Page 1

Instructions

SUBJECT: WHEELED VACUUM

8. Install the hose holder bracket by sliding the bracket down

the Wheeled Vacuum upper handlebar until it contacts the

Wheeled Vacuum lower handlebar. Secure with 1/4" U-bolts,

washers and locknuts.

9. Install the hose holder weldment to the right side of the machine on Honda models. Install the weldment to the left side

of the machine on Briggs and Stratton engines.

10. Bolt the hose holder weldment to the Wheeled Vacuum frame

with the existing 5/16" bolts and 5/16" washers.

11. Route the hose from the Wheeled Vacuum nozzle to the

hose holder bracket, then press the hose nozzle onto the

hose holder weldment.

HOSE KIT (PN 73606-00)

MODELS: ALL WHEELED VACUUMS

WARNING

BEFORE INSPECTING OR SERVICING ANY PART

OF THIS MACHINE, SHUT OFF POWER SOURCE,

DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE

STOP.

The Wheeled Vacuum Hose Kit contains everything needed to

attach a vacuum hose to the Wheeled Vacuum. Refer to the

illustration on the back page during assembly.

1. Remove the hose clamp securing the plastic cap to the

Wheeled Vacuum nozzle.

2. Remove the plastic cap from the nozzle.

3. Attach the end of the vacuum hose opposite the hose nozzle

to the nozzle of the Wheeled Vacuum.

OPERATING INSTRUCTIONS

1. Adjust the engine to the desired throttle setting (see owners

manual for starting instructions).

2. Make sure the Wheeled Vacuum is parked on level

ground.

3. Remove the hose form the hose holder weldment.

4. Use the handle attached to the hose to easily maneuver the

hose around corners, underneath bushes, etc.

5. Move the hose from side to side when vacuuming and keep

the hose as straight as possible to prevent clogging. To avoid

clogging, do not vacuum too much material at once.

6. Never attempt to move the machine by pulling on the

hose.

7. Do not allow the hose to come in contact with the mufer of

the Wheeled Vacuum.

8. If the hose becomes clogged or jammed, stop the engine to

clear the obstruction.

4. Align the hose with the machine so that the hose handle is

upright when installed.

5. Attach the vacuum hose to the nozzle with the hose clamp

removed from the plastic cap.

6. Slide the seal plate under the nozzle of the Wheeled Vacuum.

If needed, use the extra foam to seal the rear side of the

Wheeled Vacuum nozzle.

7. Connect the seal plate to the nozzle by looping the two 6"

straps around the nozzle to the tab on the other side of the

seal plate.

Instruction Sheet

WARNING

DO NOT RUN THE VACUUM HOSE WITHOUT THE SEAL PLATE

INSTALLED. WITHOUT THE PLATE, THE UNIT WILL NOT PROVIDE

THE SUCTION NECESSARY TO OPERATE THE HOSE.

WARNING

THE UNIT CAN BE OPERATED WITH THE HOSE ATTACHED

TO THE WHEELED VACUUM, PROVIDED THE SEAL PLATE IS

REMOVED FROM THE MACHINE.

PN 73688-00

Rev. 091708

Page 2

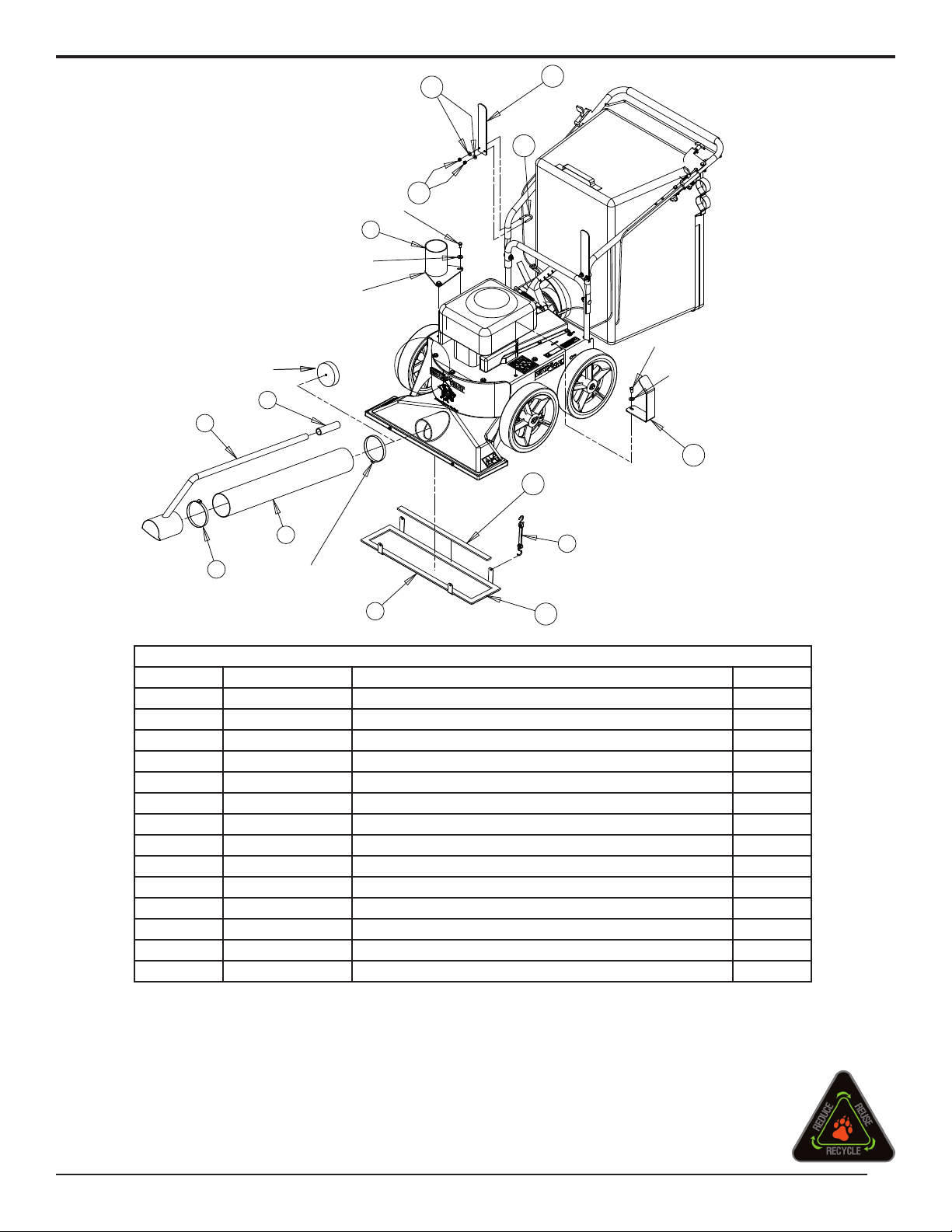

12

8

11

EXISTING 5/16" X 5/8" BOLT

EXISTING 5/16" FLAT WASHER

MOUNT ON RIGHT SIDE FOR

HONDA GXV140 ENGINE

MOUNT ON LEFT SIDE FOR BRIGGS

& STRATTON INTEC ENGINE

RETAIN PLASTIC CAP

FOR FUTURE USE

4

6

3

EXISTING HOSE CLAMP

TO BE RE-USED

13

7

EXISTING 5/16" X 5/8" BOLT

EXISTING 5/16"

FLAT WASHER

14

FOR USE WITH

10

NOZZLE WEAR PLATE.

2

5

1

APPLY FOAM AROUND

10

PERIMETER

OF SEAL PLATE.

KIT, WHEELED VACUUM HOSE (73606-00)

ITEM PART NUMBER DESCRIPTION QTY

1 12627 STRAP, 6" TARP 2

2 16194 HOSE, PVC 4" ID C 10' LONG 1

3 16196 CLAMP, 4" HOSE 1

4 16258 GRIP, 1" ID X 4.63" 1

5 73673-12 PLATE, Wheeled Vacuum HOSE KIT SEAL 1

6 73887-12 WELDMENT, 4” HOSE NOZZLE 1

7 73884-12 WELDMENT, HOSE HOLDER/PLUG 1

8 73890-12 STRIP, HOSE HANGER 2

9 73688-00 INSTRUCTION, Wheeled Vacuum VACUUM HOSE KIT 1

10 73698-00 FOAM, PLATE SEAL 1

11 15541 U-BOLT, 1/4" X 1.0" X 1.75" ZP 2

12 15030 WASHER, 1/4" FLAT ZP 4

13 15355 LOCKNUT, 1/4-20 NE NYLON ZP 4

14 74141-12 BRACKET, HOSE HOLDER 1

ECHO BEAR CAT

www.bearcatproducts.com

237 NW 12th Street, West Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 888.645.4520 • Fax: 701.282.9522

E-mail: service@bearcatproducts.com • sales@bearcatproducts.com

Instruction Sheet

Loading...

Loading...