Page 1

OWNER

OPERATORS

MANUAL

For Bear Vac

Pro

Models

75011

75111

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

www.terramarc.com

Manual P/N 14032-00

Rev. 03/02

Companion to P/N 14031-00

Page 2

Before you Begin

DEAR BEAR CAT CUSTOMER,

Thank you for purchasing a Crary Bear Cat Bear Vac Pro. The Bear Vac Pro is designed,

tested, and manufactured to give years of dependable performance. To keep your Bear Vac

Pro operating at peak efficiency, it is necessary to adjust it correctly and make regular

inspections. The following pages will assist you in the operation and maintenance of your

machine. Please read and understand this manual before operating the Bear Vac Pro.

If you have any questions or comments about this manual, please call us toll-free at 1-800-247-

7335.

If you have any questions or problems with your Bear Vac Pro, please call or write your local

factory-authorized Bear Cat dealer.

PLEASE SEND US YOUR WARRANTY CARD

A warranty card is included in your owner's kit packaged with your Bear Vac Pro. Please take

the time to fill in the information requested on the card. When you send your completed card to

us, we will register your machine and start your coverage under our limited warranty.

How to Contact

Bear Cat

A

DDRESS

Crary Bear Cat

237 NW 12th Street

PO Box 849

West Fargo, ND 58078

P

HONE

800-247-7335

701-282-5520

Fax: 701-282-9522

E

MAIL

opesales@crary.com

service@crary.com

H

OURS

EMISSION INFORMATION

WARNING

WARNING TO ALL CALIFORNIA

AND OTHER STATES OPERATING

OUTDOOR POWER EQUIPMENT

Under California Law and under the

laws of several other states you are

not permitted to operate an internal

combustion engine using hydrocarbon

fuels on any forest covered, brush

covered or grass covered land or on

land covered with grain hay or other

flammable agricultural crop, without an

engine spark arrester in continuous

effective working order.

The engine on your power equipment,

like most outdoor power equipment, is

an internal combustion engine that

burns gasoline, a hydrocarbon fuel.

Therefore, your power equipment must

be equipped with a spark arrester

muffler in continuous effective working

order. The spark arrester must be

attached to the engine exhaust system

in such a manner that flames or heat

from the system will not ignite

flammable material.

Failure of the owner/operator of the

equipment to comply with this

regulation is a misdemeanor under

California law, and may also be a

M-F, 8 a.m. to 5

p.m. Central Time

violation of other state and or federal

regulations, laws, ordinances, or

codes. Contact your local fire marshal

or forest service for specific information

about what regulations apply in your

area.

The standard muffler installed on the

Bear Cat engines is not equipped with

a spark arrester. One must be added

before use if this machine is intended

to be used in an area where a spark

arrester is required by law. Contact

the local authorities if these laws apply

to you. See your authorized engine

dealer for spark arrester options.

Page 3

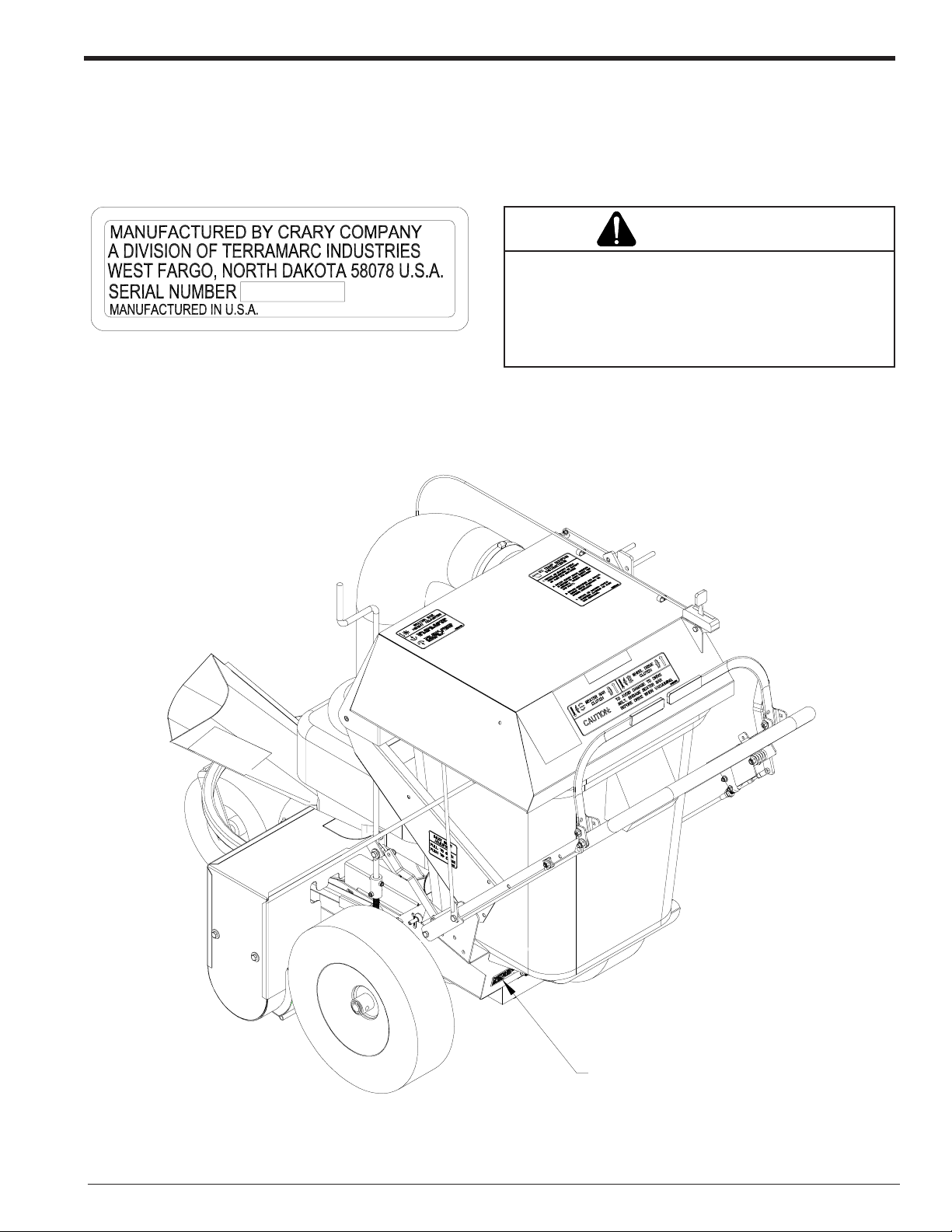

SERIAL NUMBER LOCATION

Always give your authorized Bear Cat dealer the serial number of your Crary Bear Cat Bear Vac when ordering parts,

requesting service or any other information. Please record the serial number in the space provided below and on the

warranty and registration card.

WARNING

To prevent personal injury or property damage: Shut

YXXXXX

Fig. # 1 Serial number decal

Serial Number ________________________

off engine, disconnect spark plug wire, make sure that

all moving parts have come to a complete stop, before

obtaining serial number, servicing, adjusting or repairing.

SERIAL NUMBER

DECAL

Fig. #1, Serial number decal

Bear Vac Pro Operator’s Manual

I

Page 4

Section Description Page

SAFETY .................................................................................................................................... 1

BEFORE OPERATING ................................................................................................................ 2

OPERATION SAFETY ................................................................................................................. 2

MAINTENANCE AND STORAGE SAFETY .................................................................................. 2

SAFETY DECAL LOCATIONS ..................................................................................................... 3

ASSEMBLY .................................................................................................................................... 4

ADDING MOTOR OIL TO ENGINE (ALL MODELS) ..................................................................... 4

ASSEMBLY TORQUE CHART .................................................................................................... 4

ASSEMBLY INSTRUCTIONS (ALL MODELS) ............................................................................. 5

FEATURES AND CONTROLS IDENTIFICATION .......................................................................... 6

DESCRIPTION OF OPERATION .................................................................................................. 6

OPERATION .................................................................................................................................... 9

USE OF CONTROLS ................................................................................................................... 7

FILLING THE TANK ..................................................................................................................... 9

STARTING THE BEAR VAC PRO ................................................................................................ 9

STOPPING THE BEAR VAC PRO ............................................................................................... 9

CHIPPING ................................................................................................................................. 10

VACUUMING ............................................................................................................................. 10

ENGAGING THE DRIVE ............................................................................................................ 11

BEATERBAR ADJUSTMENTS .................................................................................................. 11

EMPTYING THE TUB ................................................................................................................ 12

VACUUMING AND CHIPPING GUIDE ....................................................................................... 12

Contents

SERVICE & MAINTENANCE ............................................................................................................................ 12

MAINTENANCE SCHEDULE ..................................................................................................... 13

REPLACING THE DRIVE BELT ................................................................................................. 14

REPLACING THE BEATERBAR BELT ....................................................................................... 15

REMOVING THE CHIPPER BLADES ........................................................................................ 16

SHARPENING THE CHIPPER BLADES .................................................................................... 16

GREASING ............................................................................................................................... 17

TROUBLESHOOTING ................................................................................................................ 18

Bear Vac Pro Operator’s ManualII

Page 5

Bear Vac Pro Limited Warranty

Crary Bear Cat Bear Vacs are warranted for one year from date of sale for consumer and commercial or

rental operations.

Within the above stated period, Crary Co. will replace any part(s) found to be defective in material and/or

workmanship, after the receipt of the part in our plant. Labor costs to replace these defective parts will be

paid at a Crary established labor rate and time allowed (flat rate) for repair. All transportation charges

incurred in shipping part(s) are the responsibility of the purchaser.

This warranty is void in the case of accidents, failure to perform normal maintenance, or failure to follow

those instructions listed in the service manual. This warranty is also in lieu of all other expressed warranties

and voids any implied warranty as to the merchantability or fitness of the product for a particular purpose

and of any other obligation on the part of Crary Co. Some states do not allow limitations on how long the

implied warranty lasts, so the above limitation may not apply to you.

This warranty applies only to parts or components which are defective, and does not cover necessary

repair due to normal wear, misuse, accidents, or lack of proper maintenance. Components subject to

wear, such as filter bags, wheels, hoses, cables, fan housings, etc., are not included in the warranty.

Regular routine maintenance of the unit to keep it in proper operating condition is the responsibility of the

owner.

All warranty repair reimbursable under the Crary Co. warranty must be performed by an authorized Bear

Cat service dealer using Bear Cat approved replacement parts. Repair or attempted repair by anyone other

than an authorized Bear Cat service dealer is not reimbursable under the Crary Co. warranty. In addition,

these unauthorized repair attempts may result in additional malfunction, the correction of which is not

covered by warranty.

Crary Co. is not liable for indirect, incidental, or consequential damages in connection with the use of this

product including any cost or expense or providing substitute equipment or service during periods of

malfunction or non-use.

Some states do not allow the exclusion of incidental or consequential damages, so the above exclusion

may not apply to you. This warranty gives you specific legal rights. You may also have other rights which

vary from state to state.

Be sure to note the Bear Vac serial number in any correspondence with Crary Co. or any authorized Bear

Cat dealer.

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

www.terramarc.com

Bear Vac Pro Operator’s Manual

III

Page 6

NOTES

Page 7

1

Safety

Section

THE SAFETY ALERT SYMBOL

This is the safety alert symbol. It is used in this Owner / Operator’s Manual and on your machine

to alert you to potential hazards.

Whenever you see this symbol, read and obey the safety message that follows it. Failure to obey

the safety message could result in personal injury, death or property damage

DANGER

WARNING

CAUTION

BEFORE OPERATING

1. Read this Owner / Operator’s

manual and the separate Engine

Owner’s manual carefully before

operating this equipment. Be completely familiar with the controls

and the proper use of this equipment.

2. Before inspecting or servicing any

part of the machine, stop engine,

wait for all parts to stop moving,

and disconnect spark plug wire.

Indicates an imminently hazardous situation that, if not avoided, will result in

death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

4. Familiarize yourself with all of the

safety and operating decals on this

equipment and on any of it’s attachments or accessories.

5. Do not allow children or any person unfamiliar with the use of the

unit to use this machine.

6. Keep the area of operation clear of

all persons, particularly small children. Keep bystanders at least

50 feet (15 meters) away from the

area of operation.

7. Do not run this equipment in an

enclosed area. Engine exhaust

contains carbon monoxide gas, a

deadly poison that is odorless,

colorless, and tasteless. Do not

operate this equipment in or near

buildings, windows, or air conditioners.

8. Always use an approved fuel container. Do not remove gas cap or

add fuel when engine is running.

Add fuel to a cool engine only.

9. Do not fill fuel tank indoors. Keep

open flames, sparks, smoking materials, and other sources of combustion away from fuel.

Be aware that rotating parts slow

down gradually after engine is shut

off.

3. Keep safety decals clean and legible. Replace missing or illegible

safety decals.

10. Do not operate this machine if you

are under the influence of alcohol,

medications, or substances that

can affect your vision, balance, or

judgement. Do not operate if tired

or ill. You must be in good health

to operate this machine safely.

Page 1Bear Vac Pro Operator’s Manual

Page 8

Safety

BEFORE OPERATING

11. Use only in daylight or good artificial light.

12. Never use without proper guards

in place.

13. Wear safety glasses at all times

while operating this machine.

One pair of safety glasses is provided.

14. Wear ear protection at all times

OPERATION SAFETY

WARNING

Keep hands, feet and clothing out of

inlet opening while machine is operating to avoid personal injury.

WARNING

Wear eye, and hearing protection at

all times while operating the Bear Vac

Pro.

while operating the Bear Vac Pro.

15. Avoid wearing loose fitting clothing. Never operate this machine

wearing clothing with drawstrings that could wrap around

or get caught in the machine.

WRONG

1. Do not allow hands, or any part of

body or clothing near any moving

parts.

2. Shut off engine immediately if the

Bear Vac Pro strikes any foreign object or the machine starts vibrating.

Allow the machine to stop completely. After machine stops:

A. Shut off engine

B. Remove spark plug wire.

C. Inspect for damage.

D. Replace or repair any

damaged parts.

E. Check for and tighten any

loose parts.

3. Do not allow processed material to

build up in the discharge area; this

may prevent proper discharge and

can result in kickback of material

through the feed opening.

16. Check that all screws, nuts,

bolts, and other fasteners are

properly secured before starting

the machine. Check all screws,

nuts, bolts, and other fasteners

for proper tightness to ensure everything is in proper working condition once every 10 hours of operation.

17. Keep all guards, deflectors, and

shields in place and in good

working condition.

18. Do not transport or move machine while the machine is running.

4. Stand clear of the discharge area

when operating this machine.

5. Do not overreach. Keep proper bal-

ance and footing at all times.

6. Keep the engine clear of debris and

other accumulations.

7. Do not tamper with the engine gov-

ernor settings on the machine; the

governor controls the maximum safe

operating speed and protects the engine and all moving parts from damage caused by over speed.

8. Setting up your work site so you are

not endangering the public is critical for safety.

9. Shut off engine and allow machine

to stop completely before clearing

debris if the machine becomes

clogged.

MAINTENANCE AND STORAGE SAFETY

1. Shut off machine and disconnect the

spark plug wire when this equipment

is stopped for service, inspection,

or storage.

2. Replace any missing or unreadable

safety decals. Refer to the parts

manual for part numbers when ordering safety decals from an area

Bear Cat dealer.

3. Store the machine out of reach of

children and where fuel vapors will

Page 2 Bear Vac Pro Operator’s Manual

not reach an open flame or spark.

Drain the fuel and dispose of it in a

safe manner for storage periods of

three months or more.

4. Allow machine to cool before storing in an enclosure.

5. Never store this machine with fuel

in the fuel tank inside a building

where fumes may reach an open

flame or spark, or where ignition

sources are present such as hot

water and space heaters, furnaces,

clothes dryers, stoves, electric motors etc.

NOTE

See engine owners manual or contact the engine manufacturer for

engine safety instructions and decals.

Page 9

Safety

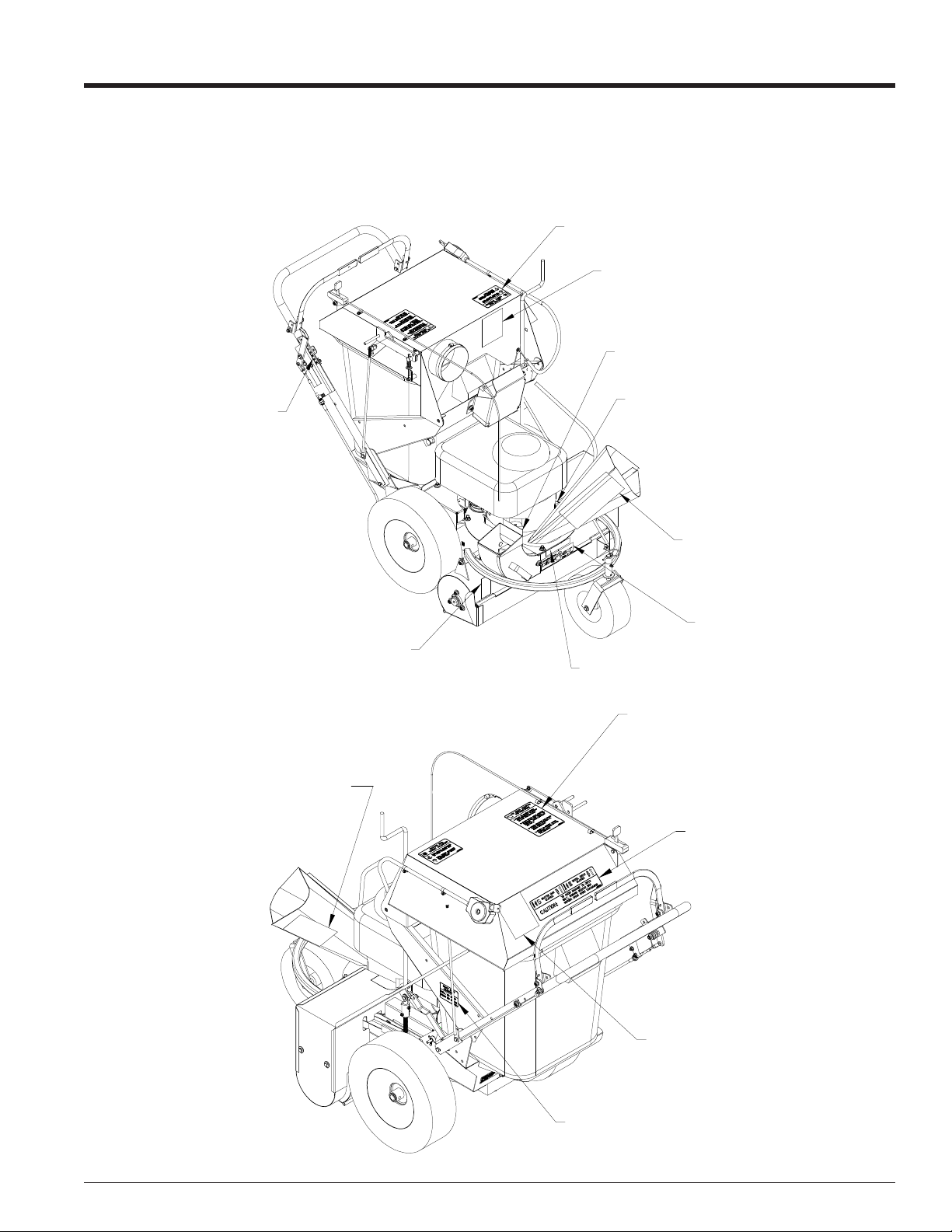

SAFETY DECAL LOCATIONS

Familiarize yourself with all of the safety and operational decals on the machine and the associated hazards. Make certain

that all safety decals and operational decals on this equipment are kept clean and in good condition. The decals are shown

below at reduced sizes. If you need a replacement decal, please refer to the parts catalog. Decals that need replacement

must be applied to their original locations.

DECAL,

BEATER BAR

DECAL,

F;YING DEBRIS

BLADE

DECAL,

ACCESS COVER

DECAL,

DECAL,

SHIFT LEVER

SHIELD DANGER

DECAL,

BLADE DANGER

DECAL,

SMALL DANGER

DECAL,

75111 MODEL

DECAL,

EZ DUMP

DECAL,

OPERATING

INSTRUCTIONS

DECAL,

SMALL BEARCAT

DECAL,

DRIVE

Fig. #2

DECAL,

REAR FLYING DEBRIS

DECAL,

INLET DOOR

Page 3Bear Vac Pro Operator’s Manual

Page 10

2

Assembly

Section

Your Bear Vac Pro may arrive totally or partially assembled. If your machine arrives partially assembled, you may need to

perform the steps in this section.

ADDING MOTOR OIL TO ENGINE (ALL MODELS)

IMPORTANT

Motor oil must be added

to the engine before it is

started.

1. The machine was shipped without

oil in the engine. Fill the engine

crankcase with the amount of oil

specified in the engine owners

manual.

2. To determine which type of oil to use,

refer to the engine owners manual

included in the owners kit of the Bear

Vac Pro.

ASSEMBLY TORQUE CHART

UNIFIED INCH BOLT TORQUE VALUES (COARSE THREAD)

(unless otherwise specified in the manual)

Bolt

Diameter

"A"

1/4" 7.5 5.5 12 9 17 12.5

5/16”1511251835 26

3/8” 27 20 44 33 63 46

7/16” 44 32 70 52 100 75

1/2” 67 50 110 80 150 115

9/16” 95 70 155 115 225 160

5/8” 135 100 215 160 300 225

3/4” 240 175 375 280 550 400

7/8” 240 175 625 450 875 650

1” 360 270 925 675 1300 975

1-1/8” 510 375 1150 850 1850 1350

1-1/4” 725 530 1650 1200 2600 1950

1-3/8” 950 700 2150 1550 3400 2550

1-1/2” 1250 930 2850 2100 4550 3350

SAE 2

(N.m) (ft - lb) (N.m) (ft - lb) (N.m) (ft - lb)

Bolt Torque *

SAE 5 SAE 8

3. Remove the oil fill plug.

4. Checking as necessary, add oil to

the motor until the dipstick shows

the correct reading.

Page 4 Bear Vac Pro Operator’s Manual

Page 11

ASSEMBLY INSTRUCTIONS (ALL MODELS)

Assembly

WARNING

To prevent personal injury or property damage: Shut off engine, disconnect spark plug wire, and make

sure that all moving parts have come

to a complete stop, before servicing, adjusting or repairing.

The Bear Vac Pro is shipped with the

handlebar not attached to the machine.

1. Thread the two tie rods into the pivot

pins located on the bucket crank

weldment. Make sure the rods are

threaded evenly -- they will adjust

how high the bucket top weldment

lifts.

2. Align the tie rod, handlebar clamp,

and handlebar with the bolt holes

called out on Fig. #3. Note: The bottom hole used will determine handlebar height.

3. Insert (4) 5/16” x 2” bolts through tie

rod, handlebar clamp, and Bear Vac

Pro frame.

4. Place washer and locknut onto ends

of bolts.

5. Check lift of bucket top weldment,

and handlebar height. Adjust as

necessary.

6. Tighten bolts to proper torque.

5/16 NUT

NYLOCK

Fig. #3

5/16 FLAT

WASHER

HANDLE BAR

CLAMP

5/16 X 2"

BOLT

TIE ROD

Page 5Bear Vac Pro Operator’s Manual

Page 12

Features & Controls

FEATURES AND CONTROLS IDENTIFICATION

Learn the location of the features and controls on your machine before operating.

HANDLEBARS

WHEEL DRIVE

CLUTCH

ENGINE

THROTTLE

GEAR SHIFT

CONTROL

EZ DUMP

HANDLES

BEATER BAR

CLUTCH

ELECTRIC START

BEATER BAR

HEIGHT ADJUSTOR

BATTERY HOUSING

CHIPPER INTAKE

ENGINE

BEATER BAR

HOUSING

Fig. #4, features and controls. (Note: Electric start and battery housing is found only on the 75111 model.)

DESCRIPTION OF OPERATION

Understanding how your machine works will help you achieve the best results when using your Bear Vac Pro.

The Bear Vac Pro vacuums in debris through the beater bar housing. Material can also enter through the chipper intake. The

debris then travels through the hose to the EZ dump container. When full, the container can be removed from the machine

and dumped.

Page 6 Bear Vac Pro Operator’s Manual

Page 13

USE OF CONTROLS

Model #75011

WARNING

To prevent personal injury or property damage: Shut off engine, disconnect spark plug wire, and make

sure that all moving parts have come

to a complete stop, before servicing, adjusting or repairing.

1. Handlebars: The height of the

handlebars is adjustable.

2. Chipper intake: Hard materials

such as branches and rolled newspaper can be chipped here.

3. Engine: Provides power for the

unit.

4. Engine Throttle: Changes engine

speed, turns the engine on and off,

and places the engine in choke.

5. Wheel Drive Clutch: This control

engages the transmission and

drives the Bear Vac. Release the

bail when shifting.

6. Gearshift control: This control shifts

the self-propelled transmission

between five forward gears and one

reverse gear. To avoid premature

transaxle failure use the clutch

when shifting the machine out of

neutral, or between the reverse and

forward setting. The clutch does

not need to be used when shifting

between forward gears, unless under heavy load.

7. Beater Bar Clutch: Engages and

disengages the beater bar.

8. Beaterbar height adjuster: Adjusts

the height of the beater bar.

9. EZ Dump handles: Used to open

the machine to allow the debris tub

to be removed and emptied. Make

sure the handles are locked before operating. Refer to the decal

(14036-00) for specific instructions

on using the air shut off and removing the tub.

10. Inlet Door Adjuster (not shown):

Adjusts how much debris enters

the beater bars, and thereby the

level of compaction.

Features & Controls

Model # 75111

WARNING

To prevent personal injury or property damage: Shut off engine, disconnect spark plug wire, and make

sure that all moving parts have come

to a complete stop, before servicing, adjusting or repairing.

The electric start model includes all the

features of the manual starting model.

The different features between the two

models are listed here.

1. Electric Start switch: On electric

start models only. This switch engages the starter. When starting

use short bursts. Long periods of

use can damage the starter.

2. Battery Housing: The battery is

nestled above the engine in this

housing.

Page 7Bear Vac Pro Operator’s Manual

Page 14

4

Operation

Section

WARNING

Before operating your machine, be

sure you read and understand all

safety, controls and operating instructions in this Owner/Operators

manual and on your machine.

Failure to follow these instructions

can result in serious injury or property damage.

As with any other piece of outdoor

power equipment, getting the “feel” for

how your machine operates and getting

to know the best techniques for

particular jobs are important to overall

good performance.

Read this section thoroughly before you

start the engine. The instructions given

here will help you become familiar with

your machine and have you operating

efficiently in a short time.

This section covers:

• Filling the tank

• Starting the Bear Vac Pro

• Stopping the Bear Vac Pro

• Chipping

• Vacuuming

• Engaging the drive

• Beaterbar adjustments

• Emptying the tub

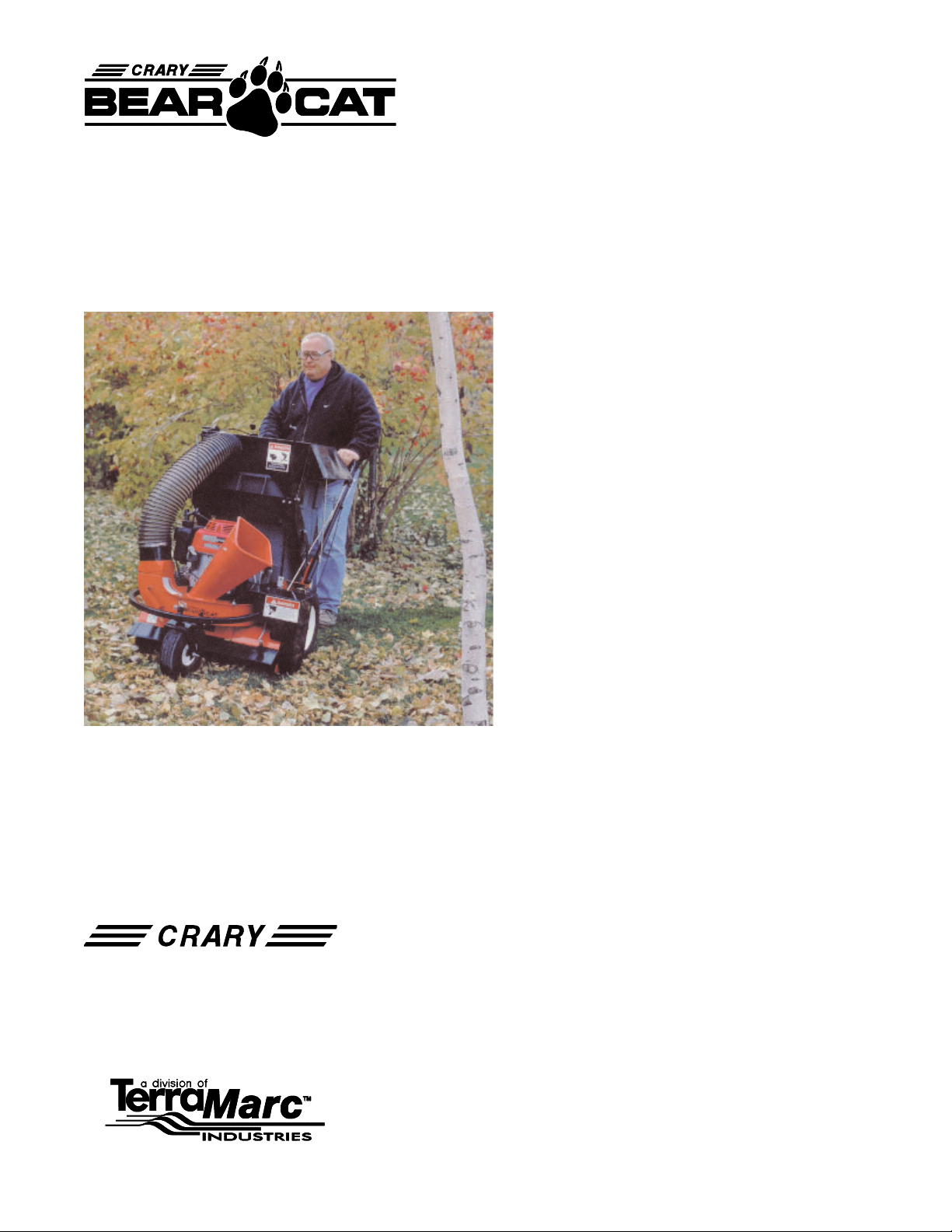

Fig. #5, Bear Vac in action

Page 8 Bear Vac Pro Operator’s Manual

Page 15

Operation

FILLING THE TANK

DANGER

Gasoline is highly flammable

and its vapors are explosive. To

prevent personal injury or property damage:

Store gasoline only in approved

containers, in well ventilated, unoccupied buildings, away from sparks

or flames. Do not fill the fuel tank

while the engine is hot or running,

since spilled fuel could ignite if it

comes in contact with hot parts or

sparks from ignition. Do not start

the engine near spilled fuel. Never

use gasoline as a cleaning agent.

FILLING THE FUEL TANK

Fuel Type:

For best results use only clean, fresh,

unleaded gasoline with a pump sticker

octane rating of 87 or higher. In countries using the Research method, it

should be 90 octane minimum.

Purchase gasoline in small quantities

and store in clean, approved containers. A container with a capacity of 2

gallons or less with a pouring spout is

recommended. Such a container is

easier to handle and helps eliminate

spillage during refueling. DO NOT MIX

OIL WITH GASOLINE.

Gasoline Alcohol blends

Gasohol (up to 10% ethyl alcohol, 90%

unleaded gasoline by volume) is approved as a fuel for Honda engines.

Other gasoline/alcohol blends are not

approved.

Gasoline Ether blends

Methyl Tertiary Butyl Ether (MTBE) and

unleaded gasoline blends (up to a maximum of 15% MTBE by volume) are

approved as a fuel for Honda engines.

Other gasoline/ether blends are not

approved.

To Add Gasoline.

1. Stop engine, wait for all parts to stop

moving, then disconnect the spark

plug wire. Allow the engine and muffler to cool for at least three minutes.

2. Clean area around fuel fill cap and

remove cap.

3. Using a clean funnel, fill fuel tank to

1/2” below bottom of filler neck to

provide space for any fuel expansion. Install fuel fill cap securely and

wipe up any spilled gasoline.

STARTING THE BEAR

VAC PRO

Move machine to a clear, level

area outdoors before starting. Do

not operate in the vicinity of bystanders. Make sure the chamber

is empty before starting. Also, do

not engage the bail while starting

self propelled models.

1. Reference the Honda Owners

Manual.

2. Check engine oil level before starting. Do not overfill or underfill oil. The

Honda engine is equipped with an

oil level sensor and will not allow the

engine to start in either scenario.

3. Place the throttle control on Honda

engines into the run or choke position, depending upon engine temperature.

4. Pull the recoil starter until the engine starts. Make sure the starting

cord retracts.

5. On electric models turn the ignition

key to the right to engage starter.

Do not engage starter for long periods.

6. Move throttle to the desired position.

7. For a Cold Engine — Gradually

return the throttle control from the

STOPPING THE BEAR VAC PRO

1. Reference the Honda Owner Manual.

WARNING

Allow the machine to come to

complete stop before inspection

or servicing.

2. Move the throttle to the “slow” or “low” idle position.

3. Allow the engine to run at idle for 30-60 seconds; then stop the engine by

moving the throttle to the off position.

choke position to the run position

as the engine warms up.

Fig. #6, electric start key switch

4. Allow machine to come to a complete stop.

Page 9Bear Vac Pro Operator’s Manual

Page 16

Operation

CHIPPING

Fig. #7, Chipping

1. Shift transaxle into neutral.

2. Select limbs that are 1/2” to 3” in diameter.

3. Trim side branches that cannot be bent over enough to fit

into the chipper chute. Hold small branches together in

bundle and feed simultaneously.

4. Place limb, butt end first, into chipper chute until it contacts the chipping blades. The actual feed rate of the

limb into the chipper will depend upon the type of material fed, the sharpness of the cutting blades and the diameter of the branch.

5. Alternately insert and retract the limb or continuously

insert at a rate that will not kill the engine. Rotating the

branch as you feed it will improve cutting action.

Tips:

-- Avoid overfeeding into the chute.

VACUUMING

NOTE

Please read and follow all safety instructions in this

manual. Failure to operate the Bear Vac Pro in

accordance with the safety instructions MAY RESULT

IN PERSONAL INJURY!

IMPORTANT

Exclude pieces of metal, rocks, bottles, and other

foreign objects when vacuuming.

TIPS:

1. Vacuum heavy, soggy, or stringy material at a slow ground

speed. Feeding too much material into the vacuum will

likely lead to clogging.

2. Check the debris tub frequently and empty if necessary.

3. Avoid vacuuming sticks and other foreign objects -- they

will jam the beater bar.

4. Loosen matted or compacted material with a rake before

vacuuming.

5. Be careful when vacuuming around gravel, gardens, lawn

ornaments, etc. Never attempt to remove objects from

the beater bar when the machine is running.

6. Vacuum frequently to avoid excessive leaf buildup.

7. To obtain greater reduction in vacuumed material, install

the shredder grate. Note: The use of the shredder grate

is optional. The speed of the beaterbar will break and/or

reduce material quite well without it. However, when using the shredding grate, wet material will have a tendency

to wrap and plug easier. The Bear Vac Pro comes with

the shredder grate installed.

-- Whenever possible chip branches when they are fresh.

Green material chips better than dry material.

-- Keep the chipper blades sharp. Severe vibration or slow

feeding are signs the blades may be dull.

-- Do not point your arms into the chute; keep them perpendicular to the branch.

-- Keep your face and body safely away from the chipper

chute and branches.

Page 10 Bear Vac Pro Operator’s Manual

Fig. #8, Shredder Grate

Page 17

Operation

ENGAGING THE DRIVE

The self propelled Bear Vac Pros are engaged with the clutch

engagement bail located on the handlebar. When the bail is

brought to the bar the clutch is engaged and the machine

moves forward. When the bail is released the speed of the

machine can be adjusted between five forward settings using the transmission shift control located on the right of the

handlebar. To shift into reverse, first release wheel drive clutch.

Then pull the shift lever out and back. Engage the transaxle

by pulling the wheel drive clutch.

BEATERBAR ADJUSTMENTS

There are two adjustments that can be made on the

beaterbar. The first will set the height of the beaterbar, and

the second limits how much material enters the beaterbar.

Beaterbar height:

The height of the beaterbar in relation to the ground can be

changed by turning the Beaterbar Height Adjuster. Turning

the lever clockwise raises the beaterbar. Turning the lever

counterclockwise lowers the beaterbar.

Adjusting Inlet Door:

The inlet door can also be adjusted. Pulling on the lever

raises the door. Pushing on the lever lowers the door. The

door must be raised when vacuuming dense or deep material.

The door must be lowered when vacuuming sparse material

to achieve the same degree of compaction. This control is a

friction device and the tension can be adjusted. Tighten or

loosen the friction point as desired.

Fig. #9, Wheel Drive Clutch

Fig. #10, Transmission shift control

Fig. #11, Adjusting Beaterbar height

Fig. #12, Adjusting Inlet Door

Page 11Bear Vac Pro Operator’s Manual

Page 18

Operation

gg

g

g

g

g

g

g

g

g

EMPTYING THE TUB

1. Lower handle B. This is the air shut off handle and will

shut off air flow into the container.

2. Turn handle A counter clockwise. This will lift up the bucket

top of the Bear Vac Pro.

3. With the bucket top open remove the tub from the Bear

Vac Pro.

4. Dump the container into a suitable storage or collection

bin.

5. Place the tub back onto the Bear Vac Pro.

6. Lower the bucket top by turning handle A clockwise.

7. Raise handle B to lock the tub in place and open the shut

off valve.

Notes:

• Use tub at all times.

Fig. #13, Lifting the tub

• Empty tub before it fills completely. A full tub will cause

performance to decrease or stop completely.

• Empty tub completely before storage.

VACUUMING AND CHIPPING GUIDE

MATERIAL BEATER BAR/VACUUM CHIPPER

Dry Leaves YES NO

Damp Leaves YES NO

Wet, Matted Leaves

Pine Needles YES NO

Cornstalks NO

Half-Rotted Compost YES YES

Grass Clippin

Vines NO

Limp, Green Ve

Newspaper YES

ht Brush NO YES

Li

Lar

er Branches NO

s YES NO

etation

YES: Vacuum heavy or so

a slow

YES: Be sure to

wrap around beater bar

round speed

y material at

o slowly so vines don't

Fig. #14, Removing the tub

NO

YES: Be sure to clean dirt from roots as

this will cause blades to dull.

YES: Cut into shorter len

into chipper chute

YES: Drop into chipper chute, use stick to

tamp if necessary

YES: Roll up a couple sections at time

and drop into chute

YES: Re

if necessary

ulate feed rate and branch size

ths and drop

Page 12 Bear Vac Pro Operator’s Manual

Page 19

5

Service & Maintenance

Section

WARNING

To prevent personal injury or property damage: Shut

off engine, disconnect spark plug wire, and make sure

that all moving parts have come to a complete stop

before, servicing, adjusting or repairing.

MAINTENANCE SCHEDULE

The following items listed in the service and maintenance

schedule are to be checked, and if necessary, corrective

action should be taken. This schedule is designed for units

operating under normal conditions. If the unit is operating in

adverse or severe usage conditions it may be necessary for

the items to checked and serviced more frequently.

See engine owners manual for further maintenance and

troubleshooting information.

NOTE:

After using the Bear Vac Pro for three hours the beaterbar

and transaxle engagment may need to be adjusted. The

handlebar levers, when cycled, should engage fully and release completely, otherwise they need to be adjusted. For

adjustment locations see Fig. # 15 and #16.

Fig. #15, Adjusting transaxle engagement

SERVICE AND MAINTENANCE SCHEDULE

COMPONENT

FUEL TANK FILL

AIR CLEANER CHECK AND CLEAN¹

AIR INTAKE CLEAN¹

ENGINE OIL CHANGE¹

ENGINE OIL CHECK

FUEL FILTER REPLACE

SPARK PLUG

NUTS AND BOLTS CHECK

BELT CONDITION CHECK

BELT TENSION CHECK

GREASE ZERKS LUBE

ENTIRE MACHINE CLEAN

¹ PERFORM MORE FREQUENTLY UNDER EXTREMELY DUSTY CONDITIONS.

MAINTENANCE

REQUIRED

CHECK CONDTION AND

GAP

Refer to Engine

Operator manual

•

•

•

•

•

Fig. #16, Adjusting beaterbar engagement

FREQUENCY

BEFORE

EACH

USE

EVERY

8

HOURS

EVERY

25

HOURS

EVERY

HOURS

•

•

•

•

•

•

50

•

Page 13Bear Vac Pro Operator’s Manual

Page 20

Service & Maintenance

REPLACING THE DRIVE BELT

1. Remove the belt guard, following Fig. #15.

2. Remove the chipper blade access cover.

3. Remove chipper blades from the rotor.

4. Loosen the belt guide surrounding the rear of the transmission belt.

5. Remove the old belt. The easiest way is to cut the belt

and slide it out.

6. Insert the new belt into the rotor housing and hook into

one of the chipper slots in the rotor. Rotate the rotor to

move the belt above the fan. Be sure the belt goes under

the fan blades and on top of the fan.

7. Pull the excess new belt to the rear of the machine and

slide it onto the top pulley of the engine. If the beaterbar

belt is attached the new transmission belt will have to be

threaded through the beater bar belt.

8. Position the belt onto the transmission pulley, sliding it

between the belt guide.

REAR BELT

5/16" FLAT

5/16" NYLOCK

GUARD

BELT GUIDE

WASHER

NUT

5/16" NYLOCK

5/16" FLAT

NUT

WASHER

TRANSAXLE

LAWNVAC

Fig. #17, Belt guide removal

DRIVE

PULLEY

1/4" TO 1/2"

DEFLECTION IS

ACCEPTABLE

DRIVEN

PULLEY

DRIVE BELT

TENSION

9. Engage the bail and set the position of the transmission

belt guide. There should be 1/8” of clearance between

the belt guide and the top of the belt.

10. To set the proper tension of the belt, set the idler arm so

there is approximately 1/8” to 1/4” of deflection on the

belt.

10. Reattach the belt covers and operate the unit as instructed.

Page 14 Bear Vac Pro Operator’s Manual

Page 21

REPLACING THE BEATERBAR BELT

Service & Maintenance

1. Remove the belt guard covering the beater bar. Never run

the machine with the belt cover off.

2. Remove the chipper blade access cover.

3. Remove chipper blades from the rotor.

4. Loosen the three belt guides.

5. Remove the idler pivot bolt.

6. Insert the new belt into the rotor housing and hook into

one of the chipper slots in the rotor. Rotate the rotor to

move the belt above the fan. Be sure the belt goes under

the fan blades and on top of the fan.

7. Remove the old belt. The easiest way is to cut the belt

and slide it out.

8. Pull the excess new belt to the rear of the machine and

slide it onto the bottom pulley.

9. Position the belt correctly. Slide it under the belt guides,

around the idler pulleys, and over the beaterbar pulley.

10. Engage the bail and set the position of the beaterbar

belt guide. There should be 1/8” of clearance between

the belt guide and the belt.

11. Reinstall the idler pivot bolt.

12. Reattach the belt covers and operate the unit as instructed.

DRIVE PULLEY

BEATER BAR

BELT

BEATER BAR

IDLER PULLEY

PULLEY

Fig. #18, Proper beaterbar belt orientation

Page 15Bear Vac Pro Operator’s Manual

Page 22

Service & Maintenance

REMOVING THE CHIPPER BLADES

Chipper blades must always be kept sharp! It is

recommended they are sharpened approximately every 8

hours of chipping operation, or when branches no longer

self feed. If the blades aren’t sharp severe vibration and

difficulty in chipping will develop.

To remove the chipper blades:

1. Start by removing the chipper blade access cover by removing the 5/16” bolt and washer.

2. Using a block of wood, or a screwdriver, secure the rotor

so it is not able to spin.

3. From the bottom, remove the 5/16” bolts holding the chipper blades onto the rotor.

4. Replace, reverse, or sharpen the blades.

5. Reinstall the 5/16” bolts and tighten to 20 ft/lbs of torque.

SHARPENING THE CHIPPER BLADES

Flip the blade or regrind the angled edge of the chipping

blades to 45 degrees. (refer to figure below) The blades can

be ground on a bench grinder or by a professional. Make

sure some type of fixture is used to correctly hold the blade

at the proper angle. Be careful when grinding so that the

blade does not become overheated and change color. (This

will remove the heat-treated properties) Use short grinding

times and cool with water or some type of liquid coolant.

Try to remove an equal amount off of each blade to maintain

rotor balance.

Never sharpen or back grind the flat side of the chipping

blade. This will cause the edge to roll and the chipper blade

will be damaged, resulting in poor chipping performance.

Small imperfections such as nicks, burrs, etc. on the flat

side of the blade will not affect the chipping performance of

the machine.

45°

5/16" FLAT

WASHER

5/16" X 3/4"

BOLT

ACCESS COVER

Fig. #19, Access panel removal

CHIPPER BLADE

5/16" FLAT

WASHER

5/16" NYLOCK

NUT

NEVER SHARPEN OR BACK GRIND THIS SIDE -

POOR FEEDING AND CHIPPING WILL RESULT.

FLAT SIDE

Fig. #20, Chipper blade sharpening

SHARPEN TO A 45° ANGLE.

Page 16 Bear Vac Pro Operator’s Manual

Page 23

GREASING

There are four grease zerks on the Bear Vac Pro. Three are

located on the castor wheel weldment, and one on the

beaterbar belt. The pictures below show the exact locations

of the zerks. They should be greased every 25 hours,

depending upon conditions.

Service & Maintenance

Fig. #21, Grease every 25 hours

Fig. #22, Grease every 25 hours

Fig. #23, Grease every 25 hours

Fig. #24, Grease every 25 hours

Page 17Bear Vac Pro Operator’s Manual

Page 24

Service & Maintenance

p

g

j

j

g

g

pty

p

TROUBLESHOOTING

Before performing any of the correction in this troubleshooting chart, refer to the appropriate information contained in this

manual for the correct safety precautions and operating or maintenance procedures. Contact your nearest dealer or the

factory for service problems with the machine.

PROBLEM POSSIBLE CAUSE CORRECTION

Chipper does not chip. Poor

performance.

Loss of vacuum.

Vacuum not functioning or beater bar

not turning.

Dull chipping blades. Sharpen or replace.

Drive belts loose or worn. Re

Too lar

e of branch. Limit branch size.

Solid object jammed in the unit. Check and remove.

Broken or missing chipper blade. Replace blade.

Intake clogged. Raise inlet door and remove obstruction.

Collection bag full. Remove and empty bag.

Processing chamber clogged. Remove front side access cover and clean area.

Engine not reaching full RPM. Refer to Engine Owners Manual.

Vacuum shut off door closed. Open vacuum shut off door.

Belts slipping or burning. Ensure beater bar is engaged before beginning to

Beater bar jammed. Remove material and revacuum at slower speed.

Beater bar chamber clogged. Remove material and revacuum at slower speed.

Solid object jammed in the unit. Check and remove obstruction.

lace drive belts.

vacuum.

Unusual vibration or noise.

Loss of traction.

Gearshift lever does not shift

properly.

Engine runs poorly.

Chipper blade loose or damaged. Tighten or replace.

Engine cylinder shaft or crankshaft is bent or

damaged.

Loose or missing bolts on unit. Tighten or replace bolts.

Cracked or broken beater bar knives. Replace cracked or broken knives.

Wheels not turning. Check key in axle and wheel assembly.

Stretched or broken drive belt. Replace drive belts.

Wheel drive bail cable not tensioned correctly. Adjust or replace spring.

Malfunction in transaxle. Contact Bear Cat dealer or call factory.

Loose gearshift lever cable. Reconnect cable to bail.

Broken gear shift lever cable. Replace gear shift lever cable.

Clevis not attached to shift arm. Reattach cable to shift arm.

Malfunction in transaxle. Contact Bear Cat dealer or call factory.

Cable not ad

Bad spark plug. Inspect spark plug and replace if necessary.

Incorrect choke settin

Dirty air filter. Clean or replace.

Stale gasoline. Drain gasoline and add fresh fuel.

Dirt or water in fuel tank. Contact engine service dealer.

usted properly.Check ad

.Chan

See Engine Service Dealer.

ustment points.

e choke setting.

Engine won't start or is hard to start.

Gas tank is em

Spark plug wire is disconnected. Connect loose wire to spark plug.

S

ark plug is defective. Replace spark plug.

Gas line is obstructed. Remove gas line at carburetor and check for

Dirty, stale, water-contaminated gas. Drain tank and fill with fresh gasoline.

Flooded engine. Put throttle control in run position and crank

Dirty or plugged air cleaner. Clean air cleaner and replace.

. Fill gas tank.

Page 18 Bear Vac Pro Operator’s Manual

obstruction. Drain gas tank and refill with fresh,

clean gasoline.

engine several times to clear out excess gas.

Page 25

Manual Improvement Program

If you have a suggestion on how to improve this manual, send it to us. Participants whose ideas are

implemented will receive a free pair of Crary genuine leather gloves.

Send your suggestions to:

Crary Company

C/O Technical Writer

237 NW 12th St. Box 849

West Fargo, ND 78078

Suggestions:

Name:

Address:

Phone Number:

Email (if applicable):

Product purchased:

Manual part number:

Page 19Bear Vac Pro Operator’s Manual

Page 26

Page 27

Manual Improvement Program

If you have a suggestion on how to improve this manual, send it to us. Participants whose ideas are implemented will

receive a free pair of Crary genuine leather gloves. The form is located after the torque chart in the manual.

HEALTH WARNING

GASOLINE, DIESEL, AND

OTHER PETROLEUM PRODUCTS

Harmful or fatal if swallowed.

Long-term exposure to vapors has caused cancer in laboratory animals.

• Avoid prolonged breathing of vapors.

• Keep face away from nozzle and gas tank/container

opening.

• Never siphon by mouth.

Failure to use caution may cause serious injury or illness.

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM ARE FOUND IN

GASOLINE, DIESEL, CRUDE OIL, AND MANY OTHER

PETROLEUM PRODUCTS AND THEIR VAPORS, OR

RESULT FROM THEIR USE.

READ AND FOLLOW LABEL DIRECTIONS AND USE

CARE WHEN HANDLING OR USING ALL PETROLEUM

PRODUCTS.

ENGINE EXHAUST FROM THIS PRODUCT CONTAINS

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS, OR

OTHER REPRODUCTIVE HARM.

Crary Company

A Division of TerraMarc Industries

237 12th St. NW • P.O. Box 849

West Fargo, ND 58078-0849

(701)282-5520 • FAX: (701)282-9522

www.bearcatproducts.com

WARNING

www.terramarc.com

Manufactured in the

United States of America

by Crary Company

Loading...

Loading...