The NUO4.0 i s fur therm or e able to wear t he ET ERNA L c r ossf ader , ECLER ’s magnetic crossfader wit h

5 years guarantee, which has been specially designed for scratching specialists.

This genuine mixer uses the best components available on the market, obtaining the highest possible sound

quality. The over 40 years of ex perience in the design of profess ional audio equipment make that the c ircuits are

extremely efficient a nd a warm and c rystal cle ar anal ogue s ound is o btained. All c ircuits ar e m ounted an d tes ted in

our factory site in Barcelona.

Furthermore, the NUO 4.0 is a mixer which has be en specially designed for a ll kinds of professional ins tallations,

thanks to its two ba lanced outputs and its t wo microphone inputs. Its desi gn and resistance turn it into the ideal

console for professional installations, as well as for mobile applications executed by trendiest DJ’s.

3. INSTALLATION

The main consideration to be taken when looking for the best setup location for the NUO4.0 has to be the

maximum commodity for the user and the easiness for realizing the necessary connections.

The NUO4.0 has been basically designed as an on desk mixer and its usual

location will be between two turntables or CD players. The mixer is 37 cm

(14.57") deep and 32 cm (12.6") wide.

Using the metallic side panel kit (o ptionally avai lable) you m ay fix your NUO4.0

directly on a support surface or on those side panels which also allow you to

skew it. The "NUORAKI" metallic holders allow you to install the mixer in a

standard 19" rack.

Because of the high gain of the PHONO and MICRO inputs, alwa ys try to place

the mixer as far away as pos sible from noise sources (dim mers, engines, etc.)

and mains wires. For th e very same reason, and und er any circumstance, you

should never remove the unit's metallic cover.

The power consumpt ion of t he NUO4 .0 is very low, so they do not n eed an y coo ling, but you sho uld a void ex treme

temperatures and the atmosphere should be as dry and dust free as possible.

The NUO4.0 operates no w with a new universal input power suppl y “Switching Power Supply” and can pe rfectly

works without any interna l modific ation from 90V to 264V – 47 to 63Hz. Make sure that t he mains-w ire is far away

from the signal-cables in order to avoid any possible audio hum.

In order to protect the unit from an eventual electric al overload it carries a T 0.5A f use. Should it ever blow up,

unplug the unit fr om mains and replace it with an identical one. If the new fuse blows again contact immediatel y

with our authorized technical service.

ATTENTION: NEVER SHORT-CIRCUIT THE SECURITY PATH NOR USE A HIGHER VALUE FUSE.

CAUTION: Fuse substitutions have to be performed by a qualified technician.

Page 6

6

Audio input connections

INPUT 1 PHONO Turntable

INPUT 1 LINE CD Deck

INPUT 2 PHONO Turntable

INPUT 2 LINE CD Deck

INPUT 3 PHONO Turntable

INPUT 3 LINE CD Deck

INPUT 3 MICRO Microphone

INPUT 4 PHONO Turntable

INPUT 4 LINE CD Deck

INPUT 4 MICRO Microphone

Phono Inputs

Phono Turntables m ust be fitted with a magnetic car tridge with nom inal output leve l between -55d BV and -25dBV

(1,77 to 56mV). T he PHONO inputs (35) of th e NUO4.0 have a high headr oom (margin before satur ation) and it

can handle higher ou tput c artr idg es than what is usual . These inputs are supp lie d wi th a nominal input sens itivity of

-40dBV(10mV).

Line Inputs

The sensitivity of the input s mark ed as LINE ( 36) is 0 dBV (1V). You ca n connec t sound so urces s uch as CD , DAT

or MP3 players, as well as keyboards and other instruments.

Microphone input

The MICRO inputs ( 13, 37) are a djusted f or a nom inal input level of -35dBV. The front al conn ector ( 13) is a c om bo

XLR3/Jack type, while the rear connector (37) is a XLR·type. These microphone inputs allow connections in

balanced mode. The connection has to be done as follows:

Hot or direct signal > Pin 2 Tip

Cold or inverted signal > Pin 3 Ring

Ground > Pin 1 Sleeve

The microphones must have low impedance (from 200 to 600Ω) and must be monophonic. For unbalanced

connections, a short circ uit m ust be done between pi n 3 and ground or th e center r ing. The NUO4.0 wears an 18V

Phantom power for c ondenser m icrophones. An int ernal jum per allows disabl ing the phantom power. T he NUO4.0

MICRO input is delivered ex works with enabled phantom power (see the configuration diagram).

Page 7

7

Audio outputs connections

MASTER Main power amplifier

BOOTH Booth/Room2 power amplifier

REC Recording

FX Send/Return External effect device (Input and Output)

Headphones Headphones

MASTER output

This stereo output feeds the PA system through balanced XLR3 connectors (38, 39) and an unbalanced RCA

connector (40). The nominal level for MASTER output is set to 0dBV (1V), but can be set to +6dBV using an

internal jumper. The MASTER output level is controlled by the MASTER potentiometer (24).

Near the MASTER c on trol l er you w ill f in d t he L +R switch (27), whic h ad ds th e lef t c hann el an d t he r ight c ha n nel f or

MASTER and BOOTH outp uts. This function is especi ally useful if a f ailure occurs on one of the channe ls during a

live session (a typical example could be a bad c ontact in the turntable ’s capsule). Enabling this switch, the mixer

will send the L+R sum to both loudspeakers, so that the major part of the audience will not notice the malfunction.

MASTER and BOOTH have a balance controller BAL (26)

BOOTH output

Normally this is used to obtain an independent output for the DJ booth. This stereo BOOTH output wears a

balanced XLR3 output and an unbalanced RCA output. The nominal level for the BO OTH output is set to 0dBV

(1V), but can be adjusted to +6dBV usi ng an intern al j um per. T he BOOT H output leve l is con trol led b y the BOO TH

potentiometer (25).

Record output

There is a REC output (22 ) on the control surface, whic h uses RCA connectors. T he nominal output level f or the

REC output is 0dBV (1V). This output is taken post-fader, before the MASTER signal.

FX Send/Return effects loop

The RCA connectors on th e FX SEND output (41) an d the FX RETURN input ( 42) allow creating a si gnal loop for

external effects processors, samplers or sequencers. The nominal l evel for the SEND output, as well as for the

RETURN input, is 0dBV (1V).

The signal sent to the FX SEND output c an be taken before or behind the fader using the PRE/ POST switch (9)

and the send level ca n be set usin g the as sociat ed po tentiom eter (8). T he NUO4. 0 also wear s a general FX SEN D

controller (17), which a dds the four channels, a general FX RET URN controller (15) and a controller for t he FX

RETURN monitoring signal, FX PFL (16).

Headphones

In order to obtain a high perf ormance, these should be of the high impedanc e type (200-600Ω). T hese are to be

connected to the headpho nes output (30) located on the controller surfac e using a stereophonic, normalized ¼’’

jack connector or a 3.5mm minijack connector. Sleeve is Ground, Ring is Right Channel and Tip is Left Channel.

Page 8

8

4. QUICK START

Install and connect the NUO4.0 as described in the INSTALLATION paragraph nº1.

We will describe a “Quick Start” procedure using the LINE input of

channel 1 and headphone monitoring output only.

1. Set the controllers to their initial position

Set the rotating controllers GAIN, HI, MID and LOW from channel 1 (3,

4, 5, 6) to their central position. Set th e channel’s fader (11) to its lower

end and assign the A/OFF/B switch (10) to position A (the channel is

now assigned to the crossfader’s A side).

2. Connect the headphones

Connect them to the headphones output (30). Set the headphones

LEVEL controller (29) to minimum level and move the SELECT (28)

controller into PFL position.

3. Connect a CD player

Connect a CD p layer to LINE input on cha nnel 1 (36), insert a CD and

play the CD.

4. Connect the mixer's power cable

Connect the power c ab le t o the mixer’s power supp ly input (43) and turn

it on using the MAI NS IN PUT s witch (45). Both elem ents are located on

the mixer’s backside.

5. Select the input source

Make sure that chann el 1’s input switc h (1) is in LINE position and that

the channel’s VU-meter (2) glows up. If this doesn’t happen, verify that

the CD player is correctly connected and that there is an audio track

being played back.

6. Adjust the input level

Move the GAIN (3) control until the VU-meter shows 0dB.

7. Send the signal to the main output

Move the fader from channel 1 (11) all the way up and set the

crossfader (12) to side A.

Page 9

9

8. Listen to the signal with your headphones

Press the PFL button (7) on c hanne l 1. Adjust the LEVEL contr ol ler (29) to obt ai n a c om f or table monitoring volume.

Now you should hear music with your headphones. Turn the SELECT controller (28) to the right to c rossfade the

PFL signal and the MIX s ignal. When this controller is c ompletely turned to the right, only the MIX s ignal will be

monitored.

9. Try the operation of the tone controllers

Experiment with this po werful 3-way stereo equal iser (4, 5, 6). This tone contr ol has been designed f or a creative

sound edition: each way can be individually isolated using the big and ergonomic rotary controllers.

10. Verify the crossfader settings.

Each channel can be assigned to the crossfader using the A/OFF/B

switch (10). T he crossfader allows melting the signals assigned to its

sides. If the switc h is in pos ition A or B, the c hanne l is assigne d to o ne

or the other side of the crossfader. The OFF position disables the

crossfader function for this channel.

11. Adjust the crossfader curve

The XFADER SHAPE control (19) allows you to precisely adjust the

skew angle of the cr ossf ader’s c urve. T urning the c ontroller com pletel y

to the left, the two songs will be melt softly. The crossfader’s curve

raises when turning the controller to the right. Moving the controller

completely to the right, th e signal will enter suddenl y with just a short

movement of the crossfader, which is a very suitable feature for

scratching techniques.

Page 10

10

5. OPERATION AND USAGE

Start-up

This can be done using the switch (45) located at the mixer’s back panel. Now the LED ON (23) indicator will

highlight. Even if the noise produced while enabling the NUO4.0 is as low as possible and gets completely

cancelled if all faders are turned down, it is always recommendable to turn on the devices using the following

sequence:

1. Sound sources.

2. Mixer, equalizers, active filters.

3. Finally, power amplifiers.

Powering off should be don e by followin g the exac t rever se sequenc e in order t o avoid an y possib le damage to the

loudspeakers.

Control Description

Input selector

Each channel features an input toggle switch selector (1).

Channel GAIN

All the NUO4.0 input channels ha ve an accessible input sens itivity GAIN control (3). The GAIN controls adjus t the

input level of each channel in order to compensate the different sources connected to the mixer.

The gain adjustments should be done with great care, using as a r ef erenc e t he V U-meter (2) on eac h chan nel. The

standard level reference used to mix audio signals is 0dBV.

The gain margin is set to ±15d B, but can be reduced to ±6dB V. This setting is independe nt for each channel and

can be done using soldering bridges. See the configuration diagram.

Equalization

The tone control system for each channel of f ers a wide range of modification from -30 to +10dB f or lo w f r eque nc ies

(6) and high frequenci es (4) and f rom -25 to +1 0dB for m iddle frequ encies (5) . This wide ran ge of var iation, kno wn

as “kill” type, can completely a ttenuate the selected fre quency range and has bee n speciall y designed f or creative

usage during live sessions.

ATTENTION: Use equalization carefully, by boosting too much the low frequency range, you can induce an

excessive displacement of the speakers membrane.

Monitoring System

The NUO4.0 is equipped with a flexible and easy monitoring system that will allow the performers to finely tune PFL

(Pre-fader listening) and M ix levels of each input t hrough the VU-MET ER and the HEAD PHONES. Each c hannel

can be monitorized visually and pre-listened pressing the dedicated PFL (7) button.

For HEADPHONES monitoring, the SEL ECT rotary potentiometer (28) allows you to blend a se lecte d PF L to geth er

with the main MIX Program. The LEVEL rotary potentiometer (29) controls the level of headphones output.

Each channel has a dedicated VU-meter that allows visual monitoring of the PFL signal (2).

Page 11

11

Sending to external effects units FX Send/Return

The 4 channels from the NUO4.0 are equipped with potent iometers (8) that allo w sendi ng the signal to an ex ternal

effects unit, sampler, etc. These potentiometers allow to precisely adjusting the signal level sent from each

channel.

The FX SEND output (4 1) has to be co nnected t o th e ef fec ts proc essor ’s input an d its o utput t o the R ET URN input

(42) or any LINE input (36).

This signal send ca n be configured either P RE or POST fader with th e PRE/POST toggle sw itch (9), so that the

level is affected or not by the channel fader.

The NUO4.0 also wears a general FX SEND con troller (17), which adds the four channels, a g eneral FX RETURN

controller (15) and a controller for the FX RETURN monitoring signal, FX PFL (16).

Faders

The NUO4.0 is equippe d with the new generat ion of ECLER 60mm faders (11) which are precise, extremely soft

and their features withstand over 4.000.000 manipulations, thanks to the ECLER VCA system (VCA: Voltage

Controlled Amplifier)

The usage of VCA technolog y allows the modif ication of the f ader's behavior. On the f rontal panel you will f ind the

FADER SHAPE potentiom eter (18), which allows adjusting the fader's curve so that the volume is proportionally

distributed on the fader’s range or that it appears suddenly.

Crossfader

Each channel can b e ass i g ned t o t he c r oss f ader (12) us ing t he A/OF F/ B switch (10). The cr oss f ader allo ws melting

the signals assigned to its sides. If the s witch is in positio n A or B, the chann el is ass igned to one or the other side

of the crossfader. The OFF position disables the crossfader function for this channel.

The NUO4.0’s crossfader includes a range of controls which allow adjusting its behavior and make it a really

accurate tool. The X FADER SHAPE co ntrol (19) allo ws you to precise ly adjust the s kew angle of the crossfader’s

curve. Turning the controlle r completely to the left, the two songs will be melt softly. T he crossfader’s c urve raises

when turning the controller to the right. Moving the c ontroller com pletely to the right, the sign al will enter suddenl y

with just a short movement of the crossfader, which is a very suitable feature for scratching techniques.

The REVERSE sw itch (20) inverts the cr ossfader’s direction . Depending on the selec ted direction, it is p ossible to

perform “cuts” as well as “transforms” moving the crossfader into the same direction.

The electronically correction for the CUT IN (21) is only effective if the NUO4.0 has been equipped with the optional

ETERNAL crossfader. If it only wears the s tandard cross fader, the CUT IN pote ntiometer m ust remain in the OFF

position. The CUT IN is the existing dist ance between the ph ysical end of the crossfader and the entering point of

the signal. The positi on with the shortest CUT IN provides a nearly instantan eous signal cut. To find t his position

the fader has to be set to an end and the C UT IN potentiometer m ust be turned rightwards until a m usical signal

can be heard. To enlarge the CUT IN time, turn the potentiometer to the left.

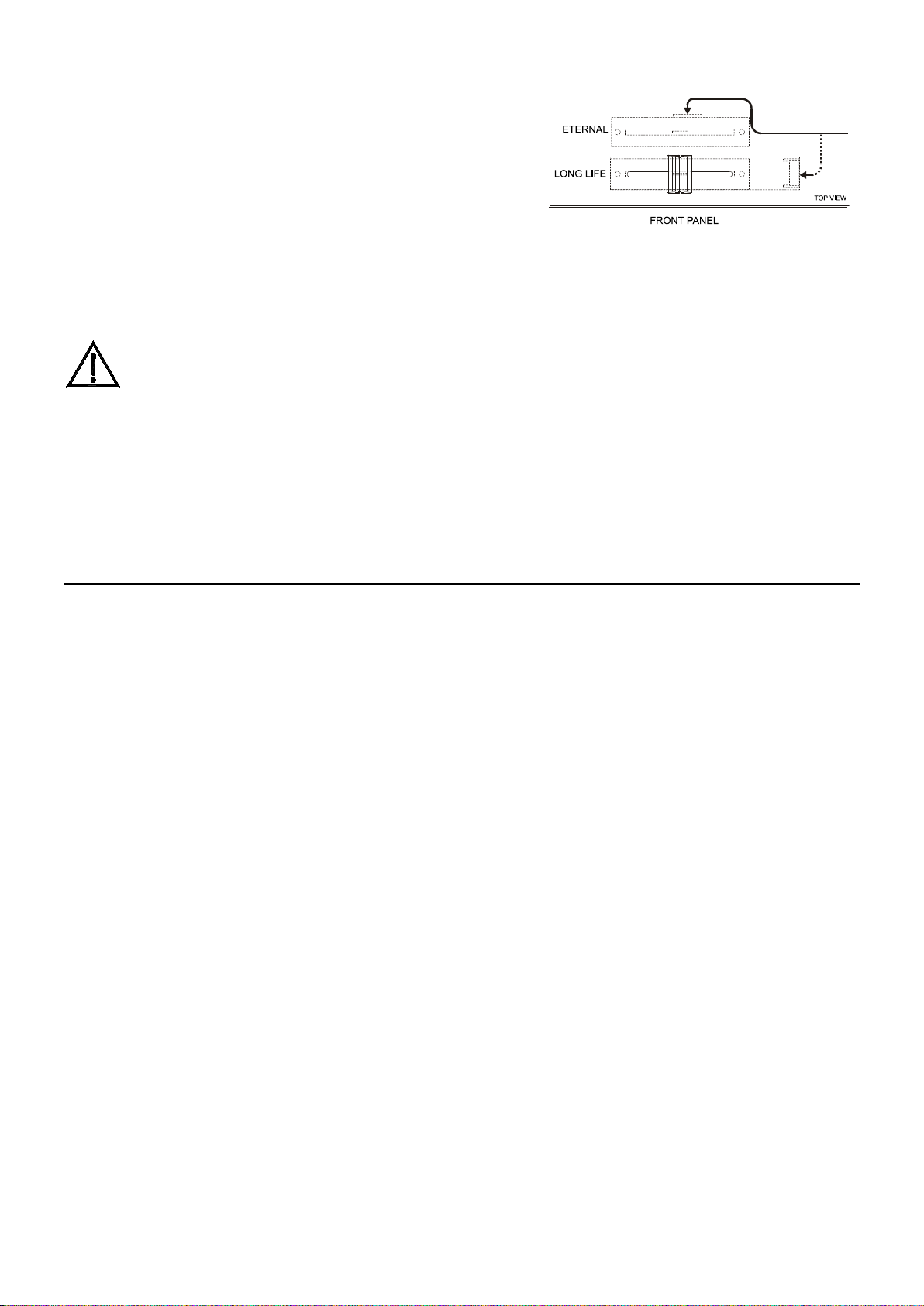

If you want to extend the life tim e of your crossfader, the NUO 4.0 allows the insta llation of the awarded ETERNAL

crossfader. This inducti ve crossfader techno logy is based on a magnet ic control s ystem and is completel y contact

free. The combination of thi s technolog y with an exc lusive, m echanical slid ing sys tem provides a s oft handli ng and

one of the most precise c rossfaders available these da ys. The inductive ETERNAL c rossfader has been specially

designed to execute ex treme turntablism techniques, which req uire an extremely soft and fast m ovement of the

crossfader.

Page 12

12

If you wish to install the ETERNAL crossfader, please accomplish the following instructions:

1. Remove the buttons from the sliding and rotating potenti ometers

of the mixer surface.

2. Unscrew the out er scr ews hol ding t he m ixer contr ol plate in place

and remove it.

3. Remove the two screws holding the crossfader in place and

remove it.

4. Carefully disconnect the multipin connector.

5. Replace the crossfader with the ETERNAL crossfader.

6. Connect the multipin connector you disconnected before.

7. Fix it with the two screws. Make sure the orientation is the one described on the drawing.

8. Put the control plate back in place and screw it tight.

9. Put the potentiometer buttons back in place.

ATTENTION: Always use original ECLER replacement parts.

WARNING: the replacement of the crossfader has to be done by a qualified technician.

MASTER and BOOTH output levels

The NUO4.0 features t wo main output level contro ls MA ST ER and BO OTH. The MASTER level is contr o ll e d b y the

MASTER (24) level knob. The BOOTH level is controlled by the BOOTH (25) level knob.

The balance potentiometer BAL (26) and the L+R switch (27) affect both outputs.

6. FURTHER CONSIDERATIONS

Ground loops

Ensure at all tim es that no signal sourc es reaching the m ixing desk and no devi ces connected to its o utput have

their earths interconn ected; that is, earth shoul d never reach them via two or more different paths, as this could

lead to humming wh ich could even in terfere with sound r eproduction qu ality. In order to avoid earth loops , ensure

that the shielding of cables, if connected to the chassis, are never connected with each other.

Background noise

The use of active circuitry can yield, depending on the conf iguration, to a significant noise lev el. The NUO4.0 has

been designed for the m inimum poss ible noise. An yway, the noise le vel will al ways depend on the c orrect u se and

installation of the m ixer. It i s not the same s etting up t he FAD ER at " 2" and the MAST ER at "10 " that th e ot her wa y

round; FADER at "10" and MASTER at "2". In the first case you get a poor signal to noise ratio that will be fully

amplified by the m aster while o n the s econd we hav e a goo d sig nal to nois e ratio onl y amplifie d b y "2". As a result,

the background noise is greater in the first case than in the second one.

Audio connections

As a general rule of thum b, make the signal connections as short as possible and use the best connecto rs and

cable available. Cables and connector s are frequently he ld cheap, forgetting t hat a bad connec tion can result i n a

poor sound quality.

Cleaning

The control panel s hould never be cle aned with solvent or abrasive substanc es as it could bec ome damaged. To

clean it, use a slightly moist soft cloth, together with a neutral liquid detergent, and then dry it with a clean cloth. It is

advisable to remove all s weat stains after use. Be caref ul to ensure that water never enter s the machine through

any of the openings.

Page 13

13

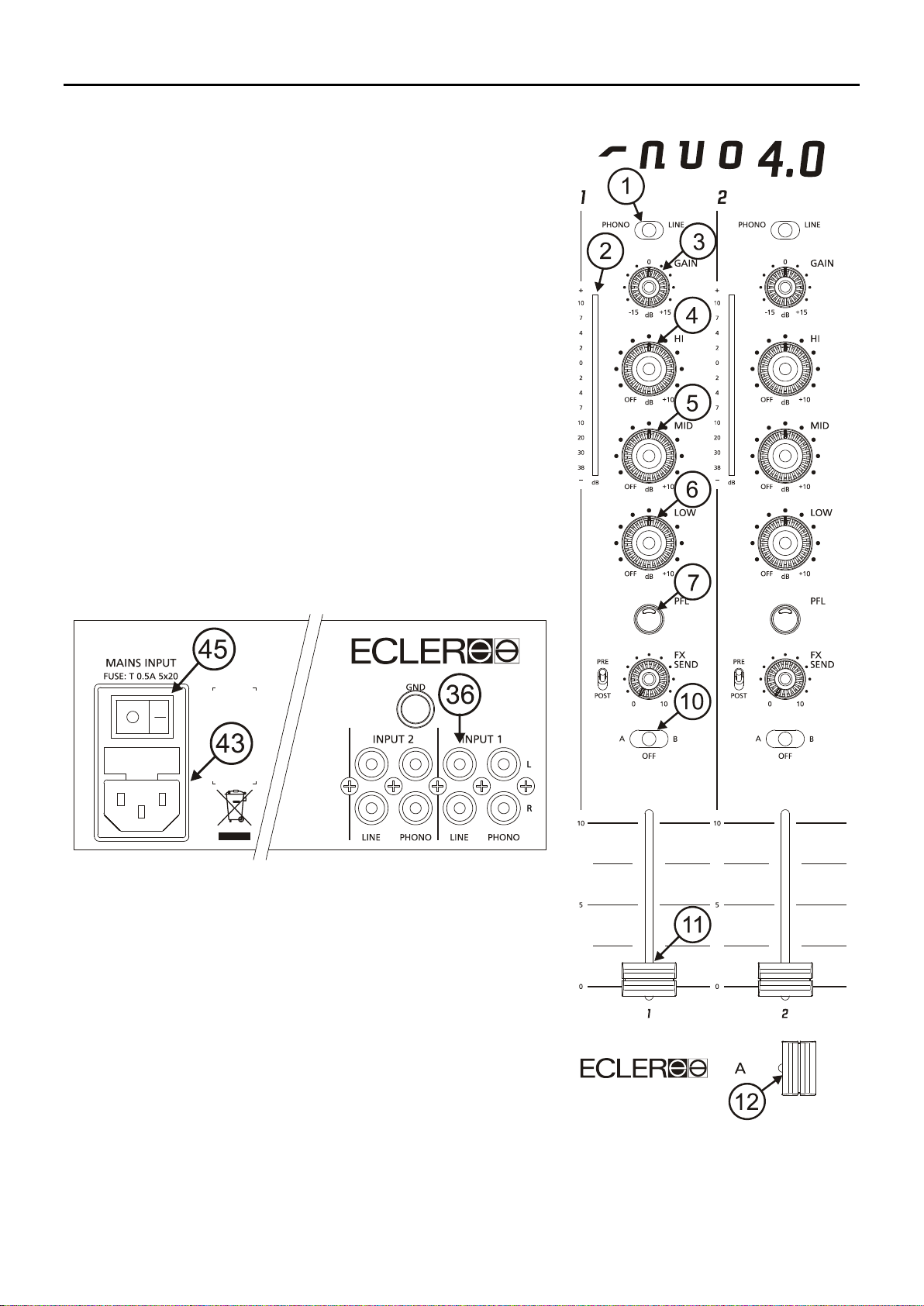

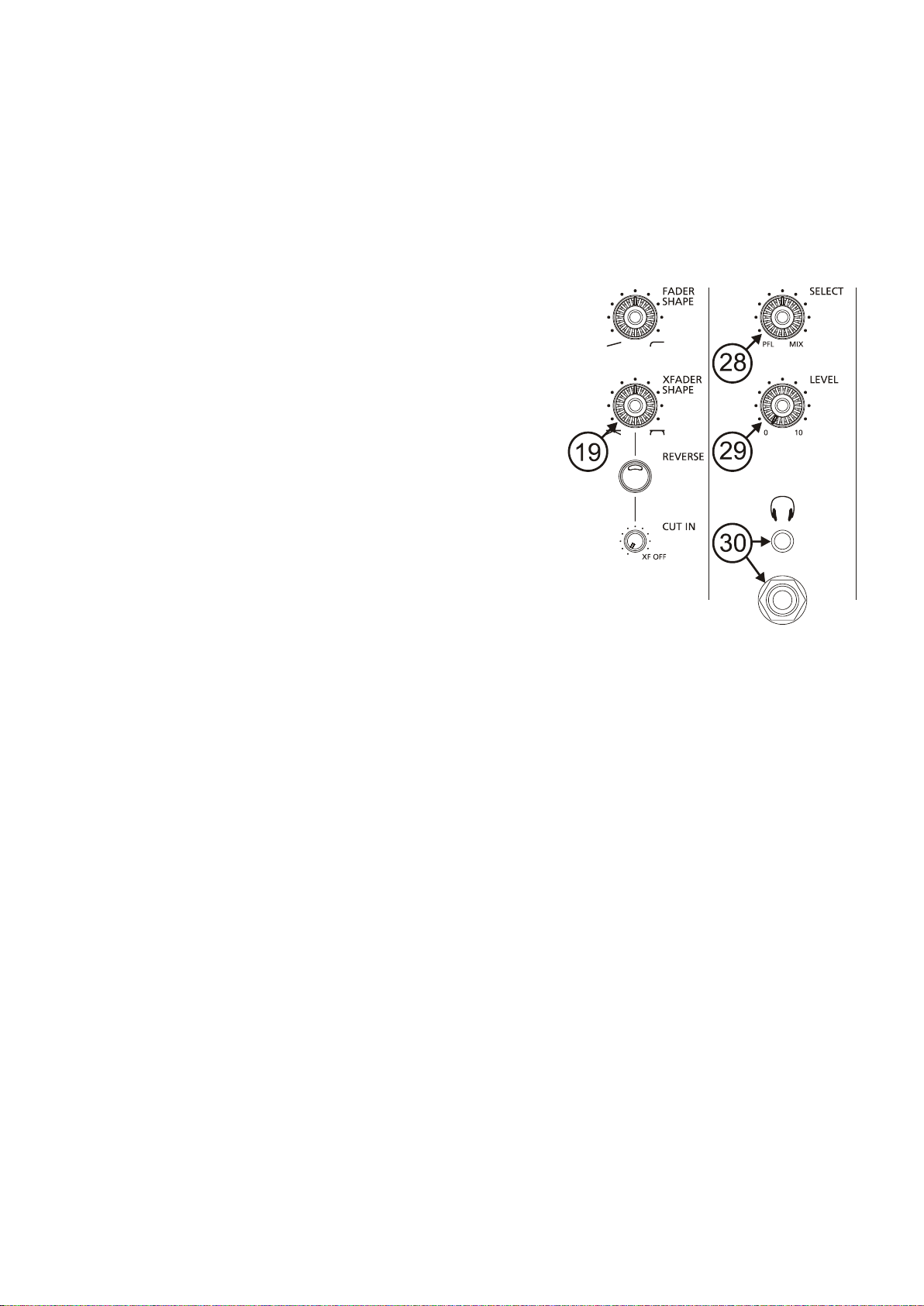

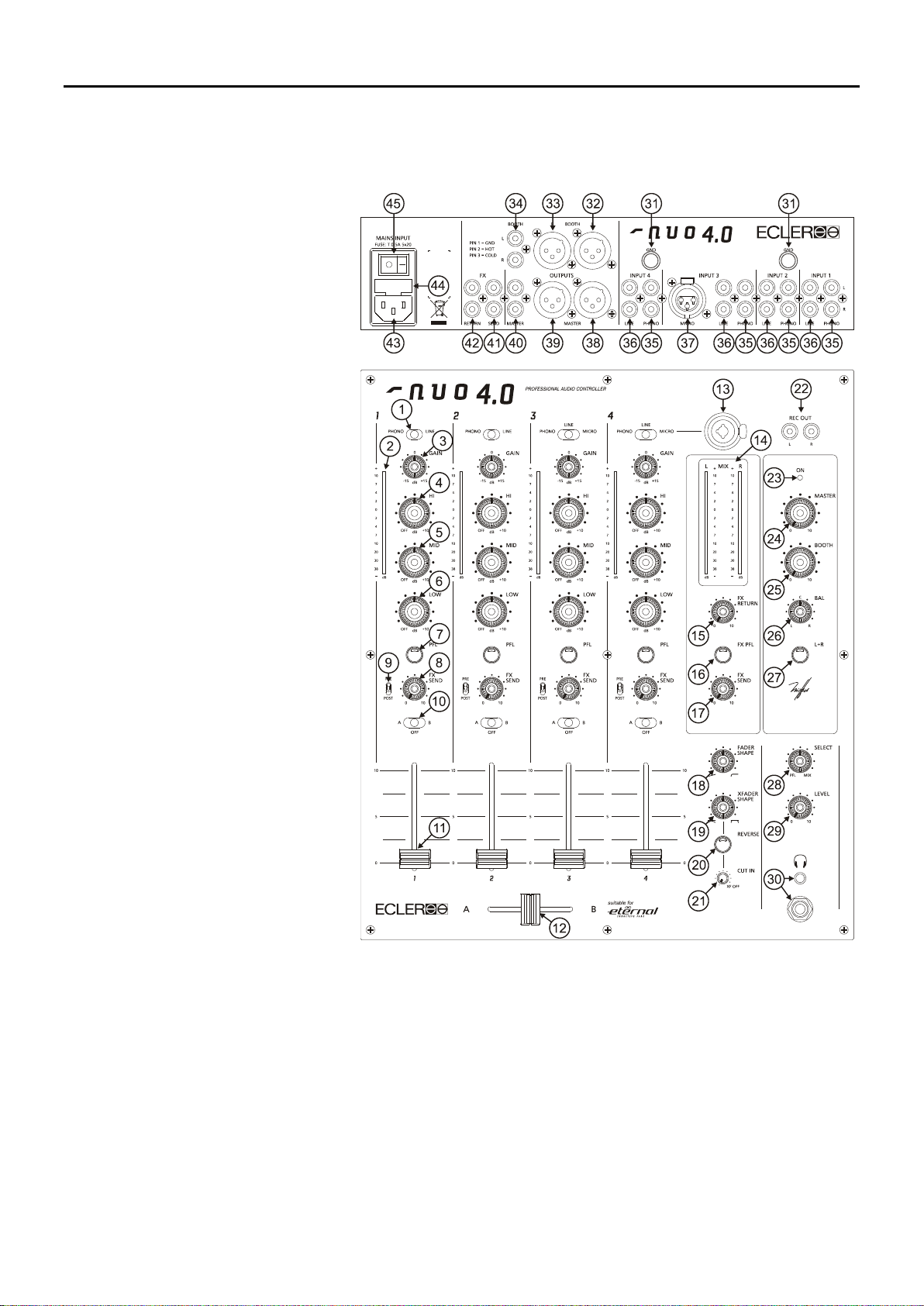

7. FUNCTION LIST 8. FUNCTION DIAGRAM

1. Input selector

2. LED VU Meter

3. Input sensitivity adjust, GAIN

4. Treble control, HI

5. Midrange control, MID

6. Bass control, LOW

7. Prefader listening control, PFL

8. Fx Send controller, FX SEND

9. Send switch to effect bus, PRE/POST

10. Send to XF switch, A/OFF/B

11. Fader

12. Crossfader control

13. Microphone XLR/JACK combo

connector, MICRO

14. LED VU Meter

15. Fx Return controller, FX RETURN

16. Prefader listening control, FX PFL

17. Fx Send controller, FX SEND

18. Fader Shape adjustment, FADER

SHAPE

19. Crossfader Shape adjuster,

XFADER SHAPE

20. Crossfader reverse function,

REVERSE

21. Crossfader "cut in time" adjustment,

CUT IN

22. Recording output, REC OUT

23. LED indicator, ON

24. Volume control, MASTER

25. Volume control, BOOTH

26. Balance control, BAL

27. Left and Right signal sum, L+R

28. PFL/MIX monitoring crossfader,

SELECT

29. Headphones volume control, LEVEL

30. Stereo jack headphones

31. Ground pin, GND

32. Left channel balanced output,

BOOTH L

33. Right channel balanced output,

BOOTH R

34. RCA output, BOOTH

35. Phono input, PHONO

36. Line input, LINE

37. Micro input, MICRO

38. Left channel balanced output,

MASTER L

39. Right channel balanced output, MASTER R

40. RCA output, MASTER

41. External FX send output, FX SEND

42. External FX return input, FX RETURN

43. Mains socket

44. Fuse holder

45. Power switch

Page 14

14 15

Page 15

ÍNDICE

1. NOTA IMPORTANTE 16

2. INTRODUCCIÓN 17

3. INSTALACIÓN 17

4. INICIO RÁPIDO 20

5. OPERACIÓN Y USO 22

6. OTRAS CONSIDERACIONES 24

7. LISTA DE FUNCIONES 25

8. DIAGRAMA DE FUNCIONES 25

9. CARACTERÍSTICAS TÉCNICAS 50

10. DIAGRAMA DE CONFIGURACIÓN 51

11. DIAGRAMA DE BLOQUES 52

Todos los datos están sujetos a variación debida a toleranc ias de producción. ECLER S.A. se reserva el derecho de

realizar cambios o mejoras en la fabricación o diseño que pudieran afectar las especificaciones.

Page 16

16

1. NOTA IMPORTANTE

Instrucciones de seguridad

Para conseguir la máxima funcionalidad del aparato y su máximo rendimiento, es muy importante antes de su

conexión, leer detenidam ente y tener m uy presentes l as c onsiderac iones que en este m anual se es pec ifican . Para

garantizar el óptimo funcionamiento de este aparato, recomendamos que su mantenimiento y eventuales

reparaciones sean llevadas a cabo por nuestros Servicios Técnicos autorizados.

Este aparato debe conectarse a tierra a través de su cable de red.

No exponer la unidad a l a lluvia o a s alpicad uras de ag ua, no col ocar r ecipient es que cont engan lí quidos

u objetos incandescentes tales como velas sobre el aparato.

Cualquier cambio e n la configuración de la unidad d ebe ser llevado a cabo por técnic os cualificados. Cualquier

conexión o desconexión de la unidad debe ser realizada, siempre, con la unidad desconectada de la red.

Descripción de la garantía

Su equipo ECLER ha superado ensayos de laboratorio y exhaustivos controles de calidad antes de salir de

fábrica. No obstante podría darse el caso que n ecesite nuestro Servici o Técnico durante el period o que cubre la

garantía o posteriorm ente. En tal caso, protej a cuidadosamente la uni dad en su caja original y envíelo a nuestro

Servicio Técnico con los gastos y el seguro pagados. Adjunte una fotocopia del certificado de garantía y una

descripción detallada del defecto observado.

ECLER S.A. garantiza e l mezclador NUO4.0 ante defectos de mat eriales o fabricación durante el period o de un

año transcurrido tras la fecha de compra original.

ECLER S.A. reparará el eq uipo defectuoso dentr o del periodo especific ado, sin cargo alguno para piezas y mano

de obra.

Para asegurar la validez de la garantía es preciso que la Garantía y la Tarjeta de Registro se rellenen

correctamente y se remitan a su distribuidor ECLER, en el plazo de 10 días después de la fecha de compra.

La garantía no es transferible y solamente protege al comprador original.

La garantía no cubre:

Daños ocasionados por malos tratos o manejo negligente, falta de cuidados elementales, desatención de las

instrucciones del manual, conexión equivocada o accidentes.

ECLER S.A., no será responsable por ningún daño directo o indirecto, pérdida o perjuicio originado por o en

relación con el equipo.

* aparatos que hayan sido manipulados, alterados o reparados fuera del Servicio Técnico autorizado.

* el mueble exterior, los componentes electromecánicos ni su desgaste por uso.

* los gastos de envío y seguros, ni los daños que el aparato pueda sufrir durante el transporte.

Esta garantía es válida sólo si las reparaciones o servicios se realizan en un Servicio Técnico autorizado.

Page 17

17

2. INTRODUCCIÓN

¡Felicidades por adquirir un auténtico equipo profesional ECLER!

El NUO4.0 es un mezclador profesional para DJ diseñado y fabricado por ECLER, una empresa con sede en

Barcelona dedicada al audio profesional desde 1965.

El NUO4.0 es un m ezclador de audio pr of es ional or ie n tado a c u alq uier ti po de DJ , gr acias a s u amplia variedad de

funciones que le con vierten en una consola apta para m ezclar cualquier estilo musical: tech no, house, minimal,

electro, hip hop...

El NUO4.0 es un mezclador apto para el scratch gracias a la versatilidad de sus ajustes de fader y crossfader. El

NUO4.0 es además apt o p ara Et er na l, e l cr oss f ader magnético de Ecler con c in c o años de gar a ntía es pec i alm ent e

diseñado para los virtuosos del scratc h.

Este genuino me zclador utiliza los mejores componentes disponibles en el mercado, obteniendo así l a más alta

calidad de sonido. Los más de 40 años de experie ncia en el diseño de equipos d e audio prof esional hacen que los

circuitos sean extrem adamente eficientes y se consiga un sonido ana lógico cálido y cristalino. Todos s us circuitos

son montados y testados en nuestra fábrica de Barcelona.

El NUO4.0 es además un mezclador especialmente apto para instalaciones profesionales de toda índole, gracias a

sus dos salidas balancea das y dos entradas de micrófono. Su f ormato y robustez hacen de él la consola ideal,

tanto para instalaciones profesionales, como para uso portátil por parte de los DJs más vanguardistas.

3. INSTALACIÓN

La principal considerac ión a tener en cuenta en el momento de buscar la u bicación de su NUO4.0 debe ser la

máxima comodidad de trabajo del operador, y su facilidad de conexionado.

El NUO4.0 está básicamente concebido como mezclador de sobremesa y su

ubicación habitual será entre dos giradiscos o reproductores de CD. El

mezclador tiene un form ato de 37 cm (14,57") de profundidad y 32 cm ( 12,6")

de anchura.

Mediante el kit de lat erales metálicos (disponibles com o opción) podrá sujetar

firmemente su NUO4.0 , ya sea d irectam ente s obre la s uperfic ie sobre la q ue se

apoye, o sobre los laterales, que también le permitirán inclinarlo. Existe otra

opción de perfiles metálicos "NUORAKI" que permiten la ubicación del

mezclador en muebles rack estándar de 19".

Dada la elevada gan ancia de las entradas de PHONO y de MICRO de be procurarse situar el m ezclador lo más

alejado posible d e fuentes de ruido (variador es de tensión, m otores , etc.) así c om o de cualquier c able d e red. Por

esta misma razón y bajo ninguna circunstancia debe quitarse la tapa metálica del aparato.

Ya que el consumo del NUO4.0 es muy bajo, éste no precisa ventilación, sin embargo debe evitarse que esté

expuesto a una temperatur a extrem a y qu e la atm ósf era del local en que es té empla zado sea lo m ás seca y limpia

de polvo posible.

El NUO4.0 funciona con una fuente de alimentación conmutada de tipo univers al permitiendo trabajar sin ningún

tipo de ajuste desde 90V a 264 V / 47-63Hz. Asegúres e de que el cable de red s e enc uentre lejos de los cabl es de

señal para evitar zumbidos.

Para proteger al m ezclador de ev entuales sobr ecargas en la línea de re d existe un f usible de re d de tipo T 0,5 A.

En caso de que éste se fu ndiera se desconec taría el aparato y se sustituiría por otro de idénticas c aracterísticas.

Si éste último se volviera a fundir, consulte con nuestro Servicio Técnico.

ATENCIÓN: EN NINGÚN CASO DEBE CORTOCIRCUITAR EL CIRCUITO DE PROTECCIÓN O

PONER UN FUSIBLE DE VALOR MÁS ELEVADO.

ADVERTENCIA: La sustitución del fusible debe ser realizada por un técnico cualificado.

Page 18

18

Conexiones de entrada de audio

INPUT 1 PHONO Plato giradiscos

INPUT 1 LINE Reproductor de CD

INPUT 2 PHONO Plato giradiscos

INPUT 2 LINE Reproductor de CD

INPUT 3 PHONO Plato giradiscos

INPUT 3 LINE Reproductor de CD

INPUT 3 MICRO Micrófono

INPUT 4 PHONO Plato giradiscos

INPUT 4 LINE Reproductor de CD

INPUT 4 MICRO Micrófono

Entradas de Phono

Los platos giradiscos de ben ir equipados con cápsula m agnética con un nivel de salida nominal entre -55dBV y

-25dBV (1,7 a 56 m V). Las entradas PHONO (35) del NUO 4.0 tienen un amplio margen antes de la saturación

(headroom) y pueden adm itir cápsulas con mayor nivel de salida de lo habitual. Estas entradas presentan una

sensibilidad de entrada nominal de -40 dBV (10 mV).

Entradas de Línea

La sensibilidad de las entradas marcadas como LINE (36) es de 0dBV (1V). Conecte fuentes de sonido como

reproductores de CD, DAT, MP3, teclados u otros instrumentos.

Entradas de Micrófono

Las entradas de MICRO (13-37) están preparadas para un nivel nominal de entrada de -35dBV. La conexión

frontal (13) es del tipo combo XLR3/Jack y la conexión posterior (37) es del tipo XLR3. Estas entradas de

micrófono admiten la conexión en modo balanceado; para ello se realizará la conexión tal y como se indica:

Vivo o señal directa > Terminal 2 Punta

Frío o señal invertida > Terminal 3 Aro central

Masa > Terminal 1 Base

Los micrófonos deben ser de baj a impedancia (de 20 0 a 600Ω) y monof ónicos. Para conex iones no balanc eadas,

cortocircuitar a masa el terminal 3 o el aro central. El NUO4.0 dispone de alimentación Phantom de 18V para

micrófonos equipados de condensador. Un jumper interno permite inhibir el funcionamiento de la alimentación

Phantom. La entrada MICRO del NUO4.0 se sirve de fábrica en posición "Phantom ON" (ver diagrama de

configuración).

Page 19

19

Conexiones de salida de audio

MASTER Amplificador de potencia principal

BOOTH Amplificador de cabina

REC Dispositivo de grabación

FX Send/Return Bus de envío auxiliar a efectos

Headphones Auriculares

Salida MASTER

Esta salida estéreo alimenta al sistema de PA a través de una c onex i ón X LR3 b al anc ead a (38, 39) y una RC A ( 40)

no balanceada. El ni vel nominal de la s alida MASTER está ajustado a 0d BV (1V), pero puede ajustarse a +6 dBV

mediante un jumper interno. El nivel de salida MASTER se controla con el potenciómetro MASTER (24).

Cerca del control MASTER se encuentra el conmutador L+R (27), que s uma las señales izquierda y derecha de

las salidas MASTER y BO OTH. Esta f unción es especialm ente útil en el caso q ue se produzca un f allo en uno de

los dos canales durante la sesión (ejem plo típico: m al contacto en la cáps ula del plato gir adiscos). Act ivando este

botón, el mezclador envía la s uma L+R a ambos altavoces, pasando el problem a desapercibido para la mayoría

del público.

MASTER y BOOTH disponen de un control de balance BAL (26).

Salida BOOTH

Habitualmente se usa para obtener una salida independiente en la cabina de l DJ. Esta salida estéreo BOOTH

incorpora una conexión X LR3 balanceada y una RCA no balancea da. El nivel nominal de la salida BOOT H está

ajustado a 0dBV (1V) , pero puede ajustarse a +6d BV mediante un jumper interno. El nivel de salida BO OTH se

controla con el potenciómetro BOOTH (25).

Salida de grabación

Hay una salida REC (2 2) sobr e la sup erf icie de co ntrol qu e em plea co nexiones RCA. El ni vel de s alida nom inal de

la salida REC es de 0dBV (1V). Esta salida es post fader, antes de Master.

Bucle externo FX Send/Return

Las conexiones de tip o RC A de sal ida FX SEND ( 41) y de e ntrad a FX R ETURN (42) perm iten la rea li zación de un

bucle externo con cualquier procesador de efectos, sampler o dispositivo secuenciador. El nivel nominal de la

salida SEND, así como la entrada RETURN es de 0dBV (1V).

La señal enviada a la salida FX SEND se selecciona antes o después del fader mediante el conmutador

PRE/POST (9), y el nivel de envío con su potenc iómetro asociado (8) . El NUO4.0 disp one además de un control

general de envío a efectos FX SEND (17) que suma las 4 vías, un control general de retorno de efectos FX

RETURN (15) y un control de pre-escucha de la señal de retorno de efectos FX PFL (16).

Auriculares

Para obtener el mejor rendimiento en su funcionamiento, éstos deber án ser de alta impedancia (200-600Ω) . Se

conectarán a la salida de auriculares (30) situada sobre la propia placa de m andos mediante un conector jack

normalizado de 1/4" ester eofónico o un conec tor mini jack de 3,5 mm. El casquillo del jac k será la mas a, el anillo

central el canal derecho y la punta el canal izquierdo.

Page 20

20

4. INICIO RÁPIDO

Instale y conecte el NUO4.0 tal y como se describe en el primer párrafo del apartado Instalación.

A continuación desc ribim os un proced imiento de inici o rápido usando la

entrada LINE de la vía 1 y monitorizan do la señal a través de la salida

de auriculares.

1. Ponga los controles en posición de inicio.

Ajuste los controles rotat ivos GAIN, HI, MID y LOW de la vía 1 (3, 4, 5,

6) en posición centr al enclavada. Sitúe el fader ( 11) del canal abajo y

asigne el selector A/OFF/ B (10) en posición A (el canal está asignado

ahora al lado A del crossfader).

2. Conecte unos auriculares.

Conéctelos a la salida de auric ulares (30). Ajuste el contr ol LEVEL (29)

de auriculares al mí nimo y lleve el control SELECT (28) a su p osición

PFL.

3. Conecte un reproductor de CD.

Conecte un reproductor de CD a la entrada LINE de la vía 1 (36),

inserte un CD y póngalo en marcha.

4. Conecte el mezclador a la red eléctrica.

Conecte el cable de red en la entrada de alimentación (43) del

mezclador y póngalo en marc ha pulsando el interruptor MAINS INPUT

(45) situados ambos en la parte trasera.

5. Seleccione la fuente de entrada.

Compruebe que el s elector de entrada de la vía 1 (1) está en posición

LINE y que se ilumina el Vu-m etro (2) de ese canal. Si no se ilumina,

asegúrese de que el reproductor de CD está b ien conectado y de que

se está reproduciendo una pista de audio.

6. Ajuste el nivel de entrada.

Mueva el control GAIN (3) hasta que el Vu-metro indique 0dB.

7. Envíe la señal a la salida principal.

Coloque el fader de la vía 1 (11) arriba y sitúe el crossfader (12) en el lado A.

Page 21

21

8. Escuche la señal en sus auriculares.

Presione el botón PFL (7) de la vía 1. Ajus te el control LEVEL (29) para obtener un nivel de escuc ha confortable.

Ahora debería escuc har la música en sus aur iculares . Mueva el contro l SELECT (28) h acia la d erecha par a fund ir

la señal PFL con la de MIX. Con este control totalmente a la derecha, tan solo escuchamos la señal MIX.

9. Compruebe el efecto del control d e tonos.

Experimente con el potente ecualizador estéreo de 3 bandas (4, 5, 6). Este contr ol de tonos está diseñado p ara la

modificación creativa del soni do: cada banda puede aislarse i ndependientemente mediant e los grandes controles

rotativos ergonómicos.

10. Compruebe el ajuste del crossfader.

Cada canal puede asignar se al c ross fader us ando el selec tor A/OFF/B

(10). El crossfader permite realizar un fundido entre las señales

asignadas a ambos lados del mismo. Con el selector en posición A o B

asignamos la vía a uno u otro lado del crossfader. La posic ión OFF

anula la función crossfader para este canal.

11. Ajuste la curva del crossfader.

El control XFADER SHAP E (19) nos per m ite ajustar la pendi ente de la

curva del c ros s f ader de manera precisa. Sit uan do el c ontrol tot almente

a la izquierda podemos mezclar dos canciones fundiéndolas

suavemente. La curva del crossfader se vuelve más afilada si

movemos el control hacia l a derecha. Situando el control totalmente a

la derecha, la señal entra de golpe con un leve movimiento del

crossfader, algo muy indicado para la técnica scratch.

Page 22

22

5. OPERACIÓN Y USO

Puesta en funcionamiento

Esta se realizará m ediante el interr uptor (45) situado en el panel pos terior. Al cabo d e unos insta ntes se i lum inará

el LED ON (23). Aunque el ruido producido por la puesta en funcionamiento del NUO4.0 es mínimo y queda

prácticamente anulado al hacerlo con los faders cerrados, siempr e resulta muy recomendable poner en m archa

todos los aparatos siguiendo la secuencia siguiente:

1. Fuentes de sonido

2. Unidad de mezclas, ecualizadores, filtros activos

3. Finalmente, amplificadores de potencia.

El paro de los aparatos debe realizarse en la secuencia inversa. Siguiendo este orden los picos o transitorios

producidos por el encendi do o apagado de los aparatos no afecta a los siguie ntes y, por consiguiente, tampoco

llegan a los altavoces.

Descripción de los controles

Selector de entrada

Cada canal principal dispone de un selector de entrada basculante (1).

Ganancia de vía

Todas las vías de entrada del NUO4.0 disponen d e un ajuste accesible de l a sensibilidad de entrada G AIN (3),

cuya misión es la de compensar las diferencias de nivel existentes entre las fuentes sonoras conectadas a la mesa

antes de ser mezcladas.

Los ajustes de gana ncia deben realizarse con sum a meticulosidad utilizando el Vu-m etro (2) de cada vía como

referencia. El nivel de referencia estándar usado para mezclar señales de audio es de 0dB.

El margen de la gana nc ia e s tá aj us tado a ± 15 dB pero s e pue de r e duc ir a ±6dBV. Este ajuste es in de pen die n te por

cada vía y se realiza mediante puentes de soldadura. Consulte el diagrama de configuración.

Ecualización

El sistema de control de t onos de cad a vía ofr ece un am plio margen de ac tuació n de -30 a +1 0dB para gr aves (6)

y agudos (4) y de -25 a +10dB para medios (5). Este amplio margen de variación del tipo "kill" atenúa

completamente la banda seleccionada y ha sido especialmente diseñado para el uso creativo en directo.

ATENCIÓN: Utilice el control de tonos con precaución, ya que la elevada ganancia máxima puede provocar

sobredesplazamientos en su sistema de altavoces.

Sistema de monitorización

El NUO4.0 está equipado con un sistema de monitorización flexible y sencillo que permite ajustar con suma

precisión los nivel es de PFL (monitorización de escucha pre-fader) y de m ezcla para cada vía a través del Vumetro y de los auriculares. Cada canal puede ser m on itorizado v isualm ente y pre-escuchado pulsand o los botones

PFL (7).

Para la monitorizaci ón a tr a vés de auriculares, e l pot e nc iómetro rotativo SELECT (28) perm ite m e zclar un P F L con

la mezcla principal MIX. El potenciómetro rotativo LEVEL (29) controla el nivel de salida de auriculares.

Cada vía cuenta además con un Vu-metro dedicado que permite monitorizar visualmente la señal PFL (2).

Page 23

23

Envío a unidades de efectos externas FX Send/Return

Las 4 vías del NUO4.0 están equipadas con potenciómetros rotativos (8) que permiten enviar la señal a una

unidad de efectos ex terna, sampler, etc . Estos potenci ómetr os permiten d osificar el nivel d e la se ñal que s e envía

desde cada una de las vías.

La salida FX SEND (41) se conecta a la entrada del procesador de efectos, y la salida de éste a la entrada

RETURN (42) o a una entrada LINE (36).

Este envío puede configurarse mediante el conmutador basculante PRE/POST (9) para que esté o no afectado por

el fader de la vía.

El NUO4.0 dispone además de un control general de envío a efectos FX SEND (17) que suma las 4 vías, un

control general de retorno de efectos FX RETURN (15) y un control de pre-es cucha de la señal de retorno de

efectos FX PFL (16).

Fader

El NUO4.0 monta una n ueva generación de faders ECLER de 6 0 mm (11) precisos, extremadam ente suaves y

con unas prestaciones que super an los 4.0 00.0 00 de maniobras gracias al s iste m a VCA de EC LER (VCA: Voltag e

Controlled Amplifier).

La utilización de tecnología VCA posibilita la modificación del comportamiento del fader. En la placa frontal

contamos con el pot enc iómetro rotativo FAD ER SHA P E ( 18) que permite regular la c urva de l mismo, de modo qu e

el volumen se distribuya de manera proporcional a lo largo del potenciómetro o por el contrario aparezca

súbitamente.

Crossfader

Cada canal puede asignars e al crossfader (12) usando el selector A/OFF /B (10). El cros sfader perm ite realizar un

fundido entre las señales as ignadas a am bos lados del m ism o. Con el selec tor en posición A o B as ign am os la vía

a uno u otro lado del crossfader. La posición OFF anula la función crossfader para ese canal.

El crossfader del N UO 4 .0 i ncor pora una serie de controles que permiten ajus tar su comportamiento, convirtiéndolo

en una precisa herramienta. El control XFADER SHAPE (19) nos permite ajustar la pendiente de la curva del

crossfader de manera precisa. Situando el control totalmente a la izquierda podemos mezclar dos canciones

fundiéndolas suavem ente. La curva del c rossfader se vuel ve más afilada si m ovemos el control h acia la derecha.

Situando el control t otalmente a la derecha, la señal entra de golpe con un leve movim iento del crossf ader, algo

muy indicado para la técnica scratch.

El conmutador REVER SE (20) inv ierte la direcció n del crossfader. Dependiendo de la dirección esc ogida, puede n

realizarse tanto "cuts" como "transforms" moviendo el crossfader en la misma dirección.

La corrección electrónica CUT IN (21) únicamente es efectiva en el caso de que el NUO4.0 haya montado el

potenciómetro ETERNAL opcional. En caso de montar el crossfader estándar, el potenciómetro CUT IN debe

quedar en posición O FF . E l CUT IN es la dist anc ia existente entre e l f in al físico del crossf ader y el primer punto de

entrada de señal. La posición más corta proporciona un corte prácticamente instantáneo. Para encontrar esa

posición, el potenciómetro debe colocarse en posición extrema y el potenciómetro CUT IN debe girarse a la

derecha hasta que se obtenga s eñal musical. Para alargar el tiempo de CUT IN, girar el potenciómetro hac ia la

izquierda.

Si desea extender la vida útil de su crossfader, el NUO4.0 permite el montaje como opción del galardonado

potenciómetro ETERNAL. Este es un crossfader de tecnología inductiva basada en un sistema de control

magnético. Esta tecnología totalmente libre de contactos, combinada con un sistema mecánico exclusivo de

deslizamiento, dan como resultado un tacto suave y uno de los crossfaders más precisos existentes en la

actualidad. El crossfader inductivo ETERNAL ha sido concebido específicamente para ejecutar técnicas de

"turntablism" extremas, dur ante las cuales el movimiento del crossf ader tiene que ser extremadamente suave y

rápido.

Page 24

24

En caso de querer colocar el crossfader ETERNAL, siga los siguientes pasos:

1. Retire los botones de los potenciómetros deslizantes y rotativos de la superficie del mezclador.

2. Desatornille los tornillos exteriores que sujetan la placa de mandos del mezclador y extráigala.

3. Retire los dos tornillos que sujetan el crossfader y extráigalo.

4. Desconecte cuidadosamente el conector multiterminal.

5. Reemplácelo por el ETERNAL.

6. Conecte el conector multiterminal que desconectó anteriormente.

7. Sujételo con los dos tornillos, respetando la orientación que

describe el dibujo.

8. Coloque y atornille la placa de mandos.

9. Vuelva a poner los botones de los potenciómetros.

ATENCIÓN: Utilice siempre repuestos originales ECLER.

ADVERTENCIA: La sustitución del crossfader debe ser realizada por un técnico cualificado.

Niveles MASTER y BOOTH

El NUO4.0 dispone de dos cont roles d e nive l de s alida MAST ER y BOOT H. El n ivel de s al ida MA STER se controla

a través del potenciómetro MASTER (24) y el nivel de salida BOOTH se controla a través del potenciómetro

BOOTH (25).

El potenciómetro de balance BAL (26) y el conmutador L+R (27) afectan a ambas salidas.

6. OTRAS CONSIDERACIONES

Bucles de masa

Procuraremos en todo momento que todas las fuente s de s eñal qu e llegu en a la mesa de mezclas, así como todos

los aparatos que estén conectados a su salida, no tengan las masas interconectadas, es decir, que nunca les

llegue masa por dos o m ás caminos distintos, ya que de esta m anera se podrían producir zumbidos que lle garían

incluso a interfer ir la ca lida d de l a repr oduc ción s onora. Los b lindaj es de los c ables , de es tar c onecta dos a c hasis,

en ningún momento deben estar unidos entre sí, de esta forma evitaremos la formación de bucles de masa.

Ruido de fondo

El empleo de circuitería activa puede aportar, según configuración, un nivel de ruido de fondo más o menos

elevado. El mezclador NUO4.0 ha sido concebido para obtener el menor ruido de fondo posible.

Independientemente de la concepción electrónica con que se haya realizado el mezclador, el nivel de ruido

dependerá directamente de la correcta utilización e instalación de la unidad de mezcla. No es lo mismo, por

ejemplo, tener el fader de una vía a " 2" y el Master a "10" q ue a la inversa. En el prim er c aso, la señal que l lega al

amplificador de mezcla, que intrínsecamente tiene un nivel de ruido de fondo propio, es débil, por lo que la relación

señal/ruido es baja (poca señal). Cuando el amplificador de salida sobredimensione indistintamente todo el

conjunto tendremos a la salida un nivel de ruido de fondo muy elevado. En el s egundo caso, al estar el fader al

máximo la señal que recibe el am plificador de mezcla es grande y por tanto c on una relación señal/ruido grand e

también, por lo tanto c uan d o es ta s eña l llegu e al Master y sea amplificada, guardar á mejor relación que e n e l c as o

anterior.

Conexiones de audio

Como norma general deberemos procurar que las conexiones de señal sean lo más cortas posible, asimismo

emplearemos conector es y cables de la mejor calidad. Norm alm ente a los cables y conectores no se les pres ta el

interés merecido. En m uchas ocasiones y debido a una mala conexión o por el us o de cables de baja calidad,

pueden aparecer importantes problemas en la reproducción sonora.

Limpieza

La carátula no deberá limpiarse con sustancias disolventes o abrasivas puesto que se corre el riesgo de

deteriorarla. Para su limpieza se utilizará un trapo ligeramente humedecido con agua y un detergente líquido

neutro, secándola a contin uació n con un paño lim pio. Se recom ienda lim piar las m anchas de s udor despué s de s u

uso. En ningún caso se debe permitir la entrada de agua por cualquiera de los orificios del aparato.

Page 25

25

7. LISTA DE FUNCIONES 8. DIAGRAMA DE FUNCIONES

1. Selector de entrada

2. Vu-metro de vía

3. Ajuste de sensibilidad de entrada, GAIN

4. Control de frecuencias agudas, HI

5. Control de frecuencias medias, MID

6. Control de frecuencias graves, LOW

7. Control de monitorización pre-fader, PFL

8. Control de envío a efectos, FX

SEND

9. Conmutador de envío a efectos pre

o post fader, PRE/POST

10. Conmutador de asignación a

Crossfader, A/OFF/B

11. Fader

12. Crossfader

13. Conexión combo XLR/Jack para

micrófono, MICRO

14. Vu-metro de MIX

15. Control general de retorno de

efectos, FX RETURN

16. Control de monitorización de

retorno de efectos, FX PFL

17. Control general de envío a efec tos,

FX SEND

18. Control de ajuste de c u r va de f ader ,

FADER SHAPE

19. Control de ajuste de curva de

crossfader, XFADER SHAPE

20. Conmutador de inversión de

crossfader, REVERSE

21. Control de ajuste de corte de

crossfader, CUT IN

22. Salida de grabación, REC OUT

23. LED indicador, ON

24. Control de nivel, MASTER

25. Control de nivel, BOOTH

26. Control de balance, BAL

27. Suma de señales izquierda y

derecha, L+R

28. Control del crossfader PFL/MIX de

auriculares, SELECT

29. Control de volumen de auriculares,

LEVEL

30. Conexión de auriculares Jack y

Mini Jack

31. Borne de toma de masa, GND

32. Salida XLR balanceada canal

izquierdo, BOOTH L

33. Salida XLR balanceada canal

derecho, BOOTH R

34. Salida RCA no balanceada, BOOTH

35. Entrada phono RCA para giradiscos, PHONO

36. Entrada RCA para línea, LINE

37. Conexión XLR para micrófono, MICRO

38. Salida XLR balanceada canal izquierdo, MASTER L

39. Salida XLR balanceada canal derecho, MASTER R

40. Salida RCA no balanceada, MASTER

41. Salida de envío a efectos, FX SEND

42. Entrada de retorno de efectos, FX RETURN

43. Base de red

44. Portafusibles

45. Interruptor de puesta en marcha

Page 26

26 27

Page 27

TABLE DES MATIERES

1. NOTE IMPORTANTE 28

2. INTRODUCTION 29

3. INSTALLATION 29

4. DEMARRAGE RAPIDE 32

5. MANUEL DE FONCTIONNEMENT ET D'UTILISATION 34

6. INFORMATIONS COMPLEMENTAIRES 36

7. LISTE DE FONCTIONS 37

8. DIAGRAMME DE FONCTIONS 37

9. CARACTÉRISTIQUES TECHNIQUES 50

10. DIAGRAMME DE CONFIGURATION 51

11. SCHÉMA SYNOPTIQUE 52

Toutes les valeurs mentionnées dans ce document sont susceptibles d’être modifiées en raison des tolérances de

production. ECLER SA se réserve le droit de changer ou d’améliorer les process us de fabrication ou la présentation de

ses produits, occasionnant ainsi des modifications dans les spécifications techniques.

Page 28

28

1. NOTE IMPORTANTE

Mesures de sécurité

Pour un fonctionnem ent et une ef ficacité optim isés de votre console de m ixage, il est T RÈS IMPORTANT – avant

tout raccordement – de lire attenti vement ce manuel et de s u ivre les ins truc ti ons e t rec om mandations qu'il co ntie nt.

Nous vous conseillons fortement de confier la maintenance de cet équipement à nos Services Techniques Agréés.

Cet appareil doit être raccordé à la terre via son cordon secteur.

Ne pas l'exposer à la pluie ou à des projections d'e au. Ne pas placer non plus de liquides ou d'objets

incandescents (tels que des bougies par exemple) sur celui-ci.

Toute modification ap portée à la configuration de l'unité doit être ex écutée par un technicien qualifié. S'il s'avère

nécessaire de procéder à une connexion / déconnexion, veiller à ce que l'alimentation secteur soit toujours coupée.

Garantie

Votre équipement ECLER a fait l'objet de tests de qu alité et de tests en laborat oire approfondis en sortie d'usine.

Néanmoins, il peut ar river que vous so yez contrai nt de contact er notre Service T echnique en cours de gara ntie ou

après expiration de celle-ci. Dans ce cas, envelopp er soigneusement votre appar eil dans son emballage d'o rigine

et adressez-le à notre Service Technique en port payé (transport et assurance). Joindre une copie de votre

Certificat de Garantie, accompagné d'une description détaillée du défaut observé.

ECLER S.A garantit la console de mixage NUO4.0 contre tout défaut de pièces ou de fabrication pendant une

période d'un an à compter de la date originale d'achat.

ECLER, S.A. s'eng age à réparer tout équipem ent défectueux dura nt la période de garantie pr écitée, sans frais de

pièces et main d'oeuvre.

Pour que votre garan tie soit valide, il est essen tiel de remplir avec soin la F iche d'Enregistrement ci-j ointe et de

l'adresser à votre distributeur ECLER dans un délai maximal de 10 JOURS à compter de la date d'achat du produit.

La Garantie n'est pas transférable et ne protège que l'acheteur d'origine.

La Garantie ne couvre pas :

Les dommages résultant d'un mauvais traitement ou d'une manipulation peu soigneuse, d'un manque de

précaution élémentaire, de la non observation des instructions données dans ce manuel, d'un mauvais

raccordement ou d'un accident.

ECLER, S.A., ne pourra être tenu responsable de tout dommage direct ou indirect, de toute perte ou autre

dommage provoqué par ou lié à l'équipement.

* Les appareils manipulés, altérés ou réparés ailleurs qu'au sein de nos Services Techniques agréés.

* Les dispositifs extérieurs ainsi que les pièces électromécaniques, pas plus que l'usure résult ant de leur uti li sation .

* Frais d'expédition et d' assurance, pas plus que les domm ages susceptibles d'être pro voqués par l'appareil (kit)

durant son transport.

Cette garantie ne s'applique qu'aux réparations ou services proposés par un Service Technique agréé.

Page 29

29

2. INTRODUCTION

Félicitations pour votre choix d'un authentique équipement professionnel ECLER !

La NUO4.0 est une cons ole de mixage professionnelle po ur DJ conçue et fabriquée par EC LER, une entreprise

basée à Barcelone qui se consacre à l'audio professionnel depuis 1965.

La NUO4.0 est une c onsol e de m ix age audio pr ofes sionne lle a daptée à tout type de DJ grâce à son vas te éventai l

de fonctions qui en font une console apte au m ixage de tout style mus ical : techno, house, m inimal, électro, hip

hop...

La NUO4.0 est une console de mixage apte au sc ratch grâce à la polyvalence de s es réglages de fader et de

crossfader. La NUO4.0 est en outre compatible Eternal, le crossfader magnétique Ecler garanti cinq ans et

spécialement conçu pour les virtuoses du scratch.

Cette console de mix age utilise les meilleurs c omposants disponibl es sur le marché, pour l a plus haute qualité de

son. Les plus de 40 ans d' ex périence de conc eption d'équ ipem ents aud io prof ess ionnels s ont à l'or igine de ci rcuits

extrêmement effic ac es et d' un s on an alogique chaud et cr istall in. T ous les c irc uits sont montés et testés dans notre

usine de Barcelone.

La NUO4.0 est en outre une cons ole de m ixage spéc ialement ad aptée aux installat ions prof essionnell es de toute s

sortes, grâce à ses deux s orties symétriques et à ses deux entrées microphone. Son for mat et sa robustesse en

font la console idéale, aussi bien pour les installations professionnelles qu'en utilisation portable par des DJ

d'avant-garde.

3. INSTALLATION

La principale considérat ion à prendre e n com pte au moment de c hercher l'em placement de s a NUO4.0 doit être le

confort de travail maximal pour l'opérateur et la facilité de connexion.

La NUO4.0 est essentiel le ment conçue comme une cons ole de table et sa place

habituelle sera entre deux platines tourne-disques ou lecteurs de CD. Elle f ait

37 cm de profondeur et 32 cm de largeur.

Au moyen du kit de corni ères latéra les (d ispon ible e n option) , vous p ourr ez fix er

fermement votre NUO4.0, soit directement sur la surface sur laquelle elle

repose, soit par les côtés, c e qui permet aussi de l'incliner. Il existe une autre

option de profilés métalliq ues "NUORAKI" qui perm et le montage de la console

dans des meubles rack standard de 19 ".

En raison du gain élevé des entrées PHONO et MICRO, veiller à toujours

installer la console le plus loin possible de sources de bruit (variateurs de tension, moteurs, etc.) et de câbles

secteur. Pour les mêmes raisons, ne retirer le capot métallique de l'appareil sous aucun prétexte.

La consommation du NUO4.0 étant très faible, aucune ventilation n'est nécessaire. Eviter cependant les

températures extrêmes et veiller à ce que l'atmosphère soit aussi sèche et exempte de poussière que possible.

La NUO4.0 fonctio nne d ésorm ais à l'aide d' une alim entat ion à déco upage de t ype u nivers el. L' utilisat eur peut a insi

travailler sans avoir à réali ser le moindre réglage pré alable à partir d'une tens ion susceptible de varier entre 90 et

264 V (47 – 63 Hz). Afin de lim iter le r isque de r onf lem ents, ve il ler à ce que le câble secteur soit él oi gné d es câbles

véhiculant les différents signaux.

En vue de protéger la cons ole d'éve ntuelles surc harges sec teur, cette der nière es t éq uipée d'un f usible T 0,5 A. En

cas de fonte de cel ui-ci, déc onnecter la cons ole e t re m placer le fus ible p ar un a utre d e carac térist iques identiq ues.

Si celui-ci devait également fondre, consulter notre service technique.

ATTENTION : NE JAMAIS COURT -CIRCUIT ER LE DI SPOSIT IF DE PROTECTION OU INSTALLER UN

FUSIBLE DE VALEUR PL U S ELE V EE.

REMARQUE : Le changement des fusibles doit être réalisé par un personnel technique qualifié.

Page 30

30

Raccordement des entrées audio

INPUT 1 PHONO Platine

INPUT 1 LINE Lecteur CD

INPUT 2 PHONO Platine

INPUT 2 LINE Lecteur CD

INPUT 3 PHONO Platine

INPUT 3 LINE Lecteur CD

INPUT 3 MICRO Microphone

INPUT 4 PHONO Platine

INPUT 4 LINE Lecteur CD

INPUT 4 MICRO Microphone

Entrées Phono

Les platines phono doivent être équipées d'un dispositif magnétique capable de délivrer un niveau de sortie

nominal compris entre -55 et -25 dBV (1,77 - 56m V). Les entrées PHONO (35) de la NUO 4.0 ayant une capacité

de surcharge importante ( mar ge avant saturation), d es disposit ifs a yant un niveau de sortie sup érieur peu vent être

admis. Ces entrées ont une sensibilité nominale de -40dBV (10mV).

Entrées Ligne

La sensibilité des entrées intitulées LINE (36) est de 0 dBV (1V). Branchez-y des sources de son comme des

lecteurs de CD, DAT, MP3, claviers ou autres instruments.

Entrées de microphone

Les entrées MICRO (13-37 ) sont prévues pour un niv eau nominal d'entrée de -35 dBV. La prise avant (13) est de

type mixte XLR3/jack et la pris e arrière (37) de type XLR3. Ces entré es de microphone accepte nt les connexions

symétriques ; pour cela, effectuez le branchement comme indiqué :

Point chaud ou signal direct > Borne 2 Pointe

Point froid ou sig na l inv e rsé > Borne 3 Bague centrale

Masse > Borne 1 Base

Les microphones doivent être de basse impédance (de 200 à 600 Ω) et monophoniques . Pour des connexions

asymétriques, relie z la masse à la broch e 3 ou au cercle centr al. La NUO4.0 dis pose d'une aliment ation fantôme

de 18 V pour microphones à condensateur. Un cavalier interne permet de désactiver l'alimentation fantôme.

L'entrée MICRO de la NUO4.0 est réglée en usine avec l'alimentation fantôme activée (voir schéma de

configuration).

Page 31

31

Raccordement des sorties audio

MASTER Amplificateur de puissance principal

BOOTH Amplificateur de puissance sortie cabine (Booth/Room2)

REC Dispositif d'enregistrement

FX Send/Return Processeur d'effet externe (Entrée et Sortie)

Headphones Écouteurs

Sortie MASTER

Cette sortie stéréo alimente la sonorisation via une connexion XLR3 symétrique (38, 39) ou cinch/RCA (40)

asymétrique. Le niveau nominal de la sortie MASTER est réglé à 0 dBV (1V), mais il peut l'être à +6 dBV au moyen

d'un cavalier interne. Le niveau de sortie MASTER se contrôle avec le potentiomètre MASTER (24).

Près du contrôle MASTER se trouve le commutateur L+R (27) qui additionne les signaux gauche et droit des

sorties MASTER et BOOTH. Cette fonct ion est particulièr ement utile en cas de défaillance d'u n des deux canaux

pendant la session (exem ple typique : mauvais contac t de la cellule de la platine tourne-disques ). En activant ce

bouton, la console de m ixage envo ie la som me L+R aux deux encei ntes s ans que la m aj orité du public s'ap erçoive

du problème.

MASTER et BOOTH disposent d'une commande de balance BAL (26).

Sortie BOOTH

Sert habituellem ent à obtenir une sort ie indépendant e dans la cabin e du DJ. Cette sort ie stéréo BOOT H possède

une connexion XLR3 s ymétrique et une con nexion c inch/R CA as ymétriqu e. Le ni veau nom inal de la sor tie B OOTH

est réglé à 0 dBV (1 V), m ais il peut l' être à +6 d BV au mo yen d'un caval ier int erne. Le n iveau de sorti e BOO T H se

contrôle avec le potentiomètre BOOTH (25).

Sortie d'enregistrement

La sortie REC (22) pr ésente sur la surface de contrô le emploie des connexions cinch/RC A. Le niveau de sortie

nominal de la sortie REC est de 0 dBV (1V). Cette sortie est post-fader, pré-Master.

Boucle de départ/retour d'effet externe (FX Send/Return)

Les connexions de type cinch/RCA pour le départ FX SEND (41) et le retour FX RETURN (42) permettent la

réalisation d'une boucle ex terne avec tout processeur d'eff ets, échantillonneur ou séquence ur. Le niveau nominal

de la sortie SEND est de 0 dBV (1V), tout comme celui de l'entrée RETURN.

Le signal envoyé à la sorti e FX SEND est pris avant ou apr ès fader selon la po sition du commutat eur PRE/POST

(9), et le niveau d'envoi se règle grâc e à son poten tiom ètre associé (8). La N UO4.0 dispos e, outre une com mande

générale d'envoi aux ef fets FX SEND ( 17) qui additi onne les 4 voies , d'une com mande générale de retour d'ef fets

FX RETURN (15) et d'une commande de pré-écoute du signal de retour d'effets FX PFL (16).

Écouteurs

Pour obtenir la meilleure performance, les écouteurs doivent être de haute impédance (200-600Ω). La sortie

casque (30) située sur la plaque de commandes elle-même accepte un connecteur jack 6,35 mm normalisé

stéréophonique ou un connecteur mini-jack de 3,5 mm. L’anneau postérieur sera la masse, l’anneau central le

canal droit et la pointe le canal gauche.

Page 32

32

4. DEMARRAGE RAPIDE

Installer et connecter la NUO4.0 en respectant les instructions du paragraphe n°1 INSTALLATION.

Cette section propose une procédure de “Démarrage Rapide” faisant

appel à l'entrée LINE de la voie 1 et à la sortie écouteurs uniquement.

1. Réglez les commandes en position initiale

Réglez les comm andes rotati ves GAIN, HI , MID et LOW de la voi e 1 (3,

4, 5, 6) en position centra le crantée. Baissez le fader (11) du c anal et

placez le sélecteur A/O FF/B (10) en position A ( le canal est m aintenant

assigné au côté A du crossfader).

2. Branchez des écouteurs

Branchez-vous à la sortie casque (30). Réglez la commande LEVEL

(29) du casque au minim um et placez la commande SELECT (28) en

position PFL.

3. Branchez un lecteur de CD

Branchez un lecteur d e CD à l'entrée LINE du canal 1 (36), insére z un

CD et mettez-le en marche.

4. Branchez la console de mixage au secteur

Branchez le câble secteur dans l'entrée d'alimentation (43) de la

console de mixage et mettez cette dernière en service en poussant

l'interrupteur MAINS INPUT (45), tous deux situés à l'arrière.

5. Choisissez la source d'entrée

Vérifiez que le sé lecteur d'entrée de la voie 1 (1) est en position LIN E

(ligne) et que le Vu-mètre (2) de ce c anal s'allume. S'il ne s'allum e pas,

vérifiez que le lecteur de CD est bien branché et q u'il reprodu it bien une

piste audio.

6. Réglage du niveau d'entrée

Bougez la commande GAIN (3) jusqu'à ce que le Vu-mètre indique 0dB.

7. Envoyez le signal à la sortie principale

Montez le fader de la voie 1 (11) et pouss ez le crossfader (1 2) du côté

A.

Page 33

33

8. Écoutez le signal aux écouteurs

Pressez le bouton PFL (7) de la voie 1. Réglez la commande LEVEL (29) pour obtenir un niveau d'écoute

confortable. Vous devriez maintenant entendre la musique dans vos écouteurs. Déplacez le sélecteur SELECT

(28) vers la droite pour mélanger l e signal de PFL avec celui de MIX. A vec cette commande à f ond à droite, vous

n'écoutez que le signal MIX.

9. Vérifiez l'effet des commandes de tonalité

Testez la puissance d e l'égalis eur stéréo à 3 ba ndes (4, 5, 6). Ces com mandes de tonal ité sont co nçues p our une

modification créativ e du son : chaque bande p eut ê tre indépendamm ent isolé e a u moyen des grandes commandes

rotatives ergonomiques.

10. Vérifiez le réglage du crossfader

Chaque canal peut être as signé au crossfader en utilisant le sélecteur

A/OFF/B (10). Le crossfader permet d'effectuer un fondu entre les

signaux assignés aux deux côtés de ce dernier. Avec le sélecteur en

position A ou B, vous assigne z la voie à l'un des côtés du cros sfader.

La position OFF annule la fonction crossfader pour ce canal.

11. Réglage de la courbe du crossfader

La commande XFAD ER SHAPE (19) vous permet de régler la pente

de la courbe du crossf ader de façon précise. E n réglant la comm ande

à fond à gauche, vous pouvez progressivement enchaîner deux

morceaux en les fond ant. La c ourbe d u cr ossf ader s' avère pl us brut ale

si vous déplacez la com mande vers la dro ite. En r églant la c omm ande

à fond à droite, le signal arr ive d'un coup suite à un m ouvement léger

du crossfader, ce qui convient très bien à la technique de scratch.

Page 34

34

5. MANUEL DE FONCTIONNEMENT ET D'UTILISATION

Démarrage

Celle-ci se fera au m o yen de l'interrupt eur (45) du p anneau ar r ière. Au bo ut de qu elques ins tants , la diode O N (23)

s'allumera. Bien que le bruit produ it par la m ise en ser vice de la NU O4.0 soit m inim al et pratiquem ent neutral isé si

les faders sont abaissés, il est toujours conseillé de mettre en marche tous les appareils dans l'ordre suivant :

1. Sources sonores

2. Console de mixage, égaliseurs, filtres actifs

3. Enfin, amplificateurs de puissance.

La mise hors tension doit respecter exactement la séquence inverse, afin d'éviter tout dommage possible aux

enceintes.

Description des commandes

Sélecteur d'entrée

Un sélecteur d'entrée (1) est assigné à chaque voie.

Commande de GAIN

Toutes les voies d'entr ée d e la NUO4.0 sont pourvues d'une c om mande accessible de la se ns ib ilité d'entrée (GAIN

(3)). Cette dernière per met d'ajuster le n iveau d'entrée de c haque voie afin de c ompenser les diff érentes sources

connectées à la console.

Les réglages de gain doive nt être faits avec un soin e xtrême en vous réf érant au Vu-m ètre (2) de chaque voie. Le

niveau de référence utilisé pour mixer des signaux audio est de 0dBV.

La marge de gain est régla ble sur ±15 dB m ais on peut réduire c ette plage à ±6 dBV. Ce réglage est indépendant

pour chaque voie et il se fait au moyen de ponts de soudure. Consultez le schéma de configuration.

Egalisation (EQ)

Le système de comm andes de tonalité de chaque voie off re une vaste plage d'action de -3 0 à +10 dB pour les

graves (6) et les ai gus (4) et de -25 à + 10 dB po ur les médiums (5). Cette vaste plage d e variation de typ e "kill"

atténue complètement la bande choisie et a été spécialement conçue pour l'utilisation créative en direct.

ATTENTION : procéder avec pr udence lor s de l' égalis ation. L e f ait de trop bo oste r la plage des f réquences bass es

peut entraîner un déplacement excessif de la membrane des enceintes.

Système de contrôle (Monitoring)

La NUO4.0 est équipée d'u n système d'écoute souple et s imple qui permet de régler avec une grande précis i on les

niveaux de PFL (écoute pré-fader) et de mix age pour chaque voie d'entrée pri ncipale au travers du VU -mètre et

des écouterurs. Chaque c anal peut être contrôlé visuellem ent et pré-écouté en press ant les boutons dédiés PFL

(7).

Pour les éc outeurs, le potentiomètre r otatif SELECT (28) permet de m ixer une écoute PFL sélect ionnée avec le

mixage principal de programme MIX. Le potentiomètre rotatif LEVEL (29) contrôle le niveau de sortie.

Chaque voie dispose en outre d'un Vu-mètre dédié qui permet de contrôler visuellement le signal PFL (2).

Page 35

35

Envoi à des unités d'effets externes par FX Send/Return

Les 4 voies de la NUO4.0 sont équipées de potentiomètres rotatifs (8) qui permettent d'envoyer le signal à une

unité d'effets externe, un échantillonn eur, etc. Ces potent iomètres permettent de doser le niveau du si gnal qui est

envoyé depuis chaque voie.

La sortie de départ FX SEN D (41) se branc he à l'entr ée du processeur d'effets , et la sortie de c elui-c i à l'entrée de

retour RETURN (42) ou à une entrée LINE (36).

Ce départ d'effet peut êtr e configuré au moyen du com mutateur basculable PRE/POST (9) de faç on à ce que le

départ soit affecté (POST) ou non (PRE) par le fader de la voie.

La NUO4.0 dispose, outr e une comm ande générale d' envoi à des eff ets FX SEND (17) qui add itionne les 4 voies ,

d'une commande générale de retour d'effets FX RETURN (15) et d'une commande de pré-éc oute du signal de

retour d'effets FX PFL (16).

Faders

La NUO4.0 est équip ée d'une n ouvelle gé nération de faders ECLER de 60 m m (11) pr écis, extrêm em ent réguliers

et avec des prestations qui dépassent les 4.000.000 de manoeuvres grâce au système VCA d'ECLER (VCA :

Voltage Controlled Amplifier ou "amplificateur contrôlé par tension").

L'utilisation de la technol ogie VCA permet la m odification du compor tement du fader. Sur la plaque s upérieure se

trouve le potentiom ètre rotatif FADER S HAPE (18) qu i perm et de régler la c ourbe du f ader de sort e que le vo lume

soit réparti de façon proportionnelle tout le long du potentiomètre ou au contraire qu'il change soudainement.

Crossfader

Chaque canal peut être as signé au crossfader (12) en utilisant le sélecteur A/OFF/B (10). Le crossfader perm et

d'effectuer un fondu en tre l es s igna ux as s ignés a ux d eux c ôtés de c e d er ni er. A v ec le sél ec teur en position A ou B,

vous assignez la voie à l'un des côtés du crossfader. La position OFF annule la fonction crossfader pour ce canal.

Le crossfader de la NUO4.0 poss ède une série de commandes qui permettent de régler son com portement, en le

transformant un outil précis . La comm ande XFADER SHAPE (19) vous permet de régler la pent e de la courbe du

crossfader de façon préc ise. En réglant la commande à fond à gauche, vous pouv ez progressivement enchaîner

deux morceaux en les f ond ant. L a c our b e du cr os sfader s'avère plus brut a le si vo us dép lac e z la c om mande vers la

droite. En réglant la commande à fond à droite, le signal arrive d'un coup suite à un mouvement léger du

crossfader, ce qui convient très bien à la technique de scratch.

Le commutateur REVE RSE (20) inverse la direc tion du crossfader . Suivant la direction cho isie, on peut effectuer

des "cuts" ou des "fades" en déplaçant le crossfader dans la même direction.

La correction électron ique CUT IN (21) n'agit que si la NUO4.0 est équipée du pote ntiomètre ET ERNAL facultatif .

Avec le crossfader standard, le potentiomètre CUT IN doit rester en position OFF. Le CUT IN est la distance

existant entre la fin physique de la c ourse du crossfader et le premier point d'entrée de signa l. La position plus

courte fournit une coup ure pratiquement instantanée . Pour obtenir cette positi on, le potentiomètre doit être placé

en position extrêm e et le potentiom ètre CUT IN doit êtr e tourné à droite jus qu'à obtention d u signal music al. Pour

allonger le temps de CUT IN, tournez le potentiomètre vers la gauche.

Si vous souhaitez prolonger la durée de vie de votre crossfader, la NUO4.0 permet de monter en option le

potentiomètre primé ETERNAL. C'est un crossfader à technologie inductive basée sur un système de contrôle

magnétique. Cette technologie totalement sans contact, combinée avec un système mécanique de glissement

exclusif, donne un toucher régulier et un des crossfaders les plus précis existant actuellement. Le crossfader