Page 1

USER MANUAL

MANUAL DE INSTRUCCIONES

NOTICE D'EMPLOI

BEDIENUNGSANLEITUNG

Page 2

Page 3

USER MANUAL

1. IMPORTANT NOTE 04

1.1. Precautions 04

2. INTRODUCTION 04

3. INSTALLATION 05

3.1. Location, assembly, ventilation 05

3.2. Mains connection 05

3.3. Signal input connections 06

3.4. Output connections 06

3.5. Ethernet port 06

3.6. RS-232 port 06

3.7. FAULT connector 06

4. OPERATION AND USAGE 07

4.1. Start up 07

4.2. Front panel LED indicators 07

4.3. Front panel handling 08

5. CLEANING 12

6. FUNCTION LIST 13

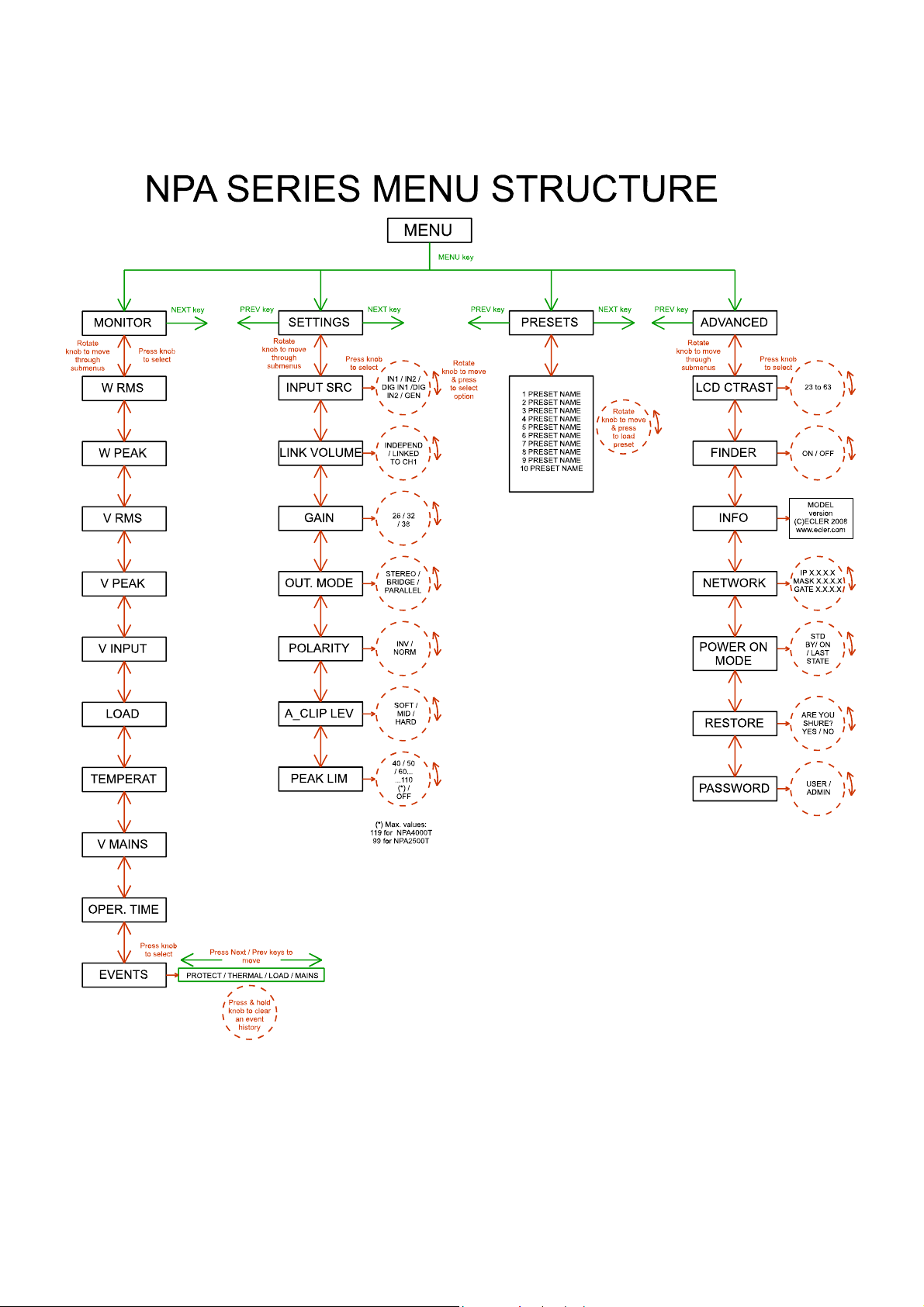

7. FUNCTION DIAGRAM 13

8. TECHNICAL CHARACTERISTICS 47

9. BLOCK DIAGRAM 50

All numbers subject to variation due to production tolerances. ECLER S.A. reserves the right to make changes or

improvements in manufacturing or design which may affect specifications.

3

Page 4

1. IMPORTANT NOTE

Congratulations! You are the owner of a carefully designed and manufactured equipment. We thank you

for trusting on us and choosing our amplifier NPA SPM (Networked All purpose Switching Power Mosfet).

In order to obtain maximum operativity and perfect functioning order, it is most important to carefully read

all considerations taken into account in this manual before connecting this amplifier.

We recommend our authorised Technical Services if any maintenance task should be needed so that

optimum operation shall be achieved.

1.1. Precautions

The amplifier should have an earth connection in good conditions (earth resistance, Rg=30Ω or less).

The environment must be dry and dustless. Do not expose the unit to rain or water splashes, and do not

place liquid containers or incandescent objects like candles on top of the unit. Do not obstruct the

ventilation grilles with any kind of material.

In case there is some type of intervention and/or connection-disconnection of the amplifier, it is most

important to previously disconnect the mains power supply.

Do not manipulate the output terminals to the loudspeakers when the amplifier is switched on, there are

voltages up to 400Vpp. The output cabling should be connected by a qualified technician. Otherwise only use premade flexible cables. There are no user serviceable parts inside the amplifier.

2. INTRODUCTION

With the PAM amplification series, ECLER introduced in early 90's a new concept to the world of

professional audio: The use of switching field effect transistors. The integration of these parts for audio applications

represents a firm and spectacular enhancement comparing to conventional amplifiers. These advantages can be

outlined as follows:

a) Lower internal resistance than bipolar transistors, which leads to less heating of the amplifier and more

powerful and controlled bass; conventional Mosfets have a 4 to 7 times higher internal resistance than switching

Mosfets.

b) The extremely high speed of these devices gives a transparency to the upper frequencies till now only

achieved by tube amplifiers. This fact also reduces TIM (transitory intermodulation) to very low levels.

The SPM-Technology (Switching Power Mosfet) has been developed and patented by ECLER Laboratorio

de Electro-Acústica, S.A. NPA line of amplifiers is a new step forward in the development of SPM amplification

technology, following in the successful DPA series footsteps.

SOA Contour following protection: the SOA is the safe operating area of transistors. A good protection

system should respect this area and its shiftings, as the SOA changes as a function of the operating temperature.

So, at 80°C it is considerably narrower than at 25°C, the start-up temperature. Some manufacturers decide to use

protection systems which compromise on the performance of the components. You get a fair protection, but the

performance remains mediocre. Others prefer to leave "dark" areas between the safe operating area and the

activation of protection, which is very risky indeed.

The new SOA contour following protection systems built into the NPA amplifiers guarantees total protection

of the amplifier at any output power, load or operating temperature, as the intelligent electronic circuitry

permanently watches for changes in the safety area, adapting itself to any situation.

Maximum damping factor: In NPA series traditional output relays have been replaced with a CROWBAR

electronic system. This device short-circuits the signal if surges that can damage the loudspeakers connected to

the amplifier are detected. On the contrary, any type of relay used in the conventional method introduces a

mechanical contact in the audio signal path to the speaker, contact that is exposed to wear and a significant

decrease in the amplifier damping factor.

4

Page 5

Ecler NPA2500T/4000T makes use of a twin power supply and N-channel mosfets. This technology, which

has been successfully implemented in the industrial product line ENVIRO, allows for very high output power

without the use of bridge configurations. The NPA2500T/4000T keeps its "All the Power All the Time" philosophy,

even when driving 4 ohm speakers with a musical programme at maximum level.

NPA series incorporates in addition important technological innovations concerning digital processing and

remote management via Ethernet, turning it into the perfect candidate to address mobile applications and fixed

installations, both centralized and distributed, requiring high level remote control and monitoring and

integration with standard Ethernet networks. NPA amplifiers include as standard an EclerNet internal module

for DSP processing and remote management, allowing physical connection between the amplifier and an Ethernet

network and its management and remote supervision from any point of it, using Windows EclerNet Manager*

software. Please refer to the EclerNet Manager software manual for more information.

* EclerNet Manager software is available on www.ecler.com.

3. INSTALLATION

3.1. Location, assembly, ventilation

The NPA2500T/4000T amplifiers are 3 RU high 19'' rack modules.

It is important that the amplifier, as a heat source, is not placed next to other equipment nor exposed to high

temperatures. Therefore, the ventilation path should be kept free to allow fresh air entering the forced ventilation

tunnel. This system pulls air from the front, directly guiding it to the power modules and transformers, diverting a

part towards capacitors and forcing its output through the rear panel of the amplifier.

In order to optimize as much as possible the correct thermal dissipation of equipment installed in a closed

rack, it is advisable not to place power amplifiers under other appliances, but upon these ones.

All NPA amplifiers are supplied with plastic washers in order not to damage the rack ears when tightening

the screws.

3.2. Mains connection

The NPA amplifiers are fed with alternate currents, depending on the country, of 110-120, 220-240V

47/63Hz. (see characteristics in the back of the unit).

WARNING!: By convention, the mains wire colour assignment is the following:

- BROWN = Phase

- BLUE = Neutral

- YELLOW/GREEN = Earth

The mains cables must not be near the shielded cables carrying the audio signal, as this could cause

humming.

5

Page 6

3.3. Signal input connections

NPA Series rear panel has analog and digital inputs. Input selection is performed from the front panel

menu or from EclerNet Manager control software. Please refer to the EclerNet Manager software manual for more

information.

• Analog inputs:

The signal input connectors are of XLR-3 type (19), electronically balanced. The pin assignment is as

follows:

HOT or direct signal > Pin 2

COLD or inverted signal > Pin 3

GROUND > Pin 1

For unbalanced connection short-circuit pin 3 to pin 1.

The "STK OUTPUT" (18) are in parallel with the inputs and are used to supply the same input signal to

other amplifiers or sound systems.

The input impedance is 22KΩ (balanced) with a nominal input sensitivity of 0dBV(1V). This impedance

makes possible to parallel several amplifiers without loosing audio quality.

• Digital inputs:

There is an XLR-3 connector for AES/EBU digital input as well as a matching digital output to re-send this

signal towards other devices.

3.4. Output connections

The "OUTPUT" section on the back panel is provided with Speakon® connectors (23).

STEREO/PARALLEL/BRIDGE operating modes are selected from the from panel menu or from EclerNet

Manager control software. Please refer to the EclerNet Manager software manual for more information.

The connection cable that joins the amplifiers outputs and the loudspeakers must be of good quality,

sufficient section and as short as possible. This is most important when the distances to cover are long ones i.e. up

to 10 meters it is recommended to use a section not inferior to 2.5mm

2

and for superior distances 4mm2.

3.5. Ethernet port

An RJ45 connector allows connecting the equipment to an Ethernet network and its management from

EclerNet Manager software. Please refer to the EclerNet Manager software manual for more information.

3.6. RS-232 port

A DB9 connector for RS-232 allows a serial connection between the equipment and an external control

system, like AMX, Crestron, Medialon, etc. (non functional at the date of printing of this manual, will be available in

a future implementation).

3.7. FAULT connector

3 pins connector, potential-free closing contact (Normally Closed, Normally opened). Its status changes

when an internal amplifier failure is detected, placing this one out of service.

6

Page 7

4. OPERATION AND USAGE

4.1. Start up

If the POWER (17) switch is operated on the rear panel, the amplifier receives mains power and can be

turned on locally or remotely (see Control panel section).

In a complete audio installation, it is important to start up the equipment in the following sequence: sound

sources, mixer, equalizers, active filters and finally power amplifiers. To turn them off the sequence should follow

an inverse pattern.

4.2. Front panel LED indicators

NPA amplifiers have a simple and effective indicators system:

• THERMAL protection indicator (2):

It indicates that the cooling tunnel temperature has exceeded the minimal risk threshold for the equipment.

The amplifier automatically restarts once the temperature drops enough.

NPA amplifiers have a thermal protection per channel. This means each protection operates independently. It

can be activated for one channel only while the other is running smoothly.

• PROTECT indicator (3):

It indicates the absence of signal at the speaker output. It can light up for the following reasons:

o At start-up and during the STANDBY time necessary to settle the amplifier internal voltages.

o Because of equipment fault preventing the normal booting (the LCD shows “PERSISTENT

PROTECT”).

o When the amplifier is delivering a very low frequency signal that could damage the speakers.

o When more than 4 short-circuits have been detected at the amplifier output over a period of 40

seconds (the LCD shows “REPETITIVE PROTECT”).

o When an internal fault occurred and the amplifier needs to be fixed (the LCD shows “FAULTY

AMPLIFIER”).

In any case, permanent lighting of these indicators is a symptom of faulty operation and the cause that led

to this activation should be investigated.

• CLIP indicator (4):

It lights up when the signal delivered to the speakers is near clipping. The CLIP system considers possible

voltage fluctuations of power supply, always giving a real indication even if they exist. It is normal for CLIP

indicators to be lit at the bass frequencies rhythm for high operating levels, as these frequencies have the higher

energy content. You must take care that these indicators do not permanently light up during normal operation of

the equipment.

• SIGNAL presence indicator (5):

It indicates a signal presence at the amplifier inputs. These indicators light up when the input signal

exceeds -40 dB.

• DATA transfer indicator (11):

It blinks to indicate data transfer activity between the amplifier and a remote control PC running EclerNet

Manager.

7

Page 8

4.3. Front panel handling

The front panel includes a series of controls and indicators:

o Backlit LCD display for displaying menus, settings and amplifier parameters.

o On / Off key (POWER ON).

o Menu navigation keys (MENU / PREVIOUS / NEXT).

o Rotary/push controls for adjusting parameters (CHANNEL 1 / CHANNEL 2).

o LED indicators (see section 4.2).

To power up the unit, press and hold the POWER key until the boot sequence starts. The shutdown will

also require pressing and shortly holding the same key.

POWER ON key has an integrated LED indicator lighting up in orange when the amplifier is in STAND BY

mode, in green when ON, and in red during the boot sequence or when the amplifier is in protect mode.

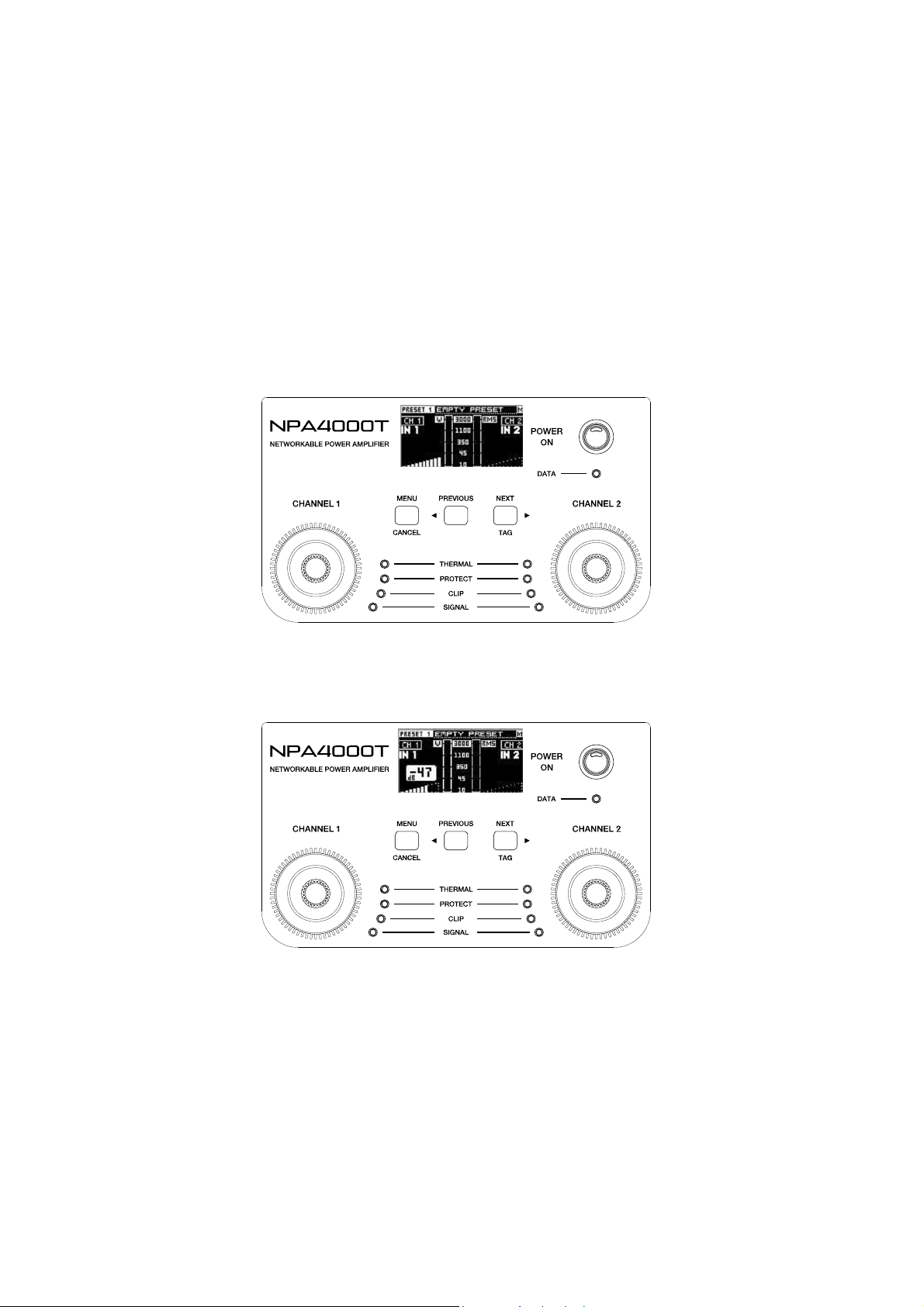

Once the power amplifier in on, the main screen appears in the LCD display, looking like the following:

From this main screen you can perform a number of basic functions on the amplifier:

• Change the volume of channel 1 or 2 (turning rotary controls CHANNEL 1 or CHANNEL 2):

A window briefly appears to show the setting in dB (-47 dB in the given example) and the volume ramp

indicator changes for this channel.

Note: when both channels are linked, the CHANNEL 1 rotary knob adjusts simultaneously both channels

volume.

8

Page 9

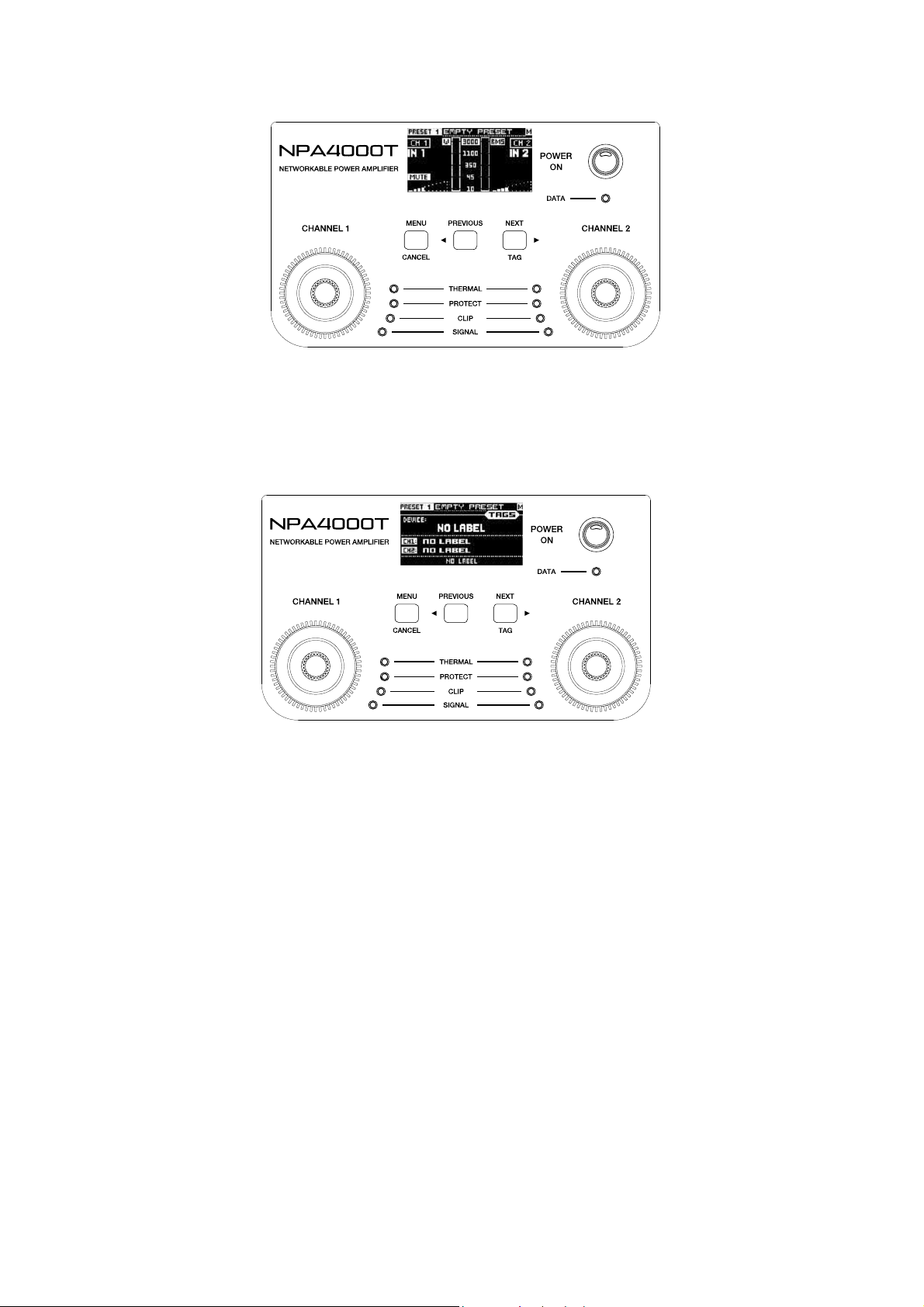

• Activate / deactivate a channel muting (by pressing and holding the CHANNEL 1 or CHANNEL 2 rotary

knob):

A label with the text "MUTE" is displayed when this feature is activated.

• Show text labels assigned to the unit and to its amplification channels (by clicking on the TAG button):

This window, named TAGS, disappears after a short time, and the main window returns.

The top line of the screen also displays the active PRESET number and name. When you modify any

setting of the amplifier a "M" label appears in the upper right corner of the screen to indicate that the PRESET has

been modified (for example, moving a volume control is sufficient to make it happen).

9

Page 10

All other amplifier functions and settings are accessed through the menu structure as described in the

following diagram:

10

Page 11

• MONITOR menu

VU-meters monitoring scale selection:

o Output power (Watts), RMS or peak.

o Output voltage (Volts), peak or RMS.

o Input signal voltage, RMS.

Display through dedicated screens:

o Load impedance, in ohms.

o Temperature, in % of the alarm triggering temperature.

o AC power supply voltage.

o Cumulative operating time of the amplifier, in hours: minutes.

o Events: digital counter of protection alarms, thermal, load impedance, AC power supply

voltage (note: from within this menu, alarm counters can be reset (value = 0) for each channel

by holding down the rotary knob for a short period of time).

• SETTINGS menu

Amplifier operating mode menus:

o INPUT SOURCE: selects the input signal for the amplifier to work with, amongst the available

ones (Analog 1, Analog 2, Digital 1, Digital 2 and internal generator).

o LINK VOLUME: determines whether the volume controls on both channels of the amplifier will

be linked (ON) or independent (OFF). In linked mode, the CHANNEL 1 rotary knob sets the

volume for both channels simultaneously and the label "LINK" is displayed.

o GAIN: selectable amplifier gain between 26, 32 or 38 dB.

o OUTPUT MODE: operating mode selection for amplified outputs between stereo, parallel or

bridge. For the two last ones, the label "PARAL" or "BRIDGE" is displayed.

o POLARITY: phase selection for the input signal, normal or inverted. The label "INV" is

displayed if the phase is inverted.

o ANTICLIP LEVEL: anti-clipping circuit level selection between soft (allowing a large clipping),

medium or hard (allowing a minimum clipping, almost negligible).

o PEAK LIMITER: allows defining a maximum voltage for the unit amplified outputs.

• PRESETS menu

Amplifier PRESETS selection in a list of 10 available memories.

Note: when loading a PRESET, its number and name appear on the top line of the display. When

you modify any setting of the amplifier an "M" label appears in the upper right corner of the screen

to indicate that the PRESET has been modified (for example, moving a volume control is sufficient

to make it happen).

11

Page 12

• ADVANCED menu

Amplifier advanced features:

o LCD CONTRAST: adjusts the LCD contrast.

o FINDER: enables / disables the display backlight flashing, useful to identify a physical unit with

its virtual equivalent in EclerNet Manager software (see EclerNet Manager manual for more

information).

o INFO: shows the amplifier model and firmware version.

o NETWORK: allows setting IP address, mask and gateway for the amplifier Ethernet interface

(The default port is 2210. You can not change it with local controls, but with EclerNet Manager

software only).

o POWER ON MODE: allows selecting the amplifier behavior at power-up (POWER switch on

the rear panel). The amplifier can start up in STANDBY mode, ON or recover its last status

before the last power supply interruption, for example in the event of a mains power recovery

after a mains power failure (LAST STATE).

o RESTORE: allows resetting all amplifier parameters to their default value, except the

cumulative operating time (erases passwords, PRESETS, DSP parameters, setup settings,

alarms counters and Ethernet network setup).

o PASSWORD: allows assigning the amplifier a user or administrator password.

• USER: once this password has been set, the unit will request it each time you try to

use any control or adjustment in the amplifier setup (on, off, volume adjustment and

access to menus).

• ADMIN (administrator): once this password has been set, only main screen controls

can be used: power on, power off, volume adjustment and muting. To adjust the

amplifier setup (access to menus, MENU key) the password is requested.

Note: To disable a password you need to rewrite it with a blank one.

Most functions described above have their equivalent in EclerNet Manager software. Please refer to the

EclerNet Manager software manual for more information.

5. CLEANING

The front panel should not be cleaned with dissolvent or abrasive substances because silk-printing could

be damaged. To clean it, use a soft cloth slightly wet with water and neutral liquid soap; dry it with a clean cloth. Be

careful that water never gets into the amplifier through the holes of the front panel.

12

Page 13

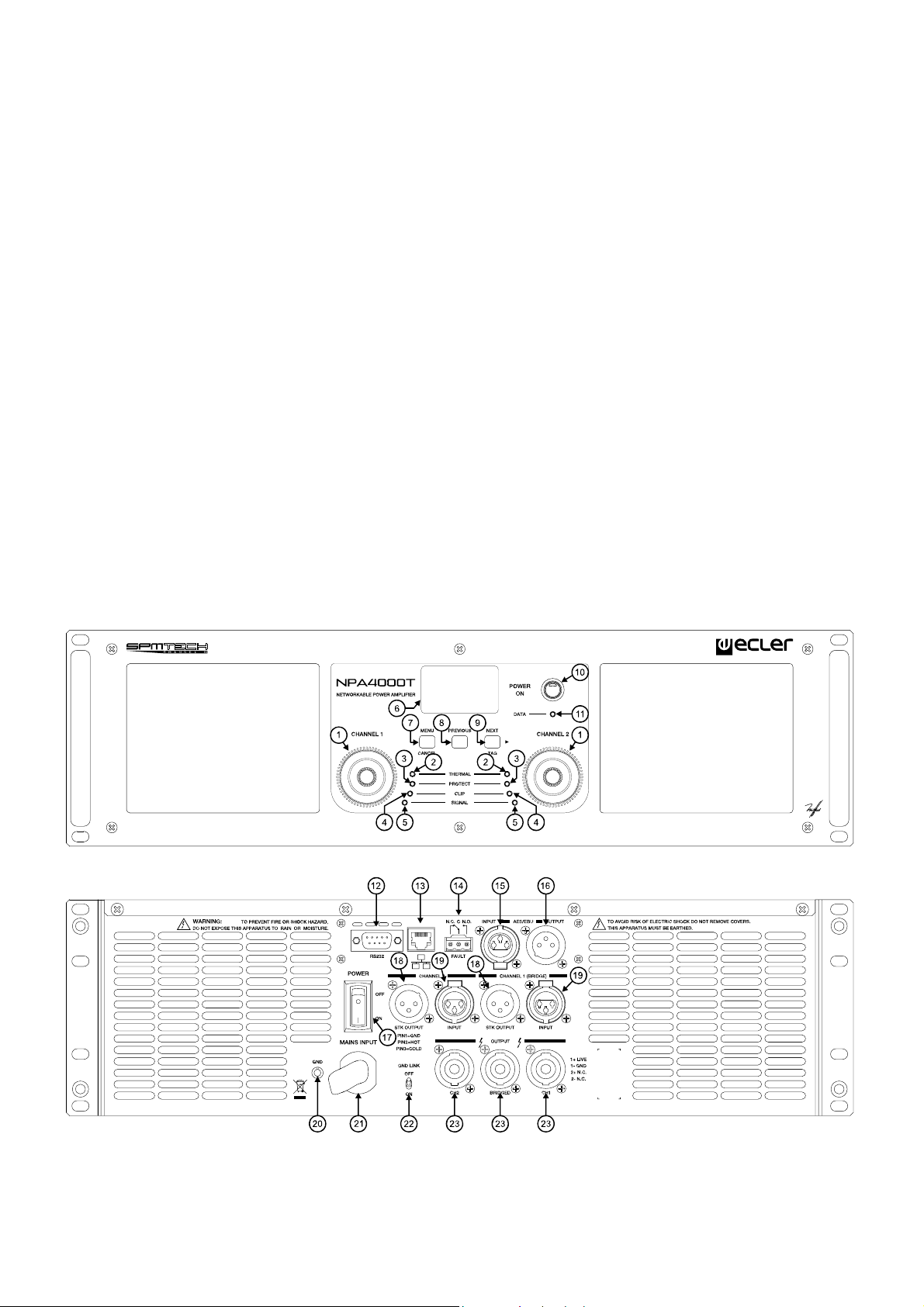

6. FUNCTION LIST

1. Input attenuator

2. Thermal protection indicator, THERMAL

3. Protection indicator, PROTECT

4. Clip indicator, CLIP

5. Signal present indicator, SIGNAL

6. Display

7. Navigation key, MENU / CANCEL

8. Navigation key, PREVIOUS

9. Navigation key, NEXT / TAG

10. On / Off key, POWER ON

11. Data transfer indicator, DATA

12. RS-232 port

13. Ethernet port

14. Binding post block, FAULT

15. Digital input XLR connector, AES-EBU INPUT

16. Digital output XLR connector, AES-EBU OUTPUT

17. Start-up switch

18. Output XLR connector to other amplifiers, STK OUTPUT

19. Input XLR connector, INPUT

20. Earth terminal, GND

21. Mains cable

22. Switch to disconnect chassis earth / electrical Ground, GND LINK

23. Speakon® connectors to the loudspeakers

7. FUNCTION DIAGRAM

13

Page 14

MANUAL DE INSTRUCCIONES

1. NOTA IMPORTANTE 15

1.1. Precauciones 15

2. INTRODUCCIÓN 15

3. INSTALACIÓN 16

3.1. Ubicación, montaje, ventilación 16

3.2. Conexión a red eléctrica 16

3.3. Conexiones de entrada de señal 17

3.4. Conexiones de salida 17

3.5. Puerto Ethernet 17

3.6. Puerto RS-232 17

3.7. Conector FAULT 17

4. FUNCIONAMIENTO 18

4.1. Puesta en marcha 18

4.2. Indicadores LED del panel frontal 18

4.3. Manejo del panel frontal 19

5. LIMPIEZA 23

6. LISTA DE FUNCIONES 24

7. DIAGRAMA DE FUNCIONAMIENTO 24

8. CARACTERÍSTICAS TÉCNICAS 47

9. DIAGRAMA DE BLOQUES 50

Todos los datos están sujetos a variación debida a tolerancias de producción. ECLER S.A. se reserva el derecho de realizar

cambios o mejoras en la fabricación o diseño que pudieran afectar las especificaciones.

14

Page 15

1. NOTA IMPORTANTE

¡Enhorabuena!. Vd. posee el resultado de un cuidadoso diseño y una esmerada fabricación. Agradecemos

su confianza por haber elegido nuestro amplificador NPA SPM (Networked All Purpose Switching Power Mosfet).

Para que pueda conseguir la máxima operatividad y un funcionamiento perfecto, antes de su conexión es

MUY IMPORTANTE que lea detenidamente las consideraciones que se detallan en éste manual.

Para asegurar el óptimo rendimiento del aparato, su mantenimiento debe ser realizado por nuestros

Servicios Técnicos.

1.1. Precauciones

La etapa debe conectarse a una toma de tierra en correctas condiciones (Resistencia de tierra, Rg =

30Ω o menos). El ambiente de trabajo deberá ser seco y estar totalmente libre de polvo. No exponga el

aparato a la caída de agua o salpicaduras, no ponga encima objetos con líquido ni fuentes de llama

desnuda, como velas. No obstruya los orificios de ventilación con ningún tipo de material. En caso de

requerir alguna intervención y/o conexión-desconexión del amplificador debe desconectarse previamente la

alimentación.

No manipular los terminales de salida hacia el altavoz con la etapa en marcha; se hallan presentes

tensiones de hasta 400 Vpp. El cableado de la salida debe ser realizado por personal técnico cualificado o usar

cables flexibles ya preparados. En el interior del amplificador no existen elementos manipulables por el usuario.

2. INTRODUCCIÓN

Con los PAM, ECLER introdujo a principios de los 90 un nuevo concepto en el audio profesional: el

empleo de los transistores de efecto de campo de conmutación (MOSFET). Su incorporación a la amplificación de

audio significa una firme y espectacular mejora en relación a los sistemas convencionales. Las ventajas de los

MOSFET de conmutación pueden resumirse así:

a) Resistencia interna menor que los bipolares, lo cual redunda en un menor calentamiento de la etapa de

potencia y en unos graves poderosos y muy bien controlados; los MOSFETs convencionales de audio presentan

una resistencia interna de 4 a 7 veces superior a los de conmutación.

b) La enorme rapidez de estos dispositivos confiere a los agudos una transparencia hasta ahora sólo

lograda con amplificadores a válvulas, al tiempo que una TIM (Distorsión por lntermodulación de Transitorios) muy

reducida.

La tecnología SPM (Switching Power MOSFET) fue desarrollada y patentada por ECLER Laboratorio de

Electro-Acústica S.A. La línea de amplificadores NPA es un nuevo paso al frente dentro de la evolución de la

tecnología de amplificación SPM, siguiendo la estela de la exitosa serie DPA.

Protecciones por seguimiento de contorno de SOA: la SOA es el área de operación segura del transistor

(Safe Operating Area). Un buen sistema de protecciones debe respetar esta área y sus cambios dado que la SOA

varía en función de la temperatura de trabajo. Así, a 80 grados es considerablemente menor que a 25 grados,

cuando se conecta el amplificador. Algunos fabricantes optan por protecciones que limitan las prestaciones de los

componentes, se obtiene seguridad pero el rendimiento es mediocre. Otros en cambio dejan zonas oscuras entre

el área de seguridad y la activación de las protecciones, lo cual es muy arriesgado.

El nuevo sistema de seguimiento de contorno de la SOA de los amplificadores NPA garantiza la

protección total del amplificador a cualquier nivel de potencia, carga o temperatura ya que un circuito electrónico

inteligente evalúa permanentemente el área de seguridad, adaptándose a cada situación puntual.

Máximo factor de amortiguamiento (DAMPING): En la serie NPA los tradicionales relés de salida han sido

sustituidos por un sistema electrónico CROWBAR. Este dispositivo deriva directamente a masa la señal en el caso

de detectar sobretensiones que puedan dañar los altavoces conectados al amplificador. Por el contrario, cualquier

tipo de relé de los empleados en el método convencional introduce un contacto mecánico en el camino de la señal

de audio hacia el altavoz, contacto que está expuesto a un desgaste y una importante disminución en el factor de

amortiguamiento del amplificador.

15

Page 16

En las NPA2500T / 4000T Ecler incorpora doble fuente de alimentación y MOSFETs de canal N. El uso de

esta nueva tecnología sobradamente probada en la línea de producto industrial ENVIRO posibilita la obtención de

muy altas potencias sin necesidad de emplear configuraciones en puente. En las NPA2500T / 4000T se continúa

manteniendo la Filosofía "All the Power All the time", toda la potencia todo el tiempo, incluso a máxima potencia y

carga de 4 ohms con programas musicales.

La serie NPA incorpora además importantes innovaciones tecnológicas a nivel de procesamiento digital y

gestión remota vía Ethernet, que la convierten en el perfecto candidato para acometer aplicaciones móviles e

instalaciones fijas, tanto centralizadas como distribuidas, que requieran de control y supervisión remotos de

alto nivel e integración con redes Ethernet estándar. Los amplificadores NPA incluyen de serie un módulo

interno de procesamiento DSP y gestión remota EclerNet, que permiten el conexionado físico del amplificador a

una red Ethernet y su gestión y supervisión remota desde cualquier punto de la misma, empleando para ello la

aplicación Windows EclerNet Manager*. Consulte el manual de la Aplicación EclerNet Manager para obtener más

información.

* La aplicación EclerNet Manager se encuentra disponible en www.ecler.com.

3. INSTALACIÓN

3.1. Ubicación, montaje, ventilación

Los amplificadores NPA2500T / 4000T se presentan en módulo rack de 19" y tres unidades de altura.

Es muy importante que, como elemento generador de calor que es, el amplificador no esté completamente

encerrado ni expuesto a temperaturas extremas. Por ello debe favorecerse el paso de aire fresco a través del

túnel de ventilación forzada. Este sistema toma el aire de la parte frontal, dirigiéndolo directamente a los módulos

de potencia y transformadores, desviando una parte hacia los condensadores y obligándolo a salir por la parte

trasera del amplificador.

Con el objeto de favorecer en la medida de lo posible la correcta disipación térmica de los equipos

instalados en armarios rack, es aconsejable no colocar los amplificadores de potencia debajo de otros aparatos,

sino encima de éstos.

Todos los amplificadores NPA se suministran con arandelas de plástico con el fin de poderlos montar en

un rack sin dañar las orejas de fijación.

3.2. Conexión a red eléctrica

Los amplificadores NPA se alimentan con corriente alterna, según el país, de 110-120, 220-240 V y

47 / 63Hz (ver placa de características en el aparato).

¡ATENCIÓN! Por convención, la asignación de colores de los cables de red es la siguiente:

- MARRÓN = Fase

- AZUL = Neutro

- AMARILLO / VERDE = Tierra

Debe evitarse que el cable de red se entremezcle y discurra paralelo a los cables blindados que

transportan la señal de audio, ya que ello podría ocasionar zumbidos.

16

Page 17

3.3. Conexiones de entrada de señal

La serie NPA dispone de entradas analógicas y digitales en su panel posterior. La selección de una u otra

entrada se realiza desde el menú del panel frontal o desde la aplicación de control EclerNet Manager. Consulte el

manual de la Aplicación EclerNet Manager para obtener más información.

• Entradas analógicas:

Los conectores de entrada analógica de señal son del tipo XLR-3, (19) balanceadas electrónicamente. La

asignación es la siguiente:

Vivo o señal directa > Terminal 2

Frío o señal invertida > Terminal 3

Masa > Terminal 1

Para conexiones NO balanceadas cortocircuitar a masa el terminal 3.

Las salidas "STK OUTPUT" (18) están en paralelo con las entradas y sirven para conectar la misma señal

que tenemos en las entradas "INPUT" a otros amplificadores o sistemas de sonido.

La impedancia de entrada es de 22 kΩ (balanceada) con una sensibilidad nominal de 0 dBV (1V). Esta

impedancia permite conectar un gran número de etapas en paralelo sin merma de la calidad sonora.

• Entradas Digitales:

Existe también una entrada digital tipo AES / EBU en formato XLR-3, con su correspondiente salida digital

para el encadenamiento de dicha señal hacia otros dispositivos.

3.4. Conexiones de salida

La sección "OUTPUT" del panel posterior está provista de conectores Speakon® (23).

Los modos de trabajo STEREO / PARALLEL / BRIDGE se seleccionan desde el menú del panel frontal o

desde la aplicación de control EclerNet Manager. Consulte el manual de la Aplicación EclerNet Manager para

obtener más información.

El cable de conexión que une las salidas del amplificador y los altavoces deberá ser de buena calidad, de

suficiente sección y lo más corto posible. Esto tiene especial importancia cuando las distancias a cubrir con el

cableado son grandes; hasta 10 metros se recomienda una sección no inferior a 2.5 mm

superiores no inferior a 4 mm

2

.

2

, y para distancias

3.5. Puerto Ethernet

Un conector tipo RJ45 permite la conexión del equipo a una red Ethernet y su gestión desde la aplicación

EclerNet Manager. Consulte el manual de la Aplicación EclerNet Manager para obtener más información.

3.6. Puerto RS-232

Un conector tipo RS-232 DB9 permite la conexión serie del equipo a un sistema de control externo tipo

AMX, Crestron, Medialon, etc. (no operativo en la fecha de edición de este manual, y de futura implementación).

3.7. Conector FAULT

Conector de 3 patillas, tipo cierre de contacto libre de potencial (Normalmente Cerrado, Normalmente

Abierto). Cambia de estado al detectarse avería interna del amplificador, quedando éste fuera de servicio.

17

Page 18

4. FUNCIONAMIENTO

4.1. Puesta en marcha

Accionando el interruptor de puesta en marcha POWER (17), en el panel posterior, el amplificador recibe

suministro eléctrico de la red y queda en condiciones de ser encendido local o remotamente (ver sección Panel de

Control).

En una instalación completa de audio es importante poner en marcha el equipo de acuerdo con la

siguiente secuencia: fuentes de sonido, mezclador, ecualizadores, filtros activos y finalmente los amplificadores de

potencia. Para pararlos, la secuencia debe seguirse a la inversa.

4.2. Indicadores LED del panel frontal

Los amplificadores NPA equipan un simple y eficaz sistema de indicaciones:

• Indicador de protección térmica THERMAL (2):

Advierte de que la temperatura del túnel de refrigeración ha superado la considerada mínima de riesgo

para el equipo. El amplificador volverá a ponerse en marcha automáticamente cuando la temperatura descienda

suficientemente.

Los amplificadores NPA incorporan protección térmica por cada canal. Esto significa que funcionan de

forma independiente, pudiéndose activar solamente la protección de un canal y funcionando el otro sin problemas.

• Indicador PROTECT (3):

Señalan la ausencia de señal en la salida de altavoces. Pueden encenderse por los siguientes motivos:

o En el instante de puesta en marcha y hasta que finaliza el tiempo de STANDBY necesario para la

estabilización de las tensiones internas del amplificador.

o Porque existe una anomalía en el equipo que le impide arrancar con normalidad (se visualiza en

pantalla el mensaje “PERSISTENT PROTECT”).

o Si el amplificador está entregando señal de muy baja frecuencia que pudiera dañar a los

altavoces.

o Si se han detectado más de 4 cortocircuitos en la salida del amplificador en un período de 40

segundos (se visualiza en pantalla el mensaje “REPETITIVE PROTECT”).

o Si se ha producido una avería interna y el amplificador precisa ser reparado (se visualiza en

pantalla el mensaje “FAULTY AMPLIFIER”).

En cualquier caso, de encenderse permanentemente estos indicadores, sería síntoma de mal

funcionamiento y debe investigarse cuál es la causa que ha originado su activación.

• Indicador CLIP (4):

Se iluminan cuando la señal entregada a los altavoces se encuentra cercano al del recorte real. Este

sistema de CLIP tiene en cuenta las posibles fluctuaciones en la tensión de alimentación, dando siempre una

indicación real aunque éstas existan. Es normal que trabajando a niveles elevados de potencia los indicadores de

CLIP se iluminen al ritmo de las frecuencias graves, que son las que poseen mayor contenido energético. Debe

procurarse que estos indicadores no queden iluminados de una forma permanente durante el régimen normal de

trabajo del equipo.

• Indicador de presencia de señal SIGNAL (5):

Advierte de la presencia de señal en las entradas del amplificador. Estos indicadores se iluminan cuando

la señal presente en la entrada supera los –40 dB.

• Indicador de transferencia de datos DATA (11):

Parpadea cuando indica actividad en la transferencia de datos entre el amplificador y el PC de control

remoto que ejecuta la aplicación EclerNet Manager.

18

Page 19

4.3. Manejo del panel frontal

El panel frontal integra una serie de controles e indicadores:

o Pantalla LCD retroiluminada para la visualización de menús, ajustes y lecturas de parámetros del

amplificador.

o Tecla de encendido / apagado (POWER ON).

o Teclas de navegación de menús (MENU / PREVIOUS / NEXT).

o Controles rotatorios con pulsación para el ajuste de parámetros (CHANNEL 1 / CHANNEL 2).

o Indicadores LED (ver apartado 4.2).

El encendido del equipo se realiza manteniendo pulsada la tecla POWER hasta que se inicia la secuencia

de arranque. El apagado también requiere de un breve tiempo de mantenimiento en la pulsación de la misma

tecla.

La tecla POWER ON dispone de un indicador LED integrado que se ilumina en color naranja cuando el

amplificador se halla en el modo de espera (STAND BY), verde en el modo encendido (ON) y rojo durante la

secuencia de arranque o bien cuando el amplificador se halla en el modo de protección.

Una vez encendido el amplificador aparece la pantalla principal en el visualizador LCD, de aspecto similar

al siguiente:

Desde esta pantalla principal es posible realizar una serie de funciones básicas sobre el amplificador:

• Modificar el volumen del canal 1 o 2 (girando los controles rotatorios CHANNEL 1 o CHANNEL 2):

Aparece brevemente una ventana mostrando el ajuste en dB (en el ejemplo –47 dB) y se modifica el

indicador en forma de rampa para el volumen de dicho canal.

Nota: en caso de estar enlazados ambos canales, el ajuste de volumen simultáneo de ambos se realiza

desde el control giratorio CHANNEL 1.

19

Page 20

• Activar / desactivar el enmudecimiento de un canal (manteniendo pulsado el control giratorio CHANNEL 1

o CHANNEL 2):

Aparece una etiqueta mostrando el texto “MUTE” en caso de activación de esta función.

• Visualizar las etiquetas de texto asignadas al dispositivo y a sus canales de amplificación (pulsando sobre

la tecla TAG):

Dicha ventana, denominada TAGS, desaparece tras un breve lapso de tiempo, regresando a la vista de la

ventana principal.

La línea superior de la pantalla también muestra el número y nombre del PRESET activo. Tan pronto

como se modifica algún ajuste del amplificador aparece también una etiqueta “M” en la esquina superior derecha

de la pantalla, indicando que el PRESET cargado ha sido modificado (basta con mover un ajuste de volumen, por

ejemplo, para que esto ocurra).

20

Page 21

Al resto de funciones y ajustes del amplificador se accede mediante la estructura de menús que se

describe en el gráfico siguiente:

21

Page 22

• Menú MONITOR

Selección de la escala de monitorización mediante vu-metros en:

o Vatios de salida, RMS o pico.

o Voltios de salida, RMS o pico.

o Voltios de señal de entrada, RMS.

Visualización mediante pantalla dedicada de:

o Impedancia de carga, en ohms.

o Temperatura, en % sobre la temperatura de disparo de alarma.

o Voltios de alimentación AC.

o Tiempo de uso acumulado del amplificador, en horas : minutos.

o Eventos: contador numérico de alarmas de protección, térmica, impedancia de carga, tensión

de alimentación AC (nota: desde su visualización dentro de este menú, los contadores de

alarma de cada canal se restablecen (valor = 0) manteniendo pulsado su control giratorio

durante un breve lapso de tiempo).

• Menú SETTINGS

Menús de ajustes del modo de trabajo del amplificador:

o INPUT SOURCE (fuente de entrada): selecciona la señal de entrada con la que trabajará el

amplificador, de las disponibles (analógica 1, analógica 2, digital 1, digital 2 y generador

interno).

o LINK VOLUME (enlace de volumen): determina si el control de volumen de ambos canales de

un amplificador se gobernará de modo conjunto (ON) o independiente (OFF). Con el modo

enlazado activo el control de volumen simultáneo de ambos canales se realiza desde el

control rotatorio CHANNEL 1, y aparece en pantalla la etiqueta “LINK”.

o GAIN: ganancia del amplificador, seleccionable entre las opciones 26, 32 o 38 dB.

o OUTPUT MODE: selección del modo de trabajo de las salidas amplificadas entre las opciones

estéreo, paralelo o bridge. Aparece en pantalla la etiqueta “PARAL” o “BRIDGE” en los últimos

dos casos.

o POLARITY: selección de fase de la señal de entrada, normal o invertida. Aparece en pantalla

la etiqueta “INV” en caso de seleccionar la inversión de fase.

o ANTICLIP LEVEL: selección del nivel de actuación del circuito anti-recortes, entre las

opciones suave (premite un recorte amplio), media o dura (permite un recorte mínimo, casi

inapreciable).

o PEAK LIMITER: permite definir un valor de tensión máxima en bornes de las salidas

amplificadas del equipo.

• Menú PRESETS

Selección de PRESETS o memorias del amplificador, de la lista de 10 posibles.

Nota: al cargar un PRESET aparecen su número y nombre en la línea superior de la pantalla. Tan

pronto como se modifica algún ajuste del amplificador aparece también un etiqueta “M” en la

esquina superior derecha de la pantalla, indicando que el PRESET cargado ha sido modificado

(basta con mover un ajuste de volumen, por ejemplo, para que esto ocurra).

22

Page 23

• Menú ADVANCED

Funciones avanzadas del amplificador:

o LCD CONTRAST: ajuste del contraste de la pantalla LCD.

o FINDER: activa / desactiva el parpadeo de la retroiluminación de la pantalla, útil para la

identificación de un dipositivo físico con su equivalente virtual en la aplicación EclerNet

Manager (ver manual de EclerNet Manager para más información).

o INFO: muestra el modelo y versión de firmware del amplificador.

o NETWORK: permite ajustar la dirección IP, máscara y puerta de enlace de la interfaz Ethernet

del amplificador (el puerto por defecto es el 2210. No es posible modificarlo desde el control

local, pero sí desde la aplicación EclerNet Manager).

o POWER ON MODE: permite seleccionar si, al aplicarle suministro eléctrico (interruptor

POWER del panel posterior), el amplificador arrancará en modo STANDBY, ON o bien si

recuperará el estado en el que se encontraba previamente a la última interrupción del

suministro eléctrico, por ejemplo, al retornar la alimentación AC tras un corte de suministro

eléctrico de la red (LAST STATE).

o RESTORE: permite restablecer a su valor por defecto todos los parámetros del amplificador,

excepto el contador de horas acumuladas de funcionamiento (se borran contraseñas,

PRESETS, parámetros DSP, ajustes de configuración, contadores de alarmas y configuración

de red Ethernet).

o PASSWORD: permite asignar una contraseña de usuario o administrador al amplificador.

• USER (usuario): una vez establecida esta contraseña el equipo la solicita cada vez

que se intenta actuar sobre algún control o ajuste en la configuración del amplificador

(encendido, apagado, ajuste de volumen y acceso a menús).

• ADMIN (administrador): una vez establecida esta contraseña sólo es posible actuar

directamente sobre los controles disponibles de la pantalla principal: encendido,

apagado, ajuste de volumen y enmudecimiento. Para realizar ajustes en la

configuración del amplificador (acceso a menús, tecla MENU) se solicita la

introducción previa de la contraseña.

Nota: para deshabilitar una contraseña es preciso almacenarla de nuevo en blanco.

La mayoría de funciones descritas anteriormente tienen su equivalencia en la aplicación EclerNet

Manager. Consulte el manual de la aplicación EclerNet Manager para obtener más información.

5. LIMPIEZA

La carátula no deberá limpiarse con sustancias disolventes o abrasivas puesto que se corre el riesgo de

deteriorar la serigrafía. Para su limpieza se utilizará un trapo humedecido con agua y un detergente líquido neutro,

secándola a continuación con un paño limpio. En ningún caso se debe permitir la entrada de agua por cualquiera

de los orificios del aparato.

23

Page 24

6. LISTA DE FUNCIONES

1. Atenuador de entrada

2. Indicador de protección térmica, THERMAL

3. Indicador de funcionamiento de las protecciones, PROTECT

4. Indicador de recorte, CLIP

5. Indicador de presencia de señal en la entrada, SIGNAL

6. Pantalla

7. Tecla de navegación, MENU / CANCEL

8. Tecla navegación, PREVIOUS

9. Tecla navegación, NEXT / TAG

10. Tecla de encendido / apagado, POWER ON

11. Indicador de transferencia de datos, DATA

12. Puerto RS-232

13. Puerto Ethernet

14. Regleta de terminales atornillables, FAULT

15. Conector XLR de entrada digital, AES-EBU INPUT

16. Conector XLR de salida digital, AES-EBU OUTPUT

17. Interruptor de puesta en marcha

18. Conector XLR de salida para conexión en cadena, STK OUTPUT

19. Conector XLR de entrada, INPUT

20. Terminal de masa, GND

21. Cable de red

22. Conmutador de desconexión masa eléctrica / masa mecánica, GND LINK

23. Conector Speakon® de conexión a los altavoces

7. DIAGRAMA DE FUNCIONAMIENTO

24

Page 25

NOTICE D'EMPLOI

1. NOTE IMPORTANTE 26

1.1. Précautions 26

2. INTRODUCTION 26

3. INSTALLATION 27

3.1. Localisation, montage, ventilation 27

3.2. Branchement 27

3.3. Branchement de l'entrée du signal 28

3.4. Branchement de sortie. 28

3.5. Port Ethernet 28

3.6. Port RS-232 28

3.7. Connecteur FAULT 28

4. MISE EN MARCHE ET UTILISATION. FONCTIONNEMENT 29

4.1. Mise en marche. 29

4.2. DEL témoins de la face avant 29

4.3. Maniement de la face avant 30

5. ENTRETIEN 34

6. LISTE DE FONCTIONS 35

7. SCHEMA DE FONCTIONNEMENT 35

8. CARACTERISTIQUES TECHNIQUES 47

9. BLOCS DE DIAGRAMMES 50

ECLER se réserve le droit d’apporter des modifications de toute sorte sur ses produits qui peuvent altérer leurs spécifications.

25

Page 26

1. NOTE IMPORTANTE

Félicitations ! Vous avez en votre possession le résultat d’un design et d’une fabrication particulièrement

soignée. Nous vous remercions de la confiance que vous nous portez en choisissant notre amplificateur NPA SPM

(Networked All purpose Switching Power Mosfet).

Pour obtenir le meilleur résultat de cet appareil, il est important de lire attentivement les instructions cidessous avant de le brancher.

Pour obtenir le meilleur rendement de cet appareil, il est important que le entretien se réalisé par notre

Service Technique Ecler.

1.1. Précautions

L'amplificateur de puissance doit être raccordé à la terre dans les conditions suivantes: Résistance de

Terre, Rg=30Ω ou moins. L’atmosphère dans laquelle doit fonctionner l’amplificateur doit être sèche et

exempte de poussière. Evitez l’humidité et tout contact de liquide avec l’appareil. Ne mettez aucun objet

compromettant (liquide, bougies...) au dessus de l’appareil. Laissez de l’espace devant les orifices de

ventilation. Débrancher l'alimentation avant d'intervenir d'une façon ou d'une autre sur l'amplificateur.

Ne pas toucher aux bornes de sorties des haut-parleurs quand l'amplificateur est en marche, des tensions

de jusqu’à 400Vpp sont présentent. Le câblage de la sortie devra être réalisé par un technicien qualifié ou bien

utilisez des câbles déjà tout préparés. Quant à l’intérieur de l’amplificateur, il n’y a aucun élément à manipuler pour

l’utilisateur.

2. INTRODUCTION

Avec les PAM, ECLER a introduit, au début des années 90, un nouveau concept dans le domaine de

l’audio professionnel : l’emploi des transistors à effet de champ de commutation ; leur incorporation à l’audio

représente une nette et spectaculaire amélioration par rapport aux systèmes conventionnels. Les avantages que

présentent ces mosfets de commutation peuvent se résumer comme suit :

a) Moins grande résistance interne que les bipolaires, ce qui se traduit par un moindre chauffage de l’étage

et par des graves puissants et parfaitement contrôlés; les mosfets conventionnels d’audio présentent une

résistance interne d’entre 4 et 7 fois supérieure à ceux de commutation.

b) La grande rapidité de ces dispositifs donne aux aigus une transparence qui, jusqu’alors, n’avait été

obtenue qu’avec des amplificateurs à lampes, de même qu’une TIM (Distorsion par lntermodulation de

Transitoires) très réduite.

La technologie SPM (Switching Power Mosfet) a été développée et brevetée par ECLER Laboratoire

d’Électro-Acoustique, S.A. La gamme d'amplificateurs NPA est un nouveau pas en avant dans l'évolution de la

technologie d'amplification SPM, dans le sillage de la série à succès DPA.

Protections pour suivi de contour de SOA: la SOA est l’aire d’opération sure du transistor (Safe Operating

Area). Un bon système de protections doit respecter cette aire et ses changements, puisque la SOA varie en

fonction de la température de travail. Ainsi, à 80 degrés, elle est considérablement moins grande qu’à 25 degrés,

lorsque l’amplificateur est connecté. Certains fabricants optent pour des protections qui limitent les performances

des composants ; ceux-ci permettent d’obtenir une certaine sécurité, mais donnent lieu à un rendement médiocre.

En revanche, d’autres fabricants laissent des zones obscures entre l’aire de sécurité et l’activation des protections,

ce qui est très risqué.

Le nouveau système de suivi de contour de la SOA des amplificateurs NPA assure la totale protection de

l’amplificateur quel que soit le niveau de puissance, de charge ou de température, puisqu’un circuit électronique

intelligent contrôle l’aire de sécurité de façon permanente, en s’adaptant à chaque situation ponctuelle.

Le facteur d’amortissement maximal (DAMPING) : dans la gamme NPA, les traditionnels relais de sortie

ont été remplacés par un système électronique CROWBAR. Ce dispositif court-circuite directement le signal vers

la masse en cas de détection de surtensions pouvant endommager les enceintes connectées à l'amplificateur. Les

relais employés dans la méthode conventionnelle, quel que soit leur type, introduisent au contraire un contact

mécanique sur le chemin du signal audio vers l’enceinte, contact qui est exposé à une usure et à une importante

diminution du facteur d'amortissement de l'amplificateur.

26

Page 27

ECLER utilise double alimentation et des mosfets de canal N pour le nouvel amplificateur de puissance

NPA2500T/4000T. L’incorporation de cette nouvelle technologie qui a déjà été utilisé avec succès sur la ligne de

produits industriels ENVIRO, permet d’obtenir des hauts niveaux de puissance sans avoir recours à une

configuration en "bridge". ECLER maintient le concept "All the power all the time" ("Toute la puissance... tout le

temps") même à très haut rendement et à 4 ohms en programme musical.

La gamme NPA intègre en outre au niveau du traitement numérique et de la gestion à distance par

Ethernet d'importantes innovations technologiques qui en font la candidate parfaite pour des applications mobiles

et des installations fixes, aussi bien centralisées que distribuées, nécessitant un contrôle et une supervision à

distance de haut niveau et l'intégration à des réseaux Ethernet standard. Les amplificateurs NPA

comprennent en standard un module interne de traitement DSP et gestion à distance EclerNet, qui permettent la

connexion physique de l'amplificateur à un réseau Ethernet ainsi que sa gestion et sa supervision à distance

depuis tout point de ce dernier, en employant pour cela l'application Windows EclerNet Manager*. Consultez le

mode d’emploi de l'application EclerNet Manager pour obtenir davantage d'informations.

* L'application EclerNet Manager est disponible sur www.ecler.com.

3. INSTALLATION

3.1. Localisation, montage, ventilation

Les amplificateurs NPA2500T/4000T se présentent en module rack de 19" et de 3 unités de hauteur.

Comme élément générateur de chaleur, il est très important que l’amplificateur ne soit ni complètement

enfermé, ni exposé à des températures extrêmes. Aussi, le passage d’air frais doit-il être favorisé à travers le

tunnel de ventilation forcée. Ce système fait entrer l'air par l’avant, le dirigeant directement vers les modules de

puissance et les transformateurs, en déviant une partie vers les condenseurs et l'obligeant à sortir par l’arrière de

l'amplificateur.

Dans le but de favoriser au mieux la dissipation thermique correcte des équipements installés dans des

armoires racks, il est conseillé de ne pas placer les amplificateurs de puissance sous d'autres appareils, mais audessus de ceux-ci.

Tous les amplificateurs NPA sont livrés avec des rondelles en plastique afin de permettre leur montage en

un rack sans endommager les languettes de fixation.

3.2. Branchement

Les amplificateurs NPA fonctionnent sur courant alternatif, selon le pays, de 110-120, 220-240V 47/63Hz.

(voir la plaque de caractéristiques à l’appareil).

ATTENTION!: Par convention, l’assignation de la couleur des câbles est la suivante:

- MARRON = Phase

- BLEU = Neutre

- JAUNE/VERT = La Terre

Éviter de mêler les cordons secteur et les cordons audio, ceci peut provoquer des ronflements.

27

Page 28

3.3. Branchement de l'entrée du signal

La gamme NPA dispose d'entrées analogiques et numériques en face arrière. La sélection de l'une ou

l'autre des entrées se fait dans le menu de la face avant ou depuis l'application de contrôle EclerNet Manager.

Consultez le mode d’emploi de l'application EclerNet Manager pour obtenir davantage d'informations.

• Entrées analogiques :

Les entrées du signal sont de type XLR-3 (19) symétriques électroniquement. L’assignation est la suivante:

Point Chaud ou signal direct > Terminal 2

Point Froid ou signal inversé > Terminal 3

Masse > Terminal 1

Pour les branchements asymétriques relier le point 3 à la masse.

Les sorties "STK OUTPUT" (18), sont en parallèle avec les entrées et, servent à brancher le même signal,

que nous avons sur les entrées "INPUT", à d’autres amplificateurs ou à d’autres sources de son.

L’impédance d’entrée est de 22kΩ (symétrique) avec une sensibilité nominale de 0dBV(1V). Cette

impédance permet de brancher un grand nombre d’amplificateurs en parallèle sans toutefois altérer la qualité

sonore.

• Entrées numériques :

Il existe aussi une entrée numérique de type AES/EBU au format XLR-3, avec sa sortie numérique

correspondante pour le renvoi de ce signal vers d'autres appareils.

3.4. Branchement de sortie.

La partie des "OUTPUT" a été conçue pour recevoir des connecteurs Speakon® (23).

Les modes de travail STEREO/PARALLEL/BRIDGE (stéréo/parallèle/ponté) sont choisis dans le menu de

la face avant ou depuis l'application de contrôle EclerNet Manager. Consultez le mode d’emploi de l'application

EclerNet Manager pour obtenir davantage d'informations.

Le câble de raccordement de l'amplificateur sur les enceintes doit être de bonne qualité et de section

suffisante surtout s'il existe une distance importante entre les amplificateurs et les haut-parleurs. Il est

recommandé d'utiliser du câble d'une section minimum de 2.5mm

2

pour distances jusqu'à 10m et de 4mm2 pour

les distances supérieures.

3.5. Port Ethernet

Un connecteur de type RJ45 permet la connexion de l'équipement à un réseau Ethernet et sa gestion

depuis l'application EclerNet Manager. Consultez le mode d’emploi de l’application EclerNet Manager pour obtenir

davantage d’informations.

3.6. Port RS-232

Un connecteur DB9 de type RS-232 permet la connexion série de l'équipement à un système de contrôle

externe type AMX, Crestron, Medialon, etc. (non fonctionnel à la date d’impression de ce notice d’emploi, il fera

l’objet d’une future mise en œuvre).

3.7. Connecteur FAULT

Connecteur 3 broches, type fermeture de contact sans potentiel (normalement fermé, normalement

ouvert). Change d'état si une panne interne est détectée dans l'amplificateur, conduisant alors à la mise hors

service de celui-ci.

28

Page 29

4. MISE EN MARCHE ET UTILISATION. FONCTIONNEMENT

4.1. Mise en marche.

En actionnant l'interrupteur de mise en marche POWER (17), en face arrière, l'amplificateur reçoit

l'alimentation électrique du secteur et est dans un mode lui permettant d'être allumé localement ou à distance (voir

la section Panneau de commande).

Dans une installation audio, il est important de mettre sous tension les appareils dans le sens suivant:

Sources, table de mixage, effets, filtres actifs et amplificateurs de puissance. Pour l'extinction, procéder à l'envers

en commençant par les amplificateurs.

4.2. DEL témoins de la face avant

Les amplificateurs NPA sont équipés d’un système de témoins simple et efficace :

• Témoin de protection thermique THERMAL (2) :

Signale que la température du tunnel de refroidissement a dépassé le seuil minimum de risque pour

l'équipement. L'amplificateur redémarrera automatiquement quand la température aura suffisamment diminué.

Les amplificateurs NPA possèdent une protection thermique par canal. Cela signifie qu'elles fonctionnent

de façon indépendante, pouvant activer la protection d'un seul canal pendant que l’autre fonctionne sans

problème.

• Témoin PROTECT (3) :

Indique l'absence de signal en sortie pour enceintes. Peut s’allumer pour les motifs suivants :

o Au moment de la mise en marche et jusqu'à ce que le temps de STANDBY nécessaire à la

stabilisation des tensions internes de l'amplificateur se soit écoulé.

o Parce qu'il existe une anomalie dans l'équipement qui empêche le démarrage normal (le message

“PERSISTENT PROTECT” s’affiche à l’écran).

o Si l'amplificateur délivre un signal de fréquence très basse qui pourrait endommager les enceintes.

o Si plus de 4 courts-circuits ont été détectés en sortie d'amplificateur sur une période de 40

secondes (le message “REPETITIVE PROTECT” s’affiche à l’écran).

o En cas de panne interne et si l'amplificateur a besoin d'être réparé (le message “FAULTY

AMPLIFIER” s’affiche à l’écran).

Dans tous les cas, l’allumage permanent de ces témoins est un symptôme de mauvais fonctionnement et

des recherches doivent être faites pour en trouver la cause.

• Témoin CLIP (4) :

S’allume quand le signal fourni aux enceintes est proche du niveau d’écrêtage réel. Ce système de CLIP

tient compte des possibles fluctuations de la tension d'alimentation, donnant toujours une indication réelle malgré

celles-ci. Il est normal qu'en travaillant à haut niveau de puissance, les témoins CLIP s’allument au rythme des

basses fréquences, qui sont celles qui possèdent le plus grand contenu énergétique. Veillez à ce que ces

indicateurs ne soient pas allumés de façon permanente en régime normal de fonctionnement de l'équipement.

• Témoin de présence de signal SIGNAL (5) :

Avertit de la présence d’un signal aux entrées de l'amplificateur. Ces témoins s’allument quand le signal

présent en entrée dépasse les –40 dB.

• Témoin de transfert de données DATA (11) :

Clignote pour indiquer de l'activité dans le transfert de données entre l'amplificateur et le PC de

télécommande qui exécute l'application EclerNet Manager.

29

Page 30

4.3. Maniement de la face avant

La face avant comprend une série de commandes et de témoins :

o Écran LCD rétroéclairé pour la visualisation des menus, le réglage et la lecture des paramètres de

l'amplificateur.

o Interrupteur d’alimentation (POWER ON).

o Touches de navigation dans les menus (MENU / PREVIOUS / NEXT).

o Commandes mixtes (rotatives et boutons poussoirs) pour le réglage des paramètres (CHANNEL 1

/ CHANNEL 2).

o DEL témoins (voir paragraphe 4.2).

L'appareil s’allume en maintenant enfoncée la touche POWER jusqu'à ce que la séquence de démarrage

commence. Son extinction se fait par un bref temps de maintien de la même touche.

La touche POWER ON dispose d'une DEL témoin intégrée qui s’allume en orange quand l'amplificateur

est en mode d'attente (STANDBY), en vert quand il est en service (ON) et en rouge pendant la séquence de

démarrage ou bien quand l'amplificateur est en mode de protection.

Une fois l'amplificateur allumé, la page principale apparaît dans l’écran LCD, avec un aspect ressemblant

à ceci :

Depuis cet écran principal, il est possible d'utiliser une série de fonctions de base de l'amplificateur :

• Modifier le volume du canal 1 ou 2 (en tournant les commandes rotatives CHANNEL 1 ou CHANNEL 2) :

Une fenêtre apparaît brièvement avec le réglage en dB (dans l'exemple – 47 dB) et l'indicateur en forme

de pente change pour le volume de ce canal.

Note : si les deux canaux sont couplés, le réglage simultané du volume des deux s’effectue avec la

commande rotative CHANNEL 1.

30

Page 31

• Activer/désactiver la coupure d'un canal (en maintenant pressée la commande rotative CHANNEL 1 ou

CHANNEL 2) :

Une bulle apparaît avec le texte “MUTE” en cas d'activation de cette fonction.

• Visualiser les bulles de texte assignées à l’appareil et à ses canaux d'amplification (en pressant la touche

TAG) :

Cette fenêtre, appelée TAGS, disparaît après un bref laps de temps, laissant la place à l’écran principal.

La ligne supérieure de l'écran affiche aussi le numéro et le nom du PRESET actif. Dès qu'on modifie un

quelconque réglage de l'amplificateur, une bulle “M” apparaît aussi dans le coin supérieur droit de l'écran,

indiquant que le PRESET chargé a été modifié (il suffit par exemple de bouger une commande de volume pour

que cela se produise).

31

Page 32

On accède au reste des fonctions et réglages de l'amplificateur par la structure en menus décrite dans le

schéma suivant :

32

Page 33

• Menu MONITOR

Sélection de l’échelle de monitoring par les VU-mètres en :

o Watts en sortie, RMS ou crête.

o Volts en sortie, RMS ou crête.

o Volts du signal d’entrée, RMS.

Visualisation par écran dédié de :

o Impédance de charge, en ohms.

o Température, en % de la température de déclenchement d’alarme.

o Volts de l'alimentation secteur (CA).

o Temps cumulé d'utilisation de l'amplificateur en heures : minutes.

o Événements : compteur numérique d'alarmes de protection, thermique, impédance de charge,

tension d'alimentation CA (note : depuis leur affichage dans ce menu, les compteurs d'alarmes

de chaque canal se réinitialisent (valeur = 0) en maintenant pressée leur commande rotative

pendant un bref laps de temps).

• Menu SETTINGS

Menus des réglages du mode de travail de l'amplificateur :

o INPUT SOURCE (source d’entrée) : sélectionne parmi ceux disponibles le signal d'entrée avec

lequel travaillera l'amplificateur (analogique 1, analogique 2, numérique 1, numérique 2 et

générateur interne).

o LINK VOLUME (couplage des volumes) : détermine si les commandes de volume des deux

canaux de l'amplificateur seront gérées conjointement (ON) ou indépendamment (OFF). En

mode couplé (ON), le contrôle simultané des volumes des deux canaux se fait au moyen de la

commande CHANNEL 1, tandis que “LINK” s’affiche à l’écran.

o GAIN : gain de l’amplificateur, réglable sur 26, 32 ou 38 dB.

o OUTPUT MODE : sélection du mode de travail des sorties amplifiées entre stéréo, parallèle ou

bridgé. Dans les derniers deux cas, “PARAL” ou “BRIDGE” apparaît à l’écran.

o POLARITY : sélection de phase du signal d'entrée, normale ou inversée. En cas d’inversion de

phase, “INV” apparaît à l’écran.

o ANTICLIP LEVEL : sélection du niveau d'action du circuit anti-écrêtage, entre les options

douce (permet un écrêtage conséquent), moyenne ou forte (permet un écrêtage minimal,

quasi indétectable).

o PEAK LIMITER : permet de définir une valeur de tension maximale aux bornes des sorties

amplifiées de l'équipement.

• Menu PRESETS

Sélection des PRESETS ou mémoires de l'amplificateur, parmi une liste de 10 possibles.

Note : Charger un PRESET fait apparaître son numéro et son nom en ligne supérieure de l'écran.

Dès qu'on modifie un quelconque réglage de l'amplificateur, une bulle “M” apparaît aussi dans le

coin supérieur droit de l'écran, indiquant que le PRESET chargé a été modifié (il suffit par exemple

de bouger une commande de volume pour que cela se produise).

33

Page 34

• Menu ADVANCED

Fonctions avancées de l'amplificateur :

o LCD CONTRAST : réglage du contraste de l'écran LCD.

o FINDER : active/désactive le clignotement du rétroéclairage de l'écran, utile pour l'identification

d'un appareil physique avec son équivalent virtuel dans l'application EclerNet Manager (voir le

mode d’emploi d’EclerNet Manager pour plus d’informations).

o INFO : affiche le modèle et la version de firmware de l'amplificateur.

o NETWORK : permet le réglage de l’adresse IP, du masque et de la passerelle de l'interface

Ethernet de l'amplificateur (le port par défaut est le 2210. Il n'est pas possible de les modifier à

l’aide des commandes locales, mais vous pouvez le faire depuis l'application EclerNet

Manager).

o POWER ON MODE : permet de choisir si, à la mise sous tension (interrupteur POWER de la

face arrière), l'amplificateur se place en mode STANDBY, ON ou reprend l'état dans lequel il

se trouvait lors de la dernière interruption de l'alimentation électrique, par exemple, au

rétablissement de l’alimentation secteur après une coupure de courant (LAST STATE).

o RESTORE : permet de rappeler les valeurs par défaut de tous les paramètres de

l’amplificateur, à l’exception du compteur cumulant les heures de fonctionnement (cela efface

les mots de passe, PRESETS, paramètres de DSP, réglages de configuration, compteurs

d'alarmes et la configuration réseau Ethernet).

o PASSWORD : permet d'assigner un mot de passe d’utilisateur ou d’administrateur à

l'amplificateur.

• USER (utilisateur) : une fois ce mot de passe établi, l'équipement le demande chaque

fois qu'on essaye d'agir sur une commande ou un réglage quelconque dans la

configuration de l'amplificateur (allumage, extinction, réglage de volume et accès aux

menus).

• ADMIN (administrateur) : une fois ce mot de passe établi, il n’est possible d'agir

directement que sur les commandes disponibles en écran principal : allumage,

extinction, réglage de volume et coupure du son. Pour effectuer des réglages de

configuration de l'amplificateur (accès aux menus, touche MENU), la saisie préalable

du mot de passe est demandée.

Note : pour désactiver un mot de passe, il est nécessaire d’en mémoriser un nouveau, vierge.

La majorité des fonctions décrites précédemment ont leur équivalence dans l'application EclerNet

Manager. Consultez le mode d’emploi de l’application EclerNet Manager pour obtenir davantage d’informations.

5. ENTRETIEN

Il est interdit d’utiliser des substances dissolvantes ou abrasives pour nettoyer la face avant, celles-ci

détériorant la sérigraphie. Nettoyer uniquement avec un chiffon humide. Attention! Jamais de l’eau ou tout autre

liquide ne doit pénétrer par les orifices du panneau de commande.

34

Page 35

6. LISTE DE FONCTIONS

1. Atténuateurs d’entrée

2. Indicateur de protection thermique, THERMAL

3. Indicateur de protection, PROTECT

4. Voyant d'écrêtage, CLIP

5. Indicateur de présence du signal, SIGNAL

6. Ecran

7. Touche de navigation, MENU / CANCEL

8. Touche de navigation, PREVIOUS

9. Touche de navigation, NEXT / TAG

10. Touche d'allumage/extinction, POWER ON

11. Témoin de transfert de données, DATA

12. Port RS-232

13. Port Ethernet

14. Borniers vissables, FAULT

15. Connecteur XLR d’entrée numérique, AES-EBU INPUT

16. Connecteur XLR de sortie numérique, AES-EBU OUTPUT

17. Interrupteur de mise en marche

18. Connecteur XLR de sortie du signal pour autres amplis, STK OUTPUT

19. Connecteur XLR en entrée, INPUT

20. Prise de terre, GND

21. Cordon secteur

22. Commutateur de séparation masse électrique / mécanique, GND LINK

23. Embases Speakon® pour les haut-parleurs

7. SCHEMA DE FONCTIONNEMENT

35

Page 36

BEDIENUNGSANLEITUNG

1. WICHTIGE VORBEMERKUNG 37

1.1. Vorsichtsmaßnahmen 37

2. EINFÜHRUNG 37

3. INSTALLATION 38

3.1. Plazierung, Montage und Lüftung 38

3.2. Netzanschluß 38

3.3. Anschluß der Signaleingänge 39

3.4. Anschluß der Ausgänge 39

3.5. Ethernet-Port 39

3.6. RS-232-Port 39

3.7. FAULT-Stecker 39

4. INBETRIEBNAHME 40

4.1. Inbetriebnahme 40

4.2. LED-Anzeigen an der Vorderseite 40

4.3. Bedienung der vorderen Bedientafel 41

5. REINIGUNG 45

6. FUNKTIONSLISTE 46

7. FUNKTIONSÜBERSICHT 46

8. TECHNISCHE DATEN 47

9. BLOCKSCHATBILD 50

Alle Angaben sind ohne Gewähr. Messwerte können produktionsbedingten Schwankungen unterliegen. ECLER S.A. nimmt

sich das Recht heraus Veränderungen am Gerät vorzunehmen, die zur Verbesserung des Produktes beitragen.

36

Page 37

1. WICHTIGE VORBEMERKUNG

Herzlichen Glückwunsch! Sie haben ein hervorragendes Gerät erworben, das mit großer Sorgfalt

entwickelt und hergestellt wurde. Wir danken Ihnen für das Vertrauen, daß Sie sich für unseren NPA SPM

(Networked All purpose Switching Power Mosfet) entschieden haben.

Um die maximale Leistung und eine zuverlässige Funktion zu erreichen, ist es sehr wichtig, vor dem

Anschluß dieses Verstärkers alle Ausführungen in dieser Bedienungsanleitung genau zu lesen.

Um die optimale Funktion dieses Gerätes sicherzustellen, sollten etwaige Reparaturen nur von unserer

technischen Serviceabteilung durchgeführt werden.

1.1. Vorsichtsmaßnahmen

Der Verstärker sollte eine gute Erdungsverbindung besitzten (Erdungswiderstand, Rg=30Ω oder

weniger). Der Arbeitsbereich, in dem das Gerät aufgestellt wird, sollte trocken und möglichst staubfrei

sein. Es darf kein Regen oder andere Flüssigkeiten in das Gerät gelangen. Stellen Sie niemals

Flüssigkeitbehälter oder flammende Gegenstände wie z.B. Kerzen auf die Gerätoberfläche. Bedecken

Sie in keinem Fall die Lüftungsschächte oder verhindern Sie die Frischluftzufuhr. Beim Ab- oder Anschluß von

Leitungen ist es sehr wichtig, vorher die Stromversorung des Verstärkers auszuschalten.

Berühren Sie nicht die Ausgangsanschlüsse zu den Lautsprechern, wenn der Verstärker eingeschaltet ist,

da Spannungen über 400Vpp auftreten. Für den Anschluß der Ausgangskabel an die Lautsprecher sollte

ausschließlich ein qualifizierter Techniker zuständig sein. Sie können jedoch auch vorgefertigte Kabel benutzen. Im

Inneren der Endstufe befinden sich keine für den Benutzer gedachte Bedienelemente.

2. EINFÜHRUNG

Mit der PAM Verstärker-Serie führte ECLER Anfang der 90er Jahre ein neues Konzept in die Welt des

professionellen Audio ein: Die Benutzung schaltender Feld-Effekt Transistoren, deren Gebrauch in

Audioanwendungen einen soliden und spektakulären Fortschritt hingegen herkömmlichen Systemen bedeutete.

Die Vorteile schaltender Mosfets in diesem Zusammenhang können folgendermaßen zusammengefasst werden:

a) Geringerer Innenwiederstand als bipolare Transistoren, welches eine mindere Erhitzung der Endstufe

zur Folge hat und zugleich für kraftvollere und kontrolliertere Bässe sorgt; herkömmliche Audio-Mosfets weisen

einen 4- bis 7-fachen Innenwiederstand als schaltende Mosfets auf.

b) Die extrem hohe Schaltgeschwindigkeit dieser Komponenten besorgen den Höhen eine bis jetzt nur

durch Röhrenverstärker erreichte Transparenz, sogleich der TIM-Wert (Verzerrung durch

Transientenübersprechen) besonders niedrige Werte einnimmt.

Die SPM-Technologie (Switching Power Mosfet) ist von ECLER Laboratorio de Electroacústica, S.A.

entwickelt und patentiert worden. Die Verstärkerlinie NPA ist ein weiterer Schritt nach vorn in der Entwicklung der

Verstärker-Technologie SPM und baut auf der erfolgreichen DPA-Serie auf.

Schutzvorrichtung durch Verfolgen der SOA-Kontur: das SOA ist der Bereich, in denen Transistoren in

sicheren Umständen arbeiten (Safe Operating Area). Ein effizientes Schutzsystem muß also diesen Bereich und

dessen Schwankungen respektieren, da das SOA in Fuktion der Arbeitstemperatur sich verändert. So ist es bei

80° C beträchtlich schmaler als bei 25° C, beim Einschalten des Geräts. Einige Hersteller bevorzugen eine

Schutzschaltung, die die potentielle Leistung der Komponenten begrenzt. Dabei erhält man zwar einen sicheren

Betrieb, die Leistung des Verstärkers ist jedoch nur mittelmäßig. Andere Hersteller lassen hingegen "dunkle

Zonen" zwischen den sicheren Arbeitsberich und der Aktivation der Schutzschaltung, was zweifelslos äußerst

riskant ist.

Das neue SOA-Kontur Verfolgungssystem in den NPAs garantiert einen totalen Schutz Ihres Verstärkers

bei jeder Ausgangsleistung, Lastimpedanz oder Arbeitstemperatur, da eine intelligente elektronische Schaltung

permanent den Arbeitsbereich nachspürt und die Sicherheitsverhältinisse in jeden Moment der Situation anpasst.

Die beste Dämpfung bei Verstärkern seiner Klasse.

Maximaler Dämpfungsfaktor (DAMPING): In der NPA-Serie wurden die herkömmlichen Ausgangsrelais

durch das elektronische System CROWBAR ersetzt. Dieses System leitet, sobald eine Überspannung festgestellt

wird, welche den an den Verstärker angeschlossenen Lautsprechern Schaden zufügen könnte, das Signal direkt

an Masse weiter. Im Gegensatz dazu schaltet jedes Relais, das bei der herkömmlichen Methode zur Anwendung

kommt, einen mechanischen Kontakt auf dem Weg des Audiosignals zum Lautsprecher. Dieser Kontakt ist ein

Verschleißteil und kann zu einer bedeutenden Minderung des Dämpfungsfaktors des Verstärkers führen.

37

Page 38

Die Ecler NPA2500T/4000T basiert auf ein Dual-Netzteil un N-channel mosfets. Diese Technologie hat

sich bei der industriellen Produktlinie ENVIRO höchst effizient erwiesen, da eine extrem hohe Ausgangsleistung

ohne Bridge-Konfigurationen ermöglicht wird. Sogar bei maximaler Austeuerung eines Musiksignals an 4 Ohm

Lastimpedanzen bleibt die "All the Power All the Time" Philosophie erhalten.

Die Serie NPA enthält ausserdem bedeutende technologische Innovationen im Bereich der digitalen

Signalverarbeitung und der Fernsteuerung über Ethernet und wird dadurch zum perfekten Kandidaten, wenn es

darum geht, mobile oder feste Installationen auszurüsten, die sowohl zentral als auch dezentral sein können, und

die eine Steuerung und Überwachung mittels Fernsteuerung auf hohem Niveau sowie die Integration in

Standard-Netzwerke vom Typ Ethernet erforderlich machen. Die NPA-Verstärker sind serienmäßig mit einem

internen Signal-Prozessor-Modul DSP ausgestattet sowie mit einer Fernsteuerung EclerNet. Das ermöglicht den

physischen Anschluss des Verstärkers an ein Ethernet-Netzwerk und seine Steuerung und Überwachung von

jedem Punkt des Netzwerks aus. Hierfür dient die Anwendung Windows EclerNet Manager*. Nähere Information

hierzu finden Sie im Handbuch der Applikation EclerNet Manager.

* Die Applikation EclerNet Manager steht Ihnen unter www.ecler.com zur Verfügung.

3. INSTALLATION

3.1. Plazierung, Montage und Lüftung

Die NPA2500T/4000T Verstärker sind im 19'' Rack-Format konzipiert und sind 3 HE hoch.

Es ist äusserst wichtig, daß der Verstärker, als hitzeerzeugendes Element, weder komplett eingeschlossen

zwischen andere Geräte plaziert wird, noch extremen Temperaturen ausgesetzt ist. Deshalb sollte die

Frischluftzufuhr in den Lüftungstunnel gefördert werden. Dieses System saugt Frischluft an der Vorderseite an und

leitet diese direkt an die Leistungsmodule und Transformatoren weiter, wobei ein Teil zu den Kondensatoren

umgeleitet und an der Rückseite des Verstärkers wieder ausgeblasen wird.

Um so weit wie möglich eine ordnungsgemäße Wärmeverteilung der in Racks eingebauten Geräte zu

ermöglichen, ist es ratsam, den Leistungsverstärker nicht unter anderen Geräten einzubauen, sondern darüber.

Die NPA Verstärker werden mit Plastikflanschen geliefert, um die Montageprofile Ihres Verstärkers beim

Einbau in ein Rackgehäuse nicht zu beschädigen.

3.2. Netzanschluß

Die NPA Verstärker können mit Wechselspannungen von 110-120, 220-240V 47/63Hz betrieben werden

(siehe Aufkieber auf dem Gerät).

WARNUNG! Die normierte Farbcodierung der Netzleitungen ist wie folgt:

- BRAUN = Phase

- BLAU = Nulleiter

- GELB/GRÜN = Erde (Schutzleiter)

Das Netzkabel darf nicht in der Nähe von den abgeschirmten, signalführenden Leitungen verlegt werden,

da dies ein Brummen verursachen könnte.

38

Page 39

3.3. Anschluß der Signaleingänge

Die NPA-Serie verfügt an der Rückseite über analoge und digitale Eingänge. Die Auswahl der Eingänge

erfolgt entweder vom Menü an der vorderen Bedientafel aus oder mit Hilfe der Fernsteuerungs-Applikation

EclerNet Manager. Nähere Information hierzu finden Sie im Handbuch der Applikation EclerNet Manager.

• Analoge Eingänge:

Die Signaleingaänge sind als elektronisch symmetrierte XLR-3 Buchsen (19) ausgeführt. Die Pinbelegung

ist wie folgt:

Direktes Signal oder Phase > Pin 2

Invertiertes Signal oder Gegenphase > Pin 3

Masse > Pin 1

Für einen unsymmetrierten Anschluß muß Pin 3 nach Pin 1 kurzgeschlossen werden.

Die "STK OUTPUT" Ausgänge (18) sind mit den Eingängen parallel geschaltet und werden verwendet, um

das gleiche Eingangssignal zu anderen Verstärkern oder Geräten zu senden.

Die Eingangsimpedanz beträgt 22kΩ (symmetriert) mit einer nominalen Eingangsempfindlichkeit von

0dBV(1V). Diese Eingangsimpedanz ermöglicht eine Parallelschaltung mehrerer Verstärker, ohne die

Klangqualtität zu beeinflussen.

• Digitale Eingänge:

Des weiteren ist ein digitaler AES/EBU Eingang im Format XLR-3 vorhanden mit entsprechendem digitalen

Ausgang für die Verkettung des Signals mit anderen Systemen.

3.4. Anschluß der Ausgänge

Der Lautsprecher Ausgang "OUTPUT" auf der Rückseite ist mit Speakon® Anschlüssen (23) ausgestattet.

Die Betriebsarten STEREO / PARALLEL / BRIDGE werden entweder im Menü an der vorderen Bedientafel