Page 1

USER MANUAL

MANUAL DE INSTRUCCIONES

MANUEL UTILISATEUR

BEDIENUNGSANLEITUNG

Page 2

2

Page 3

User Manual Contents

1. IMPORTANT REMARK 04

1.1. Safety Instructions 04

1.2. Warranty Descriptions 04

2. INTRODUCTION 05

3. INSTALLATION 05

3.1. Audio inputs connections 06

3.2. Audio outputs connections 07

4. QUICK START 08

5. OPERATION AND USAGE MANUAL 09

5.1. Start-up 09

5.2. Control Description 09

6. MIDI CONTROLS 12

7. MIDI CONTROL OPERATION 15

8. FURTHER CONSIDERATIONS 18

9. FUNCTION LIST 19

10. FUNCTION DIAGRAM 19

11. TECHNICAL CHARACTERISTICS 71

12. DIAGRAMS 72

12.1. Figures 72

12.1.1. Connection diagram 72

12.1.2. Rack ear system (Fig1) 73

12.1.3. Internal jumper configuration 74

13. BLOC DIAGRAM 75

All numbers subject to variation due to production tolerances. ECLER S.A. reserves the right to make changes or

improvements in manufacturing or design which may affect specifications.

3

Page 4

1. IMPORTANT REMARK

1.1. Safety Instructions

In order to get the optimum operation and efficiency from your mixing unit, it is VERY IMPORTANT - before you

plug anything - to read this manual very carefully and take seriously into account all considerations specified within

it. We strongly recommend that its maintenance be carried out by our Authorised Technical Services.

This apparatus must be earthed through its mains cable.

Do not expose the unit to rain or water splashes, and do not place liquid containers or incandescent

objects like candles on top of the unit. Do not obstruct the ventilation shafts with any kind of material.

Any change in the configuration of the unit must be carried out by a qualified technician. Should any

connection / disconnection task be done, always disconnect the unit from the mains supply.

1.2. Warranty Descriptions

Your ECLER equipment has undergone exhaustive laboratory and quality control tests before leaving the factory.

Nevertheless, your may be in need of our Technical Service during the period covered by the Guarantee or

afterwards. In that case, carefully protect your equipment in its original packet and send it to our Technical Service

with the transport and insurance paid. Attach a photocopy of your Guarantee Certificate and a detailed description

of the defect you have observed.

ECLER, S.A. guarantees its ECLER products against material or fabrication defects for a ONE-YEAR period (3

YEAR period in SCLAT and NUO series mixers and in the SPM technology amplifiers and 5 YEAR in the

ETERNAL potentiometers) after the date of original purchase.

ECLER, S.A., will repair the defective equipment within the aforementioned period, with no charge for parts and

labour.

To ensure the validity of the Guarantee, it is essential that the attached Guarantee, Registration Card is filled out

correctly and remitted to your ECLER distributor, within 10 DAYS after date of purchase.

The Guarantee is non-transferrable and protects the original buyer only.

The Guarantee does not cover:

- Damages caused by mistreatment or negligent handling, lack of elementary precautions, disregard to the

instructions in the manual, faulty connection or accidents.

- Sets that have been manipulated, altered or repaired other than at the authorized Technical Service centers.

- The exterior fittings and electro-mechanical parts, nor their wear due to use.

- Shipping and insurance expenses, nor for damages the set may incur during its transport.

ECLER, S.A., will not be held responsible for any direct or indirect damage, loss or other damage originated by or

relating to the set.

This Guaranteed is valid only for repairs or services carried out at an authorized Technical Service Center.

4

Page 5

2. INTRODUCTION

Congratulations! You are the owner of a genuine ECLER professional equipment. The NUO4 has been carefully

designed in collaboration with leading dj performers and advance music producers, developed with the highest

quality components, and manufactured in-house (Barcelona-Spain) under strict quality controls.

The NUO4 is a five-channel stereo mixer with capacity for 11 separate sound sources.

Due to its robustness and format, the NUO4 is mainly dedicated to professional mixing applications (club,

homestudio), or anywhere where a compact sized, high performance mixer is required.

3. INSTALLATION

The first thing to take into consideration when placing your NUO4 is your comfort and an easy access to all the

connections. The NUO4 is basically conceived as a tabletop mixer and its usual placement will be between two

vinyls or CD players. The mixer has a 14.57’’ (37cm) depth and 12.6’’ (32cm) width format. The optional metallic

side profiles kit allows you to firmly fix your mixer to the surface over which it is placed or over its own profiles

(Fig.1). These profiles also allow to tilt the mixer's position for an easier operation. There is another metal brackets

option ('NUORAKI') that allows the mixer mounting in a standard 19" rack.

Because of the high gain of the PHONO and MICROPHONE inputs, always try to place the mixer as far away as

possible from noise sources (dimmers, engines, etc.) and mains wires. For the very same reason, and under any

circumstance, you should never remove the unit's metallic cover.

The power consumption of the NUO4 is very low, so they do not need any cooling, but you should avoid extreme

temperatures and the atmosphere should be as dry and dust free as possible.

The NUO4 operates now with a new universal input power supply “Switching Power Supply” and can perfectly

works without any internal modification from 90V to 264V – 47 to 63Hz. Make sure that the mains-wire is far away

from the signal-cables in order to avoid any possible audio hum.

In order to protect the unit from an eventual electrical overload it carries a T 500mA fuse. Should it ever blow up,

unplug the unit from mains and replace it with an identical one. If the new fuse blows again contact immediately

with our authorized technical service.

ATTENTION: NEVER SHORT-CIRCUIT THE SECURITY PATH NOR USE A HIGHER VALUE FUSE.

CAUTION: Fuse substitutions have to be performed by a qualified technician.

5

Page 6

3.1. Audio inputs connections

Input 1 H-LINE CD player

Input 1 PHONO Turntable

Input 1 L-LINE Computers, Recorders...

Input 2 H-LINE CD player

Input 2 PHONO Turntable

Input 3 H-LINE CD player

Input 3 PHONO Turntable

Input 4 PHONO Turntable

Input 4 H-LINE CD player

Input 4 MIC Microphone

Input 5 (computer) AUDIO IN Sound card

PFL Monitoring

- Phono Inputs:

Phono Turntables must be fitted with a magnetic cartridge with nominal output level between -55dBV and -25dBV

(1,77 to 56mV). The PHONO inputs (42) of the NUO4 have a high headroom (margin before saturation) and it can

handle higher output cartridges than what is usual. These inputs are supplied with a nominal input sensitivity of

-40dBV (10mV). The NUO4 has two oversized ground terminals to connect the turntables ground wire.

- Line Inputs:

Given the important level differences between usual LINE and CD sources, the NUO4 provides specialized inputs

for each source. The sensitivity of the HIGH LINE (41) input is 0dBV (1V), while the LOW LINE (43) sensitivity is

-10dBV (316mV). CD Players, DAT, MP3, and DVD Audio should be connected to the HIGH LINE input. Tape

players, tuners and some production devices (samplers, sequencers) should be connected to the LOW LINE input.

- Microphone Inputs:

The MIC input (49) is ready for a nominal input level of -50dBV (3.16mV) and is equipped with a XLR3 connectors.

The MIC ATT switch on the rear panel (48) allows a 20dB attenuation on the input sensibility, so that it is changed

from –50 to –30dB (3.16 to 31.6 mV). The connection of balanced signals is as follows:

Hot or direct signal > Pin 2

Cold or inverted signal > Pin 3

Ground > Pin 1

Low impedance (200 to 600Ω) monophonic microphones must be used. In case of working with an unbalanced

connection Pin 1 and Pin 3 must be short-circuited. The NUO4 features a Phantom power supply for the

connection of condenser microphones. A set of internal jumpers allow you to inhibit the phantom power for the

microphone. The default setting of these jumpers on the NUO4 is "Phantom ON". See configuration diagram.

- Computer input

AUDIO IN: This input has a -10dB rated sensitivity, for a correct level matching with sound cards outputs, allowing

a gain adjustment between -∞ and 0dB.

PFL: It has a rated sensitivity of 0dB. This input is designed for prelistening with audio mixing software. It must be

connected to a second sound card's output.

6

Page 7

3.2. Audio outputs connections

Out 1 Main power amplifier

Out 2 Booth/Room2 power amplifier

Rec Recording

External FX External effect device

(Send and Return) (Input and Output)

Monitor Headphones

- Master Output 1:

These stereo outputs feed the main house P.A. system through a XLR3 Balanced connections. The OUT 1 (55-56)

level is set at 0dBV (1V) but can be changed to +6dBV (2V) through internal jumpers. OUT 1 is controlled by

MASTER 1 (24) level potentiometer.

- Master Output 2:

Commonly used as an independent local "Booth" output for the DJ. This stereo OUT 2 (54) has unbalanced RCA

connections and its level is set at 0dBV (1V) but can be changed to +6dBV (2V) through internal jumpers. The

OUT 2 level controlled by the MASTER 2 (25) potentiometer.

OUT 1 and OUT 2 additionally have a BAL balance control (27) and a common L+R mono/stereo switch (26) for

both outputs.

- Recording Output:

This output pair uses RCA type connectors. REC (53) is placed on the rear connection panel. The nominal level of

the REC output is 0dBV(1V).

- External loop:

The RCA type EXTERNAL FX output SEND (51) and input RETURN (52) allow you to create an external loop with

any effect, sampler or sequencer device. The signal sent to EXTERNAL FX SEND output is selected PRE- or

POST-fader by the FX SEND (11) toggle switch, while its associated knob (10) determines the level.

The nominal levels of the SEND output and RETURN input is 0dBV (1V).

- Headphones:

In order to obtain a high performance, these should be of the high impedance type (200-600Ω). Plug them in of the

two MONITOR outputs (21), in the front panel or top panel, by means of a standard stereo jack. Sleeve is Ground,

Ring is Right Channel and Tip is Left Channel.

7

Page 8

4. QUICK START

Install and connect the NUO4 as described in the INSTALLATION paragraph nº1.

We will describe a “Quick Start” procedure using the H-LINE input of channel 1 and headphone monitoring output

only.

1

st

- Set the channel controls. Set the input switch (2)

to H-L. Set Channel 1 GAIN, TREBLE, MID, BASS

(1, 5, 6 y 7) rotary controls to their detented centre

position. Set the BASS OFF (8) switch to its up

position (BASS ON). Set the channel fader (13) to its

down position and assign the XFA/MIX/XFB (12)

selector to XFA (your channel is assigned to

crossfader A side).

2

nd

- Adjust the MONITOR VOL (22) to its minimum,

and move the MONITOR PFL/MIX (23) control to

MIX position.

3

rd

Connect a CD player to the channel 1 H LINE

input (41).

4th- Connect a pair of headphones to the MONITOR

Jack output (21).

5

th

- Connect the AC main power cord (58) to the

back of the mixer and switch ON (57) the mixer.

6th- Check that the POWER LED below the

VU-Meter (28) is lit.

7th- Start the reproduction of a CD music track.

8th- Press the yellow led PFL (9) button on channel 1

and adjust GAIN so that the left VU-Meter stays

around 0dBV.

9

th

- Set the channel fader (13) to its up position and

place the crossfader (14) on the "A" side.

10

th

- Adjust the MONITOR VOL (22) in order to

reach a "comfort" sound level in your headphones.

11th- Check the powerful 3 band stereo equalization

(5-6-7). The EQ system is designed for creative

sound performance: each band can be

independently isolated (OFF) through a large

ergonomic rotary control, and a BASS OFF switch

allows a fast bass frequency “kill” effect.

12

th

- Check the crossfader (14) action

MIX position bypasses the crossfader function. The crossfader will allow you to fade the signals assigned at each

side A & B of the slider. The movement of the crossfader allows you to create a smooth music track blend or a fast

"scratch" sound cuts. The fade curve can be very precisely adjusted thanks to the CUT-IN (19) knob* (fade-in

point), the SWITCH/FADE selector (17) (Rounded or Squared curve), the REVERSE selector (18) (Reverse the

sense of the crossfader) and fine curve control (20).

For further operations, please read the rest of this manual.

*Only if an “eternal” crossfader is installed.

8

Page 9

5. OPERATION AND USAGE MANUAL

5.1. Start-up

To switch the mixer on push the switch labelled POWER (57) located in the rear panel. After a short time, the

POWER LED below the VU-Meters will light up. Although the switching noise produced by the NUO4 is very low

and almost inexistent when starting up the NUO4 with the main faders down, we highly recommend the "safe

power-up sequence", which means that you should switch on your audio devices in the following order:

1. Sound sources.

2. Mixer, equalizers, active filters.

3. Finally, power amplifiers.

Powering off should be done by following the exact reverse sequence in order to avoid any possible damage to the

loudspeakers.

5.2. Control Description

5.2.1. Input selector

Each channel features an input toggle switch selector (2).

5.2.2. Channel gain

All NUO4 inputs have an accessible input GAIN/sensitivity control (1) to compensate existing level differences

between connected sound sources and the console before mixing. The gain settings must be made with extreme

care using SP (Signal Present) (3) and PEAK (2) LEDs, Vu-Meter and/or phones monitoring as a reference. The

standard reference level to mix audio signals is 0dBV. In order to obtain an optimal mixing, set the input level as

close as possible from 0dBV on the PFL Vu-Meter and make sure to never reach the clipping level, using red

PEAK LEDs as a warning for each channel.

5.2.3. Equalization

The rotary tone controls for each channels provide a +10/-30dB boost/cut range for the bass (7) and treble (5)

bands, and +10/-25dB at the mid range (6). This great attenuation range is specially designed for creative live

performance. Also the bass frequencies can be “killed on the fly“ activating the BASS OFF switch (8) located below

each BASS rotary knob.

ATTENTION: Use equalization carefully, by boosting too much the low frequency range, you can induce an

excessive displacement of the speakers membrane.

5.2.4. Monitoring System

The NUO4 is equipped with a flexible and easy monitoring system that will allow the performers to finely tune PFL

(Pre-fader listening) and Mix levels of each input through the VU-METER and the HEADPHONES.

Each channel can be monitorized visually and pre-listened pressing the dedicated yellow led PFL (9) button.

For HEADPHONES monitoring, the PFL/MIX rotary potentiometer (23) allows you to blend a selected PFL together

with the main MIX Program. The VOL rotary potentiometer (22) controls the level of headphones output.

The NUO4 can display (28) at the same time PFL R+L signal (on the first left VU-METER bar) together with the

Main MIX Right and Left signals (second and third VU-METER bars).

9

Page 10

5.2.5. Channel send to external effect units, FX SEND

All 4 channels of the NUO4 are equipped with rotary potentiometers (10), which allow you to send the channel

signal to an external effects unit (reverb, sampler, etc.). These pots determine the amount of signal that is sent for

each channel. The SEND output (51) must be connected to the input of the effects processor, and the output of the

latter can be fed back via the RETURN input or a LINE input.

This signal send can be configured either PRE- or POST-fader with the PRE/POST toggle switch (11), so that the

level is affected or not by the channel fader.

5.2.6. Channel Faders

The NUO4 uses a new generation of 60mm ECLER faders (13) featuring an improved precision and very smooth

movement, a very fast cut-in-time, and extra long life performance tested up to 4.000.000 operations when

combined to the ECLER VCA system (VCA=Voltage Controlled Amplifier).

The use of VCAs makes possible to edit the fader behaviour. In the front panel FADER SHAPE section, there are

two controls: NORMAL/REVERSE switch (15) allows to reverse fader operation, 0 for an open channel, 10 for a

closed one (channels 1 and 4). Rotary potentiometer SOFT/HARD (16) allows to shape the curve between these

two ends, smooth or abrupt arrival in the four main channels.

All 4 channels can be routed to the NUO4 crossfader using the toggle switch (12). “XFA” position routes the

channel to the A side of the crossfader, and “MIX” position means the channel will not be affected by the crossfader

(assigned to the main MIX always).

5.2.7. Crossfader / “eternal” crossfader upgrade

If you want to extend the crossfader operation life, the NUO4 allows an upgrade to the renowned “eternal”

potentiometer.

The ECLER ETERNAL Crossfader is an inductive fade technology based on a magnetic control. An extremely light

aluminium screen (0,5 gr.) cuts the flux lines of a magnetic field created between two sets of coils. This

electromagnetic modulation controls an assigned Voltage Controlled Amplifier that modifies the gain/attenuation of

the signal. The contactless technology is combined with a custom high quality glides mechanism to offer a very

smooth touch and succeed the most accurate Crossfader system! The ETERNAL concept does have obvious

advantages upon other existing systems using optical technology. Unlike optoelectronic elements, the inductive

concept is resistant to smoke, moisture, temperature and aging. The ETERNAL inductive crossfader has been

specifically designed for performing “turntablism” techniques.

The ETERNAL Crossfader also features new “tuning” features grouped in the XFADER SHAPE section that will

give the NUO4 the most accurate Crossfader adjustment:

SWITCH/FADE selector (17): depending of how sharp you want to get your “scratches”, the NUO4 allows you to

set-up the crossfader performance in FADE or SWITCH. The FADE Mode will give the crossfader a progressive

“roll-off” curve meanwhile the SWITCH Mode will “square” the crossfader curve in order to perform almost as a

Switch for fast “scratches”. Additionally, Both curve modes can be finely tuned with the dedicated potentiometer

(20).

NORMAL/REVERSE Switch (18): so-called “Hamster Switch”, which reverses the crossfader normal direction.

Depending on the chosen "fader direction", you can perform “cuts” and “transforms” by moving the Crossfader in

the same direction.

Electronic CUT-IN-TIME correction (19): This feature is only available if the optional “eternal” crossfader is

installed. In case the standard crossfader is used, the CUT IN adjustment should be turned OFF. The “Cut-in-time”

is the distance between the extreme end of the crossfader and the very first “fade-in” point. The shortest position

will give you almost an instant “Cut-in-time”; to find the shortest “Cut-in-time”, the crossfader must be locked on the

very end of the potentiometer in fade-out position (the PGM is fully attenuated) and the CUT-IN-TIME knob must be

turned to the right until (just before) you get the sound. To lengthen the crossfader “Cut-in-time”, turn the knob to

the left.

10

Page 11

Both standard and “eternal” potentiometers share the same type of connection. To install the “eternal” crossfader,

please follow these steps.

5.2.8. Replaceable VCA Faders and Crossfaders / “eternal” upgrade

Once any of these components has reached the end of its operating life, it can be easily replaced following these

simple steps:

1. Remove the buttons and the screws on the bottom panel.

2. Remove the two screws that hold the potentiometer to be replaced, and take it out of the mixer.

3. Disconnect the multipin connector.

4. Replace the part with an identical one or with the “eternal” crossfader.

5. Connect the multipin connector.

6. Place the fader back in the mixer and secure it with the two screws.

7. Secure the bottom cover plate with its screws and insert the buttons back in.

Always use original ECLER replacement parts.

5.2.9. MASTER Levels

The NUO4 features two main output level controls MASTER 1 (24) and MASTER 2 (25). The OUT 1 (55-56) level

is controlled by the MASTER 1 level knob. The OUT 2 (54) level is controlled by the MASTER 2 level knob.

The BAL balance potentiometer (27) affects MASTER 1 output as well as MASTER 2 output.

11

Page 12

6. MIDI CONTROLS

The NUO4 is a DJ mixer that allows to control external devices using MIDI protocol. MIDI functions that are

assigned to each control are user programmable with Ecler Control 4 Lab software.

MIDI (Musical Instruments Digital Interface) is a standard communication protocol between electronic musical

instruments and computers. A MIDI device can operate as a slave (controlled) or master (controller). NUO4

operates as a master unit, which means that it is able to control other electronic musical instruments (synthesizers,

sequencers, rhythm machines, and software... even light controllers). Also, the NUO4 can receive MIDI messages

but only for programming with Ecler Control 4 Lab software.

MIDI OUT connection is done through a standard 5-pin DIN connector (180º). The mixer also incorporates a

USB-MIDI interface to send and receive MIDI information between the mixer and a computer through USB port.

NUO4's MIDI messages belong to 'Channel Messages' and 'System Messages' categories. Transmitting and

receiving devices must be set on the same channel for the message to be communicated.

The NUO4 sends three different types of MIDI messages:

• Note-On and Note-Off messages

• Control Change messages

• System Real-Time Messages

6.1. Connections

There are two audio input connection modes for MIDI-controlled external devices:

• Connecting the external device to any NUO4 H-LINE input.

• Connecting the external device to NUO4 Input 5 (equipped with a gain control)

Device connection is especially important when using DJ software. For this reason, a soundcard with at least two

outputs is recommended.

There are two operating modes to use DJ software with NUO4:

• Using the DJ software virtual mixer that is MIDI-controllable from channels 2 and 3 of the NUO4. In this

case, you would have two outputs on the sound card: one for the MASTER signal and another one for the

PFL signal, which connect respectively to INPUT 5's AUDIO IN and PFL of your mixer.

• Without the software virtual mixer, therefore using channels 2 and 3 of the NUO4 in analog mode. In this

case, the two sound card's outputs are for the two virtual players and will be connected to any H-LINE

input.

6.2. Mixer channels with MIDI messages sending capabilities

Channels 2 and 3 of the NUO4, in addition to their analog operation with PHONO and H-LINE, allow to send MIDI

messages controlling external devices. In order to do that, you have to select the MIDI option with the input

selector. The main application is the control of similar functions (GAIN, EQ, FADER...) on a DJ software virtual

mixer.

12

Page 13

Available MIDI Controls for each channel:

• 5 rotary controls sending Control Change messages (GAIN, BASS, MID, TREBLE and FX SEND)

• 2 sliders sending Control Change messages (FADER and CROSSFADER)

• 2 switches sending Note-On/Off messages (BASS OFF and PFL)

These MIDI controls are not affected by LAYOUT and A/B selectors in MIDI CONTROL section.

At least one channel input selector and the same channel crossfader assignment must be simultaneously set in

MIDI mode for the crossfader to operate in MIDI mode. In MIDI mode the curve controls do not affect fader and

crossfader operation. Physical position of the rotary and sliding controls can slightly differ between NUO4 and

software.

MIDI controls absolute position for channels 2 and 3 does not automatically update in the external device when you

select MIDI with the input selector. The rotary commands update their position when you move them for the first

time, independently of the external control it is linked to.

As an alternative, to update all controls for a channel, keep the TAP button pressed while you select MIDI with the

input selector.

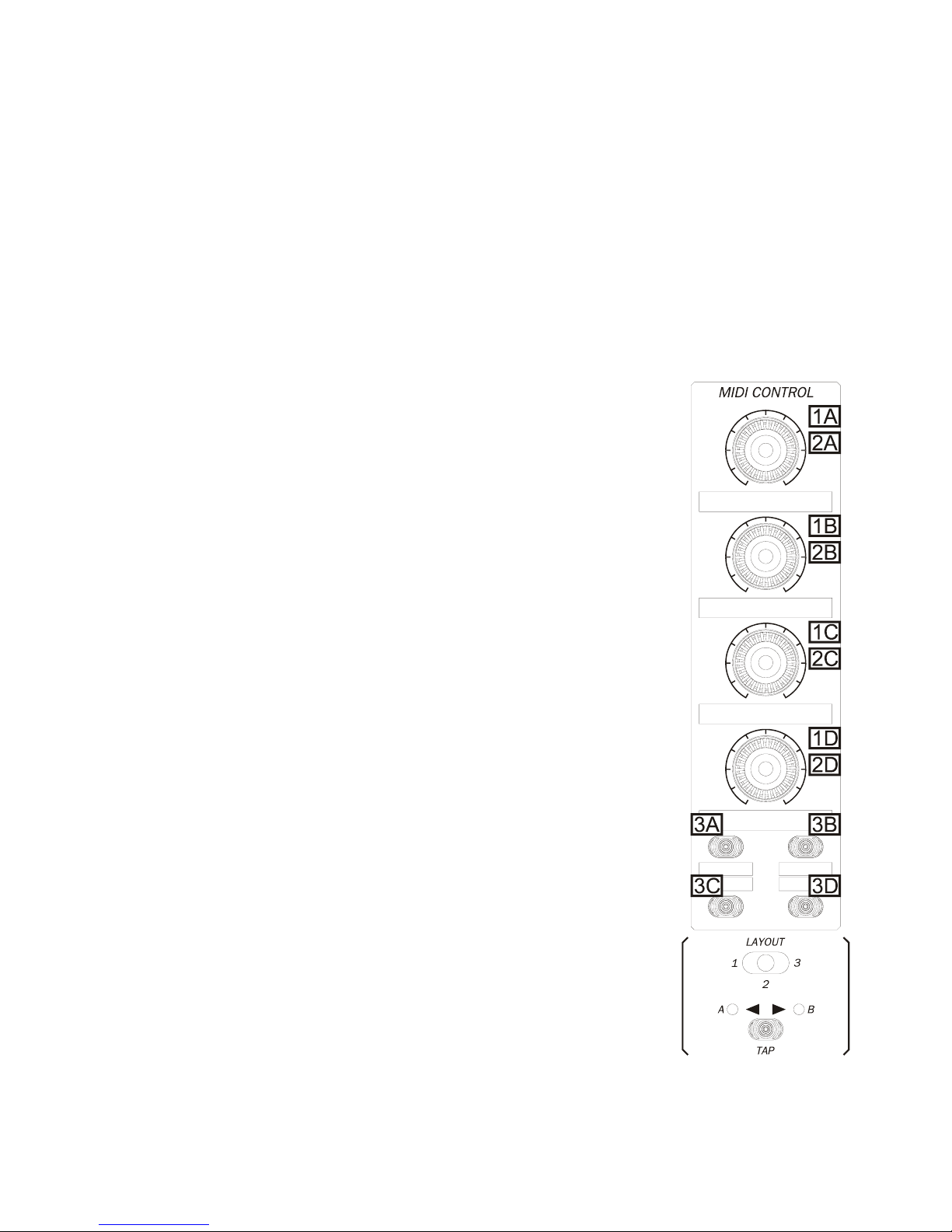

6.3. Dedicated MIDI control area

The NUO4 has 12 controls exclusively dedicated to send MIDI messages:

• 4 rotary controls (1A - 1D)

• 4 buttons (integrated to the rotary controls) (2A - 2D)

• 4 buttons (3A - 3D)

LAYOUT and A/B selectors do not send MIDI messages but allow the 12 controls

described above to send different messages. This multiplies the amount of messages

to be sent by specific MIDI controls.

A/B switch allows to double the 12 MIDI controls functions. A natural use for A/B switch

is to assign the same mixer button to a same function for two different channels in DJ

software.

For example, let's suppose that you have a DJ software with a mixer and two virtual

players. You want to assign PLAY to the 3B button; A/B switch allows you to send two

different MIDI messages and thus to execute the same function for each player. This

way you obtain:

• PLAY for left player: press 3B with switch in A position

• PLAY for right player: press 3B with switch in B position

LAYOUT selector allows you to send three different messages from each one of the 12

MIDI controls. Its natural use is to assign all the NUO4 MIDI section to three different

parts of DJ software.

For example, let's suppose that you want to control player, effects and sampler parts of

your DJ software. You'll distribute NUO4 MIDI controls this way:

• LAYOUT in position 1: control of DJ software player section

• LAYOUT in position 2: control of DJ software effect section

• LAYOUT in position 3: control of DJ software sampler section

13

Page 14

Therefore, 3B button could for example execute these functions:

• To activate PLAY: press 3B with LAYOUT in position 1

• To activate FLANGER: press 3B with LAYOUT in position 2

• To activate REC SAMPLER: press 3B with LAYOUT in position 3

In addition, with A/B switch described above, you can execute all these functions for a channel or another one in

your DJ software. This way:

• To activate REC SAMPLER for right player: press 3B with LAYOUT in position 3 and A/B switch in

position A

• To activate REC SAMPLER for left player: press 3B with LAYOUT in position 3 and A/B switch in

position B

In summary, LAYOUT and A/B combinations allow to send 6 different MIDI messages from each of the 12 NUO4

dedicated MIDI controls. Therefore, you can send a total of 72 different MIDI messages.

The controls of the specific MIDI control section can be related to any NUO4 MIDI channels (INPUT2 or INPUT3) or

can operate independently. If they operate as independent controls, they will always send MIDI messages even if

MIDI is not selected with these two channels input selectors. On the contrary, if a control is related to a specific

channel, it will only send MIDI messages with this channel in MIDI mode. This assignation is done with

Ecler Control 4 Lab software.

6.4. Real-time messages

6.4.1. MIDI Clock

The NUO4 transmits a standard timing message named MIDI Clock, to synchronize one or several external MIDI

devices. The synchronization signal is the same message sent 24 times per quarter note.

To control a MIDI device, remember this device has to operate in slave mode (external Clock).

The NUO4 has no internal processor for BPM calculation. The tempo for a specific musical part has to be manually

set, repeatedly pressing the TAP button (a minimum of 5 times) to the desired tempo. The TAP button blinks to the

BPM rate you established.

A more precise BPM adjustment can be done assigning one of the MIDI controls to this function with

Ecler Control 4 Lab software.

MIDI Clock can be deactivated by holding down the TAP button more than 3 seconds. When this happens, TAP

button does not blink. Once deactivated, it will not operate until you explicitly activate it by holding down the TAP

button more than 3 seconds. The selected mode will be maintained after shutdown.

Tempo default value is 120 BPM after each shutdown or MIDI Clock activation.

6.4.2. Start, Stop and Continue messages

When an external device is synchronized by MIDI Clock, standard Start, Stop and Continue messages are used to

control the playing.

Any NUO4 MIDI button can send these messages. Programming is done with Ecler Control 4 Lab software.

14

Page 15

7. MIDI CONTROL OPERATION

7.1. Drivers installation

To connect the NUO4 to a computer using USB-MIDI interface, you must previously install USB and MIDI drivers

(provided on the CD). The process varies according to the operating system in use. The only supported operating

systems are Windows® 2000 (SP4) and XP.

7.1.1. Windows® 2000

Warning: before connecting the NUO4 to its computer, please perform the following steps. Any other kind of

installation could cause the computer to unexpectedly reboot. This is due to certain peculiarities in Windows® 2000

concerning MIDI devices support through USB.

1. Before connecting the NUO4 to the computer for the first time, run 'install.exe' from the 'Driver' folder on the

CD.

2. When the installer screen comes up, check that the NUO4 is disconnected and press 'Yes' to continue.

3. The 'Digital Signature Not Found' error message may appear during USB driver installation. If it does, click

YES to proceed with installation.

4. Restart your computer when the wizard tells you to do so.

5. After restart, connect the USB cable between the NUO4 and the computer.

6. The operating system will automatically detect the device. There may be a long pause while the operating

system detects the device until the end of the process.

7. Again, if the 'Digital Signature Not Found' error message appears, click YES to proceed with installation

8. Once the process completed, the NUO4 is identified as 'Ecler USB Midi' by the operating system.

9. To safely disconnect NUO4 USB cable, follow the Windows® 2000 standard method to 'Unplug or eject

hardware'. If the USB cable is directly removed a warning appears to inform you that the device extraction

has not been safely done.

7.1.2. Windows® XP (home or professional)

1. Check that the NUO4 USB cable is disconnected and start your computer.

2. Run 'install.exe' program form the “Driver” folder on the CD.

3. Install program will request the user to connect the NUO4 USB cable to the computer and to wait until the

operating system completes the drivers automatic default installation. Do not click 'Accept' until

Windows® XP tells you that the new device is ready to use (If you do it before, the installer tells you that he

can't complete installation and you have to restart the computer before retrying. Carefully follow all the

steps indicated in this manual). Caution: There may be a long pause while the operating system

detects the device until the end of the process.

4. Once Windows® XP tells you that the new device is ready to use, click 'Accept' to proceed with installation.

5. If XP Logo testing warning windows appears indicating that the driver you're going to install is not certified,

click 'Continue anyway' to proceed with installation.

6. Once the process completed, the NUO4 is identified as 'Ecler USB Midi' by the operating system and is

ready to use.

15

Page 16

ATTENTION: With Windows® XP, if you connect the NUO4 to different USB ports on your computer, you'll have to

repeat the installation for each port and to restart your equipment each time. On the contrary, if you use

Windows® 2000 and connects the NUO4 to different USB ports on your computer, you won't have to repeat the

installation for each one of them, the system automatically identifies them.

We recommend visiting Ecler's web page (www.eclerdjdivision.com) in order to check if driver or software updates

are available.

7.1.3. NUO4 driver uninstall

In order to uninstall NUO4 drivers from any operating system, disconnect first NUO4 USB cable from the computer.

Run 'uninstall.exe' program from the 'Driver' folder on the CD.

1. Follow the wizard instructions.

2. Once the process completed, NUO4 USB-MIDI drivers are uninstalled from your operating system.

This utility uninstalls drivers for all ports on the same computer.

7.2. Controls programming

A same MIDI control can be configured to send different types of message depending on the specific needs of the

external device the user has to control. Programming is done from Ecler Control 4 Lab software.

7.2.1. Rotary controls

The different messages MIDI rotary controls can send are:

• Incremental control: it sends a control change message with the value increase to be done on the related

control; if it is rotated to the right, increments are sent (value 1 to 4) and if it is rotated to the left,

decrements are sent (value -1 to -4). This type of message is well suited for NUO4 MIDI rotary controls 1A

to 1D when you want to manipulate rotary or sliding controls, since they correctly operate independently of

the absolute position they have.

• Absolute control: it sends a control change message with the current absolute value the related control

must have. The value range is 0 (completely to the left) to 127 (completely to the right). The rotary and

sliding controls of NUO4 channels 2 and 3 only accept this mode. Although this mode is not so useful with

NUO4's MIDI controls 1A to 1D, it has been implemented for compatibility.

• Two unlatch buttons: turning to the right sends a Note-On/Off message and turning to the left sends a

different one. This type of message is well suited when you want to control a pair (like up/down, +/-…) with

a rotary button.

• Any NUO4 MIDI control 1A to 1D can be used to finely adjust the tempo (BPM). In this mode no MIDI

command is sent.

16

Page 17

7.2.2. Control buttons

The different MIDI messages that control buttons can send are:

• Unlatch button (normal push switch): it sends two different note messages (Note-On when pressed and

Note-Off when released). It is well suited to control functions needing a temporary state change while the

button is pressed. An example is pitch adjustment that you activate as long as the button is pressed.

• Latch button (toggle push switch): it sends only one Note-on message whenever it is pressed. It is

appropriate when you want to control functions needing a permanent state change when pressing the

button. An example is the play function of a CD player that is activated by a simple pressing on the button

and vice versa.

• Any NUO4 MIDI button can send real-time messages (Start, Stop and Continue). Programming is done

with Ecler Control 4 Lab software.

7.2.3. Recommendations

As starting point we recommend to configure all rotary controls in incremental mode and buttons in momentary

mode, and to match your software MIDI control configuration to obtain optimal operation.

If your software does not allow suitable settings of these controls, try to modify the MIDI message that the NUO4

sends with Ecler Control 4 lab.

7.3. Assignment advice for external device functions

There is no universal method to assign functions, since each external device has its own particularities.

Our first advice is to spend the necessary time for indepth knowledge of MIDI control capabilities and how to

program them. Most of the external devices with MIDI control can be set; it means you can define the message

each control will respond to.

The second step consists of choosing the external device functions to control and assigning them to the NUO4

MIDI controls. As you should consider different aspects, we pointed out some of the most relevant ones:

• Allocate controlled functions in a logical manner, grouping them by blocks in the three LAYOUT sections

(1/2/3). For example, try to group all player-related functions in a same LAYOUT (Play, Cue, Pitch Up...),

all the effect-related ones in another LAYOUT (Flanger, Echo, Delay...).

• Consider if certain functions have to be kept on the same button independently of LAYOUT position. For

example, if you want the 3B button to execute the PLAY function whatever the LAYOUT and A/B selectors

position is.

• Think if you want to use channels 2 and 3 in analog or MIDI mode.

In order to reach these objectives, you'll probably need to first edit the NUO4 internal programming and to correctly

configure the external device. From Ecler Control 4 Lab check (and if necessary correct):

• that the NUO4 controls send the appropriate type of message to execute the desired function in the

external device

• that the MIDI channel used by the NUO4 is the appropriate one for your external device

• that messages are the appropriate ones for your external device

• that controls having a same function send identical messages

17

Page 18

Once the configuration has been set up, update your mixer firmware. Then configure your external device so that it

responds to MIDI messages the NUO4 sends. Each external device has its own learning method:

• select the MIDI learning mode

• choose a function on the external device

• move a NUO4 control to send a MIDI message

• the external device combines this MIDI message with that function and store it

7.4. Label printing

Once concrete functions have been assigned to NUO4 MIDI controls, you'll have to identify each button's function.

For this, the NUO4 incorporates an innovative label system.

On the Ecler Control 4 Lab CD-ROM, you'll find a folder dedicated to label printing with two files: one

Microsoft® Word file (.doc) and one CorelDRAW® file (.cdr).

Type the name of the functions that are assigned to MIDI controls and print labels, preferably on transparent paper.

Trim the labels and place them in front of the windows of the magnetized plate through lateral grooves.

8. FURTHER CONSIDERATIONS

8.1. Ground loops

Ensure at all times that no signal sources reaching the mixing desk and no devices connected to its output have

their earths interconnected; that is, earth should never reach them via two or more different paths, as this could

lead to humming which could even interfere with sound reproduction quality. In order to avoid earth loops, ensure

that the shielding of cables, if connected to the chassis, are never connected with each other.

When you connect computer and sound equipment, 'hum' frequently appears, caused by an earth loop. In this

case, it is usually advisable to make the connection through an accessory known as earth loop eliminator, available

in specialized shops.

8.2. Audio connections

As a general rule of thumb, make the signal connections as short as possible and use the best connectors and

cable available. Cables and connectors are frequently held cheap, forgetting that a bad connection can result in a

poor sound quality.

8.3. Background noise

The use of active circuitry can yield, depending on the configuration, to a significant noise level. The NUO4 has

been designed for the minimum possible noise. Anyway, the noise level will always depend on the correct use and

installation of the mixer. It is not the same setting up the FADER at "2" and the MASTER at "10" that the other way

round; FADER at "10" and MASTER at "2". In the first case you get a poor signal to noise ratio that will be fully

amplified by the master while on the second we have a good signal to noise ratio only amplified by "2". As a result,

the background noise is greater in the first case than in the second one.

8.4. Cleaning

The front panel should not be cleaned with dissolvent or abrasive substances because silk-printing could be

damaged. To clean it, use a soft cloth slightly wet with water and neutral liquid soap; dry it with a clean cloth. Be

careful that water never gets into the unit through the holes of the front panel.

18

Page 19

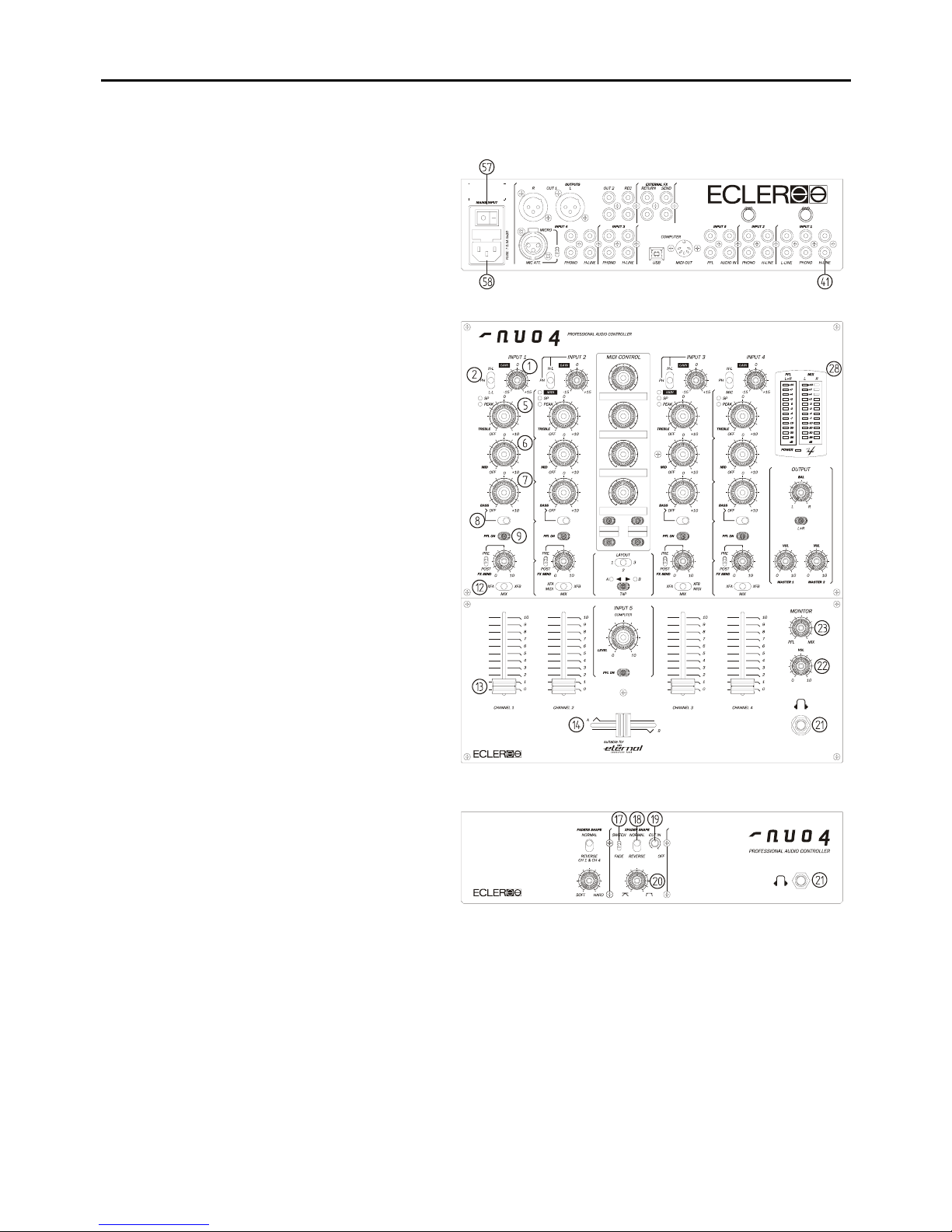

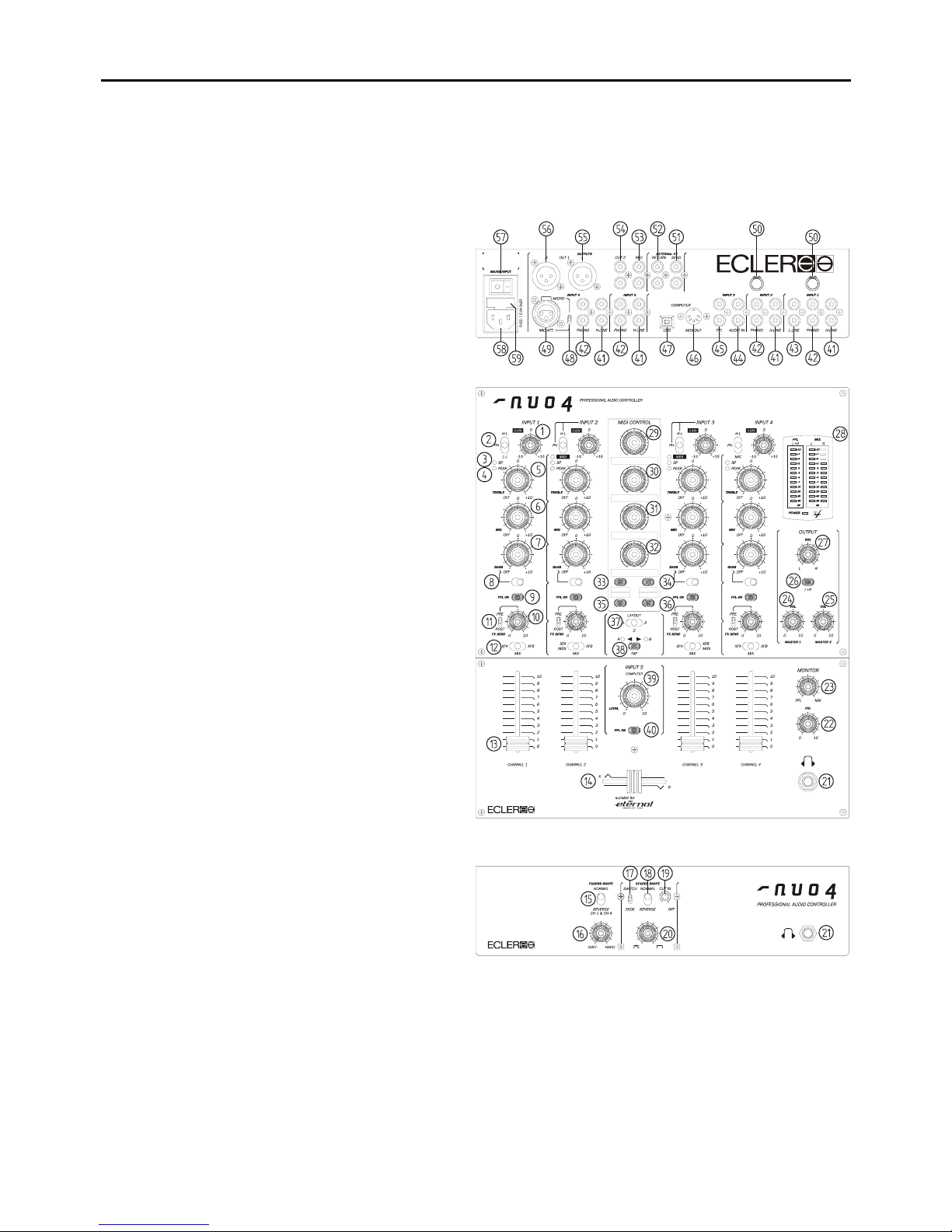

9. FUNCTION LIST 10. FUNCTION DIAGRAM

1. Input sensitivity adjust, GAIN

2. Input selector

3. Signal present indicator, SP

4. Peak level indicator, PEAK

5. Treble frequency control, TREBLE

6. Midrange frequency control, MID

7. Bass frequency control, BASS

8. Bass frequency isolation switch

9. Prefader listening control, PFL

10. Effect send control, FX SEND

11. Send switch to effect bus

12. Send to XF switch, XFA/MIX/XFB

13. Fader

14. Crossfader

15. Fader reverse function

16. Crossfader Shape adjuster, SOFT HARD

17. Crossfader curve mode, SWITCH FADE

18. Crossfader reverse function

19. Crossfader "cut in time" adjustment, CUT IN

20. Crossfader Shape adjuster

21. Headphones stereo jack connector

22. Headphones volume control, VOL

23. PFL/MIX monitoring crossfade

24. Output 1 level control, MASTER 1

25. Output 2 level control, MASTER 2

26. Left and Right signal sum, L+R

27. Balance control, BAL

28. PFL and MIX vu-meter

29. MIDI rotary control

30. MIDI rotary control

31. MIDI rotary control

32. MIDI rotary control

33. MIDI button

34. MIDI button

35. MIDI button

36. MIDI button

37. LAYOUT Selector

38. A/B switch

39. Input 5, LEVEL control

40. Pre-fader listening control, PFL

41. High Line RCA inputs, H-LINE

42. Turntable phono RCA inputs, PHONO

43. Low Line RCA inputs, L-LINE

44. RCA inputs for computer, AUDIO IN

45. RCA inputs for computer, PFL

46. MIDI OUT

47. USB port

48. Micro input sensitivity switch

49. Microphone input, MICRO

50. Ground pin, GND

51. External effect SEND output, SEND

52. External effect RETURN input, RETURN

53. Recording RCA connector, REC

54. RCA output, OUT2

55. Left channel balanced output, OUT1 L

56. Right channel balanced output, OUT1 R

57. Mains OFF/ON Switcher, O/I

58. Mains socket

59. Fuse holder

19

Page 20

Contenido del manual

1. NOTA IMPORTANTE 21

1.1. Instrucciones de seguridad 21

1.2. Descripción de la garantía 21

2. INTRODUCCIÓN 22

3. INSTALACIÓN 22

3.1. Conexiones de entrada de audio 23

3.2. Conexiones de salida de audio 24

4. INICIO RÁPIDO 25

5. OPERACIÓN Y USO 26

5.1. Puesta en funcionamiento 26

5.2. Descripción de los controles 26

6. CONTROLES MIDI 29

7. USO DEL CONTROL MIDI 32

8. OTRAS CONSIDERACIONES 35

9. LISTA DE FUNCIONES 36

10. DIAGRAMA DE FUNCIONES 36

11. CARACTERÍSTICAS TÉCNICAS 71

12. DIAGRAMAS 72

12.1. Figuras 72

12.1.1. Diagrama de conexiones 72

12.1.2. Sistema de montaje en rack 73

12.1.3. Configuración interna de los jumpers 74

13. DIAGRAMA DE BLOQUES 75

Todos los datos están sujetos a variación debida a tolerancias de producción. ECLER S.A. se reserva el derecho de realizar

cambios o mejoras en la fabricación o diseño que pudieran afectar las especificaciones.

20

Page 21

1. NOTA IMPORTANTE

1.1. Instrucciones de seguridad

Para conseguir la máxima funcionalidad del aparato y su máximo rendimiento, es muy importante antes de su

conexión, leer detenidamente y tener muy presentes las consideraciones que en este manual se especifican. Para

garantizar el óptimo funcionamiento de este aparato, recomendamos que su mantenimiento y eventuales

reparaciones sean llevadas a cabo por nuestros Servicios Técnicos autorizados.

Este aparato debe conectarse a tierra a través de su cable de red.

No exponer la unidad a la lluvia o a salpicaduras de agua, no colocar recipientes que contengan líquidos

u objetos incandescentes tales como velas sobre el aparato. No obstruya las rejillas de ventilación.

Cualquier cambio en la configuración de la unidad debe ser llevado a cabo por técnicos cualificados. Cualquier

conexión o desconexión de la unidad debe ser realizada, siempre, con la unidad desconectada de la red.

1.2. Descripción de la garantía

Su equipo ECLER ha superado ensayos de laboratorio y exhaustivos controles de calidad antes de abandonar la

fábrica. No obstante podría darse el caso que necesite nuestro Servicio Técnico durante el periodo que cubre la

garantía o posteriormente. En tal caso, proteja cuidadosamente la unidad en su caja original y envíelo a nuestro

Servicio Técnico con los gastos y el seguro pagados. Adjunte una fotocopia del certificado de garantía y una

descripción detallada del defecto observado.

ECLER, S.A. garantiza sus productos ECLER ante defectos de materiales o fabricación durante el periodo de UN

AÑO (TRES AÑOS en el caso de mezcladores de las series SCLAT y NUO y en los amplificadores de tecnología

SPM y CINCO AÑOS para los potenciómetros ETERNAL) transcurridos tras la fecha de compra original.

ECLER, S.A. reparará el equipo defectuoso dentro del periodo especificado, sin cargo alguno para piezas y mano

de obra.

Para asegurar la validez de la garantía es preciso que la Garantía y la Tarjeta de Registro se rellenen

correctamente y se remitan a su distribuidor ECLER, en el plazo de 10 días después de la fecha de compra.

La garantía no es transferible y solamente protege al comprador original.

La garantía no cubre:

- Daños ocasionados por malos tratos o manejo negligente, falta de cuidados elementales, desatención de las

instrucciones del manual, conexión equivocada o accidentes.

- Aparatos que hayan sido manipulados, alterados o reparados fuera del Servicio Técnico autorizado.

- El mueble exterior, los componentes electromecánicos ni su desgaste por uso.

- Los gastos de envío y seguros, ni los daños que el aparato pueda sufrir durante el transporte.

ECLER, S.A., no será responsable por ningún daño directo o indirecto, pérdida o perjuicio originado por o en

relación con el equipo.

Esta garantía es válida sólo si las reparaciones o servicios se realizan en un Servicio Técnico autorizado.

21

Page 22

2. INTRODUCCIÓN

¡Felicidades! Por adquirir un auténtico equipo profesional ECLER. El NUO4 ha sido diseñado cuidadosamente en

colaboración con prestigiosos artistas, DJs y productores, desarrollado con componentes de última generación y

fabricado en nuestra planta de Barcelona bajo estrictos controles de calidad.

El NUO4 es un mezclador estéreo de cinco canales con capacidad para 11 fuentes de sonido.

Debido a su formato y robustez, el NUO4 está principalmente concebido para aplicaciones de mezcla profesional

(club, estudio...) donde se requiere un mezclador de tamaño compacto pero excelentes prestaciones.

3. INSTALACIÓN

La principal consideración a tener en cuenta en el momento de buscar la ubicación de su nuevo NUO4 debe ser la

máxima comodidad de trabajo del operador, permitir una total facilidad en la realización de las conexiones de las

que el mezclador va a ser punto de partida y llegada. El NUO4 está básicamente concebido como mezclador de

sobremesa y su ubicación habitual será entre dos reproductores de discos compactos o de vinilo. El mezclador

tiene un formato de 14.57'' (37 cm) de profundidad y 12.6'' (32 cm) de anchura. Mediante el kit de laterales

metálicos (disponibles como opción) (Fig. 1) podrá sujetar firmemente su NUO4, ya sea directamente sobre la

superficie sobre la que se apoye o sobre los laterales, también le permitirán inclinar el mezclador. Existe otra

opción de perfiles metálicos "NUORAKI" que permiten la ubicación del mezclador en muebles rack estándar de

19".

Dada la elevada ganancia de las entradas de PHONO y de MICRÓFONO debe procurarse situar el mezclador lo

más alejado posible de fuentes de ruido (variadores de tensión, motores, etc.) así como de cualquier cable de red.

Por esta misma razón y bajo ninguna circunstancia debe quitarse la tapa metálica del aparato.

Ya que el consumo del NUO4 es muy bajo, éste no precisa ventilación, sin embargo debe evitarse que esté

expuesto a una temperatura extrema y que la atmósfera del local en que esté emplazado sea lo más seca y limpia

de polvo posible.

El NUO4 funciona con una fuente de alimentación conmutada de tipo universal permitiendo trabajar sin ningún tipo

de ajuste desde 90V a 264V – 47/63Hz. Asegúrese de que el cable de red se encuentre lejos de los cables de

señal para evitar zumbidos.

Para proteger al mezclador de eventuales sobrecargas en la línea de red existe un fusible de red de tipo T 500mA.

En caso de que éste se fundiera se desconectaría el aparato y se sustituiría por otro de idénticas características.

Si éste último se volviera a fundir, consulte con nuestro Servicio Técnico.

ATENCIÓN: EN NINGÚN CASO DEBE CORTOCIRCUITAR EL CIRCUITO DE PROTECCIÓN O

PONER UN FUSIBLE DE VALOR MÁS ELEVADO.

ADVERTENCIA: La sustitución del fusible debe ser realizada por un técnico cualificado.

22

Page 23

3.1. Conexiones de entrada de audio

Input 1 H-LINE Reproductor CD

Input 1 PHONO Plato giradiscos

Input 1 L-LINE Ordenadores, Magnetófonos...

Input 2 H-LINE Reproductor CD

Input 2 PHONO Plato giradiscos

Input 3 H-LINE Reproductor CD

Input 3 PHONO Plato giradiscos

Input 4 PHONO Plato giradiscos

Input 4 H-LINE Reproductor CD

Input 4 MIC Micrófono

Input 5 (computer) AUDIO IN Tarjeta de sonido

PFL Preescucha

- Entradas de Phono:

Los platos giradiscos deben ir equipados con cápsula magnética con un nivel de salida nominal entre –55dBV y

-25dBV (1,77 a 56mV). Las entradas PHONO (42) del NUO4 tienen un amplio margen antes de la saturación

(headroom) y pueden admitir cápsulas con mayor nivel de salida de lo habitual. Estas entradas presentan una

sensibilidad de entrada nominal de –40dBV (10mV). El NUO4 dispone de dos bornes de masa

sobredimensionados para conectar el cable de tierra de los platos giradiscos.

- Entradas de Línea:

Dadas las importantes diferencias de nivel existentes entre las Fuentes del tipo CD y de LINE convencional, el

NUO4 incorpora entradas diferenciadas para cada uno de estos elementos. Así la sensibilidad de las entradas

marcadas como HIGH LINE (41) es 0dBV (1V) y la de LOW LINE (43) es -10dBV (316mV). Reproductores CD,

DAT, MP3, DVD Audio... se conectarán a las entradas HIGH LINE. Magnetófonos, cassettes, sintonizadores, y

algunos equipos de producción (samplers, secuenciadores) se conectarán a la entrada LOW LINE.

- Entradas de Micrófono:

La entrada de MICRO (49),está preparada para un nivel nominal de entrada de -50dBV (3.16mV). La conexión es

del tipo XLR3. A través del conmutador ubicado en el panel posterior (48), en posición MIC. ATT efectúa una

reducción de 20dB de la sensibilidad de esta entrada, pasaría pues de –50 a –30dB (3.16 a 31.6mV). Esta entrada

de micrófono admite la conexión en modo balanceado para ello se realizará la conexión tal y como se indica:

Vivo o señal directa > Terminal 2

Frío o señal invertida > Terminal 3

Masa > Terminal 1

Los micrófonos deben ser de baja impedancia (de 200 a 600Ω) y monofónicos. Para conexiones NO balanceadas

cortocircuitar a masa el terminal 3. El NUO4 dispone de alimentación phantom para micrófonos equipados de

condensador. Un jumper interno permite inhibir el funcionamiento de la alimentación phantom. La entrada MICRO

del NUO4 se sirve de fábrica con el jumper interno en posición "phantom ON". Ver diagrama de configuración.

- Entrada computer

AUDIO IN: La sensibilidad nominal de esta entrada es de -10dB, para una correcta adaptación al nivel de salida de

las tarjetas de sonido, permite un ajuste entre -∞ y 0dB de ganancia.

PFL: Tiene una sensibilidad nominal de 0dB. Esta entrada esta prevista para la preescucha de los programas de

mezcla de audio sobre ordenador. Debe conectarse a una segunda salida de la tarjeta de sonido.

23

Page 24

3.2. Conexiones de salida de audio

Out 1 Amplificador de potencia principal

Out 2 Amplificador de cabina

Rec Dispositivo grabador

External FX Procesador de efectos externo

(Send y Return) (Entrada y Salida)

Monitor Auriculares

- Master Output 1:

Estas salidas estéreo alimentan al sistema de P.A. a través de conexiones XLR3 balanceadas. El nivel nominal de

la salida OUT1 (55-56) está ajustado a 0dBV (1V), pero puede elevarse a +6dBV (2V) mediante puentes internos.

El nivel de salida OUT 1 se controla con el potenciómetro MASTER 1 (24).

- Master Output 2:

Habitualmente se usa para obtener una salida independiente en la cabina del DJ. Esta salida estéreo OUT 2 (54)

incorpora conexiones RCA no balanceadas y su nivel nominal de salida está ajustado a 0dBV (1V), pero puede

elevarse a +6dBV (2V) mediante puentes internos. El nivel de salida OUT 2 se controla con el potenciómetro

MASTER 2 (25).

OUT 1 y OUT 2 disponen adicionalmente de un control de balance BAL (27) y un conmutador mono estéreo L+R

(26) común a ambas salidas.

- Salida de grabación:

Esta salida emplea conexiones RCA. REC (53) se encuentra situada en el panel posterior. El nivel de salida

nominal de la salida REC es de 0dBV (1V).

- Bucle externo:

Las conexiones de tipo RCA de salida EXTERNAL FX SEND (51) y de entrada RETURN (52) permiten la

realización de un bucle externo con cualquier efecto, sampler o dispositivo secuenciador. La señal enviada a la

salida EXTERNAL FX SEND se selecciona antes o después del FADER mediante el conmutador FX SEND (11) y

el nivel con su potenciómetro asociado (10).

El nivel nominal de la salida SEND, así como la entrada RETURN es de 0dBV (1V).

- Auriculares:

Para obtener el mejor rendimiento en su funcionamiento, éstos deberán ser de alta impedancia (200-600Ω). Se

conectarán a una de las dos salidas MONITOR (21) situadas en la placa frontal o sobre la propia placa de mandos

mediante un conector jack normalizado de ¼" estereofónico. El casquillo del jack será la masa, el anillo central el

canal derecho y la punta el canal izquierdo.

24

Page 25

4. INICIO RÁPIDO

Instale y conecte el NUO4 tal y como se describe en el primer párrafo del apartado INSTALACIÓN.

Se describe a continuación un procedimiento de “inicio rápido” usando la entrada H-LINE del canal 1 junto a una

monitorización a través de la salida de auriculares.

1º Ajuste los controles de canal. Sitúe el conmutador

de entrada (2) en H-L. Ajuste los controles rotativos

GAIN, TREBLE, MID y BASS (1, 5, 6 Y 7) en su

posición central enclavada. Posicione el conmutador

BASS OFF (8) en su estado levantado (BASS ON).

Sitúe el fader de canal (13) abajo y asigne el selector

XFA/MIX/XFB (12) en posición XFA (el canal está

asignado ahora al lado A del crossfader).

2º Ajuste el MONITOR VOL (22) al mínimo y lleve el

control MONITOR PFL/MIX (23) a su posición MIX.

3º Conecte un reproductor de CD en la entrada

H-LINE del canal 1 (41).

4º Conecte unos auriculares a la salida MONITOR

(21).

5º Conecte el cable de alimentación (58) en la parte

trasera del mezclador y enciéndalo (57).

6º Compruebe que se ilumina el LED POWER situado

bajo el VU-Metro (28).

7º Inicie la reproducción de una pista del CD.

8º Presione el botón con LED amarillo PFL (9) del

canal 1 y ajuste el GAIN hasta que el VU-Metro

izquierdo marque 0dBV.

9º Coloque el fader de canal (13) arriba y sitúe el

crossfader (14) en el lado "A".

10º Ajuste el MONITOR VOL (22) para obtener un

nivel de escucha confortable en sus auriculares.

11º Compruebe el potente ecualizador estéreo de 3

bandas (5-6-7). El ecualizador está diseñado para la

modificación creativa del sonido: cada banda puede

aislarse independientemente (OFF) mediante los

grandes controles rotativos ergonómicos y el

conmutador BASS OFF permite un rápido efecto "kill"

sobre las bajas frecuencias.

12º Compruebe el funcionamiento del crossfader (14).

La posición MIX provoca que la señal no se vea afectada por el crossfader. El crossfader permite realizar un

fundido entre las señales asignadas a ambos lados A y B del mismo. El movimiento del crossfader permite crear

un fundido suave entre pistas de música o rápidos cortes de sonido tipo “scratch”. La curva de fundido se puede

ajustar de manera muy precisa gracias a los controles CUT IN* (19) (punto de fade in), el selector SWITCH / FADE

(17) (curva redondeada o cuadrada), el selector REVERSE (18) (se invierte el comportamiento del crossfader) y el

control fino de curva (20).

Para más detalles, consulte por favor el resto de este manual.

* Solo en el caso de montar el crossfader "eternal".

25

Page 26

5. OPERACIÓN Y USO

5.1. Puesta en funcionamiento

Esta se realizará mediante el interruptor (57) situado en el panel posterior, al cabo de unos instantes se iluminará

el LED inferior, POWER, del VU-metro. Aunque el ruido producido por la puesta en funcionamiento del NUO4 es

mínimo y queda prácticamente anulado al hacerlo con los faders cerrados, siempre resulta muy recomendable

poner en marcha todos los aparatos siguiendo la secuencia siguiente:

1. Fuentes de sonido

2. Unidad de mezclas, ecualizadores, filtros activos

3. Finalmente, amplificadores de potencia.

El paro de los aparatos debe realizarse en la secuencia inversa. Siguiendo este orden los picos o transitorios

producidos por el encendido o apagado de los aparatos no afecta a los siguientes y, por consiguiente, tampoco

llegan a los altavoces.

5.2. Descripción de los controles

5.2.1. Selector de entrada

Cada canal principal dispone de un selector de entrada basculante (2).

5.2.2. Ganancia de vía

Todas las vías de entrada del NUO4 disponen de un ajuste accesible de la sensibilidad de entrada GAIN (1), cuya

misión es la de compensar las diferencias de nivel existentes entre las fuentes sonoras conectadas a la mesa

antes de ser mezcladas. Los ajustes de ganancia deben realizarse con suma meticulosidad utilizando los LEDs de

SP (Signal Present) (3) y PEAK (2), el VU-Metro y/o los auriculares como referencia. El nivel de referencia

estándar usado para mezclar señales de audio es de 0dBV. Para obtener una mezcla óptima, ajuste su entrada a

un valor lo más cercano posible a 0dBV leído en el VU-Metro PFL y asegúrese de no alcanzar nunca el nivel de

"clipping", tomando como referencia de los LEDS rojos de aviso PEAK de cada canal.

5.2.3. Ecualización

El sistema de control de tonos para cada vía ofrece un amplio margen de actuación: -30 a +10dB para la vías de

graves (7) y agudos (5) y -25 a +10dB para la vía de medios (6). Este amplio margen de variación ha sido

especialmente diseñado para el uso creativo en directo. Adicionalmente, las bajas frecuencias se pueden “matar al

vuelo” por medio del conmutador BASS OFF (8) situado debajo de cada control rotativo BASS.

ATENCIÓN: Utilice el control de tonos con precaución, la elevada ganancia máxima puede provocar

sobredesplazamientos en su sistema de altavoces.

5.2.4. Sistema de monitorización

El NUO4 está equipado con un sistema de monitorización flexible y sencillo que permite ajustar con suma

precisión los niveles de PFL (monitorización de escucha pre-fader) y de mezcla para cada vía de entrada principal

a través del VU-Metro y de los auriculares.

Cada canal puede ser monitorizado visualmente y pre-escuchado pulsando los botones PFL (9), iluminados de

color amarillo.

Para la monitorización a través de auriculares, el potenciómetro rotativo PFL/MIX (23) permite mezclar un PFL

seleccionado con la mezcla principal de programa MIX. El potenciómetro rotativo VOL (22) controla el nivel de

salida de auriculares.

El NUO4 puede visualizar en su display (28) la señal PFL L+R (en la primera columna del VU-metro) junto con el

nivel de mezcla izquierda y derecha (segunda y tercera columna del VU-metro).

26

Page 27

5.2.5. Envío a unidades exteriores de efectos, FX SEND

Las 4 vías principales del NUO4 están equipadas con potenciómetros rotativos (10) que permiten realizar un envío

a una unidad de efectos exterior, sampler, rever... Estos potenciómetros permiten dosificar el nivel de señal que se

envía de cada una de las vías. La salida SEND (51) se conectará a la entrada del efecto y la salida de éste puede

conectarse a la entrada RETURN o a una entrada LINE.

Este envío puede configurarse mediante el conmutador basculante PRE/POST (11) para que el envío esté o no

afectado por el fader de vía.

5.2.6. Faders de canal

El NUO4 monta una nueva generación de faders ECLER de 60 mm (13) precisos, extremadamente suaves, con

un “cut in time” súper rápido y unas prestaciones que superan los 4.000.000 de maniobras combinados con el

sistema VCA de ECLER (VCA: Voltage controlled Amplifier).

La utilización de VCA’s posibilita la modificación del comportamiento del fader. En la sección FADER SHAPE de la

placa frontal existen dos controles: el conmutador NORMAL/ REVERSE (15) permite invertir el funcionamiento del

fader, 0 vía abierta, 10 vía cerrada en los canales 1 y 4. El potenciómetro rotativo SOFT/HARD (16) permite

regular la curva entre estos dos extremos, entrada suave o entrada brusca en los cuatro canales principales.

Los cuatro canales pueden ser direccionados hacia el CROSSFADER del NUO4 gracias a los conmutadores

basculantes (12). "XFA" asigna el canal al lado A, del crossfader mientras que la posición "MIX" significa que el

canal no se verá afectado por el crossfader, sino asignado a la mezcla principal siempre.

5.2.7. Crossfader / Crossfader "eternal" adaptable

Si desea extender la vida útil de su crossfader, el NUO4 permite el montaje como opción del galardonado

potenciómetro Eternal.

El Crossfader ECLER ETERNAL emplea tecnología inductiva basada en un sistema de control magnético. Una

pantalla de aluminio extremadamente ligera (0,5gr) corta al desplazarse las líneas de campo magnético generadas

entre dos juegos de bobinas. La variación de flujo electromagnético comanda a su vez un amplificador controlado

por tensión que se encargará, directamente, de actuar sobre la señal de audio. Esta tecnología totalmente libre de

contactos combinada con un sistema mecánico exclusivo de deslizamiento dan como resultado un tacto suave y

uno de los crossfaders más precisos existentes en la actualidad. El concepto ETERNAL tiene ventajas obvias con

relación a otros sistemas existentes que utilizan tecnología óptica. A diferencia de los sistemas ópticos, el

concepto inductivo es resistente al humo, humedad, temperatura y envejecimiento. El crossfader inductivo

ETERNAL ha sido concebido específicamente para ejecutar técnicas de “turntablism”.

El crossfader del NUO4 incorpora una serie de controles agrupados en la sección XFADER SHAPE que permiten

“afinar” su comportamiento convirtiéndolo en una precisa herramienta:

SELECTOR SWITCH/FADE (17). Dependiendo de lo “afilados” que deban ser los “scratches” el NUO4 posibilita la

selección entre los modos FADE (fundido) o SWITCH (interruptor). En modo FADE se obtiene una curva muy

progresiva mientras que en modo SWITCH su comportamiento es prácticamente el de un interruptor, óptimo para

rápidos “scratches”. Además ambos modos pueden ajustarse de forma “fina” mediante el potenciómetro de ajuste

asociado (20).

El conmutador NORMAL/REVERSE (18), también denominado HAMSTER, invierte la dirección normal del

crossfader. Dependiendo de la dirección escogida pueden realizarse tanto “cuts” como “transforms” moviendo el

crossfader en la misma dirección.

La corrección electrónica del CUT IN (19) únicamente es efectiva en el caso de que el NUO4 haya montado el

potenciómetro "eternal" opcional. En caso de montar el XFADER estándar el potenciómetro CUT IN debe quedar

en posición OFF. El “Cut in time” es la distancia existente entre el final físico del crossfader y el primer punto de

entrada de señal. La posición más corta proporciona un “cut in time” prácticamente instantáneo, para encontrarla

el potenciómetro debe colocarse en posición extrema (programa musical totalmente atenuado) y el potenciómetro

CUT IN debe girarse a la derecha hasta que se obtenga señal musical. Para alargar el tiempo de “cut in time” girar

el potenciómetro hacia la izquierda.

27

Page 28

Tanto el potenciómetro estándar como el Eternal comparten el mismo tipo de conexionado, para instalar el

potenciómetro eternal siga el procedimiento descrito a continuación.

5.2.8. Faders y Crossfader con VCA reemplazables / Incorporación "eternal"

Una vez ha llegado al límite de vida útil cualquiera de estos elementos pueden ser fácilmente reemplazados

siguiendo los siguientes pasos:

1. Retire los botones y los tornillos de la carátula inferior.

2. Retire los dos tornillos del potenciómetro a reemplazar y extráigalo de su cavidad.

3. Desconecte el conector multiterminal.

4. Reemplace el elemento por otro igual o "eternal" en el caso del crossfader.

5. Conecte el conector multiterminal.

6. Colóquelo en su cavidad i sujételo con sus dos tornillos.

7. Coloque la carátula inferior con sus tornillos y botones

Utilice siempre repuestos originales ECLER.

5.2.9. Niveles MASTER

El NUO4 dispone de dos controles de nivel de salida principal MASTER 1 (24) y MASTER 2 (25). El nivel de

OUT 1 (55-56) se controla a través del potenciómetro MASTER 1. El nivel de OUT 2 (54) se controla a través del

potenciómetro MASTER 2.

El potenciómetro de balance BAL (27) afecta tanto a la salida MASTER 1 como a MASTER 2.

28

Page 29

6. CONTROLES MIDI

El NUO4 es un mezclador DJ que permite controlar dispositivos externos mediante el protocolo MIDI. Las

funciones MIDI asignadas a cada control son programables por el usuario mediante el software

Ecler Control 4 Lab.

MIDI (Musical Instruments Digital Interface) es un protocolo de comunicación estándar entre instrumentos

musicales electrónicos y ordenadores. Un dispositivo MIDI puede funcionar como esclavo (controlado) o como

maestro (controlador). El NUO4 trabaja como una unidad maestra, lo que significa que es capaz de controlar a

otros instrumentos musicales electrónicos (sintetizadores, secuenciadores, cajas de ritmo, software... e incluso

controladores de luz). Asimismo, el NUO4 puede recibir mensajes MIDI pero únicamente para realizar funciones

de programación mediante el software Ecler Control 4 Lab.

La conexión MIDI OUT se realiza a través de un conector estándar del tipo DIN 5 pin (180º). El mezclador

incorpora también un interface USB-MIDI que permite enviar y recibir información MIDI entre el mezclador y un

ordenador utilizando el puerto USB.

Los mensajes MIDI del NUO4 pertenecen a la categoría de “Mensajes de Canal” y “Mensajes de Sistema”. Es

indispensable que los dispositivos emisor y recetor del mensaje utilicen el mismo canal para que puedan

comunicarse.

El NUO4 envía tres tipos de mensajes MIDI diferentes:

• Mensajes de disparo de notas (“Note-On” y “Note-Off”)

• Mensajes de cambio de control (“Control Change”)

• Mensajes de tiempo real (“System Real Time Messages”)

6.1. Conexionado

Disponemos de dos modos de conexión de entrada de audio de dispositivos externos controlables vía midi:

• Conectando el dispositivo externo al NUO4 a través de cualquier entrada H-LINE.

• Conectando el dispositivo externo al NUO4 a través de la entrada Input 5 (para la cual disponemos de un

control de volumen).

El conexionado de dispositivos cobra especial relevancia al trabajar con software DJ. Para ello, recomendamos

una tarjeta de sonido con al menos dos salidas.

Existen dos modos de operar un software DJ en conjunto con el NUO4:

• Utilizando el mezclador virtual del software DJ, el cual podremos controlar desde las vías 2 y 3 del NUO4

en modo MIDI. Dispondremos en este caso de dos salidas desde la tarjeta de sonido: una para la señal

MASTER y otra para la señal PFL, que conectaremos a las entradas INPUT 5 AUDIO IN y PFL

respectivamente de nuestro mezclador.

• Prescindiendo del mezclador virtual del software, utilizando así las vías 2 y 3 del NUO4 en modo

analógico. Dispondremos en este caso de dos salidas desde la tarjeta de sonido, que corresponderán a

los dos reproductores virtuales del software, los cuales conectaremos a cualquier entrada H-LINE.

6.2. Vías del mezclador con posibilidad de generar mensajes MIDI

Las vías 2 y 3 del NUO4, además de su uso analógico con PHONO y H-LINE, permiten enviar mensajes MIDI para

controlar dispositivos externos. Para ello debemos seleccionar la opción MIDI en el selector de entradas. La

aplicación principal a la que están orientados es el control de funciones equivalentes (GAIN, EQ, FADER...) de un

mezclador virtual en un software para DJ.

29

Page 30

Los controles MIDI disponibles en cada una de estas vías son:

• 5 controles rotativos que generan mensajes del tipo “Control Change” (GAIN, BASS, MID, TREBLE y

FX SEND)

• 2 controles deslizantes que generan mensajes del tipo “Control Change” (FADER y CROSSFADER)

• 2 conmutadores que generan mensajes del tipo “Note-On/Off” (BASS OFF y PFL)

Estos controles MIDI no se ven afectados por los selectores LAYOUT y A/B de la sección MIDI CONTROL.

Para que el crossfader funcione en modo MIDI al menos en una vía el selector de entradas y el de asignación del

crossfader de dicha vía deben estar simultáneamente en modo MIDI. Los controles de curvas no afectan al fader y

al crossfader al operar en modo MIDI. Puede haber ligeras diferencias entre la posición física de los controles

rotativos y deslizantes en el NUO4 y en el software.

La posición absoluta de los controles MIDI de las vías 2 y 3 no se actualiza de forma automática en el dispositivo

externo al seleccionar la posición MIDI en el conmutador de entradas. Los botones rotativos actualizan su posición

al moverse por primera vez, independientemente de la posición del control externo asociado.

Como alternativa, para actualizar todos los controles de una vía, pulse el botón TAP mientras acciona el modo

MIDI en el selector de entradas.

6.3. Zona específica de control MIDI

El NUO4 dispone de 12 controles dedicados exclusivamente al envío de mensajes

MIDI:

• 4 controles rotativos (1A a 1D)

• 4 pulsadores (incorporados en los controles rotativos) (2A a 2D)

• 4 pulsadores (3A a 3D)

Los conmutadores LAYOUT y A/B, incluidos en esta sección, no envían mensajes

MIDI sino que posibilitan que los 12 controles arriba descritos envíen mensajes

diferentes. De este modo multiplicamos la cantidad de mensajes que los controles

específicos MIDI pueden enviar.

El conmutador A/B nos permite duplicar las funciones de los 12 controles MIDI. El

cometido natural del conmutador A/B es el de asignar el mismo botón del mezclador a

una misma función en dos vías diferentes de un software DJ.

Por ejemplo, supongamos que disponemos de un software para DJ con un mezclador

y dos reproductores virtuales. Deseamos asignar la función PLAY al pulsador 3B; el

conmutador A/B nos permite distinguir dos mensajes MIDI diferentes y así ejecutar esa

misma función en cada uno de los reproductores. De este modo conseguimos:

• PLAY en el reproductor izquierdo: pulsar 3B con el conmutador en posición A

• PLAY en el reproductor derecho: pulsar 3B con el conmutador en posición B

El selector LAYOUT nos permite ejecutar tres funciones diferentes con cada uno de los

12 controles MIDI. La aplicación natural es asignar toda la sección MIDI del NUO4 a

tres bloques diferentes de un software DJ determinado.

Por ejemplo, supongamos que deseamos controlar los bloques de reproductor, efectos

y sampler de nuestro software DJ. Distribuiremos los controles MIDI del NUO4 de este

modo:

• LAYOUT en posición 1: control de la sección de reproductor del software DJ

• LAYOUT en posición 2: control de la sección de efectos del software DJ

• LAYOUT en posición 3: control de la sección de sampler del software DJ

30

Page 31

Así pues, el pulsador 3B por ejemplo podría ejecutar estas funciones:

• Activar PLAY: pulsar 3B con el LAYOUT en posición 1

• Activar FLANGER: pulsar 3B con el LAYOUT en posición 2

• Activar REC SAMPLER: pulsar 3B con el LAYOUT en posición 3

Además, de acuerdo con lo arriba descrito, con el conmutador A/B podemos ejecutar todas estas funciones en una

vía o en otra de nuestro software DJ. De este modo:

• Activar REC SAMPLER en el reproductor derecho: pulsar 3B con el LAYOUT en posición 3 y el

conmutador en posición A

• Activar REC SAMPLER en el reproductor izquierdo: pulsar 3B con el LAYOUT en posición 3 y el

conmutador en posición B

En resumen, la combinación de LAYOUT y A/B permite enviar 6 mensajes MIDI diferentes con cada uno de los 12

controles específicos MIDI del NUO4. Así pues, podemos llegar a enviar un total de 72 mensajes MIDI diferentes.

Los mandos de la sección específica de control MIDI pueden asociarse a alguna de las dos vías MIDI del NUO4

(INPUT2 o INPUT3) o bien funcionar con independencia de ellas. Si funcionan como controles independientes,

siempre enviarán mensajes MIDI aunque ninguna de las dos vías tenga seleccionado el modo MIDI en el selector

de entradas. Por el contrario, si relacionamos un control con una vía determinada, solo enviará mensajes MIDI

cuando dicha vía esté también en modo MIDI. Está asignación se hace mediante el software Ecler Control 4 Lab.

6.4. Mensajes de tiempo real

6.4.1. MIDI Clock

El NUO4 trasmite un mensaje estándar de sincronización denominado MIDI Clock, que permite sincronizar uno o

varios dispositivos MIDI externos. La señal de sincronización consiste en un mismo mensaje repetido regularmente

24 veces por cada BPM.

Para que un dispositivo MIDI pueda ser controlado, recuerde que deberá configurarlo para funcionar en modo

“esclavo” (Clock externo).

El NUO4 no dispone de procesador interno para el cálculo de BPM. La definición del tempo de un determinado

pasaje musical se realizará de forma manual pulsando el botón TAP repetidamente (un mínimo de 5 veces) al

ritmo que queramos imprimir. El botón TAP se ilumina al ritmo de los BPM que hayamos establecido.

Se puede realizar un ajuste más preciso de BPM destinando uno de los controles MIDI a esta función mediante el

software Ecler Control 4 Lab.

Se puede desactivar el MIDI clock pulsando el botón TAP durante más de 3 segundos. Cuando esto pasa, el botón

TAP no parpadea. Una vez desactivado no volverá a funcionar hasta que no se active explícitamente pulsando de

nuevo la tecla TAP durante más de 3 segundos. El modo seleccionado se conservará incluso tras apagar el

aparato.

Por defecto, después de cada encendido o bien al activar el MIDI Clock, el tempo será de 120 BPM.

6.4.2. Mensajes Start, Stop y Continue