Page 1

3 InCH

MADE WITH PRIDE IN THE...

CHIPPer/sHreDDers

70050 - 5.5 HP 75311 - 11 HP

70080 - 8 HP 70050S - 5 HP

70085 - 8 HP ELECTRIC 70080S - 8 HP ELECTRIC

70180 - 8 HP 70180S - 8 HP

70380 - 8 HP 70380S - 8 HP

f - mANuEL du PROPIÉTAIRE

70385 - 8 HP ELECTRIC 70580S - 8 HP ELECTRIC

70580 - 8 HP TOWABLE

PN: 14846-00 R071204

en - OWNER's mANuAL

Companion to 14849-00

owner's manual

eS - mANuAL dEL PROPIETARIO

Page 2

Before You Begin

MANUFACTURED BY CRARY INDUSTRIES

MANUFACTURED IN U.S.A.

XXXXXX

WEST FARGO, NORTH DAKOTA 58078 U.S.A.

SERIAL NUMBER

Dear eCHo Bear CaT CusTomer

Thank you for purchasing an ECHO Bear Cat product. The ECHO Bear Cat line is designed, tested, and manufactured to give

years of dependable performance. To keep your machine operating at peak efciency, it is necessary to adjust it correctly and

make regular inspections. The following pages will assist you in the operation and maintenance of your machine. Please read and

understand this manual before operating your machine.

If you have any questions or comments about this manual, please call us toll-free at 1-800-247-7335.

If you have any questions or problems with your machine, please call or write your local authorized ECHO Bear Cat dealer.

This document is based on information available at the time of its publication. ECHO Bear Cat is continually making improvements

and developing new equipment. In doing so, we reserve the right to make changes or add improvements to our product without

obligation for equipment previously sold.

Please senD us Your warranTY CarD

A warranty card is included in your owner's kit packaged with your machine. Please take the time to ll in the information requested on the card. When you send your completed card to us, we will register your machine and start your coverage under our limited

warranty.

ParTs orDerInG InFormaTIon

For service assistance or parts, contact your nearest authorized ECHO Bear Cat dealer or the factory. your nearest

authorized dealer will need to know the serial number of your

machine to provide the most efcient service. See below for

information on how to identify and record the serial number for

your machine.

if you need engine service or parts:

For engine service pr parts, contact your nearest authorized

engine dealer. An authorized engine dealer can handle all

parts, repairs, and warranty service concerning the engine.

serIal numBer loCaTIon

Please record the serial number in the space provided and on

the warranty and registration card.

rePlaCemenT ParTs

Only genuine ECHO Bear Cat replacement parts should be

used to repair the machine. Replacement parts manufactured

by others could present safety hazards, even though they may

t on this machine. Replacement parts are available from your

ECHO Bear Cat dealer.

Provide the following when ordering parts:

The sERIAL NumBER of your machine.

The PART NumBER of the part.

The PART dEsCRIPTION.

The QuANTITy needed.

serIal numBer

How To ConTaCT eCHo Bear CaT

addreSS Phone e-mail hourS

237 NW 12th street

P.O. Box 849

West Fargo, Nd 58078

800-247-7335

701-282-5520

FAx: 701-282-9522

opesales@crary.com

service@crary.com

© 2006, CRARy INdusTRIEs, ALL RIgHTs REsERvEd. PROduCEd ANd PRINTEd IN THE u.s.A.

monday - Friday,

8 am to 5 pm

Central Time

Page 3

LIMITED WARRANTY

This warranty applies to all AG and Outdoor Power Equipment manufactured by Crary Industries.

Crary Industries warrants to the original owner each new Crary Industries product to be free from defects

in material and workmanship, under normal use and service. The warranty shall extend 1 year from date of

delivery for income producing (commercial) applications and 2 years from date of delivery for non-income

producing (consumer) use of the product. The product is warranted to the original owner as evidenced by a

completed warranty registration on file at Crary Industries. Replacement parts are warranted for (90) days

from date of installation.

ThE WARRANTY REgIsTRATIoN MusT bE coMpLETED AND RETuRNED To cRARY INDusTRIEs

WIThIN 10 DAYs of DELIvERY of ThE pRoDucT To ThE oRIgINAL oWNER oR ThE WARRANTY

WILL bE voID.

In the event of a failure, return the product, at your cost, along with proof of purchase to the selling Crary

Industries dealer. Crary Industries will, at its option, repair or replace any parts found to be defective in material

or workmanship. Warranty on any repairs will not extend beyond the product warranty. Repair or attempted

repair by anyone other than a Crary Industries dealer as well as subsequent failure or damage that may occur

as a result of that work will not be paid under this warranty. Crary Industries does not warrant replacement

components not manufactured or sold by Crary Industries.

This warranty applies only to parts or components that are defective in material or workmanship.

1.

This warranty does not cover normal wear items including but not limited to bearings, belts, pulleys, filters

2.

and chipper knives.

This warranty does not cover normal maintenance, service or adjustments.

3.

This warranty does not cover depreciation or damage due to misuse, negligence, accident or improper

4.

maintenance.

This warranty does not cover damage due to improper setup, installation or adjustment.

5.

This warranty does not cover damage due to unauthorized modifications of the product.

6.

Engines are warranted by the respective engine manufacturer and are not covered by this warranty.

7.

Crary Industries is not liable for any property damage, personal injury or death resulting from the unauthorized

modification or alteration of a Crary product or from the owner’s failure to assemble, install, maintain or operate

the product in accordance with the provisions of the Owner’s manual.

Crary Industries is not liable for indirect, incidental or consequential damages or injuries including but not

limited to loss of crops, loss of profits, rental of substitute equipment or other commercial loss.

This warranty gives you specific legal rights. You may have other rights that may vary from area to area.

Crary Industries makes no warranties, representations or promises, expressed or implied as to the performance

of its products other than those set forth in this warranty. Neither the dealer nor any other person has any

authority to make any representations, warranties or promises on behalf of Crary Industries or to modify the

terms or limitations of this warranty in any way. Crary Industries, at its discretion, may periodically offer limited,

written enhancements to this warranty.

cRARY INDusTRIEs REsERvEs ThE RIghT To chANgE ThE DEsIgN AND/oR spEcIfIcATIoNs

of ITs pRoDucTs AT ANY TIME WIThouT obLIgATIoN To pREvIous puRchAsERs of ITs

pRoDucTs.

Page 4

conTenTS

SecTion deScriPTion Page

SafeTY ......................................................................................................................................................................... 3

1.1 THE sAFETy ALERT symBOL ...................................................................................................................................................................... 3

1.2 EmIssION INFORmATION ..............................................................................................................................................................................

1.3 BEFORE OPERATINg ..................................................................................................................................................................................... 3

1.4 OPERATION sAFETy ...................................................................................................................................................................................... 4

1.5 mAINTENANCE ANd sTORAgE .....................................................................................................................................................................

sAFETy .........................................................................................................................................................................................................

1.6 TOWINg sAFETy ............................................................................................................................................................................................

1.7 BATTERy sAFETy ..........................................................................................................................................................................................5

1.8 sAFETy dECALs ............................................................................................................................................................................................ 6

1.9 sAFETy dECAL LOCATIONs ......................................................................................................................................................................... 8

1.9.1 mOdEL 70050 ......................................................................................................................................................................................8

1.9.2 mOdELs 70080, 70085, 70180, 70380, 70385 ...................................................................................................................................

1.9.3 mOdEL 70580 ......................................................................................................................................................................................8

1.9.4 mOdEL 70050s ...................................................................................................................................................................................9

1.9.5 mOdELs 70080s, 70180s, 70380s ....................................................................................................................................................9

1.9.6 mOdEL70580s ....................................................................................................................................................................................

aSSemblY ................................................................................................................................................................. 10

2.1 INsTALLINg THE HANdLE ........................................................................................................................................................................... 10

2.2 INsTALLINg THE HOPPER ..........................................................................................................................................................................

2.3 INsTALLINg THE CHIPPER CHuTE ExTENsION ......................................................................................................................................10

2.4 INsTALLINg THE WIdE ANd NARROW dIsCHARgE AssEmBLy ............................................................................................................10

2.5 INsTALLINg THE WHEELs, jACk ANd HITCH ........................................................................................................................................... 10

2.6 INsTALLINg THE BATTERy .........................................................................................................................................................................10

2.7 CHECkINg/AddINg mOTOR OIL TO ENgINE .............................................................................................................................................11

2.8 FILLINg THE TANk .......................................................................................................................................................................................11

10

3

5

5

8

9

feaTureS & conTrolS .........................................................................................................................................12

3.1 ENgAgEmENT HANdLE .............................................................................................................................................................................. 12

3.2 ENgINE THROTTLE ......................................................................................................................................................................................12

3.3 ENgINE CHOkE ............................................................................................................................................................................................ 12

3.4 kEy sWITCH ................................................................................................................................................................................................. 13

3.5 sHREddER CHuTE ...................................................................................................................................................................................... 13

3.6 sHREddER kNIvEs ..................................................................................................................................................................................... 13

3.7 CHIPPER CHuTE .......................................................................................................................................................................................... 13

3.8 CHIPPER BLAdEs ........................................................................................................................................................................................ 13

3.9 jACk sTANd ................................................................................................................................................................................................. 13

oPeraTion ................................................................................................................................................................ 14

4.1 sTARTINg ELECTRIC mOdELs .................................................................................................................................................................. 14

4.2 sTARTINg RECOIL mOdELs ...................................................................................................................................................................... 14

4.3 sTOPPINg THE CHIPPER/sHREddER ...................................................................................................................................................... 15

4.4 CHIPPINg guIdE .........................................................................................................................................................................................15

4.5 sHREddINg guIdE ....................................................................................................................................................................................15

Service & mainTenance ...................................................................................................................................... 16

5.1 mAINTENANCE sCHEduLE ........................................................................................................................................................................16

5.2 CHIPPER BLAdEs ........................................................................................................................................................................................ 17

5.2.1 REmOvINg THE BLAdEs ................................................................................................................................................................17

5.2.2 sHARPENINg THE BLAdEs ............................................................................................................................................................17

5.2.3 INsTALLINg THE BLAdEs ...............................................................................................................................................................17

5.3 sETTINg CHIPPINg BLAdE CLEARANCE ..................................................................................................................................................18

5.4 REPLACINg THE sHREddER kNIvEs ...................................................................................................................................................... 18

5.5 CHANgINg THE dIsCHARgE sCREEN.....................................................................................................................................................19

5.6 BELT guIdE AdjusTmENTs ...................................................................................................................................................................... 19

5.7 REmOvE/REPLACE dRIvE BELT ...............................................................................................................................................................20

5.8 CLEARINg A PLuggEd ROTOR.................................................................................................................................................................20

5.9 REmOvINg ROTOR .....................................................................................................................................................................................

5.10 TRAILER sERvICE TIPs ..................................................................................................................................... 20

5.11 gREAsEABLE BEARINgs ANd PIvOTs ..................................................................................................................................................21

20

TroubleShooTing ................................................................................................................................................ 22

SPecificaTionS .......................................................................................................................................................23

7.1 NON-TOWABLE mOdELs ............................................................................................................................................................................ 23

7.2 TOWABLE mOdELs .....................................................................................................................................................................................

7.3 BOLT TORQuE ............................................................................................................................................................................................. 24

7.4 sPECIAL TORQuE REQuIREmENTs ......................................................................................................................................................... 25

2

3 INCH CHIPPER/SHREDDERS

23

Page 5

1

Section

Safety

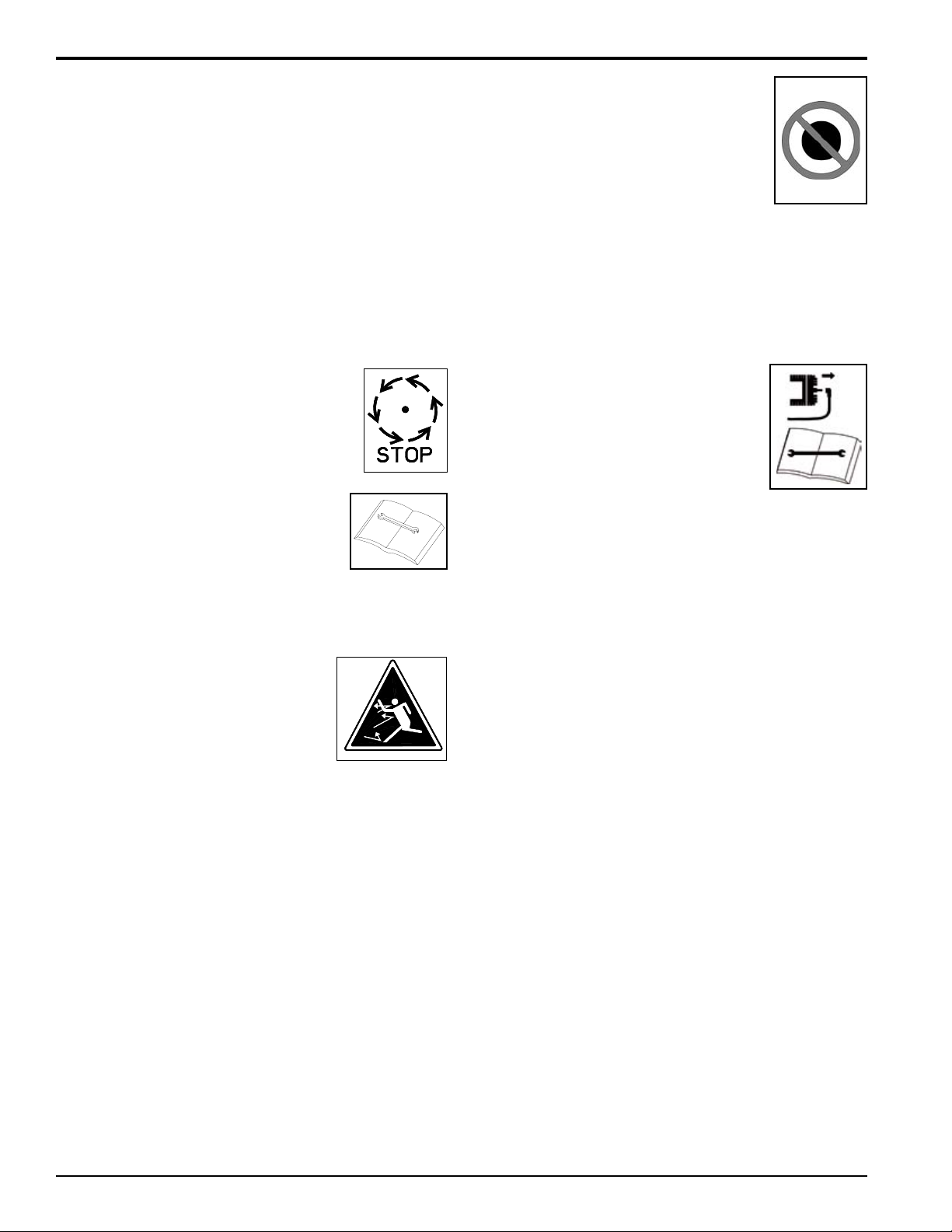

1.1 The SafeTY alerT SYmbol

The Owner/Operators manual uses this symbol

to alert you of potential hazards. Whenever

you see this symbol, read and obey the safety

message that follows it. Failure to obey the

safety message could result in personal injury,

death or property damage.

danger

Indicates an imminently hazardous situation that, if not

avoided, will result in death or serious injury.

Warning

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

cauTion

Indicates a potentially hazardous situation that, if not avoided,

may result in minor or moderate injury.

1.2 emiSSion informaTion

Warning To all california and oTher STaTeS

oPeraTing ouTdoor PoWer eQuiPmenT

under California Law and under the laws of

several other states, you are not permitted

to operate an internal combustion engine

using hydrocarbon fuels on any forest

covered, brush covered or grass covered

land or on land covered with grain, hay

or other flammable agricultural crops, without an engine spark

arrester in continuous effective working order.

The engine on your power equipment, like most outdoor power

equipment, is an internal combustion engine that burns gasoline

(a hydrocarbon fuel). Therefore, your power equipment must be

equipped with a spark arrester muffler in continuous effective

working order. The spark arrester must be attached to the engine

exhaust system in such a manner that flames or heat from the

system will not ignite flammable material.

Failure of the owner/operator of the equipment to comply with

this regulation is a misdemeanor under California law and may

also be a violation of other state and/or federal regulations, laws,

ordinances, or codes. Contact your local fire marshal or forest

service for specific information about which regulations apply

in your area.

The standard muffler installed on the engine is not equipped

with a spark arrester. one must be added before using this

machine in an area where a spark arrester is required by law.

Contact the local authorities if these laws apply to you. see your

authorized engine dealer for spark arrester options.

1.3 before oPeraTing

Read and understand this Owner/Operators manual. Be

1.

completely familiar with the controls and the proper use of

this equipment.

Familiarize yourself with all of the safety and operating

2.

decals on this equipment and on any of its attachments or

accessories.

3.

keep safety decals clean and legible. Replace missing or

illegible safety decals.

Obtain and wear safety glasses and

4.

use hearing protection at all times

when operating this machine.

Avoid wearing loose fitted clothing.

5.

Never operate this machine wearing clothing with drawstrings that

could wrap around or get caught

in the machine.

6.

do not operate this machine if you are under the influence of

alcohol, medications, or substances that can affect your vi-

sion, balance or judgement. Do not operate if tired or ill. You

must be in good health to operate this machine safely.

7.

do not operate this equipment in

the vicinity of bystanders. keep the

area of operation clear of all persons,

particularly small children. It is recommended that bystanders keep at

least 50 feet (15 meters) away from

the area of operation.

8.

do not allow children to operate this equipment.

9.

use only in daylight or good artificial light.

3 INCH CHIPPER/SHREDDERS

3

Page 6

SAFETY

do not run this equipment in an enclosed area. Engine ex-

10.

haust contains carbon monoxide gas, a deadly poison that is

odorless, colorless and tasteless. do not operate this equipment in or near buildings, windows or air conditioners.

11.

Always use an approved fuel container. do not remove gas

cap or add fuel when engine is running. Add fuel to a cool

engine only.

12.

do not fill fuel tank indoors. keep open flames, sparks,

smoking materials and other sources of combustion away

from fuel.

13.

do not operate machine without shields in place. Failure to

do so may cause serious injury or death.

14.

keep all guards, deflectors, and shields in good working

condition.

Before inspecting or servicing any part

15.

of this machine, shut off power source,

disconnect spark plug wire from spark

plug and make sure all moving parts have

come to a complete stop.

Check that all screws, nuts, bolts, and

16.

other fasteners are secured, tightened

and in proper working condition before

starting the machine and once every 8

hours of operation.

17.

do not transport or move machine while

the machine is operating or running.

1.4 oPeraTion SafeTY

Always stand clear of discharge area

1.

when operating this machine. keep face

and body away from feed and discharge

openings.

2.

keep hands and feet out of feed and

discharge openings while machine is

operating to avoid serious personal injury. Stop and allow machine to come to a complete stop before clearing

obstructions.

3.

set up your work site so you are not endangering traffic and

the public. Take great care to provide adequate warnings.

4.

do not climb on machine when operating. keep proper bal

ance and footing at all times.

Check cutting chamber to verify it is empty before starting

5.

the machine.

Lower lever slowly to engage machine. Pull lever up to

6.

disengage machine. Chipper/shredder rotor will continue to

rotate when clutch is disengaged. shut off power source,

disconnect spark plug wire from spark plug and make sure

all moving parts have come to a complete stop. do not

operate without discharge screen, inlet flaps and all shields

in place.

7.

do not insert branches larger than 3/4 inch into shredder or

machine damage may occur.

8.

do not insert branches larger than 3 inches in diameter into

chipper or machine damage may occur.

When feeding shreddable material into

9.

machine, do not allow metal, rocks, bottles,

cans or any other foreign material to be fed

into chipper or shredder.

Ensure debris does not blow into traffic,

10.

parked cars, or pedestrians.

11.

keep the machine clear of debris and other accumula

tions.

12.

do not allow processed material to build up in the discharge

area. This may prevent proper discharge and can result in

kickback of material through the feed opening.

13.

shut off machine immediately if the machine becomes

clogged, the cutting mechanism strikes any foreign object,

or the machine starts vibrating or making an unusual noise.

shut off power source, disconnect spark plug wire from spark

plug and make sure all moving parts have

come to a complete stop. After machine

stops:

Inspect for damage.

A.

Replace or repair any damaged

B.

parts.

Check for and tighten any loose parts.

C.

On electric start models, disconnect cables from battery

14.

before doing any inspection or service.

Check blade bolts for proper torque after every 8 hours of

15.

operation. Check blades and rotate or resharpen daily or as

required to keep blades sharp. Failure to do so may cause

poor performance, damage or personal injury and will void

the machine warranty.

-

3 inch

76 mm

-

4

3 INCH CHIPPER/SHREDDERS

Page 7

SAFETY

danger / PoiSon

sHIELd EyEs

ExPLOsIvE gAsEs

CAN CAusE

BLINdNEss OR

INjuRy

NO

• sPARks

• FLAmEs

• smOkINg

suLFuRIC

ACId

CAN CAusE

BLINdNEss OR

sEvERE BuRNs

FLusH EyEs

ImmEdIATELy

WITH WATER

gET

mEdICAL

HELP

FAsT

kEEP OuT OF THE REACH OF CHILdREN. dO NOT TIP. kEEP vENT CAPs TIgHT ANd LEvEL.

1.5 mainTenance and STorage

SafeTY

Before inspecting, servicing, storing, or changing an acces-

1.

sory, shut off power source, disconnect spark plug wire from

spark plug and make sure all moving parts have come to

a complete stop.

Replace any missing or unreadable safety decals. Refer

2.

to the parts manual for part numbers when ordering safety

decals from an area ECHO Bear Cat dealer.

Allow machine to cool before storing in an enclosure.

3.

4.

store the machine out of reach of children and where fuel

vapors will not reach an open flame or spark.

Never store this machine with fuel in the fuel tank inside a

5.

building where fumes may may be ignited by an open flame

or spark. Ignition sources can be hot water and space heaters, furnaces, clothes dryers, stoves, electric motors, etc.

6.

drain the fuel and dispose of it in a safe manner for storage

periods of three months or more.

1.6 ToWing SafeTY

Towing laws may vary in different countries/regions/states.

1.

It is recommended that you contact your local motor vehicle

department for any special rules that pertain to towing and

to know the rules of any country/region/state you may travel

through.

Connect hitch safety chains. Tighten and secure trailer

2.

hitch bolts. do not attempt to tow the trailer if vehicle is not

equipped with the proper size hitch ball.

Check wheel lug bolts periodically to ensure they are tight

3.

and secure.

Place the jack stand on the trailer in the UP position to clear

4.

the ground while towing. Place the jack stand on a level

surface and secure it in the dOWN position before using.

Never allow passengers to ride on the chipper.

5.

If applicable, shut off fuel supply when towing.

6.

1.7 baTTerY SafeTY

Improper use and care of the battery on electric start models

can result in serious personal injury or property damage. Always

observe the following safety precautions.

danger / Poison - Causes severe Burns. The battery con-

1.

tains sulfuric acid. Avoid contact with skin, eyes or clothing.

keep out of reach of children.

anTidoTe-external contact: Flush immediately with lots

of water.

anTidoTe-internal: drink large quantities of water or

milk. Follow with milk of magnesia, beaten egg or vegetable

oil. Call a physician immediately.

anTidoTe-eye contact: Flush with water for 15 minutes.

get prompt medical attention.

2.

The battery produces explosive gases. keep sparks, flame

or cigarettes away. ventilate area when charging battery.

Always wear safety goggles when working near battery.

3.

The battery contains toxic materials. do not damage bat

tery case. If case is broken or damaged, avoid contact with

battery contents.

Neutralize acid spills with a baking soda and water solu-

4.

tion.

Properly dispose of a damaged or worn-out battery. Check

5.

with local authorities for proper disposal methods.

6.

do not short circuit battery. severe fumes and fire can

result.

Before working with electrical wires or components, dis-

7.

connect the negative (-) cable first. disconnect the positive

(+) cable second. Reverse this order when reconnecting

battery cables.

-

3 INCH CHIPPER/SHREDDERS

5

Page 8

SAFETY

1.8 SafeTY decalS

see section 1.9 for decal locations. Familiarize yourself with all of the safety and operating decals on the machine and the associated

hazards. see the engine owners manual or contact the engine manufacturer for engine safety instructions and decals. make certain

that all safety and operational decals on this machine are kept clean and in good condition. The decals are shown below at reduced

sizes. Refer to the parts catalog if you need a replacement decal. decals that need replacement must be applied to their original

locations.

1

P/n 14942-00

2

P/n 12171

kEEP HANds ANd FEET OuT OF INLET ANd dIsCHARgE

OPENINgs WHILE mACHINE Is OPERATINg TO AvOId

sERIOus PERsONAL INjuRy. sTOP ANd ALLOW mACHINE

TO COmE TO A COmPLETE sTOP BEFORE CLEARINg

OBsTRuCTIONs.

3

P/n 12174

dO NOT OPERATE mACHINE WITHOuT sHIELds IN PLACE.

FAILuRE TO dO sO mAy CAusE sERIOus INjuRy OR

dEATH.

5

P/n 12176

dO NOT INsERT BRANCHEs LARgER THAN 3/4 INCH INTO

sHREddER OR mACHINE dAmAgE mAy OCCuR.

6

P/n 12250

CHECk BLAdE BOLTs FOR PROPER TORQuE AFTER

EvERy 8 HOuRs OF OPERATION. CHECk BLAdEs ANd

ROTATE OR REsHARPEN dAILy OR As REQuIREd TO

kEEP BLAdEs sHARP. REFER TO OWNERs mANuAL FOR

INsTRuCTIONs. FAILuRE TO dO sO mAy CAusE POOR

PERFORmANCE, dAmAgE OR PERsONAL INjuRy ANd

WILL vOId THE mACHINE WARRANTy.

4

P/n 12175

kEEP HANds ANd FEET OuT OF INLET ANd dIsCHARgE

OPENINgs WHILE mACHINE Is OPERATINg TO AvOId

sERIOus PERsONAL INjuRy. sTOP ANd ALLOW mACHINE

TO COmE TO A COmPLETE sTOP BEFORE CLEARINg

OBsTRuCTIONs.

6

3 INCH CHIPPER/SHREDDERS

Page 9

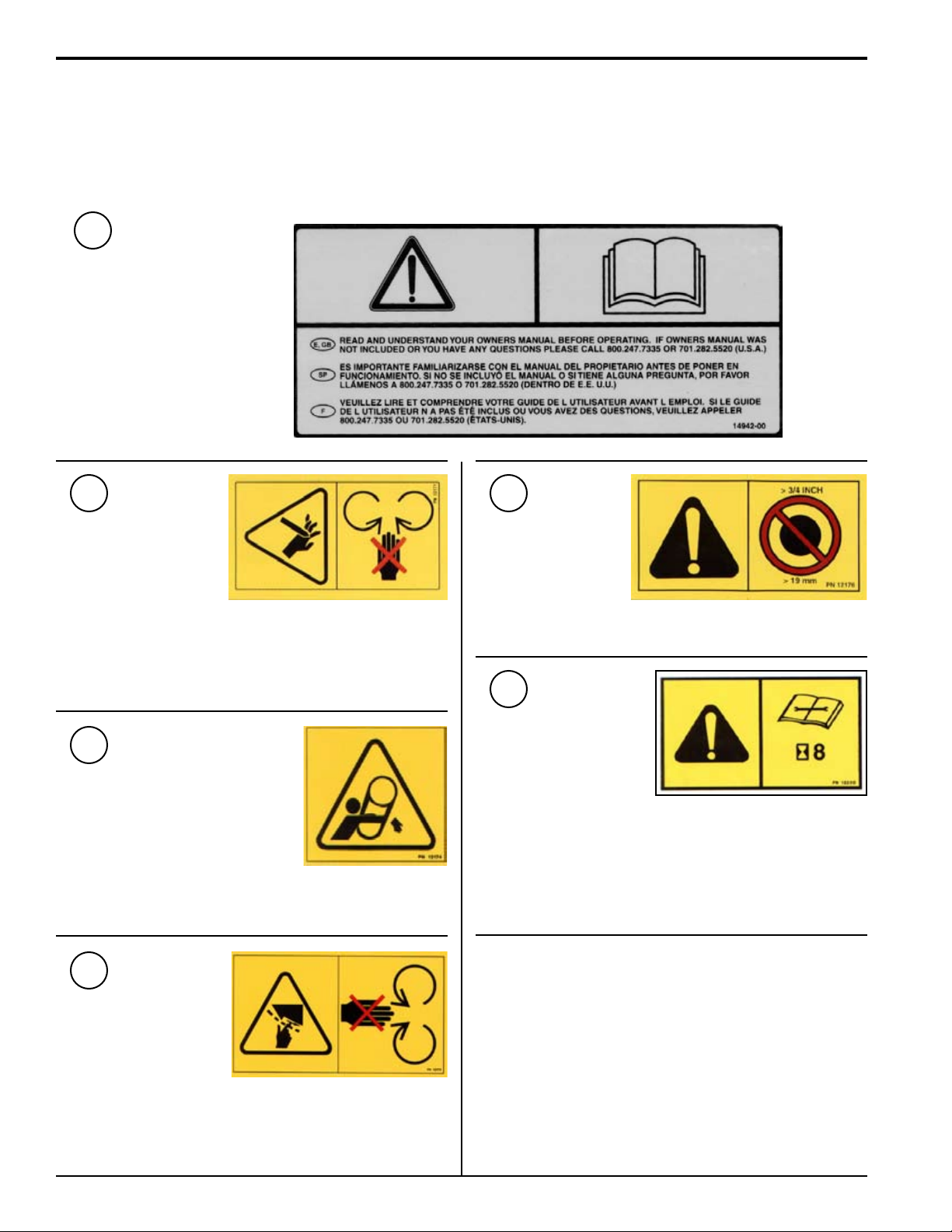

7 8

SAFETY

P/n 14938-00

dO NOT INsERT BRANCHEs LARgER THAN 3 INCHEs

IN dIAmETER INTO CHIPPER. mACHINE dAmAgE mAy

OCCuR. REFER TO OWNERs mANuAL FOR OPERATINg

INsTRuCTIONs ANd RECOmmENdATIONs.

9

dO NOT OPERATE THIs

EQuIPmENT IN THE vICINITy OF

BysTANdERs. dO NOT ALLOW

CHILdREN TO OPERATE THIs

EQuIPmENT.

P/n 14965-00

P/n 14703-00

LOWER LEvER sLOWLy TO ENgAgE CHIPPER. PuLL

LEvER uP TO dIsENgAgE CHIPPER. CHIPPER/

sHREddER ROTOR WILL CONTINuE TO ROTATE WHEN

CLuTCH Is dIsENgAgEd. sTOP ENgINE ANd REmOvE

sPARk PLug WIRE BEFORE CLEANINg dEBRIs FROm

dIsCHARgE AREA OR sERvICINg THIs mACHINE. dO

NOT OPERATE WITHOuT dIsCHARgE sCREEN, INLET

FLAPs ANd ALL sHIELds IN PLACE.

ALWAys sTANd CLEAR OF

dIsCHARgE AREA WHEN

OPERATINg THIs mACHINE.

kEEP FACE ANd BOdy AWAy

FROm FEEd ANd dIsCHARgE

OPENINgs.

OBTAIN ANd WEAR sAFETy

gLAssEs ANd usE HEARINg

PROTECTION AT ALL TImEs WHEN

OPERATINg THIs mACHINE.

BEFORE INsPECTINg OR

sERvICINg ANy PART OF THIs

mACHINE, sHuT OFF POWER

sOuRCE, dIsCONNECT sPARk

PLug WIRE FROm sPARk PLug

ANd mAkE suRE ALL mOvINg

PARTs HAvE COmE TO A

COmPLETE sTOP.

3 INCH CHIPPER/SHREDDERS

WHEN FEEdINg sHREddABLE

mATERIAL INTO CHIPPER, dO

NOT ALLOW mETAL, ROCks,

BOTTLEs, CANs OR ANy OTHER

FOREIgN mATERIAL TO BE FEd

INTO CHIPPER OR sHREddER.

BEFORE INsPECTINg OR

sERvICINg ANy PART OF THIs

mACHINE, sHuT OFF POWER

sOuRCE, dIsCONNECT sPARk

PLug WIRE FROm sPARk PLug

ANd mAkE suRE ALL mOvINg

PARTs HAvE COmE TO A

COmPLETE sTOP.

7

Page 10

SAFETY

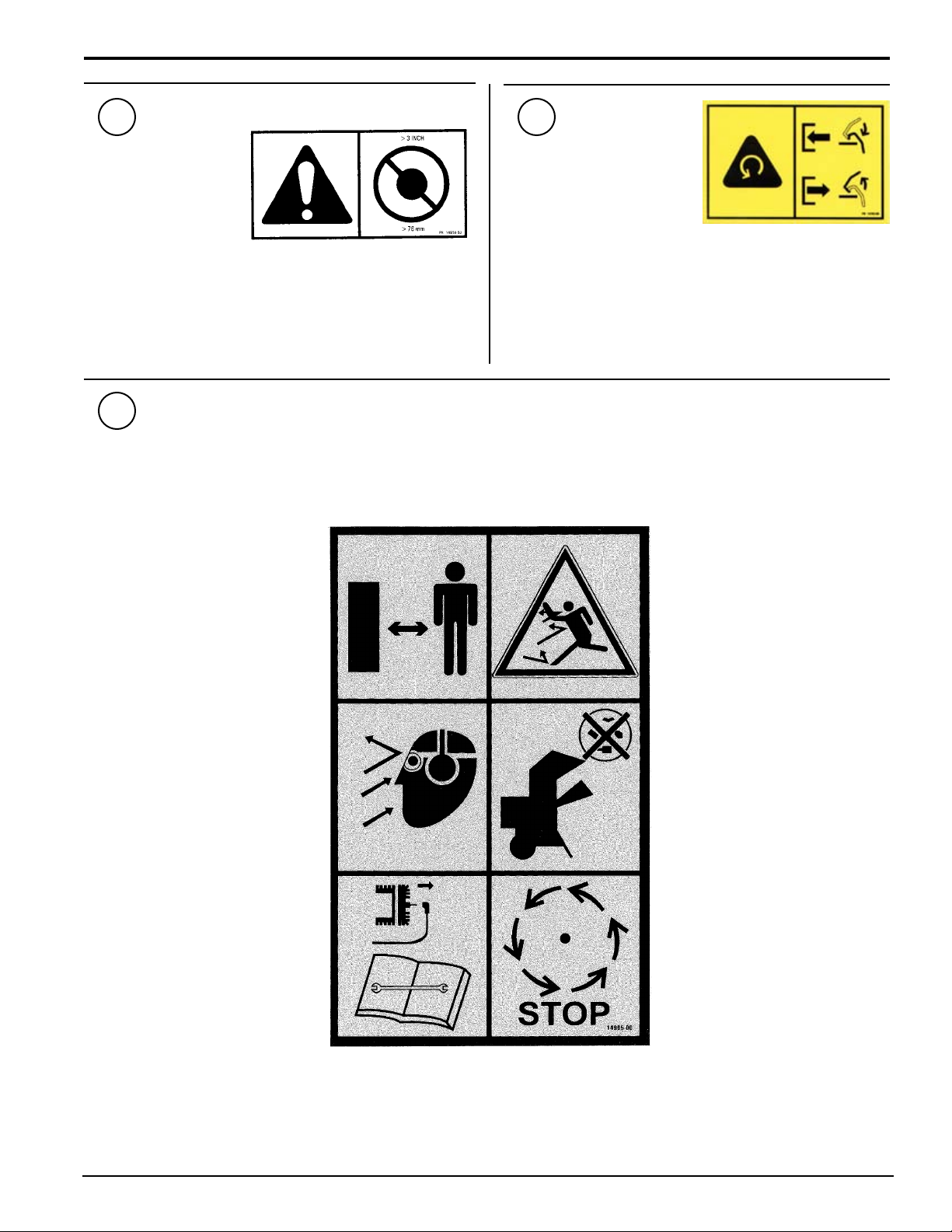

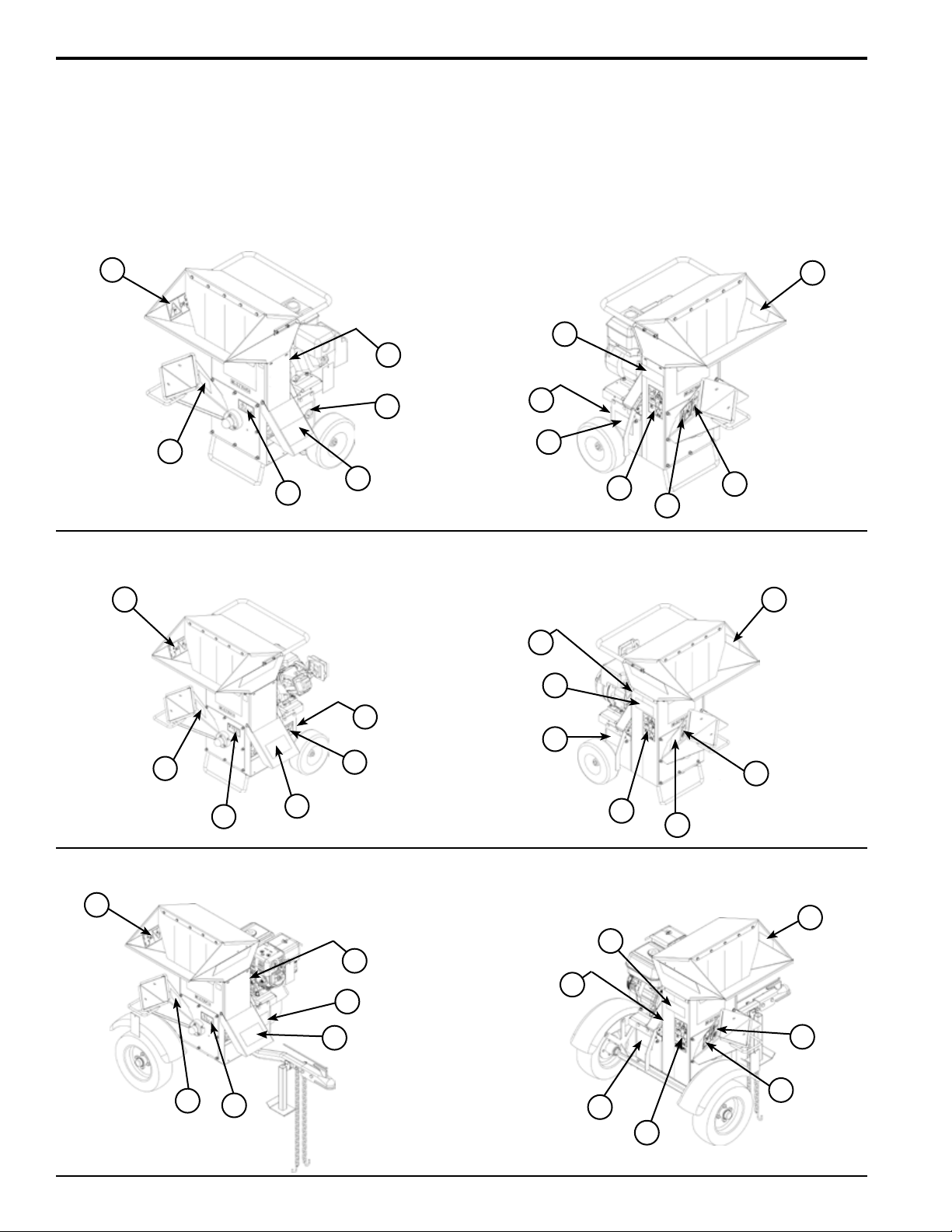

1.9 SafeTY decal locaTionS

The numbers below correspond to the decals in section 1.8. Familiarize yourself with all of the safety and operational decals on the

machine and the associated hazards. see the engine owners manual or contact the engine manufacturer for engine safety instructions

and decals. make certain that all safety and operating decals on this machine are kept clean and in good condition. The decals are

shown below at reduced sizes. Refer to the parts catalog if you need a replacement decal. decals that need replacement must be

applied to their original locations.

1.9.1 model 70050

4

3

4

1

4

6

1.9.2 modelS 70080, 70085, 70180, 70380, 70385

4

3

1

4

5

1

3

8

9

7

4

5

3

1

8

7

1.9.3 model 70580

4

1

8

6

4

9

4

5

1

3

3

4

4

7

4

6

8

9

3 INCH CHIPPER/SHREDDERS

Page 11

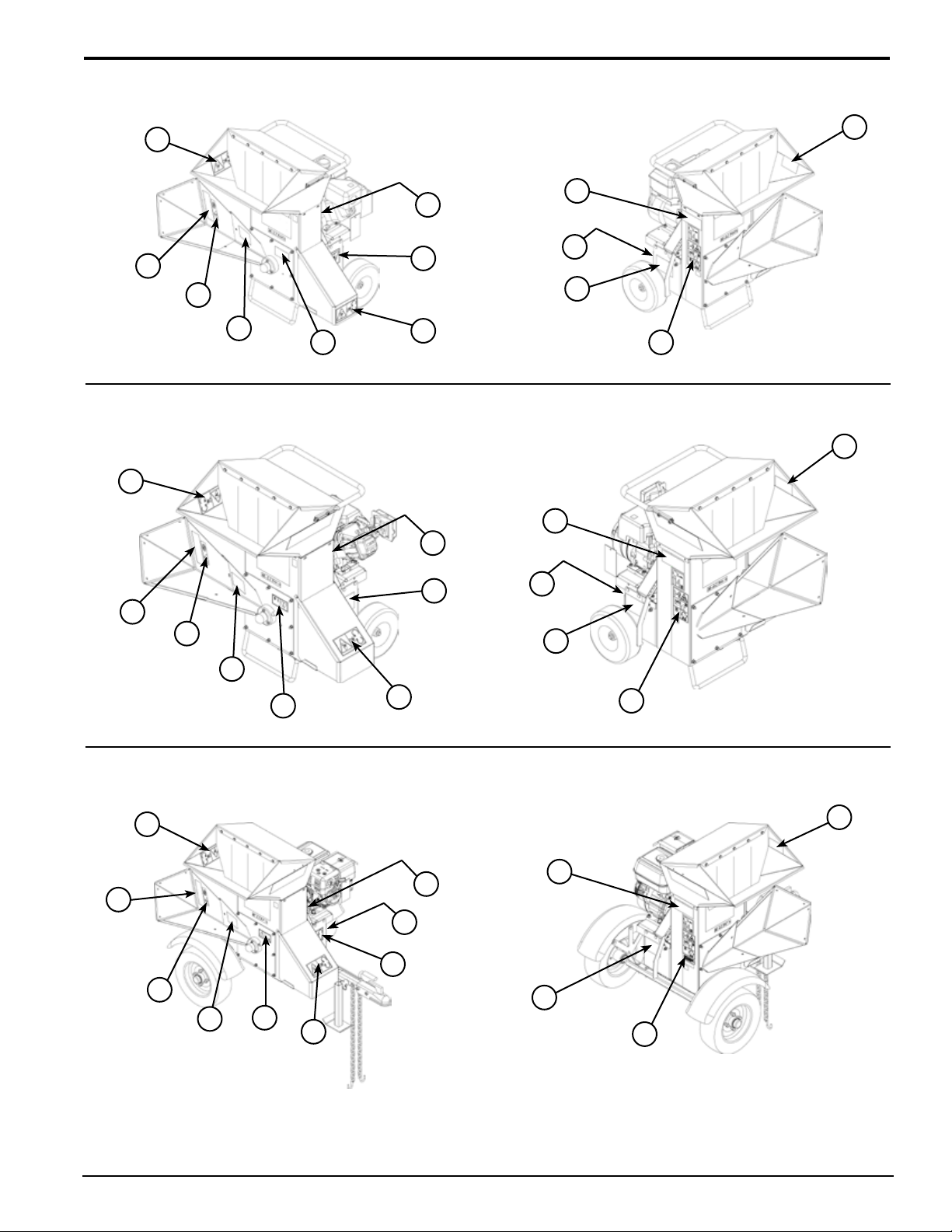

1.9.4 model 70050S

SAFETY

4

4

7

1

6

1.9.5 modelS 70080S, 70180S, 70380S

4

5

1

3

4

3

8

4

9

5

1

3

4

7

1

1.9.6 model70580S

4

4

7

1

4

3

8

6

4

9

5

1

3

3

4

8

6

4

9

3 INCH CHIPPER/SHREDDERS

9

Page 12

2

assembly

Section

Warning

Before inspecting or servicing any part of this machine, shut

off power source, disconnect spark plug wire from spark plug

and make sure all moving parts have come to a complete

stop.

imPorTanT

If any bolts or nuts are dropped in the machine, be sure to

remove them before starting the machine. Remove items

from the shredder area by removing the discharge screen.

2.4 inSTalling The Wide and narroW

diScharge aSSemblY

modelS: all “S” modelS

Place the discharge weldment onto the chipper. The holes on

1.

the weldment should line up with holes on the chipper.

2.

secure the top of the discharge weldment using one 5/16" x

7-1/2" bolt (narrow door) or one 5/16" x 10" bolt (wide door)

and 5/16" nuts. Tighten to proper torgue

3.

secure the bottom of the discharge weldment using two

5/16" x 3/4" bolts and 5/16" nuts. The head of the bolt should

be located inside the discharge assembly. Tighten to the

proper torque.

2.1 inSTalling The handle

modelS: all modelS excePT 70580 & 70580S

Remove the chipper/shredder and hopper assembly from

1.

the shipping box and pallet.

2.

Install four 5/16" x 3/4" bolts so the head of the bolt is located

on the inside of the hopper. Fasten bolts with 5/16" nylock

nuts and 5/16" flat washers.

2.2 inSTalling The hoPPer

modelS: all modelS

Assemble the hopper assembly to the frame so the handle

1.

is located above the engine and the opening is toward the

chipper chute.

2.

Install twelve 5/16" x 3/4" bolts so the head of the bolt is

inside the hopper. Fasten bolts with 5/16" flat washers and

5/16" nylock nuts.

2.3 inSTalling The chiPPer chuTe

exTenSion

modelS: all “S” modelS

Place the chipper chute extension onto the chute. Line up

1.

the four holes located on the bottom of the extension and

the top of the chute.

2.

Install four 5/16" x 3/4" bolts so the head of the bolt is located

on the inside of the chipper chute. Fasten bolts with 5/16"

nuts. Tighten nut until snug against the chute extension.

2.5 inSTalling The WheelS, jack and

hiTch

modelS: 70580 & 70580S

1.

slide one wheel onto a hub and align the wheel lug holes

with the hub lug holes.

Thread the wheel bolts into the holes and tighten to the

2.

proper torque. Follow an alternating cross pattern when

tightening wheel bolts.

Repeat for the remaining wheel.

3.

Install hitch jack onto hitch pole and install snap pin.

4.

Align the hitch pole assembly to the frame and secure using

5.

two 3/8" x 2-1/2" bolts, 3/8" flat washers and 3/8" nylock

nuts.

2.6 inSTalling The baTTerY

modelS: 70085 & 70385

The machine may or may not have been shipped with a battery

depending on your area. If you did not receive a battery with your

machine, you will need to purchase one.

use a battery that meets or exceeds the following

specifications:

battery category, lawn and garden

bci group Size u1

200-250 cca

7-3/4" x 5-3/16" x 7-5/16"

Suggested Source:

exide cutting edge, Type gT-h

After purchasing your battery, fill, charge and install the battery

according to the battery owners manual.

10

3 INCH CHIPPER/SHREDDERS

Page 13

Warning

ASSEMBLY

2.8 filling The Tank

To avoid sparks and a possible explosion or fire due to a

short circuit:

do not touch the positive (+) battery terminal and any

surrounding metal wit h tools, jewelry or other metal

objects.

When installing battery cables, connect the positive (+) cable

first and the negative (-) cable last.

2.7 checking/adding moTor oil To

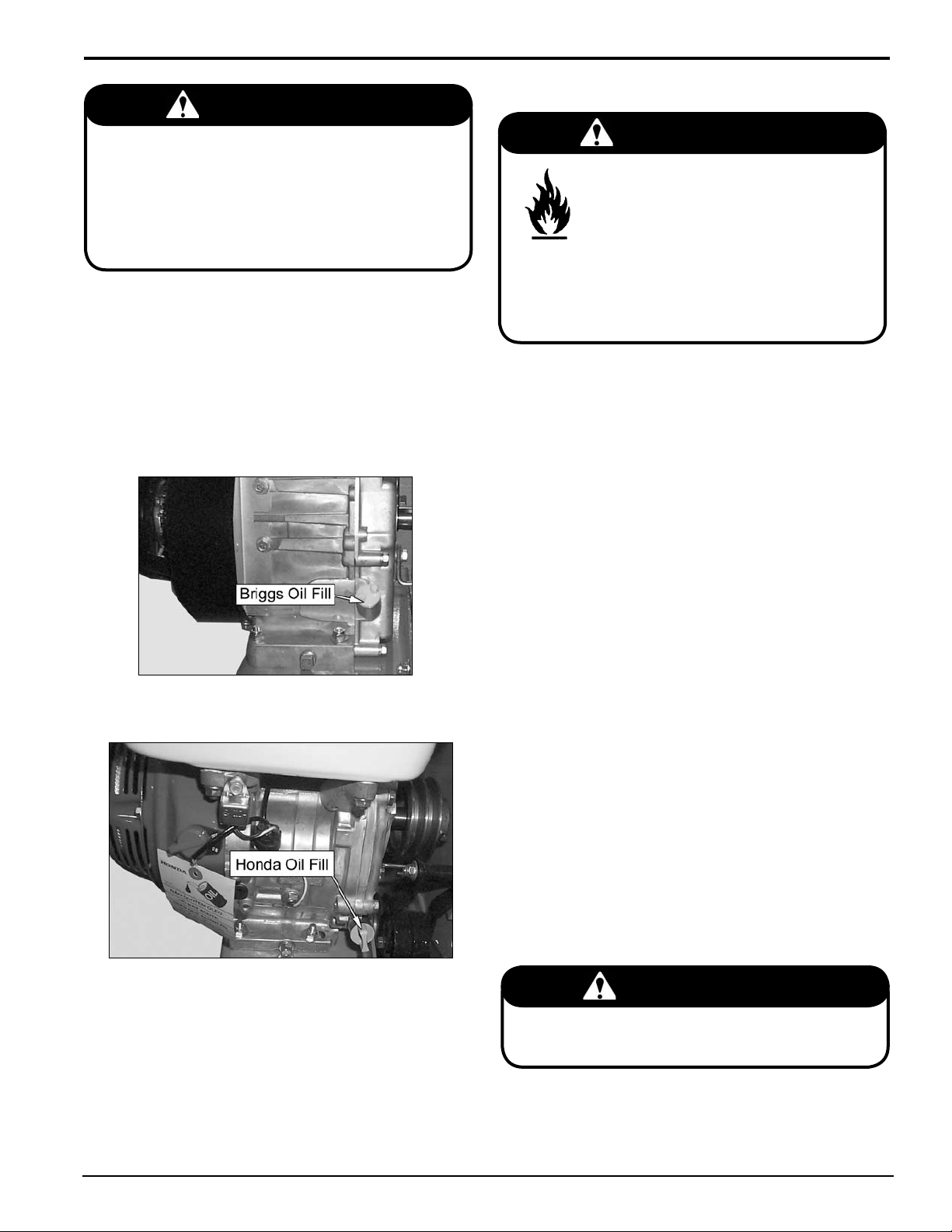

engine

modelS: all modelS

Check the oil level and if needed fill the engine crankcase with the

type and amount of oil specified in the engine owners manual.

danger

gasoline is highly flammable and its vapors

are explosive. To prevent personal injury or

property damage:

store gasoline only in approved containers, in

well ventilated, unoccupied buildings, away from

sparks or flames. do not fill the fuel tank while the engine is

hot or running. spilled fuel could ignite if it comes in contact

with hot parts or sparks from ignition. do not start the engine

near spilled fuel. Never use gasoline as a cleaning agent.

fuel TYPe

For best results use only clean, fresh, unleaded gasoline with a

pump sticker octane rating of 87 or higher. In countries using the

Research method, it should be 90 octane minimum.

Purchase gasoline in small quantities and store in clean,

approved containers. A container with a capacity of 2 gallons or

less with a pouring spout is recommended. such a container is

easier to handle and helps eliminate spillage during refueling.

dO NOT mIx OIL WITH gAsOLINE.

gaSoline alcohol blendS

gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline by

volume) is approved as a fuel for Briggs and Honda engines.

Other gasoline/alcohol blends are not approved.

Figure 2.1 - Briggs Oil Fill

Figure 2.2 - Honda Oil Fill

gaSoline eTher blendS

methyl Tertiary Butyl Ether (mTBE) and unleaded gasoline blends

(up to a maximum of 15% mTBE by volume) are approved as a

fuel for Briggs and Honda engines. Other gasoline/ether blends

are not approved.

To add gaSoline

1.

stop engine, wait for all parts to stop moving and disconnect

spark plug wire. Remove key from key switch. Allow the

engine and muffler to cool for at least three minutes.

Clean area around fuel fill cap and remove cap.

2.

3.

using a clean funnel, fill fuel tank to 1/2" below bottom of filler

neck to provide space for any fuel expansion. Install fuel fill

cap securely and wipe up any spilled gasoline.

imPorTanT

do not attempt to start the engine at this time. Wait until you

have read the complete starting instructions in the Operation

section of this manual.

3 INCH CHIPPER/SHREDDERS

11

Page 14

3

Section

features & controls

understanding how your machine works will help you achieve

the best results when using your chipper/shredder. The following

descriptions define the features and controls of your machine.

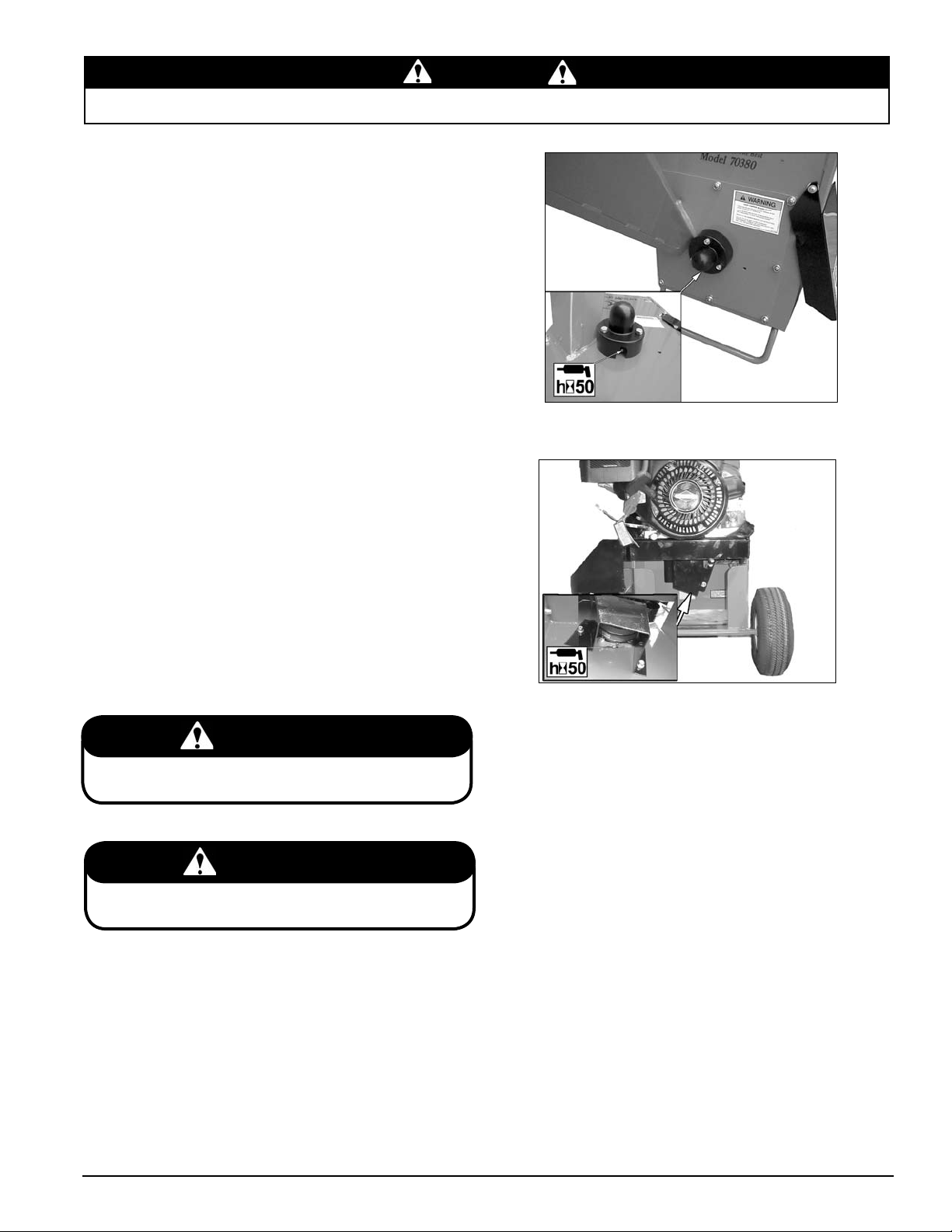

3.1 engagemenT handle

modelS: all modelS

during engine start-up, the engagement handle must be in the

disengaged position (Figure 3.1). With engine at full throttle,

carefully engage the rotor by slowly pushing the engagement

handle down, allowing the rotor to speed up gradually (Figure

3.2). Engaging the clutch too quickly with the engine at full or

half throttle will bog down the engine and will shorten the life of

the belt. To disengage the rotor, first idle the engine down and

then lift the engagement handle up

Figure 3.1

Disengaged Clutch

3.2 engine ThroTTle

modelS: all modelS

Changes engine speed. Push lever to 1/2 throttle for starting.

Push lever to slow for idle and warm-up. Push throttle lever to

slow throttle to shut engine off. Refer to engine manual for further

engine operating instructions. When chipping or shredding, the

engine should be at full throttle.

3.3 engine choke

modelS: all modelS

use when starting a cold engine. move lever to the choke position

when starting. move lever to the run position when engine is

running (Figures 3.3 and 3.4). Refer to engine manual for further

engine operating instructions.

Figure 3.3

Briggs Throttle and

Choke Locations

12

Figure 3.4

Honda Throttle and

Choke Locations

Figure 3.2

Engaged Clutch

3 INCH CHIPPER/SHREDDERS

Page 15

FEATURES & CONTROLS

3.4 keY SWiTch

modelS: all modelS

The key switch is used to start or stop the engine. see Figures

3.5 thru 3.8 for keyswitch locations. Refer to the engine manual

for further operating instructions.

Figure 3.5

Honda On/Off switch

Figure 3.6

Honda Eectric

Key Switch

3.5 Shredder chuTe

modelS: all modelS

materials to be shredded are fed through the shredder chute to

the shredder knives.

3.6 Shredder kniveS

modelS: all modelS

The shredder knives shred material that is fed into the shredder

chute.

3.7 chiPPer chuTe

modelS: all modelS

materials to be chipped are fed through the chipper chute to the

chipper blades.

3.8 chiPPer bladeS

modelS: all modelS

The chipper blades chip material that is fed into the chipper

chute.

3.9 jack STand

modelS: 70580 & 70580S

Always have the jack stand retracted from the ground when

moving the unit. When in use, be sure the jack stand is down

and locked in position with the snap pin.

Figure 3.7

Briggs Electric

On/Off Switch

Figure 3.8

Briggs Commercial

On/Off Switch

3 INCH CHIPPER/SHREDDERS

13

Page 16

4

Section

operation

As with any other piece of outdoor power equipment, getting

the feel for how your machine operates and getting to know the

best techniques for particular jobs are important to overall good

performance.

chiPPing oPeraTion

The chipping operation takes place on the right side of the

machine, where hardened steel chipper blades are mounted on

a rotating rotor assembly. material fed into the chipper chute is

sliced into small chips and propelled out through a discharge

screen. The chips can be diverted into a container or onto the

ground.

Shredding oPeraTion

In this operation, hardened steel shredder knives grind up material

fed into the shredder chute. The shredded material then leaves

the shredder area by traveling through the discharge screen.

The shredded material can be diverted into a container or onto

the ground.

Warning

Before operating your machine, be sure you read and

understand all safety, controls and operating instructions in

this Owner/Operators manual and on your machine. Failure

to follow these instructions can result in serious injury or

property damage.

4.1 STarTing elecTric modelS

move the machine to a clear, level area outdoors before starting.

do not operate in the vicinity of bystanders. make sure the cutting

chamber is empty before starting.

do not crank the engine continuously for more than 10 seconds

at a time. If the engine does not start, allow a 60 second cool

down period between starting attempts. Failure to follow these

guidelines can burn out, or permanently damage, the starter

motor.

If the engine develops sufficient speed to disengage the starter

but does not keep running (a false start), the engine rotation

must be allowed to come to a complete stop before attempting

to restart the engine. If the starter is engaged while the flywheel

is rotating, damage to the starter may result.

If the starter does not turn the engine over, shut off starter

immediately. do not make further attempts to start the engine

until the condition is corrected. Do not jump start using another

battery. Follow the steps below to start the machine.

Check engine oil level before starting.

1.

Place the throttle control midway between the slow and fast

2.

positions. Place the choke control into the choke position.

3.

start the engine by activating the key switch. Release the

switch as soon as the engine starts.

move throttle to full position.

4.

5.

slowly push the engagement handle down to engage the

chipper/shredder.

6.

for a cold engine — gradually return the choke control to the

off position after the engine starts and warms up. The machine

may be operated during the warm up period, but it may be necessary to leave the choke partially on until the engine warms up.

for a Warm engine — Return choke to the off position as

soon as engine starts.

4.2 STarTing recoil modelS

move the machine to a clear, level area outdoors before starting.

do not operate in the vicinity of bystanders. make sure the cutting

chamber is empty before starting.

1.

Check engine oil level before starting.

2.

Place the throttle control midway between the slow and fast

positions. Place the choke control into the choke position.

3.

Turn the key switch to on (if equipped). Pull the recoil

starter until the engine starts. make sure the starting cord

retracts.

4.

move throttle to full position.

5.

slowly push the engagement handle down to engage the

chipper/shredder.

for a cold engine — gradually return the choke control to

the off position after the engine starts and warms up. The

machine may be operated during the warm up period, but

it may be necessary to leave the choke partially on until the

engine warms up.

for a Warm engine —

soon as engine starts.

Return choke to the off position as

14

3 INCH CHIPPER/SHREDDERS

Page 17

4.3 SToPPing The chiPPer/Shredder

move the throttle to the slow idle position.

1.

2.

disengage the engagement handle.

Allow the engine to run at idle for 30-60 seconds; stop the

3.

engine by moving the throttle to the low position or turn off

ignition.

Allow machine to come to a complete stop.

4.

Warning

allow the machine to come to complete stop before

inspection or servicing. The rotor is heavy and has inertia

built up that will allow the rotor to turn for some time after the

clutch has been disengaged. you can tell when the rotor has

come to a complete stop when there is no noise or machine

vibration present. you can reengage the clutch to slow the

rotor to a stop.

4.4 chiPPing guide

The chipper chips a variety of materials into a more readily

decomposed or handled condition. The following guidelines can

help you get started.

1.

Run unit at full operating speed before starting to chip

material.

2.

select limbs that are up to 3 inches in diameter. Trim side

branches that cannot be bent enough to feed into the chipper

chute. Hold small diameter branches together in a bundle

and feed in simultaneously.

3.

Exclude pieces of metal, rocks, bottles, cans, and other

foreign objects when feeding chipable material into the

machine.

4.

Feed brush from the side of the chipper chute, rather than

from the front. step aside to avoid being hit by the brush

moving into the chipper.

5.

Do not lean over the chipper chute to push objects into the

cutting device. use a push stick or brush paddle.

6.

Never use shovels or forks to feed brush. They can be

chipped, are expensive to replace, and cause extensive

damage. In addition, metal pieces can be ejected from the

chipper chute and cause serious injury or death.

7.

Never feed brush into the chipper chute with your feet.

8.

Place limb, butt end first, into the chipper chute until it contacts the chipper blades. The actual feed rate of the limb

into the chipper will depend on the type of material fed and

sharpness of the cutting blades.

9.

stop the material feeding and allow the engine to recover if

the engine slows to where it may stall.

10.

Remove the branch and rotate it before reinserting it into the

chute if the chipper jams.

OPERATION

Alternately insert and retract the limb or insert continuously

11.

at a rate that will not kill the engine.

Chipping dead, dry material will create heat and dull the

12.

chipping blades quickly.

Alternate greener material with dry material to lubricate the

13.

chipping blades for longer life and better performance.

The chipping blades will become dull and will require periodic

14.

sharpening. Refer to the service and maintenance section

for sharpening instructions.

4.5 Shredding guide

Place materials to be shredded (grass, leaves, garden re-

1.

fuse, sticks and branches less than 3/4 inch diameter and

24 inches long, etc.) into the hopper.

Exclude pieces of metal, rocks, bottles, cans, and other

2.

foreign objects when feeding chipable material into the

machine.

Never use hands or feet to clear material that has built up

3.

inside the shredder chute.

4.

Never use shovels or forks to feed brush. They can be

chipped, are expensive to replace, and cause extensive

damage. In addition, metal pieces can be ejected from the

chipper chute and cause serious injury or death.

Feed material evenly into the shredder so that the engine

5.

does not bog down or the shredder becomes plugged.

Attempting to use the clutch to clear a plugged rotor will cause

6.

belt damage. Refer to the service and maintenance section

for instruction on clearing a plugged rotor.

Branches or items that plug or cause the machine to stall

7.

should be fed in more evenly or put through the chipper

chute.

8.

stop the material feeding and allow the engine to recover if

the engine slows to where it may stall.

Alternate greener material with dry material to lubricate the

9.

shredder knives for longer life and better performance.

3 INCH CHIPPER/SHREDDERS

15

Page 18

5

Service & maintenance

Section

5.1 mainTenance Schedule

The items listed in the service and maintenance schedule are to be checked, and if necessary, corrective action taken. This schedule

is designed for units operating under normal conditions. If the unit is operating in adverse or severe usage conditions it may be

necessary for the items to be checked and serviced more frequently.

see engine owners manual for further maintenance and troubleshooting information.

Service and mainTenance Schedule

freQuencY

comPonenT

ENgINE OIL CHECk OIL LEvEL

FuEL TANk FILL

AIR CLEANER CHECk & CLEAN

AIR INTAkE CLEAN

NuTs & BOLTs CHECk

CHIPPER BLAdEs

PRE-CLEANER

ELEmENT

sHREddER

kNIvEs

BELT/PuLLEy

ALIgNmENT

BELT CONdITION CHECk

TIRE PREssuRE CHECk

ENTIRE mACHINE CLEAN

ROTOR BEARINg gREAsE

ENgINE OIL CHANgE

COOLINg

sHROuds

sPARk PLug

sTARTER dRIvE sERvICE

sOLONOId sHIFT

sTARTER

FuEL FILTER REPLACE

BATTERy

CONNECTIONs

1

Perform more frequently in dusty, dirty or severe usage conditions.

2

Have a Briggs or Honda engine service dealer perform this service.

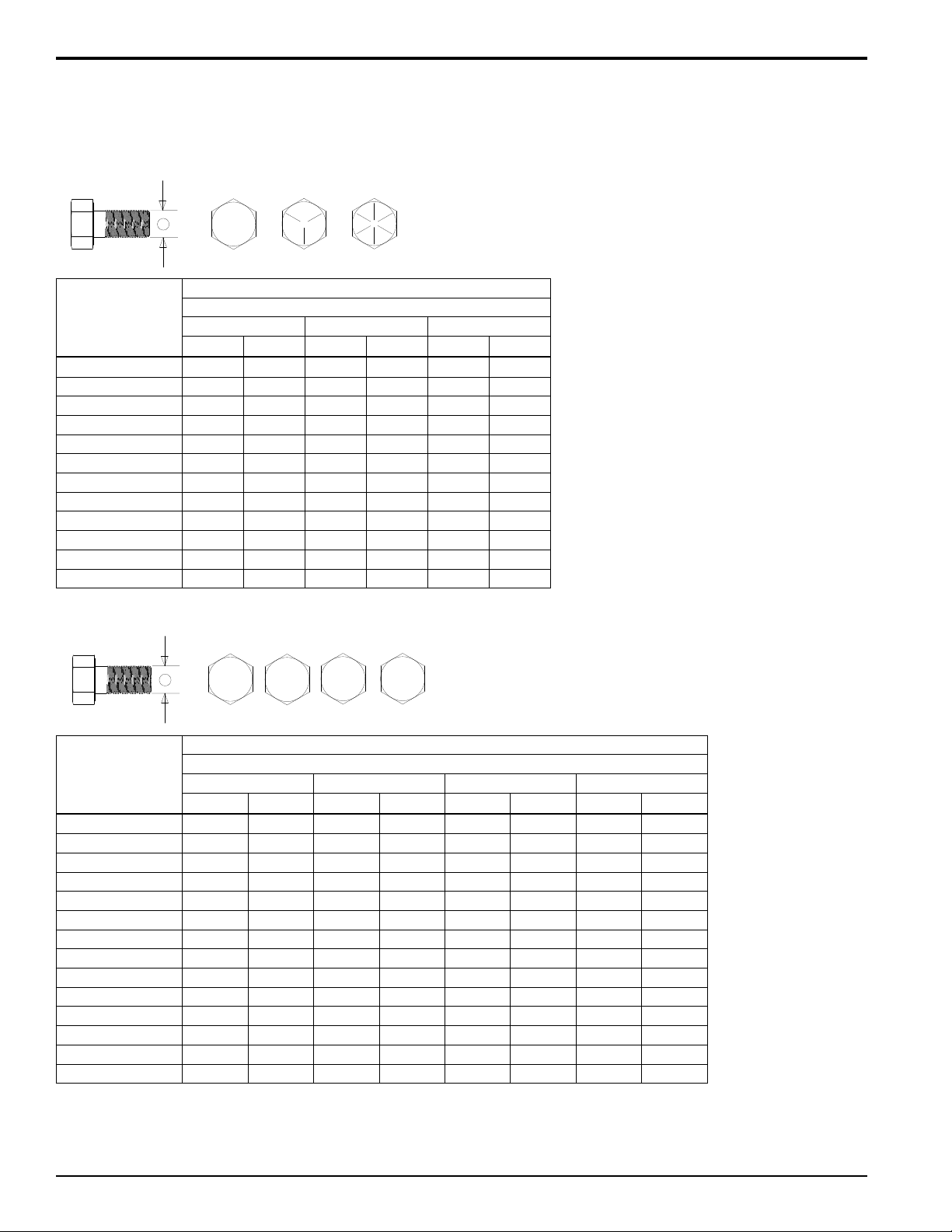

3

It is a good sign that your chipper blades need sharpening when material stops self feeding.

mainTenance

reQuired

1

CHECk, sHARPEN IF

NEEdEd

CLEAN

CHECk CONdITION

CHECk

CLEAN

CHECk CONdITION

ANd gAP

dIsAssEmBLE ANd

CLEAN

CHECk

3

1

1

1

2

2

before

each uSe

1

everY

8

hrS

everY

25

hrS

everY

50

hrS

everY

100 hrS

everY

200 hrS

everY

500 hrS

everY

1500

hrS

16

3 INCH CHIPPER/SHREDDERS

Page 19

SERVICE & MAINTENANCE

MOUNTING SURFACE

DO NOT GRIND

SHARPENED

SURFACE

SHARPENED

SURFACE

DO NOT GRIND

MOUNTING SURFACE

.25

45°

1/8"

Warning

dIsCONNECT sPARk PLug WIRE FROm sPARk PLug ANd mAkE suRE ALL mOvINg PARTs HAvE COmE TO A COmPLETE sTOP.

BEFORE INsPECTINg OR sERvICINg ANy PART OF THIs mACHINE, sHuT OFF POWER sOuRCE,

5.2 chiPPer bladeS

Warning

Chipping blades and shredder knives are sharp! use caution

when working on machine to avoid injury.

The chipper blades will eventually become dull, making chipping

difficult and adding extra strain on the machine. Poor chipping

performance is usually a result of dull chipping blades. It is

recommended that the blades be sharpened every 5 - 15 hours

or if your chipper’s performance has decreased. Check for the

following symptoms and sharpen the blades if needed.

1.

severe vibration when feeding material into the chipper.

2.

small diameter branches do not self-feed.

3.

Chips discharge unevenly or have stringy tails, especially

when chipping green branches.

Before you sharpen the chipping blades, check for permanent

damage. Replace the blade if:

1.

There are cracks, broken corners or nicks greater than 1/8"

(Figure 5.1).

2.

The base of the cutting edge is worn or has been re-sharpened so that it sits too close to the rotor chipping slot.

5.2.2 SharPening The bladeS

Never sharpen or grind the mounting surfaces of the blades.

1.

This will cause the edge to roll and the blade will be damaged, resulting in poor chipping performance.

Regrind the angled edge of the chipping blades to 45 de-

2.

grees (Figure 5.2).

The blades can be ground on a bench grinder or by a profes-

3.

sional.

4.

make sure some type of fixture is used to correctly hold the blade

at the proper angle.

Be careful when grinding so that the blade does not become

5.

overheated and change color. This will remove the heattreated properties.

6.

use short grinding times and cool with water or some type of

liquid coolant.

Remove an equal amount off each blade to maintain rotor

7.

balance.

8.

small imperfections such as nicks and burrs on the flat side

of the blade will not affect the chipping performance of the

machine.

For blades that have been repeatedly sharpened, ensure

9.

that the sharpened surface extends past the chipping slot

opening. If it does not extend past the opening, the blades

should be replaced.

Figure 5.2 - Double Edged Blade

Figure 5.1 - Causes for Replacement

5.2.1 removing The bladeS

Flip the discharge door up. For "s" models, remove the

1.

discharge assembly.

Remove the 5/16" x 7/8" bolt and nylock nut holding the

2.

shredder screen to the bottom of the frame.

3.

disconnect and remove the shredder screen from the

5.2.3 inSTalling The bladeS

Place a blade on the rotor and attach with two 5/16" x 1-1/2"

1.

bolts. Torque to 25 Ft-lb. Repeat for the second blade.

Attach the shredder screen to the machine with one 5/16"

2.

x 7/8" bolt and nylock nut.

Lower the discharge door into the normal operating position.

3.

For "s" models, reinstall the discharge assembly.

machine.

Remove the two 5/16" x 1-1/2" hex bolts securing the chipper

4.

blade to the rotor. Repeat for the second blade.

Inspect blades to see if cracks or nicks are visible. If cracks

5.

are present, replace the blades. If nicks can not be removed

by sharpening blade, replace the blade.

3 INCH CHIPPER/SHREDDERS

17

Page 20

SERVICE & MAINTENANCE

Warning

dIsCONNECT sPARk PLug WIRE FROm sPARk PLug ANd mAkE suRE ALL mOvINg PARTs HAvE COmE TO A COmPLETE sTOP.

BEFORE INsPECTINg OR sERvICINg ANy PART OF THIs mACHINE, sHuT OFF POWER sOuRCE,

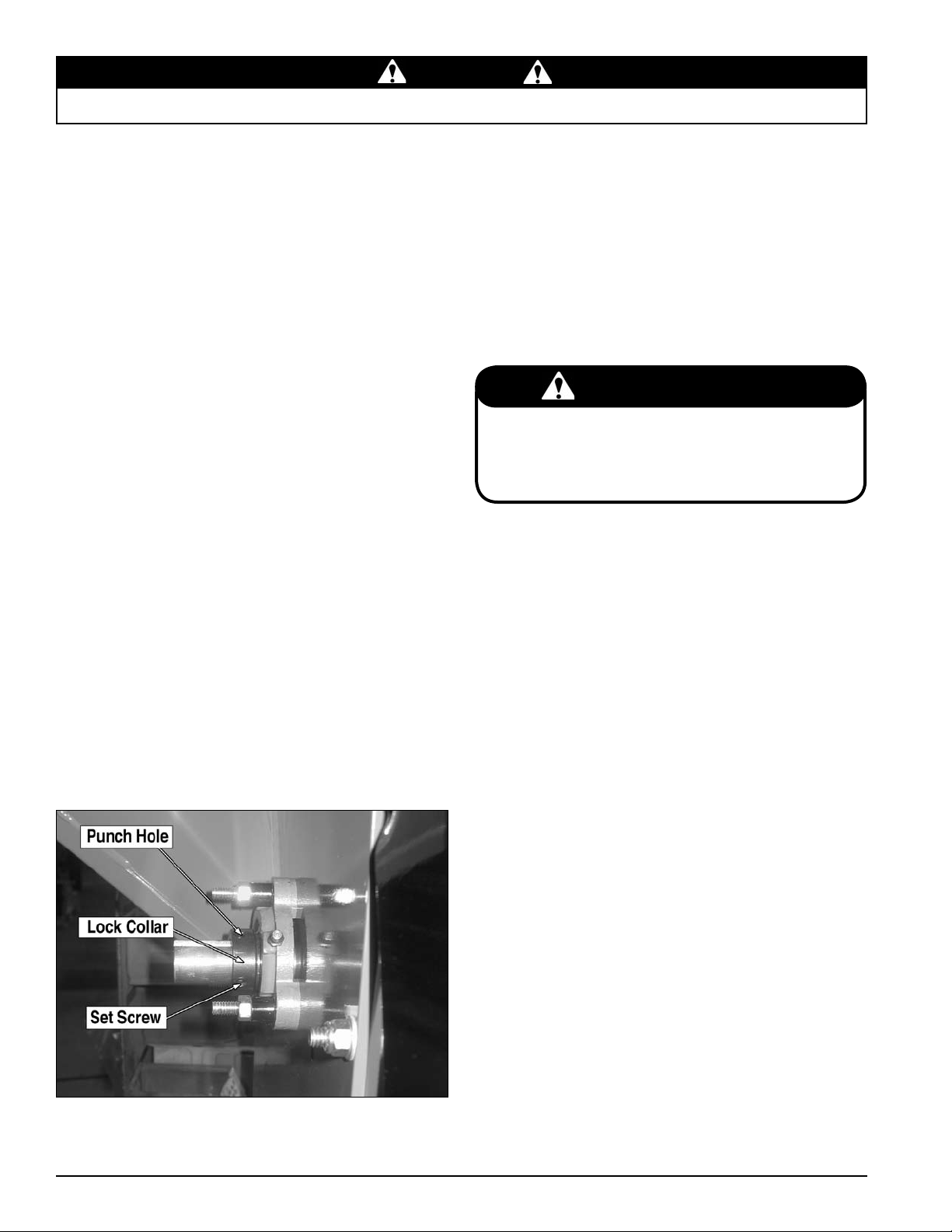

5 . 3 S e T T i n g c h i P P i n g b l a d e

clearance

The chipping blades should clear the chipper block, located inside

the frame on the bottom edge of the chipper chute intake, by 1/16"

to 1/8". To adjust the blade clearance, proceed as follows:

Remove the rotor shaft end cap and upper shield.

1.

Loosen the set screws holding the lock collars on the chute

2.

side and engine side bearings (Figure 5.3).

3.

use a punch and hammer to tap the lock collars in the oppo

site direction of normal rotation. on the chute side bearing,

tap punch in a cW rotation. on the engine side bearing,

tap punch in a ccW rotation

4.

using a rubber mallet tap the end of the rotor shaft to obtain

1/16" to 1/8" clearance. Rotate the rotor and check the clearance on all chipping blades.

Once clearance has been set, the lock collars must be re-

5.

placed and retightened. using a punch and a hammer, tap

the lock collars in the direction of shaft rotation (clockwise

on the engine side bearing and counterclockwise on

the chute side bearing) and set them with a hammer tap.

Tighten the lock collar set screws.

Loosen the set screws holding the belt pulley on the rotor

6.

shaft. move the pulley on the shaft so it is aligned with the

engine drive pulley. The pulley should be moved the same

amount the rotor was moved, only in the opposite direction.

Torque pulley set screw to 160 In-lbs.

Insure the pulley drive key is completely seated under the

7.

pulley and tighten the set screws.

Check pulley alignment by laying a straightedge across the

8.

pulley faces. Pulley faces should line up. If not, repeat steps

6 and 7 until the pulley is lined up.

5.4 rePlacing The Shredder kniveS

The Rectangular shredder knife kit is a replacement kit to

replace existing dull or damaged knives. The serrated shredder

knives are designed to offer long life and can be reversed if they

become dull. This shredder kit uses an improved knife pattern to

provide more complete shredding, durability, and easier feeding.

Ensure the knives and spacers are properly installed to maintain

rotor balance.

Refer to the Parts manual for shredder knife kit. To remove the

knives or to install a new shredder kit proceed as follows.

-

imPorTanT

The serrated edge of the shredder knives should face the

same direction as the cutting edge of the chipper blades.

Never reuse the #10-24 nut and bolt. Never reuse shafts or

spacers if they show signs of wear or abuse. Always install

new parts when repairing.

1.

Remove the lower belt guard from under engine frame,

remove discharge door and discharge screen.

2.

Remove the 10-24 x 1-3/8" bolts and nuts from knife

shafts.

3.

Align shaft with the 5/8" hole in rear of frame and the small

hole in front of frame by the chipper chute.

4.

using a small punch or rod, push the shaft out the 5/8" hole

in rear of frame.

5.

To assemble, insert shaft through the 5/8" hole in rear of

frame and slide knives and spacers in their proper order onto

the shaft. install a new 10-24 x 1-3/8" bolt and nut.

6.

Repeat steps 3 through 6 to assemble the other three

shafts.

7.

When completed, install the discharge screen, discharge door

and torque all 3/8" bolts to 33 Ft-lbs. Test run machine.

18

Figure 5.3 - Lock Collar

3 INCH CHIPPER/SHREDDERS

Page 21

SERVICE & MAINTENANCE

Warning

dIsCONNECT sPARk PLug WIRE FROm sPARk PLug ANd mAkE suRE ALL mOvINg PARTs HAvE COmE TO A COmPLETE sTOP.

BEFORE INsPECTINg OR sERvICINg ANy PART OF THIs mACHINE, sHuT OFF POWER sOuRCE,

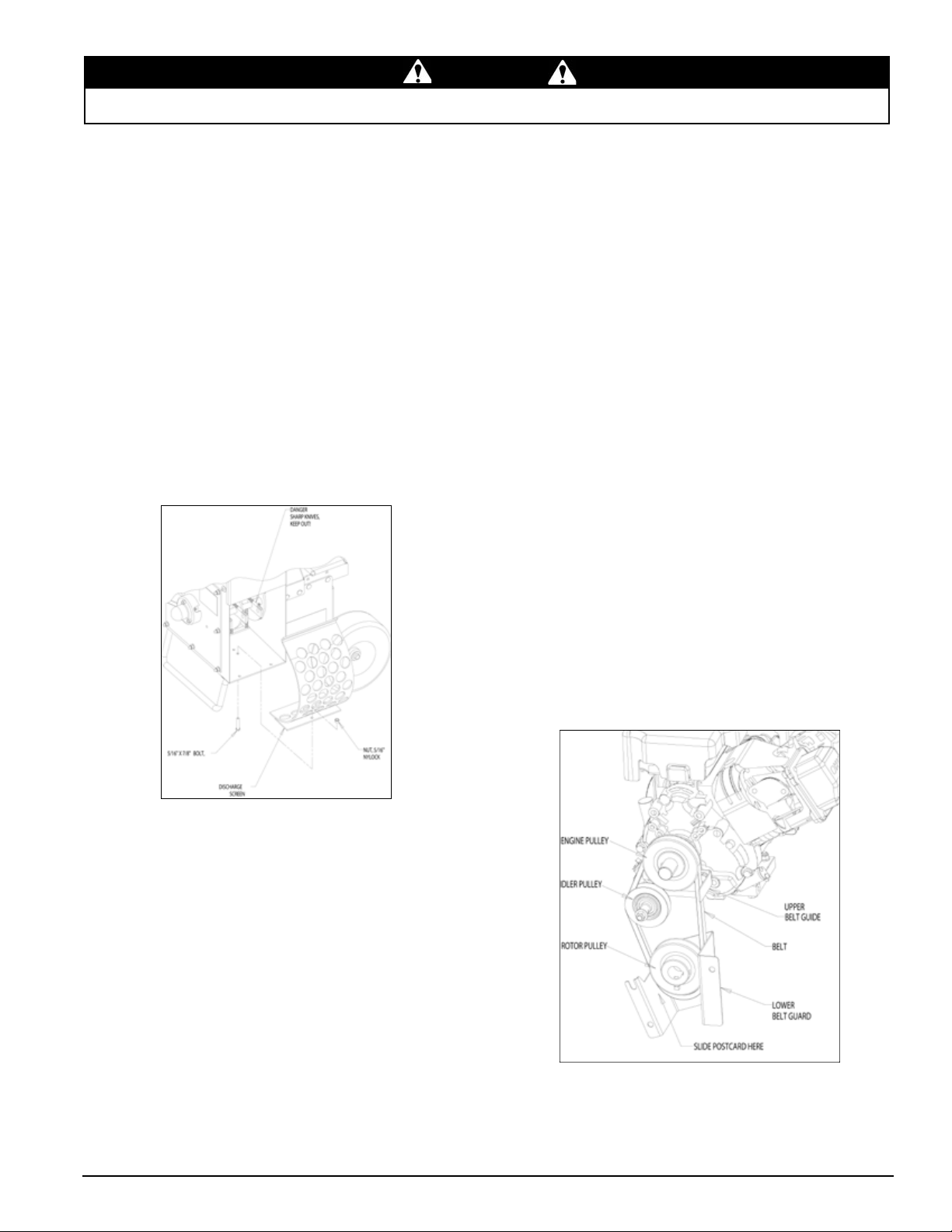

5.5 changing The diScharge Screen

There are several optional discharge screens available in different

sizes. different size discharge screens produce different size

chips. To change the discharge screen proceed as follows:

Lift discharge door to gain access to the discharge

1.

screen.

Remove the 5/16" x 7/8" bolt and nut securing the discharge

2.

screen to the frame (Figure 5.4).

Pull discharge screen out from the bottom and rotate the

3.

top down.

Clean any trash or debris out from the screen area.

4.

Insert the top of the replacement screen into the slot in the

5.

chipper body and push the bottom of the screen inward so

bolt holes align.

Install the bolt from the underside upward through the frame

6.

and screen, attach nut and tighten to specified torque.

5.6 belT guide adjuSTmenTS

The belt guide aids in disengaging the chipper/shredder. If

problems arise with engaging and disengaging the unit, follow

the instructions below. These instructions also adjust the lower

belt guard.

Remove upper shield to expose the belt and pulleys.

1.

Loosen set screws and using a straightedge align the en-

2.

gine pulley with the idler pulley and the rotor pulley with the

engine pulley. Tighten all set screws.

Engage the clutch with the belt in place and check idler

3.

engagement. The idler pulley should impact the belt in the

center of the pulley. All pulleys must be in perfect alignment.

Torque pulley set screws to 160 In-lbs.

If idler pulley will not remain in alignment with engine and

4.

rotor pulleys, it may be necessary to replace the idler bracket

bushings. Contact the ECHO Bear Cat service department

for more information.

There should be 1/8" clearance between the belt and the

5.

lower belt guard when the clutch is engaged. Adjust by

loosening the mounting bolts and repositioning the guide.

Retighten mounting bolts.

Reinstall upper shield.

6.

From underneath, check the alignment of lower belt guard

7.

with a post card (Figure 5.5). With the clutch engaged, there

should be enough room between the belt and the side of

the guard for the card to slide along the belt. With the clutch

disengaged, the card should not be able to slide. Adjust if

necessary.

Figure 5.4 - Replacing the Discharge Screen

3 INCH CHIPPER/SHREDDERS

Figure 5.5 - Belt Guide Adjustments

19

Page 22

SERVICE & MAINTENANCE

Warning

dIsCONNECT sPARk PLug WIRE FROm sPARk PLug ANd mAkE suRE ALL mOvINg PARTs HAvE COmE TO A COmPLETE sTOP.

BEFORE INsPECTINg OR sERvICINg ANy PART OF THIs mACHINE, sHuT OFF POWER sOuRCE,

5.7 remove/rePlace drive belT

Check the condition of the drive belts annually or every 50 hours

of operation, whichever comes first. Replace the belt if cracked,

frayed or worn. To replace the belt, proceed as follows:

Remove the upper shield, upper belt guide and lower belt

1.

guard.

2.

Remove idler pulley.

3.

slip the drive belt off the belt pulleys.

Inspect pulleys for wear. Replace the pulleys if they are

4.

cracked or worn so that the belt contact area is not smooth

and flat.

5.

Place the new belt over pulleys. do not force or pry the belt

over pulleys as this may cause cord breakage.

Reinstall the idler pulley.

6.

7.

Check alignment (section 5.6).

Replace all shields, guides and guards.

8.

5.8 clearing a Plugged roTor

Remove the bolt securing the discharge screen to the frame

1.

and remove the shredder screen.

Clean the debris out of the shredding rotor and/or chipper

2.

discharge area and tube. Turn the rotor by hand to be sure

it is free to rotate.

Install discharge screen and retaining bolt.

3.

5.10 Trailer Service TiPS

Check wheel bolt torque every 8 hours of towing use.

1.

Check air pressure in tire every 8 hours. Fill to the recom-

2.

mended PsI located on the tire sidewall.

Check and repack wheel bearings with grease every year.

3.

5.9 removing roTor

Remove discharge cover, screen and rotor shaft end cap.

1.

Loosen the set screws on the lock collar securing the chute

2.

side bearing on the rotor shaft.

3.

using a punch and hammer, tap the lock collar in the op

posite direction of normal rotation until loose; remove lock

collar and bearing.

Remove the upper shield, upper belt guide and lower belt

4.

guard to allow access to the engine side bearing.

5.

Remove the drive belt (section 5.7).

Loosen the set screws holding the belt pulley on the rotor

6.

shaft and remove the pulley.

Repeat steps 2 and 3 on the engine side rotor bearing.

7.

Remove the bolts securing the chipper chute cover to the

8.

frame and remove chipper chute cover.

Remove rotor.

9.

-

20

3 INCH CHIPPER/SHREDDERS

Page 23

SERVICE & MAINTENANCE

Warning

dIsCONNECT sPARk PLug WIRE FROm sPARk PLug ANd mAkE suRE ALL mOvINg PARTs HAvE COmE TO A COmPLETE sTOP.

BEFORE INsPECTINg OR sERvICINg ANy PART OF THIs mACHINE, sHuT OFF POWER sOuRCE,

5.11 greaSeable bearingS and

PivoTS

mounted unit ball bearings (referred to as “Insert Bearings) are

pre-lubricated at our factory and are ready for operation.

re-lubricaTion:

determined by operating conditions and environment. Relubricate standard bearings with a LITHIum based grease.

greaSing inTervalS:

will require more frequent greasing intervals.

greaSe fill amounTS:

fill amounts due to wide variances in applications, greasing

equipment and operating conditions. The quantities shown in

the pictures are recommended amounts. In most cases, it is

best to relube in small amounts, under low pressure, until a thin

bead of fresh grease is visible at the seal lip area.

Care should be taken when re-greasing bearings to avoid

overfilling. Overfilling can lead to excessive heat and or unseating

of the seals. grease should be introduced in small increments

and under light pressure. Whenever possible, the bearing should

be rotated slowly while grease is being added to ensure equal

distribution throughout the raceways.

The chipper models described in this manual have two (2)

greaseable bearings and pivots that require greasing. Refer to

pictures for greasing intervals and quantities.

Re-lubrication of insert bearings is

Bearings in extreme environments

It is preferred that experience dictate

Figure 5.6 - Chute Side Bearing.

Chute side bearing (Figure 5.6).

1.

Engine side bearing (Figure 5.7).

2.

noTe

Polyuria and lithium based greases are not compatible.

mixing the two grease types may lead to premature failure.

noTe

The use of pneumatic grease equipment is not recommended

unless low pressure is assured.

Figure 5.7 - Engine Side Bearing.

3 INCH CHIPPER/SHREDDERS

21

Page 24

6

Troubleshooting

Section

Before performing any of the corrections in this troubleshooting chart, refer to the appropriate information contained in this manual

for the correct safety precautions and operating or maintenance procedures. Contact your nearest dealer or the factory for service

problems with the machine.

Problem PoSSible cauSe remedY

1.

Improper control settings.

1.

Lack of fuel.

2.

Engine will not start.

Engine or rotor stalls or stops.

Engine overheats.

Hard to feed chipper; requires

excessive power to chip.

shredder requires excessive

power or stalls.

Engine stalls or belt squeals

when engaging clutch.

material from chipper wraps

around rotor shaft.

Excessive vibration while running.

Rotor will not turn.

Cannot engage clutch.

Excessive belt wear.

Trailer sways during towing. Tire air pressure not correct1. Check tire sidewall for inflation limits.1.

spark plug disconnected.

3.

dirty, stale or contaminated gas.

4.

Internal engine problems.

5.

Obstructed discharge.

1.

Plugged rotor.

2.

Feeding material too large into shredder.

3.

Cooling system plugged.

1.

Improper oil level.

2.

1.

dull chipper blades.

Obstructed discharge.

2.

Improper blade clearance.

3.

Obstructed discharge.

1.

Plugged rotor.

2.

Wet or green material will not discharge.

3.

Engaging clutch too fast.

1.

Plugged rotor.

2.

Belt tension too loose.

3.

1.

stringy, green material bypasses chipper

blades.

dull chipper blades.

2.

Improper blades clearance.

3.

drive system vibration.

1.

Rotor out of balance.

2.

Chipper blade to chipper block clearance is

3.

incorrect.

drive belt too loose or broken.

1.

Obstructed discharge.

2.

Plugged rotor.

3.

Improper belt installation; belt not under belt

1.

guide.

Improper belt tension.

2.

Not using correct belt.

1.

Pulley(s) damaged or worn.

2.

Pulley(s) not in alignment.

3.

Belt(s) tension too loose.

4.

use proper settings.

Fill fuel tank.

2.

Connect spark plug.

3.

Refill gas tank with fresh, clean unleaded regular gaso-

4.

line.

see your dealer.

5.

Use branch or similar object to clear discharge.

1.

Clear rotor. Feed material more evenly.

2.

Reduce size of material being fed into shredder.

3.

Clean cooling fan and fins.

1.

Fill engine to correct oil level. Refer to the engine own-

2.

ers manual.

Reverse or sharpen blades.

1.

Use branch or similar object to clear discharge.

2.

Adjust clearance between chipper block and chipper

3.

blades.

Use branch or similar object to clear discharge.

1.

Clear rotor, feed material into shredder more evenly.

2.

Alternately feed dry material or install larger discharge

3.

screen.

Lower engagement handle more slowly.

1.

Clear rotor. Feed material more evenly.

2.

Replace belt or spring.

3.

Rotate branch or material when feeding to cut com-

1.

pletely.

sharpen blades.

2.

Adjust clearance between chipper block and chipper

3.

blades.

Check drive belts and pulleys for bad or worn areas. Check

1.

for dull chipper blades or shredder knives.

Inspect rotor for broken or missing chipper blades and

2.

shredder knives; replace if needed. Check rotor to see if

it wobbles. Check to see if rotor is assembled correctly.

set chipper blade/block clearance to recommended dis

3.

tance (1/16" to 1/8").

Replace belt or spring.

1.

Use branch or similar object to clear discharge.

2.

Clear rotor. Feed material more evenly.

3.

Install belt properly; install belt under belt guide.

1.

Replace belt or spring.

2.

Contact your nearest authorized dealer to order the correct

1.

belt for your chipper/shredder.

Replace pulley(s).

2.

Align pulley(s) with straight edge.

3.

Replace belt or spring.

4.

-

22

3 INCH CHIPPER/SHREDDERS

Page 25

7

Specifications

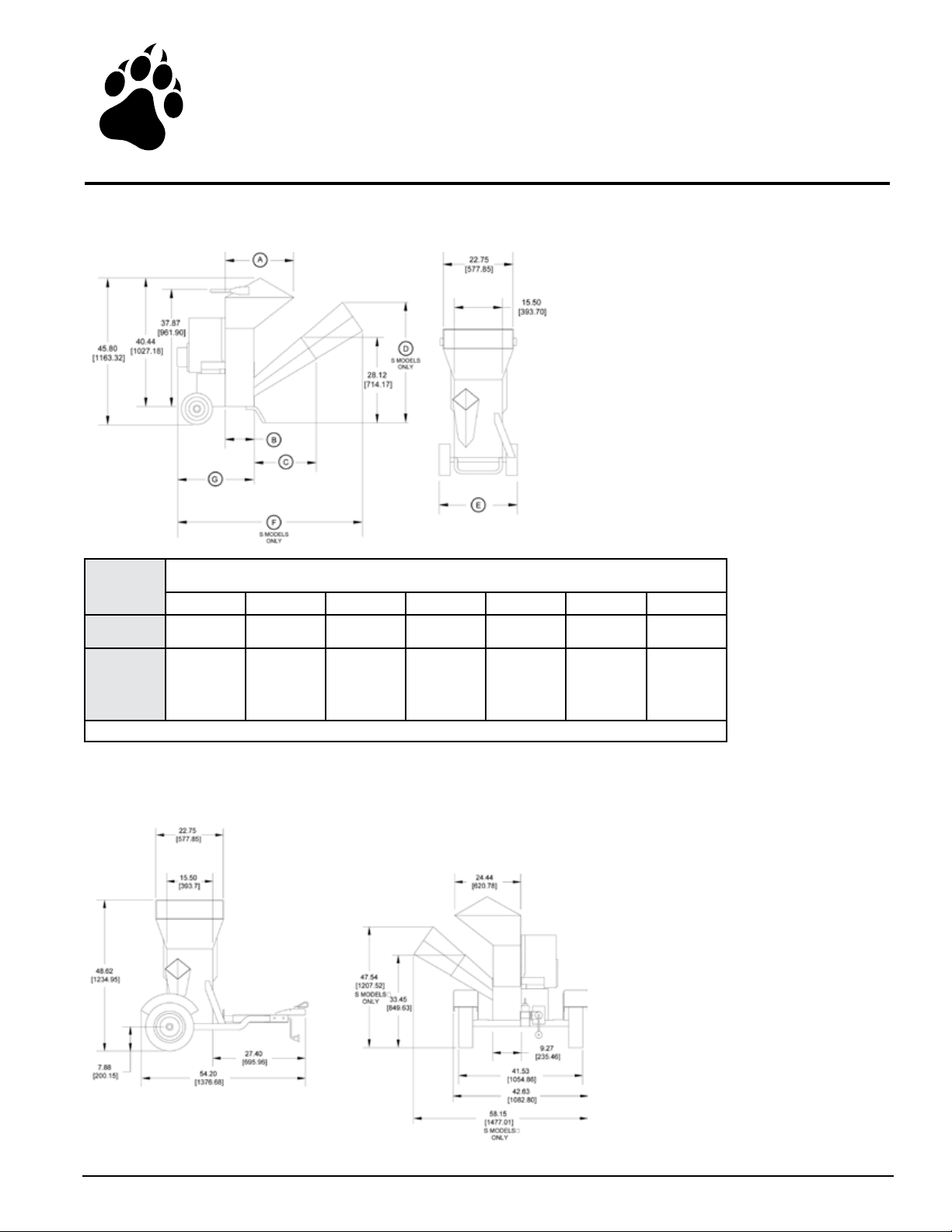

Section

7.1 non-ToWable modelS

model

a b c d * e f * g

70050 (s)

70080 (s)

70085

70180 (s)

70380 (s)

70385

* s mOdELs ONLy

22.16

[562.86]

24.44

[620.78]

6.67

[169.42]

9.27

[235.46]

7.2 ToWable modelS

15.34

[389.64]

20.04

[509.02]

meaSuremenT

in [mm]

43.25

[1098.55]

44.48

[1129.79]

23.98

[609.09]

23.75

[603.25]

51.00

[1295.40]

54.00

[1371.60]

21.32

[541.53]

25.61

[650.49]

3 INCH CHIPPER/SHREDDERS

23