Page 1

Page 2

SOREMEC - CEHESS

Department “ECLAIR INTERNATIONAL”

41-45, rue Galilee - 75116 Paris

Tel: 723.78.56 +

Telex: 610 663 F ECLAIRE

Cable: ECLAIRCAM PARIS

2

Page 3

Technical Characteristics

Weight:

4.3 kg without lens

Overall dimensions:

275 x 180 x 160 mm, without lens (11" x 7" x

6" 1/2)

Capacity:

pre-loaded 60 meter (200ft) or 120 m (400ft)

snap-on magazine

16mm film:

• double or single perforation

• A winding (emulsion out)

• B winding (emulsion in)

• on 50 mm (2 in) core-120 meter rolls

• on 30 or 60 m (100 or 200 ft) daylight loading spools

Climatic conditions:

Temperature - 20° C (4° F) to + 60° C (140°

F)

Humidity: up to 95% RH

Film Transport:

claw movement controlled by an excentric

and a fixed cam.

Reflex veiwing:

by a half-speed oscillating mirror.

Shutter:

plane type with a 175° opening.

Viewfinder:

for left and/or right eye, rotatabhle through

360° with image re-erected, dioptry adjustment

and eyepiece shutter.

Gelatine holder:

built-in and positioned between the C mount

and the reflex mirror.

Lens Mounts:

in C mount, screwed directly on the camera,

in Cameflex, Arriflex or Nikon mounts,

adapted to the camera by means of intermediate

mount.

Exposure indicator:

by 7 LED (light emmitting diodes) in vertical

display seen in the viewfinder.

Motor:

12 volts multiduty type, brushless, Hall effect,

6 crystal controlled speeds 8, 12, 24, 25

50, 75 frames per second. Automatic stop

in viewing position.

Power consumption:

from 0.8 to 1.2 Amps at 12 volts (20 C to 68° F)

Batteries:

12 volts MIBAC type: weight 0.640 gr (1.5 lbs)

(capacity 1.2 ah); rechargeable in less than

30 minutes equivalent to eight to ten 60 m

magazines or 12 volts BAKEL type:

weight 1.650 kg, capacity 4 ah equivalent

to ten to fifteen magazines

Noise level:

Quiet functioning that permits sync, filming

without any blimp.

Flat base:

standard 3/8"x16 threads per inch taping

for using a tripod or a polo stick.

Hand-grip:

adjustable lateral type with "ON/OFF"

micro-switch.

Standard screw:

on top of the camera for attachment

of accessories such as handle, boost lighting

mike support, etc.

3

Page 4

DESCRIPTION

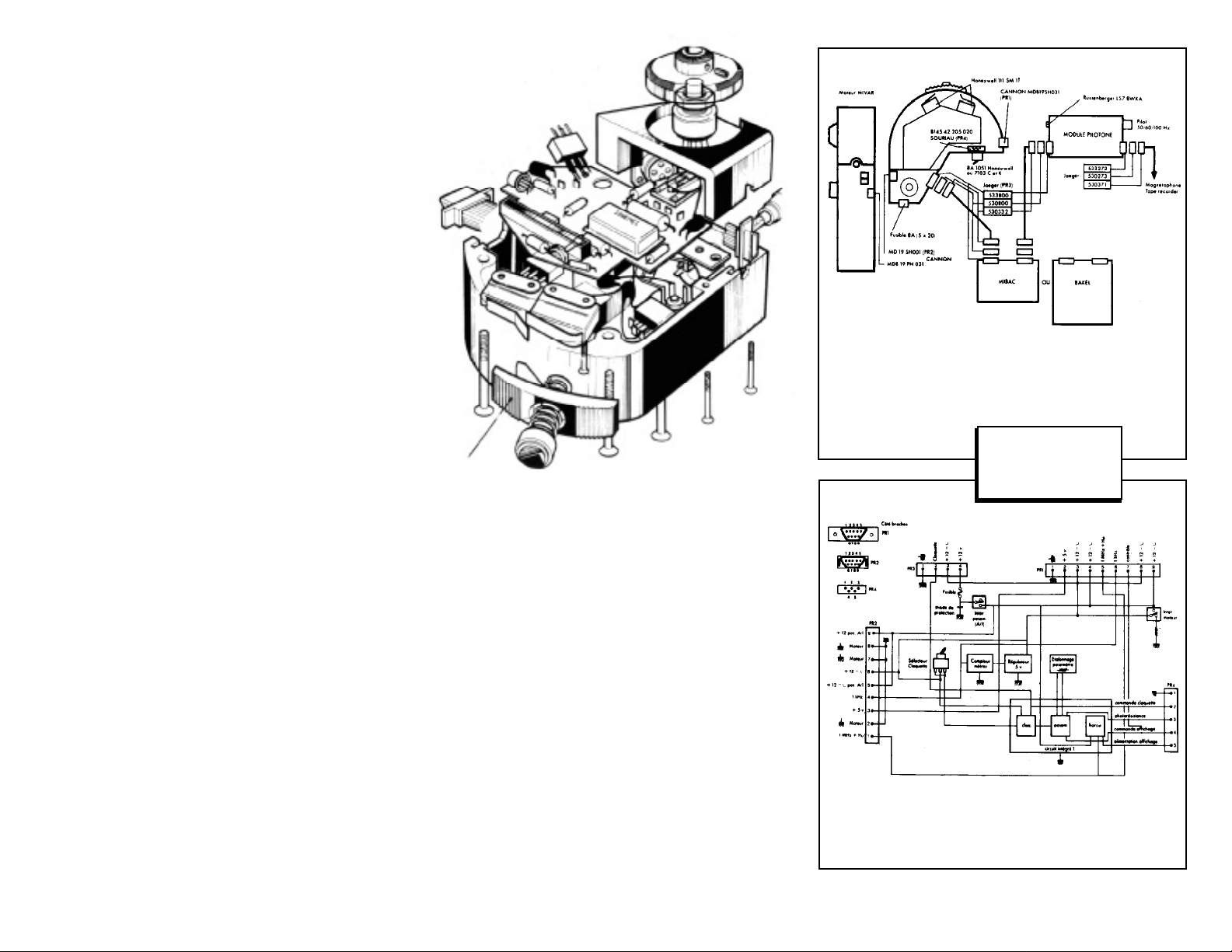

THE CAMERA HEAD (Code MIPEX)

The camera head (Fig A) in special

aluminum alloy supports the lens mounts (1)

in stainless steel, the interchangeable gelatine-holder (2), the reflex viewfinder (3), the

motor (6) with its control for electronics (7),

the electronic base (8) incorporating the

sliding on/off switch (32), the lateral support

(75) of the hand-grip (36) with its micro-switch

(76), the magazine lock release lever (16)

with its safery catch (17) and the removable

hand-grip (36).

On the rear (Fig B): the mechanism

plate (9) on which are mounted film gate (10),

2

the fixed guide bar (11) and its side pressure bar

(12), the magazine drive shaft (18), the 4 pin

power supply socket (19) for connection with the

battery, the clapper switch (20) and the potentiometer (34) of the exposure indicator.

Inside: the claw mechanism (13), the

oscillating mirror (14), the plane shutter (15) and

the exposure indicator unit.

The snap-on 60m, or 120m magazine

are attached onto the camera head as well as

the fixed focal or zoom lenses.

3

NOTA. The above camera head can be supplied without Exposure indicator unit; its

commercial code is MITAN.

29

30

17

16

9

1

14

10

11

12

13

18

34

19

75

76

6

7

20

32

8

Fig. A

Camera head front view.

Viewfinder positioned

for the left eye.

Fig. B

Camera head rear view.

Viewfinder positioned

for the right eye.

4

Page 5

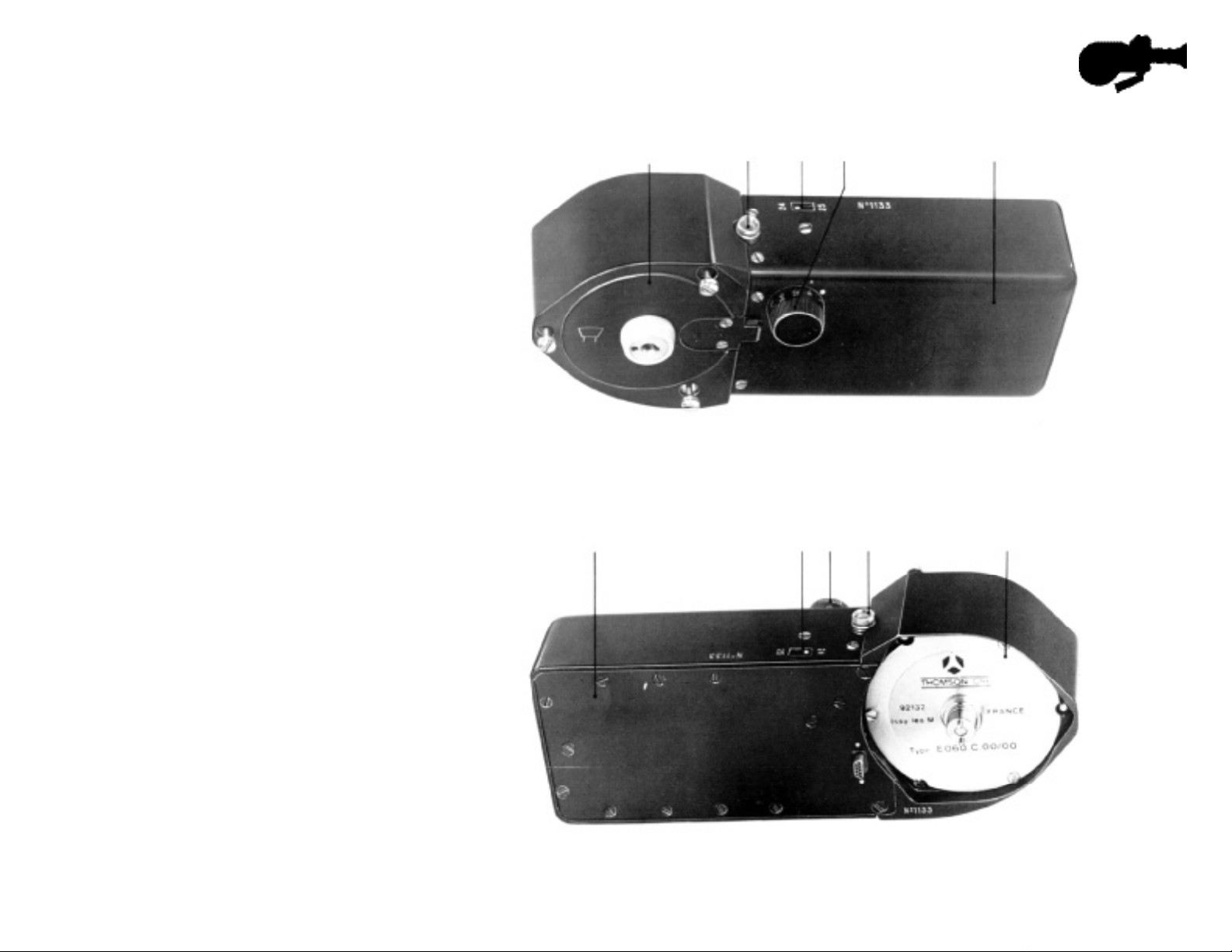

THE MULTIDUTY MOTOR (MIVAR)

This brushiess motor (6) has a very

high efficiency (from 0.8 to 1.2 amp. consumption at 12 volts to drive the camera at

20°C (68° F) and has permitted a weight

reduction not only in the camera but also in

the battery (37) - page 12 - which weighs only

640 grammes enabling one hour of filming

between recharges, i.e. eight to ten 60 m

magazines.

The incorporated electronics (7)

control the sync. speed by crystal ; changing

from 24 to 25 f.p.s. or vice-versa is made by

shifting switch (38) so that the white spot

mark is adjacent to the desired speed. Others

speeds : 8.12.50 and 75 are obtained by

setting the engraved button 35 accordingly.

The MIVAR will stop the camera

automatically in viewing position,

i.e. the mirror being in the aperture axis

allows the cameraman to frame and focus

without

loss of time. See pages 24 and 30.

The motor will only operate when it is

attached to the camera.

The lamp (47) on the motor lights up

until the marked speed is attained. In the

event of speed reduction (flat battery for

6

Fig. D. - Front part of the MIVAR.

7

47

38 35

38

35 47 6

7

Fig. E. - Rear part of the MIVAR.

5

Page 6

THE 60 m MAGAZI N E

The two chambers of this snap-on coaxial magazine are separated by a median

partition and are connected by a light tight

ramp for the passage of the film from the feed

side to the take-up side (Fig F).

THE 120 m MAGAZINE

Bearing in mind the versatility and light

weight of the 60 m magazine which can be

changed almost instantaneously, there are

occasions where a « long take » in excess of

60 m is required and for this purpose a 120 m

capacity magazine is available.

This co-axial magazine retains all the

characteristics of simple threading and snapon action for which the Eclair equipment is

famous.

Fig. G

Fig. F

Fig. H

Fig. I

6

Page 7

Fig. J

36

THE HAND-GRIP

The portability of the ACL is increased by

the use of the hand-grip (36) supplied with the

camera.

Adjustable in the horizontal and the

vertical plane, it permits the choice of the most

confortable position. It can be screwed either

under the camera base or on the right hand side

of the camera (fig K).

To carry the camera, the hand-grip (36)

with its knurled knob (79) - fig. QR - can also be

screwed on top of the camera head.

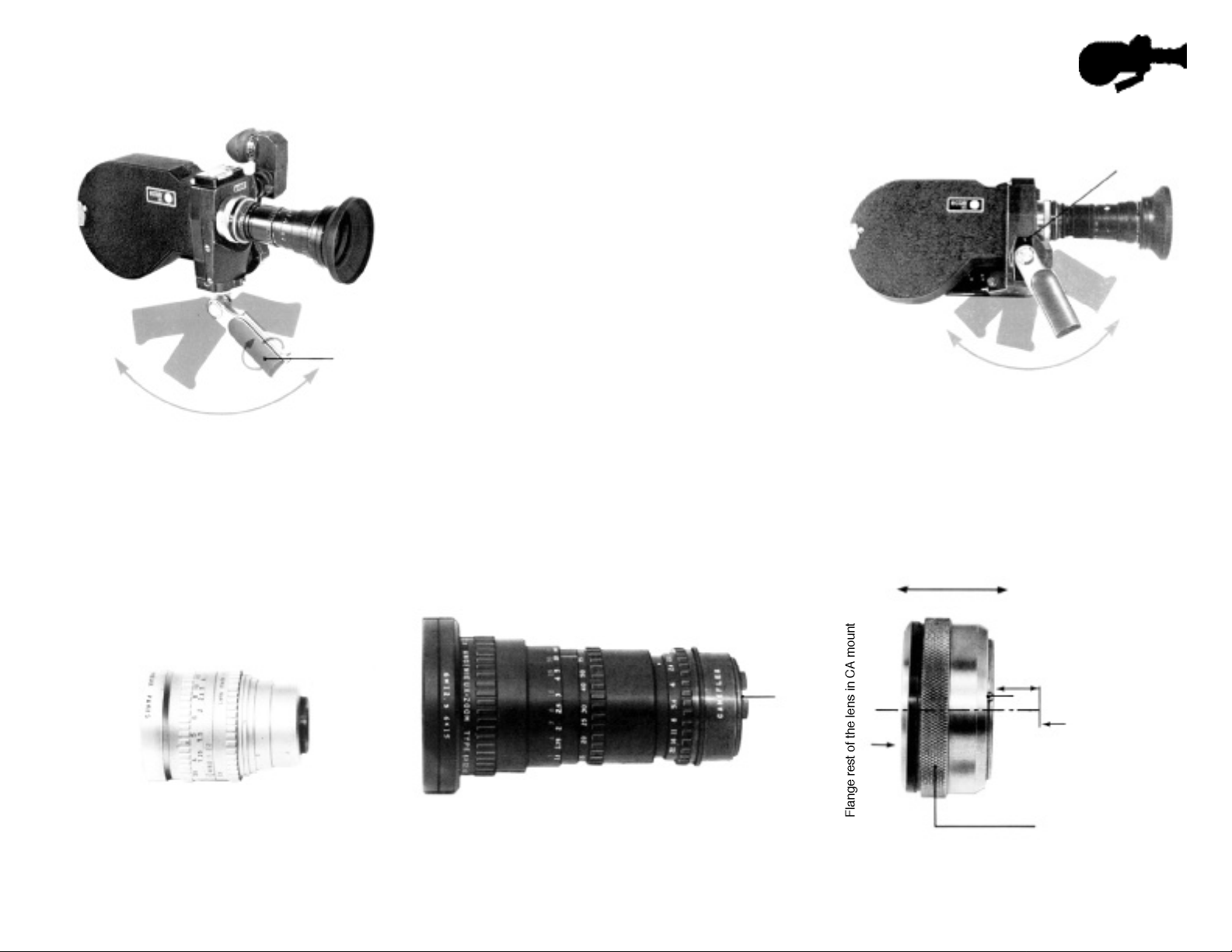

MOUNTS AND LENSES

The ACL has been designed to accept

« C » mount lenses (fig Q, the mechanical back

focal distance of which are 17.52 mm, and also

other professional mounts such as Eclair CA (fig

M) Arriflex, Nikon, etc... the mechanical back

focal distances of which are greater than 17.52

mm.

75

Fig. K

Fig. L

Lens in C mount

Fig. M

Lens in CA Eclair mount

26

48 mm

Ca mechanical back focal distance

C mechanical back focal distance

17.52 mm

24

Film plane

25

Fig. N

Intermediate mount

7

Page 8

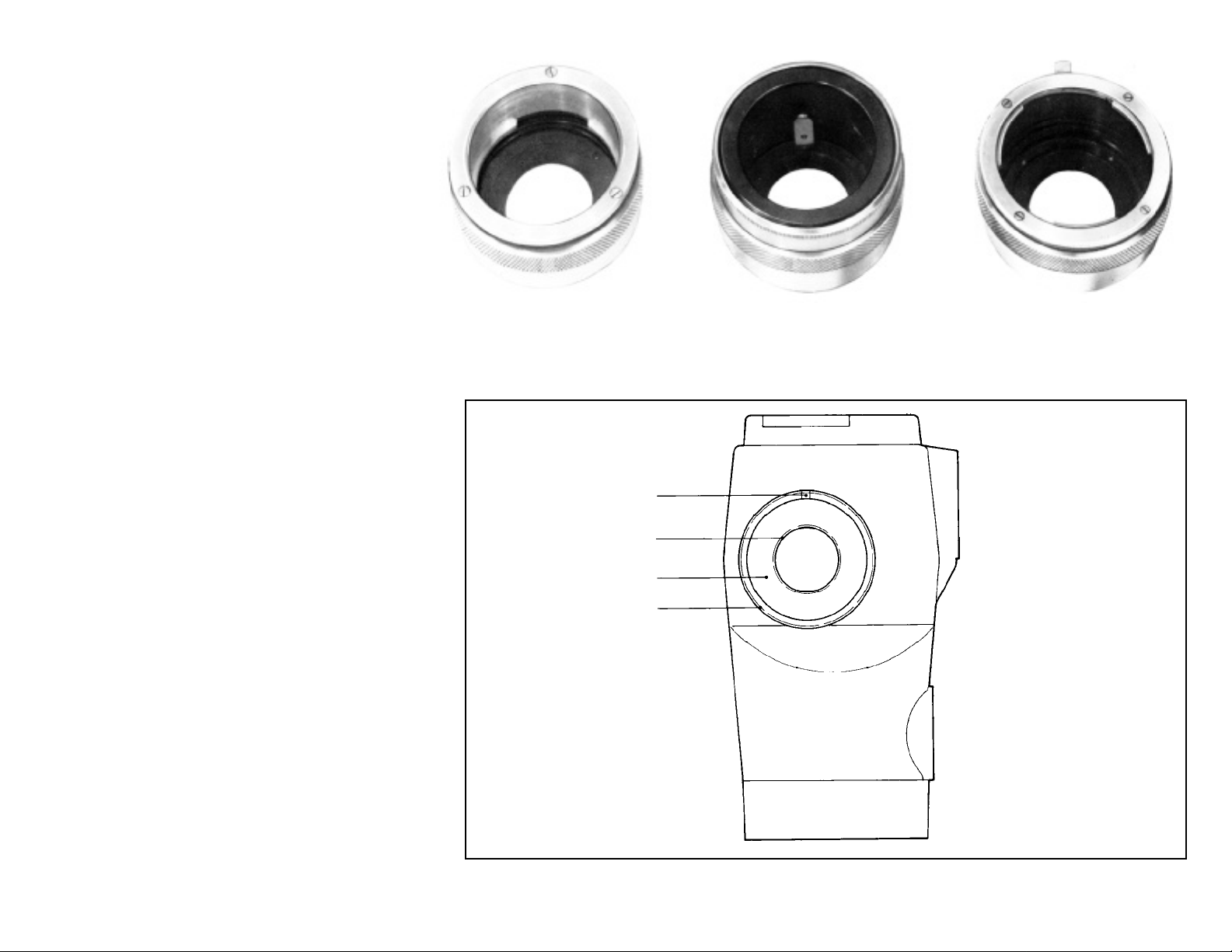

The mechanical back focal distances

(fig N) being different according to the professional equipment manufacturers 48 mm for

ECLAIR (Eclair CA), 52 mm for

Arriflex, 46 mm for Nikon, corresponding

intermediate Eclair TS mounts (Fig P-P’-P”-)

can be supplied for these different makes of

lenses for use with the ACL camera. For Arrif

lex, specify « normal mount » or « new steel

bayonet mount ».

Hence, the ACL lens support (1)

comprises an internal threading (21) the

diameter and the thread pitch or which correspond to the C lenses standards and an

external threading (22) for the Eclair TS

mounts (Fig P-P’-P”); the orientation of the

lens is ensured by the slot (23) at tfie top of

the flange.

ACCESSORIES

The principal additional accessories of an

“ACL” equipment are :

• The 12 volts battery type VR 1,2

• The connection

cable camera/battery VR 1,2 .............

• The rapid charger ...............................

or

• 12 volts battery type VR 4 ..................

• The connection

cable Camera battery VR 4 ...............

• The compact charger .........................

• The connection

cable Charger/battery ........................

• The pilotone module ...........................

• The connection

cable Module/recorder

(according to the make of the recorder)

• The transport case ..............................

Code MIBAC

MIBLE

MIRAP

BAKEL

BABAC

CIBRE

COURE

MODUL

MALAC

Fig. P

Intermediate mount

for lenses in CA mount

23

21

22

Fig. O

Fig. P’

Intermediate mount

for lenses in Arriflex mount

Fig. P’’

Intermediate mount

for lenses in Nikon mount

1

8

Page 9

GENERAL INFORMATION

REFLEX SIGHT

The reflex image is obtained with an

oscillating mirror (14) moving at half camera

speed, which transmits the image formed by

the lens onto the ground glass during the

descent of the film.

The viewf inder (focussing tube) is a

new mechanical /optical realization which

gives an exceptionally bright image.

As on the Eclair 16, the ground glass

gives a field of view greater than the recorded

image, which eliminates the possible intrusion

of microphones, etc... into the recorded

picture. (Fig Q).

This viewfinder - 10 x enlargement can be used for left eye or right eye viewing it

can pivot through 360' parallel to the camera

thus allowing the cameraman to frame and to

focus in the most comfortable conditions

whatever the position of the camera; for

example, he can shoot with his back facing

the subject. The eyepiece is adjustable of ±

5dioptres.

The standard ground glass is engraved with the 16 mm frame (10,2

x 7,4 mm), the TV frame and a cross in the

centre (UER standard).

Gelatine filter holder

Each ACL is equipped with a gelatine

holder 2 (Fig A and R) which is located between

the C mount and the reflex mirror close to the

rear element of the taking lens. Its advantages

are :

• It is not necessary to change filter at each lens

change.

• It is possible to check the presence and type of

gelatine through the viewf inder.

• It eliminates the requirement for front glass

filters for each lens diameter, the price of which

is very high compared to that of gelatine filters

which are readily obtainable.

2

Fig. R

27

• Its position, away from the fi I m plane ensures any small dust or finger marks on the

gelatine that may occur are out of focus on the

final result and rarely visible.

Shutter

Contrary to reflex cameras in which the

mirror mounted at 45' acts as a shutter, the

ACL has a plane shutter of large diameter

completely independant of the mirror (14). It is

placed very close to the film plane with an

opening of 175'. Cutting the image in the

direction of the smallest dimension gives a

perfect exposure, maximum definition and

reduction of jerky effect on some panning

shots. The exposure time is 1 /51 of a second

at 25 frames per second and 1 / 49 of a second at 24 frames per second (page 33).

+

0

-

Fig. Q

9

Page 10

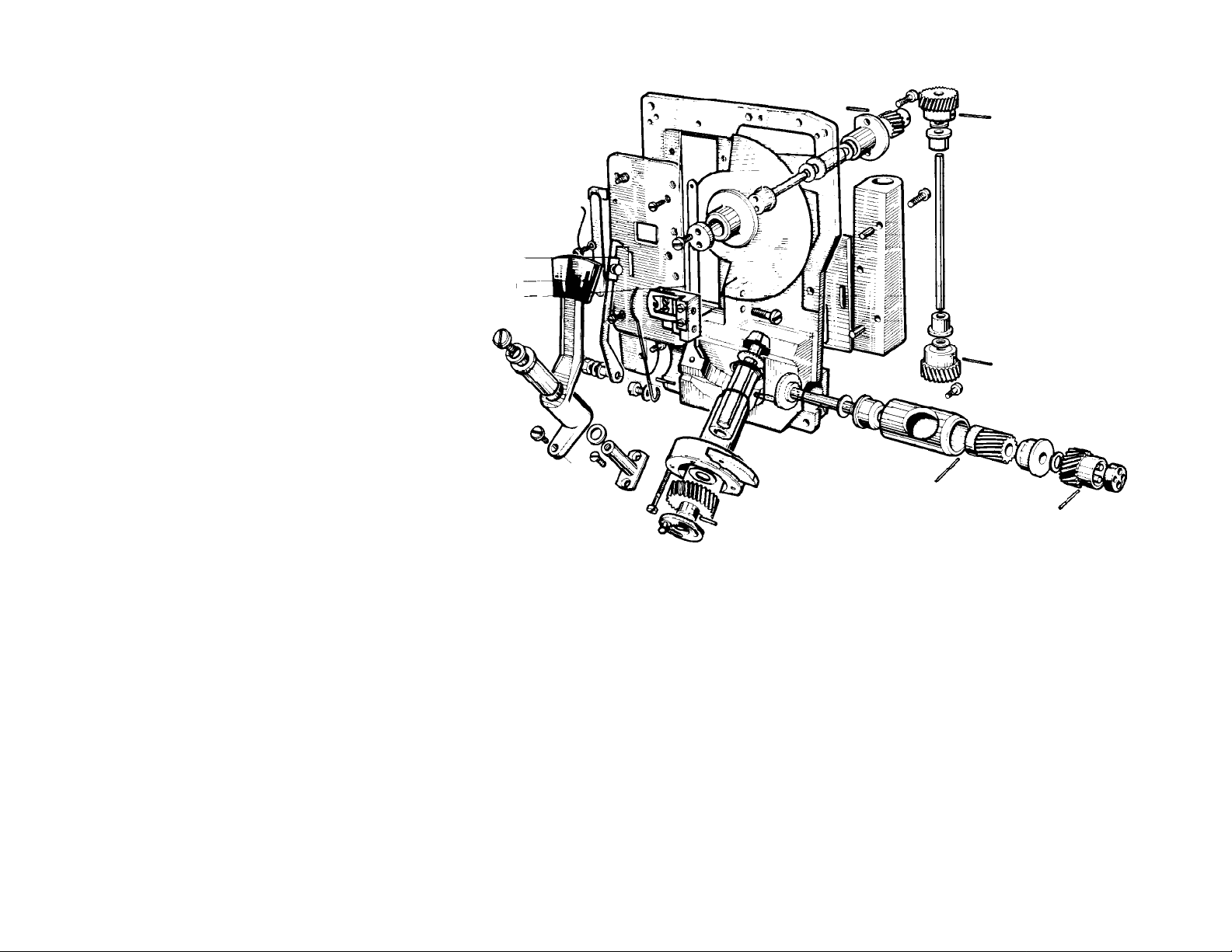

Mechanism

The complete silent mechanism is

mounted on the mechanism plate which

greatly reduces the time required for the

normal overhaul and cleaning which we

would strongly recommend to be carried out

by one of our agents.

The claw movement (13) is controlled

by an excentric and a fixed cam (39), the

security is ensured by a counter-cam.

The four drive shafts run in selflubrificated bearings and the camera mechanism should NEVER be oiled.

As already indicated page (4), the

aperture plate of hard chromium-plated steel

has, on the left, a fixed guide (11) which is the

edge reference for the film and a spring

loaded guide (12) on the right, which maintains the film against the fixed guide.

The two guides (29-30) fig B position

the magazine nose onto the mechanism

plate.

Fig. S

13

14

39

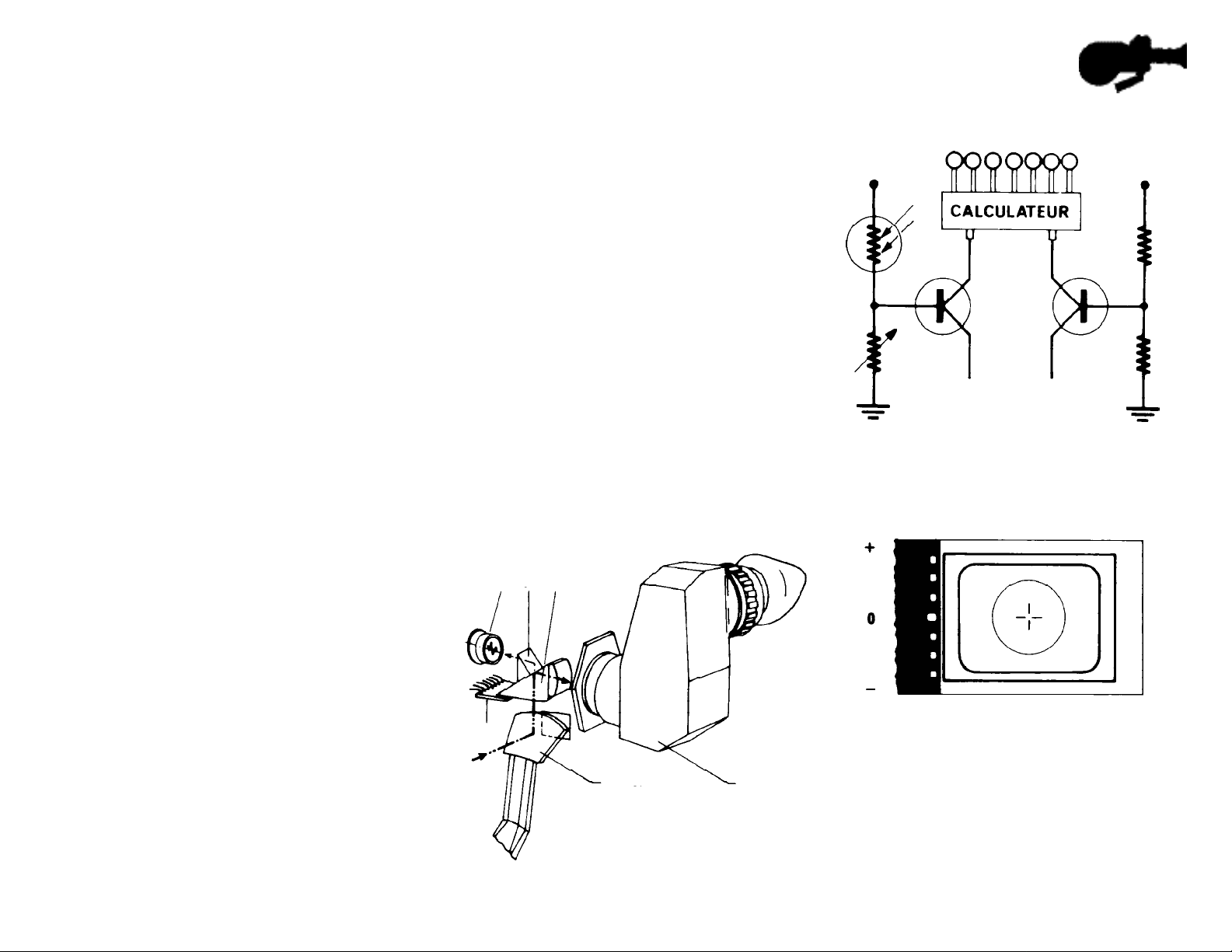

Exposure indicator

The ACL camera had to have a very

safe « Exposure Indicator device » because

of the professional work it must ensure. It

could not be question of an ordinary photocell system due to the fragility of moving

parts; on the other hand, a 100% automatic

device leaves the cameraman no change of

artistic creation.

The basic idea is to leave the cameraman freedom to determine the exposure of

the film and thus give him the possiblility of

working according to his own technique; in

other words he must have the possibility of

10

adjusting the diaphragm if he needs a special

effect by under or over exposure, e.g. contrast.

Before filming, the operator sets the

exposure indicator with the aid of his professional photo- cell exposure meter indicating the

diaphragm opening (stop) of the lens; it gives

him a reference lighting intensity « EO ». The

camera being connected to the battery, he

adjusts the sensitivity potentiometer (34) so that

only the middle diode EO, visible in the

viewfinder, lights up. Thus the camera is now

matched to the exposure meter.

During filming, if the lighting intensity of

the subject varies, the control diodes visible in

the viewf inder will be seen light up either + or . The operator wiII then correct the diaphragm

of his lens so as to maintain the lighting intensity on the film to a value of EO, if he deems it

necessary.

Page 11

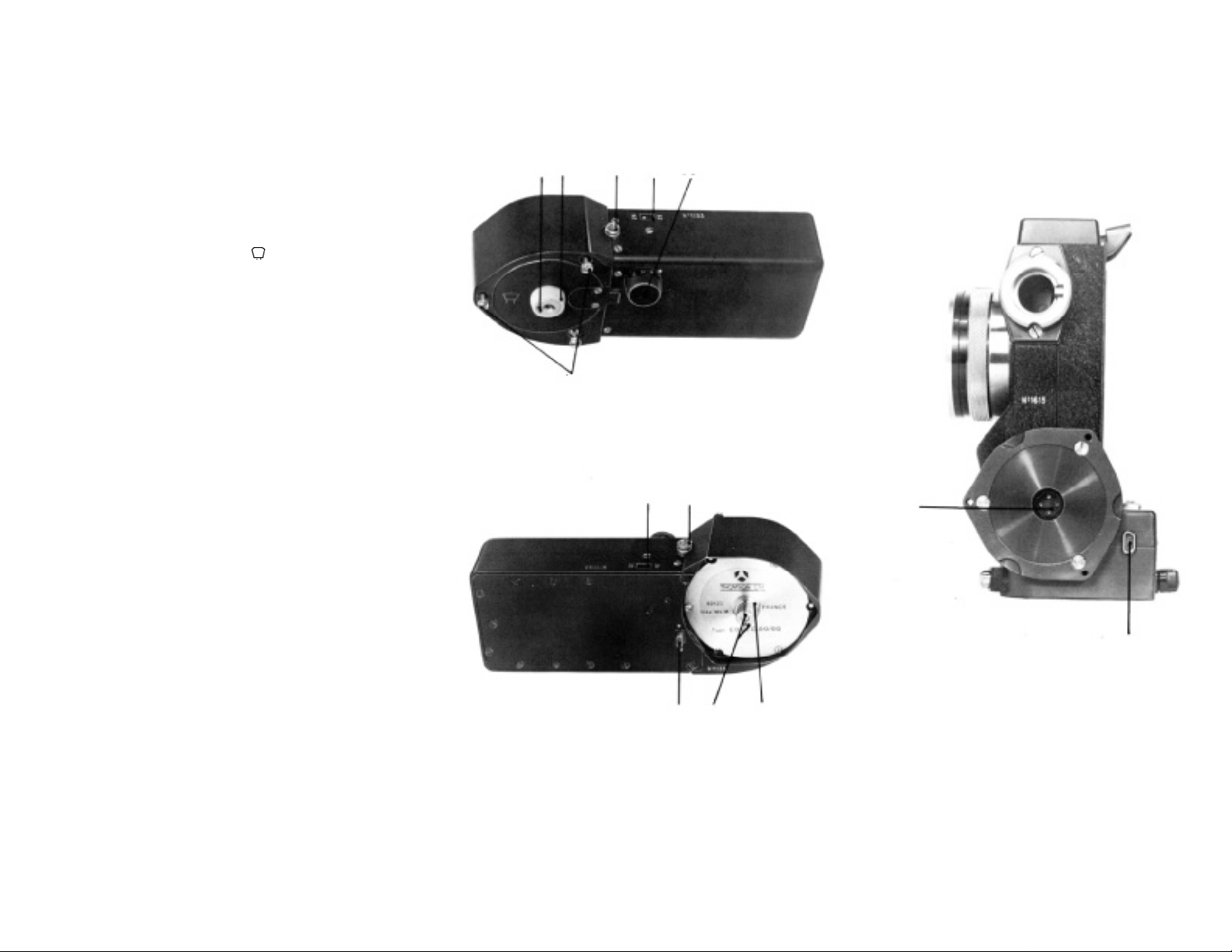

ELECTRONIC BASE 150 E

This unit (8) forms a flat base

for the camera body and consists of:

• 1 Jaeger socket (19) for power supply

to the camera.

• 1 Sliding on/off switch (32) at the front part.

• 1 Cannon socket (33) for the accessory

power supply.

• The stabilized 5 volt supply.

• 1 Souriau socket for electrical connections

with the camera head.

• 1 sensitivity potentiometer (34)

for adjustment of the exposure indicator.

• 1 Clapper switch (20).

This flat base is provided with the stan-

dard congress 3/8 tapped hole for tripod mounting or hand- grip mounting (36).

Fig. X

Magnetic recorder side

Fig. Y

34

19

20

PILOTONE MODULE

The ACL servo-control led crystal motor

33

8

allows the shooting of sync. sound without any

cable connection between the camera and the

tape recorder if the latter is equipped with a

crystal controlled motor (e.g. Nagra 4,

Perfectone E P 6 A2, Stellavox). Such a system

(diagram KL) does not permit the use of the

clapper.

If, however, the two units Camera and

recorder are connected by a cable, the clapper

will function (diagram L M). See additional

information page 29 for connection and use.

When the recorder has no crystal, the

synchronization can be ensured by using the

Eclair pilotone- module (option) which contains

its own signal.

THE ECLAIR PILOTONE MODULE is

contained in a metal cover. Its size: 92 x 66 x 23

mm is slightly larger than a packet of 20 cigarettes (fig. Y and Z). it is a crystal pilot f req

uency generator 50-60 and 100 H Z.

8

32

Fig. X’

Camera side

Fig. Z

11

Page 12

THE BATTERY (MIBAC)

The low torque ot the camera and the

high efficiency output of the motor have

allowed the construction of a low power

battery (1,2 amp-hour) which at 20°C (68°F)

provides power for ten 60 m (200 ft) magazines i.e. for about 600 meter of film. This

battery (37) weighs less than 1-4 lbs (640

grammes). It is a Saft type VIR 1.2 ten cell

cadmium-nickel which is enclosed in a polyurethane case (48) fig. AB.

The battery is equipped with a textile

shoulder strap although its small size will

allow it to be slipped into a coat or trousers

pocket.

The connections with the camera and

the pilotone-module can be made from either

of the Jaeger 4 pin-sockets (49). The central

Socapex socket (50) is provided for the rapid

charger.

CABLE. The same type of cable

(MIBLE) is required for connecting the camera, the battery and the pilotone-module. It is

fitted with two Jaeger plugs ref : No 530800.

Our V.R. mini-cell battery has been

conceived for a recharge in less than 30

minutes by means of our MIRAP charger

connected to the mains between 115 and 220

volts A.C.

THE CHARGER (MIRAP)

The MK2 charger specially made for our

MIBAC battery is automatic and very simple to

use.

It ensures a charge feed regulation of

± 20 % for a variation of the main supply tension

of ± 10 %. It stops the high speed automatically

as soon as the battery has attained a tension

which is related to the charge rate and the

temperature of the battery.

The cut-off precision is approximately 1

Immediately after the high speed charge has

been cut-off, the charger switches automatically

to the low charge rate.

The thermostatic protection is ensured

by a thermal limiting device which cuts off the

charge if the battery temperature becomes

abnormaly high e.g. because of irregularity in

the cut off safety circuit

Diagram CD

48

Fig. AB

12

49 50

49

37

Diagram DE

Fig. BC

Page 13

BATTERY (BAKEL)

CHARGER (CIBRE)

If a battery having a larger capacity

than the MIBAC battery is desired, especially

if the camera is often used at higher speed

than the standard, we can supply the BAKEL

battery (of the Eclair NPR 16) type VR 4 (4

amp-hour). It is a 12 volts cadmium-nickel

battery - Fig EF - with a discharge controller

(Schoeller galvanometer) and is supplied in a

plastic box made of unbreakable black polyethylene with a carrying textile belt.

It is composed of 10 insulated cells

SAFT type and weighs 1,650 kg; its dimensions are 230 x 150 x--40-mm and its capacity is equivalent to ten to fifteen 120 m (400 ft)

reels. Its use necessitates a connection cable

« Camera/ Battery » (BABAC), a 220/110 v 12 V charger (CIBRE) and a connection cable

« Charger-battery » (COURT).

The BAKEL battery can be also suppl

ied in a leather belt with built-in charger, its

code is BACHA. Its weight 2.750 Kg; only the

connection cable « Camera/ Battery »

(BABAC) is necessary.

The new compact charger CIBRE type

76 is very smal I : 125 x 64 x 40 mrn and

weighs only 420 grammes.

An internal tension selector permits its

utilization on 220 or 110 volts; safety is ensured by a 500 mA fuse. A 2 metre connection cable « Main/Charger » is supplied.

The CIBRE charger bears, at one end,

a 3 pin socket (mains side) and at the other

end a 4 pin Amphenol socket for connection

to the battery; two control lamps : one red and

one green light up as soon as the charger is

connected to the main. The green light cuts

off when the load is over.

The select the voltage in the charger

(110 or 220 volts) or to replace the safety fuse,

unscrew the 4 screws of the lid ; take- off the lid

without dropping the screws, select the tension

or replace the fuse, put the lid back and tighten

the screws.

Fig. EF

Fig. FG

CARRYING CASE

Made in shape of a rigid suit-case(fig

GH) and not like an ordinary transport case, the

framework is anodized aluminium supporting

two shells in ABS which is a very high impact

resistance material. The inside is entirely padded with expanded polyethylene cut out to the

form of a complete ACL equipment : Camera

with motor, viewfinder and 60 m or 120 m

magazine mounted, extra 60 or 120 m. magazine, battery, charger, cables, pilotone module

and miscellaneous (fig. HI).

Fig. GH

Fig. HI

13

Page 14

CABLES AND PLUGS

Taking into account the preceding

information, will you please find hereafter

diagrams that will help you to understand

easily

the instruction manual; they will also help you

should you have to order cables or plugs you

may need.

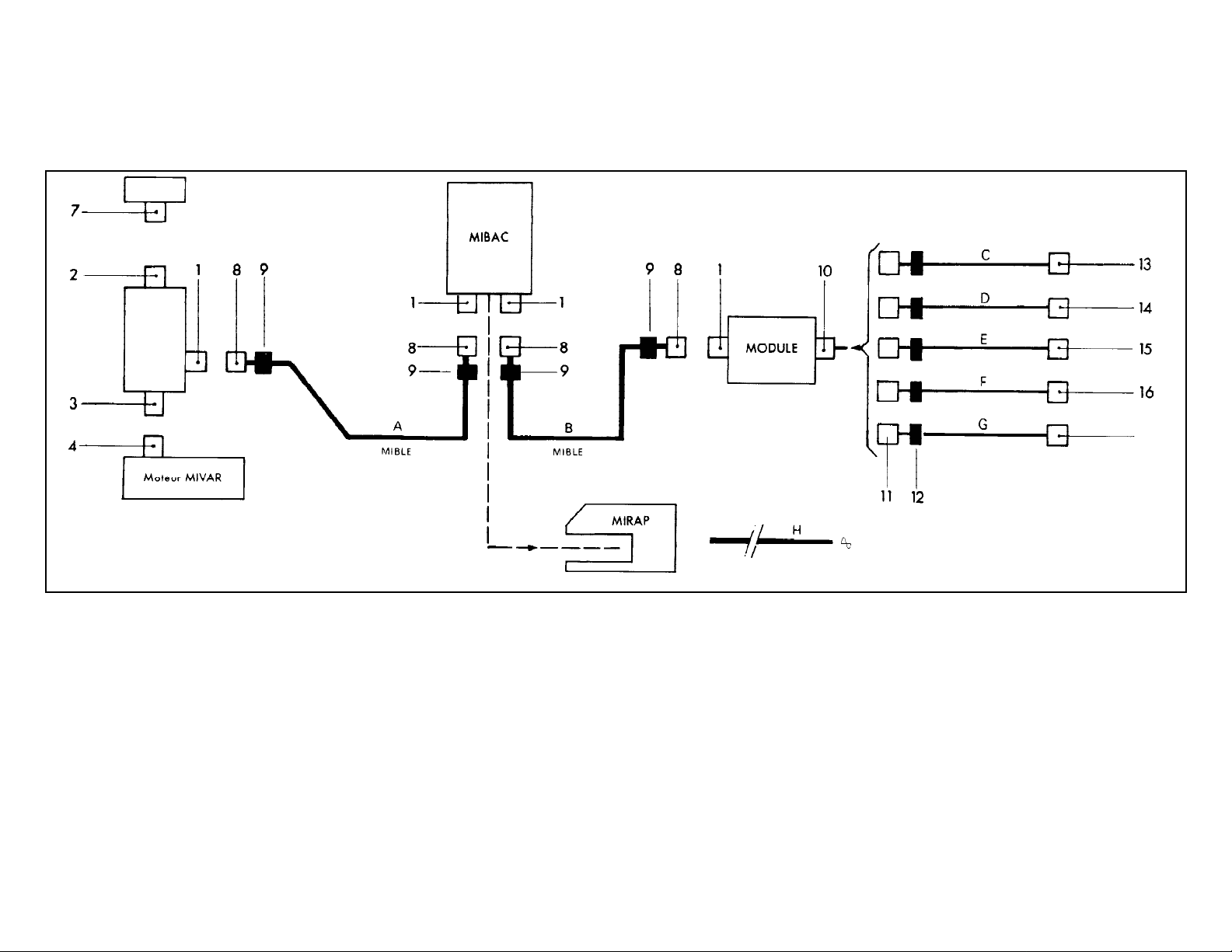

Diagram JK

1 - JAEGER female socket 533800 Camera-battery-module A - Feed cable

2 - CANNON female plug MDB 19 SH 031 Camera B - Connecting cable battery/camera

3 - CANNON female plug MD 19 SH 031 Camera C - Sync cable Nagra iii

4 - CANNON male plug MDB 19 PH 031 Motor D - Cable Nagra IV

7 - CANNON male plug MD 19 PH 031 Handgrip side support E - Sync. cable Perfectone EP6 A II

8 - JAEGER male plug 530800 Mible feed cable F - Sync. cable Stellavox

9 - JAEGER cable flange 530332 Mible feed cable G - Sync. cable Uher (*)

10 - JAEGER female socket 533272 Module H - Feed cable mains to battery charger

11 - JAEGER male plug 530273 Sync. cable

12 - JAEGER cleat 530371 Sync. cable

13 - TUCHEL plug 3401/1 ou /2 Sync. cable for NAGRA III

14 - TUCHEL plug 3300/1 ou /2 Sync. cable for NAGRA IV

15 - Jack PL 55 Sync. cable for PERFECTONE EP6 A II

16 - PREH plug 7140-4-250 Sync. cable for STELLAVOX

(*) In case of « Uher 1000 Report »

recorders state serial number of the

machine.

14

Page 15

UNITS CONNECTIONS

Schema KL Schema LM

Equipment

• Camera with crystal controlled

motor

• Recorder with crystal controlled

motor

Schema MN

Equipment

• Camera with crystal controlled

motor

• Recorder with crystal controlled

motor

• Pilotone module fed by the

camea battery

Possibilities

Sync. without connection cable

No clapper

Possibilities

Sync. with connection cable

Clapper

Equipment

• Camera with crystal controlled

motor

• Recorder with crystal controlled

motor

Schema NO

Equipment

• Camera with crystal controlled

motor

• Recorder without crystal controlled motor

• Pilotone module fed by an external power

supply: MIBAC 12 volts battery whenever

possible

Possibilities

Sync. with connection cable

Clapper

(shunt 3 and 4 by the Jaeger plug)

Possibilities

Sync. without connection cable

No clapper

15

Page 16

16

Page 17

INSTRUCTION MANUAL

2nd PART -

When you receive your equipment for

the first time we recommend you examine

every unit individually in accordance with the

information given in this brochure.

After that, you will be able to follow the

instructions for use more easily.

MOUNTING A “C” LENS

• Remove from the camera the protective cap

of the lens mount.

• Remove from the lens the cap protecting the

thread.

• Remove any dust from the flange with your

finger.

• Screw in the lens in 21. Fig. 0.

If the distances and stops engraved

on the lens barrel cannot be read by the

cameraman in the normal operating position :

take the lens off the camera.

The threaded ring at the bottom of the

lens is mounted in contact with a special

spring washer. Without touching the rear lens

element, press down firmly on that threaded

ring and turn it to modify the orientation of the

distances and stop marks with respect to the

thread start.

MOUNTING AN ECLAIR “CA”

MOUNT LENS

• Remove the protective cap and the guard ring.

• Remove any dust from the flange with your

finger.

• Locate the intermediate TS-CA mount (fig. P)

on the lens support plate ensuring that the

locating pin (24) enters the slot (23) of the

flange.

• Screw up the retaining ring (25).

• Position the lens so that the slot (26) in the CA

mount is vertical. 9 Push the lens into the TS

intermediate mount and lock by turning the lens

clockwise.

As you will notice the Eclair intermediate

TS mount is exceptionally robust with a large

locating diameter and thrust face. The use of

lens supports with the mount is not necessary.

It is strongly recommended that each

zoom lens is fitted with an intermediate TS

mount to prevent the deterioration of the limit

stops on the lens after repeated locking in place

on the camera.

17

Page 18

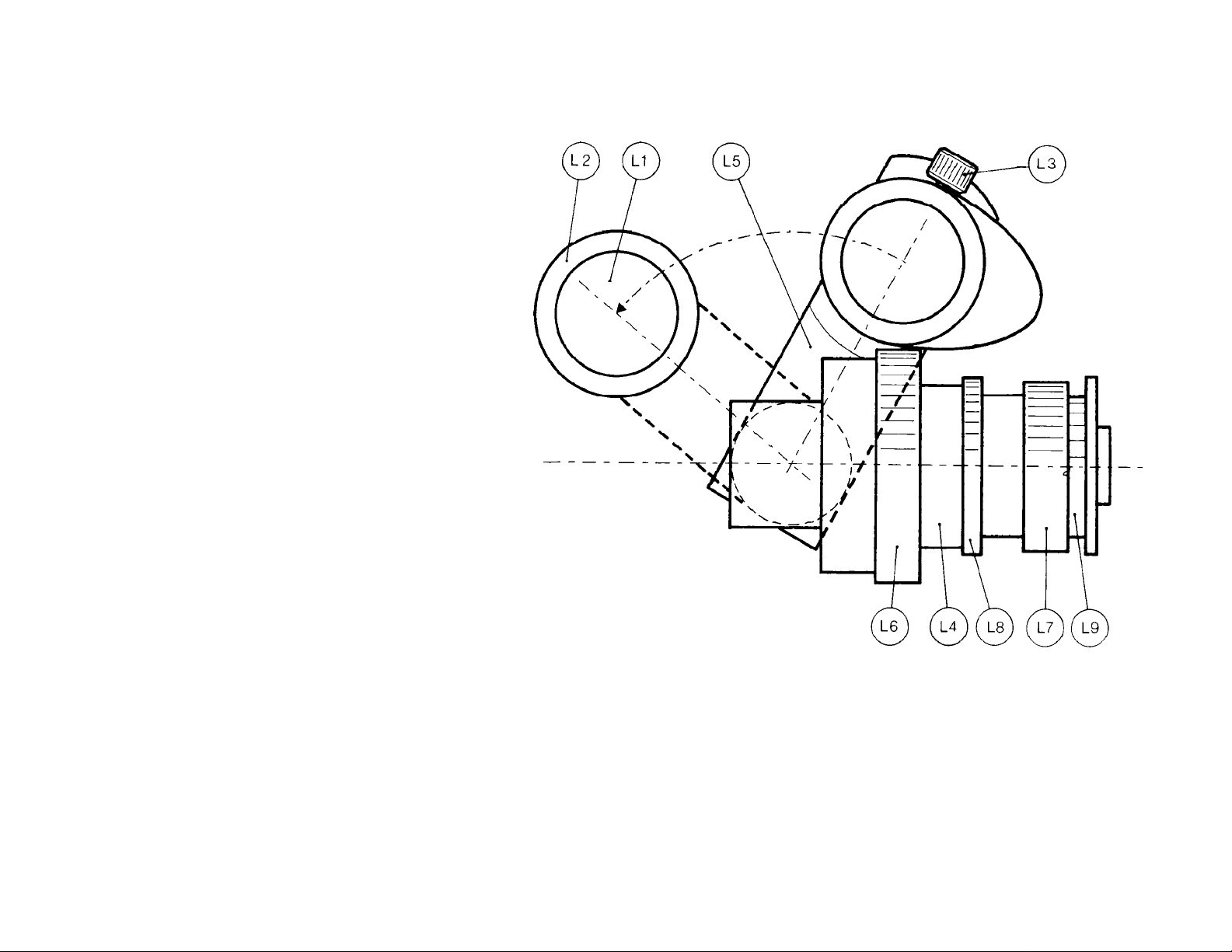

DIOPTRY ADJUSTMENT

OF THE VIEWFINDER

Legend of the external parts of the viewfinder:

Ll - Eyepiece with shutter and rotatable rubber

eyecup.

L2 - Control ring of eyepiece shutter.

L3 - Locking knob of the dioptry adjustment ring.

L4 - 360' rotatable viewf 1 nder unit.

L5 - Eyepiece support with rocking motion

for left and right eye sight.

L6 - Locking ring of the rotation of the eyepiece

support.

L7 - Adjusting ring for partial positioning

of the ground glass image.

L8 - Clutch for final adjustment of the ground

glass image.

Everyone having a different keenness of sight, it

is necessary for the camera user to set exactly and then

lock the dioptry adjustment which corresponds to his

vision. This can be done with or without lens mounted

on the camera.

Adjustment with a lens:

1. Place L5 to the right or to the left according to the eye

you normally use.

2. Make sure that the reflex mirror is in the front of the

aperture, if not, turn knurled button 31 which controls the

motor axle (see page 24, par. 5)

3. Turn control ring L2 to open the eyepiece shutter.

4. Focus the lens on infinity.

5. Diaphragm wide open or slightly closed to darken the

ground glass.

6. Loosen knob L3 and turn slowly in one way and in the

other the dioptry control ring until the frame and cross

engraved on the ground glass are perfectly sharp.

7. Take note of the number of dioptries in + or - that

corresponds to your sight. Lock the dioptry control ring in

that position by tightening the button L3.

This setting should always be kept as it will permit

you to focus sharply at any distance.

18

Fig. PQ

Page 19

Adjustment without lens :

Direct the camera towards a well

lighted part (sky, for example) and follow the

preceding instruction 1-2-3-6- and 7.

Instruction for use

Position L5 for your left or your right

eye, as needed. Make sure the dioptry adjustment is correct and the button L3 is perfectly

tightened.

If the image on the ground glass is not

optically horizontal, turn ring L7 in one way or

the other to level the image. If you.come to

the thrust before the image is in the right

position, turn L8 in the reverse way and move

again L7. Once the image has been so

erected the viewf inder can be pivoted

through 3600, a Wollaston prism will keep it in

the correct position.

If you shift L5 from left to right or viceversa the image will reverse gradually until it

is up side down; just turn L8 to declutch L7

and turn same to reset the image to its normal position. A positioning "clic-stop" is

provided in L6 to set the eyepiece Ll in horizontal and vertical positions.

GELATINE HOLDER

Fitting a gelatine to the holder

• Pull out the gelatine holder

• Open the holder by pressing the button (27)

• Place a 2" margin (5Ox5O mm) gelatine

in the holder and close it.

• Cut the gelatine closely to the shape

of the holder with a razor blade.

• Replace the holder in the camera, chamfered

side forward.

• The correct positioning of the holder can be

verified by checking that the aperture

is concentric with the C mount aperture.

NB. Never place more the one gelatine in the

holder.

Always film with the holder in place (with

or without a gelatine) to avoid the possible

fogging of the film.

The fact of filtering behind the rear

element of the taking lens may cause a slight

alteration of the focussing distances engraved

on the lens which will be automatically compensated if focussing is done through the reflex

viewfinder.

FITTING THE HANDGRIP

Under the camera :

• Screw the handgrip support - Fig. QR into the electronic base using the knurled

ring (27)

• Fix the handgrip (36) in the hole (80)

of the support.

• Loosen the ring (79), set the position

of the handgrip and tighten the ring (79).

• Loosen the half-moon (81), set the handgrip

at the desired angle and retighten lock (81).

Onto the right hand side of the camera:

• Fix the handgrip (36) to the side support (75)

and lock it in the best position by means of lock

(81).

NB. The unit (79-80) - Fig. QR - is not used in

this case.

79

80

Fig. QR

81

78

Fig. RS

36

75

82

Fig. ST

77

76

77

19

Page 20

FUNCTIONS OF THE

ELECTRONIC BASE 150 E

a) On/off switch (32)

This is a double action switch : it puts

under tension the diodes of the exposure

indicator, without starting the camera. Or it

sends the power supply to the motor to start

the camera. tee page 24 detailed instruction.

b) The clapper switch (20)

In the central position this switch

provides no clapper.

In outside right position : the clapper is

automatic and provides fogging of the film for

0,3 secondes at each start.

In inside left position : the clapper

functions (0,3 seconds) at every manual

pressure when the camera is running; this

allows, for example, to clap at the end of

filming, before switching off the motor.

Thus, the clapper ensures two functions 1 0 - Automatic fogging of the film during

0,3 seconds at each start of the camera or

manually at any moment. 20 - The supply of

an 8 volt signal to the battery during 0,3

seconds (bloop) if the pilotone module is

connected to the battery and the recorder, the

signal triggers a 1 Kc signal on the recording

tape.

c) The running signal:

A 12 volt signal available from the Jeager

socket supplies the pilotone module and

ensures that the module only produces a 12

volt signal when the camera is running.

This signal can also be used to start a

sound recorder from a distance.

20

32

Fig. TU

d) The output signal :

1 - Tachometric signal

This 3,8 volts square signal (peak to

peak) is supplied by the motor. Its frequency is

given by the motor speed multiplied by 40, that

is to say 1000 Hz for 25 images per second and

960 Hz for 24 images per second. This signal

directly supplied by the motor can be used for

various purposes after it has been divided.

2 - Crystal signal (for MIALA motor only) :

This is a 100 mV sine signal (peak to

peak). Its frequency is 1024 KHz for 25 frames

per second and 983.04 KHz for 24 frames

persecond.

Schema UV

Schema VX

To see the

big-ass view

go to page 35!

Page 21

LOADING THE FILM

60 meter (200 ft) magazine:

To load a film on a 2" (50 mm) core,

proceed as follows:

Feed side (fig. XY)

(to be done in a dark room or in a changing bag)

• Put the magazine on its side, nose to the left.

• Depress the safety lock button and turn the lid

catch anti-clockwise; lift the part of the latch that

projects over the edge of the magazine. At the

same time pull the lid backwards to clear it from

the magazine.

• Lift the counter arm (53) which locks up

utornatically.

• Holding the film reel in the left hand position,

feed the end of the film (about 30 cm) between

the two rollers at the entry of the guide (54).

Note: the emulsion must be towards the exterior

of the magazine between these rollers.

• Push approximately 15 cm (6") into the guide.

• Place the core onto the support f lange (55).

• Replace the Iid:

insert the spring strip, at the left of the lid, into the

magazine body (56), push the lid down and

forward to locate it in the body and turn the lid

catch clockwise to lock the lid.

• The counter arm (53) drops into place automatically as its catch (57) is released by the Iid.

58

73

72

59

74

56

60

57

65

53

55

61

54

• Open the two guide shoes (64-67) by pressing simultaneously the two catches (65).

• Place the film behind the two rollers and

between the sprocket (66) and the upper guide

shoe; make sure that the sprocket teeth are

perfectly engaged in the perforations.

• Close the upper shoe toward the sprocket; it

locks automatically.

• Place the film between the sprocket and the

lower shoes (67); adjust the loop size by

pulling the film upwards outside the magazine

until the loop is level with the magazine locking

tongues (68). This is important.

68

62

Take-up side (fig. YZ)

(this can be loaded in, preferably in the shade)

• Turn the magazine and lay it on its side with the

nose (58) to the right.

• Remove the lid.

• Pass the film between the rollers (59) and (60)

and place the end into the upper film guide (61)

of the nose; if necessary press on the pressure

guide (62) to aid the entry.

• Pull the film through sufficiently to introduce it

into the lower film guide (63).

• Pull 50 cm (20") of film into the magazine.

65

S

63

58

64

• Close the lower shoe (67) against the s

69

procket and divide the film equally over and

under the film separator (69) in the magazine

66

nose.

67

• Wind the film onto the core and place it on

the flange (70). This flange is interchangeable

with flange (55).

• Replace the Iid.

Note: the « S » part is an audible warning unit

(see page 25).

21

Page 22

Loading a daylight loading spool

to the magazine

• Choose a shaded area if possible.

• Pull and lift vertically the flange catches (71)

on the supply and take-up sides.

• Remove the flanges (70).

• Load the film as for a core load.

• Lock the spools in place with the catches

(71) ensuring that they are pushed firmly

home.

NB. In order to ensure the lowest noise level

check that the spools are not warped and that

they are firmly locked onto the axle as indicated above.

If it is not intented to use the magazine

at once, place the protector on the nose.

Take-up side (fig. AC)

• Put the magazine, flat on a table, nose (58) to

the right.

• Take-off the lid as per the supply side.

• Load the film as per a6O rn magazine.

Note - The same recommandat ions for the fiIm

loop must be applied.

Footage counter :

As in the 60 m magazine, the counter

arm comes into operation automatically. Outside, on the feed side, two dials engraved in

meters and in feet move in front of a guide

mark and respectively indicate the amount of

unexposed film used : either a 120 m reel on a

50 mm core or a 60 m daylight spool.

Fig. ZZ

The counter (72)

As already noted, the counter arm

comes into operation automatically. The

pointer (73) indicates the amount of unexposed film remaining; a red portion of the

counter dial indicates the imminence of the

end of film.

120 m (400 feet) magazine:

Loading the 120 rn magazine in dark

room on a 2" (50 mm) core:

Supply side

• Place the magazine, flat on a table, nose

(58) to the left.

• To remove the I id, press on button (83) and

turn downwards the white lock (84) for about

20 mm.

• Lift slightly the rear part of the lid and pull it

to the right to disengage the spring which

maintains the front part of the I id to the nose.

• Load the film according to the information

given for the 60 rn magazine.

58

Fig. AC

70 (55)

71

83

84

22

Page 23

MOUNTING THE MAGAZINE ON THE

CAMERA:

Before snapping on the magazine,

check the loop and ensure that the aperture

plate (10) is clean as well as the side guides

(11-12), make sure that the pressure guide

(12) is working correctly.

Make sure also that the outside loop

of film is equalized (up and down) in front of

the gate.

With the magazine tilted backwards

(fig. G) place the lower part of the magazine

nose at the bottom of the aperture plate, the

magazine drives shafts (18-74) are aligned.

Pivot the magazine on its locating

points and push it at home. The lock operates

automatically and a sharp click indicates that

the magazine is firmly in place.

16

17

The safety catch 17 of the lock 16 will

avert accidental disconnection of the magazine that could be caused by a chance manipulation of lock 16.

To remove the magazine:

• Hold the magazine by the top, the camera

being supported by the other hand.

• Lift up the safety catch 17 with the top of the

fore finger.

• Press on lock 16 with the forefinger.

• Pull the magazine down and back to clear it

from the camera.

Fig. G

23

Page 24

STARTING THE CAMERA

Having fitted a lens and the magazine

on the camera and checked the dioptry

adjustment of the viewfinder:

• Attach the battery to the camera with the

cable MIBLE (or with the cable BABAC if you

are using a BAKEL battery).

• Make sure that the motor has been set at

the right speed : for 24 frames per second,

move the switch (38) to the right so that the

white spot will be in front of 24. Turn the knob

35 so the letter N faces the datum mark. For

25 f.p.s., move the switch (38) to the left to

have the white spot in front of 25; the knob 35

should be placed as indicated above, i.e.

« N » in front of the datum mark.

• For other speeds : 8-12-50 and 75 f.p.s.

place the desired speed engraved on the

knob 35 in front of the datum mark.

• Frame and focus through the viewfinder. If,

by chance the reflex m 1 rror is not in the

viewing position, adjust-it by turning the

knurled knob (31) anti-clockwise. Normally,

the MIVAR motor always stops the camera in

viewing position (page 5 par. 3).

• Set the clapper switch to the required

position : central : no clapper right : automatic

clapper at each start. manuel clapper is

operated when the switch is moved to the left

(see page 27).

Start the camera by pushing the button

(32) in and sliding it to the left-position-3- (towards the motor) or by moving the side microswitch 76 upward after the button 32 has been

pushed to the right- position 2-.

• The stop in viewing position (shutter in front of

aperture) is automatically obtained if the microswitch 76 has been used. It is also obtained if

the switch 32 is brought back from position 3

« run » to position 4 « stop ».

• When the camera has been stopped by the

switch 32, from position 3 to position 1, the

reflex may not completely cover the aperture;

turn knob 31 anti-clokwise.

• When the camera has been stopped, the

warning light 47 on the motor body remains lit a

few seconds and then goes out. It this lamp

lights up during f liming, it indicates the battery

is flat or motor is out of phase.

1°

It is important to resume the 4 functions

of the switch 32 on an ACL equipped with

electronic base 150 E incorporating the Exposure indicator.

Pos. 1. The switch (32) being in central

position is « off » position. When depressing

the button (test position), the exposure indicator is put under tension and the LED diodes

light up.

Pos. 2. When sliding the switch (32) to

the right, (looking though viewfinder) the test

position is retained (camera stopped) for

determination of the diaphragm stop.

The starting and the automatic stop in

viewing position can be obtained by the switch

76.

Pos. 3. The switch 32 being slid to the

left starts the camera and the LED remain

illuminated.

Pos. 4. The switch 32 being slid back to

the right, the LED remain illuminated the

shutter wi ll stop in viewing position.

2°

24

3°

Fig. CE

4°

Page 25

Audible warning device in magazine:

This system S (fig. YZ) also called

« ghost indicator » functions if the film loop is

resorbed; it produces a clicking sound which

warns the cameraman.

In that case :

• Stop the camera and remove the magazine.

• Check the loop and divide it normally.

• Re-mount the magazine on to the camera.

• Restart the camera.

Should this occur again, check in a

changing bag the threading of the magazine;

you will probably find a film jamming due to

some damaged perforations.

EXPOSURE INDICATOR

Characteristics

• Type of photometer: to adjust by comparison

manual setting of aperture ring.

• Type of measurement: behind the lens (T.T.L.)

semi-spot 4 mm dia, angle 100 with F. 25 mm

semi- spot 7 mm dia, balanced at 50%.

• Sensitivity range: 25 to 400 ASA.

• Sensing element : rapid response C D S cell.

compensated sensitivity range.

• Display: 7 Light emissive diodes (LED) resolution interval, 0,5 dia/1 dia/1.5 diaphragm.

• Light computation : resolving prism (= 25 % on

the CIDS cell) neutrallsing the semi-reflective

deposits.

• Compensation Stop-go: electronic compensation; automatic compensation.

Diodes LED

This being temperature compensated

(-25° to + 60°C) the setting remains constant

for several weeks.

The measuring system and display

assembly is situated immediatly next to the

ground glass, supporting the viewfinder frame

(fig. T).

A resolving prism (01) which is semiref lecting is stuck to the prism block (02) and

ref racts part of the I ig ht rays emerg 1 ng

from the ground glass towards the photo

resistive element (03).

The light intensity received by the

photo resistive element is compared with the

reference determined by the gauge, and

intensity already memorised by the computer

(fig. U).

The seven diodes are mounted on a ceramic

base situated next to the ground glass,

outside the field of view (fig. T); they indicate

the zero or the difference in aperture (either +

or The maximum recordable difference is ±

1.5 stops, each diode representing about one

half stop (fig. U).

04

03

01

02

reflex

Fig. U

Fig. V

viseur

Fig. T

25

Page 26

Advantages of the system

• Compactness of the measuring assembly

and display situated next to the ground glass

This lay out requires the minimum of optical

components, no reflection, no intermediate

optics, (no risk of misalignment).

• System of setting up by comparison

No setting imposed by the manufacturer, the operator is the judge of the optimum

fighting for the film.

No variable density disc, no compensation for non-linearity of the CDS cell

respose.

No corrections to be made on the

sensitivity adjustment in spite of ageing and

the history of the CDS cell.

• Application of LED:

Unlimited life for the whole unit (even

when subjected to heftier shocks that is likely

to occur to the system during transportation)

No Iight reflecting device to be indicated by a lively balanced pointer. Constant

light emission from the L.E.D.'s.

• Seven diodes : one central zero and six

indicating + 0,5 stop, 1 stop, 1 .5 stop

- 0,5 stop, 1 stop, 1.5 stop

• Progressive lighting up of the diodes (one,

two, three) ensures a positive indication of

difference in exposure.

INSTRUCTIONS FOR USE:

1° Setting up:

• Connect the battery to the camera.

• Look in the viewfinder to make sure the camera is in viewing position (mirror in front of

aperture).

• Move the switch (32) to the right. The diodes

will light up (camera stopped).

Determine with your. light meter, the

setting of your diaphragm taking into account

the speed of the emulsion and the filming

speed.

• Adjust your lens according to the setting

indicated by your light meter (f. 5.6 for example).

• Looking through the viewfinder, turn with one

finger of the right hand the sensitivity potentiometer 34 one way or the other so that only the

central diode lights up. This being done, your

camera is now set up.

2° Filming

Obviously, for keeping a normal exposure, the central diode only must be lighted. If

the lighting intensity of the object varies, the

control diodes will be seen lit up either + or -,

visible in the viewfinder; this will indicate that

you overexpose or underexpose. The operator

will then adjust his diaphragm by closing or

opening it accordingly to come back to the

normal exposure which will be shown by the

illumination of the central diode only. In effect

the operator has a continuous indication of light

variations to within plus or minus 1 1/2 stops

from the normal exposure and which he can

vary at will (eg. for contrast effects).

26

Page 27

MIBAC BATTERY

To plug in a Jaeger plug simply turn

and push the plug onto the socket until the

locking ring clicks into place. To remove the

plug, pull on the ridged ring.

At the end of the charge, it passes automatically on the maintenance charge TRICKLE

(green diode).

The slow charge increases the life of

the battery.

MIRAP BATTERY CHARGER

It might be useful here to give a simple

outline of the operation of the rapid charge

system : when recharging a battery with a

current in the order of C 5 Amps a clear and

reproducible increase in voltage becomes

apparent towards the end of the charge,

whatever the initial level of charge of the

battery. It is thus possible to cut off the high

charge rate and pass automatically to the low

charge rate (the voltage increases as the

charge rate increases) and also the temperature of the battery (the voltage increases as

the temperature descends).

It should be noted that the most

favorable charge rate for the ACL battery is 2

C 5 A and that a recharge can be accomplished with a battery temperature between 20° C and + 40° C. The batteries are

equipped with a group of silicon diodes in low

series resistance and this system compensates for variations in temperature which

might otherwise affect the charge cut-off

voltage. The graph DE page 12 represents

the law governing the variation in charge cutoff voltage with respect to temperature. The

capacity obtained after a high speed charge

is very satisfactory (500 cycles 800 mAh) but

does not give the maximum possible capacity

which can be obtained by proceeding the

charge at a lower rate.

The MIRAP charger is provided with a

switch permitting the choice between the

rapid charge FAST (red diode) and the slow

charge SLOW (yellow diode).

Operation

Plug the cable into the socket (51) - fig

DF - at the rear of the charger taking care to

position it correctly for the corresponding

voltage : 117 volts or 220 volts A.C. 50 cycles

or 115 volts AC 60 cycles. Plug the other end

into the power supply using a plug corresponding to the mains supply socket. This

connecting cable is provided with an earth

wire which is yellow/green in compliance with

the international standard.

Insert the battery into the charger, the

red point on top facing the red point which is

on the charger. If the battery is correctly

pushed in place, its plug (50 - fig AB -) enters

the socket of the charger and the control lamp

lights up. The charge will not take place if the

two red marks do not coincide. - fig EG -.

The consumption is 11,3 Amp at 220

volts.

When the battery is fully charged the

signal lamp will go out.

The ensemble -charger/battery- may

be left indefinitely connected to the main,

without any danger. On the other hand, never

leave a battery in the charger if the latter is not

connected to the main because the battery will

discharge.

A safety fuse 52 of 800 milli-amp.

protects the charger; it blows in case of excessive voltage increase. Two spare fuses are

stored in the two rear feet of the charger

-fig FH -

52

51

Spare

fuses

Removable feet

Fixed foot

Fig. DF

Signal lamp

Red points

Fig. EG

Fig. FH

27

Page 28

BAKEL BATTERY

CIBRE CHARGER

The BAKEL battery - fig GI - the

principal characteristics of which are described page 13, is always supplied discharged after a complete cycle of charge and

discharge.

The technical characteristics of the

CIBRE charger -fig HJ -are:

• Dimensions: 125 x 64 x 40 mm

• Power supply :115 or 220 volts AC by

voltage selector, 50 or 60 cycles. 9 Weight:

0,420 kg.

• Safety : fuse on the alterning current, type

01 0,25 amp.

• Rate of charge : 320 mA.

BAKEL

Fig. GI

CIBRE

Fig. HJ

Charge

According to the mains supply 115 or

220 V., connect the charger to the mains by

means of the cable; the two indicator lamps

light up.

Connect the 4 pin Cannon sockets of

the battery to the charger by means of the

CICAB cable.

Charge for 14 hours.

The green indicator lamp goes out at

the end of the charge.

Partial charge

Very often the battery will be recharged before having been fully utilized; the

following table indicates the charging time

necessary :

Number of 120 m magazines

used ............ 2 3 6 12 or more

Number of hours

of charge ..... 3 6 8 16

Charge indicator

Discharged battery : the pointer is in the red

area.

Charged battery:

the pointer is in the middle of the white area.

If, while the camera is operating, the

pointer is between the two areas (for an

11.5 voltage) the battery will only last for

one or two 120 m magazines.

Never use a part section of the battery as the cells would become unbalanced

and the polarity of some of them could be

reversed.

Maintenance

No maintenance is necessary. Check

to wiring from time to time. Never alter it.

However, if a battery does not hold its

charge, or if the duration of its performances

reduces, it should undergo the following

operation:

a) discharge the complete battery down to

9 volts.

b) discharge each cell using a 1 -Ohm

resistance inserted between the terminals,

down to 0 volt.

c) let the cells stand for one hour.

d) recharge the battery for 18 hours.

If then the battery has not regained

its full performance it is because one of the

cells has been damaged and must be

changed. A new cell can be inserted into

the battery only under the condition that all

the cells have a zero voltage.

28

Page 29

ACCESSORIES

MAINTENANCE

PILOTONE MODULE

As already said, this accessory is a

crystal pilot frequency generator 50-60 and

100 hz. Its precision is ± 510 within a temperature limit of - 20° C to + 60° C (- 4° F to

+ 140° F). The output tension is 1 v. effective.

A three position switch 50-60-100

selects the pilot frequency recorded on the

magnetic tape corresponding to the standard

used when transfering the sound to 16 or

35 mm perforated film.

Our pilotone-module provides two

possibilities :

1. If the clapper is required connection

by cable (diagram IVIN) of the image units

(camera/ battery) to the sound units (recorder/ pilotone module), the MIBAC camera

battery supplies the pilotone module. The

cable allows the operation of the pilotone

module when the camera is running and the

recording of the « bloop » information on the

magnetic tape. This associates the crystal

generator regularity with the automatic clapper advantages.

2. If no clapper is needed: working

without a connection cable between the

image units and the sound units (diagram

N.O.). In this case, supply of the pilotone

module must be ensured by a second MIBAC

battery, the first one feeding the camera.

5

RECOMMANDATIONS

If there are deposits in the gate (10)

(channel) particulary along the side pressure

bars, remove them carefully with a tooth pick or

preferably a manicure orange stick. Never use

any metal object.

It is important that the spring load pressure guide (12) and the pressure plate of the

magazine (62) operate smoothly and freely. If

they do not work satisfactorily the equipment

should be returned to the supplier for adjusting.

Avoid the use of brushes since they are

generally dirty and have loose hairs. If a hair is

caught in the claw slot it may damage the

movement; if it is caught in the aperture it will

very likely appear on the projection of the film.

Using a clean chamois leather occasionally moistened a small amount of alcohol

clean the plate, rubbing up and down. Care

should be taken not to catch the claw (13) with

the chamois.

CLEANING THE MAGAZINE

The sprocket drum and the pressure

plate roller-guides may be cleaned with a fluff le

cloth slightly moistened with alcohol. For the

interior it is preferable to use an air syringe.

AFTER SALES SERVICE

As all cinematographic equipment for

professional users, a general overhaul carried

out from time to time by the maintenance

service of your supplier will avoid troubles and

waste ot time and money.

The spare parts catalogue N * 7011

shows the ACL in the form of exploded diagrams that illustrate the location of all the

components that go to make up the camera,

motor and magazines.

INSPECTION AND REPAIR TOOL KIT

A full set of tools is available for the

work necessary to keep the ACL in tip-top

condition.

The catalogue NO 7011 and a maintenance booklet are available, on request, to all

users who have at their disposal a repair

workshop for the cameras.

GELATINE HOLDER WALLET

Designed for five gelatine holders (in

supplement to that in the camera and the two

included in the standard handgrip) the wallet

gives the possibility of having a set of f i Iters

to cover conditions that.might be encountered

during filming.

For the optical parts use an air syringe.

Any other cleaning, even with optical or above

all tissue paper, could slightly scratch the surfaces.

29

Page 30

CHANGING THE MOTOR

If you must replace your motor, please

proceed as follows

Removal:

• Disconnect the battery from the camera before

this operation is carried out.

• Take the lens off the camera.

• Turn the knurled knob 31 to bring the reflex

mirror in the aperture centre. In this position the

screw 46 of the knurled knob 31 of the motor is

adjacent to the guide mark engraved on the

motor casing - fig IK -; this position vertically the

two driving spigots 42 of the motor - fig JIL - and

the two corresponding holes of the camera rubber

driver (41) - fig KM -.

• Undo the three captive screws (40) with a screwdriver or a coin and pull the motor out along its

drive axis.

NOTE. For checking purpose, the bottom

screw (40) is sealed. Take the seal off with a small

screwdriver or a small pointed tool to allow access

to the screw.

Replacement

Fig. IK

46

31

46

47

38

38

35

47

41

• Make sure that the screw 46 of the knurled knob

31 is perfectly in line with the guide Q mar and

that the ref lex mirror is in the centre of the aperture.

Align the camera plug (44) on the motor

with its socket (45) on the camera and push the

motor into place along its drive axis - fig JL and

KM-. The two drive spigots (42) on the motor

must be perfectly in place in the two holes of

the camera rubber driver 41.

• Tighten the three screws 40.

• Check that the drive is correctly engaged by

turning the knurled knob (31) anti-clockwise. It

should run ireely.

• Re-connect the battery.

30

Fig. JL

44

42

43

Fig. KM

45

Page 31

RECOMMENDATIONS

FOR USING OUR CAMERAS

UNDER EXTREME CLIMATIC

CONDITIONS

FILM AND TEMPERATURE

Storage

The package in metal cans conserves

the sensitometric and mechanical characteristics of the f ilm (raw stock material). On the

following table, we indicate the maximum

temperatures for storage not exceeding a

period of 6 months.

Black & white negative film 12° C = 53° F.

Black & white positive film 18° C = 64° F.

Color film 10° C = 50° F.

Lower temperatures would not entail

any inconvenience. The desired temperature

will be reached faster under cold climatic

conditions.

Bringing the film to shooting temperature

Before opening the cans bring the

film to « location temperature ». The following

table indicates in hours the time necessary to

compensate the temperature differences.

Temperature 15° Centig 30° Centig

difference 59° F 86° F

Relative

humidity rates 70° 90° 70° 90°

Insulated 16mm can 1/2 1h 1h 2h

Insulated 35mm can 1 1/2h 3h 3h 6h

Cardboard 16mm & 18h 36h 36h 72h

35mm

Cold. If a film has a too high temperature

under cold climatic conditions, it dries up

rapidly and becomes brittle. Cracks can

occur near the loops and the sprocketlwheels.

Heat. If a film has a too low temperature, in hot

climates, it is susceptible of condensation on the

surface; as a result the emulsion becomes soft

and sticky that leaves in the camera gate emulsion deposits which result in scratches and film

jammings.

Exposure

The sensitivity of cinematographic films

is conserved to - 20° C (4° F) and one would

have to reach a temperature of - 55° C (- 67* F)

for obtaining a loss of the diaphragms sensitivity.

In summary:

• Keep the film at indicated temperature.

• Avoid unnecessary temperature variations.

• Make sure that film-cans have shooting temperature.

• Do not leave the film in the camera more than

necessary.

• Develop the film as soon as possible.

HOT CLIMATES

Tropical and equatorial climates

The characteristics of these climates are

high relative humidity passing 70 % associated

with temperature of 30 a C (86 OF). We

(ecommend to transport cameras and films in

carrying-cases containing dessiccating agents

(moisture-absorbing product). If the carryingcases are not suff iciently water-vapor proof use

air-tight plastic-bags.

ECLAIR put these desiccatives in the carryingcases; keep them as they can be reused indefinitely. Just expose them at a temperature of

120° C (248° F). The humidity which saturates

the atmosphere is condensed when the temperature falls slightly; before sun-down put the

material into the transport case and never leave

the film in the camera over night.

Desert climates

The characteristics are very high

temperatures during the day and chilly nights.

As a result it is essential to use isothermic

containers to protect the film from these temperature variations. These chilly nights will

allow to store the film at an acceptable temperature. The air-tight plastic bags are protecting the camera from dust, sand and laterite.

Utilisation

Keep the material in the shade of an

airy place, avoid direct sun-light and storage in

cars ETC...

• Bring the film to ambient temperature.

• Camera should not be loaded until immediately before use.

• After the end of shooting, place the exposed

film and the short-ends in the original containers. Use dry black paper only.

• If the relative humidity rate is lower than 70 %

seal the film cans by sticking adhesive tape on

the periphery.

• If the relative humidity rate is higher than

70%, stick the tape diagonally around the can

and put the exposed f ilm in an hermetically

sealed container provided with a desiccative

agent (avoid refrigerators).

• Develop the films as soon as possible.-

The above mentioned precautions are

valid for a period of approximately one month.

Would you kindly consult us for longer periods

which will of course necessitate other precautions.

31

Page 32

COLD CLIMATES

Preparation

Check whether the camera has al ways

been maintained and repaired by one of our

agents; the use of appropriate lubricants, the

respect of mounting tolerances for all moving

parts etc... all this will give you the best guarantee for satisfactory service under frigid conditions.

For temperature lower than - 15° C

(+ 5° F) would you please consult one of our

agents. He will carry out a « Winterizing treatment » which has been elaborated by our

research department.

Also check the lubrif ication of the

adjusting rings of your lenses.

Temperature variations

Although the camera bears easily

considerable and brutal slumps of temperature,

a fast rise of temperature would be on the other

hand, hazardous for the mechanism owing to

the associated condensation.

The warming-up should take place

slowly and not'in warm air. Therefore, put the

material in sealed transport cases or better in

air-tight plastic bags.

Utilisation

Brings the film at outside temperature

before opening the cans (see table « Film and

Temperature »). Don't load the magazine until

immediately before use.

After the end of shooting, unload the film

and the short ends at the ambient temperature,

then put them back in the original containers.

Films cans should be sealed by sticking adhesive tape on the periphery.

Send the film as soon as possible to a

laboratory. Make sure that the film was warmedup before opening and before immerging it into

the developing bath. If not, bring film and shortends to the desired storage temperature.

Pack the material always at outside

temperature in the transport case or in air-tight

plastic bags.

It is now possible to bring the film to a

heated location. But wait about two hours for

compensating a temperature difference of 20° C

(68° F) before opening the carrying cases or

bags.

Batteries

The driving torque of the camera increases in

the cold, the consumption can double so that

the batteries must be fully charged. Keep the

maintenance charge until the last moment

(position E).

The contact between skin and cold metal

is painful and could even be dangerous (loss of

skin).

We recommend to cover with cloth tape

all parts of the camera which could be in contact

with skin and to wear silk gloves for all essential

operations.

Snow

When shooting during snowfall, all

corners and nooks will be filled with snow.

Before entering with the camera in a heated

location, brush off very carefully the snow; then

put it in an air-tight bag, in order to avoid unnecessary humidity in the transport case. Once

warmed up, lay out separately all parts of the

camera, clean them with care, dry them (i.e.

with a hair dryer) and make a running test.

These above-mentioned precautions

concern a short storage period only (approximately one month). Would you kindly consult

us for longer periods.

32

Page 33

USEFUL INFORMATION

Weights and sizes:

Camera front head . 1,175kg 160x85x1 15 mm

Mivar motor ......... 0,845 kg 176x72x45 mm

with intermediate plates and screws

Angenieux

viewfinder ...... 0,610 kg 1 00x87x1 25 mm

Lens protector....... 0,030 kg 068 mm

Handgrip ............... 0,270 kg 158x47x35 mm

60 m (200 ft)

magazine ........ 1,735 kg 242xl 65x67 mm

120 m (400 ft)

magazine ........ 2,900 kg 289x2O2x78 mm

Mible feed cable ... 0,235 kg 1-2 metres

Pilotone module .... 0,245 kg 102x67x33 mm

ACL TIME EXPOSURE

Formula: T =

Example: =

C x S

1

49th

O

360 x 24

175

Zoom 6x9,5

(9,5/57 mm) ... 0,890 kg 165x67 mm

Zoom 10x12

(12/120 mm) .. 0,945 kg 180xl 20 mm

Zoom 6x12,5

(12,5/75mm) .. 0,530 kg 140x59 mm

Mibac battery ....... 0,640 kg 150x95x29 mm

Mirap charger ...... 2,190 kg 200xl 00x95 mm

Bakel battery ....... 1,650 kg 230xl 60x4O mm

Cibre charger ...... 0,420 kg 125x64x4O mm

Bakel belt battery 2,750 kg -

Carrying case ...... 6,300 kg0,70x0,50x0,19 mm

T = time exposure

C = circonference

S = speed of filming (images per second)

O = opening of the shutter

i.e. 8 frames per second = 1/16th

12 » = 1/24

24 » = 1/49

25 » = 1/51

50 » = 1/102

75 » = 1/154

33

Page 34

Ref. NUMBERS AND FIGURES

Ners DESIGNATION PAGES

Ners DESIGNATION PAGES

1 Lens mount support ............................................. 4-8

2 Gelatine holder .................................................... 4-9-19

3 Reflex viewfinder ................................................. 4-9-18

6 Multiduty mivar motor .......................................... 4-5

7 Motor electronics ................................................. 4-5

8 Electronic base 150 E ........................................ 4-11-24

9 Mechanism plate ................................................. 4

10 Film gate ............................................................. 4-10-23

11 Fixed guide bar..................................................... 4-10-23

12 Spring loaded side pressure bar ......................... 4-10-23-29

13 Claw .................................................................... 4-10

14 Oscillating mirror ................................................. 4-9-10

15 Shutter ................................................................. 4-23

16 Magazine lock release lever ................................ 4-23

17 Safety catch ........................................................ 4-23

18 Magazine drive shaft ........................................... 4-23

19 4 pin power supply socket ................................... 4-11

20 Clapper switch ..................................................... 4-11-20-24

21 Internal thread for C lenses ................................ 8-17

22 External thread for intermediate lens mount ....... 8

23 Intermediate mount location slot ......................... 8-17

24 Intermediate mount location tongue .................... 7-17

25 Intermediate mount grooved ring ........................ 7-17

26 CA mount slot ...................................................... 17

27 Gelatine holder button ......................................... 9-19

28 Hole for eventual film marking system ................ 10

29 Magazine guide ................................................... 4-10

30 Magazine guide ................................................... 4-10

31 Motor knurled knob ............................................. 5-24-30

32 On/off switch of the electronic base .................... 4-11-20-24

33 Accessory power supply cannon socket ............. 11

34 Sensitivity potentiometer (exposure indicator) .... 4-11-10

35 Speed control button on MIVAR motor ................ 5-24-30

36 Handgrip .............................................................. 7-19-11

37 MIBAC battery ..................................................... 5-12

38 24/25 frames per second switch ......................... 5-24-30

39 Claw control cam ................................................. 10

40 Motor retaining screws ........................................ 30

41 Rubber driver ...................................................... 30

42 Motor drive spigots .............................................. 30

43 Motor driver ......................................................... 30

44 Cannon plug (motor power supply) ..................... 30

45 Cannon socket (motor power supply) .................. .30

46 Screw of the hand control knob of the motor ...... 30

47 Battery condition warning lamp ........................... 5-24-30

48 Battery polyurethane case .................................. 12

49 4 pin socket on MIBAC battery ............................ 12

50 Socapex central socket on battery ..................... 12-27

51 Charger main supply socket ................................ 27

52 Charger safety fuse ............................................. 27

53 Magazine counter arm ........................................ 21

54 Magazine light tight ramp .................................... 21

55 Magazine flange .................................................. 21

56 Magazine body .................................................... 21

57 Counter arm lock ................................................. 21

58 Magazine nose .................................................... 21-22

59 Magazine upper roller ......................................... 21

60 Magazine upper roller ......................................... 21

61 Magazine upper film guide .................................. 21

62 Pressure pad ....................................................... 21-29

63 Magazine lower film guide ................................... 21

64 Magazine upper roller shoe ................................. 21

65 Upper and lower shoes catch .............................. 21

66 Feed sprocket ..................................................... 21

67 Magazine lower roller shoe ................................. 21

68 Magazine location tongues ................................. 21

69 Loop separator .................................................... 21

70 Magazine flange (interchangeable with 55) ........ 22

71 Spool lock ............................................................ 22

72 Footage counter dial (60 rn magazine) ............... 21-22

73 Footage counter pointer ...................................... 21-22

74 Magazine drive shaft ........................................... 21-23

75 Handgrip side support ......................................... 4-7-19

76 On/off switch of the handgrip side support .......... 4-19-24

77 Handgrip side support fixing screws ................... 19

78 Spare gelatine holder .......................................... 19

79 Knurled ring of the handgrip support ................... 19

80 Hole of the handgrip support ............................... 19

34

Page 35

The big-ass view from page 20!

Schema UV

Schema VX

35

Page 36

About this .PDF document

This document probably originated from this website:

The online Eclair ACL 16mm camera manual:

http://www.biksco.com/acl/

The site has all sorts of links and info about the Eclair ACL, including the original Eclair ACL I manual in .PDF format.

Here’s the whole sorrid tale of the creation of this document:

This document started as a series of 300 d.p.i. full-page scans of an original Eclair ACL 1.5 manual.

The person who did this original scanning was Luis Enrique Osorio, who lives in Bogotá, Colombia.

Luis eventually sent Perry Paolantonio a copy of the scans to him in Boston. Perry has a fine website dedicated to

the Eclair ACL.

Check out Perrys Eclair ACL website:

http://www2.shore.net/~perryp/acl/

Perry eventually caught wind that Eric Bickernicks of Marlborough, Massachusetts had created a .PDF document of

an Eclair ACL I manual. He bang-out a CD-R of these scans and sent them to him.

36

The text was OCR’ed with Omnipage Pro 8.0. The images were down-sampled to 150 d.p.i TIFFs with Photoshop

5.0.2. (All line art were converted to 300 d.p.i. bitmaps) The original layout of the manual was recreated in Adobe

PageMaker 6.5. (I’ve even left in the few words that didn’t make the translation from French to English.) Adobe

Acrobat 4.0 was used to compress the images and imbed the index links with the final .PDF document. This was all

done on a crappy Radius 8100/110 Macintosh clone.

I don’t claim to own the copyright of the information within this document. I just hope that on one attempts to print out

copies of THIS document and try to sell them on ebay or something. (or at least cut me in on th edeal!) :-) There

doesn’t seem to be alot of information out there about his camera, so if anyone HAS any info please feel free to

contact me. I understand there may be a different manual for the Eclair ACL II camera. If anyone is willing to send

me some scans of that, I’d love to recreate it in .PDF format. I’m also looking for an Eclair NPR manual to digitize.

Eric Bickernicks can be contacted (as of September 1999) at these e-mail addresses:

biksco@mediaone.net

eclair@biksco.com

Loading...

Loading...